Movable shooting device for on-site pipeline flaw detection

A technology for pipes and moving parts, which is applied to measuring devices, material analysis using radiation, material analysis using wave/particle radiation, etc. The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

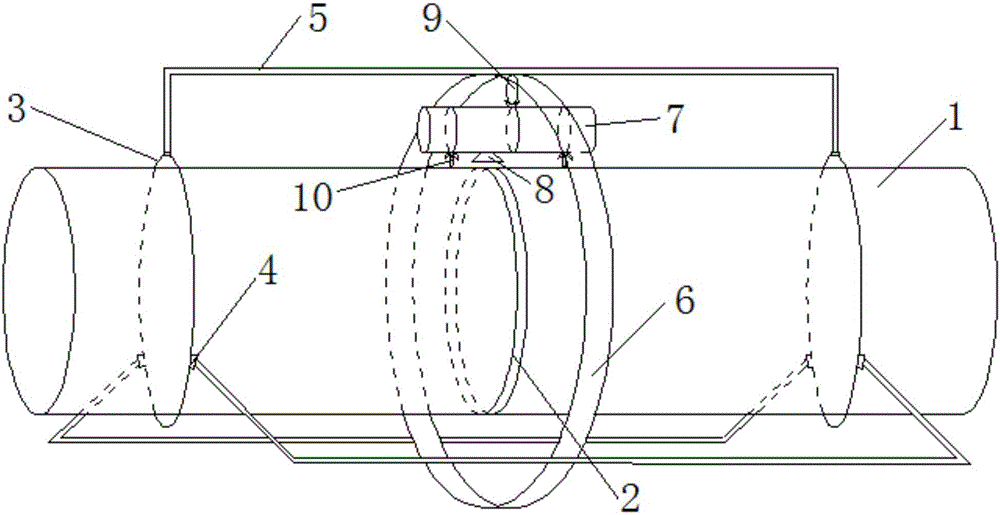

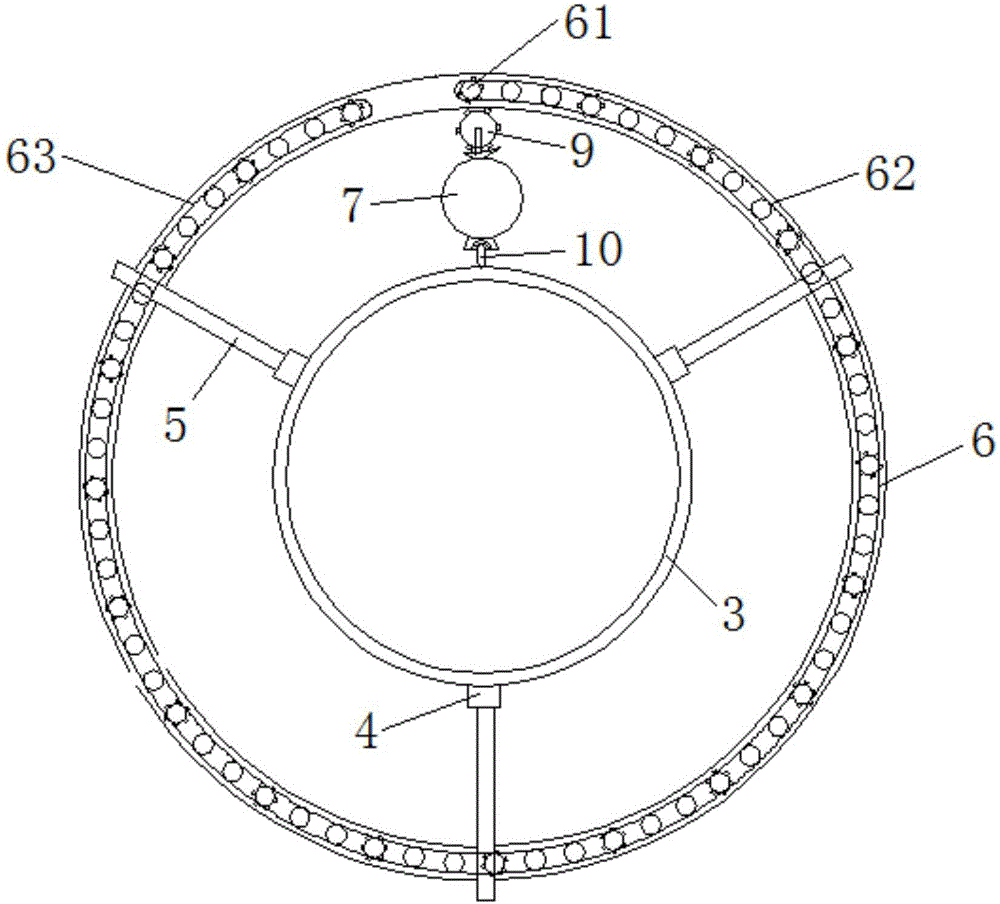

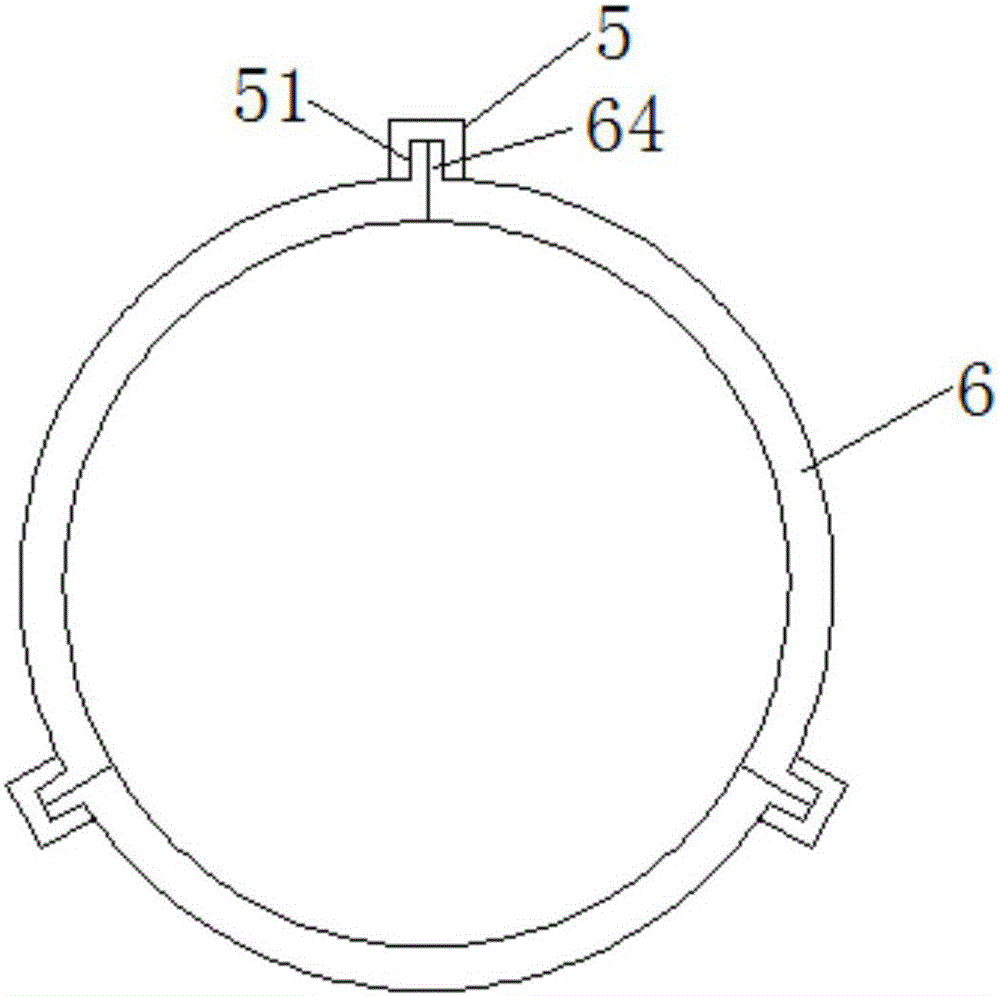

[0035] Such as figure 1 , figure 2 , image 3As shown, a mobile filming device for on-site pipeline flaw detection of the present invention includes a support frame, a running mechanism and a running mechanism. The support frame is installed on the outer surface of the pipeline 1 to be tested, and the running mechanism is installed on the On the support frame, the running mechanism is located between the running mechanism and the pipeline 1 to be tested. The support frame provides stable support for the whole device, especially to improve the support point for the track 6 in the running mechanism. The combination of the running mechanism and the running mechanism makes The X-ray machine 7 is free to circle around the outer surface of the pipeline 1 to be tested, which is convenient for the X-ray machine 7 to find the flaw detection position and improve the flaw detection efficiency; the support frame includes a fixed ring 3, a fixed connection end 4 and a connecting rod 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com