Patents

Literature

138results about How to "Improve flaw detection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eddy current inspection equipment

InactiveCN101241108AEasy to operateComprehensive flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSortingEddy currentMaterial resources

The present invention provides an eddy-current inspector including ultrasonic flaw detector, eddy current detector and computer, whose structure comprises of feeding rack, feeding orbit, pressing wheel mechanism, testing mainframe, blanking orbit and blanking rack, feeding orbit, pressing wheel mechanism, testing mainframe, pressing wheel mechanism and blanking orbit are connected in turn, feeding rack and blanking rack are set on one side of feeding orbit and blanking orbit respectively. The eddy-current inspector of present invention has merits of reasonable design and simply operation, and saves a great deal manpower and material resources, so it has a well widely use value.

Owner:山东济宁模具厂

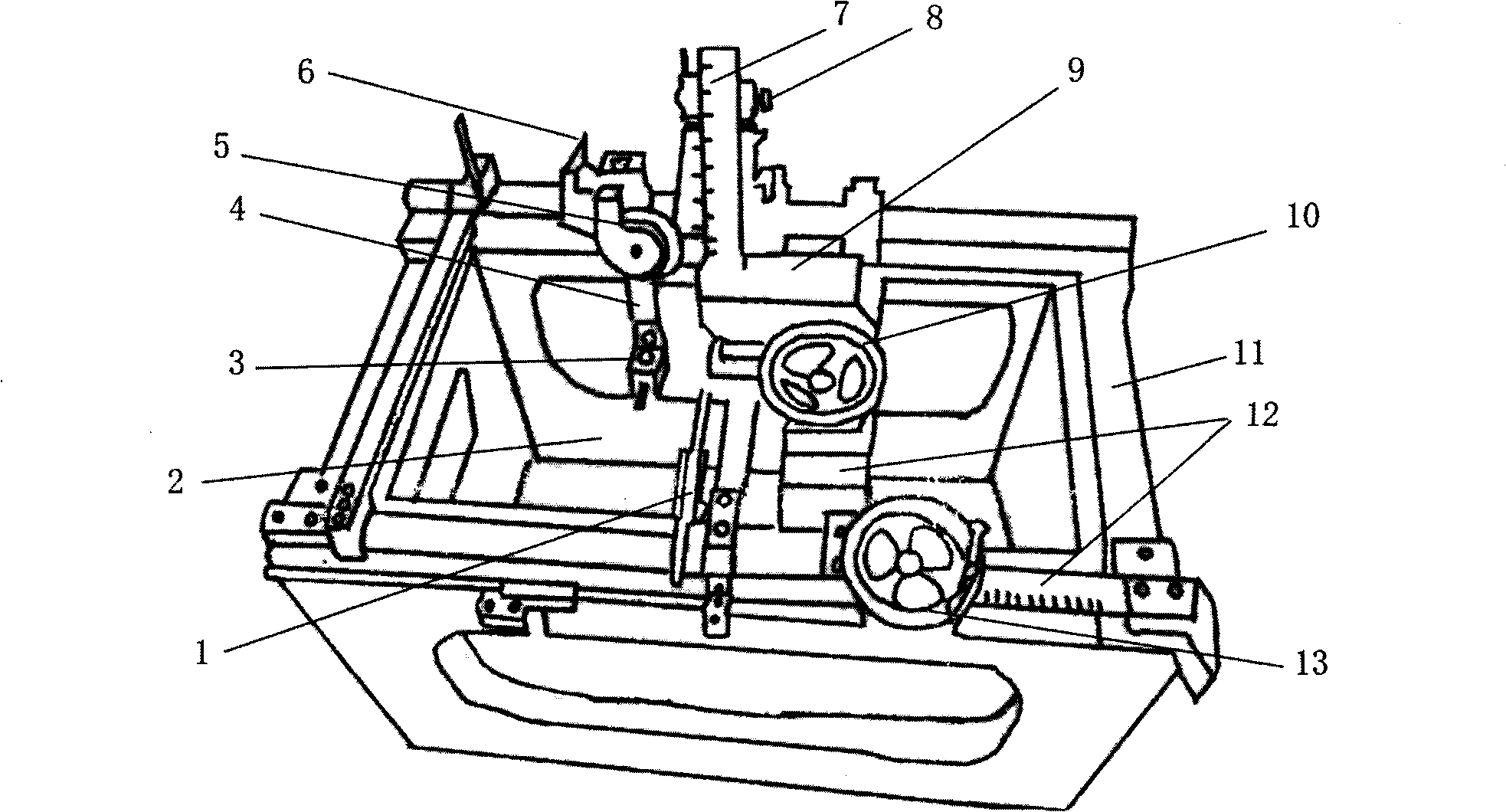

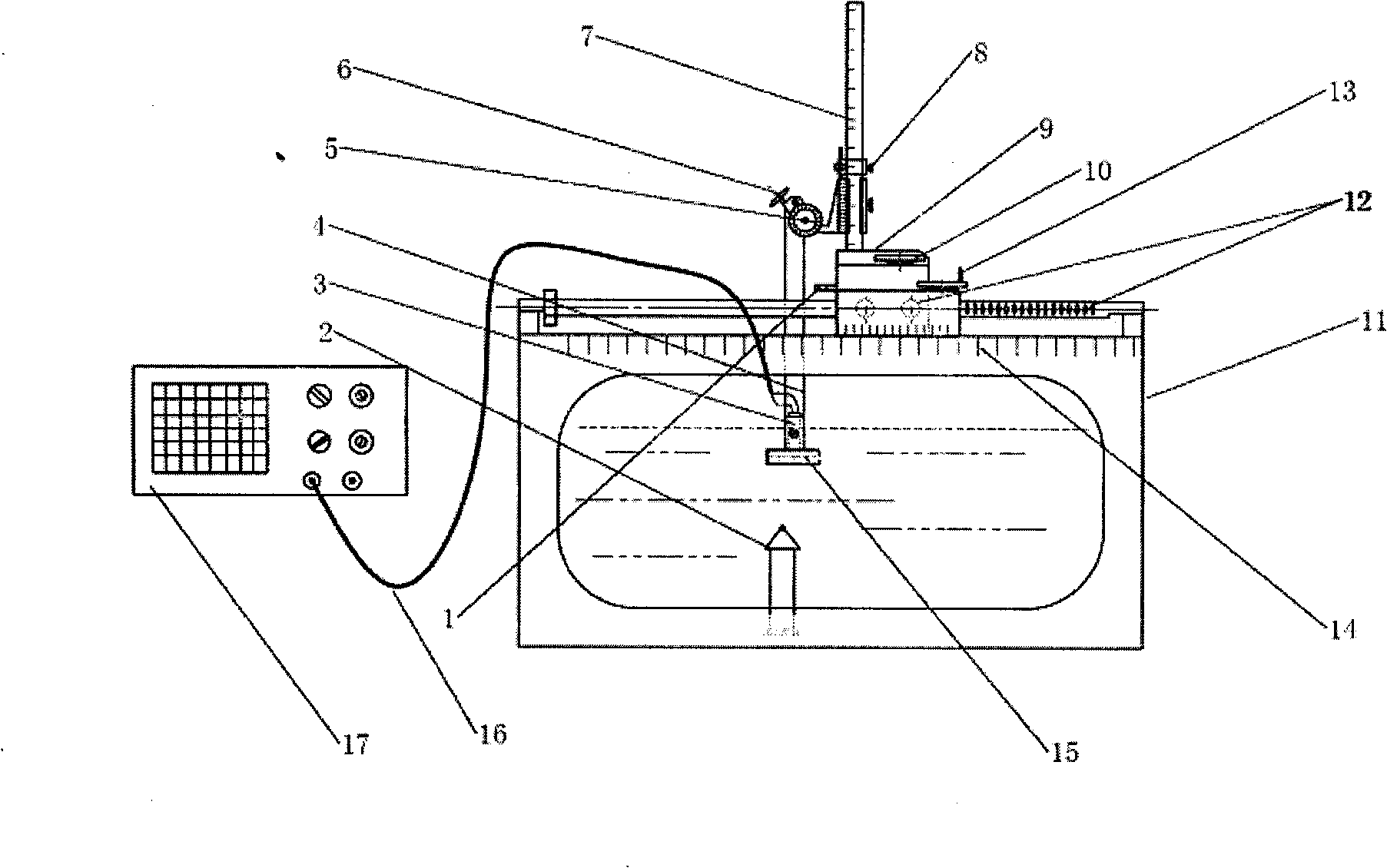

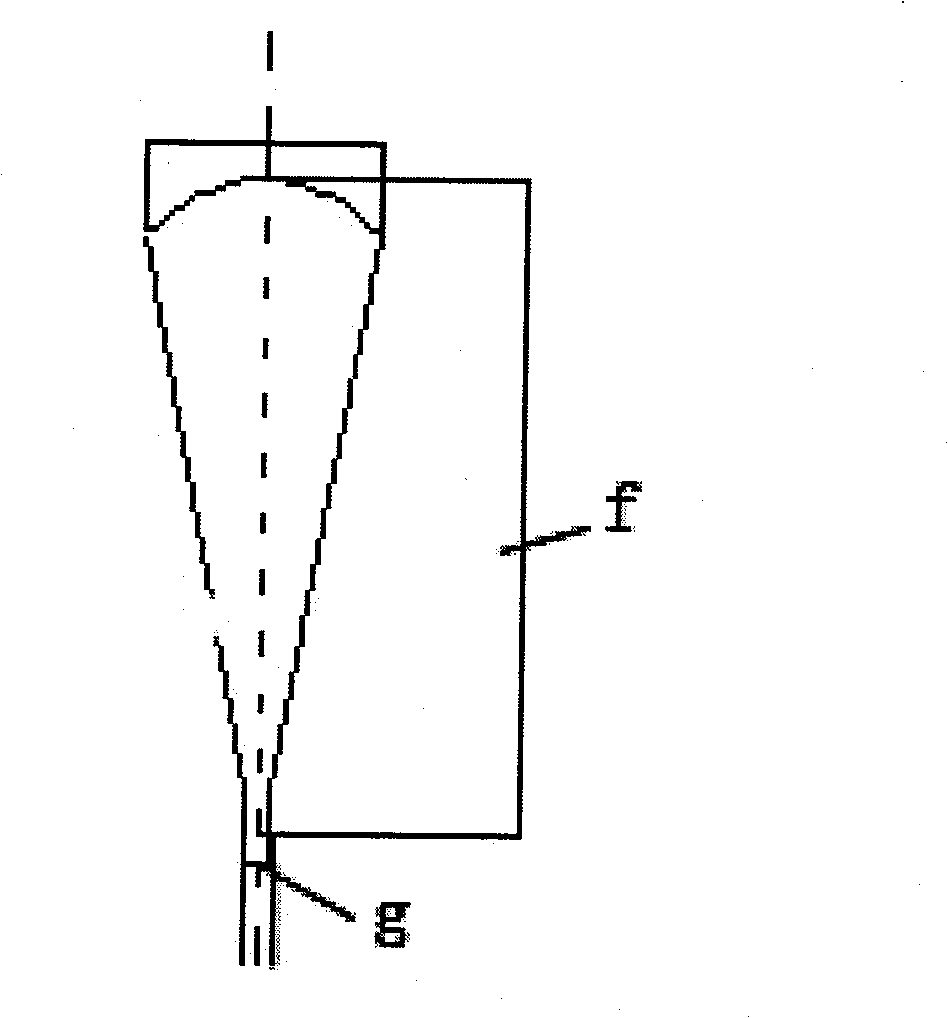

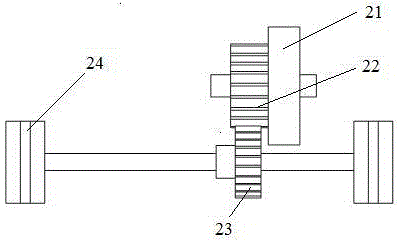

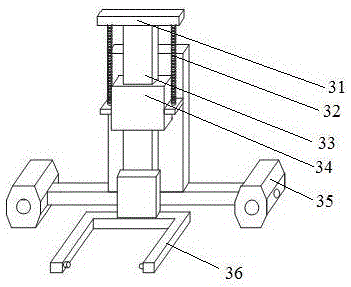

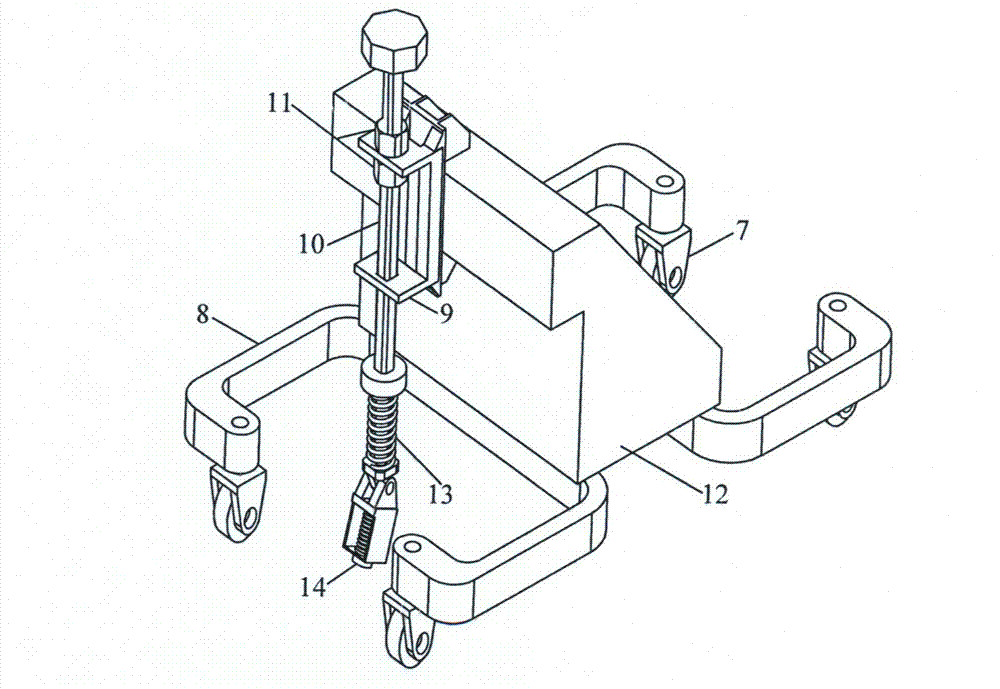

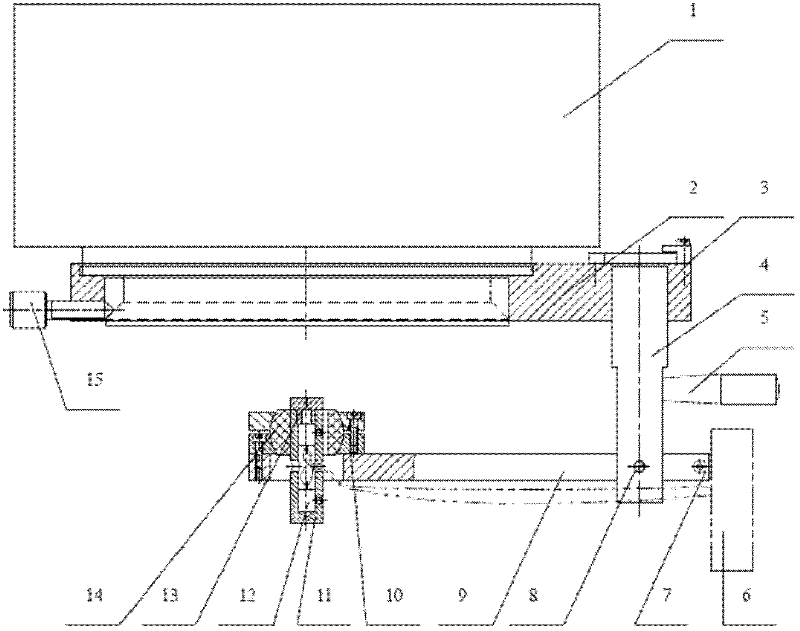

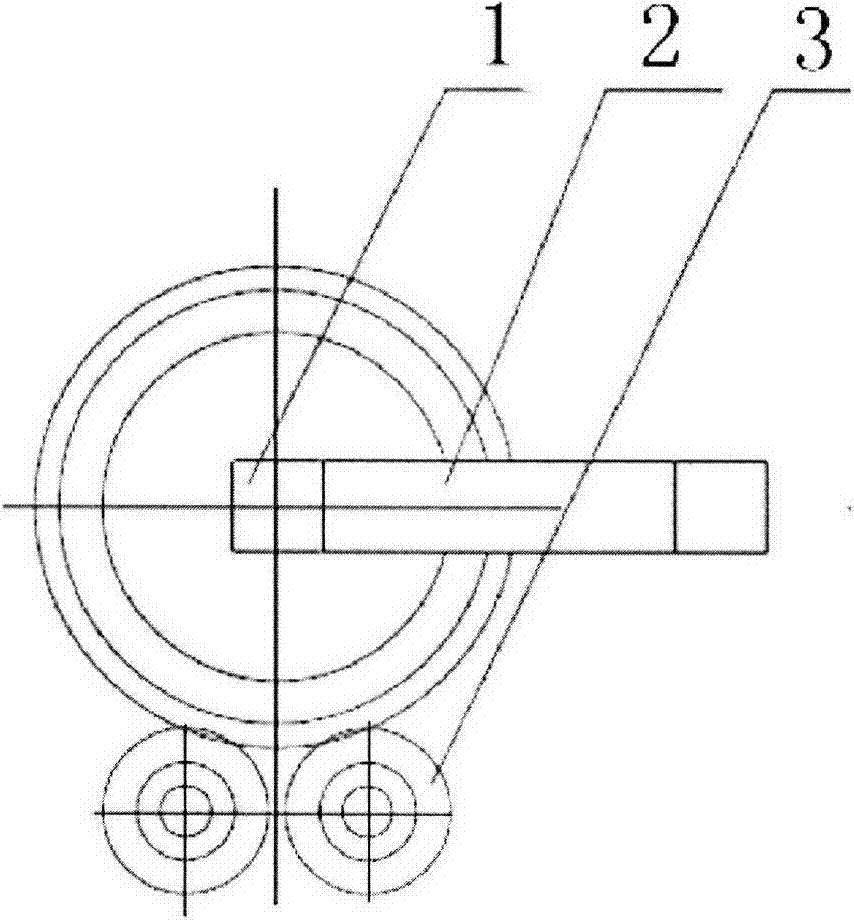

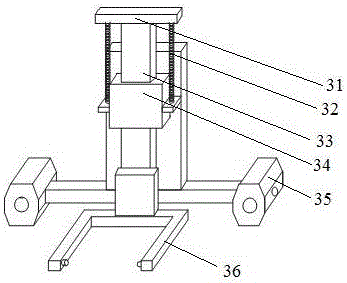

Performance test device for water immersion focusing probe and test method thereof

ActiveCN101539542AEasy to testIncreased effective beam widthMaterial analysis using sonic/ultrasonic/infrasonic wavesReflected wavesWater immersion

The invention relates to a performance test device for a water immersion focusing probe and a test method thereof. A steel ball is placed on a reference reflection seat of the performance test device placed in a water tank, the corresponding upside of the steel ball is provided and aligned with a probe to be tested, the probe to be tested generates ultrasonic signals to the steel ball through an ultrasonic gauge, and the performance difference of the probe is tested through the variation of reflection signals. A three-dimensional guide adjusting device is adjusted to test the position and variable quantity of the probe in real time so that reflection echo signals of the probe on the steel ball reaches maximum. Effective reflected wave is received by the probe and displayed on a display screen of the ultrasonic gauge in a form of wave height; scale numerical values on X axis, Y axis and Z axis of a graduated scale are recorded respectively; and various performance indexes of the probe are determined by observing the variation of the wave height. The performance test device for the water immersion focusing probe and the test method thereof are simple and practical, and can test the indexes such as focus, sound width, focus diameter, sound offset angle, sensitivity surplus, sensitivity deflection of a multi-chip probe and the like without depending on special laboratory equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

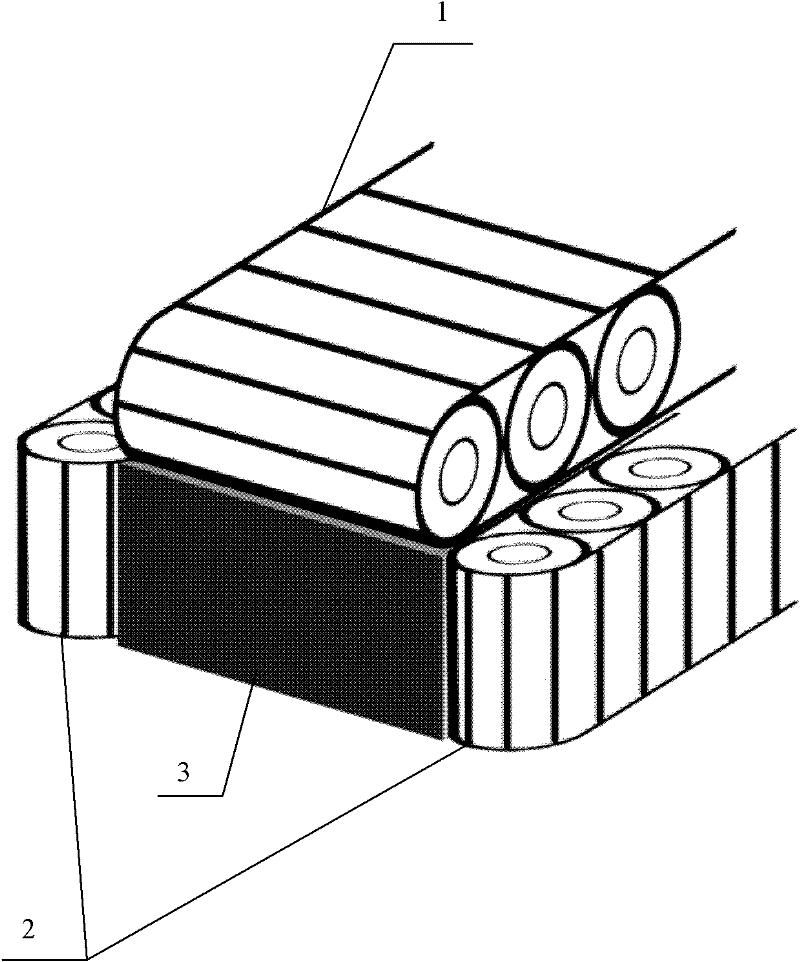

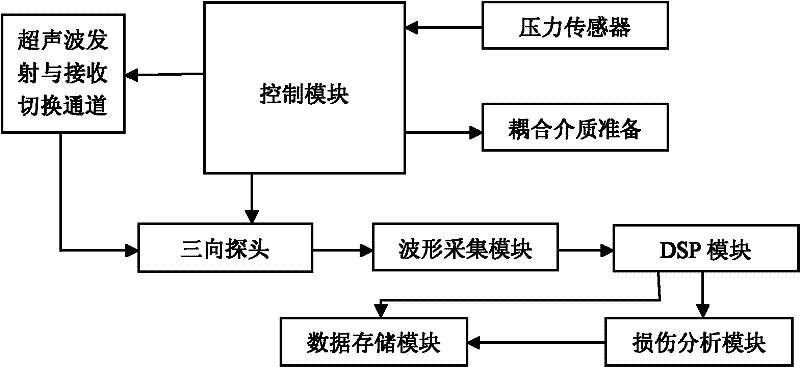

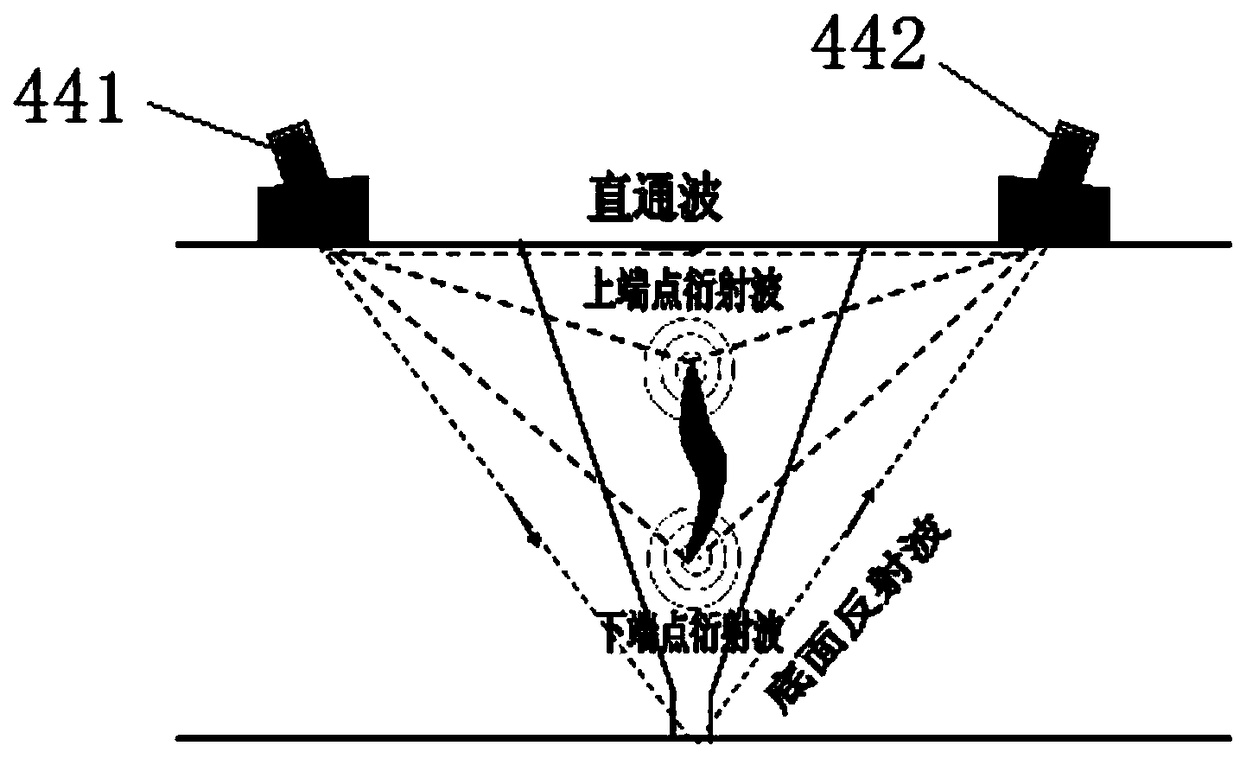

Device and method for flaw detection of small crawler-type rails based on three-way ultrasonic diffraction

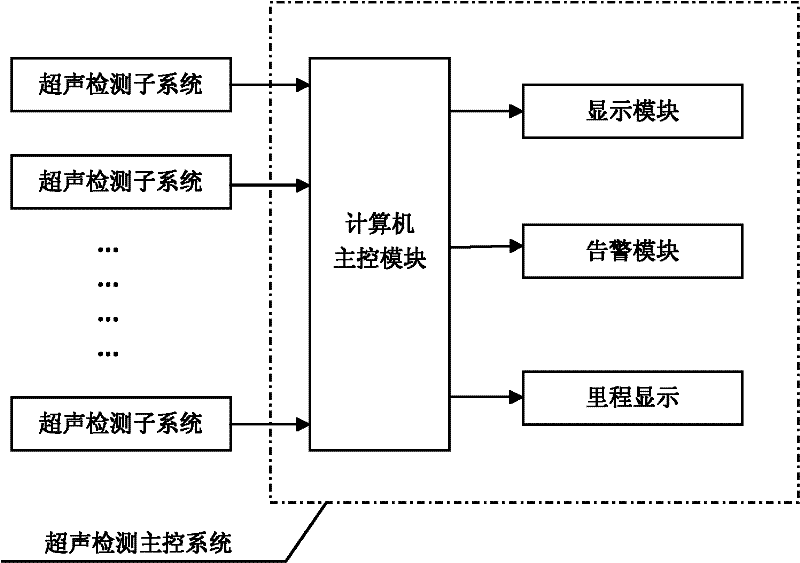

InactiveCN102230915AOvercoming the defect of echo lossHigh speed runningAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound attenuationControl system

The invention provides a device and a method for flaw detection of small crawler-type rails based on three-way ultrasonic diffraction. The device provided by the invention comprises a three-way crawler-type travel system, an ultrasonic detection master control system and a plurality of three-way ultrasonic diffraction detection sub-systems, wherein, all the three-way ultrasonic diffraction detection sub-systems and the ultrasonic detection master control system are configured on the three-way crawler-type travel system, and the three-way detector of each three-way ultrasonic diffraction detection sub-system is embedded in the crawler of the three-way crawler-type travel system. The method provided by the invention comprises the following steps: by means of the operations of all the three-way ultrasonic diffraction detection sub-systems and the ultrasonic detection master control system, carrying out crawler-type flaw detection, thus largely increasing the data sampling time in an areaof the rail at the same detection speed; and simultaneously based on the three-way structure, carrying out flaw estimation by means of the propagation sound path of diffracted waves so as to be not sensitive to the energy and amplitude of received echo pulses, thereby still ensuring accurate work in the detection condition with large energy attenuation.

Owner:SOUTH CHINA UNIV OF TECH

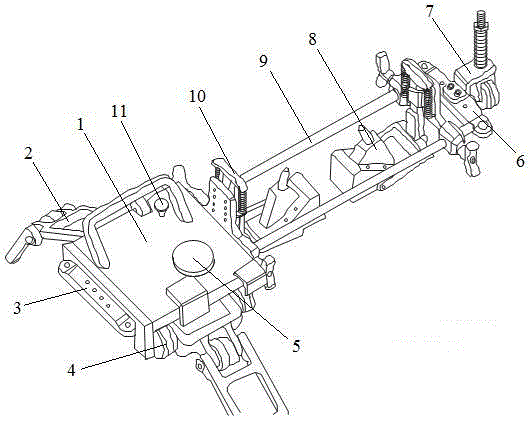

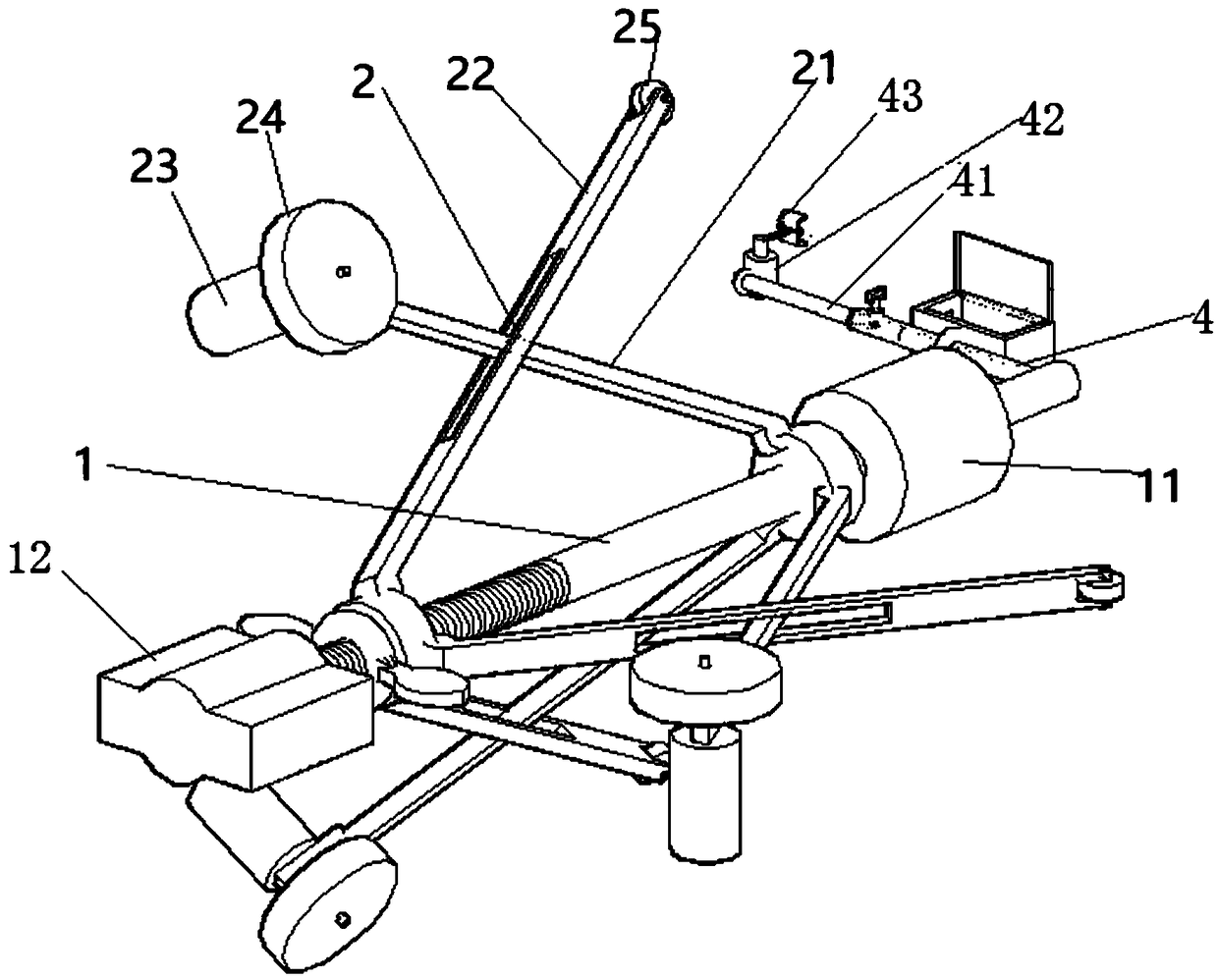

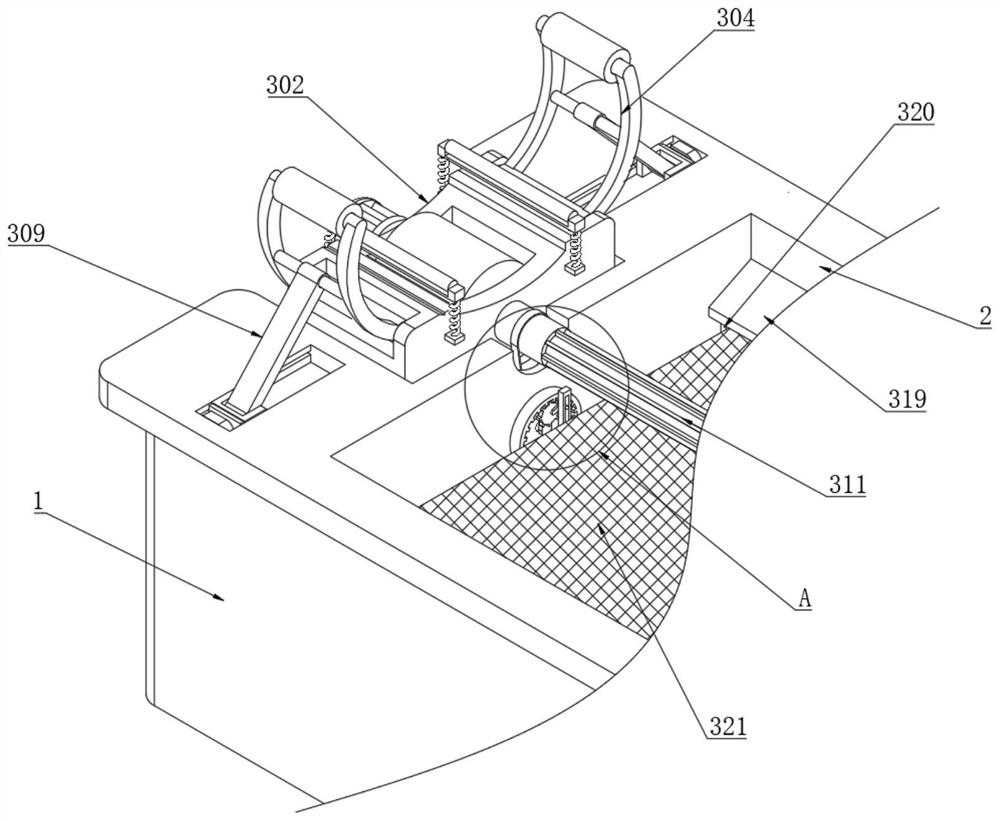

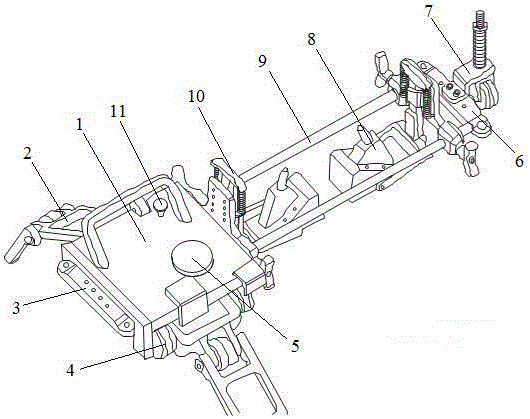

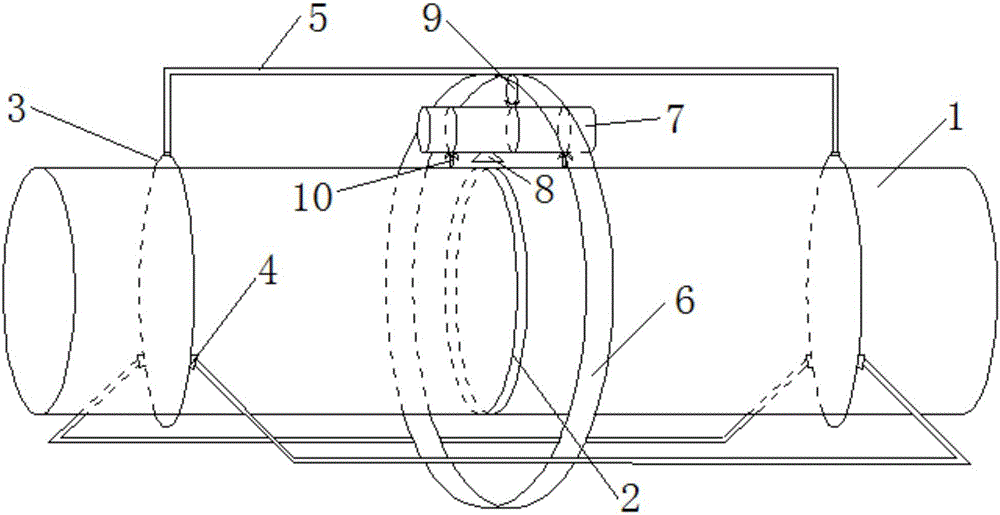

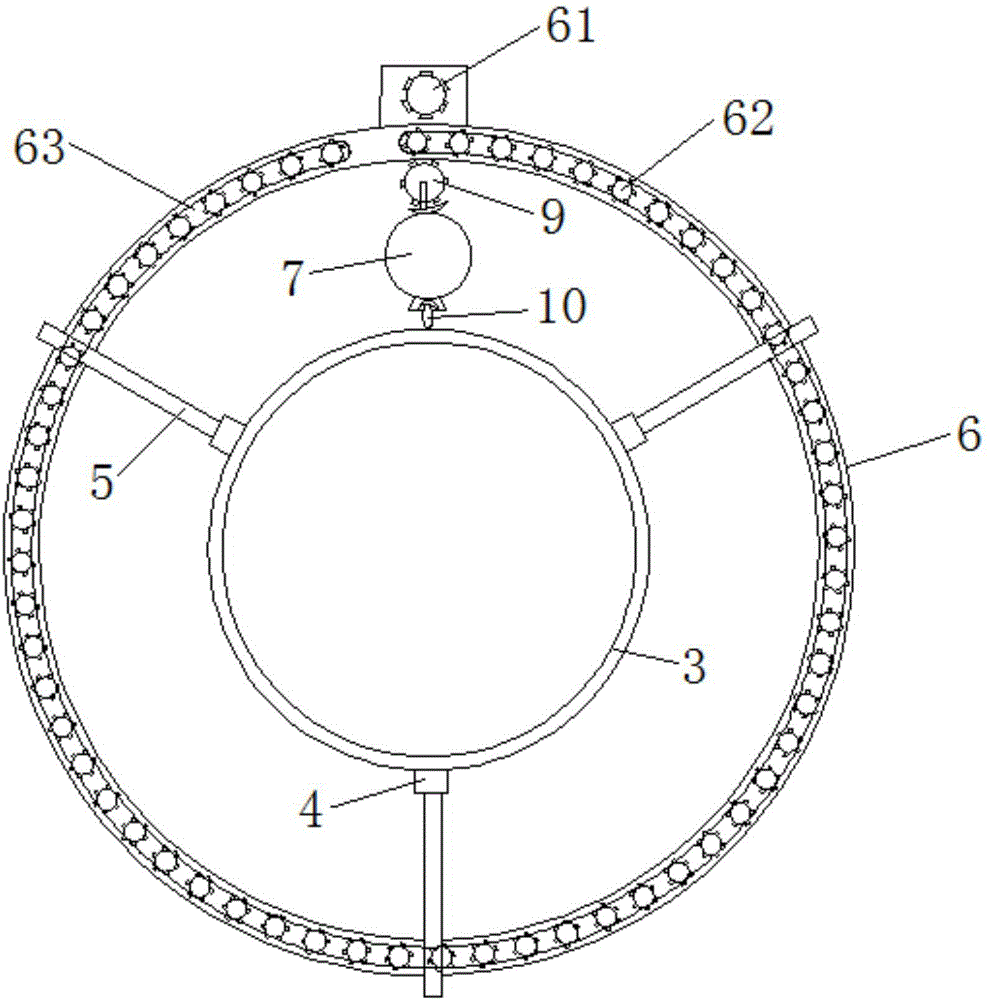

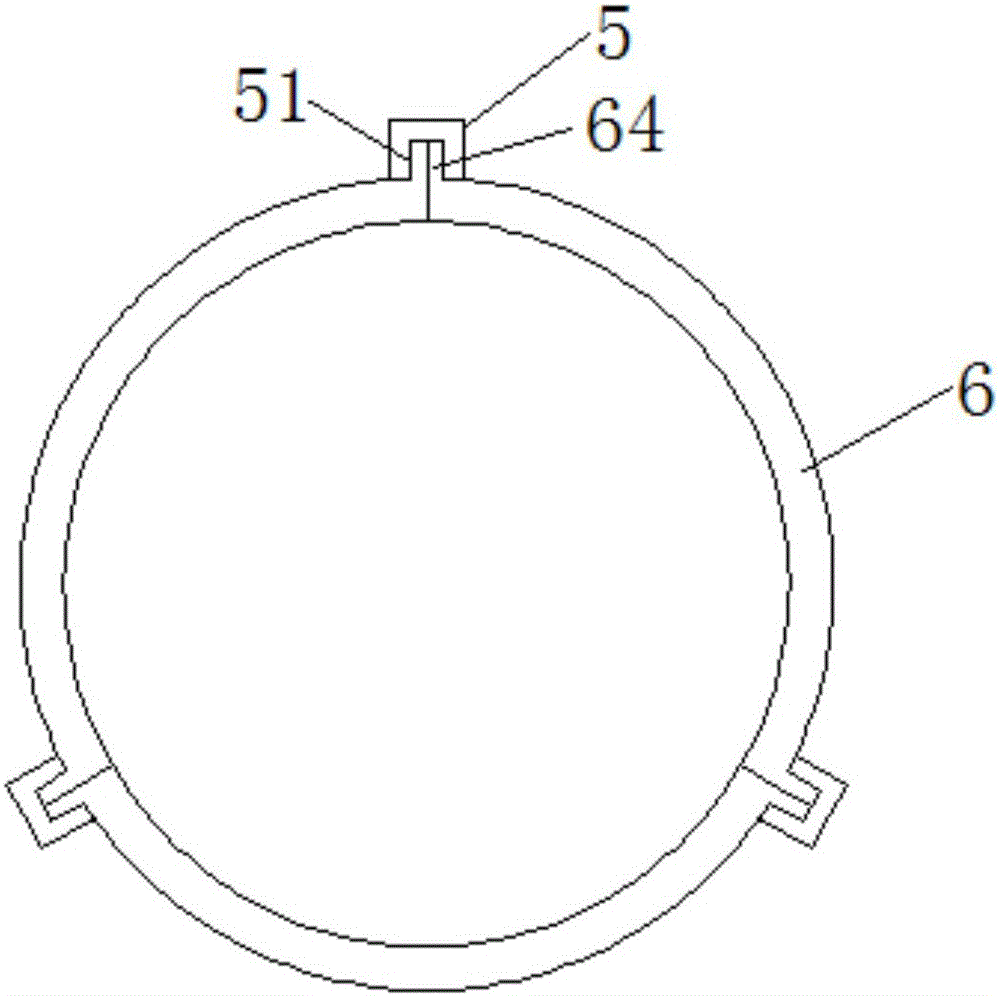

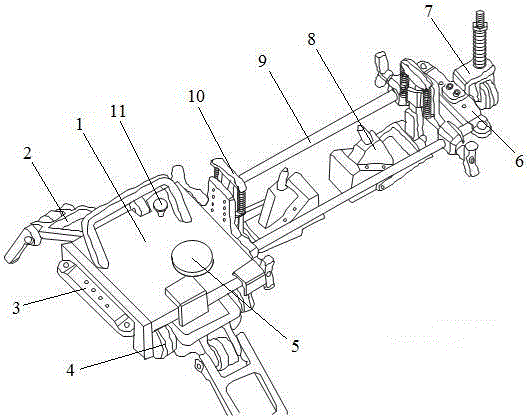

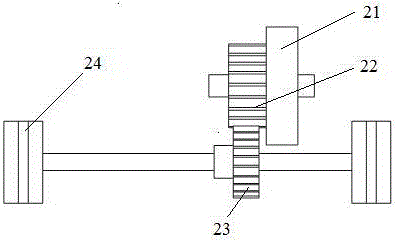

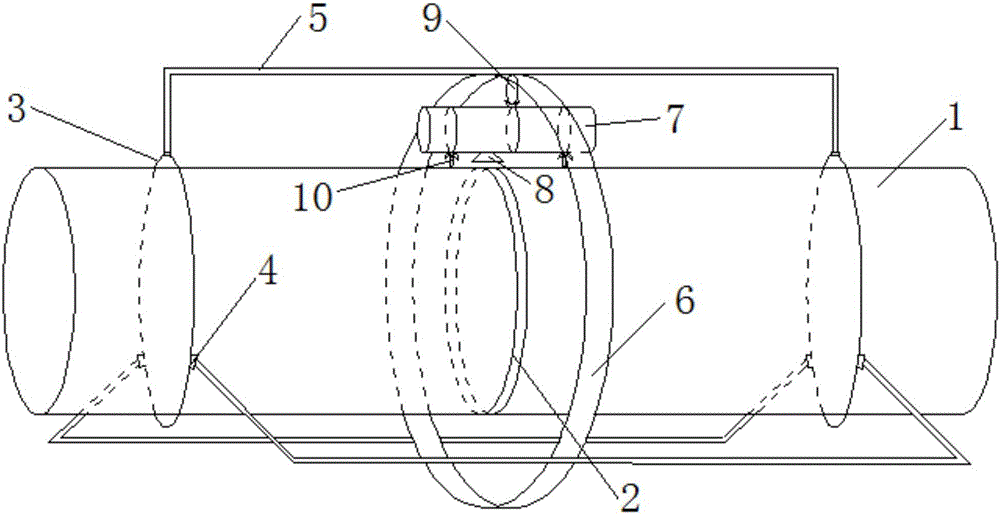

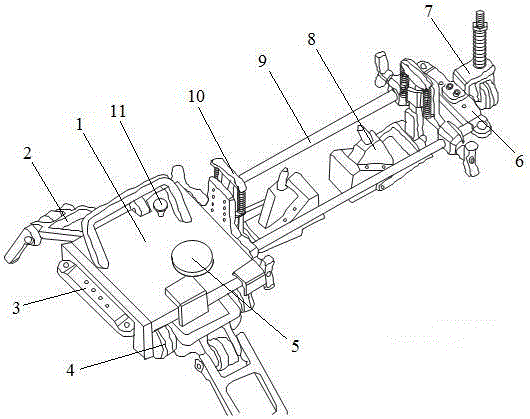

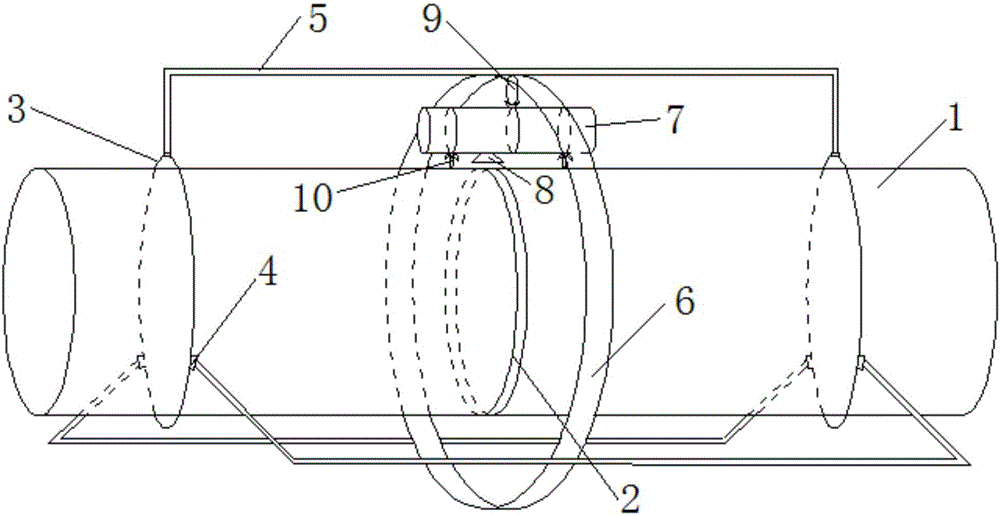

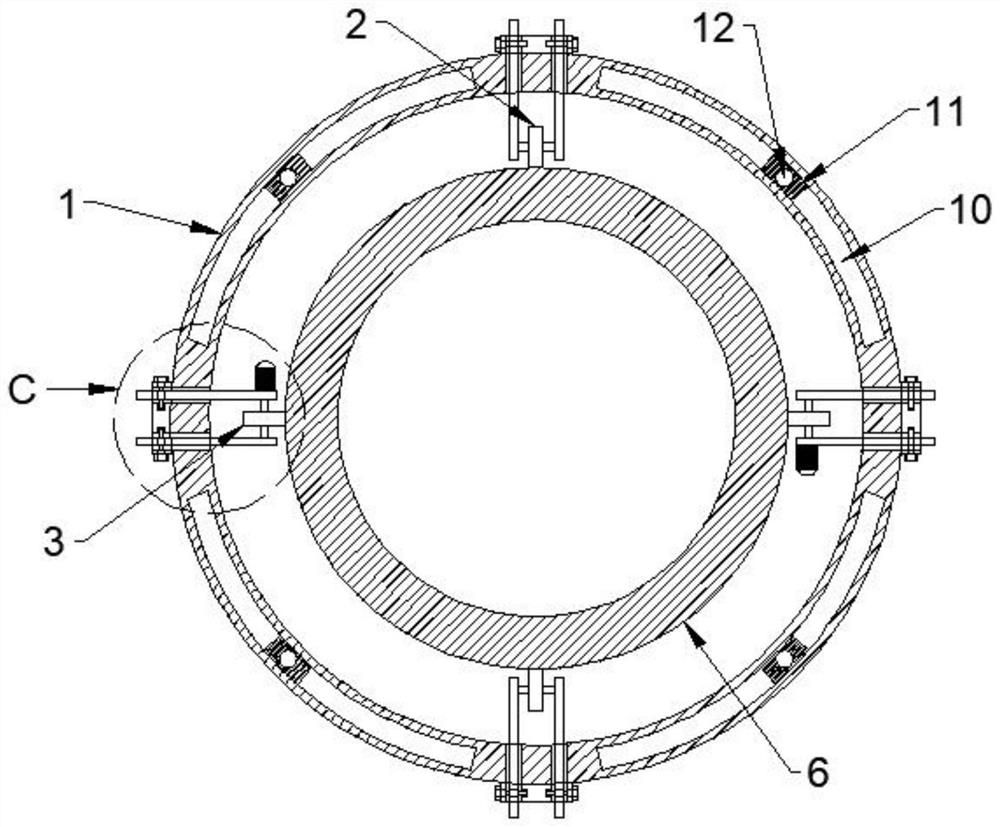

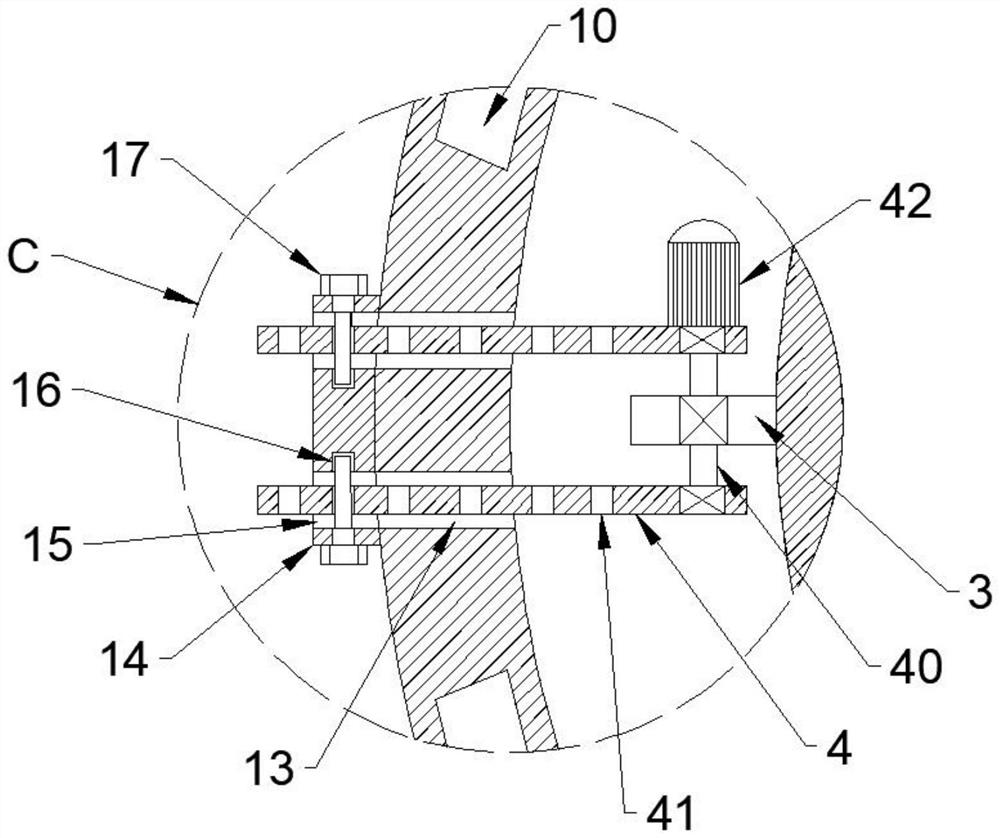

Multifunctional ultrasonic phased array pipeline circumferential weld detection equipment

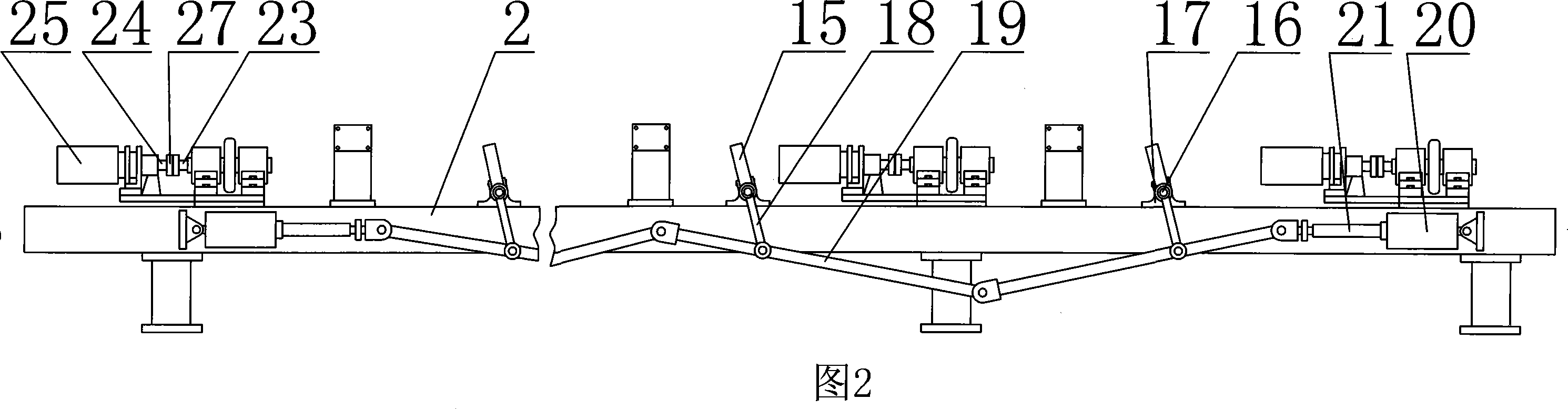

ActiveCN105158336AImprove reliabilityEasy to moveAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic pressureEngineering

The invention provides multifunctional ultrasonic phased array pipeline circumferential weld detection equipment which comprises a main body, a magnetic pressure wheel mechanism, an auxiliary support, a fastening device, a left flaw detection probe bracket, a right flaw detection probe bracket, a left flaw detection probe and a right flaw detection probe, wherein the main body comprises a base, a first slide bar, a second slide bar, a slide bar jackscrew, a left slide bar connecting rack, a right slide bar connecting rack, magnetic wheels and an axle; the fastening device is used for fastening the main body on a pipeline to-be-detected; the magnetic pressure wheel mechanism is arranged between the first slide bar and the second slide bar; the auxiliary support is connected with the first slide bar and the second slide bar of the main body; the flaw detection probe brackets are connected with the flaw detection probes and help the flaw detection probes to detect a weld joint of the pipeline to be detected. The equipment can rotate around the flaw detection pipeline smoothly during pipeline circumferential weld detection, thereby preventing impact of accidental conditions such as vibration on the detection effect, enlarging the application range of the equipment, and improving the flaw detection sensitivity and the detection efficiency.

Owner:中国石油天然气第一建设有限公司

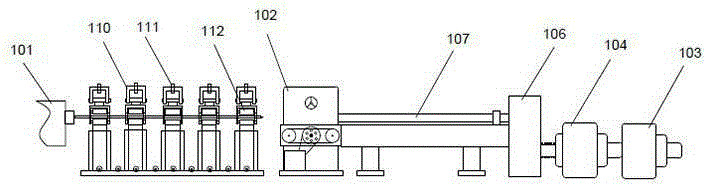

High-efficiency steel pipe flaw detection device

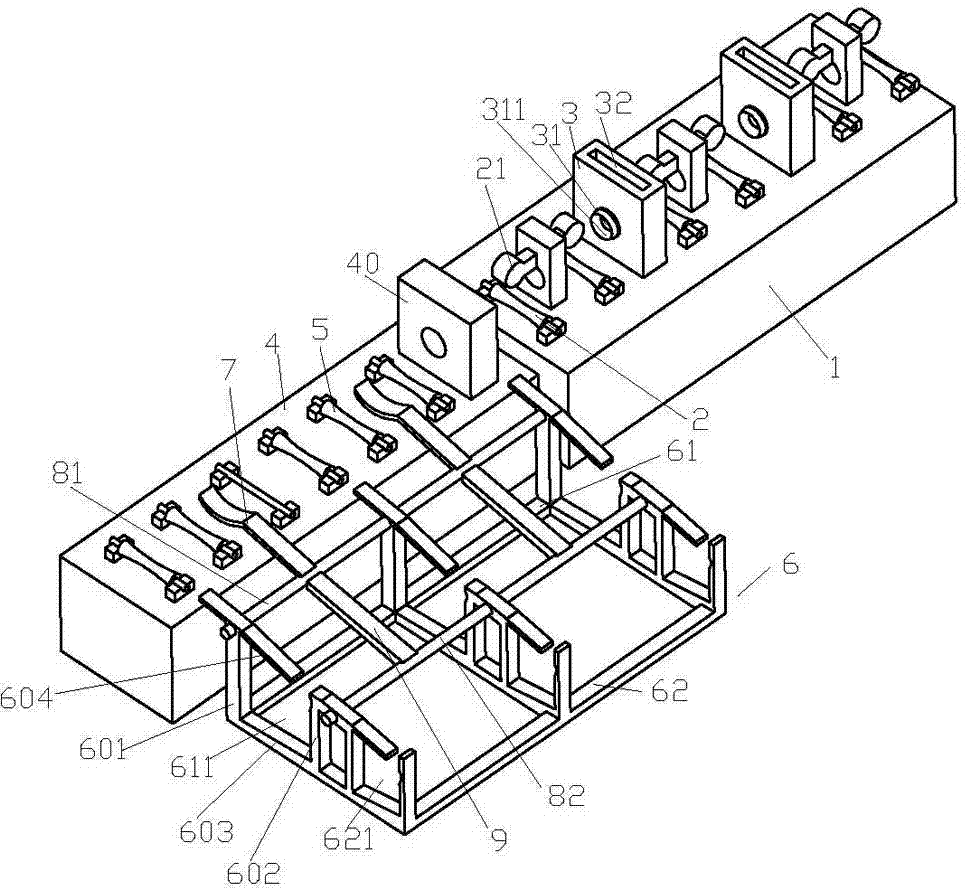

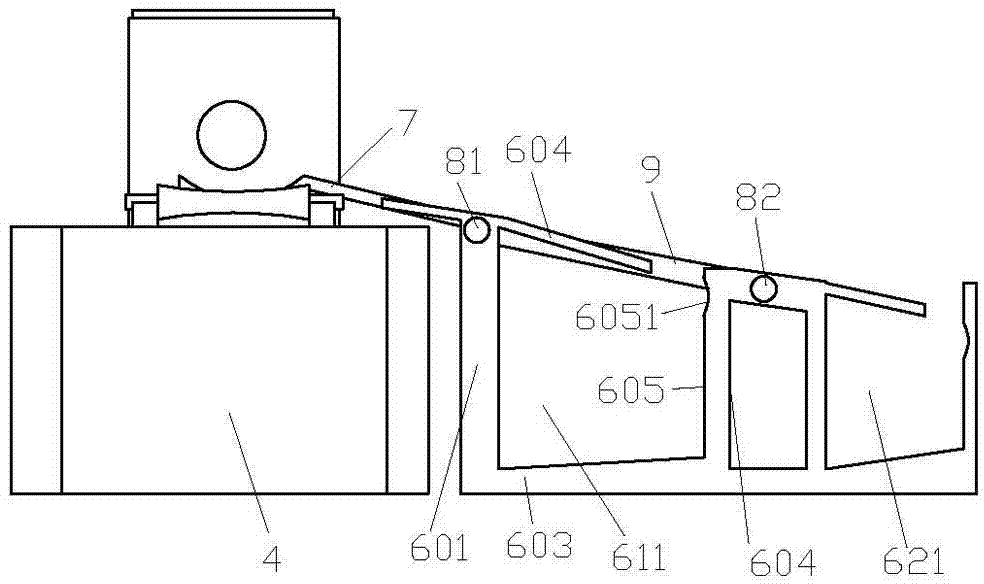

InactiveCN103399086AEasy to collect and stackImprove flaw detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesSortingDemagnetizing deviceClassical mechanics

The invention relates to the field of steel pipe flaw detection equipment and in particular relates to a high-efficiency steel pipe flaw detection device. The high-efficiency steel pipe flaw detection device comprises a detection stander, wherein a row of conveying wheels are arranged on the detection stander; liftable guide pressing wheels are arranged on the conveying wheels; flaw detection devices are arranged in the conveying directions of the conveying wheels and comprise flaw detectors and fixed boxes which are used for holding the flaw detectors and guiding steel pipes; a collection stander is also arranged at a position close to an outlet of the detection stander; a demagnetization device is arranged at an inlet of the collection stander; a row of bearing wheels positioned in the conveying directions of the conveying wheels are also arranged on the collection stander; collection frames are arranged on any one side or two sides of the bearing wheels along the conveying directions and comprise qualified product frames close to the bearing wheels and unqualified product frames away from the bearing wheels; collection rods for collecting the steel pipes are also arranged on the collection frames or the collection stander and are positioned in clearances between the bearing wheels. The high-efficiency steel pipe flaw detection device is firm in structure and very high in efficiency.

Owner:ANJI PENGDA STEEL PIPE

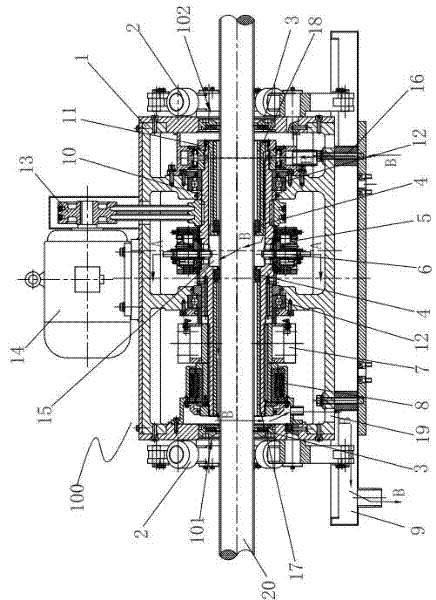

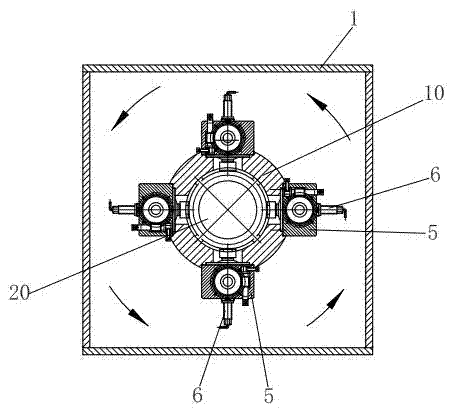

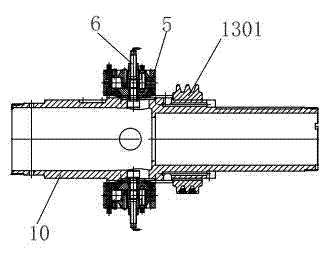

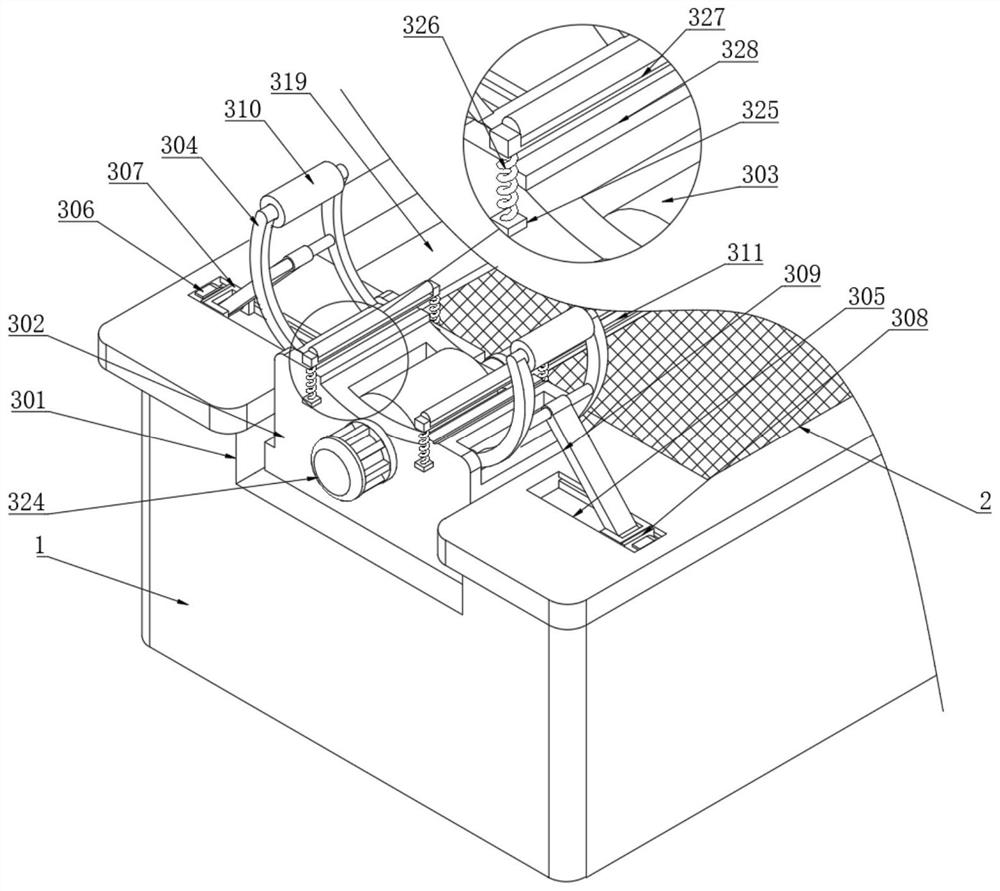

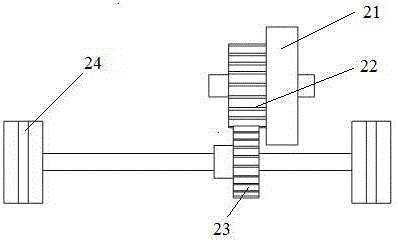

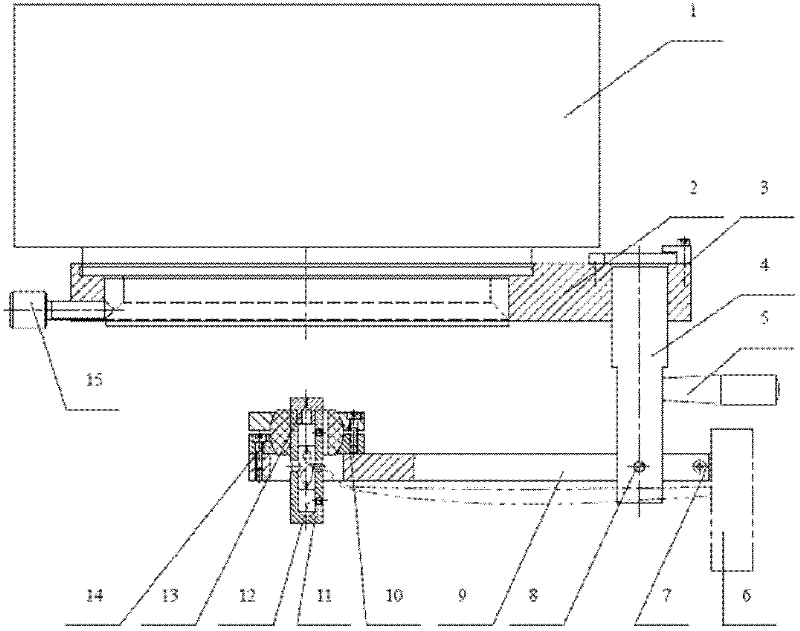

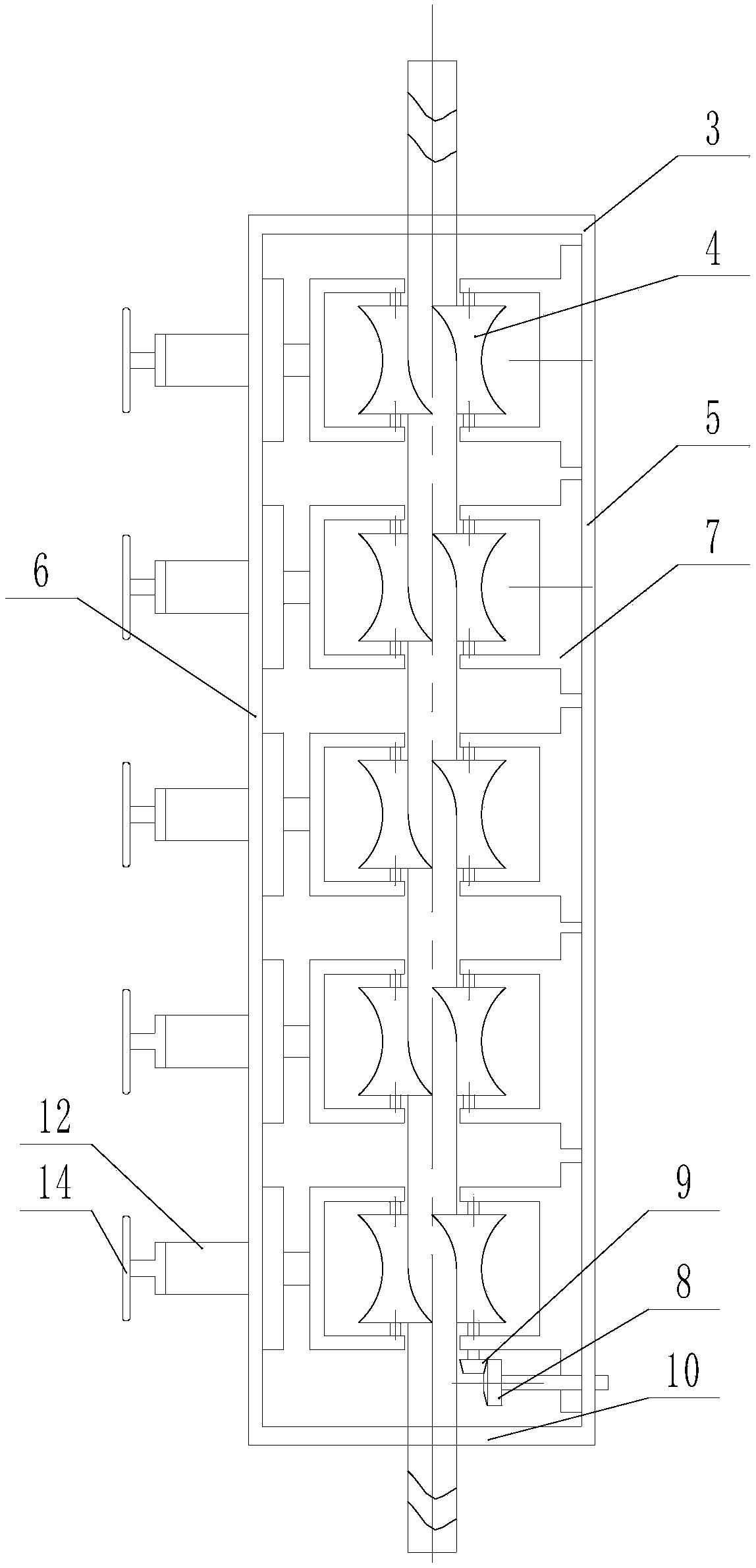

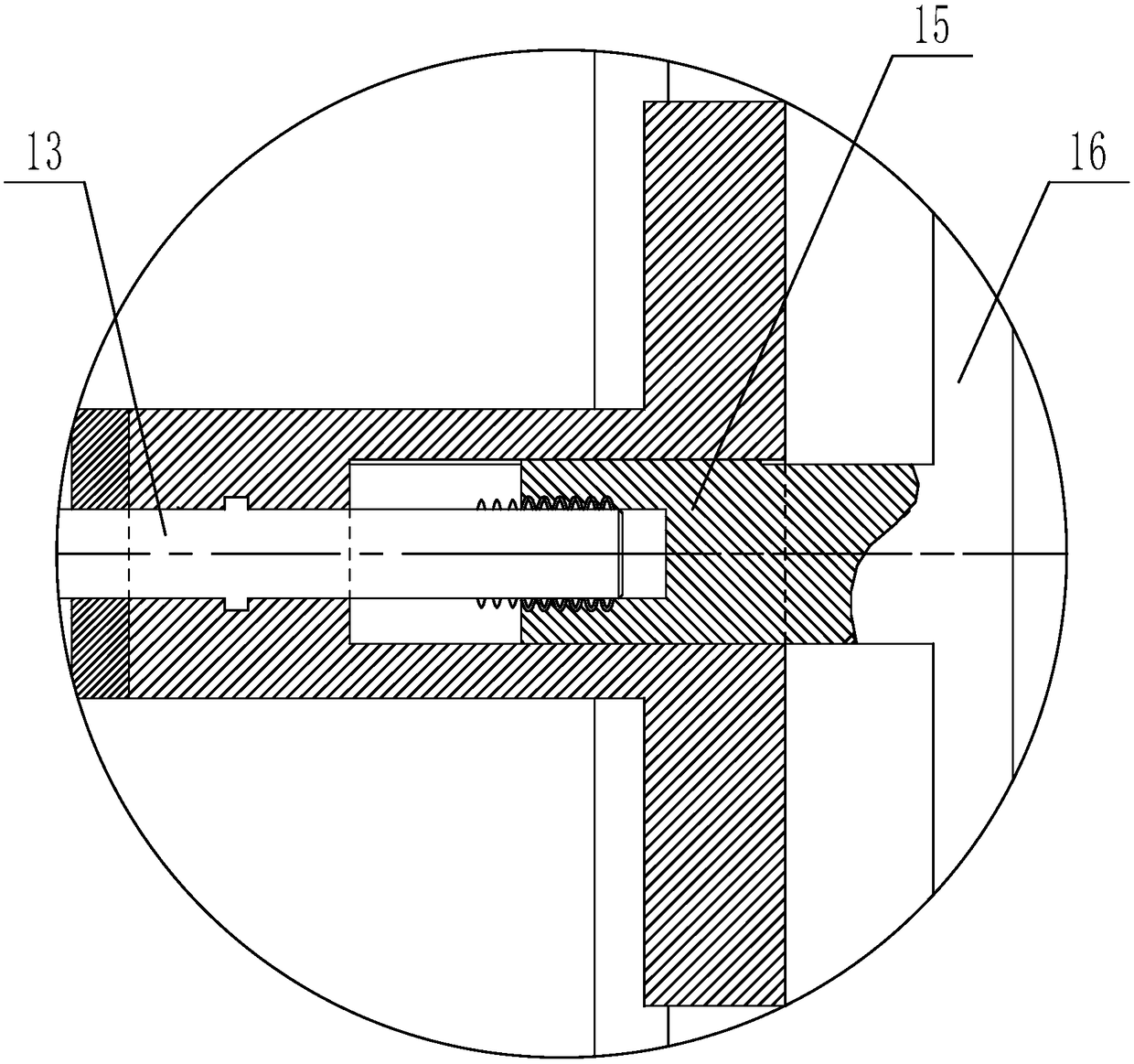

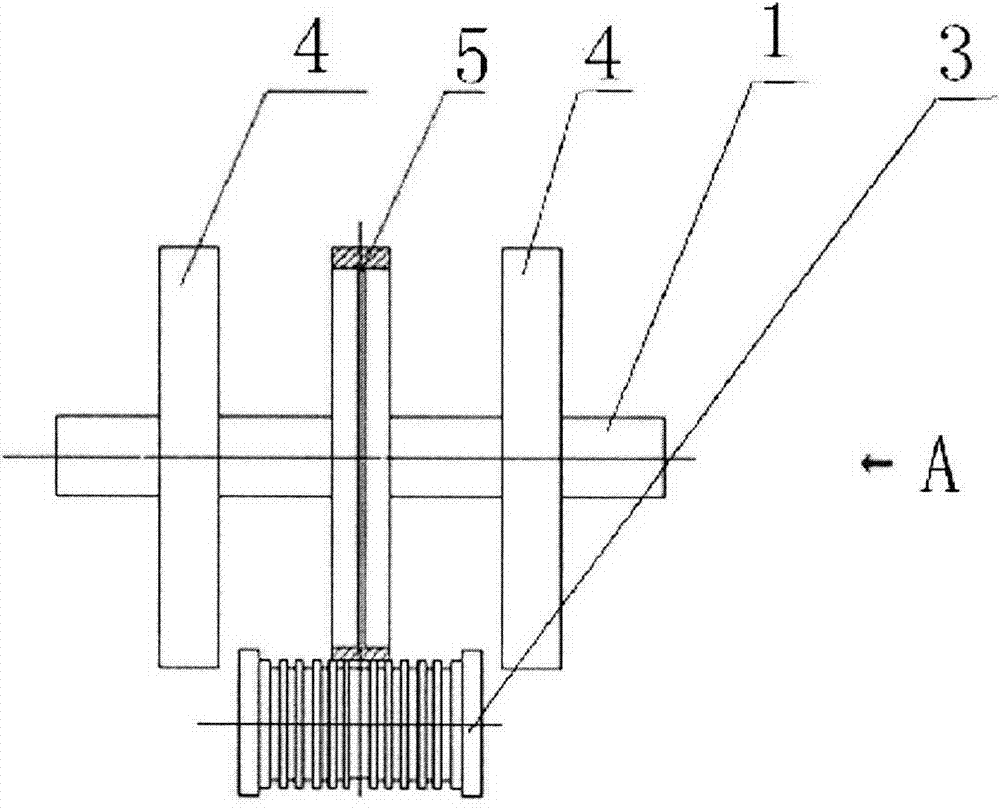

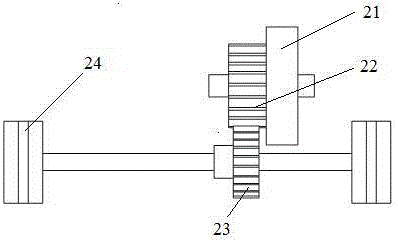

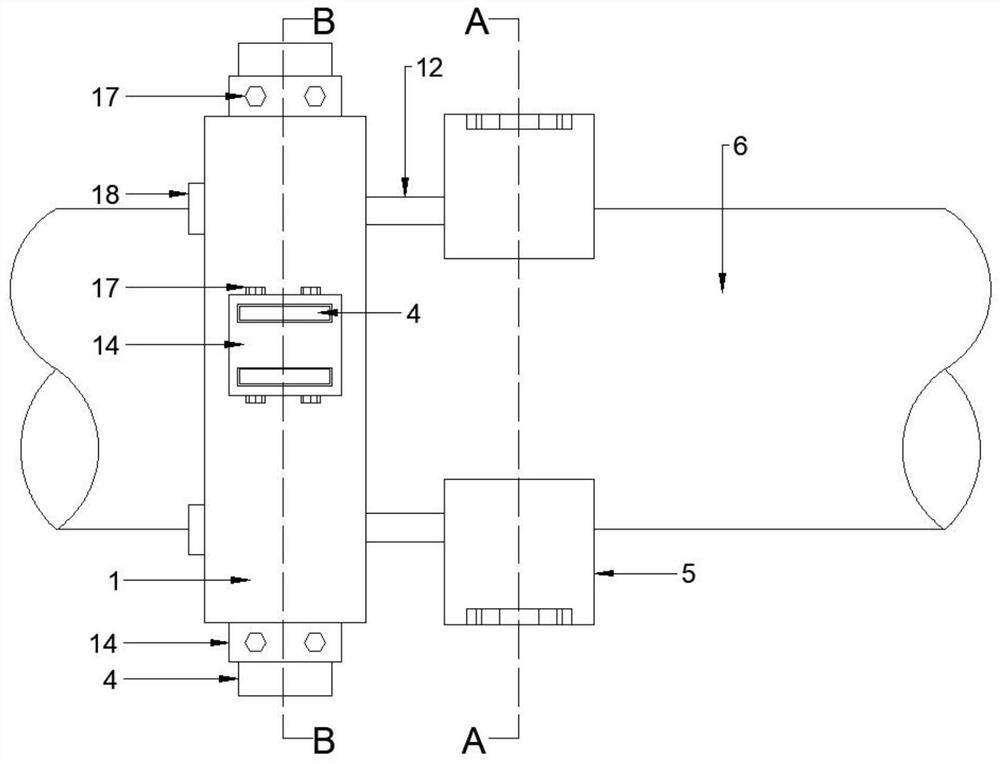

Ultrasonic flaw-detecting machine for steel pipes

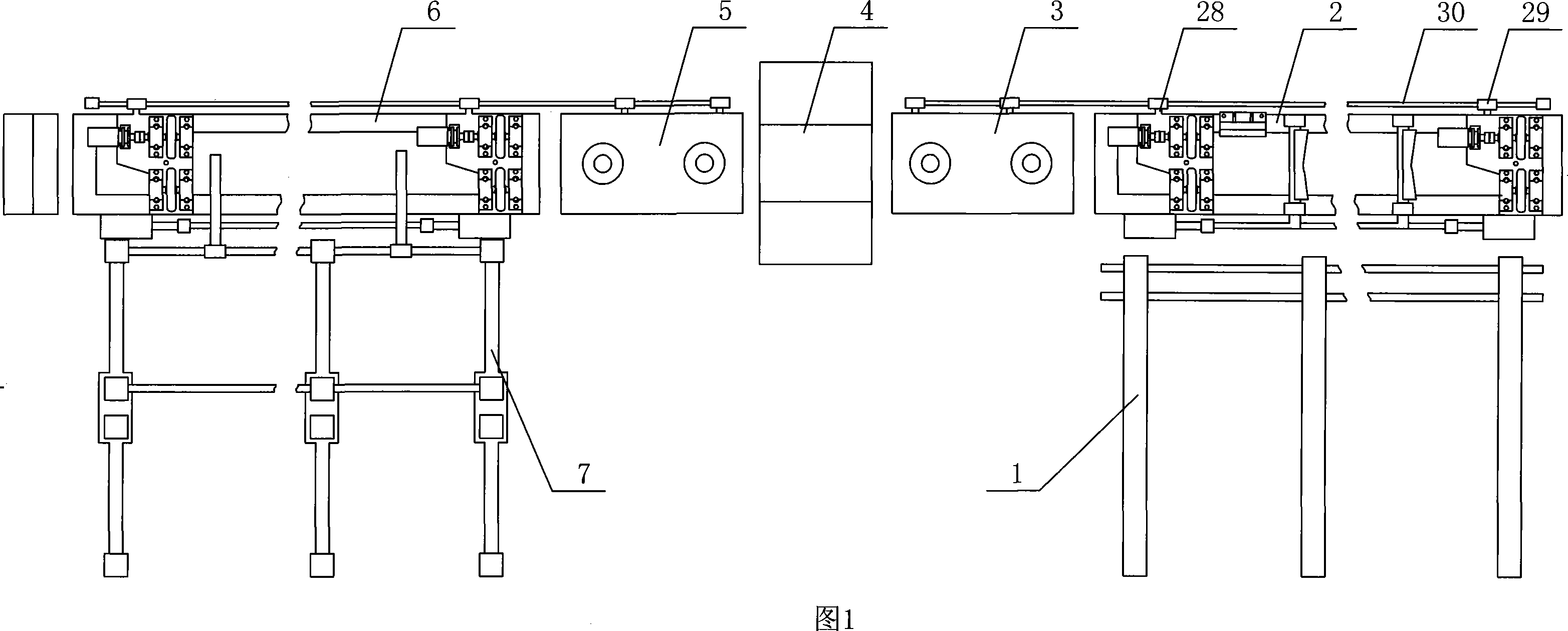

InactiveCN102565196AIncreased propulsion speedImprove flaw detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringAir bubble

The invention relates to an ultrasonic flaw-detecting machine for steel pipes. The ultrasonic flaw-detecting machine for the steel pipes is characterized in that: a flaw detection host machine comprises a box body, and two adjustable three-wheel centering devices are arranged at an inlet and an outlet on two sides of the box body respectively; a hollow spindle is arranged in the box body in a rotatable way, and a measured steel pipe passes through the hollow spindle, the inlet and the outlet; and the middle part of the hollow spindle is provided with at least three probe adjustment devices, an ultrasonic probe is arranged on each probe adjustment device, a power generation device and a signal pre-processing device are arranged outside the hollow spindle, and the signal pre-processing device is connected with the ultrasonic probes, and transmits detection data to an ultrasonic flaw detector of a control system by using a wireless signal. A structural form that the steel pipes are linearly pushed and the ultrasonic probes rotate is adopted, so that the pushing speed of the steel pipes is improved, and the flaw detection efficiency is improved; and the centrifugal force produced by the high-speed rotation of the hollow spindle extrudes the air in a detection cavity, and water is supplied by using an interlayer between an inner sleeve and the hollow spindle, so that the water supply quantity is large, bubbles are reduced, and the detection accuracy is improved.

Owner:无锡莱林检测机械有限公司

Pipeline inner wall automatic flaw detection, carbon arc gouging and welding robot

ActiveCN109488836AGuarantee welding qualityImprove safety and reliabilityPigs/molesWelding apparatusEngineeringUltimate tensile strength

Owner:NANTONG INST OF TECH

Welding technology for longitudinal joints of pipe-plug type channel of composite-plate type air cooler

ActiveCN105499749AImprove corrosion resistanceWelding shrinkage deformation is reducedArc welding apparatusMetal working apparatusShielded metal arc weldingEngineering

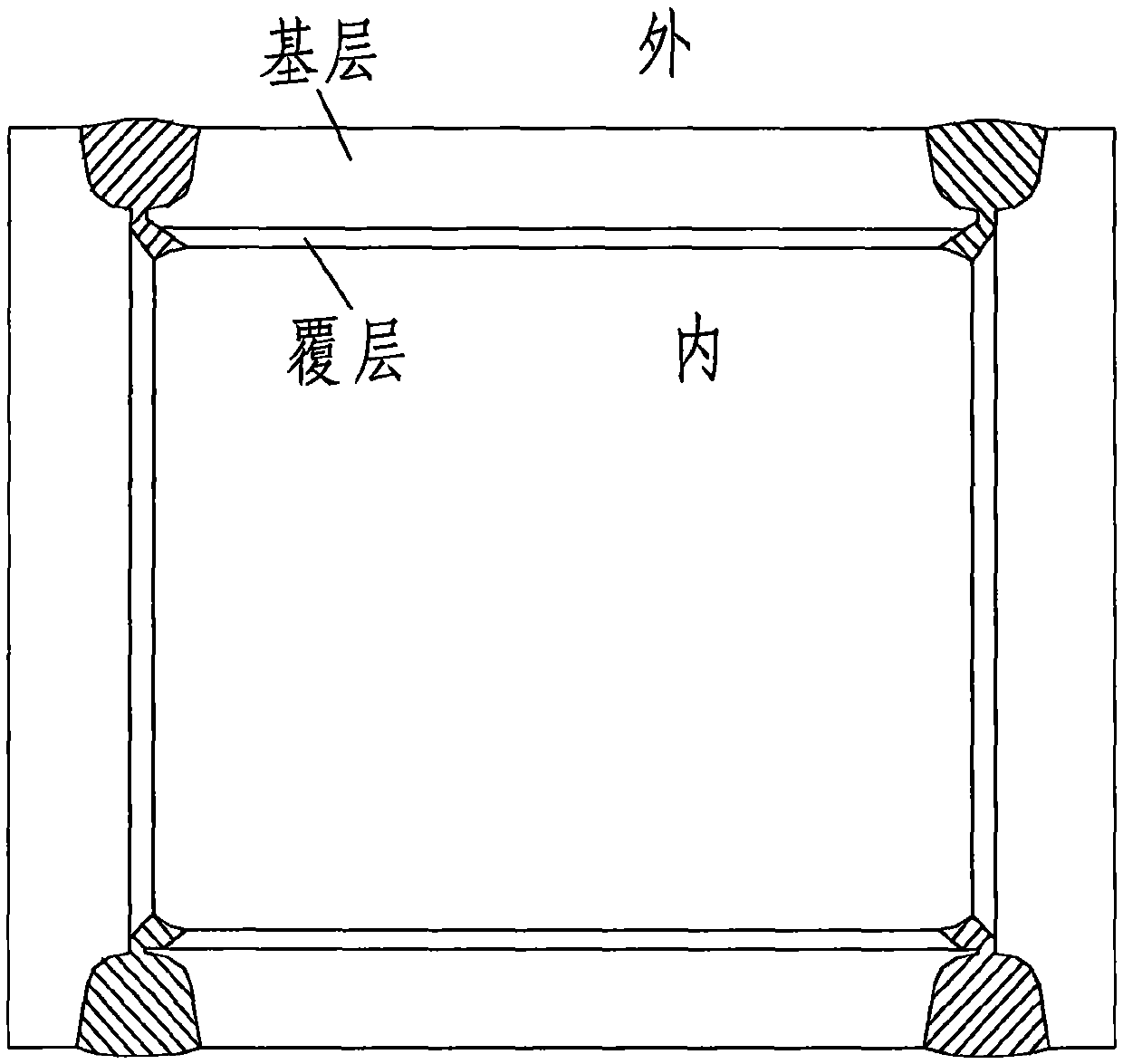

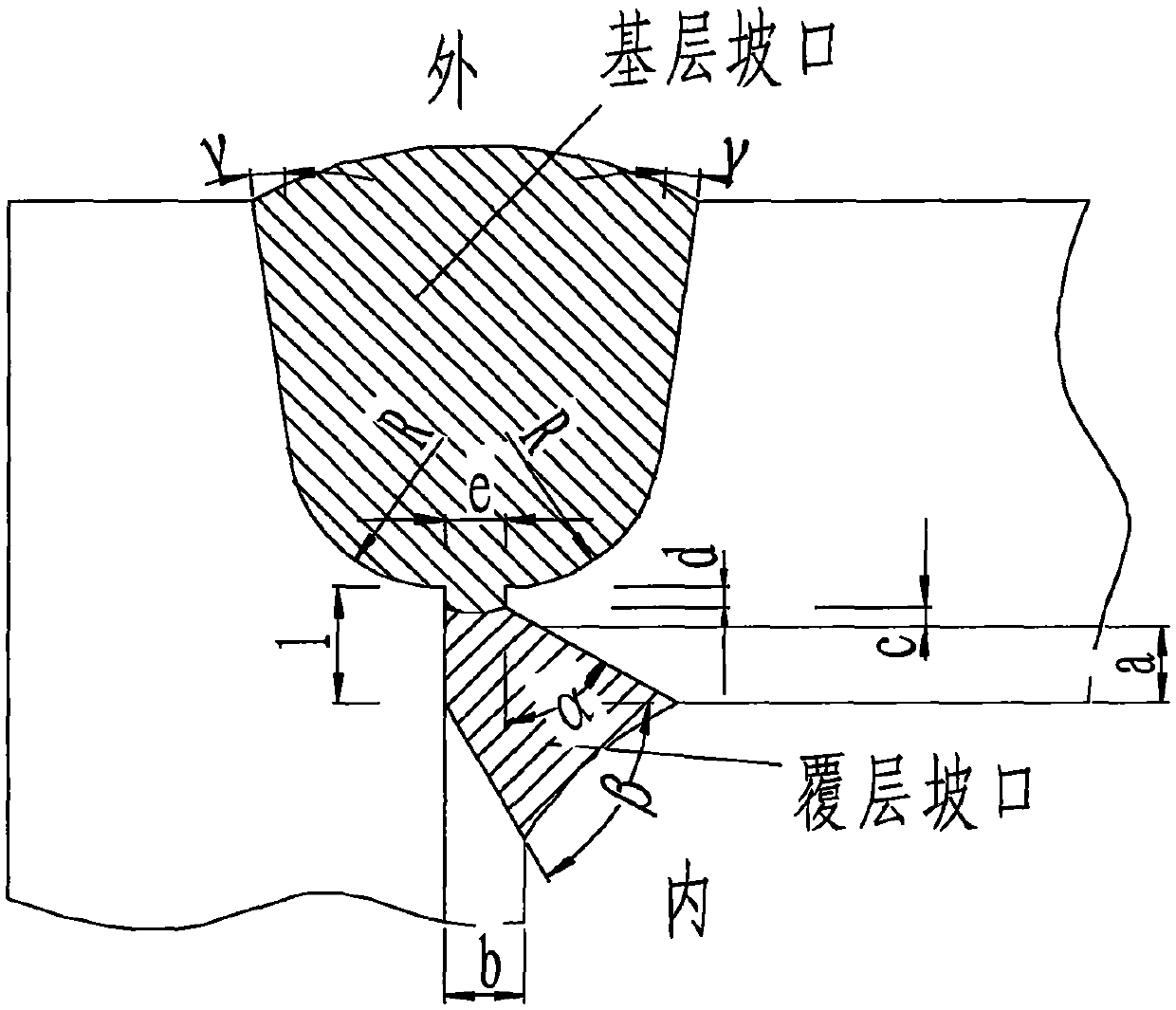

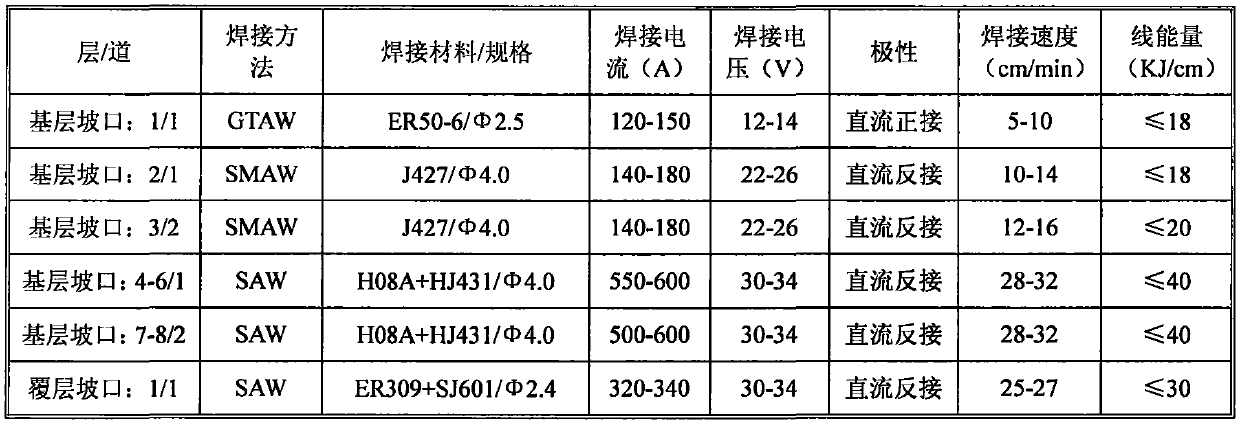

Disclosed is a welding technology for longitudinal joints of a pipe-plug type channel of a composite-plate type air cooler. An outer layer of the channel is a base layer, an inner layer of the channel is a coating, each of longitudinal channel joints is formed between each two adjacent perpendicular composite plates, a base layer groove is formed between the base layers, on the outer layer of each longitudinal channel joint, of each two corresponding composite plates, and a coating groove is formed between the coatings, on the inner layer of each longitudinal channel joint, of each two corresponding composite plates. The welding technology includes welding the base layer grooves and the coating grooves sequentially, wherein the base layer grooves are bottomed by argon arc welding and filled with two layers by shielded metal arc welding, the rest parts of the base layer grooves are covered by submerged arc welding, and then the inner coating grooves of the channel are welded on an inner-angle submerged arc welding machine. The welding technology has the advantages that welded joints are high in heat conductivity and small in linear expansion coefficient, channel welding shrinkage distortion amount is small, and welding material cost is reduced substantially; since the base layer grooves and the coating grooves are welded sequentially, the welded joints in the coating grooves can be protected from secondary heating, and corrosion resistance of the welded joints of the coating grooves is improved; production cost is reduced and production efficiency is improved.

Owner:LONGHUA TECHNOLOGY GROUP (LUOYANG) CO LTD

Steel pipe machining system

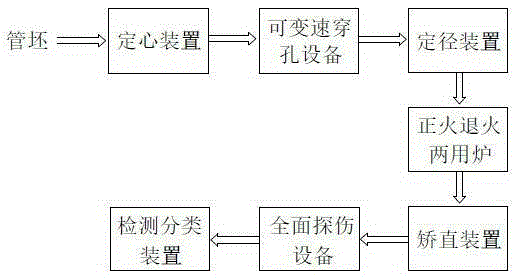

ActiveCN105268760ARealize a wide range of speed changesEfficient cooperationFurnace typesHeat treatment furnacesLow speedEngineering

The invention discloses a steel pipe machining system and belongs to the technical field of steel pipe machining. The steel pipe machining system comprises a centering device, variable-speed perforating equipment, a normalizing and annealing two-purpose furnace, a sizing device, a straightening device, comprehensive flaw detection equipment and a detection and classification device. Different rotating speeds are provided for the variable-speed perforating equipment through the cooperation of a high-speed motor, a low-speed motor and a reduction gearbox so that different types of steel pipes can be perforated. According to the normalizing and annealing two-purpose furnace, two heat treatment processes are achieved through one furnace body. The comprehensive flaw detection equipment integrates an eddy current flaw detection method and an ultrasonic flaw detection method, so that the detection quality of the steel pipes is guaranteed. According to the whole system, the efficiency of the steel pipe machining process is high, and the quality of the steel pipes is guaranteed.

Owner:ANJI PENGDA STEEL PIPE

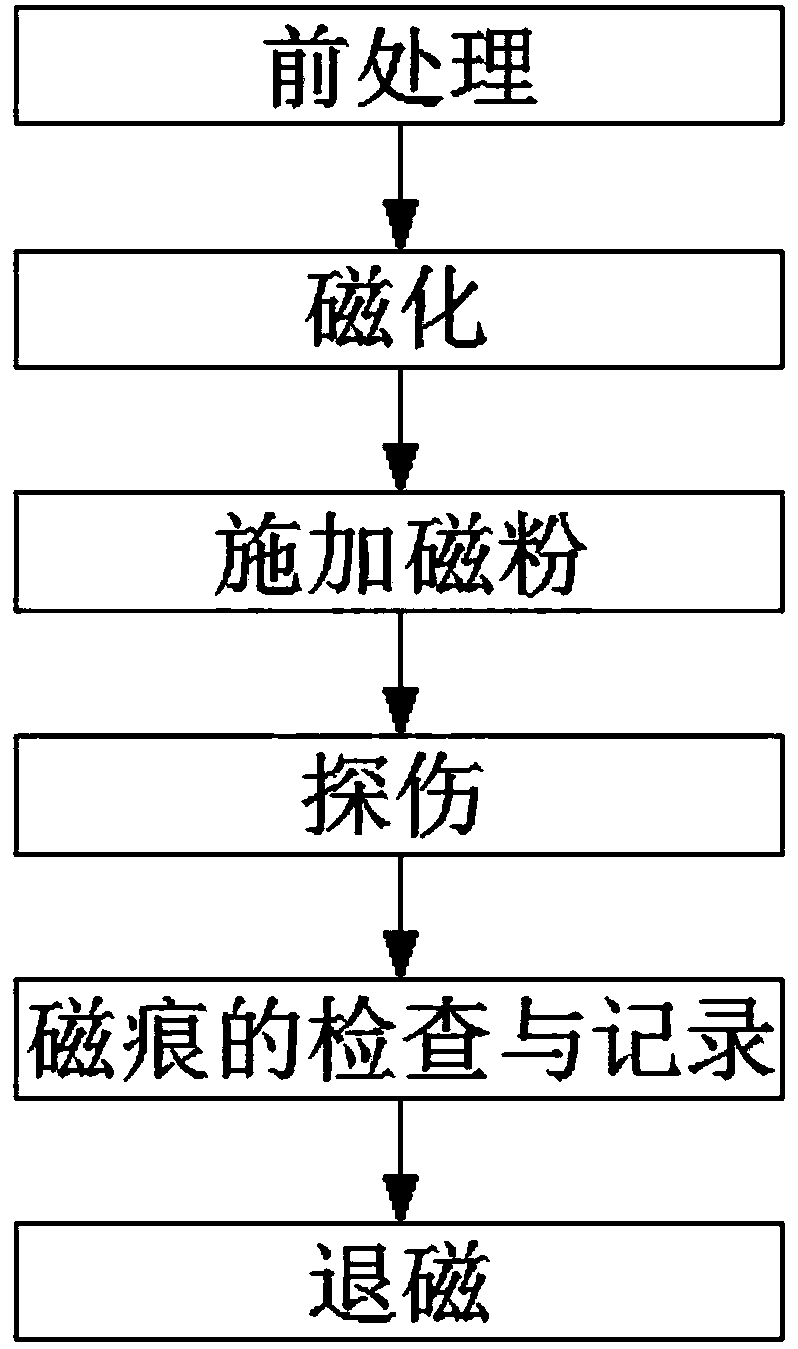

High-frequency impulse magnetic powder inspection method

InactiveCN108120763AImprove stabilityImprove flaw detection efficiencyMaterial magnetic variablesPre treatmentMaterials science

The invention discloses a high-frequency impulse magnetic powder inspection method and belongs to the technical field of magnetic powder inspection. The high-frequency impulse magnetic powder inspection method comprises the following steps: S1, pre-treatment: cleaning the surface of a workpiece to be inspected thoroughly to remove attachments on the surface of the workpiece, and cleaning and drying the workpiece; S2, magnetization: putting the workpiece in an electrified coil to magnetize the surface of the workpiece; S3, magnetic powder application: uniformly applying the magnetic powder to an inspection surface in an effective inspection range, wherein the magnetic powder is adsorbed to defective parts, then electrifying an instant current to the workpiece, and pouring a magnetic suspension for 2-3 times after power off; S4, inspection: inspecting the surface of the workpiece by using an electromagnetic probe which outputs high frequency impulse signals; S5, examination and recordingof magnetic traces; and S6, demagnetization: detecting the demagnetized workpiece with a magnetometer, and carrying out inspection with the high frequency impulse signals. The method is high in stability, low in cost and high in inspection efficiency, the detection precision is improved, and the method is convenient to operate and meets the production demands.

Owner:JIANGYIN YONGXING MACHINERY MFG

Weld joint nondestructive testing device for pipeline flaw detection

InactiveCN112505059AScientific and reasonable structureEasy to useTransportation and packagingSpraying apparatusLiquid storage tankStructural engineering

The invention discloses a weld joint nondestructive testing device for pipeline flaw detection. The device comprises a machine base, a liquid storage tank is formed in the middle of the top end of themachine base, a wastewater discharging mechanism is arranged in the liquid storage tank, and limiting and screening mechanisms are symmetrically arranged at the positions, corresponding to the two sides of the liquid storage tank, of the top end of the machine base, an efficient spraying mechanism is arranged at the top end, corresponding to the top of the liquid storage tank, of the machine base; each limiting and screening mechanism comprises an embedded groove, a supporting seat and a bearing wheel. The device is scientific and reasonable in structure and safe and convenient to use, the limiting and screening mechanisms are arranged, side guide rollers are pressed to descend through the self-weight of a pipeline, electrode plates at the bottom ends of the side guide rollers are attached to electrode plates at the top ends of bottom blocks, power is supplied to an electromagnet, and electromagnets are matched with magnetic strips, and sliding blocks are pushed to slide, meanwhile, the magnetic force of the electromagnets is increased according to the current conveying strength, and the pushing force of the electromagnets for pushing the magnetic strips is increased, therefore the moving effect of the sliding blocks is guaranteed.

Owner:徐子明

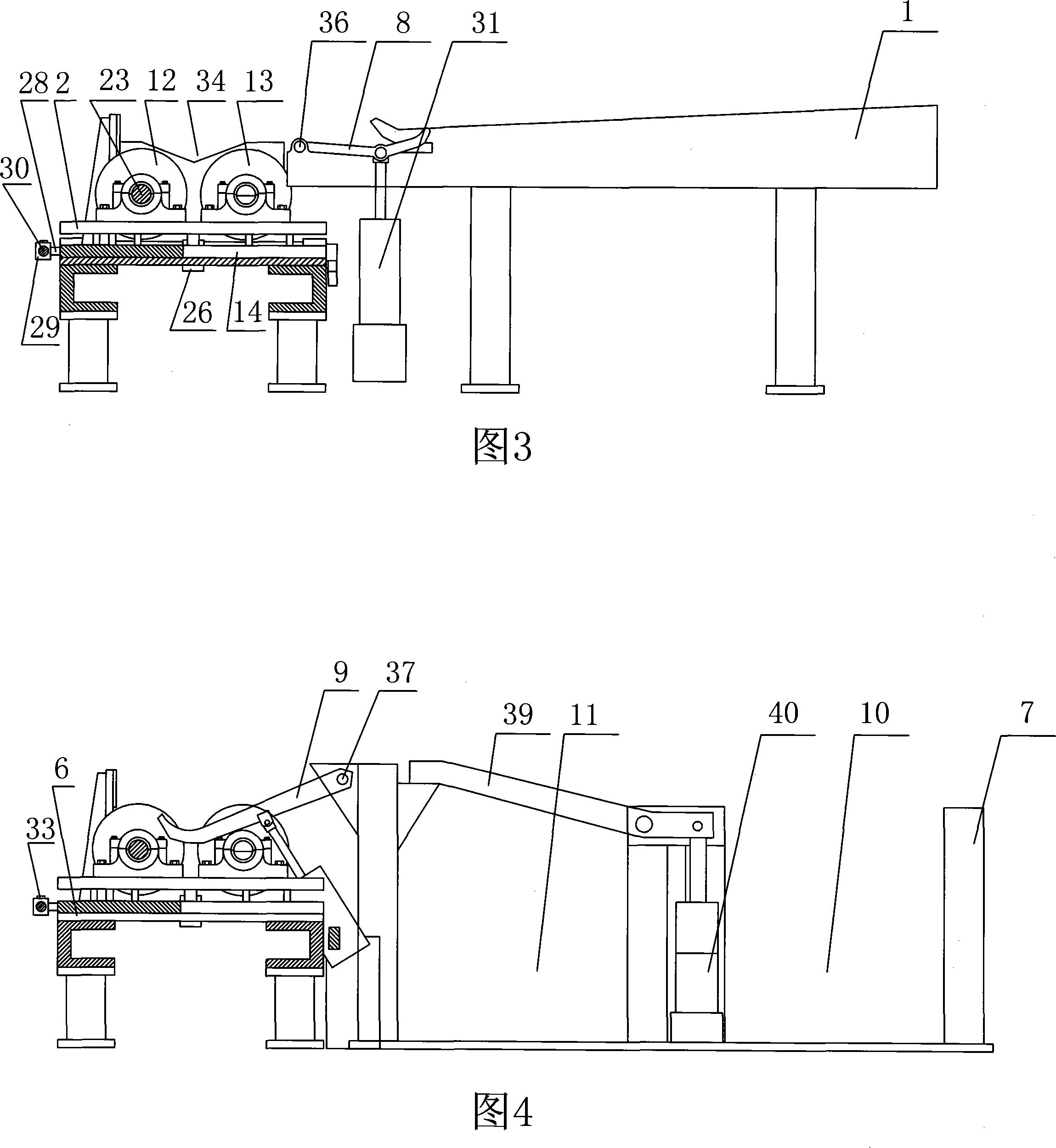

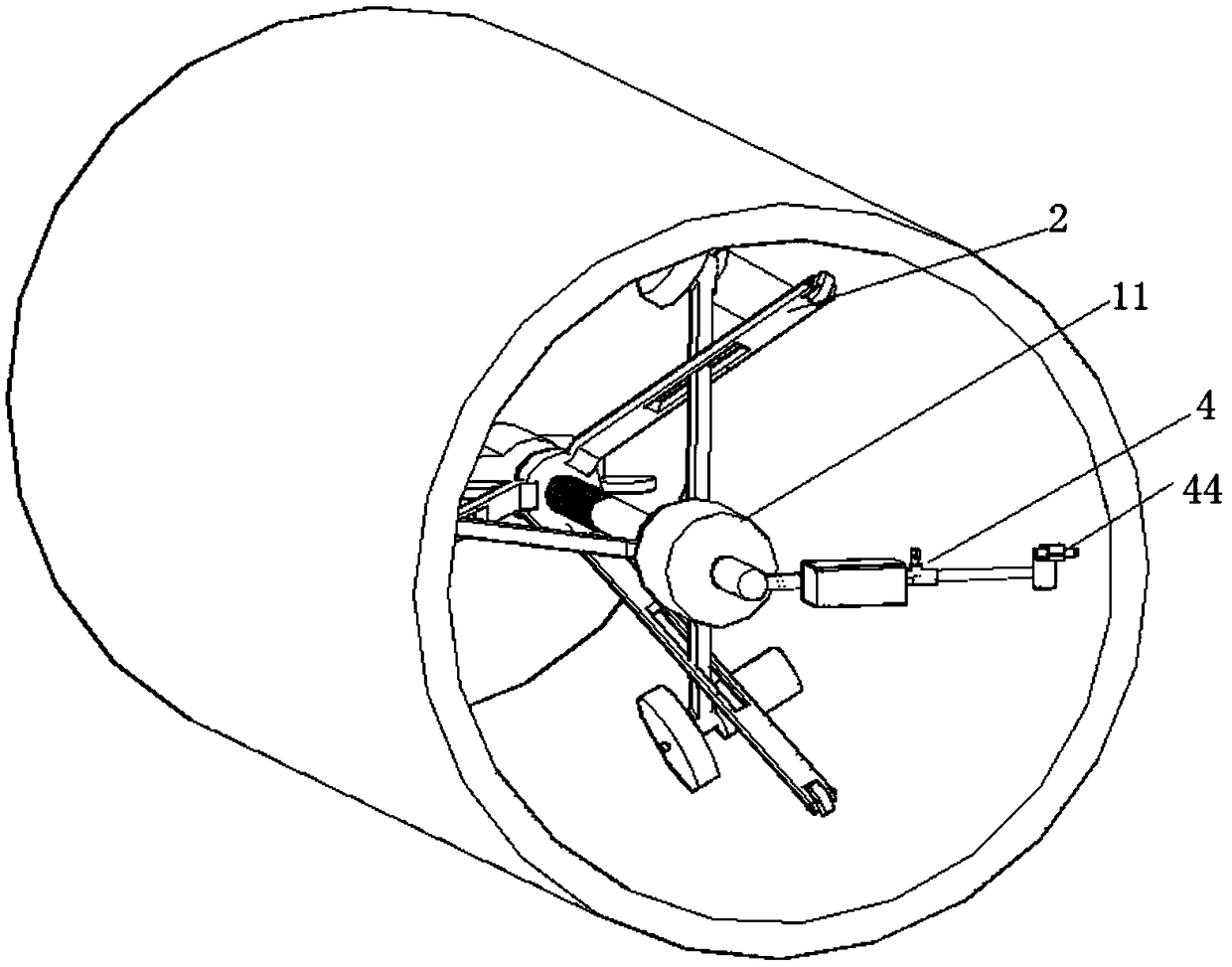

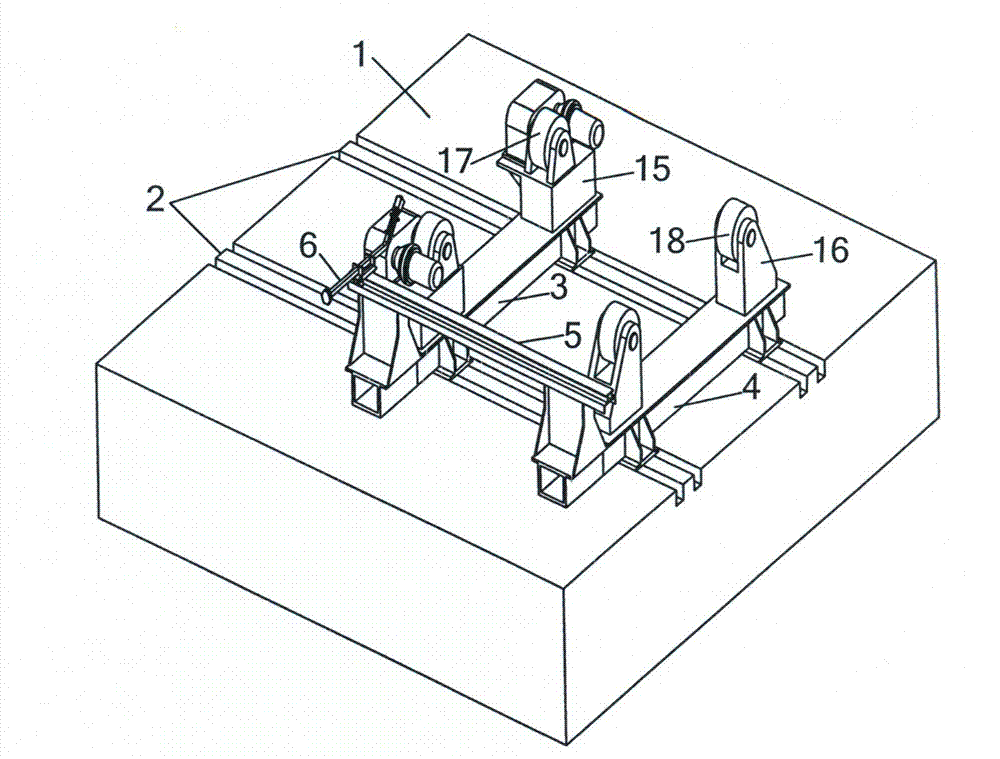

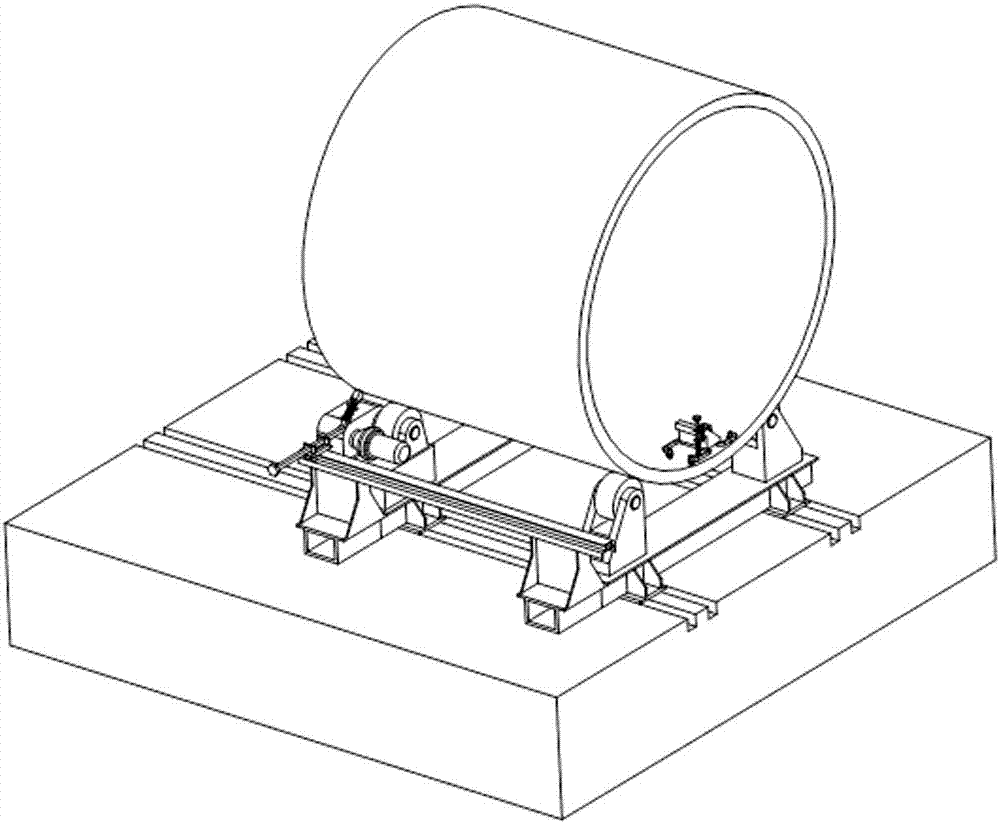

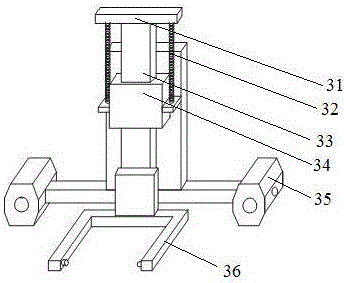

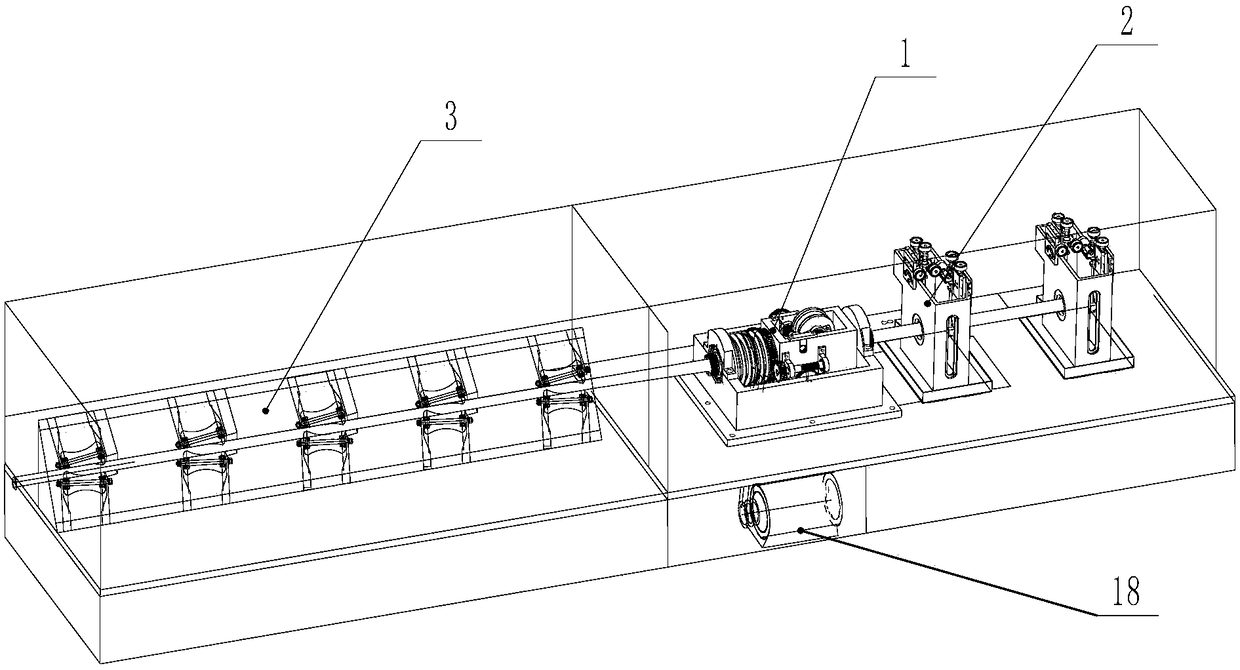

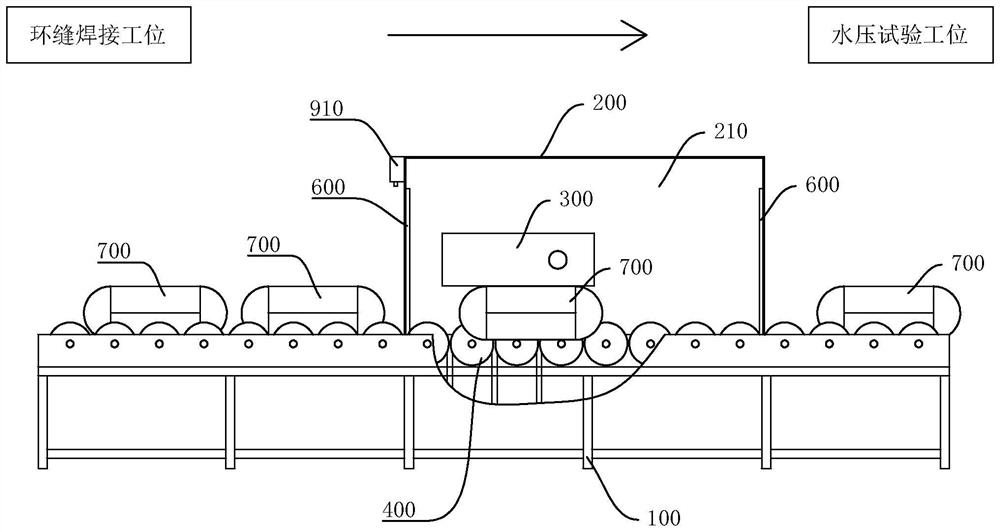

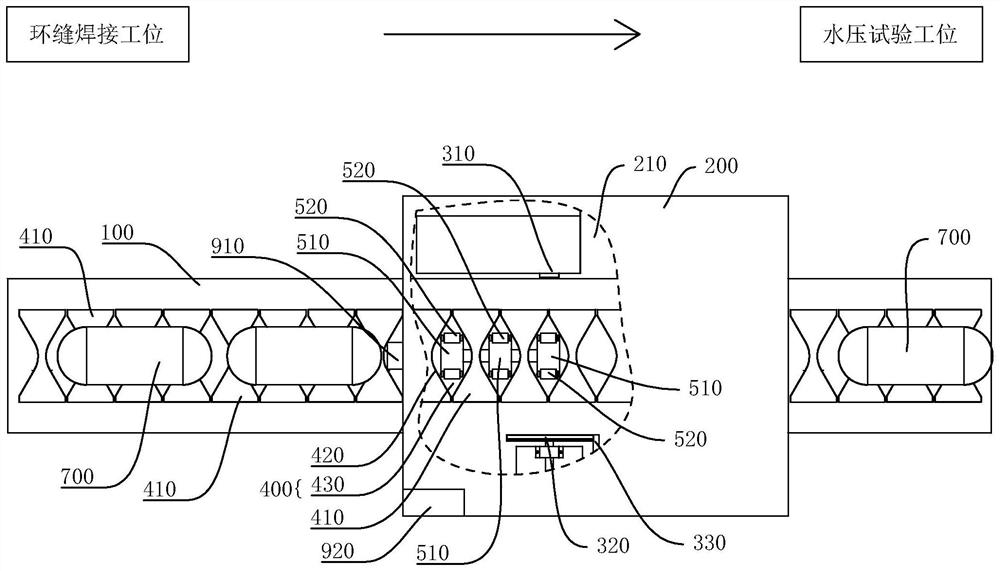

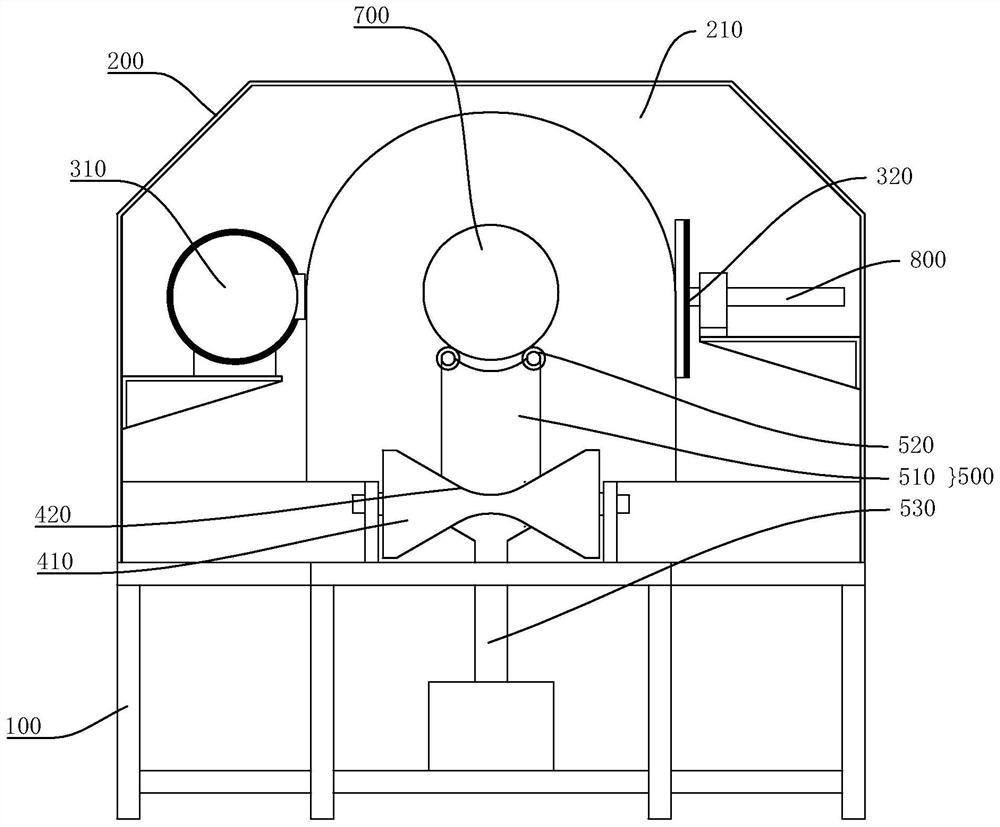

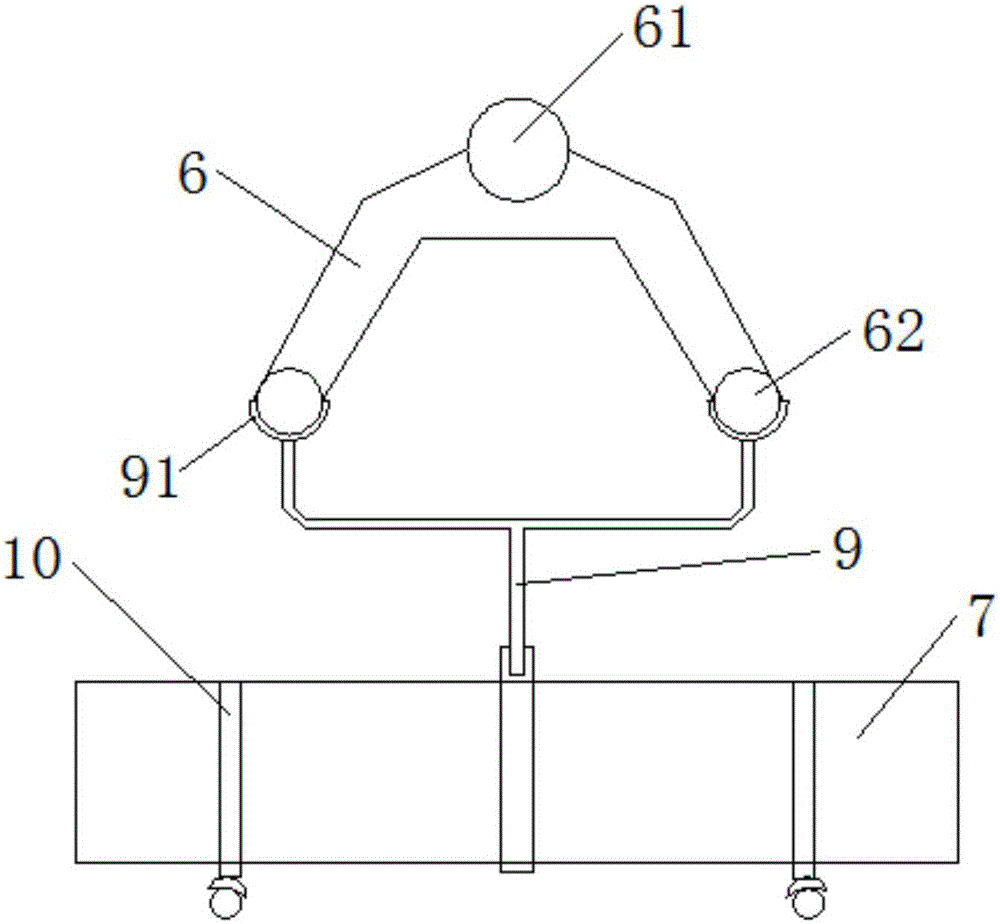

Trolley type automatic ultrasonic flaw-detecting machine with built-in robot for large cylindrical shell section parts

InactiveCN102809608AImprove flaw detection efficiencyShorten the production cycleAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringMechanical engineering

The invention relates to a trolley type automatic ultrasonic flaw-detecting machine with a built-in robot for large cylindrical shell section parts. The trolley type automatic ultrasonic flaw-detecting machine comprises a working platform, a robot flaw-detecting trolley and an outer flaw-detecting device, and is characterized in that two parallel straight guide rails are arranged on the working platform, a driving roller carrier beam is perpendicularly and fixedly connected to axial ends of the two straight guide rails, a driven roller carrier beam is movably connected to the other ends of the two straight guide rails, two driving roller supports are arranged at two ends of the driving roller carrier beam, two driven roller supports are arranged at two ends of the driven roller carrier beam, and driving rollers and driven rollers are respectively supported on the driving roller supports and the driven roller supports by rotating pairs; and an outer guide rail is arranged on the same side of the driving roller carrier beam and the driven roller carrier beam, and the outer flaw-detecting device is movably connected onto the outer guide rail. The trolley type automatic ultrasonic flaw-detecting machine has the advantages of simplicity in operation, safety, reliability, simple structure, low cost, small occupied space and capability of automatically ultrasonically detecting flaws of the large cylindrical shell section parts.

Owner:YANSHAN UNIV

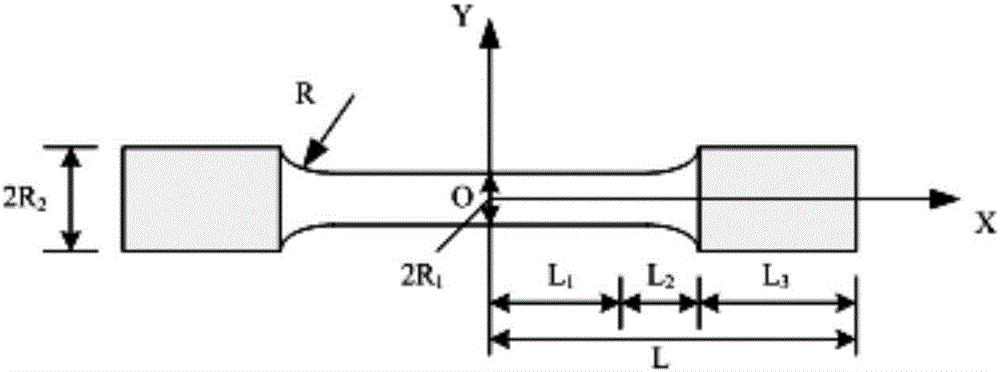

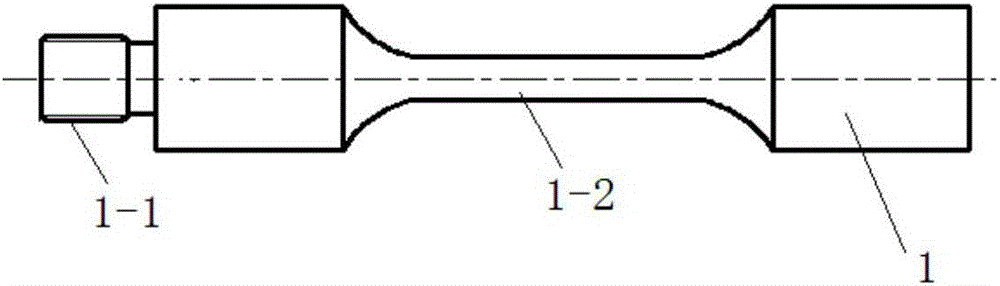

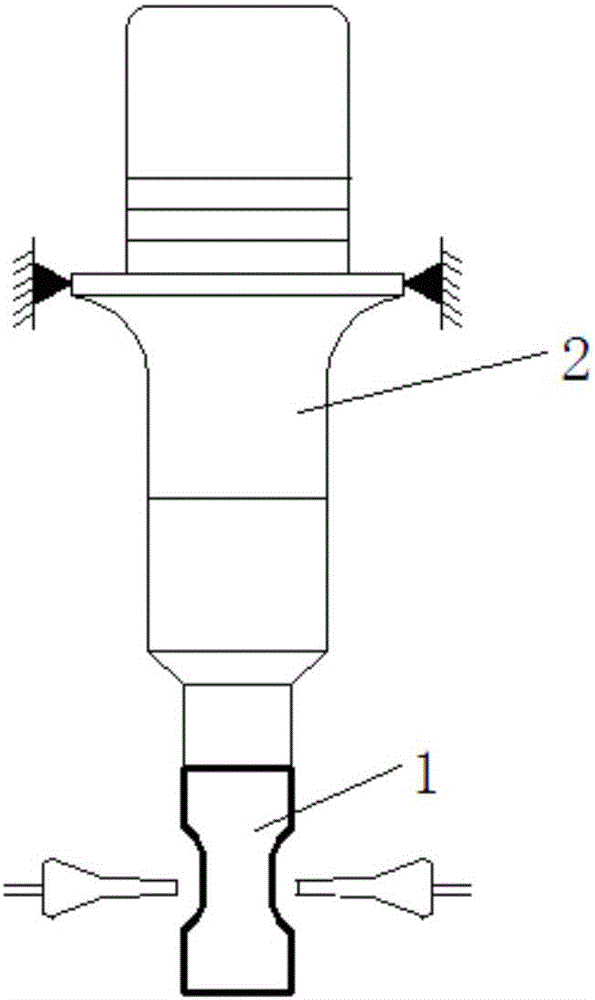

Method for detecting micro defect inside metal material

InactiveCN106644718ASolve the defect that can only detect more than 0.5mmIntuitivePreparing sample for investigationMaterial strength using tensile/compressive forcesDefect sizeTest sample

The invention discloses a method for detecting a micro defect inside a metal material. The method comprises the following steps: (1) designing a variable-section ultrasonic fatigue test sample having a circular cross section and containing a constant-section segment according to an elastic modulus and a density value of a metal material to be detected, wherein the size of the test sample is designed according to a following formula: (as shown in the specification); (2) installing the test sample on an ultrasonic fatigue test machine to perform a fatigue test until the test sample is broken; and (3) observing a fracture of the broken test sample, measuring a defect size on the fracture of the test sample, that is a maximum defect size of the metal material. The method can rapidly, intuitively and quantitatively determine the defect in the metal material and can determine the micro defects which are 0.1 mm or smaller and even 10 micrometers or smaller inside the metal material.

Owner:武汉钢铁有限公司

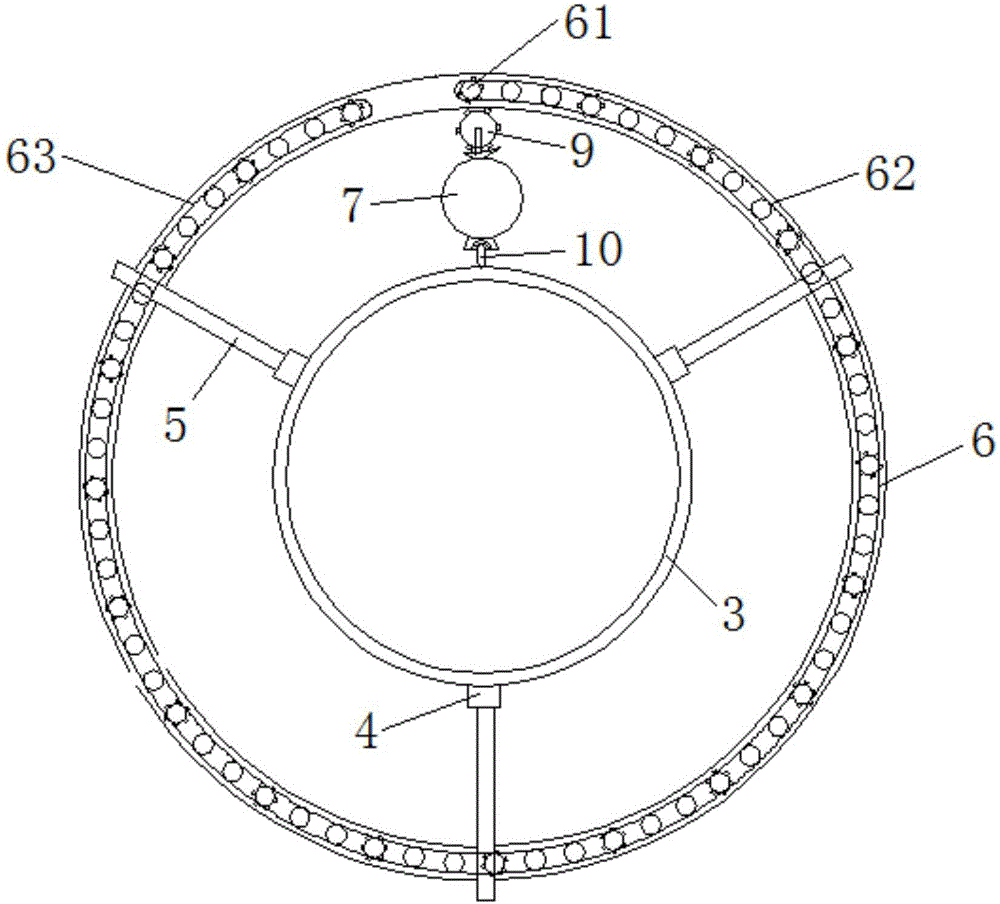

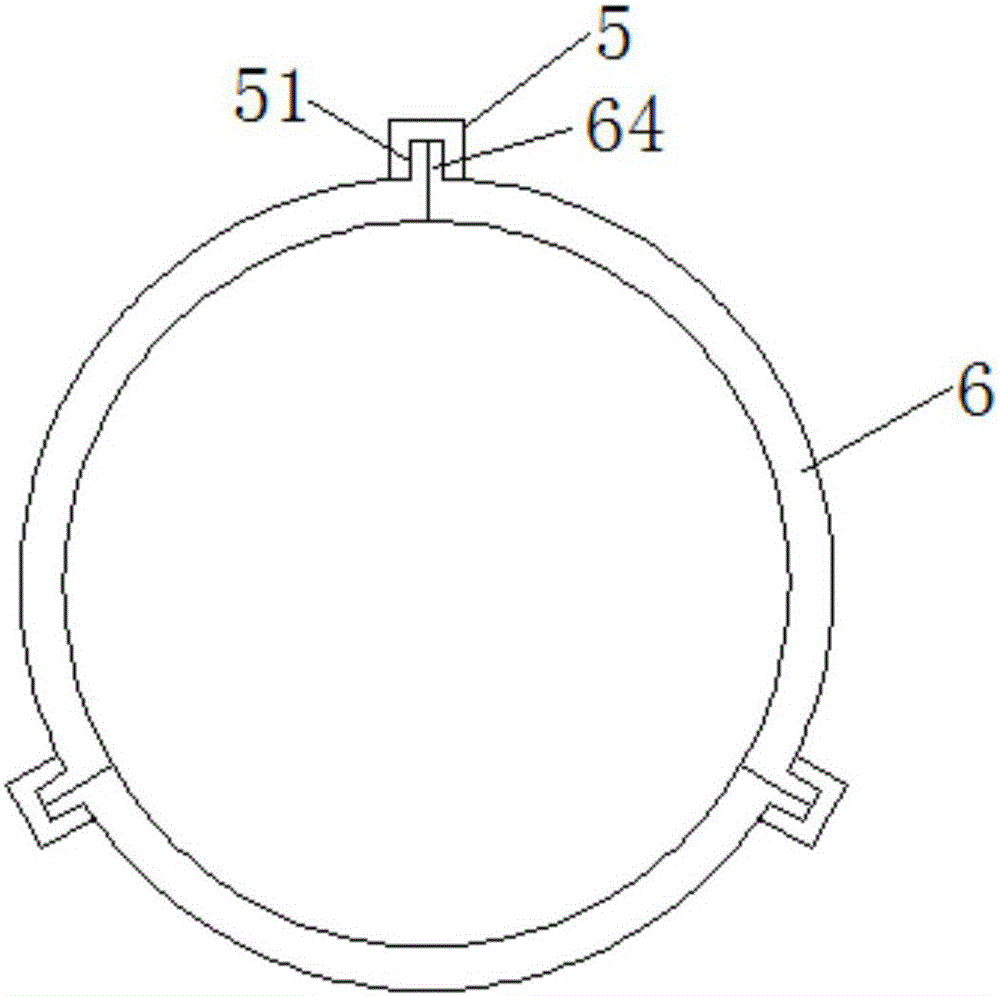

Adjustable phased array pipeline girth weld detection device

ActiveCN105891335AEasy to moveImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringPhased array

The invention provides an adjustable phased array pipeline girth weld detection device which comprises a body, a magnetic pressing wheel mechanism, an auxiliary bracket, a tightening device, a left flaw detection probe bracket, a right flaw detection probe bracket, a left flaw detection probe and a right flaw detection probe; the body comprises a foundation support, a first sliding rod, a second sliding rod, a sliding rod jackscrew, a left sliding rod linkage frame, a right sliding rod linkage frame, magnetic wheels and wheel shafts; the tightening device is used for tightening the body onto a pipeline to be detected, the magnetic pressing wheel mechanism is arranged between the first sliding rod and the second sliding rod, the auxiliary bracket is connected with the first sliding rod and the second sliding rod of the body, and the flaw detection probe brackets are connected with the flaw detection probes and assist the flaw detection probes in conducting detection on the girth weld of the pipeline to be detected. When the device is used for detecting the pipeline girth weld, the device can rotate steadily around the flaw detection pipeline, therefore the situation that the detection result is affected by vibration and other accidents is prevented, and the device can have the advantages of being wide in applicable range, high in flaw detection sensitivity, high in detection efficiency and the like.

Owner:中国石油天然气第一建设有限公司

Central laser alignment device for X-ray instrument

ActiveCN102590241AEasy to observeEasy to adjustMaterial analysis by transmitting radiationInterference fitX-ray

The invention discloses a central laser alignment device for an X-ray instrument. The device comprises a connecting plate connected with the X-ray instrument; the connecting plate is locked through a locking screw; the connecting plate is connected with one end of a rotating shaft, the rotating shaft is limited through a positioning block fixed on the connecting plate, and the other end of the rotating shaft is connected with a guiding block; a ball seat is fixed on the guiding block; an adjusting universal ball is arranged on the ball seat; a laser main seat is arranged on the adjusting universal ball in interference fit; and a laser is fixedly arranged in the laser main seat. A laser secondary seat is arranged together with the laser main seat in interference fit. A power supply module is also arranged on the guiding block, and the power supply module is connected with the laser. By using the device, the flaw detection imaging of the X-ray instrument can be clear and accurate, the flaw detection success rate is improved, waste of negative films is reduced, and the cost is reduced. Meanwhile, by adopting the device, repeated labor can be reduced, and the flaw detection efficiency is improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

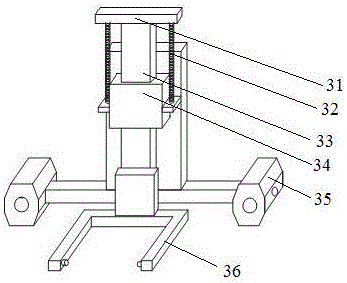

Movable field X-ray rolling shooting device for pipeline

ActiveCN105866143AFind the flaw detection positionIncrease the support pointMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a movable field X-ray rolling shooting device for a pipeline, and belongs to the technical field of flaw detection. The movable field X-ray rolling shooting device for the pipeline comprises a supporting frame, an operating mechanism and a walking mechanism, wherein the supporting frame is mounted on the external surface of a to-be-detected pipeline; the operating mechanism is mounted on the supporting frame; the walking mechanism is located between the operating mechanism and the to-be-detected pipeline. The movable field X-ray rolling shooting device for the pipeline, which is provided by the invention, is reasonable in structural design and is simple to make; not only can the special putting up of a detecting platform for an X-ray flaw detector be avoided and can the engineering cost be reduced, but also the all-around flaw detection for welds on the pipeline is realized; when the flaw detection is carried out on the welds on the same pipeline, the trouble of repeated disassembly and assembly is omitted; the flaw detection efficiency is greatly promoted; the engineering progress is quickened; a detector is enabled to keep far away from an area to be subjected to the flaw detection in a flaw detection process; the injury of radiographic flaw detection to the detector is reduced; a strong guarantee is provided for engineering safety.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

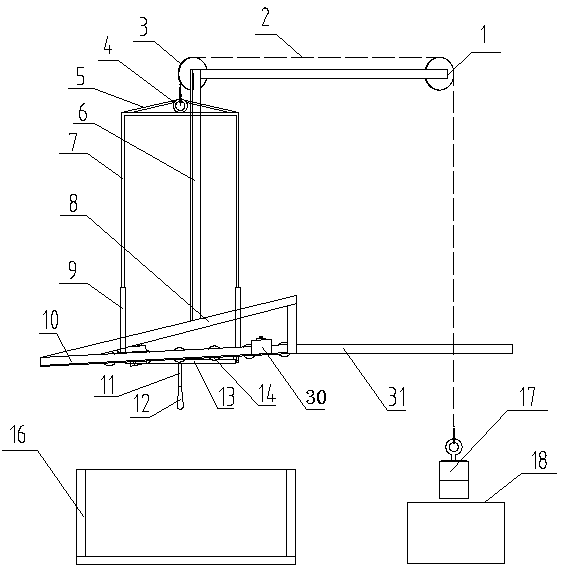

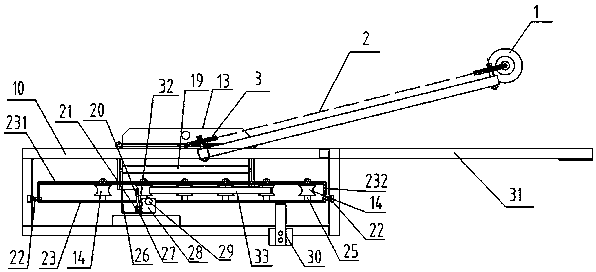

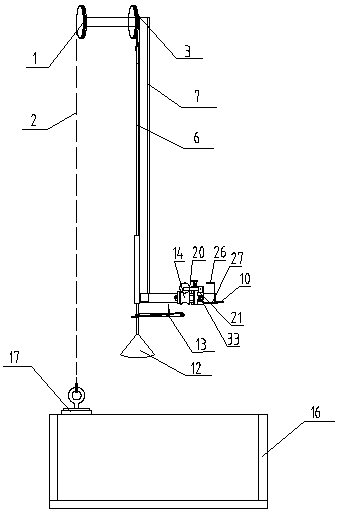

Self-gravity unloading device

PendingCN109368289AReduce weightReduce labor intensityBottle emptyingLoading/unloadingEngineeringUltimate tensile strength

The invention discloses a self-gravity unloading device. The lower end framework of a rack is mounted in an inclined mode; a turnover mechanism comprises a deflection disc which can be rotatably fixedon the lower end framework of the rack, a transportation roller way which is mounted on the rear end part of the deflection disc, a counterweight block which is fixedly arranged at the front end of the deflection disc, a movable block, a limiting plate which is fixedly arranged on the movable block, a hollow sleeve, a shifting fork shaft which is arranged in the sleeve in a penetrating mode and is fixed by a torsion spring, and a turnover trigger gear mechanism of upper and lower shifting forks which are positioned outside the sleeve and are integrated with the shifting fork shaft; when all workpieces are on the transportation roller way of the deflection disc, weight of the transportation roller way side on the deflection disc is greater than that of the counterweight board side; and a lifting mechanism comprises a lifting frame, a material tray capable of turning over, a lifting frame guide sleeve, two guide slide wheels, a steel wire rope, a counterweight and a material tray turnover mechanism, wherein a storage and transfer box is positioned below the material tray. The self-gravity unloading device can completely avoid manual unloading, greatly reduces labour intensity of a shaft lever flaw detector, improves flaw detecting efficiency of the flaw detector, and does not damage the workpieces.

Owner:耐世特凌云驱动系统(涿州)有限公司

A flaw detection structure for steel pipe surface defect detection

ActiveCN109425660ASimple structureIncrease the areaAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesArchitectural engineeringSteel tube

A flaw detection structure for steel pipe surface defect detection is disclosed. The structure includes a steel pipe transmission device for driving a steel pipe to move along an axial direction and asteel pipe flaw detection device disposed on the movement path of the steel pipe. The structure is characterized in that the steel pipe flaw detection device includes a detection tank; side plates atfront and rear sides, of the detection tank, in the direction of forward movement of the steel pipe are provided with a through hole respectively; a set of flaw detection mechanism is mounted on eachof the front and rear side plates of the detection tank; the flaw detection mechanisms have probes in the detection tank for flaw detection; the probes for flaw detection are fixed to the lower endsof adjusting bars vertically arranged; the upper ends of the adjusting bars are mounted on the side plates of the detection tank; and the probes of the two flaw detection mechanisms are at two sides of a steel pipe forward movement path and face the steel pipe forward movement path. The flaw detection structure has advantages of simple structure, and capability of improving flaw detection area andefficiency, avoiding detection leakage and improving flaw detection reliability.

Owner:宝武特冶航研科技有限公司

Ultrasonic flaw detection method of surfacing steel pipe from base material side

InactiveCN102967654AImprove flaw detection efficiencyDefective ability is goodAnalysing solids using sonic/ultrasonic/infrasonic wavesSteel tubeEnvironmental geology

The invention discloses an ultrasonic flaw detection method of a surfacing steel pipe from a base material side. The method is characterized by comprising a single straight probe detection from the base material side of the pipe and a phased array detection from the base material side of the pipe, wherein the single straight probe detection comprises using a single straight probe, correcting base line by using a flat-bottomed hole and a bottom echo, correcting and detecting sensitivity by using the flat-bottomed hole, so that echo of artificial flat-bottomed hole can reach 80 %; confirming scanning sensitivity of workpieces; and scanning the workpieces by using the single straight probe; and the phased array detection comprises selecting a phased array flaw detector and selecting probe and curvature wedge; correcting the phased array flaw detector and the probe and selecting a sector scanning and calibrating block; and scanning the workpieces by using the phased array detection. The method has characteristics of high flaw detection efficiency, accurate positioning, convenient repair, etc.

Owner:上海锐迈重工有限公司 +1

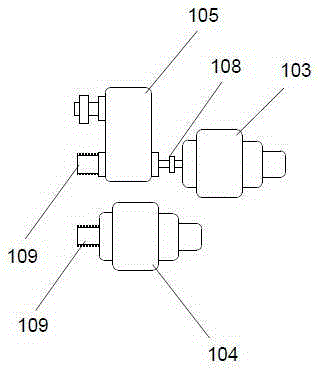

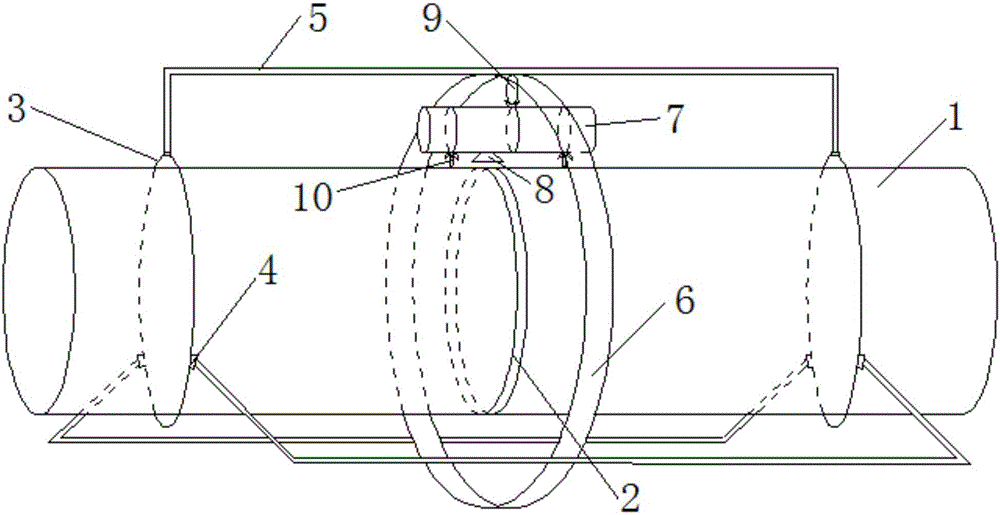

Ultrasonic phased array pipeline ring weld detection mechanism capable of moving stably

ActiveCN105891334AEasy to moveImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringPhased array

The invention provides an ultrasonic phased array pipeline ring weld detection mechanism capable of moving stably. The ultrasonic phased array pipeline ring weld detection mechanism comprises a body, a magnetism pinch roller mechanism, a fastening device, a left flaw detection probe support, a right flaw detection probe support, a left flaw detection probe and a right flaw detection probe. The body comprises a base, a first sliding rod, a second sliding rod, a sliding rod jackscrew, a left and right sliding rod connecting frame, magnetism wheels and an axle. The fastening device is used for fastening the body to a pipeline to be detected, the magnetism pinch roller mechanism is arranged between the first sliding rod and the second sliding rod, and the flaw detection probe supports are connected with the flaw detection probes and assist the flaw detection probes in carrying out detection work on welds of the pipeline to be detected. The mechanism can stably rotate around the flaw detecting pipeline in pipeline ring weld detection work, and thus it is avoided that a detection result is influenced by accidental situations such as vibration; thus, the mechanism has the advantages of being wide in application range, high in flaw detection sensitivity and detection efficiency and the like.

Owner:中国石油天然气第一建设有限公司

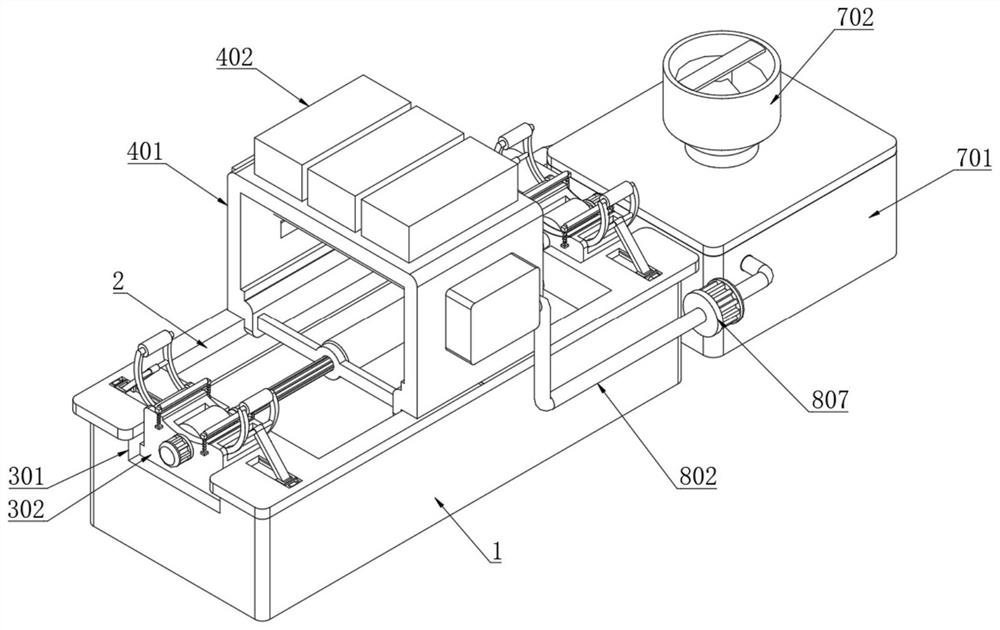

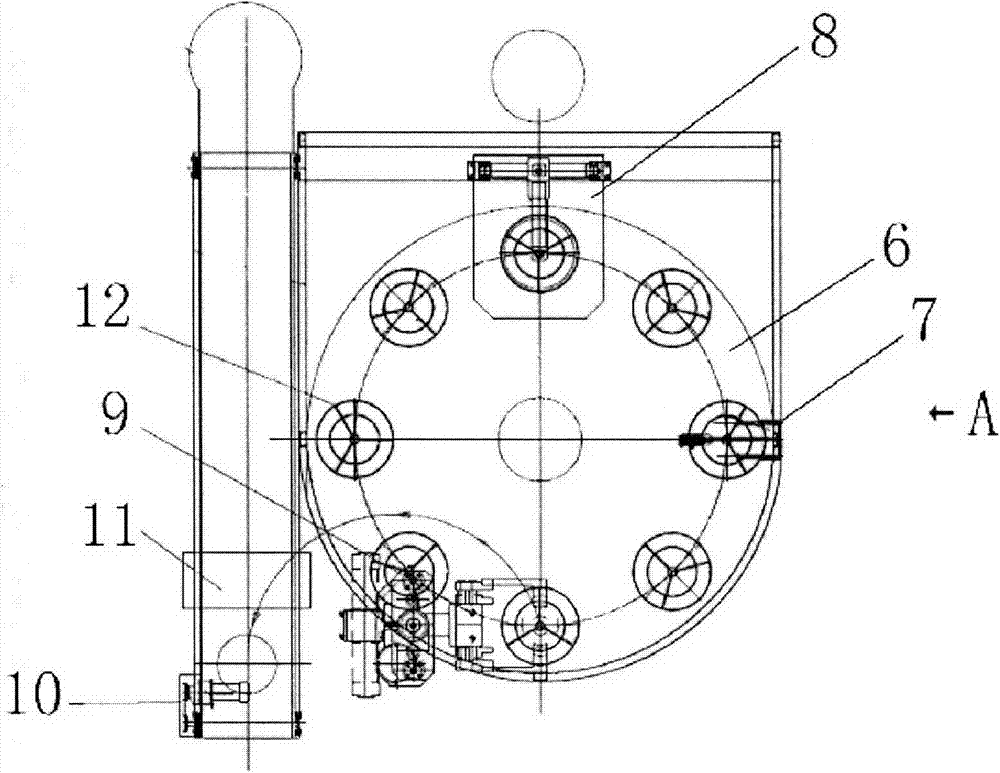

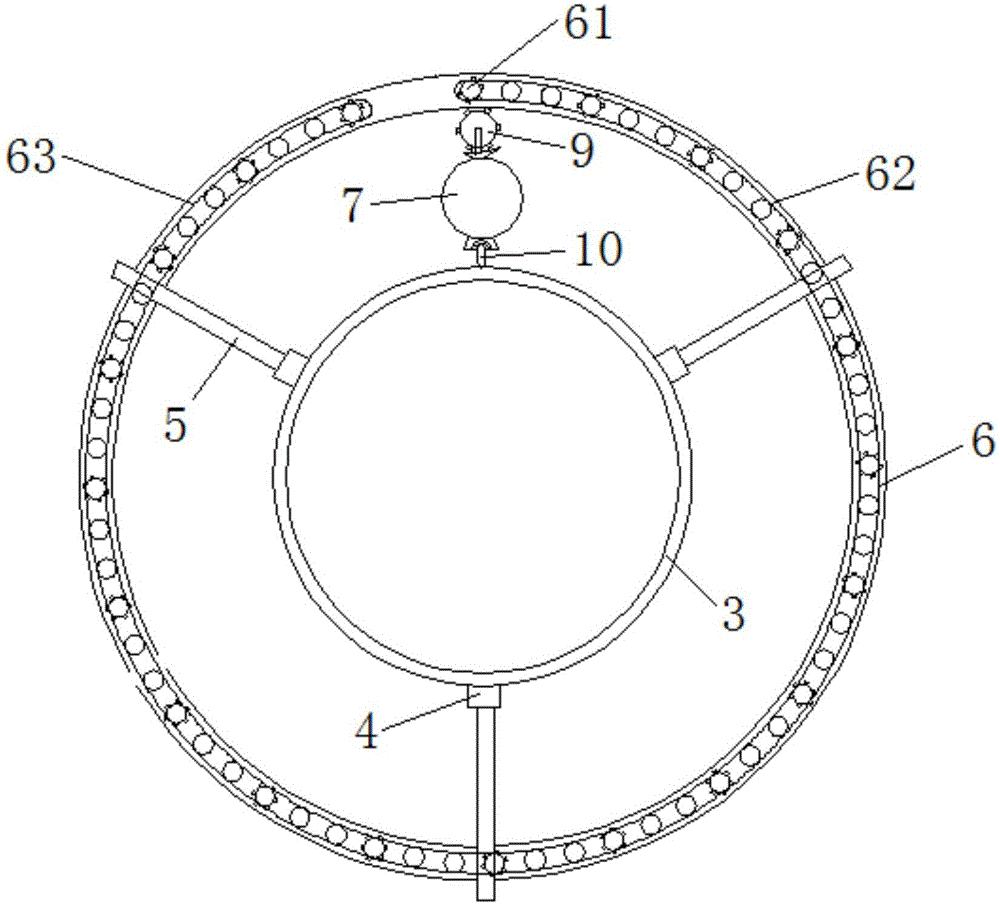

Method and device for magnetic powder inspection on annular workpiece

ActiveCN103543197APrevents sensitivity interference and power lossImprove the efficiency of magnetic particle inspectionMaterial magnetic variablesMagnetic particle inspectionElectric energy

The invention relates to the technical field of magnetic powder inspection and discloses a method and a device for magnetic powder inspection on an annular workpiece. 8-station flow process layout is adopted so that the whole inspection process frequency only depends on magnetic powder inspection observation time and thus magnetic powder inspection efficiency is maximumly improved and magnetic powder inspection requirements on various batch annular workpieces are satisfied. An annular workpiece is horizontally and firmly placed on a workpiece tray without an assistant clamping device, the workpiece tray is provided with three strip peak-shaped support frames which are arranged in angle of 120 degrees, the end surface of the bottom of the annular workpiece contacts with only three peak lines of the support frames so that a dead zone caused by a support surface is maximumly avoided, and the annular chassis of the workpiece tray is provided with an open structure so that the interference produced by a ring induced current on detection sensitivity and an electric energy loss are effectively prevented.

Owner:厉伟

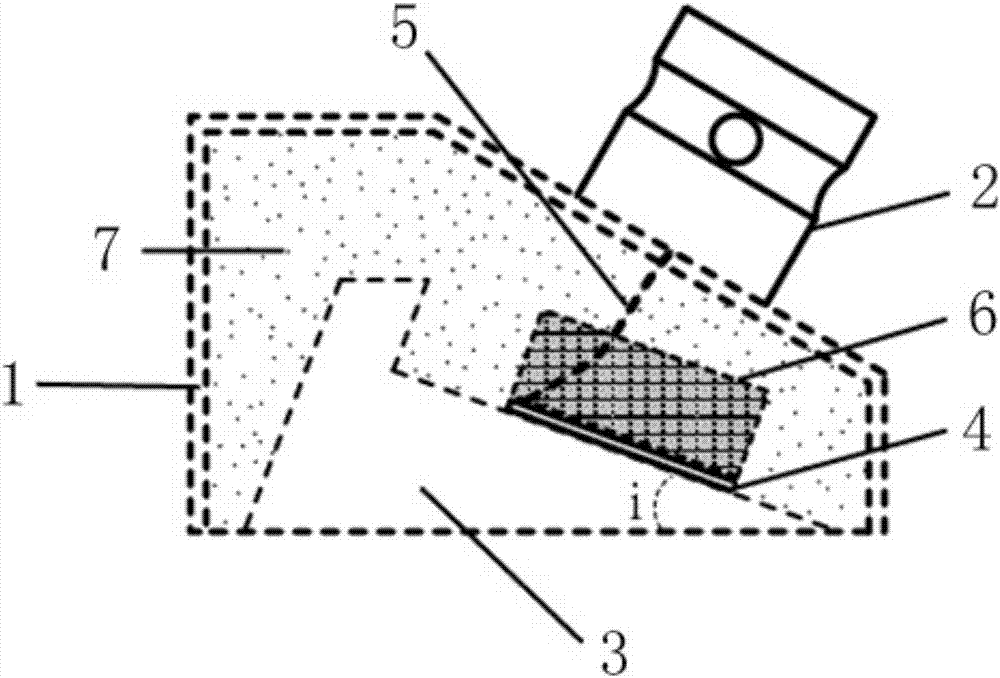

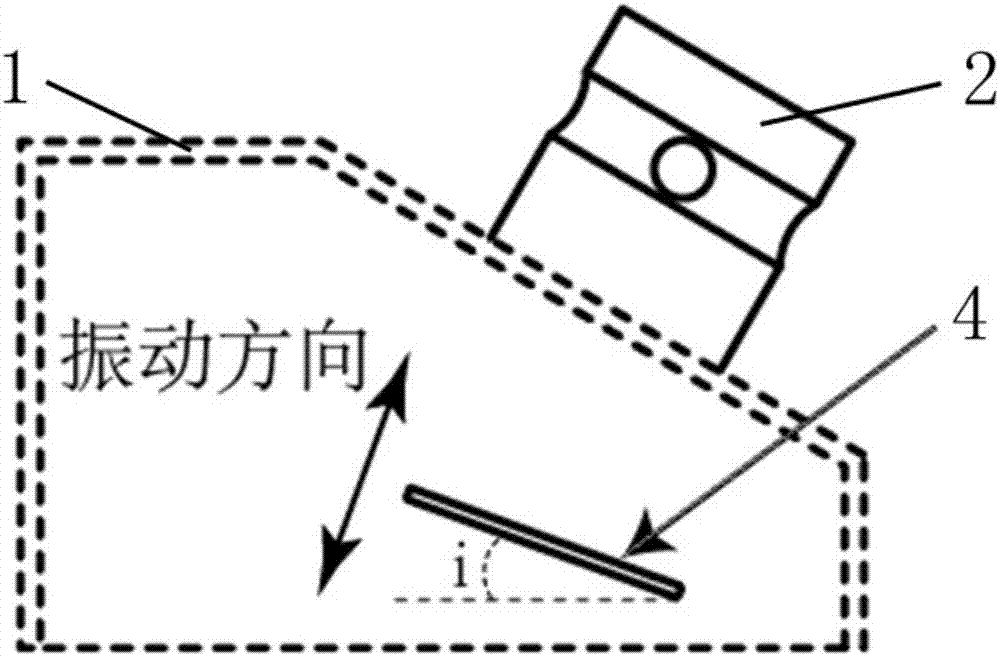

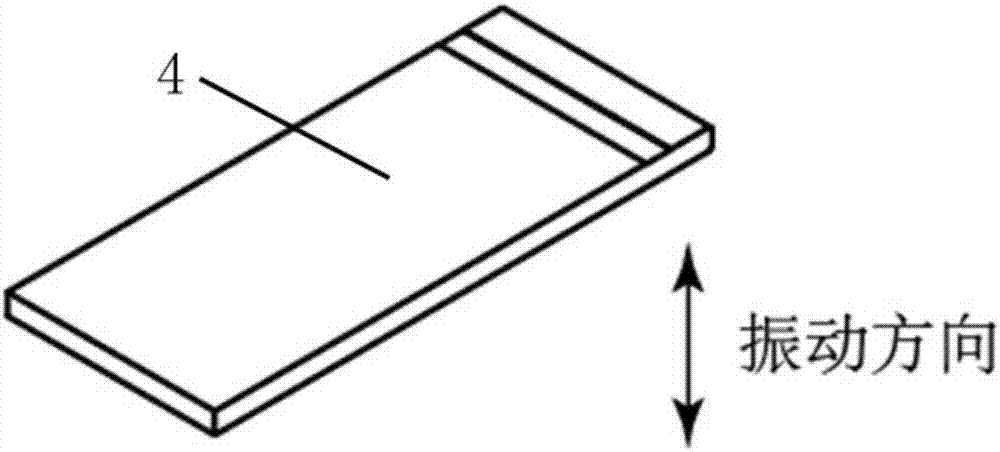

Steel rail flaw detection ultrasonic waveguide inclined probe and flaw detection method thereof

PendingCN108008021AResponsiveImprove signal-to-noise ratioAnalysing solids using sonic/ultrasonic/infrasonic wavesDielectricElectricity

The invention discloses a steel rail flaw detection ultrasonic waveguide inclined probe and a flaw detection method thereof. The probe comprises a shell, a sound absorption filler, at least one dielectric unit and at least one interface, wherein each dielectric unit is arranged inside the shell and comprises a wedged block, a dielectric wafer, a cable wire and a damping block; the dielectric waferis a dielectric ceramic piece of a thickness vibration mode; an included angle is formed between one surface of the wedged block and the horizontal plane; one surface perpendicular to a vibration direction, of the dielectric wafer, is flatly adhered to the surface of the wedged block; the damping block is tightly adhered to another surface perpendicular to the vibration direction, of the dielectric wafer; the sound absorption filler is arranged inside a vacant space except the dielectric unit inside the shell; the interface is arranged on one surface of the shell and is connected with the dielectric wafer through the cable wire. Due to adoption of the dielectric wafer of the thickness vibration mode, the probe is high in signal to noise ratio, low in cost and convenient to popularize, inaddition can be applied to flaw detection on rail heads and rail bottoms, and is long in single detection distance.

Owner:DONGGUAN UNIV OF TECH

Rolling photographing device for on-site pipeline flaw detection

ActiveCN105784739AFind the flaw detection positionIncrease the support pointMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a rolling photographing device for on-site pipeline flaw detection, and belongs to the technical field of flaw detection. The rolling photographing device comprises a supporting frame, a running mechanism and a walking mechanism, wherein the supporting frame is mounted on the outer surface of the pipeline to be detected; the running mechanism is mounted on the supporting frame; the walking mechanism is positioned between the running mechanism and the pipeline to be detected. The rolling photographing device for on-site pipeline flaw detection is reasonable in structural design and easy to manufacture; a special detection platform does not need to be built for an X-ray flaw detector, so that the engineering cost is reduced; furthermore, all-round flaw detection for pipeline welds is realized, the flaw detection efficiency is greatly improved, and the engineering progress is accelerated; meanwhile, a detection person can get away from a flaw detection region in the flaw detection process, so as to relieve the harm of ray flaw detection to the detection person and provide great insurance for the safety of the engineering.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

High-stability ultrasonic phased array pipeline ring welding seam detection apparatus

ActiveCN106093198AEasy to moveImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWeld seam

The invention discloses a high-stability ultrasonic phased array pipeline ring welding seam detection apparatus, which comprises a main body, a magnetic wheel pressing mechanism, a fastening device, a left and right flaw detection probe bracket and a left and right flaw detection probe, wherein the main body comprises a base, a first sliding rod, a second sliding rod, sliding rod ejection wires, a left and right sliding rod linking frame, magnetic wheels and wheel shafts, the fastening device is used for fastening the main body on a pipeline to be measured, the magnetic wheel pressing mechanism is arranged between the first sliding rod and the second sliding rod, and the flaw detection probe bracket is connected to the flaw detection probe and assists the flaw detection probe to perform detection work on the welding seam of the pipeline to be measured. According to the present invention, the apparatus can stably rotate around the flaw detection pipeline during the pipeline ring welding seam detection work so as to prevent the influence of vibration and other accidents on the detection effect, such that the apparatus has advantages of wide application range, high flaw detection sensitivity, high detection efficiency, and the like.

Owner:CHINA PETROLEUM FIRST CONSTR CORP

Double-track type high-speed stable ultrasonic flaw detector

PendingCN111497894ADoes not affect flaw detection operationsRealize U-turn in situAnalysing solids using sonic/ultrasonic/infrasonic wavesRailway auxillary equipmentEngineeringSlow speed

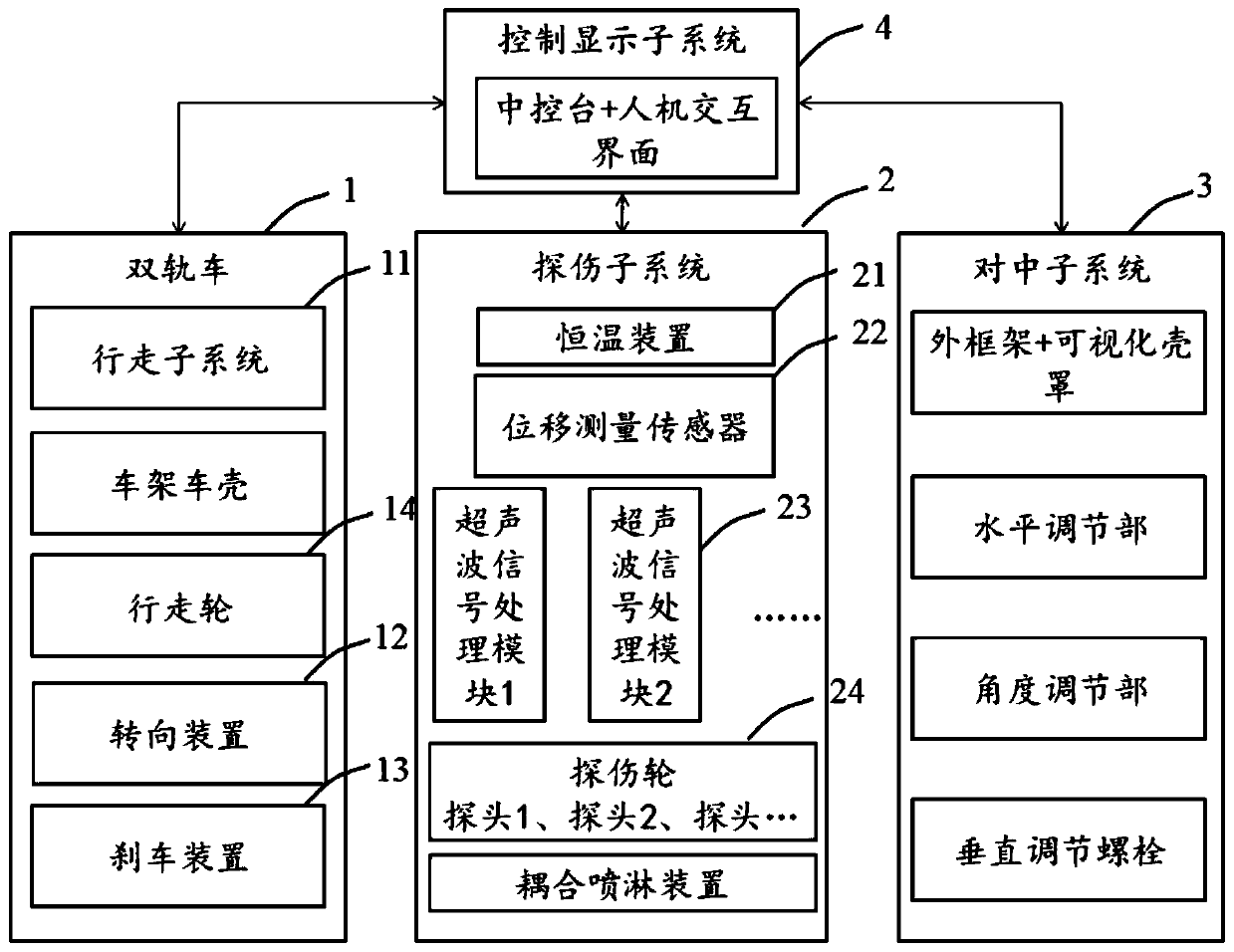

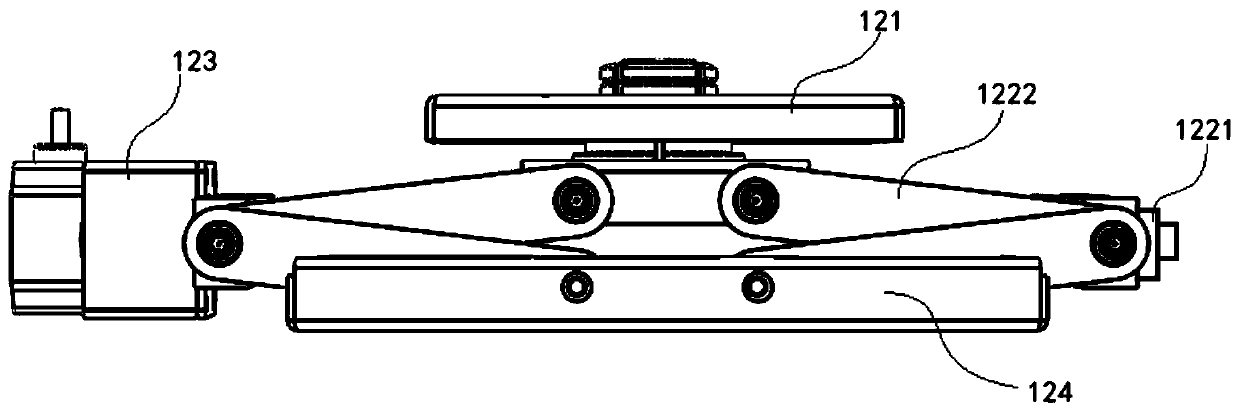

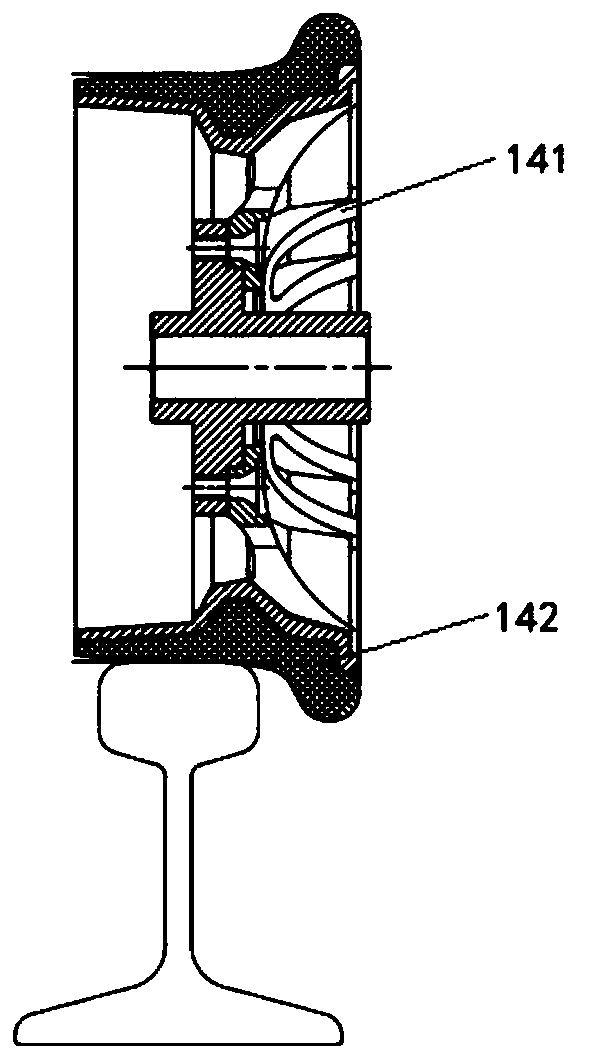

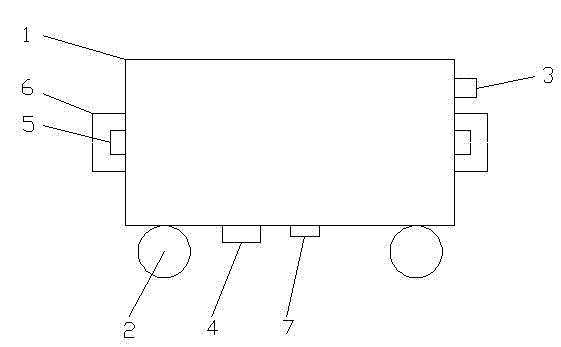

The invention discloses a double-track type high-speed stable ultrasonic flaw detector. The flaw detector comprises a double-track vehicle provided with a walking subsystem, a flaw detection subsystem, a centering subsystem and a control display subsystem, and a steering device used for pivot steering is arranged on a chassis of the double-track vehicle; the flaw detection subsystem comprises a plurality of ultrasonic signal processing modules; the plurality of ultrasonic signal processing modules are used for respectively processing data of different probes of a flaw detection wheel; the centering subsystem comprises a horizontal adjusting part and an angle adjusting part; and the horizontal adjusting part and the angle adjusting part are respectively used for detecting and automaticallyresetting the horizontal position and angle of the flaw detection wheel. The detection speed is integrally improved, the problems of missed detection, low detection rate, increased jittering of flaw detection wheels, poor equipment safety, difficult equipment maintenance and the like caused by speed increase are solved, the problems that reversing detection is not safe and not beneficial to observation, the detection speed is low, reversing detection is not suitable for long-distance driving and the like are solved, and the technical characteristics of high detection speed, high detection stability and convenient steering are achieved.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

Automatic flaw detection trolley

InactiveCN102830180AImprove flaw detection efficiencyExtended service lifeMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringDrive wheel

Owner:JIANGSU SANHE SOUND SOURCE ULTRASONIC TECH

Container flaw detection device and container production technology

PendingCN114062400AReduce labor intensityEnsure safetyMaterial strength using tensile/compressive forcesDomestic vesselsInformation controlStructural engineering

The invention discloses a container flaw detection device and a container production technology. The container flaw detection device comprises a base frame, a shielding shell internally provided with a flaw detection cavity, a flaw detection module, a conveying mechanism, a form positioning detection component, a deflection adjusting mechanism, an identification mechanism and a control module, the shielding shell is provided with an opening communicated with the flaw detection cavity, the flaw detection module is arranged on the base frame and located in the flaw detection cavity, the flaw detection module can detect different containers to be detected, part of the transmission mechanism is arranged in the flaw detection cavity through the opening, the transmission mechanism can transmit a to-be-detected container to get in and out of the flaw detection cavity, the form positioning detection component is used for obtaining welding seam position information of the to-be-detected container, the deflection adjusting mechanism can drive the to-be-detected container to rotate, and the control module is connected with the form positioning detection component, the transmission mechanism and the deflection adjusting mechanism so as to control the transmission mechanism and the deflection adjusting mechanism to operate according to the welding seam position information of the to-be-detected container. The flaw detection efficiency can be improved, and the safety of a user is guaranteed.

Owner:ZHONGSHAN POLYTECHNIC

Field pipeline flaw detection device

InactiveCN105699405AIncrease the support pointFind the flaw detection positionMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a field pipeline flaw detection device and belongs to the technical field of flaw detection. The device comprises a supporting frame, a track and a traveling mechanism, wherein the supporting frame is installed on the outer surface of a pipeline to be detected, the track is installed on the supporting frame, and the traveling mechanism is located between the track and the pipeline to be detected. The device is reasonable in structural design, easy to manufacture, and capable of avoiding the construction of a detection platform special for an X-ray flaw detector so as to reduce engineering cost, achieving comprehensive flaw detection of pipeline welding seams, improving flaw detection efficiency greatly, accelerating work progress, and allowing detection staff to be away from the flaw detection area during flaw detection so as to reduce the harm of radiographic inspection to detection staff, so that engineering safety is guaranteed reliably.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

Automatic detection frame for metal pipeline flaw detector

The invention discloses an automatic detection frame for a metal pipeline flaw detector, which comprises an automatic pushing frame, a detection frame and a metal pipe fitting, wherein the automatic pushing frame is integrally arranged on the outer wall of the metal pipe fitting in a sleeving mode. A follow-up pulley and a driving pulley are supported on the inner wall of the automatic pushing frame in a sliding manner; a diameter adjusting device is arranged between the inner wall of the automatic pushing frame and the outer surface of the metal pipe fitting; the detection frame is suspendedon the upper side and the lower side of the metal pipe fitting through a plurality of connecting rods fixed to the side wall of the automatic pushing frame, and angle adjusting mechanisms used for driving the connecting rods to rotate along the center of the automatic pushing frame are arranged between the bottom of the connecting rod and the side wall of the automatic pushing frame. Forward flawdetection of the flaw detector on the surface of the metal pipe fitting can be automatically completed; the process is more accurate than handholding, the deviation of a flaw detection path is reduced, the arranged angle adjusting mechanism ensures that the detection frame can carry out all-around coverage flaw detection on the surface of the metal pipe fitting, the working intensity of an operator in flaw detection work is reduced, and the flaw detection efficiency is improved.

Owner:广东省功夫建设工程质量检测有限公司

Movable shooting device for on-site pipeline flaw detection

InactiveCN105758878AFind the flaw detection positionIncrease the support pointMaterial analysis by transmitting radiationX-rayPetroleum engineering

The invention discloses a movable shooting device for on-site pipeline flaw detection and belongs to the technical field of flaw detection.The movable shooting device comprises a supporting frame, a running mechanism and a traveling mechanism, the supporting frame is mounted on the outer surface of a to-be-detected pipeline, the running mechanism is mounted on the supporting frame, and the traveling mechanism is positioned between the running mechanism and the to-be-detected pipeline.The movable shooting device is reasonable in structural design, setting up of a detection platform special for an X-ray flaw detector can be avoided, engineering cost is reduced, and omnibearing flaw detection of pipeline welding joints is realized; when flaw detection is performed on welding joints on a same pipeline, trouble of repeated mounting and demounting is omitted, flaw detection efficiency is improved greatly, engineering process is accelerated, detection personnel can be away from a flaw detection area in the flaw detection process, damage to the detection personnel by ray flaw detection is reduced, and a powerful guarantee is provided for engineering safety.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com