Manufacturing method of test block having surface artificial crack defect used for magnetic particle testing

An artificial crack and magnetic particle detection technology, applied in the preparation of test samples, material magnetic variables, etc., can solve the problems of poor controllability of crack direction, irregular crack defects, and difficult to determine the specific position of crack defects, etc., to achieve crack direction Controllable, good forming quality, realistic effect of crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] ① Use a sawing machine to process a saw groove with a depth of 6mm and a width of 1.2mm on the upper surface of the base material Q245R test block with a specification of 300mm×300mm×12mm;

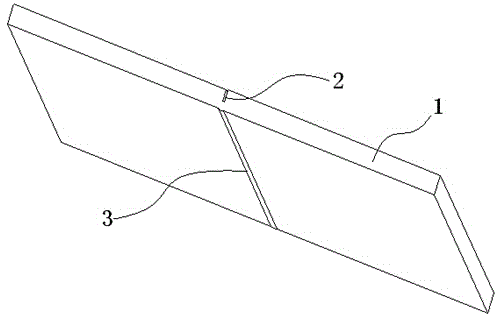

[0026] ②Welding a layer of weld I with a thickness of 2~3mm on the lower surface of the test block directly opposite the saw groove, such as figure 1 Shown

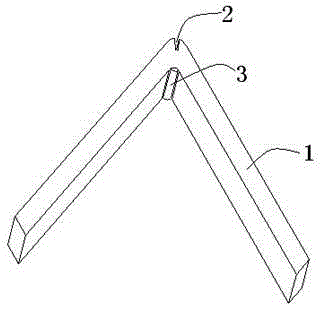

[0027] ③Before the test block is cooled, immediately use the weld Ⅰ as the central axis to mechanically make the test block bend, such as figure 2 As shown (the welding seam is outside the inner saw groove), after the cracks appear at the bottom of the saw groove, restore the test block to a horizontal shape;

[0028] ④ Process the saw groove into a U-shaped groove with a depth of 5mm and a width of 8mm;

[0029] ⑤ Fill the U-shaped groove in three layers of welding. The welding parameters of the first layer are J422Φ3.2 type electrode, the welding current is 130A, the voltage is 24±2V, and the welding speed is 15mm / min; the welding pa...

Embodiment 2

[0033] ① Use a sawing machine to process a saw groove with a depth of 8mm and a width of 1.2mm on the upper surface of the Q245R test block with a specification of 300mm×300mm×12mm;

[0034] ②Welding a layer of weld with a thickness of 2~3mm on the lower surface of the test block facing the saw groove Ⅰ;

[0035] ③ Immediately before the test block is cooled, use the weld as the central axis to mechanically bend the test block. After the cracks appear at the bottom of the saw groove, restore the test block to a horizontal shape;

[0036] ④ Process the saw groove into a U-shaped groove with a depth of 7mm and a width of 7mm;

[0037] ⑤ Fill the U-shaped groove in three layers of welding. The welding parameters of the first layer are J422Φ3.2 type electrode, the welding current is 130A, the voltage is 24±2V, the welding speed is 15mm / min, and the welding parameters used for the second and third layers It is: J422Φ3.2 electrode, welding current 170A, voltage 24±2V, welding speed 10mm / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com