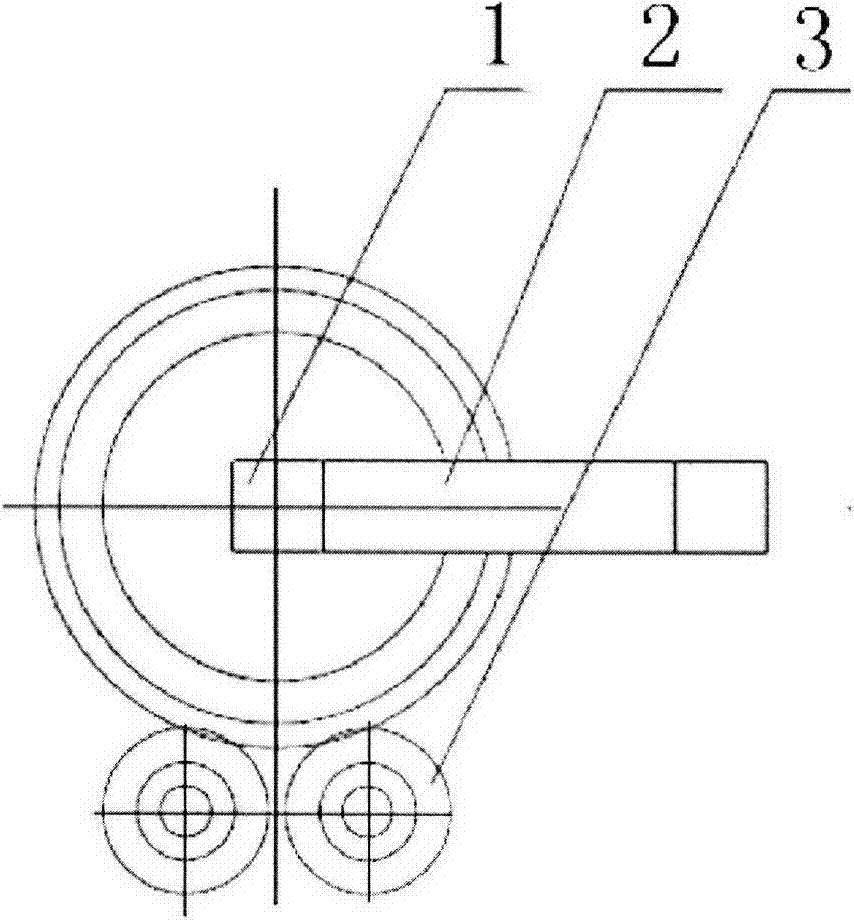

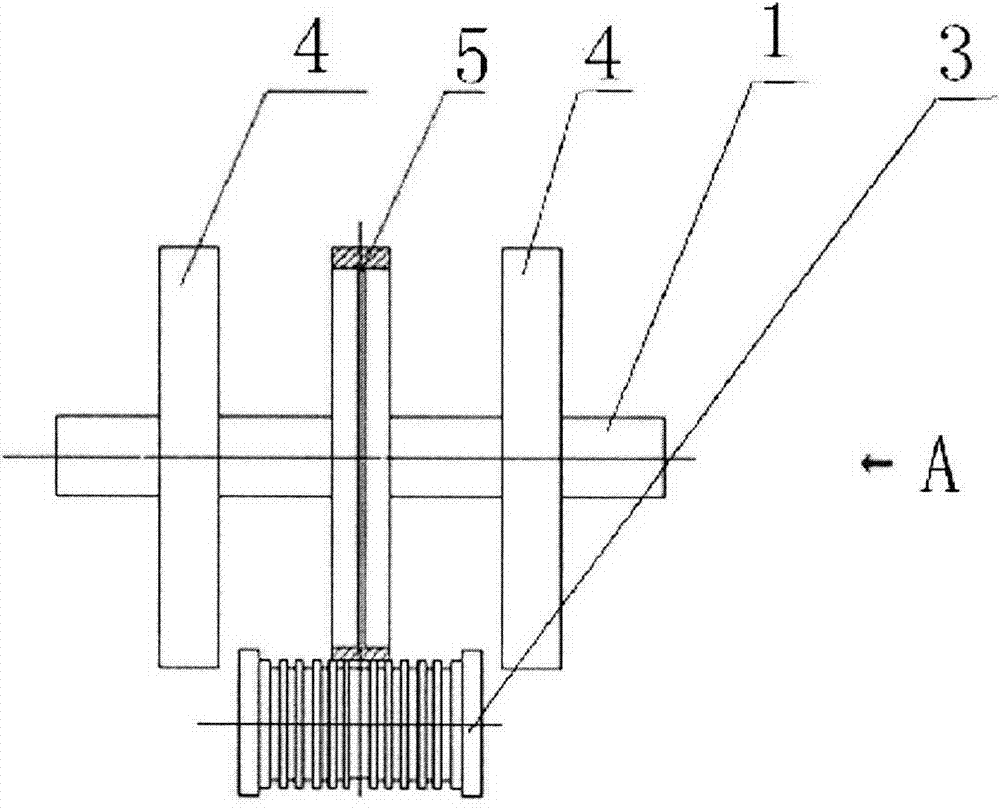

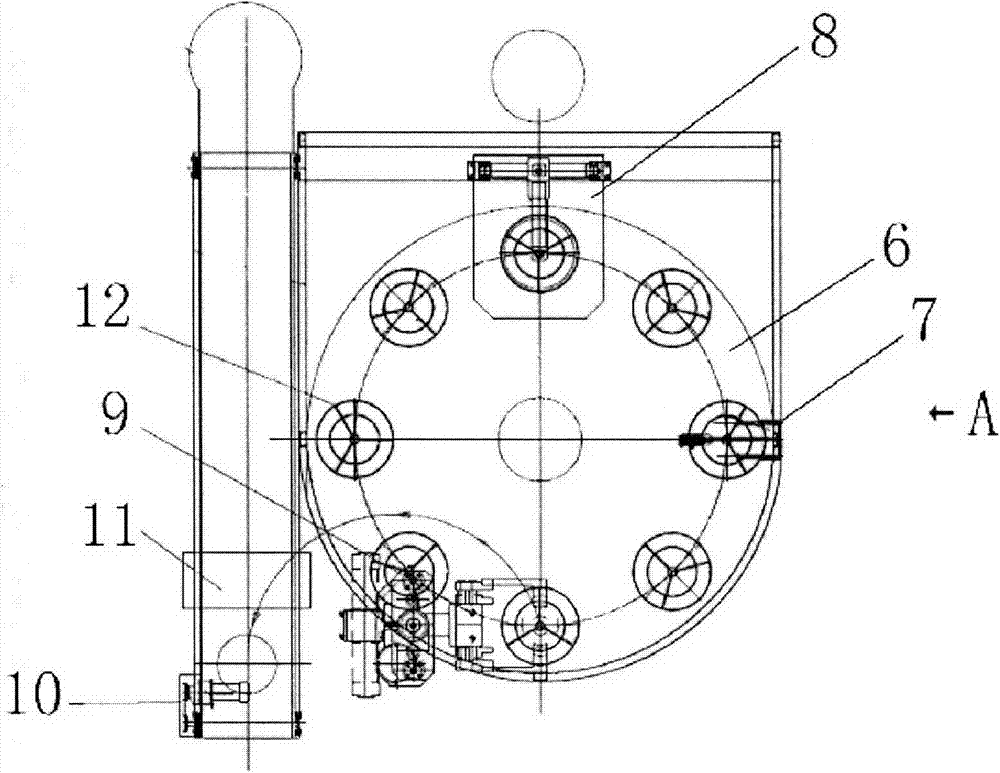

Method and device for magnetic powder inspection on annular workpiece

A technology of magnetic particle inspection and annular workpiece, applied in the direction of material magnetic variables, etc., can solve the problems of affecting inspection accuracy, time-consuming and labor-intensive, low work efficiency, etc., to improve the efficiency of magnetic particle inspection and prevent sensitivity interference and power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments. Herein, the exemplary embodiments and descriptions of the present invention are used to explain the technical solutions of the present invention, but are not intended to limit the present invention.

[0038] This example:

[0039] This embodiment provides a method for magnetic particle flaw detection of an annular workpiece, comprising the following steps:

[0040] Step 1: Set the workpiece model and diameter parameters through the host computer software, and the equipment automatically controls the feeding alignment device to ensure that the workpiece is aligned with the center in the horizontal direction of the pallet;

[0041] Step 2: Place the workpiece on the workpiece bracket at the loading level through a loading device such as a row crane (or cantilever crane) to achieve horizontal center alignment;

[0042] Step 3: The 8-station step-by-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com