Patents

Literature

229results about How to "Prevent disappearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

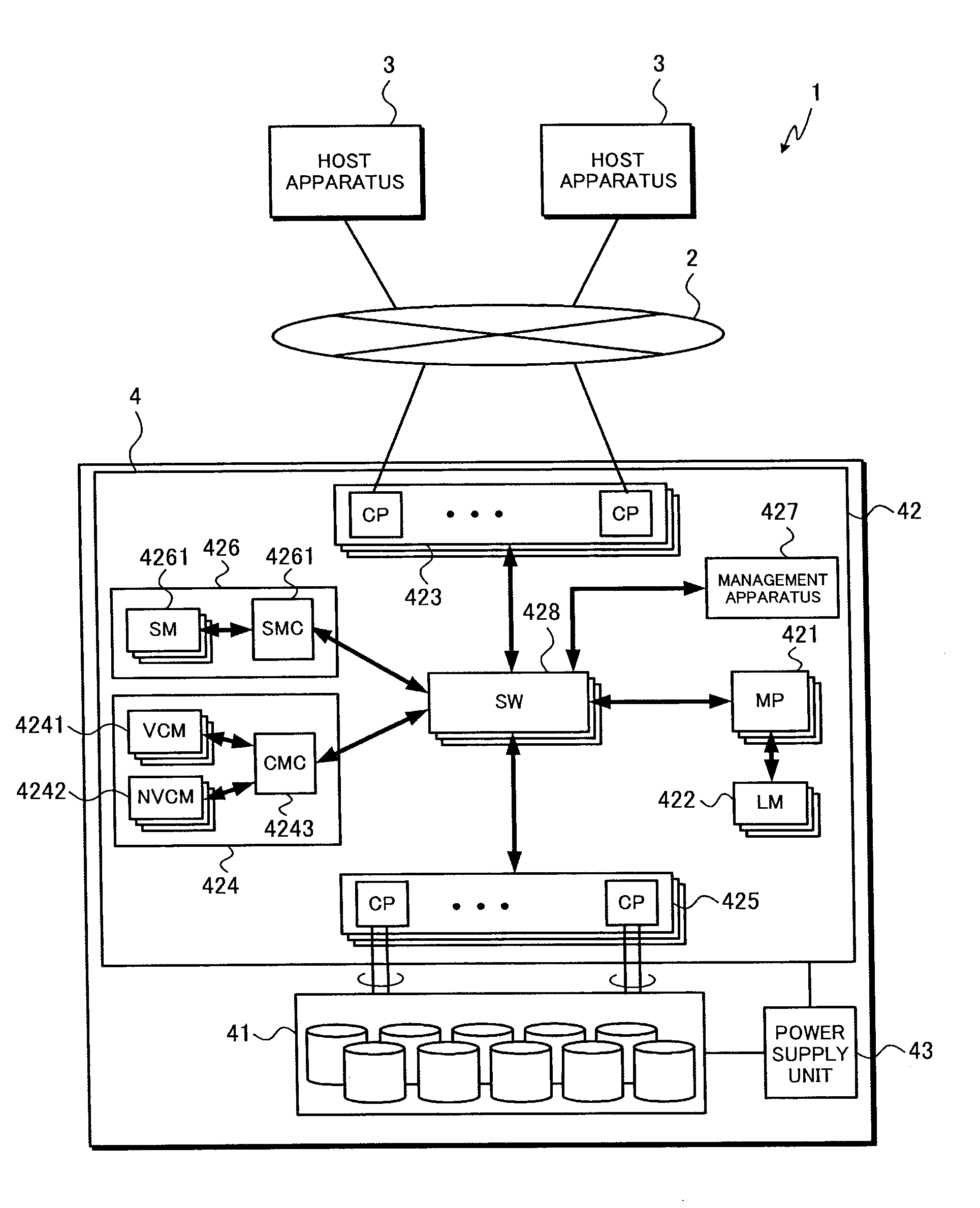

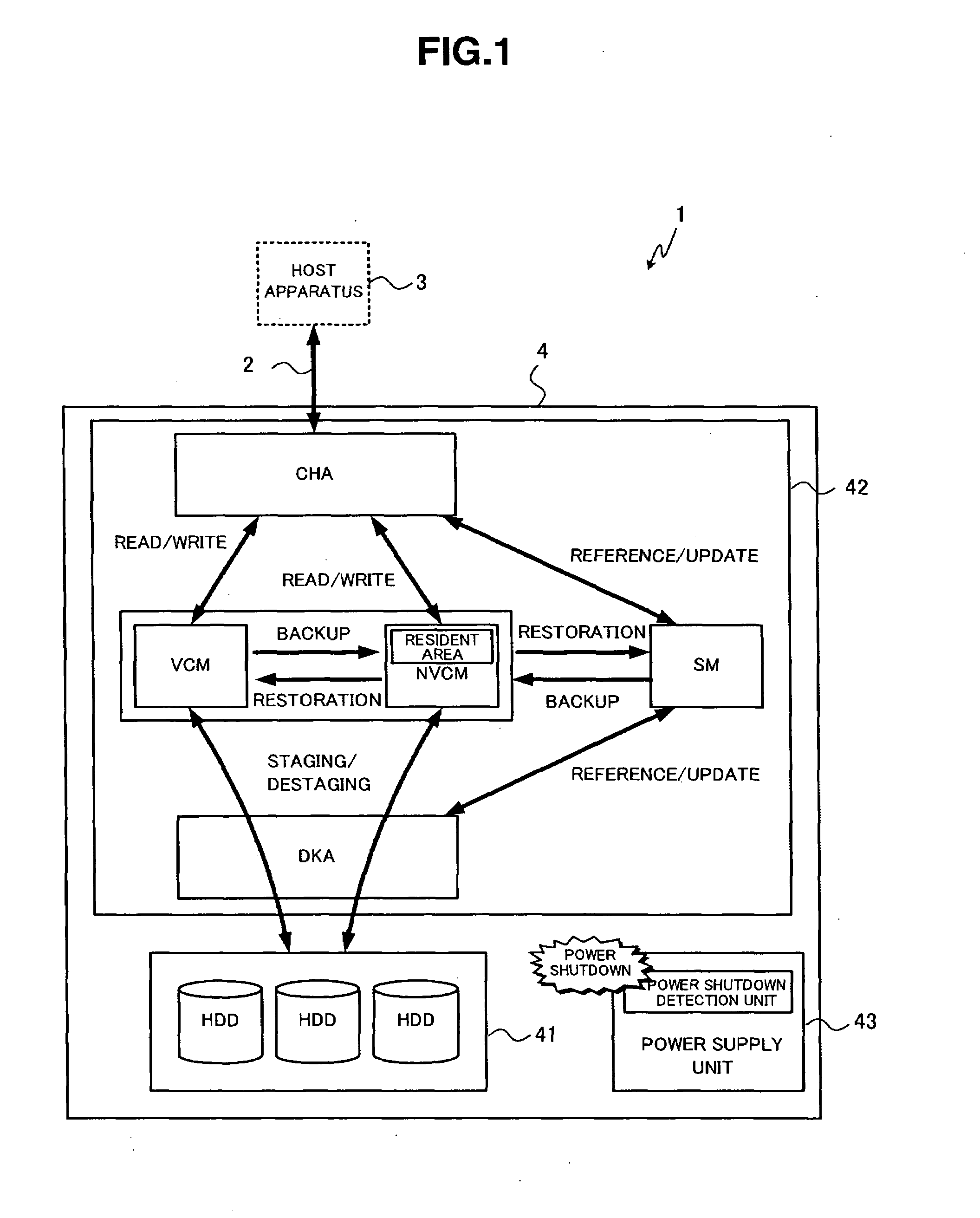

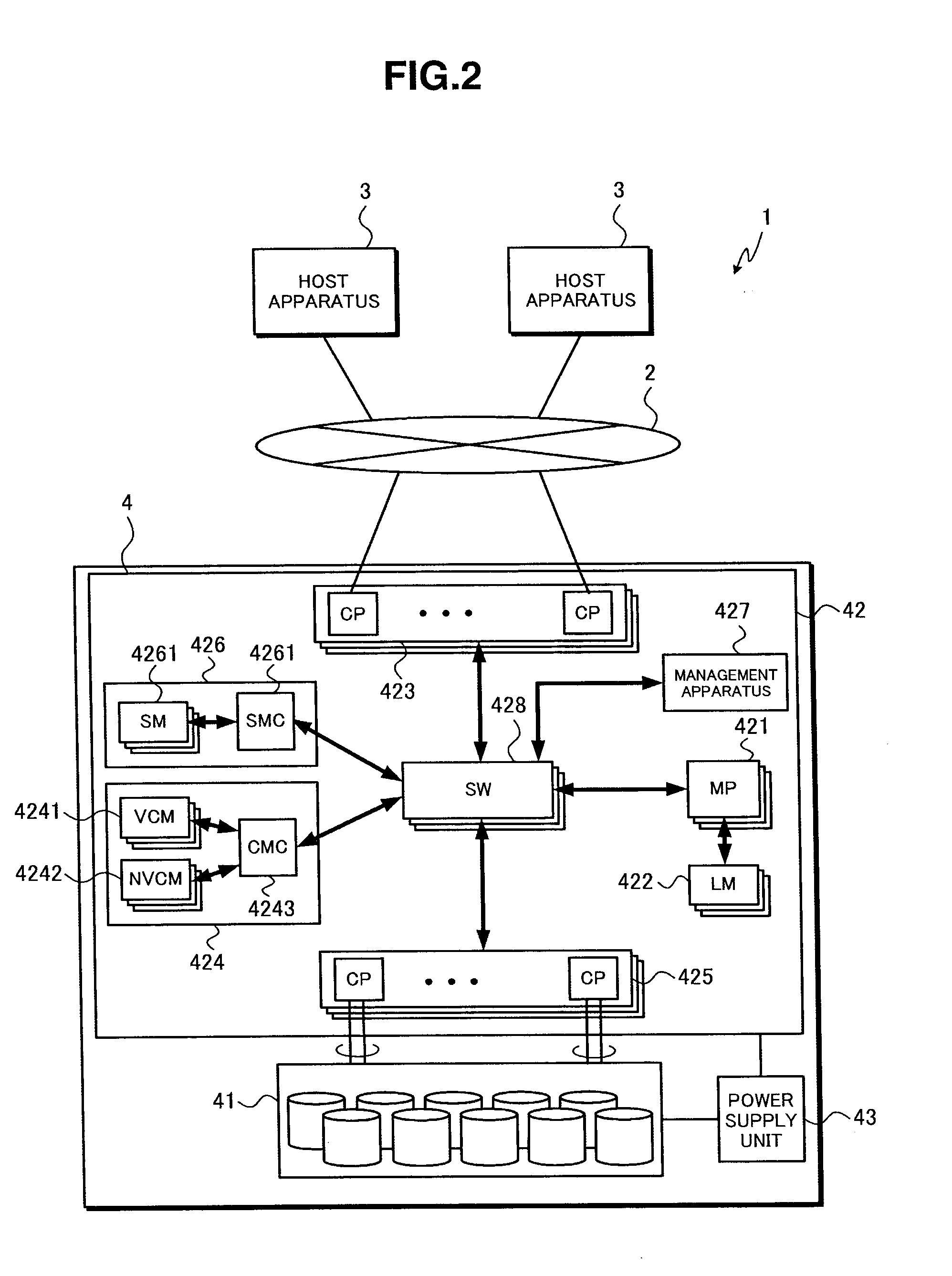

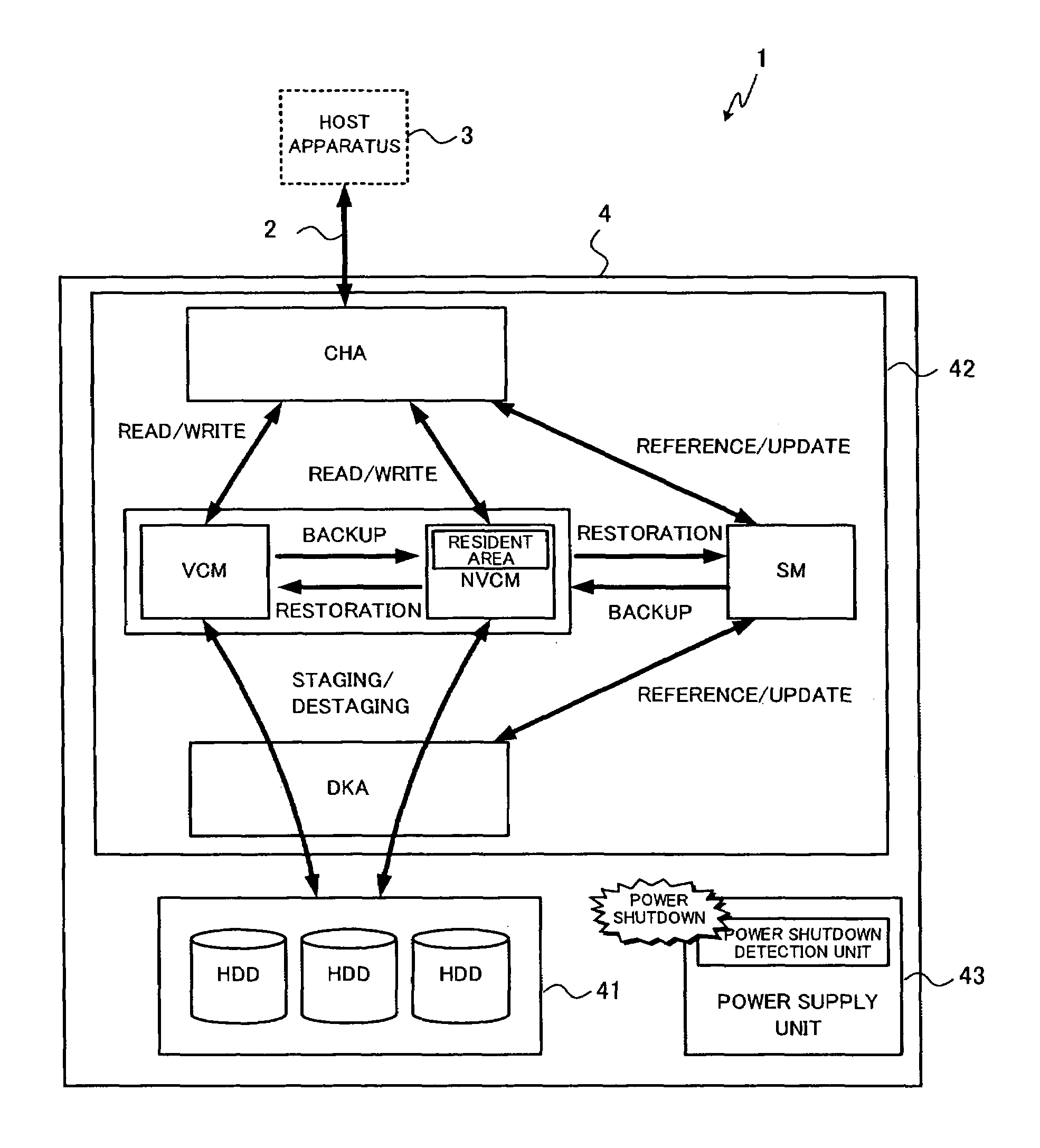

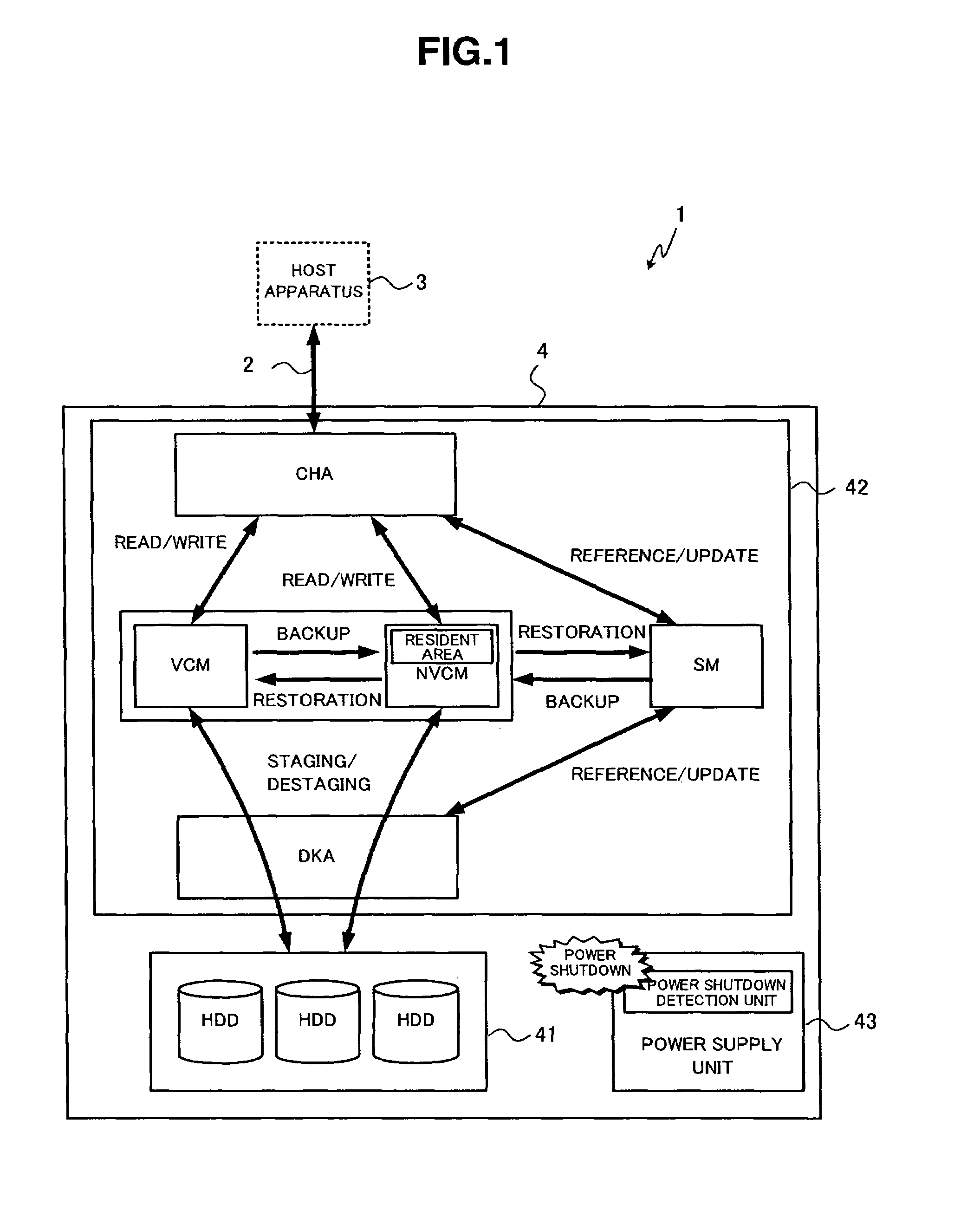

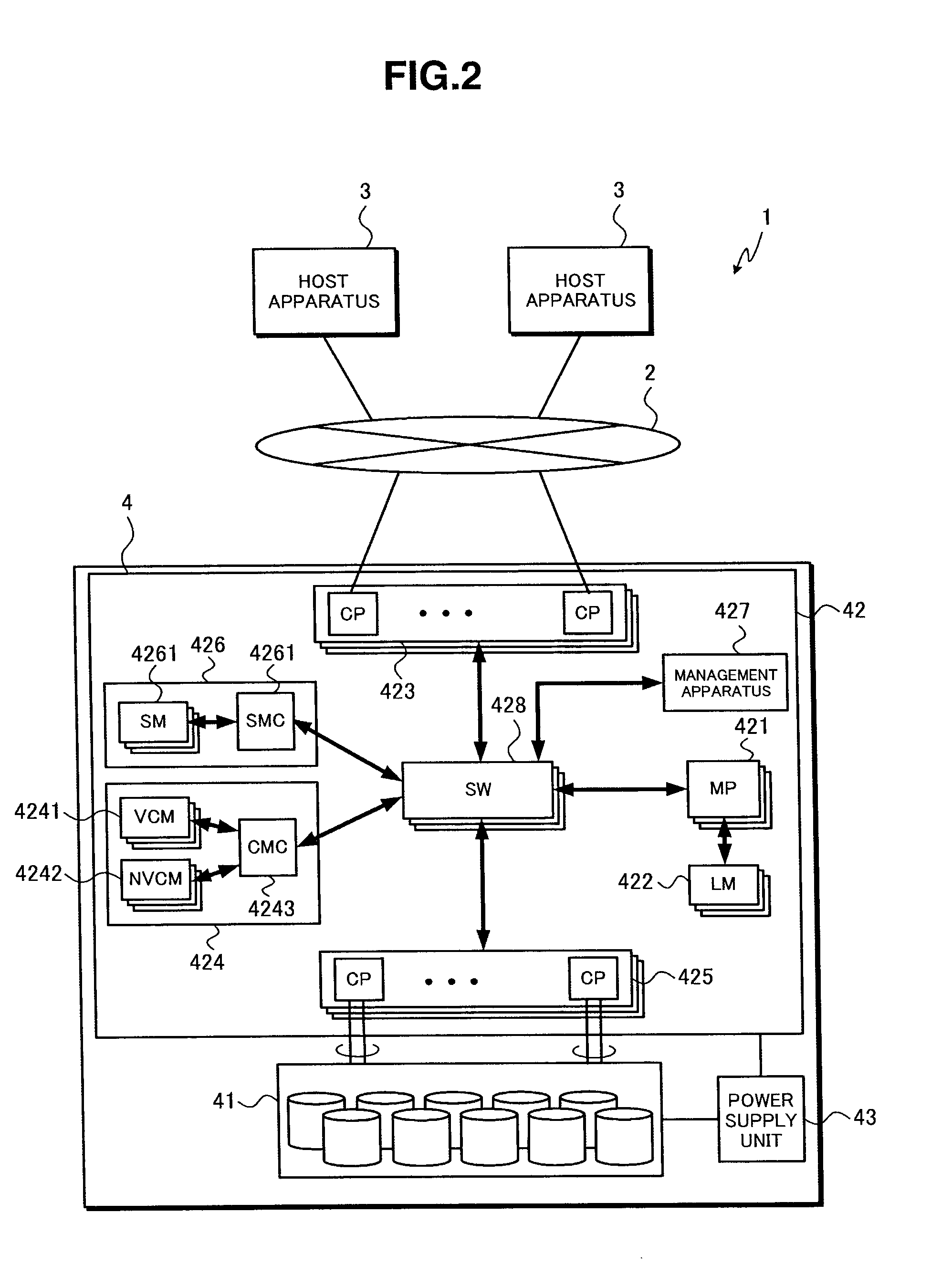

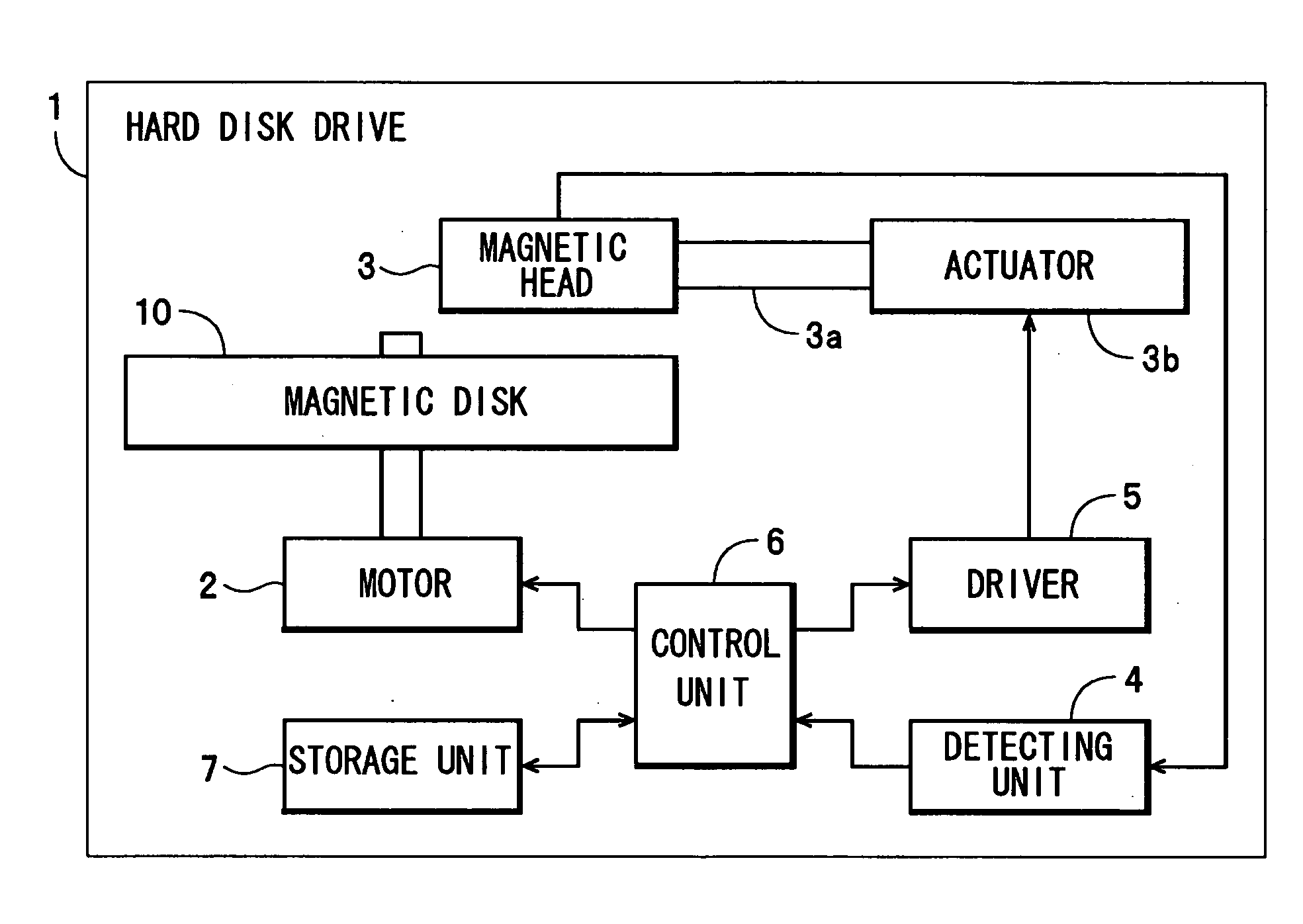

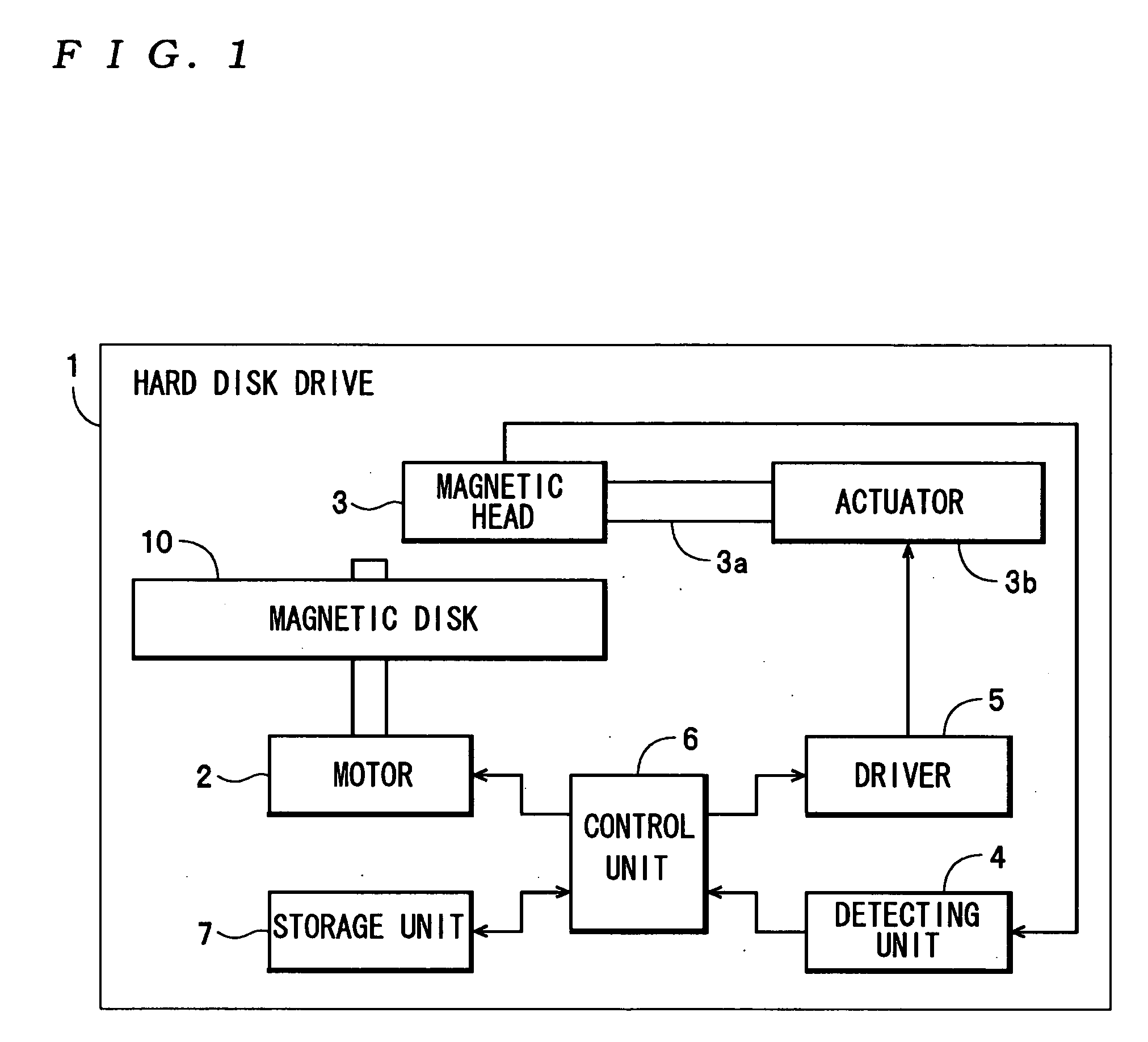

Storage apparatus and data management method in the storage apparatus

ActiveUS20090077312A1Effective supportEfficiently and reliably storedMemory architecture accessing/allocationEnergy efficient ICTDirty dataData management

A storage apparatus sets up part of non-volatile cache memory as a cache-resident area, and in an emergency such as an unexpected power shutdown, backs up dirty data of data cached in volatile memory to an area other than the cache-resident area in the non-volatile cache memory, together with the relevant cache management information. Further, the storage apparatus monitors the amount of the dirty data in the volatile cache memory so that the dirty data cached in the volatile cache memory is reliably contained in a backup area in the non-volatile memory, and when the dirty data amount exceeds a predetermined threshold value, the storage apparatus releases the cache-resident area to serve as the backup area.

Owner:HITACHI LTD

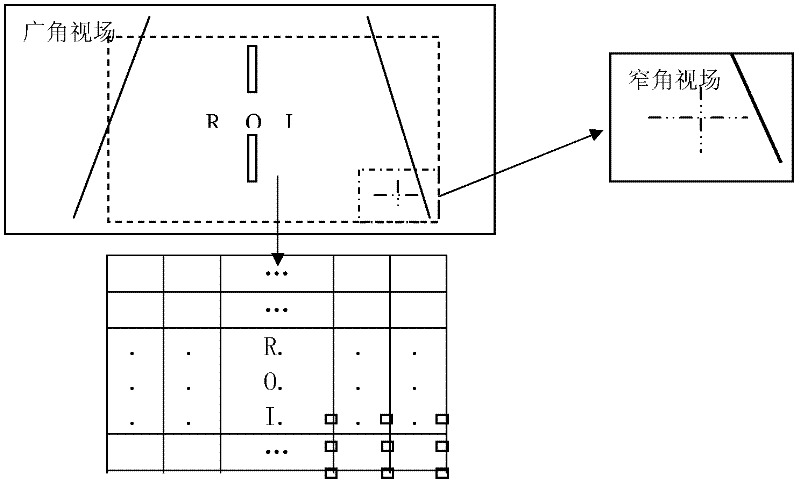

Dual-camera automatic cooperative multi-target eagle-eye observation system and its observation method

InactiveCN102291569AEasy to operateSuitable for realizationTelevision system detailsImage analysisVideo monitoringObservation system

The invention relates to a double-camera automatic coordination multi-target eagle eye observation system and an observation method thereof. The system comprises a hardware platform, a wide angle camera, a pan / tilt / zoom (PTZ) camera, a processor and a multi-channel video acquisition card. The observation method comprises the following steps of: calibrating two cameras to obtain an angle that a moving camera rotates and aligns with any position of the wide angle camera; detecting moving targets from the wide angel camera, and tracking and marking; selecting a target; controlling the PTZ camerato zoom and track if the target moves fast; amplifying the target if the target moves slowly; positioning interested characteristics; and secondarily amplifying and observing an interested region. The system has the advantages of low cost, simple implementation and the like, and can be widely applied to multi-target video tracking fields such as robots, intelligent transportation, video monitoring and the like.

Owner:SHANGHAI JIAO TONG UNIV

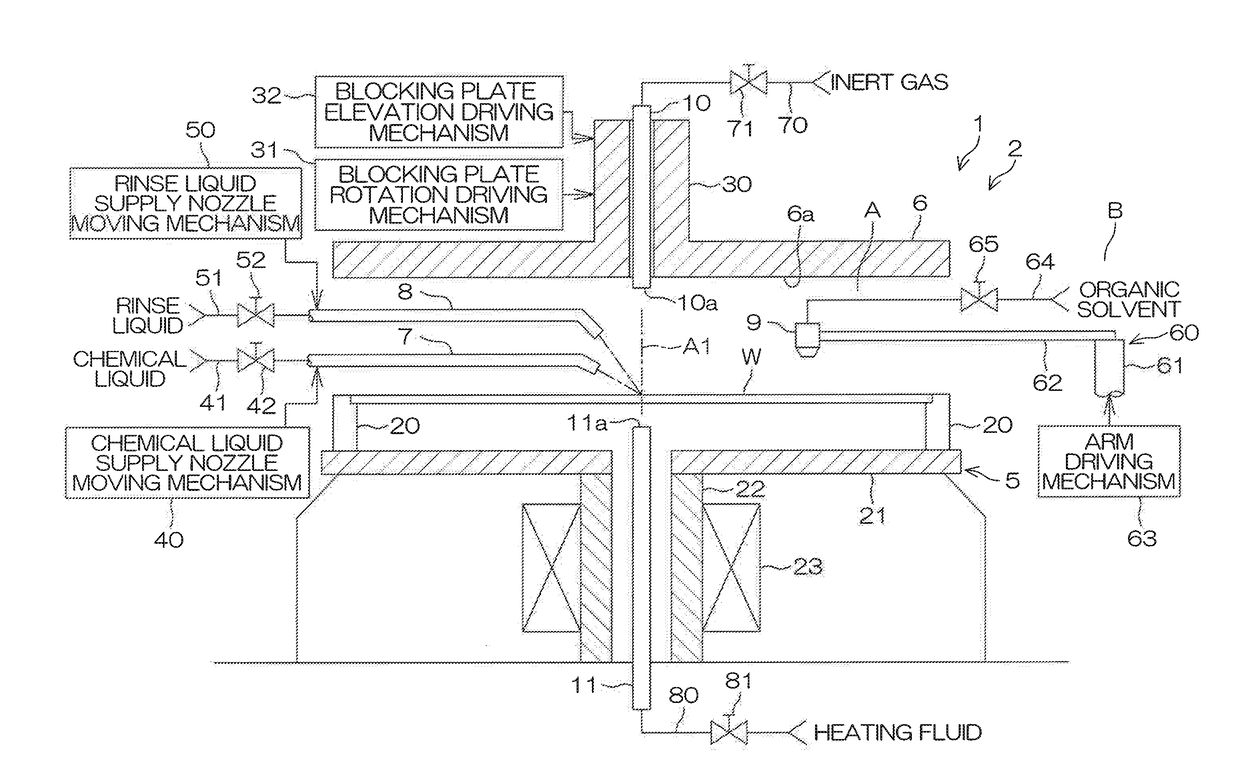

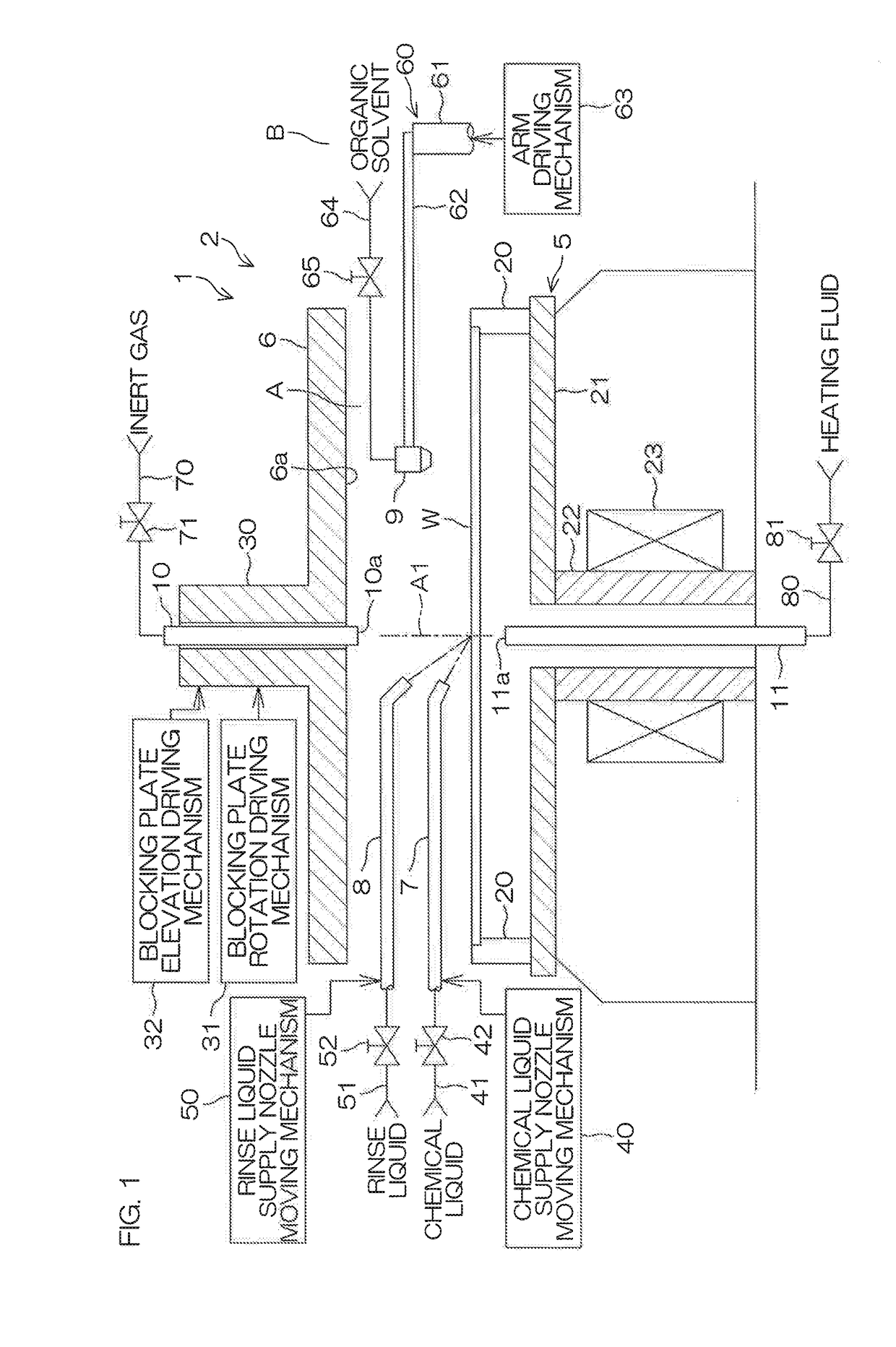

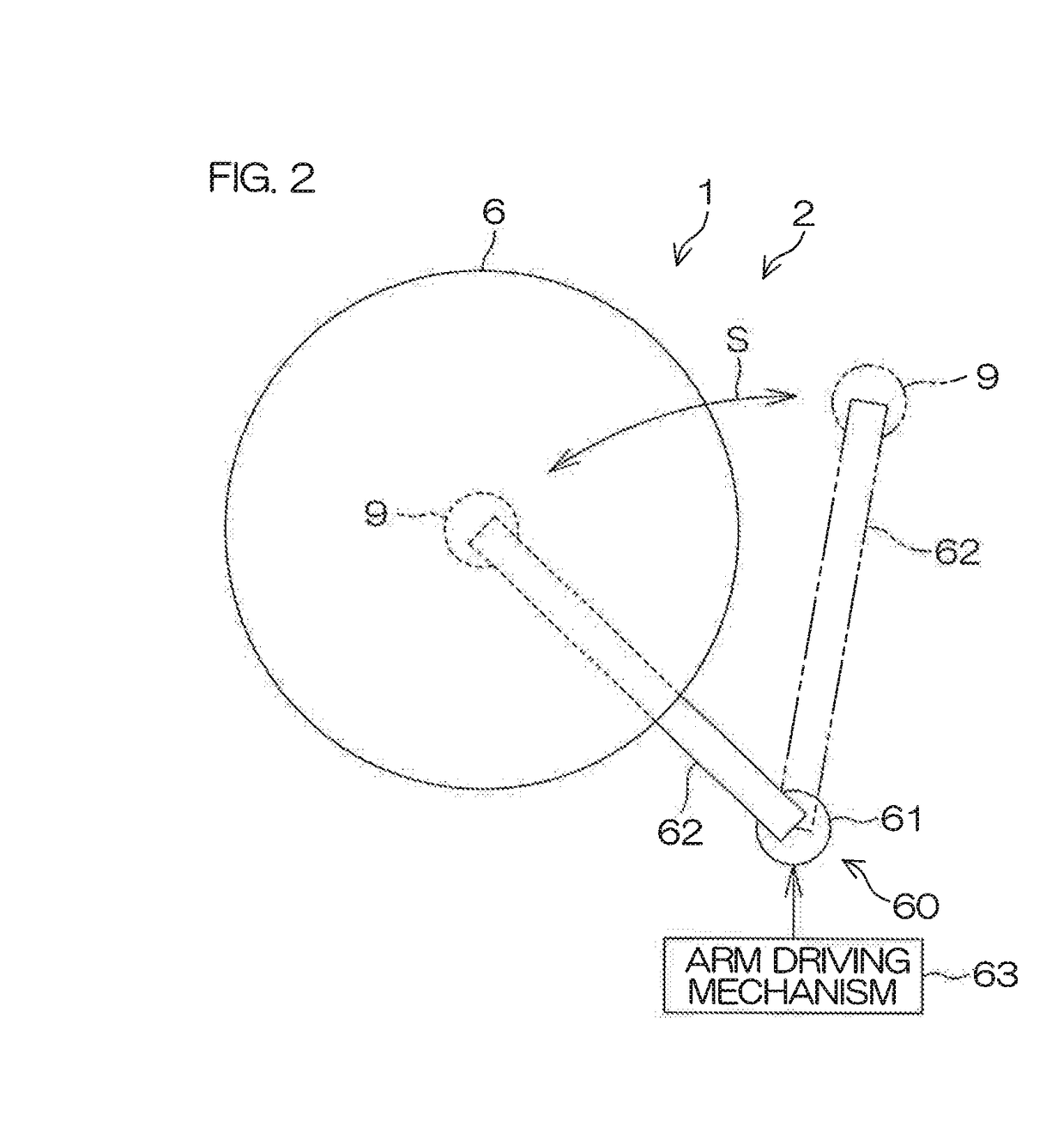

Substrate processing apparatus and substrate processing method

ActiveUS20170186599A1Expand smoothlyDry fastSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The controller is programmed to cause a low-surface-tension liquid supply unit to supply a liquid film of a low-surface-tension liquid to a front surface of a substrate so as to form a liquid film of the low-surface-tension liquid. The controller is programmed to control the substrate rotating unit and the inert gas supply unit so that an inert gas is supplied toward the rotational center position while rotating the substrate, thereby forming an opening spreading from the rotational center position to be formed in the liquid film, and enlarging the opening in a direction away from the rotational center position, and to control the landing-position changing unit to change the landing position of the low-surface-tension liquid to at least two positions except the rotational center position in accordance with enlargement of the opening so that the landing position is placed outside the peripheral edge of the opening.

Owner:DAINIPPON SCREEN MTG CO LTD

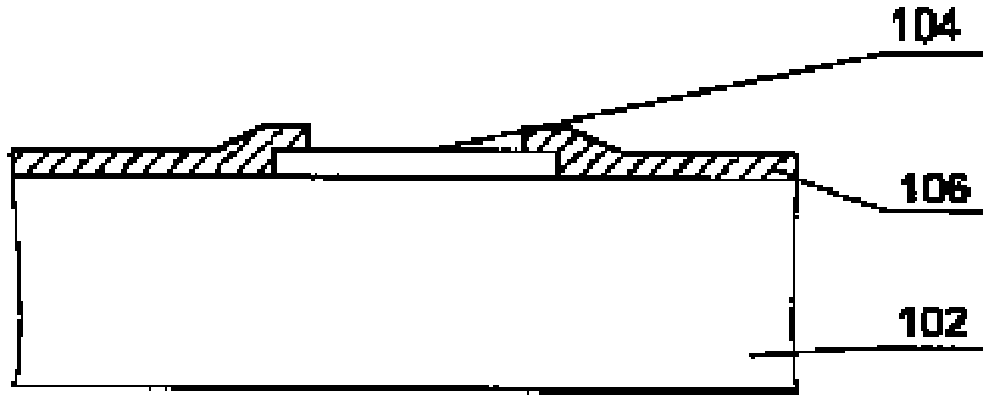

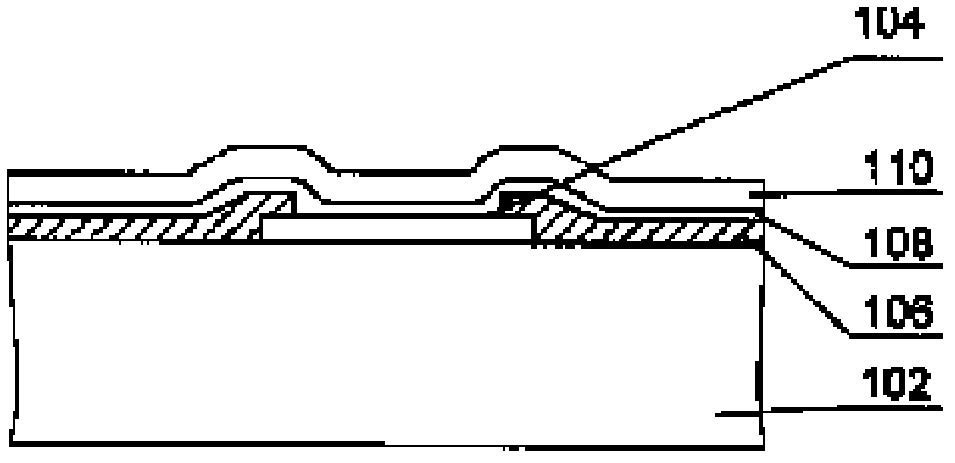

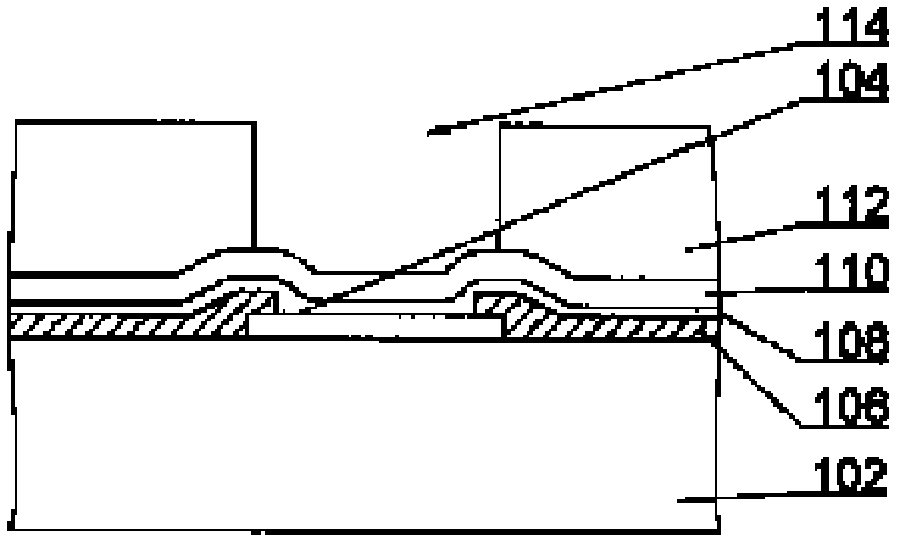

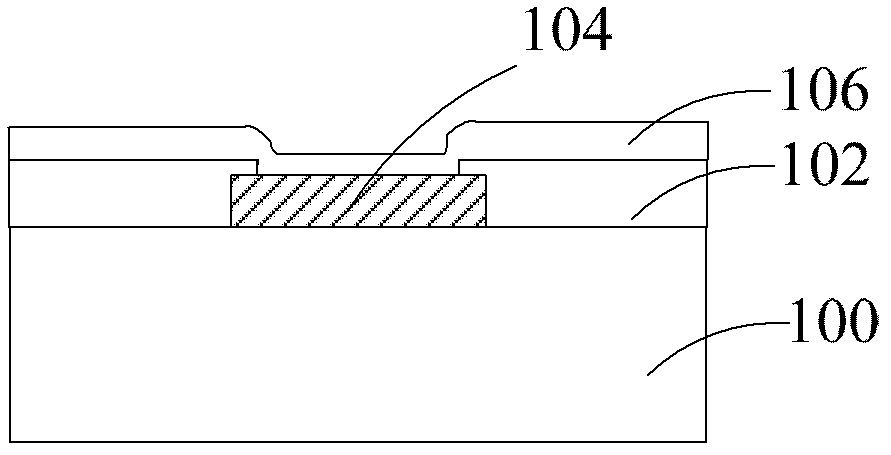

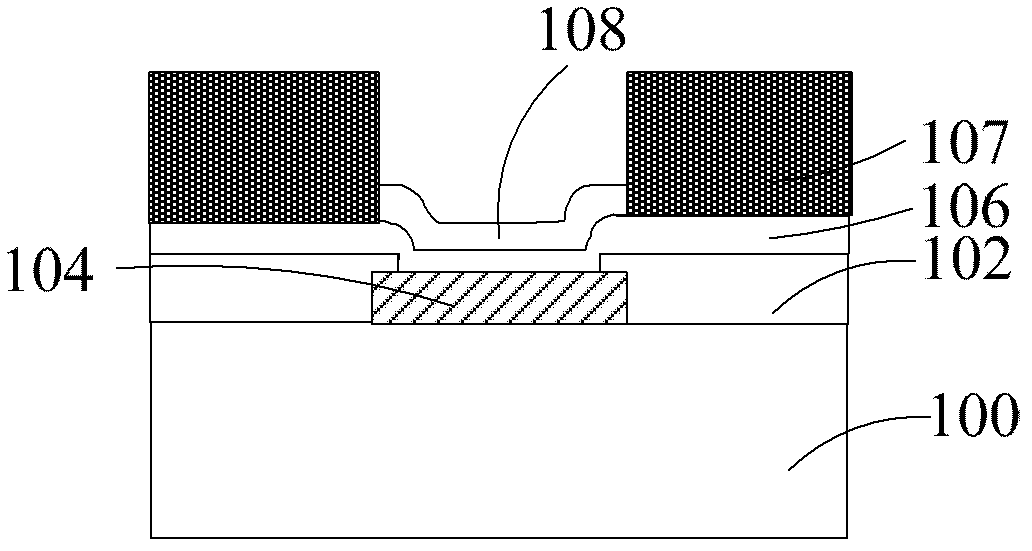

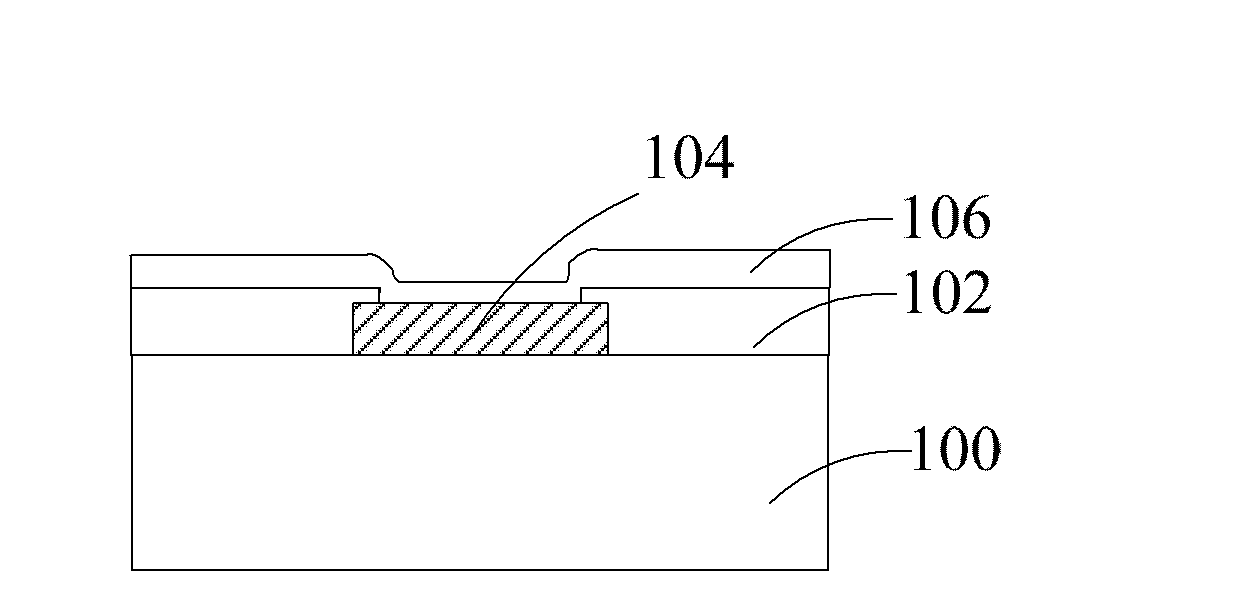

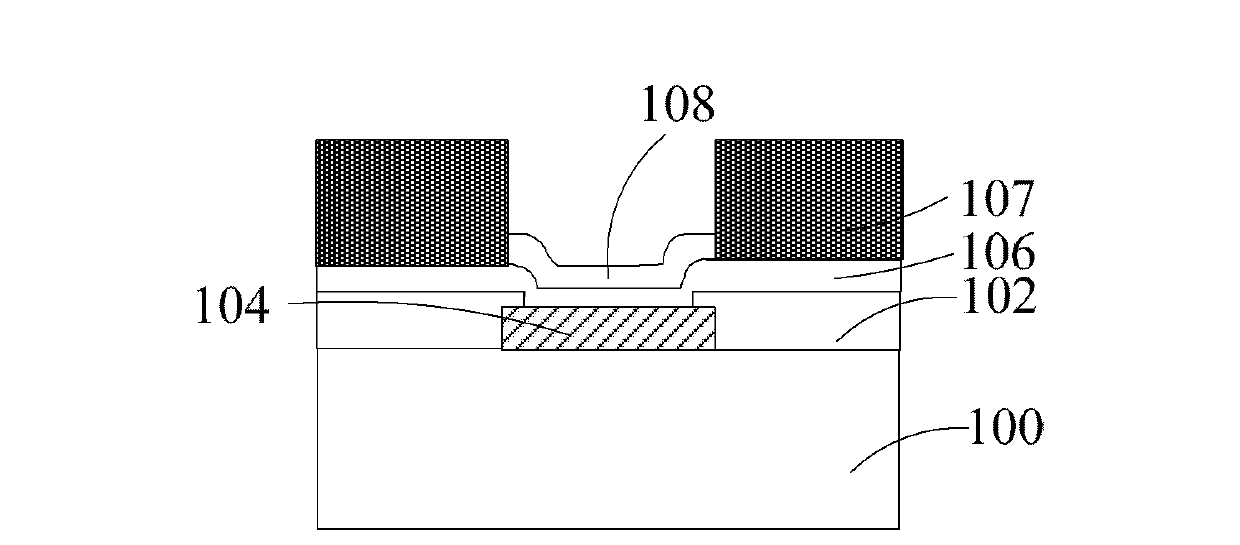

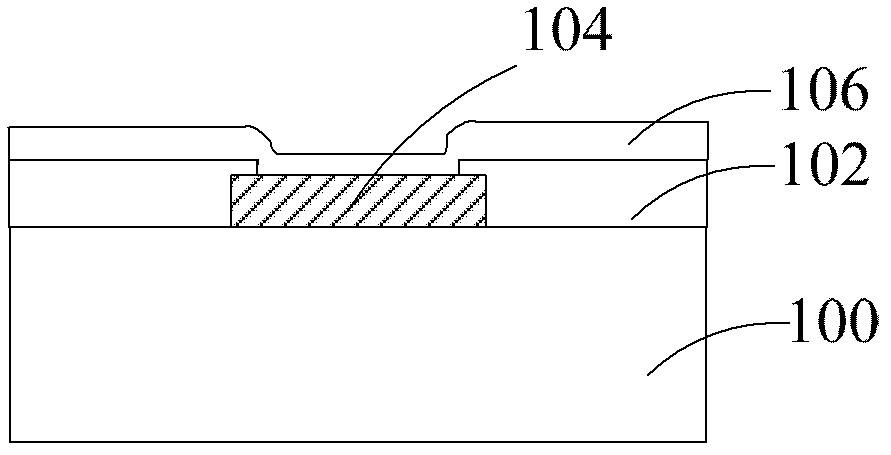

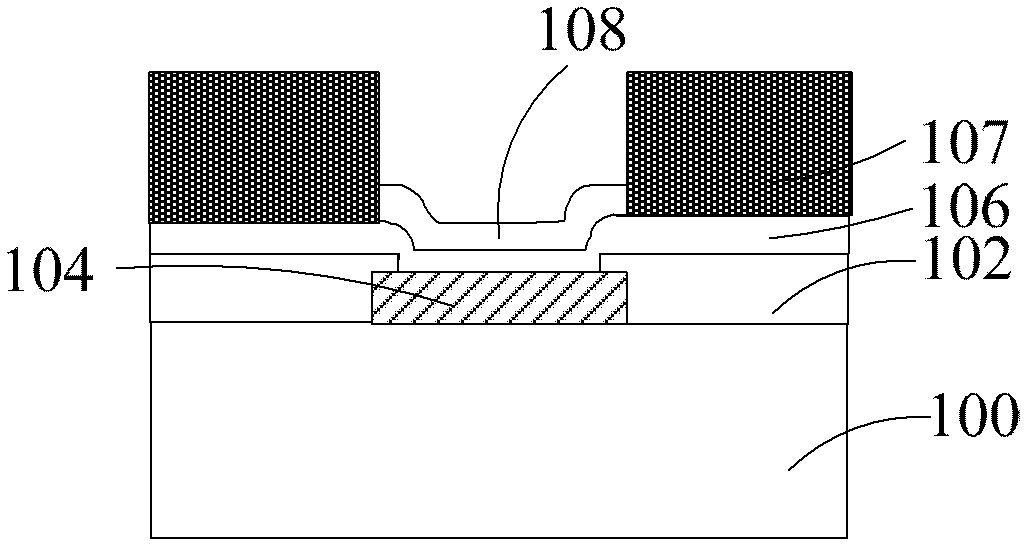

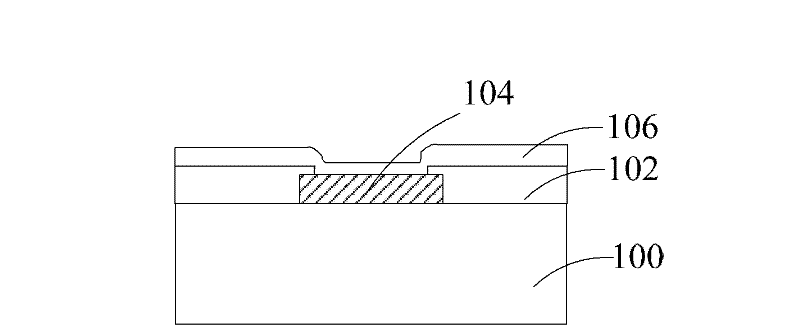

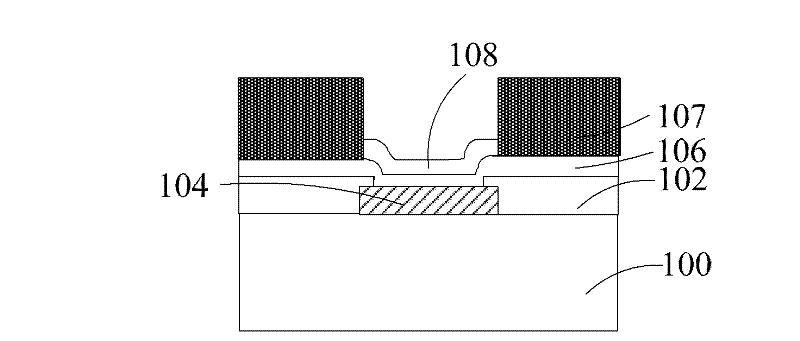

Method for forming solder bump

ActiveCN102496580ASmall sizeIncrease the number of function output portsSolid-state devicesSemiconductor/solid-state device manufacturingSolder pastePhotoresist

The invention provides a method for forming a solder bump. The method comprises the following steps of: forming a heat resistant metal layer and a metal wetting layer on a pad and a passivation layer of a chip in sequence; forming a photoresist on the metal wetting layer, wherein the photoresist is provided with an opening to expose the metal wetting layer above the pad of the chip; forming an adhesion layer and a barrier layer on the metal wetting layer in the opening in sequence; forming solder paste on the barrier layer; removing the photoresist; etching the heat resistant metal layer and the metal wetting layer on the passivation layer until the passivation layer is exposed; and ensuring the solder paste to reflow to form a pillar bump. The method has the effect of improving the electrical property and reliability of the solder bump and is suitable for chip scale package with the requirements of fine pad pitch and multiple output functions.

Owner:NANTONG FUJITSU MICROELECTRONICS

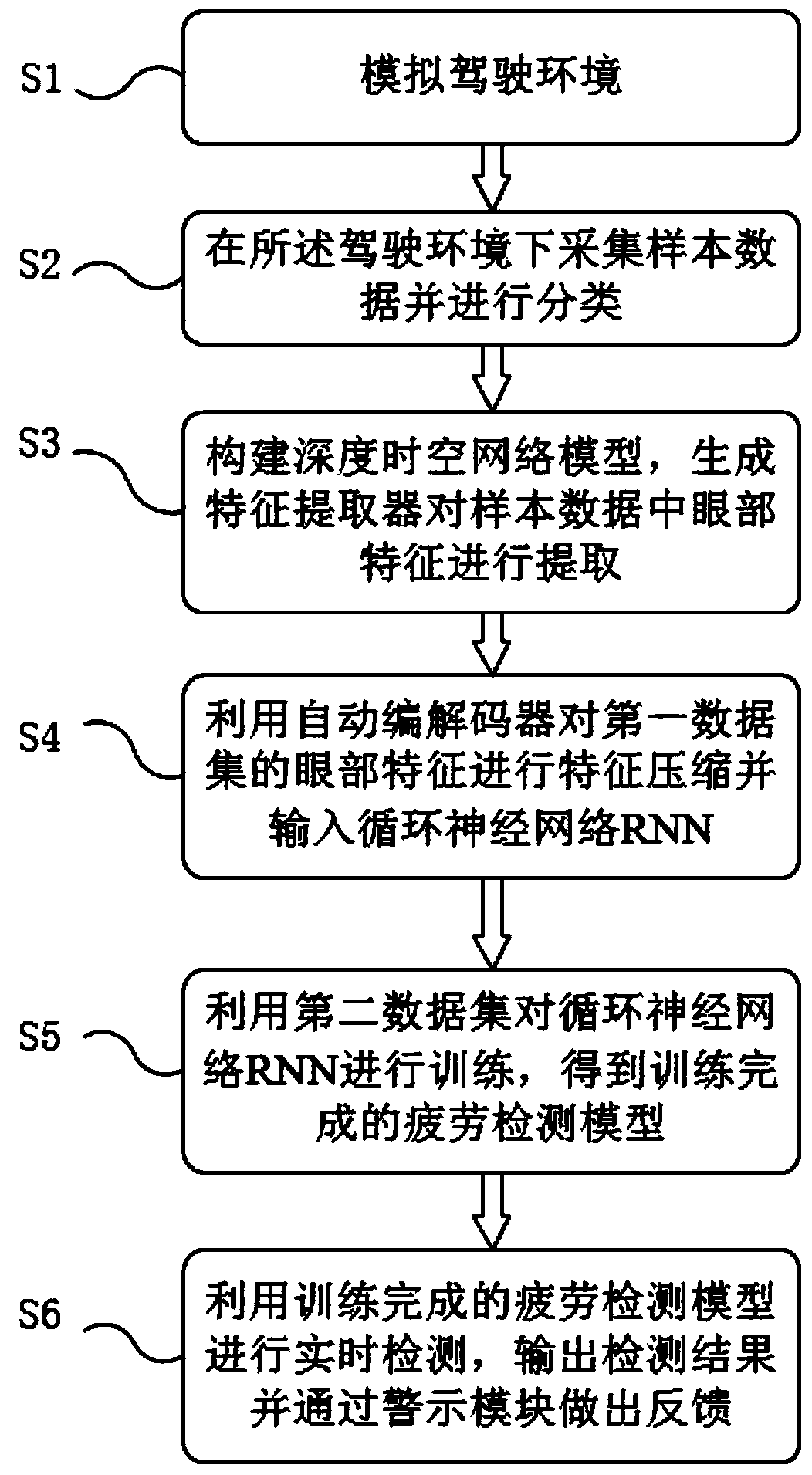

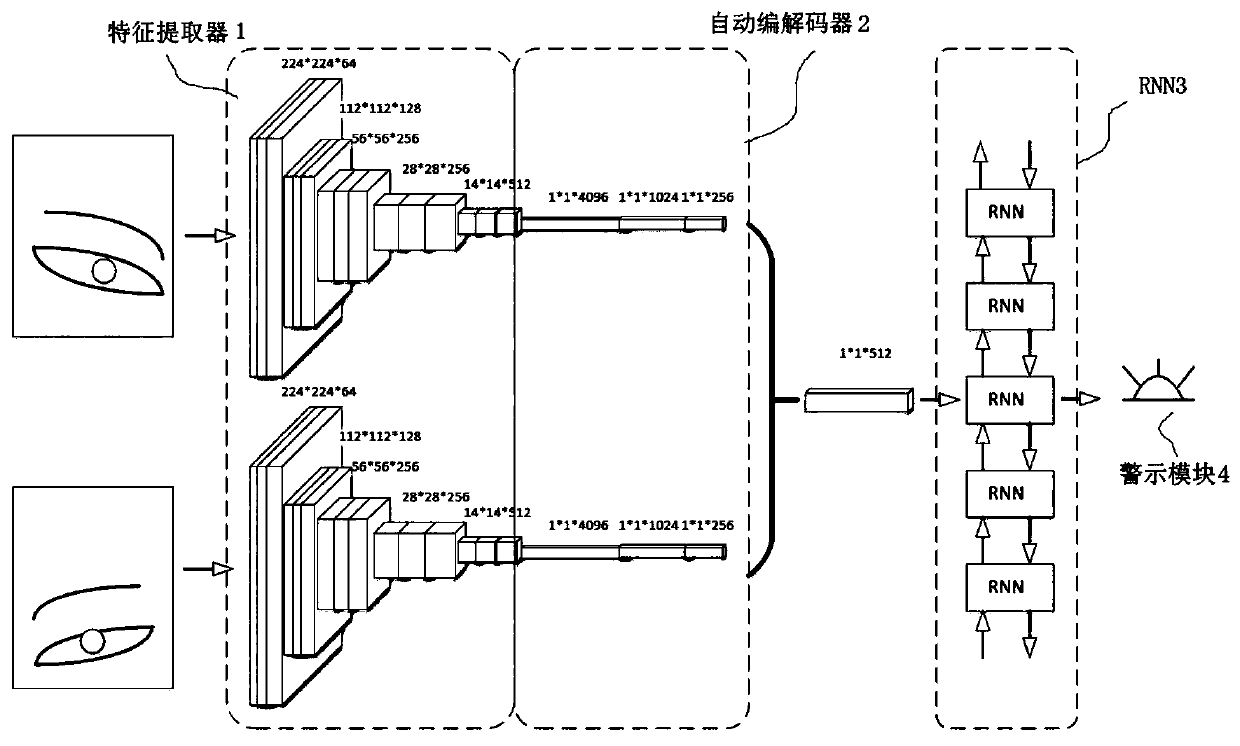

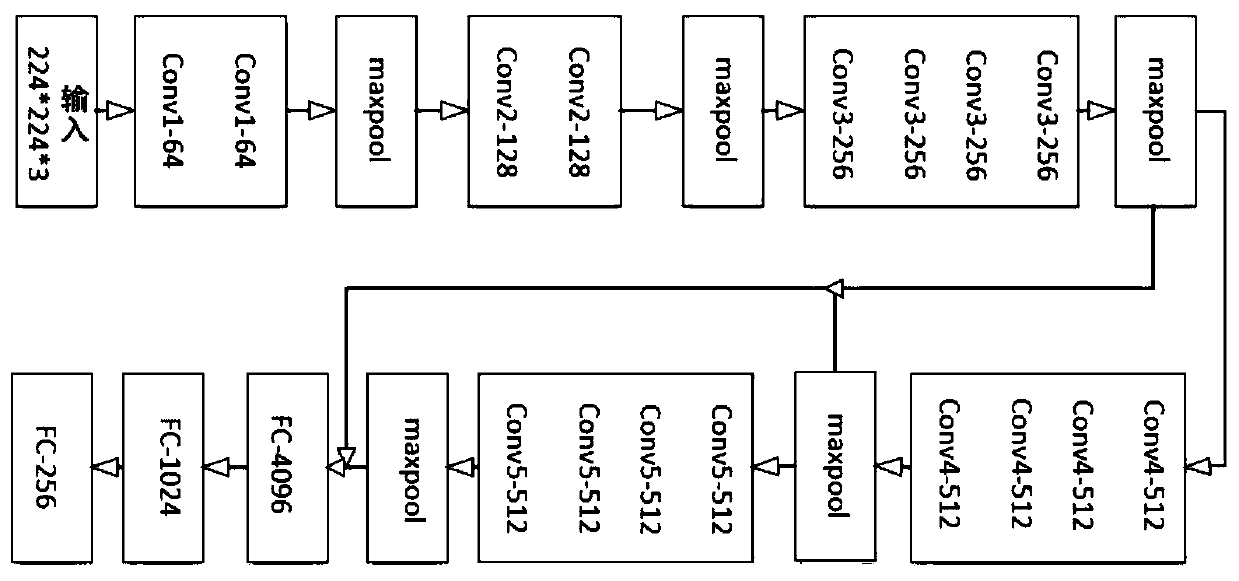

Fatigue detecting method based on deep space-time network

ActiveCN109770925AAvoid Gradient ExplosionsPrevent disappearingDiagnostic recording/measuringSensorsState of artData set

The embodiment of the invention discloses a fatigue detecting method based on a deep space-time network, and relates to the technical field of machine learning. The method comprises the steps that driving environments are simulated, wherein the driving environments comprise driving environments under different weathers and road conditions; sample data is collected and classified under the drivingenvironments, wherein the sample data comprises a first data set and a second data set; a deep space-time network model is constructed, and a feature extractor is generated to extract eye features inthe sample data; the eye features of the first data set are subjected to feature compression by using an automatic codec and input into a recurrent neural network RNN; the second data set is used fortraining the recurrent neural network RNN to obtain a trained fatigue detecting model; the trained fatigue detecting model is used for real-time detection, a detection result is output, and feedback is performed through a warning module. The fatigue detecting method based on the deep space-time network can solve the problems that the fatigue detecting method in the prior art cannot accurately classify the fatigue degrees and is inconvenient to operate.

Owner:MINJIANG UNIV

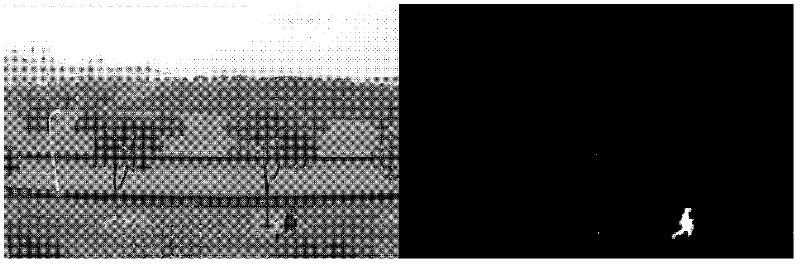

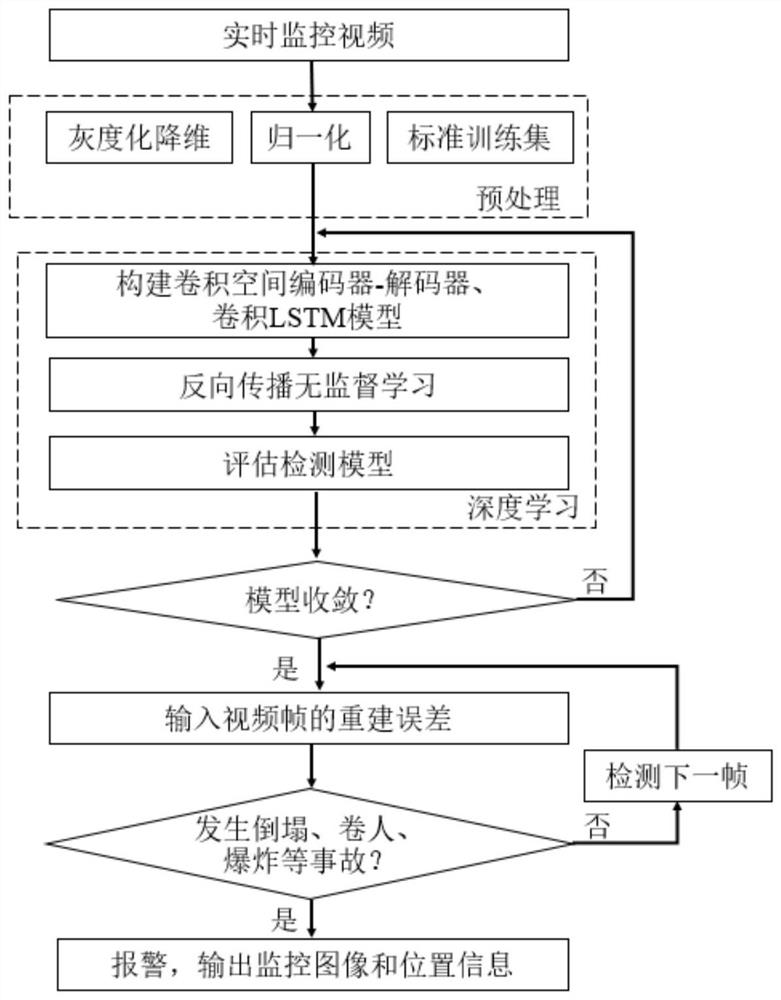

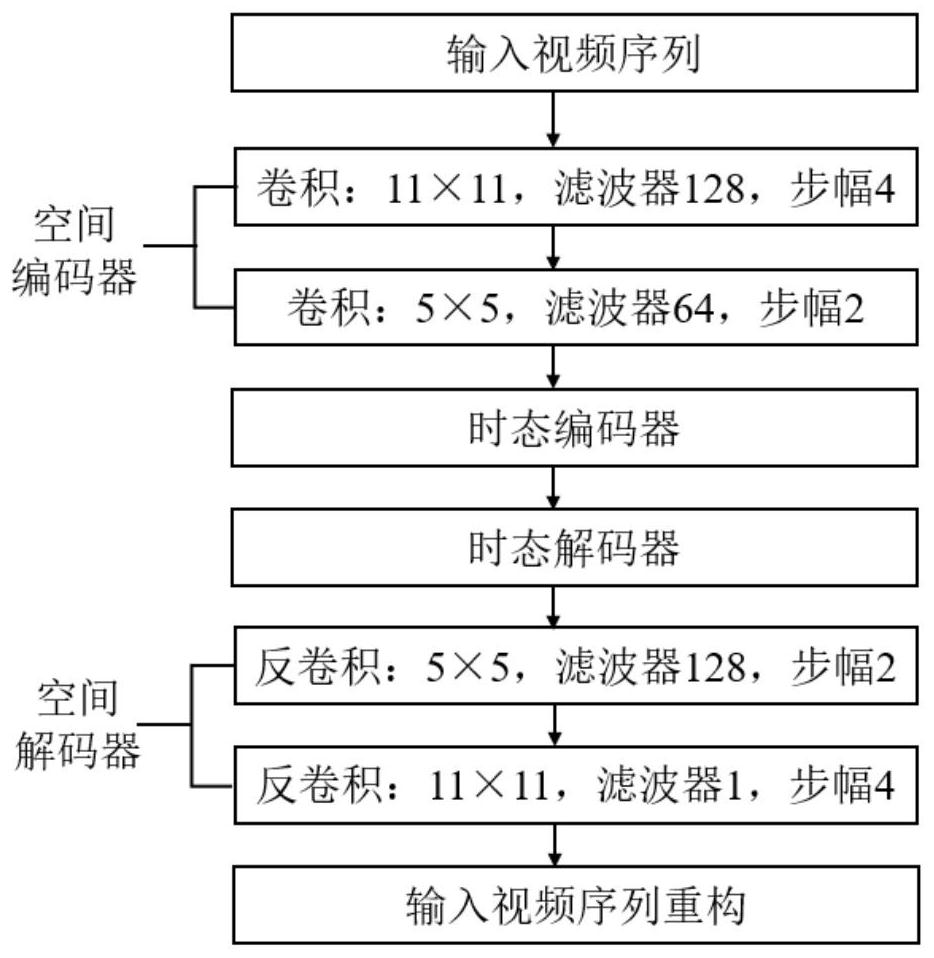

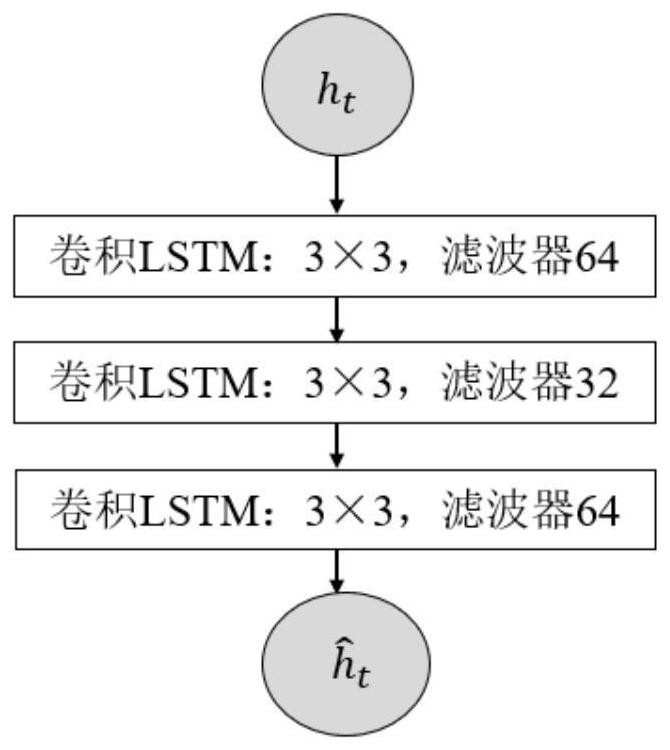

Dangerous working area accident automatic detection and alarm method based on deep learning

PendingCN112287816AReduce reconstruction errorIncrease reconstruction errorCharacter and pattern recognitionClosed circuit television systemsReconstruction errorEngineering

The invention discloses a dangerous working area accident automatic detection alarm method based on deep learning, and the method comprises the steps: obtaining original video data, carrying out the preprocessing, and converting a video into an input training set acceptable for a deep learning network; learning a feature mode in a training video through a convolutional space-time automatic encoderdecoder, and performing training optimization by using the training set to obtain a workshop accident detection model; and acquiring a real-time monitoring video to be detected, detecting the reconstruction error of each frame of monitoring video image by adopting the workshop accident detection model, and if the local minimum reconstruction error of a plurality of continuous real-time monitoringimages is greater than a threshold value, sending corresponding alarm information and corresponding monitoring position information to a workshop administrator terminal. On the basis of analysis of alarge number of videos, video special learning of a normal scene is carried out, a fully trained detection model is obtained, abnormal accidents in a workshop can be rapidly and accurately detected,and accident detection can be carried out in any workshop scene.

Owner:XI AN JIAOTONG UNIV

Storage apparatus and data management method in the storage apparatus

InactiveUS8024516B2Effective supportEfficiently and reliably storedMemory architecture accessing/allocationEnergy efficient ICTDirty dataData management

Owner:HITACHI LTD

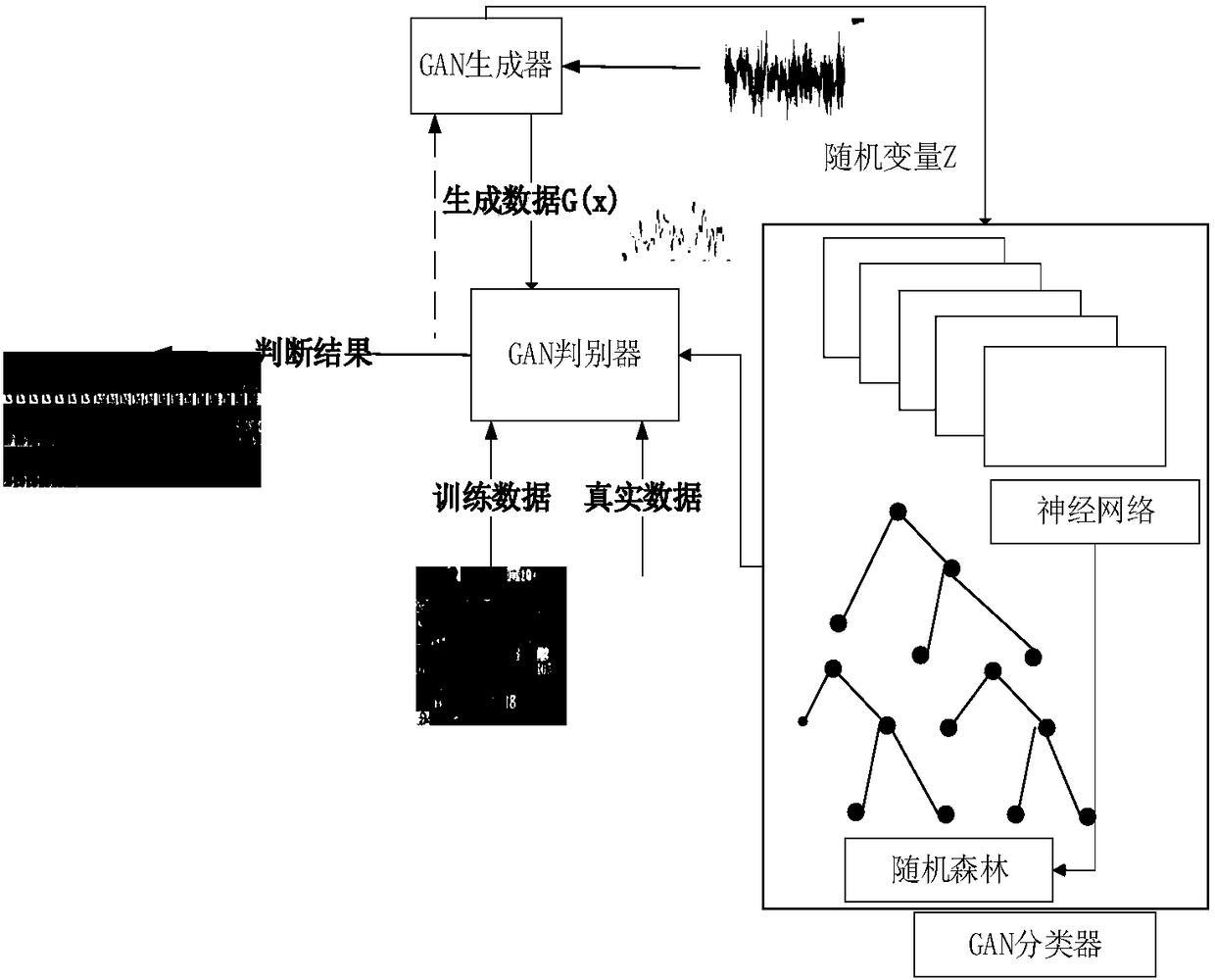

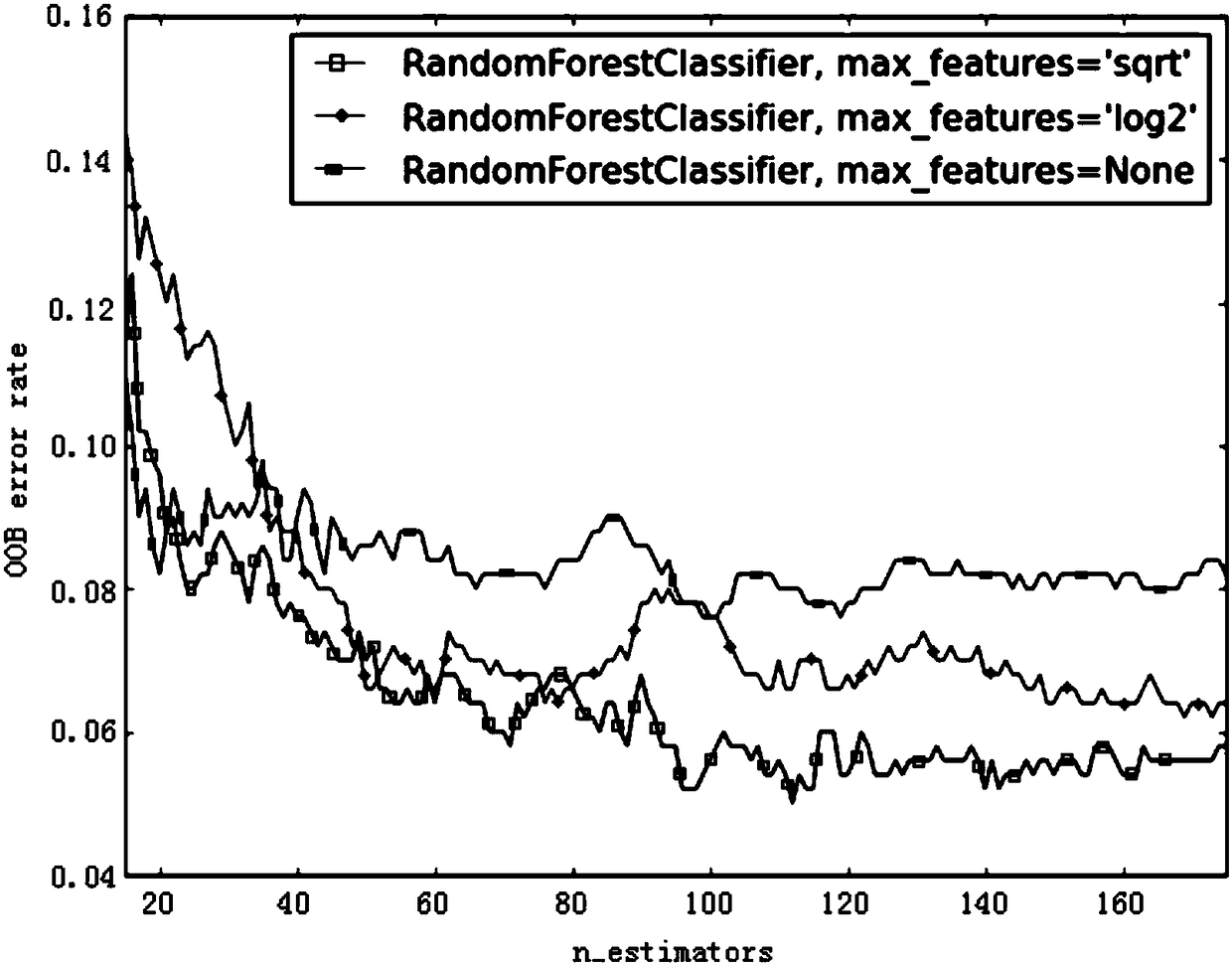

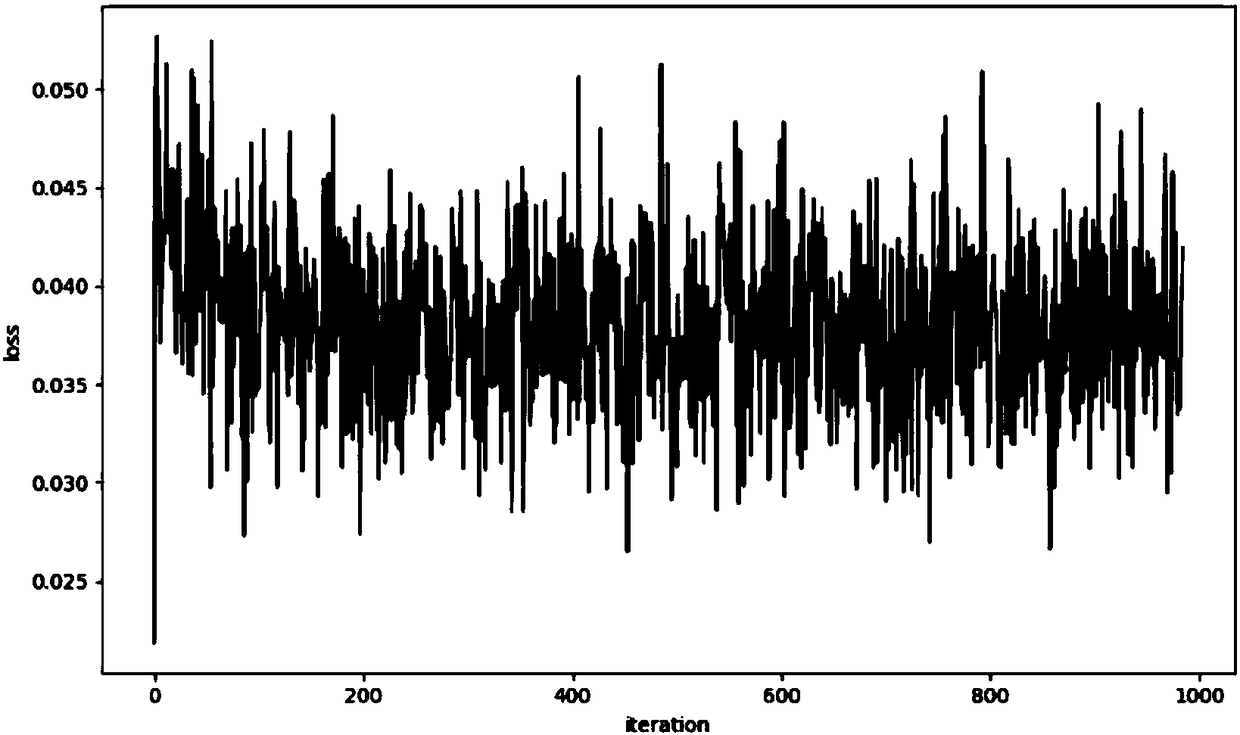

Classification method based on Triple-GAN

ActiveCN108520282AGood anti-noise performanceNot easy to fitCharacter and pattern recognitionNODALGenerative adversarial network

Generative adversarial networks (GAN) display a great development prospect in image generation and semi-supervised learning, and have been developed to Triple-GAN. However, there are two problems requiring solving based on the classification method based on Triple-GAN, wherein the two problems comprise a problem that KL-based divergence distribution construction is easy to generate gradient disappearance to cause unstable training and a problem that the Triple-GAN employs a manual mode to perform mark of tags for samples to cause too large workload of manual marking and non-uniform marking. Based on this conditions, RandomForests are employed to perform classification of real samples to perform automatic marking of tags of blade nodes, and the ideal of the least square generative adversarial networks (LSGAN) are employed to construct a loss function to avoid gradient disappearance.

Owner:XIANGTAN UNIV

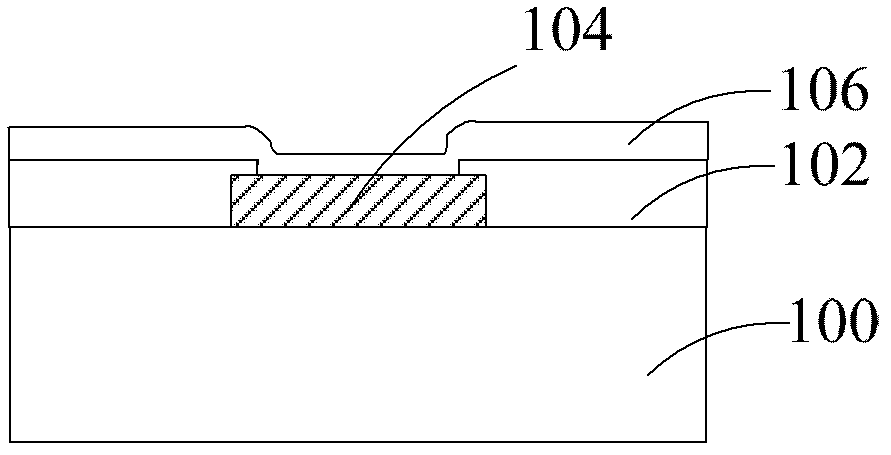

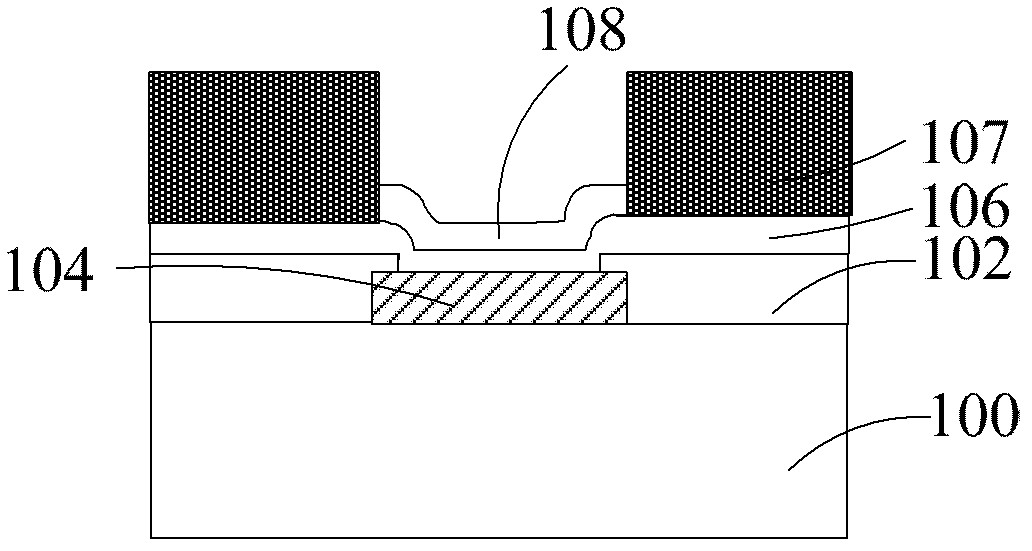

High-reliability chip scale packaging method

InactiveCN102437065ABlocking poresPrevent disappearingSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveProtection layer

The invention discloses a high-reliability chip scale packaging method. The method comprises the following steps: forming a heat-resisting metal layer and a metal wetting layer sequentially on a welding pad and a passivation layer on a chip; forming a photoresist on the metal wetting layer, wherein the photoresist is provided with the metal wetting layer with an opening exposed above the welding pad of the chip; forming a blocking layer and a welding flux protection layer sequentially on the metal wetting layer in the opening; removing the photoresist; etching the heat-resisting metal layer and the metal wetting layer which are positioned on the passivation layer until the passivation layer is uncovered; forming a protection adhesive layer on the chip, wherein the welding flux protection layer is covered by a protection adhesive; exposing the protection adhesive above a connection layer so as to form an opening, and uncovering the upper surface of the welding flux protection layer; and forming a welding flux bump on the welding flux protection layer and reflowing. According to the invention, the electric property and reliability of products are improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

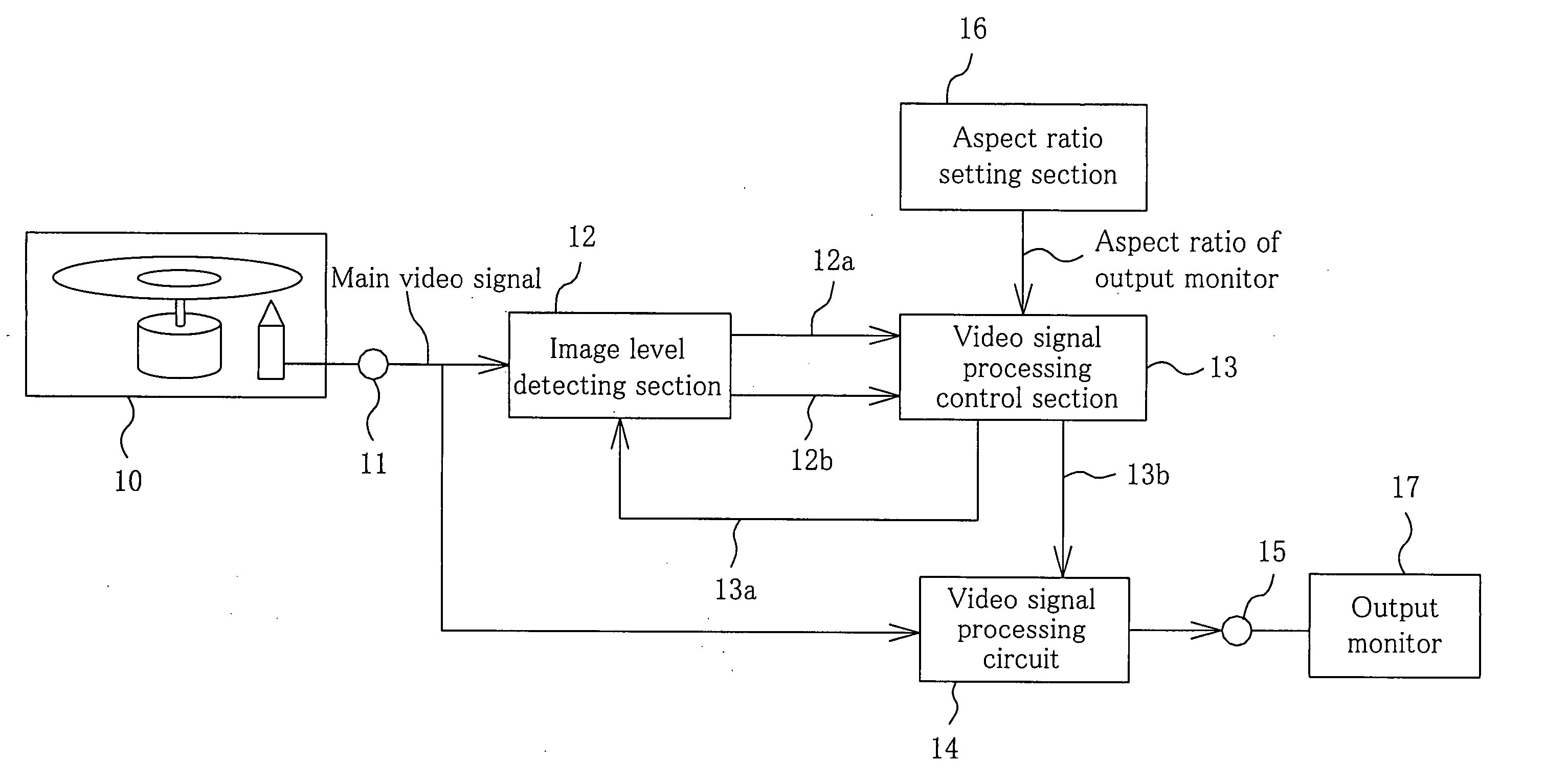

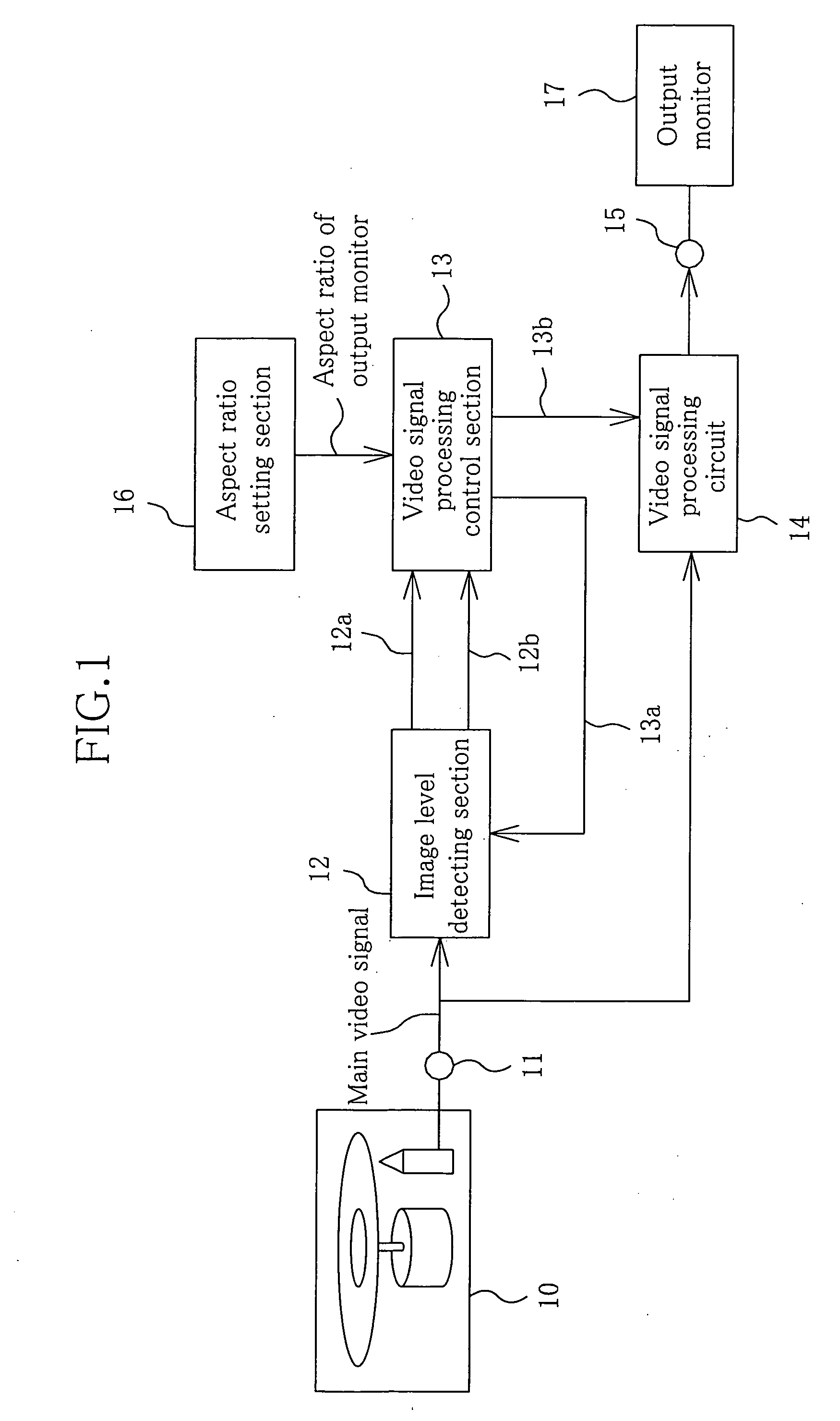

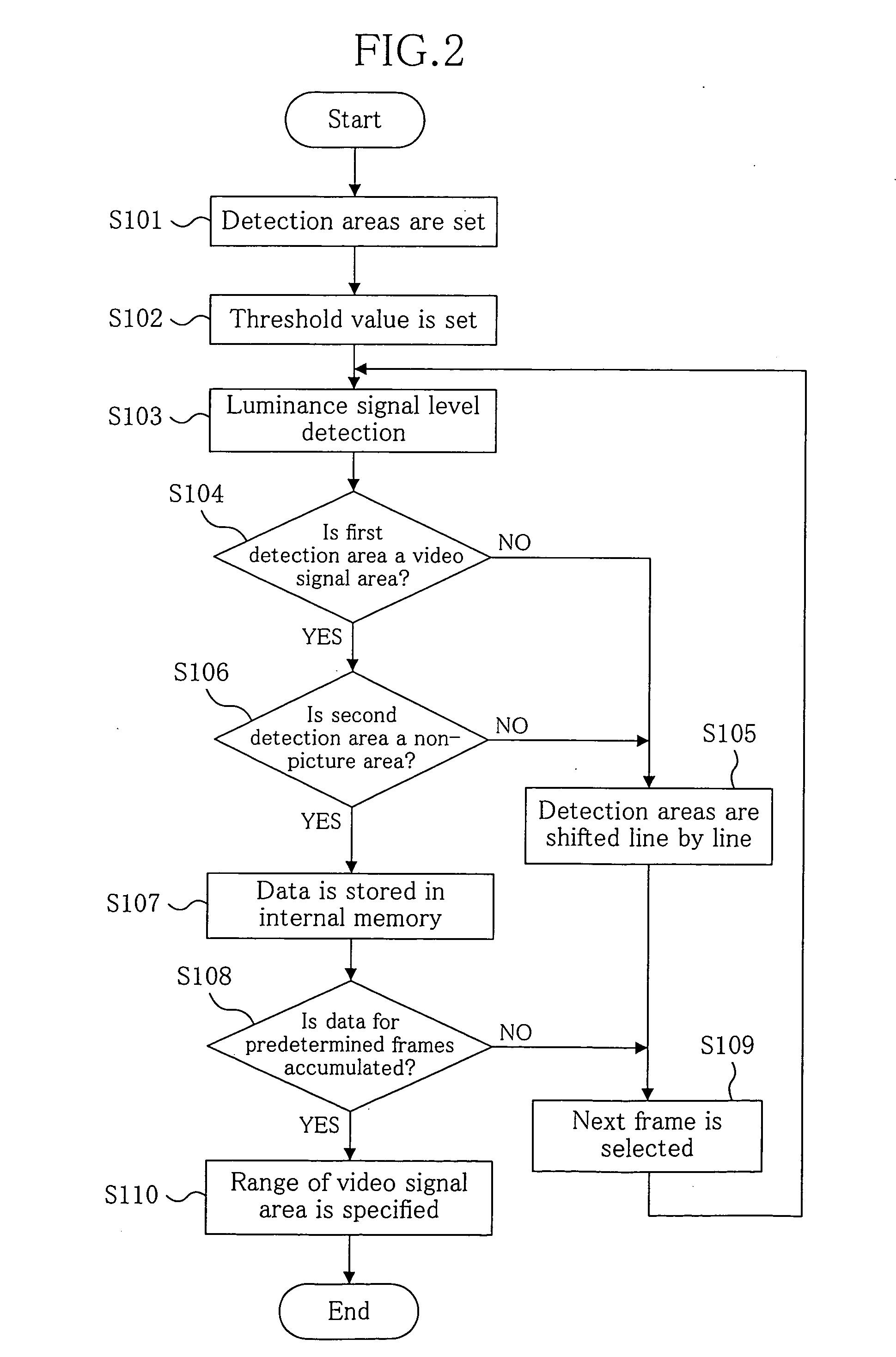

Video signal display unit

InactiveUS20050179817A1Prevent disappearingInhibition of informationTelevision system detailsTelevision system scanning detailsSignal processing circuitsControl signal

An image-level detecting section detects luminance levels in detection areas specified by a video signal processing control section. The video signal processing control section analyzes the detection results to determine the position and range of a non-picture area, and then calculates an optimum vertical magnification which allows only a video signal area to be displayed in the same size as the screen size of an output monitor. A video signal processing circuit clips only the video signal area based on a control signal provided from the video signal processing control section and magnifies the video signal area, thereby displaying the video signal area that should be viewed without causing any disappearance thereof.

Owner:PANASONIC CORP

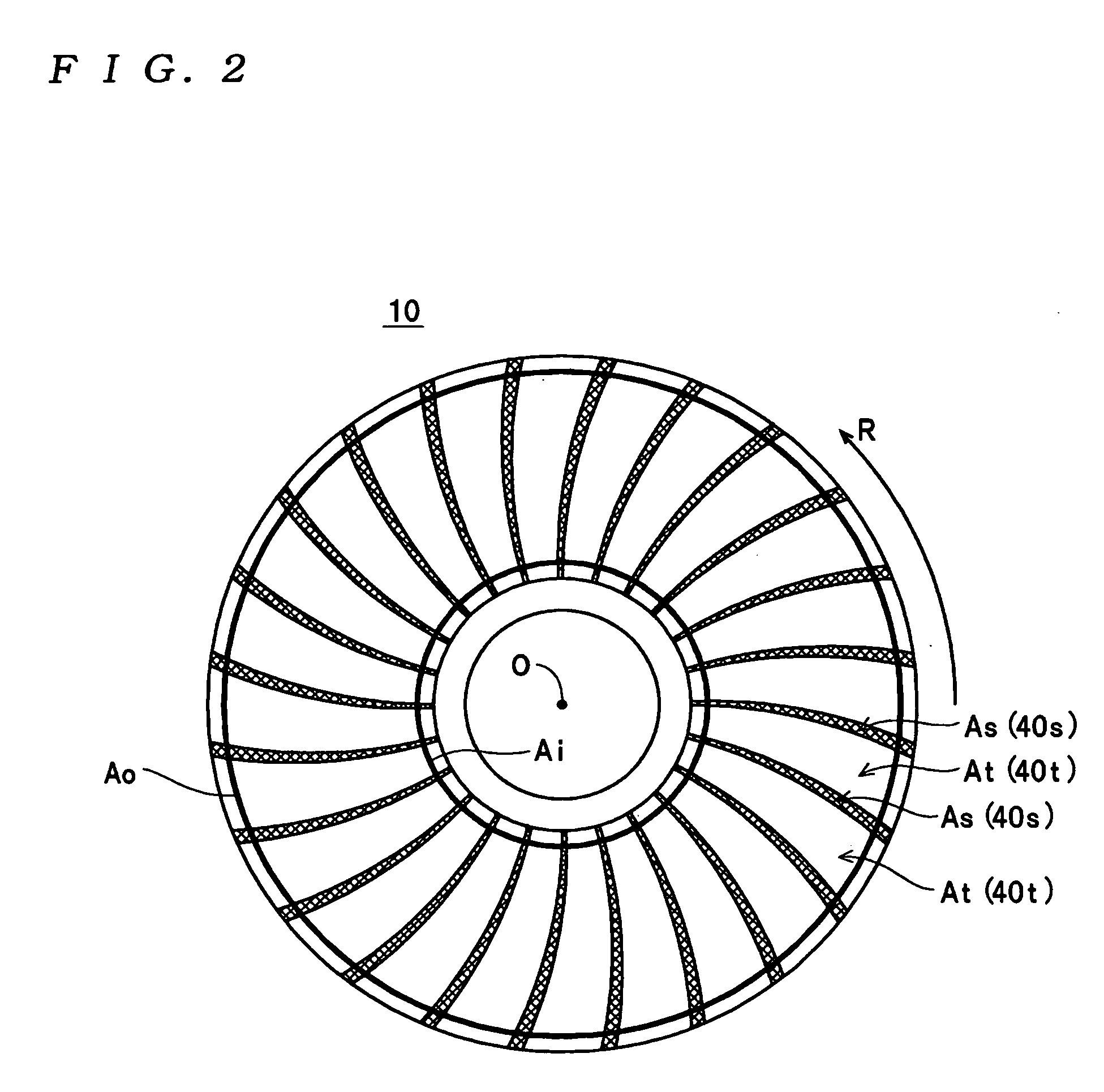

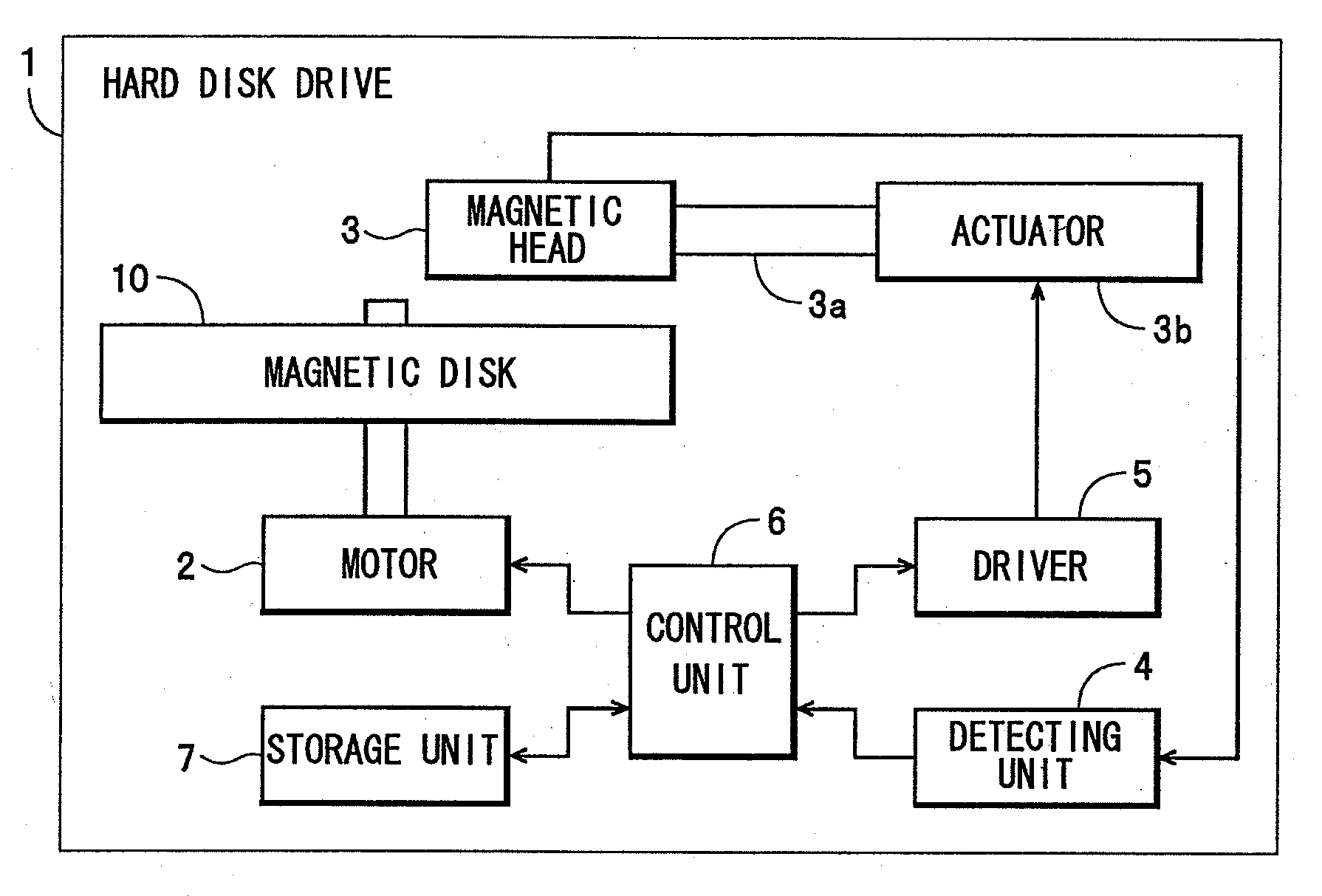

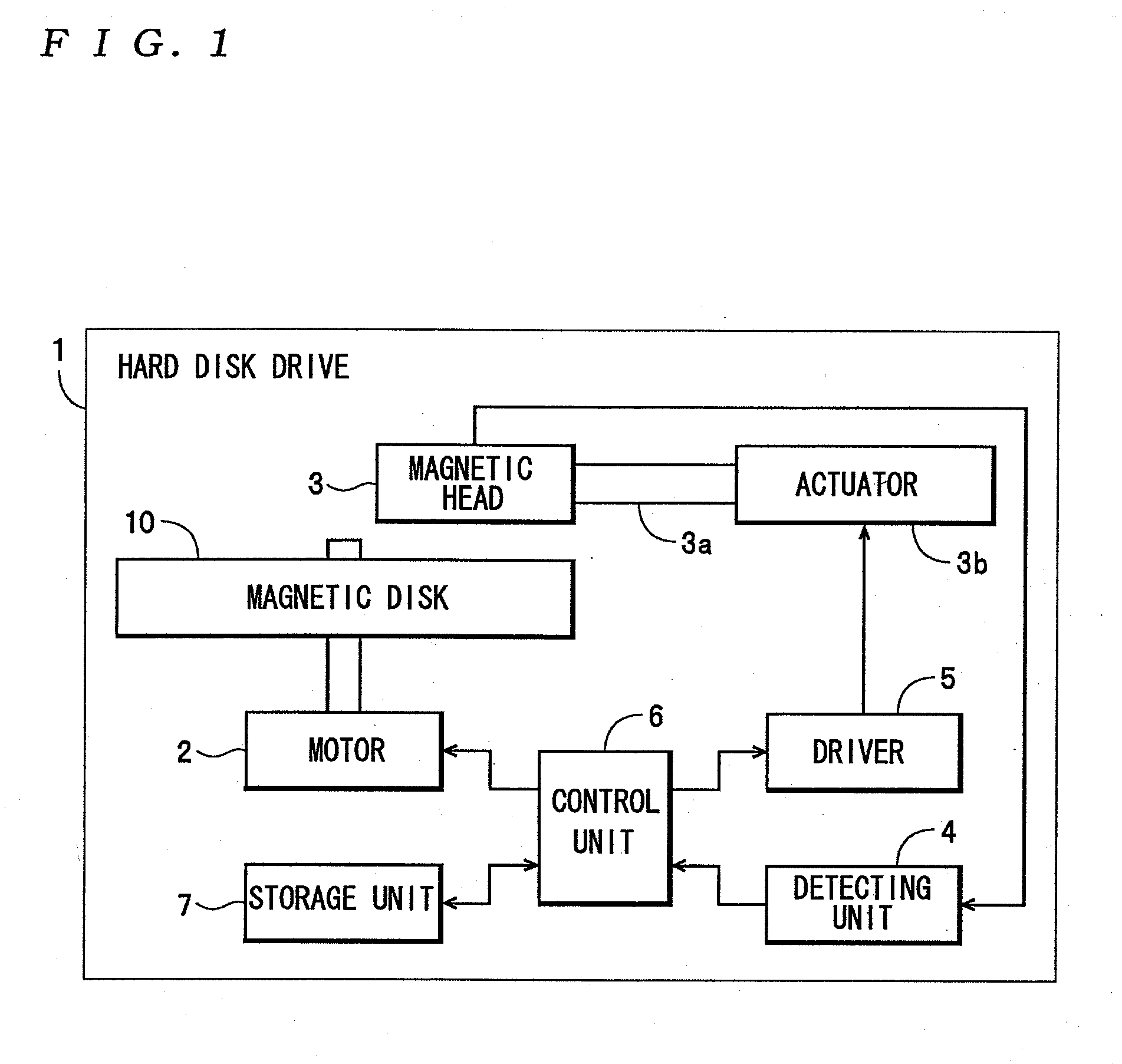

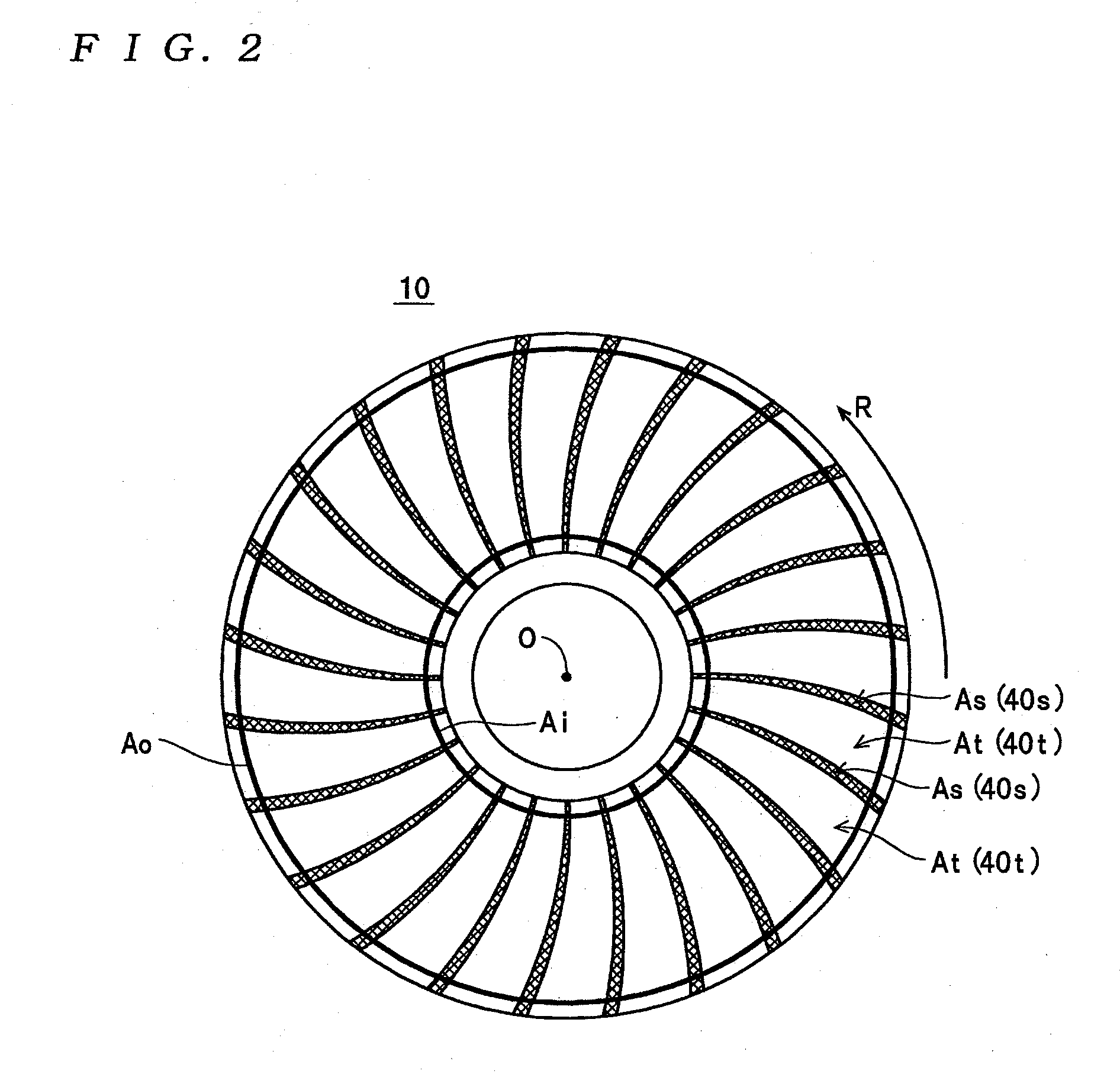

Magnetic recording medium, recording/reproducing apparatus, and stamper

InactiveUS20060176606A1Improve smoothnessReliable readRecord information storageAlignment for track following on disksMaximum diameterEngineering

A servo pattern is formed in a servo pattern region on at least one surface of a substrate of a magnetic recording medium by a concave / convex pattern including a plurality of convex parts, at least protruding end parts of which are formed of magnetic material, and at least one concave part. The servo pattern region includes an address pattern region and a burst pattern region. The at least one concave part is formed in the servo pattern region so that a larger of an inscribed circle with a largest diameter out of inscribed circles on protruding end surfaces of the convex parts formed in the address pattern region and an inscribed circle with a largest diameter out of inscribed circles on protruding end surfaces of the convex parts formed in the burst pattern region is an inscribed circle with a largest diameter out of inscribed circles on protruding end surfaces of the convex parts formed in the servo pattern region.

Owner:TDK CORPARATION

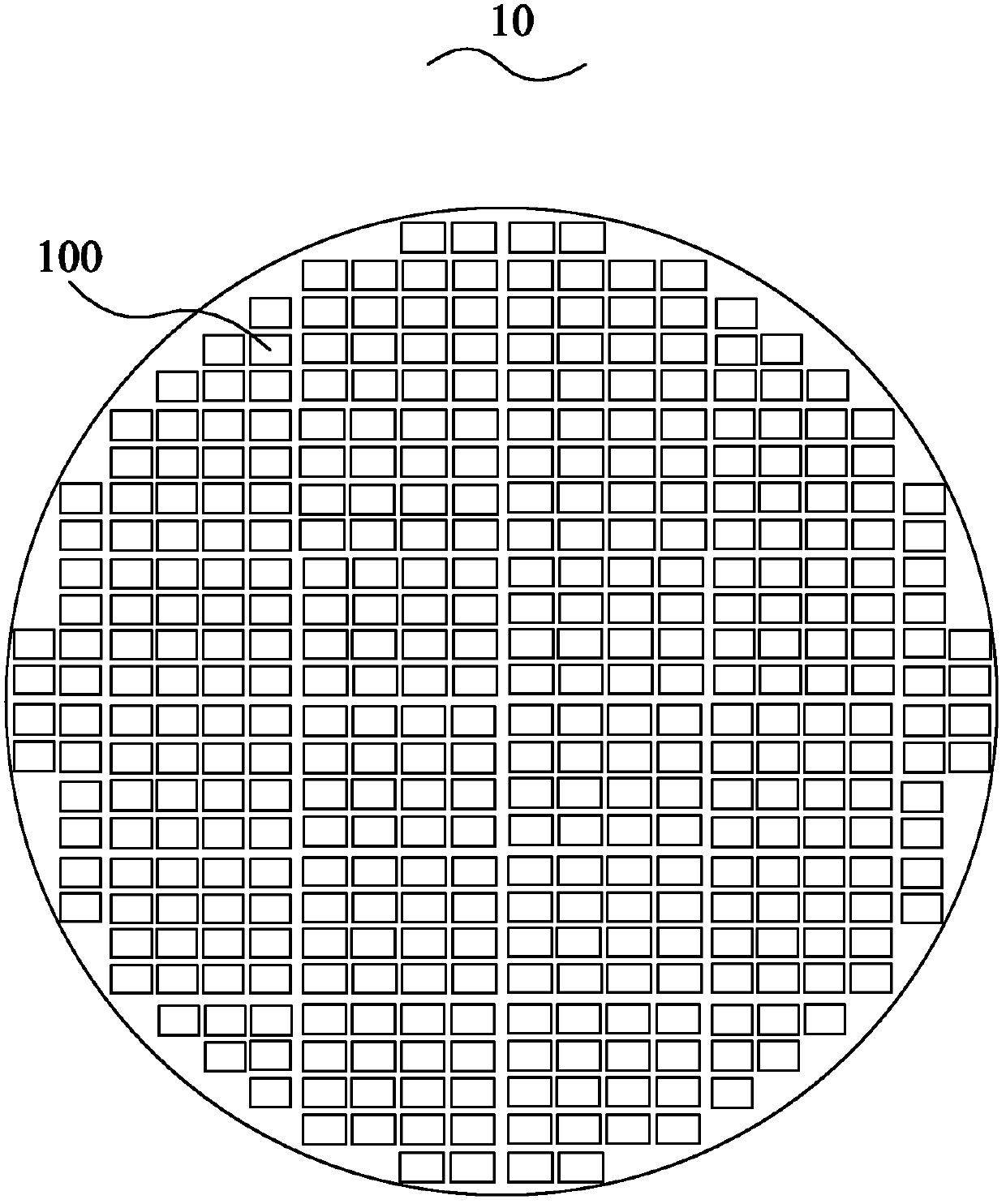

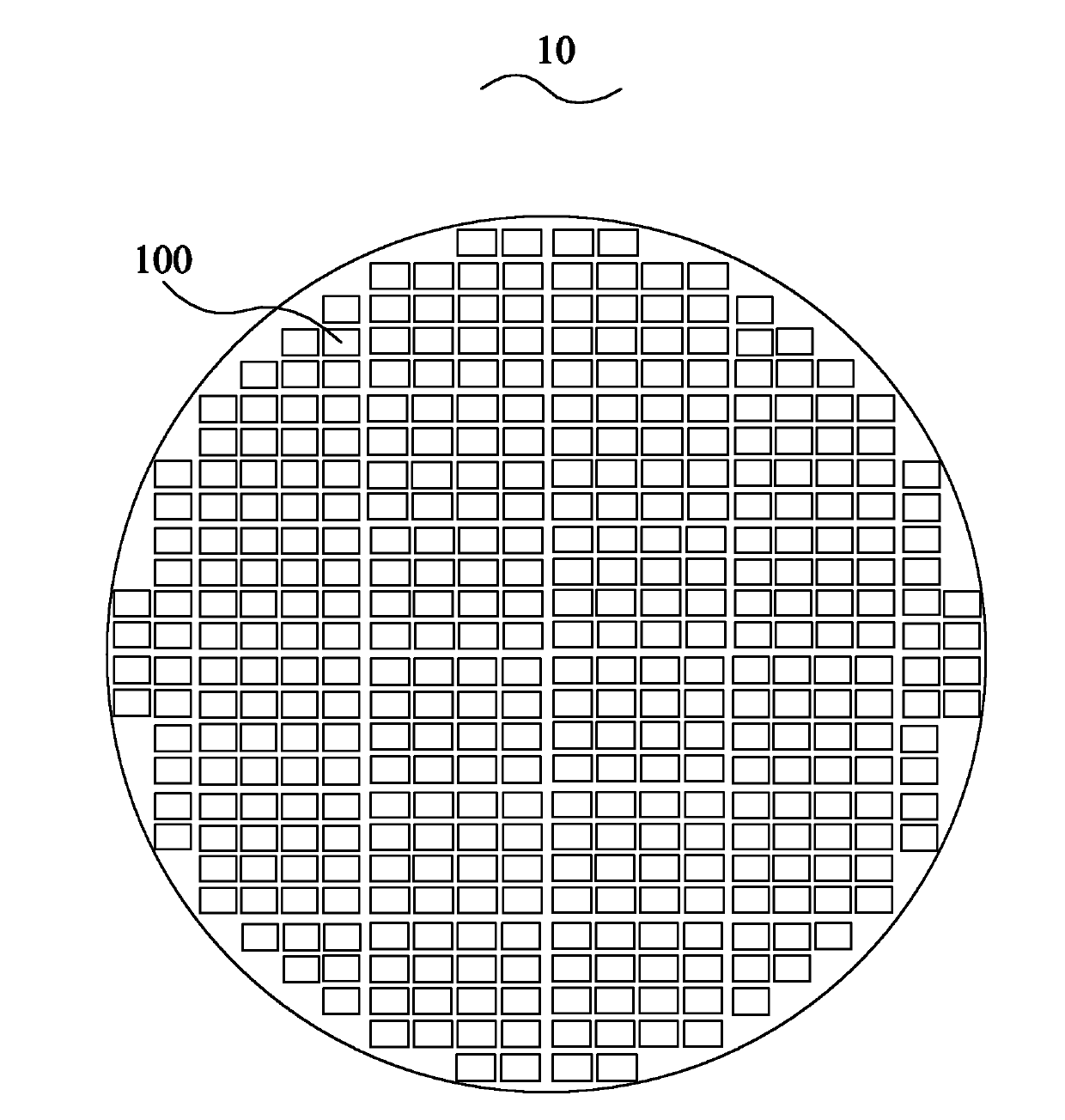

High-reliability wafer-level columnar bump packaging method

InactiveCN102437066ASmall sizeIncrease the number of function output portsSolid-state devicesSemiconductor/solid-state device manufacturingAdhesivePhotoresist

The invention discloses a high-reliability wafer-level columnar bump packaging method. The method comprises the following steps: forming a heat-resisting metal layer and a metal wetting layer sequentially on a welding pad and a passivation layer on a chip; forming a photoresist on the metal wetting layer, wherein the photoresist is provided with the metal wetting layer with an opening exposed above the welding pad of the chip; forming a connection layer on the metal wetting layer in the opening, wherein the connection layer comprises an adhering layer and a blocking layer which are formed sequentially; removing the photoresist; etching the heat-resisting layer and the metal wetting layer which are positioned on the passivation layer until the passivation layer is uncovered; forming a protection adhesive layer on the chip, wherein the protection adhesive layer covers the connection layer; grinding the protection adhesive layer, thus the blocking layer in the connection layer is uncovered; and forming a welding flux bump on the blocking layer and reflowing. According to the invention, the electric property and reliability of wafer-level packaging are improved, and the packaging method is suitable for wafer-level packaging with fine pitches for the welding pad and multiple output functions.

Owner:NANTONG FUJITSU MICROELECTRONICS

Columnar bump packaging process

InactiveCN102543766AMeet application needsLow costSolid-state devicesSemiconductor/solid-state device manufacturingElectrical performanceCopper

A columnar bump packaging process comprises the following steps: forming lower metal bump layers on a welding pad and a passivation layer of a chip; forming photoresist on the lower metal bump layers, wherein the photoresist is provided with an opening so as to expose the lower metal bump layer above the welding pad of the chip; forming a copper column on the lower metal bump layer in the opening; forming a welding bump on the copper column; removing the photoresist; etching the lower metal bump layer on the passivation layer till the passivation layer is exposed; forming an oxide layer on the surface of the exposed copper column; and removing oxide on the surface of the welding bump, and refluxing the welding bump. The columnar bump packaging process of the invention improves the electrical performance and the reliability of the welding bump and is applicable to chip-level packaging of the welding pad with a dense spacing and multiple output functions.

Owner:NANTONG FUJITSU MICROELECTRONICS

Cylindrical bump packaging structure

InactiveCN102543898AMeet application needsLow costSemiconductor/solid-state device detailsSolid-state devicesElectrical performanceCopper

The invention relates to a cylindrical bump packaging structure. The cylindrical bump packaging structure comprises a chip, an under bump metallization layer, copper columns, oxide layers and solder bumps, wherein bonding pads and a passivation layer are arranged on the upper surface of the chip, the passivation layer is covered on the upper surface outside openings of the bonding pads of the chip, the under bump metallization layer is arranged on the bonding pads, the copper columns are arranged on the under bump metallization layer, the oxide layers are wrapped on the side surfaces of the copper columns, and the solder bumps are arranged above the copper columns. According to the cylindrical bump packaging structure disclosed by the invention, the electrical performances and the reliability of the solder bumps can be improved, and the cylindrical bump packaging structure is suitable for chip level packaging with close intervals of the bonding pads and multiple output functions.

Owner:NANTONG FUJITSU MICROELECTRONICS

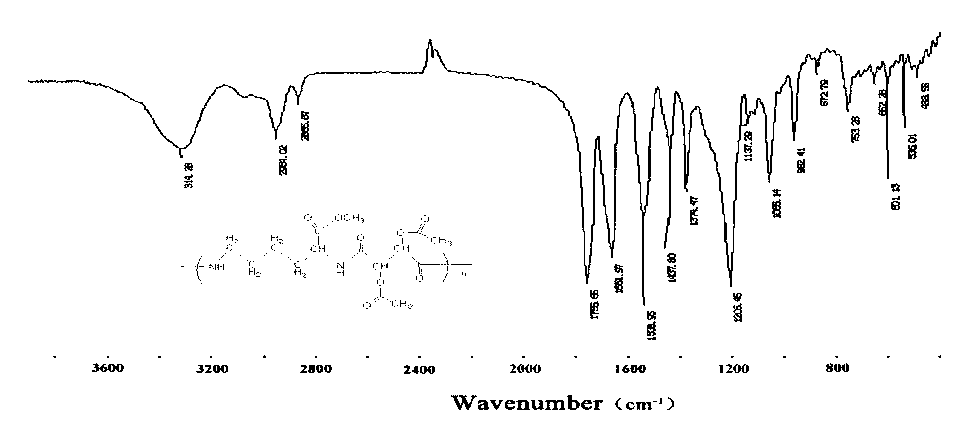

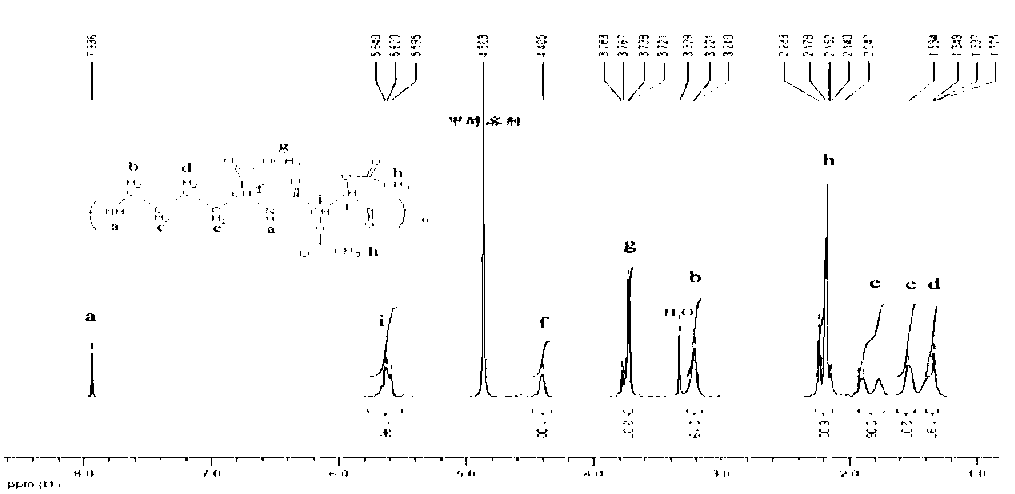

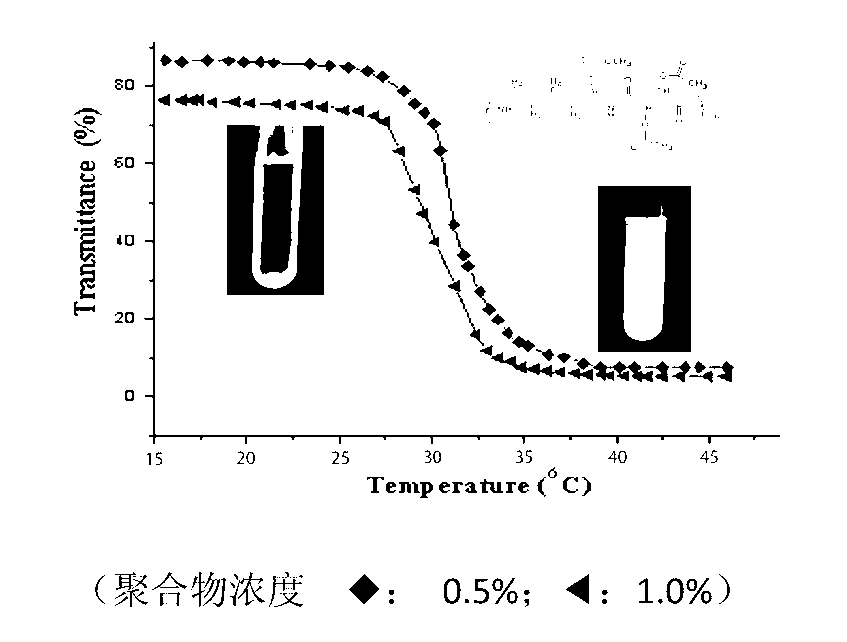

Temperature sensitive polymer material with biodegradability and biocompatibility and preparation method thereof

The invention discloses a temperature sensitive polymer material with biodegradability and biocompatibility. A preparation method of the material comprises the following steps of: firstly synthesizing monomers with specific structures by using the basic raw materials including lysine, tartaric acid, and malic acid, and carrying out polymerization reaction on the monomers with different ingredients to prepare the heterochain type polymer material. The polymer not only has good temperature sensitivity, but also has good biodegradability and biocompatibility. The preparation method disclosed by the invention is simple and easy to implement and has good industrial prospect.

Owner:HEBEI UNIVERSITY

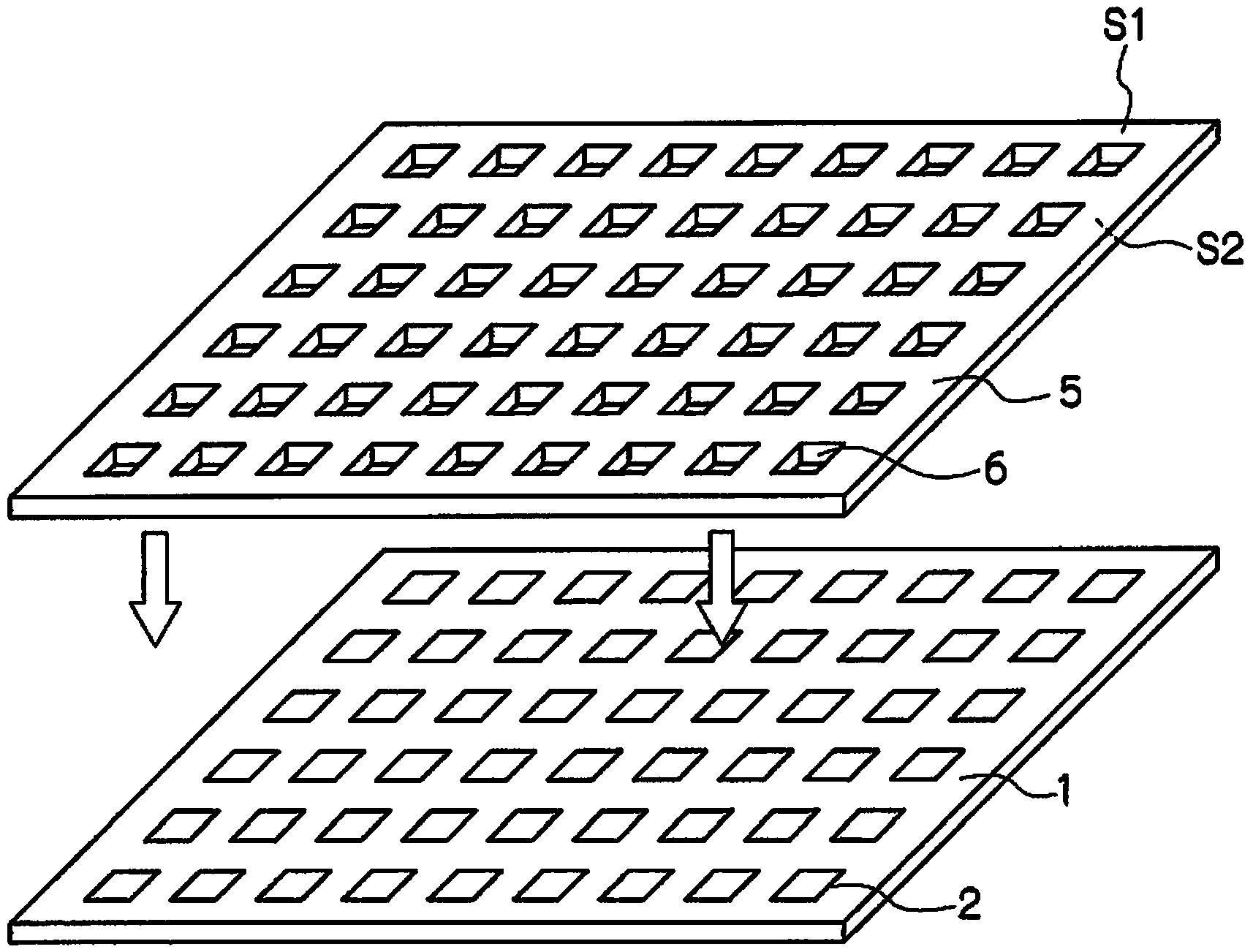

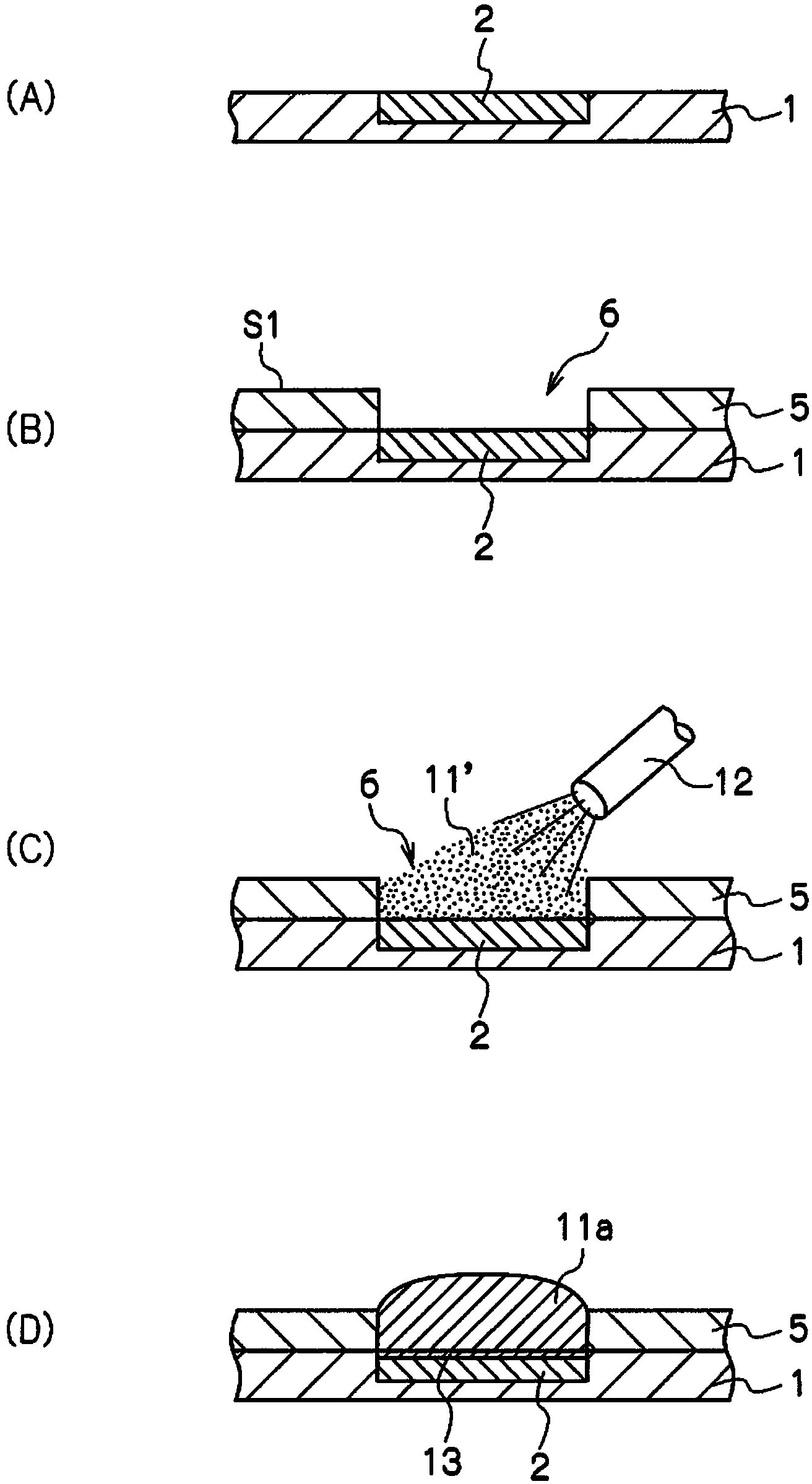

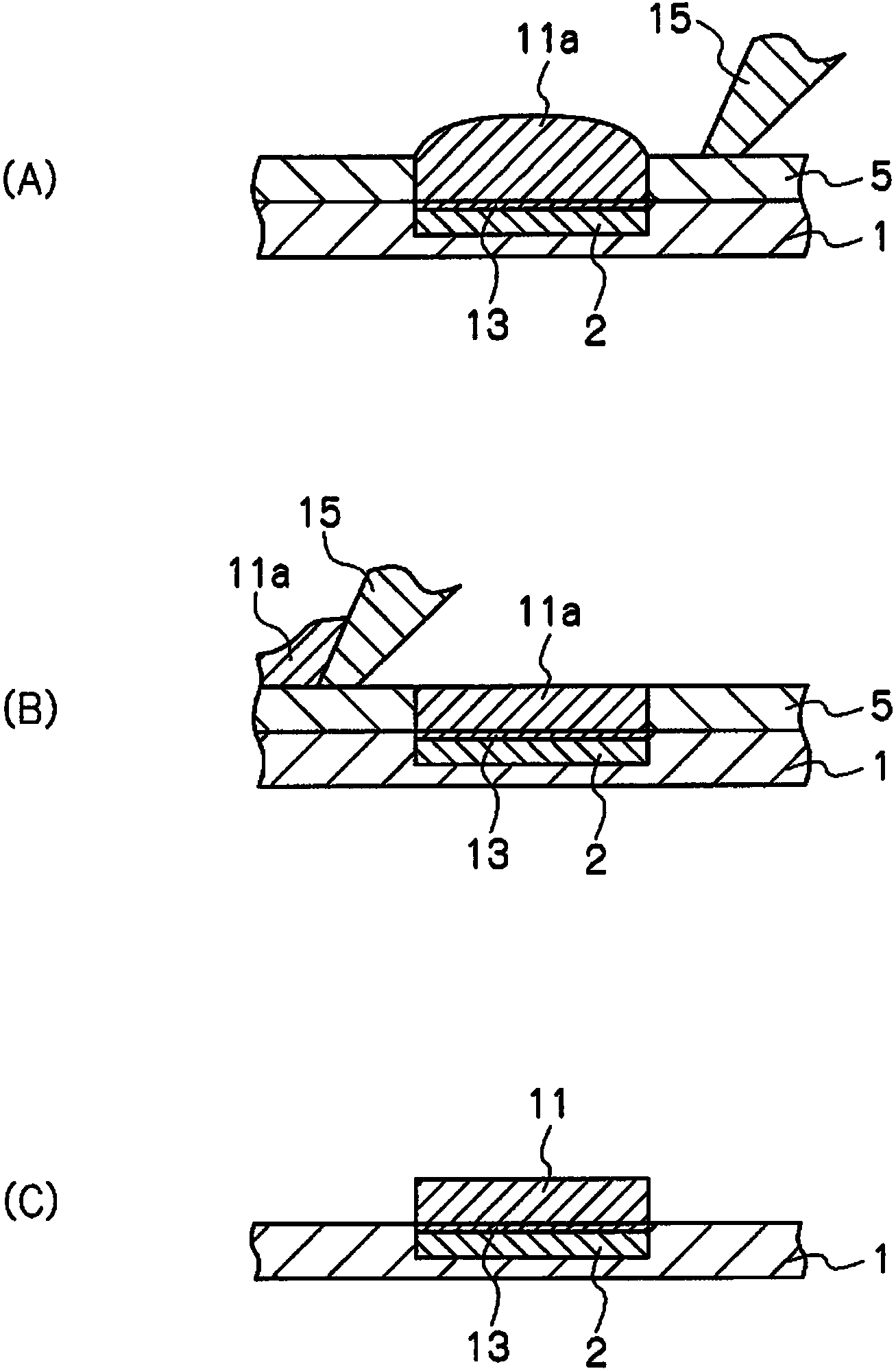

Solder bump and forming method therefor, and substrate having solder bump and manufacturing method for substrate having solder bump

ActiveCN104246996AAvoid defectsPrevent disappearingSemiconductor/solid-state device detailsWelding/cutting auxillary devicesCopper electrodePrinted circuit board

The invention provides a solder bump forming method capable of forming solder bumps having a desired constant thickness, without any failure such as copper corrosion, on a mounting board such as a printed circuit board having fine copper electrodes. The solder bump forming method includes: a process in which a prepared mask (5) is placed on a prepared substrate (1) and then a molten solder jet is blown to fill an opening of the mask (5) with molten solder (11a) until the molten solder (11a) exceeds the thickness of the mask (5); a process of removing a part of the molten solder (11a) that exceeds the thickness of the mask (5) to form a solder bump (11) having a predetermined thickness; and a process of removing the mask (5). The molten solder (11a) is molten lead-free solder that includes tin as a main ingredient and at least nickel as a sub ingredient, and further includes one or more other ingredients such as silver, copper, and germanium. The part of the molten solder (11a) that exceeds the thickness of the mask (5) is removed by using a blade or an air cutter or by spraying a solution (18) that includes organic fatty acid having 12 to 20 carbon atoms.

Owner:TANIGUROGUMI CORP

Wafer-level packaging method

InactiveCN102446780ASmall sizeIncrease the number of function output portsSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveSolder ball

The invention relates to a wafer-level packaging method, which comprises the steps of sequentially forming a heat-resistant metal layer and a metal wetting layer on the pad and the passivation layer of a chip; forming photoresist on the metal wetting layer, wherein the photoresist is provided with an opening for exposing the metal wetting layer above the pad of the chip; forming a connecting layer on the metal wetting layer in the opening; removing the photoresist; etching the heat-resistant metal layer and the metal wetting layer on the passivation layer till the passivation layer is exposed; forming a protection adhesive layer on the chip, wherein protection adhesive covers the connecting layer; exposing the protection adhesive above the connecting layer to form an opening to expose the upper surface of the connecting layer; and forming and refluxing solder ball bumps on the connecting layer. The wafer-level packaging method improves the electrical performance and reliability of wafer-level packaging and is suitable for the wafer-level packaging of chips with dense pad spacing and multiple output functions.

Owner:NANTONG FUJITSU MICROELECTRONICS

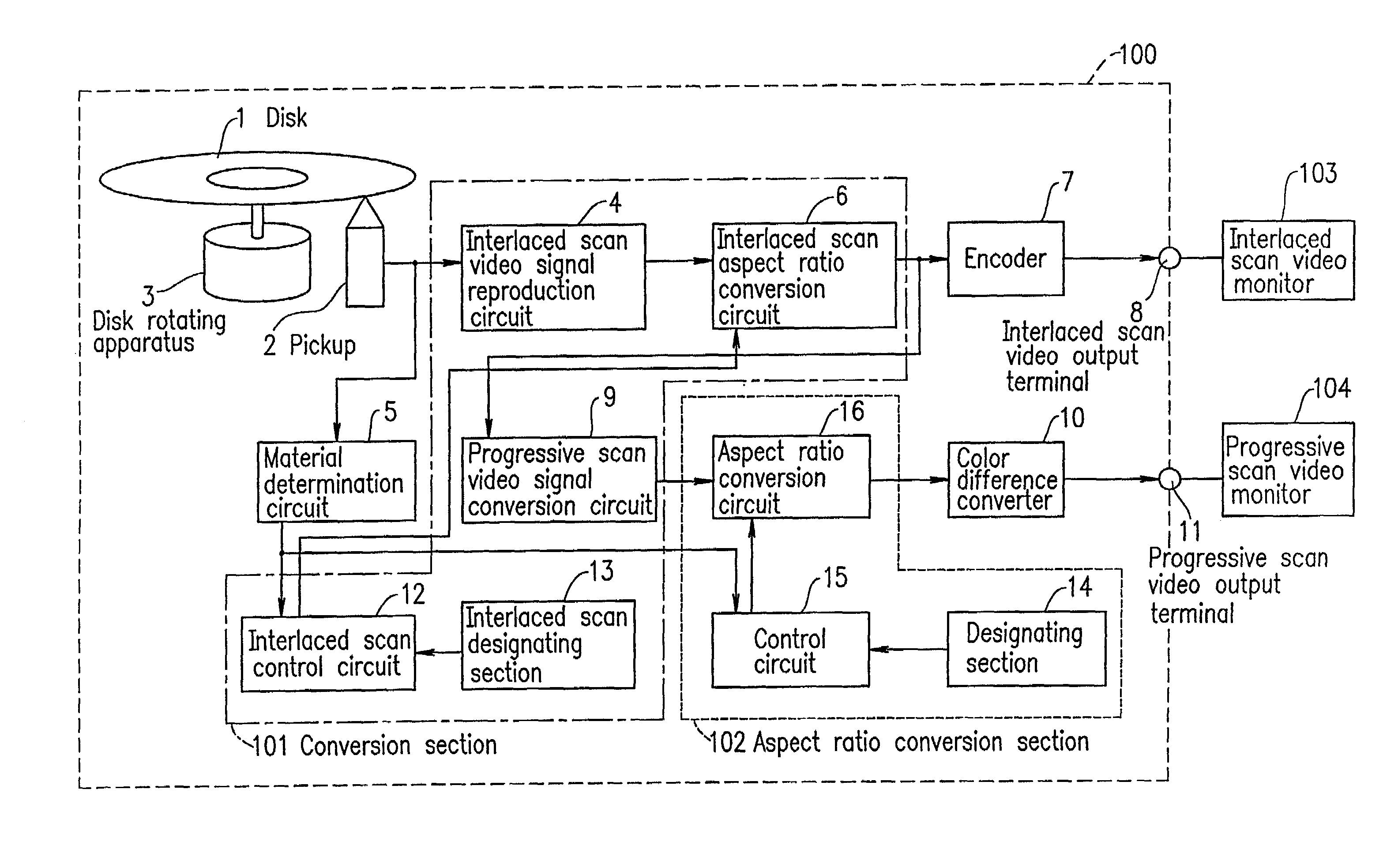

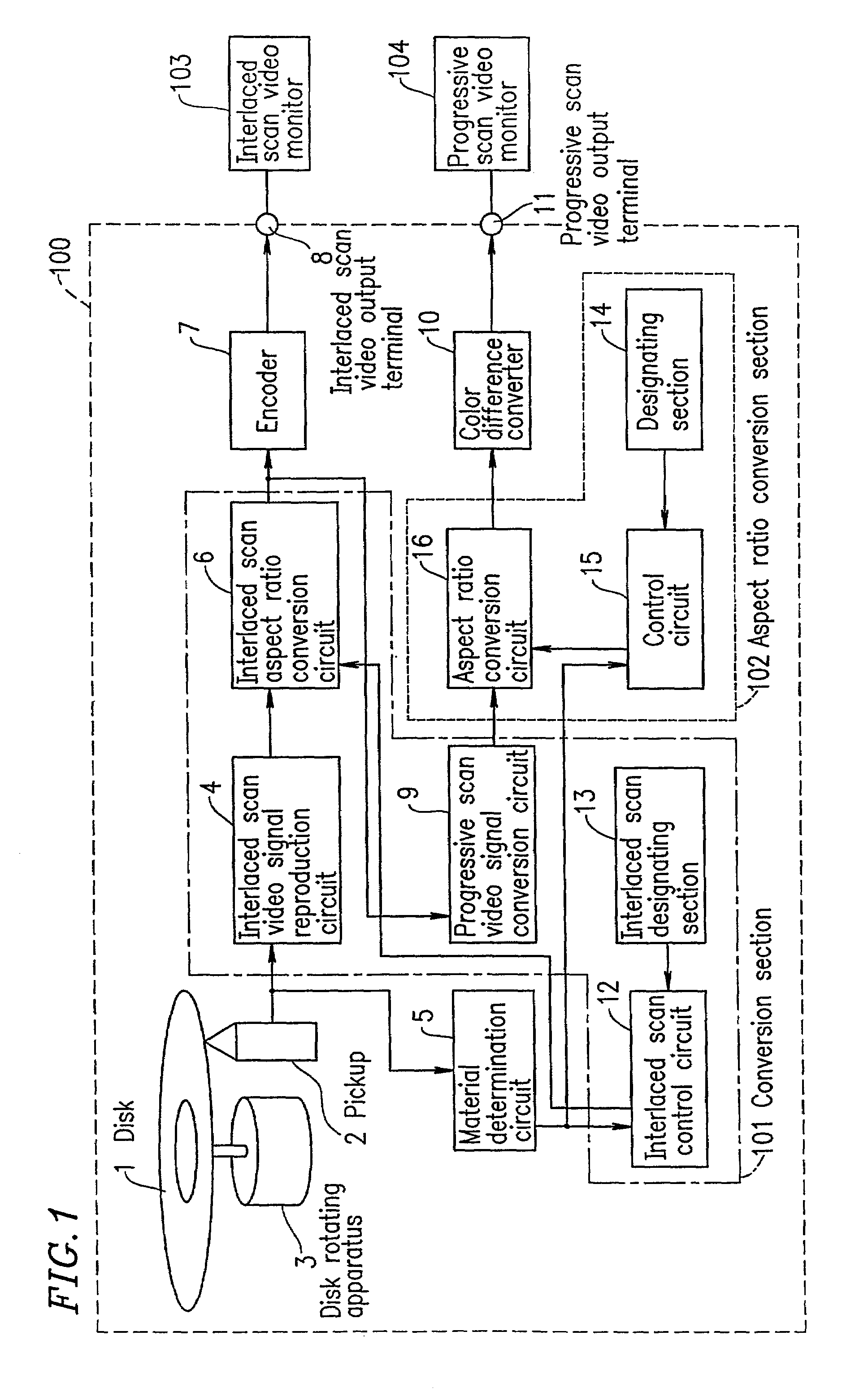

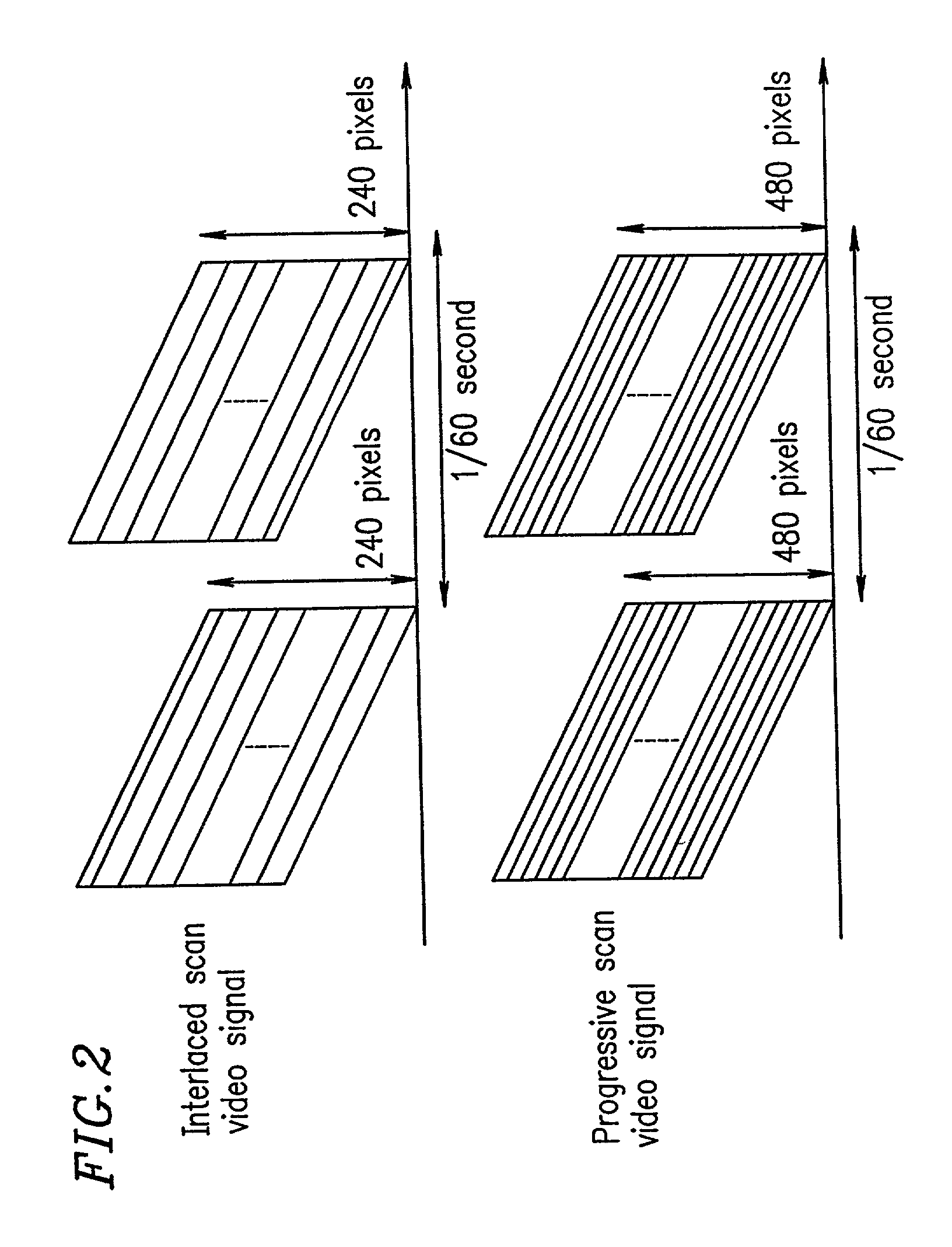

Video signal reproduction apparatus

InactiveUS7099570B2Prevent disappearingTelevision system detailsTelevision system scanning detailsComputer hardwareProgressive scan

A video signal reproduction apparatus for receiving an information signal including a video signal and a determination signal indicating a type of the video signal, and reproducing the video signal included in the information signal. The apparatus comprises a conversion section for converting the video signal to a progressive scan video signal, and an aspect ratio conversion section for converting an aspect ratio of the progressive scan video signal output from the conversion section and outputting the converted progressive scan video signal to a progressive scan video monitor. The aspect ratio conversion section converts the aspect ratio of the progressive scan video signal based on the determination signal indicating the type of the video signal and monitor information indicating a type of the progressive scan video monitor.

Owner:PANASONIC CORP

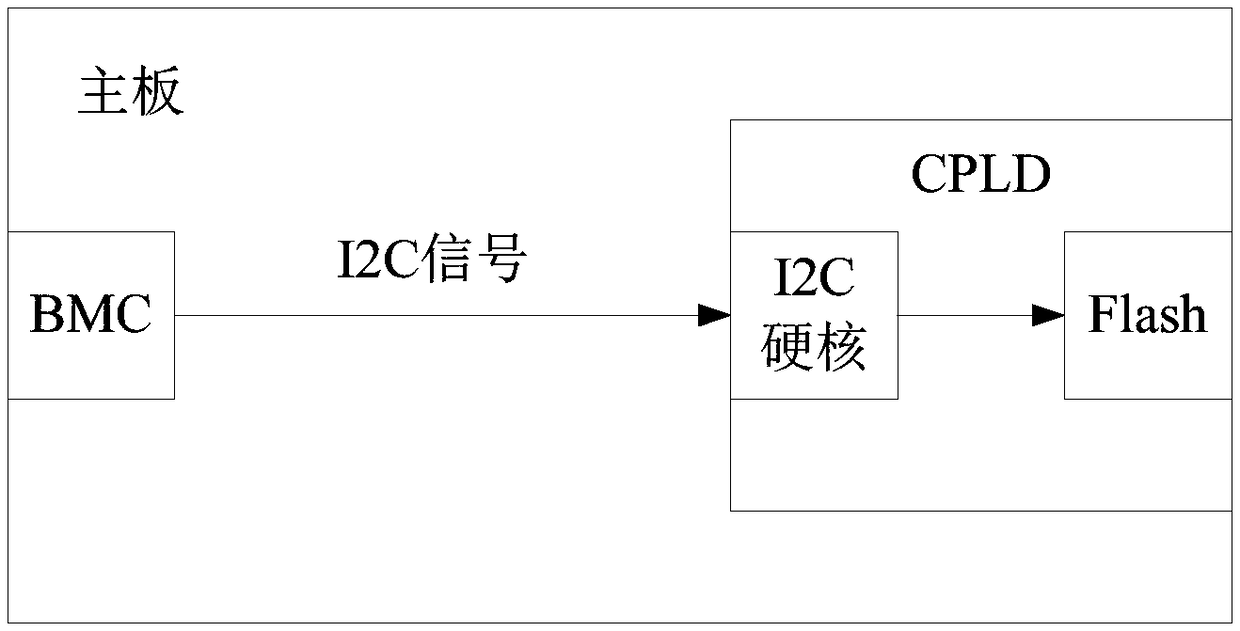

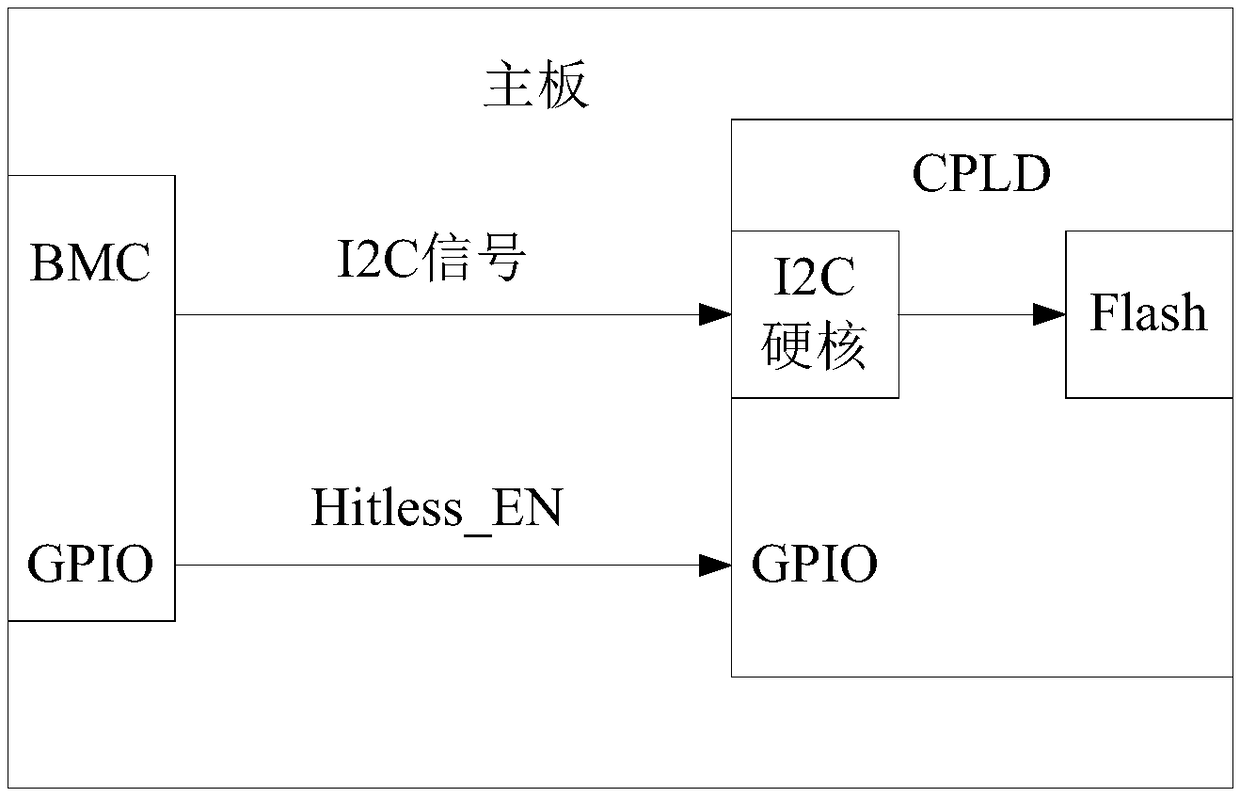

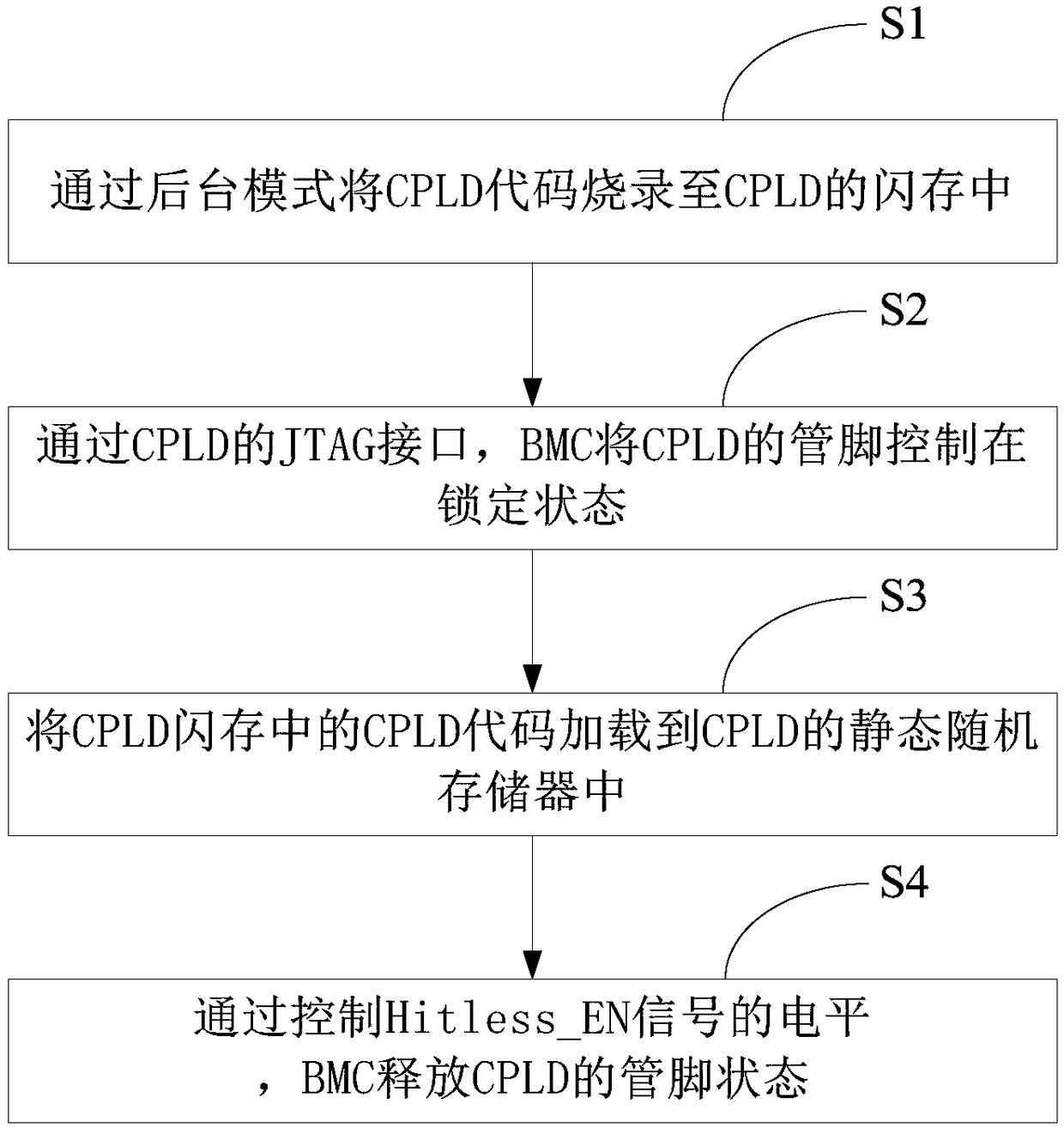

A method and a system for upgrading a CPLD based on Whitley platform

InactiveCN109271178AImprove stabilityImprove reliabilitySoftware deploymentStatic random-access memoryJoint Test Action Group

The invention discloses a method and a system for upgrading a CPLD based on a Whitley platform. The method comprises the following steps: a CPLD code is burned into a flash memory of the CPLD througha background mode; Through the JTAG interface of CPLD, BMC controls the pin of CPLD in the locked state,the CPLD code in the CPLD flash memory is loaded into the static random access memory of the CPLD, By controlling the level of the Hitless_EN signal, the BMC releases the pin state of the CPLD. The system includes four parts: a burning module, a first locking module, a loading module and a releasing module. The method and the system in the present application can avoid the out-of-control state of the CPLD pin lock, thereby avoiding the unstable state of the performance that may be caused inthe CPLD upgrading process, greatly improving the stability and reliability of the CPLD upgrading, and truly realizing seamless burning and recording.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Magnetic recording medium, recording /reproducing apparatus, and stamper

InactiveUS20090034115A1Improve smoothnessReliable readRecord information storageAlignment for track following on disksMaximum diameterEngineering

A servo pattern is formed in a servo pattern region on at least one surface of a substrate of a magnetic recording medium by a concave / convex pattern including a plurality of convex parts, at least protruding end parts of which are formed of magnetic material, and at least one concave part. The servo pattern region includes an address pattern region and a burst pattern region. The at least one concave part is formed in the servo pattern region so that a larger of an inscribed circle with a largest diameter out of inscribed circles on protruding end surfaces of the convex parts formed in the address pattern region and an inscribed circle with a largest diameter out of inscribed circles on protruding end surfaces of the convex parts formed in the burst pattern region is an inscribed circle with a largest diameter out of inscribed circles on protruding end surfaces of the convex parts formed in the servo pattern region.

Owner:TDK CORPARATION

Webpage refreshing method, webpage system and electronic equipment

ActiveCN110209966AImprove experiencePrevent disappearingSpecial data processing applicationsWeb data browsing optimisationWeb pageDatabase

The invention provides a webpage refreshing method, a webpage system and electronic equipment, the webpage comprises at least one sub-frame, the sub-frame is used for displaying one page in at least one target page, and the method is characterized by comprising the following steps: storing a page identifier of the target page displayed by the sub-frame as a page identifier record; when a page is loaded, obtaining the page identifier; and setting a target page to be displayed by the sub-frame according to the acquired page identifier. By the adoption of the webpage refreshing method, system andequipment, the sub-frame page content before refreshing can be reserved after the user refreshes the webpage, and the user experience is greatly improved.

Owner:YOUXINPAI BEIJING INFORMATION TECH CO LTD

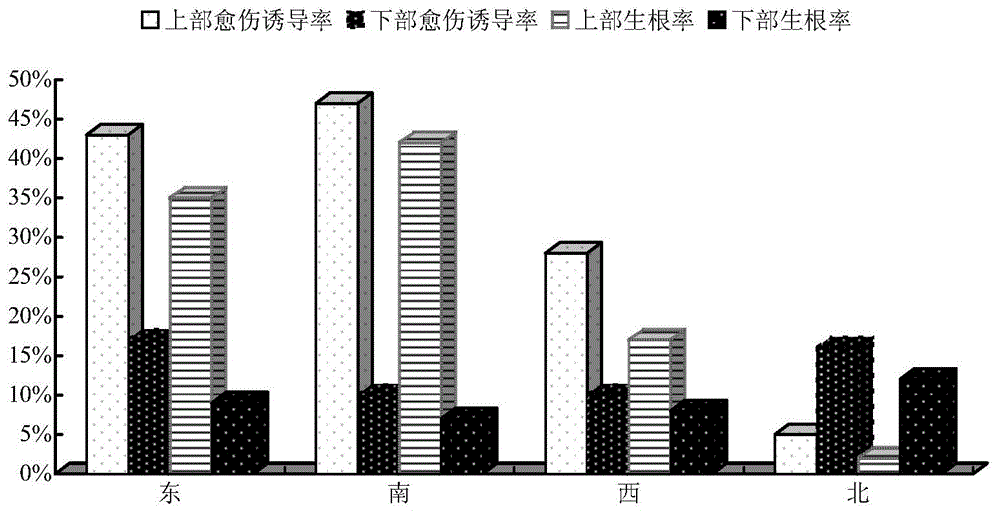

Cutting propagation method for ancient platycladus orientalis

InactiveCN104620832APrevent disappearingCultivating equipmentsHorticultureObserved SurvivalSurvival rate

The invention discloses a cutting propagation method for an ancient platycladus orientalis. The method includes the steps: sequentially using potassium permanganate, sodium lignite and hormone for treating cuttings of the ancient platycladus orientalis to obtain treated cuttings; subjecting the treated cuttings to cuttage and cultivation in a matrix to realize cutting propagation of the ancient platycladus orientalis. According to experimental results, the cutting propagation method has the advantages that survival rate in clonal propagation of the ancient platycladus orientalis is increased, rooting time of the ancient platycladus orientalis is shortened, and references are provided for research on clonal propagation of other ancient trees.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

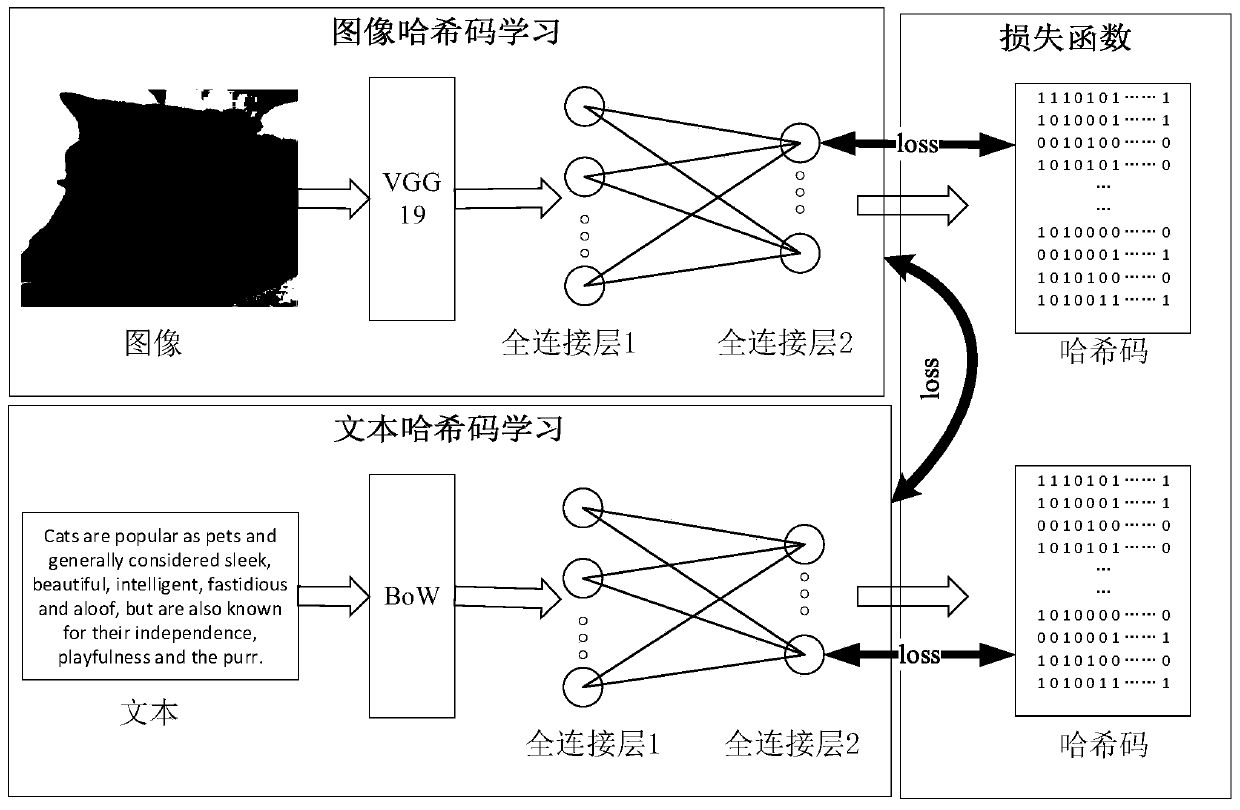

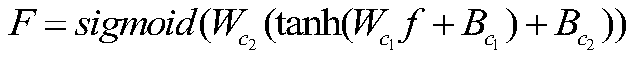

Image-text cross-modal hash retrieval method based on large-batch training

ActiveCN111209415AHigh precisionIncrease training speedDigital data information retrievalEnergy efficient computingPattern recognitionBatch training

The invention relates to an image-text cross-modal hash retrieval method based on large-batch training, and belongs to the field of cross-modal retrieval, and is used for solving the problems that theexisting deep learning-based cross-modal hash retrieval method, particularly a triple-based deep cross-modal hash method, is long in small-batch training time, limited in obtained sample number and not good enough in gradient, so that the retrieval performance is influenced. The method comprises the following steps: preprocessing an image and text data; carrying out hash code mapping; establishing a target loss function L; inputting the triple data training model in a large-batch manner; and performing cross-modal hash retrieval by using the trained model. According to the scheme provided bythe invention, the triple data is input in a large-batch manner for training, so that the time of each round of training is shortened; because more training samples exist when the parameters are updated each time, a better gradient can be obtained, orthogonal regularization is used for the weight, the gradient can be kept during gradient transmission, model training is more stable, and the retrieval accuracy is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

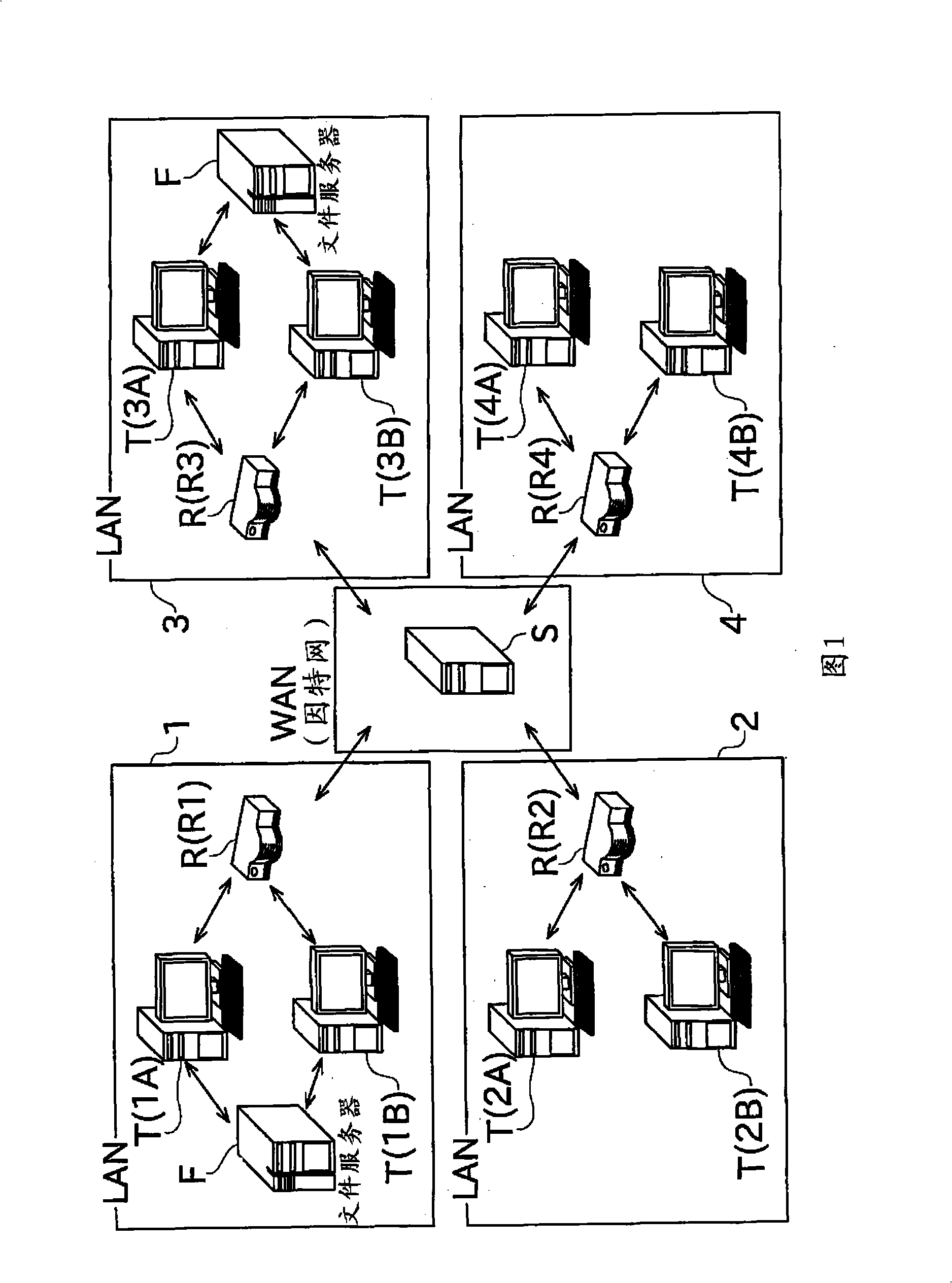

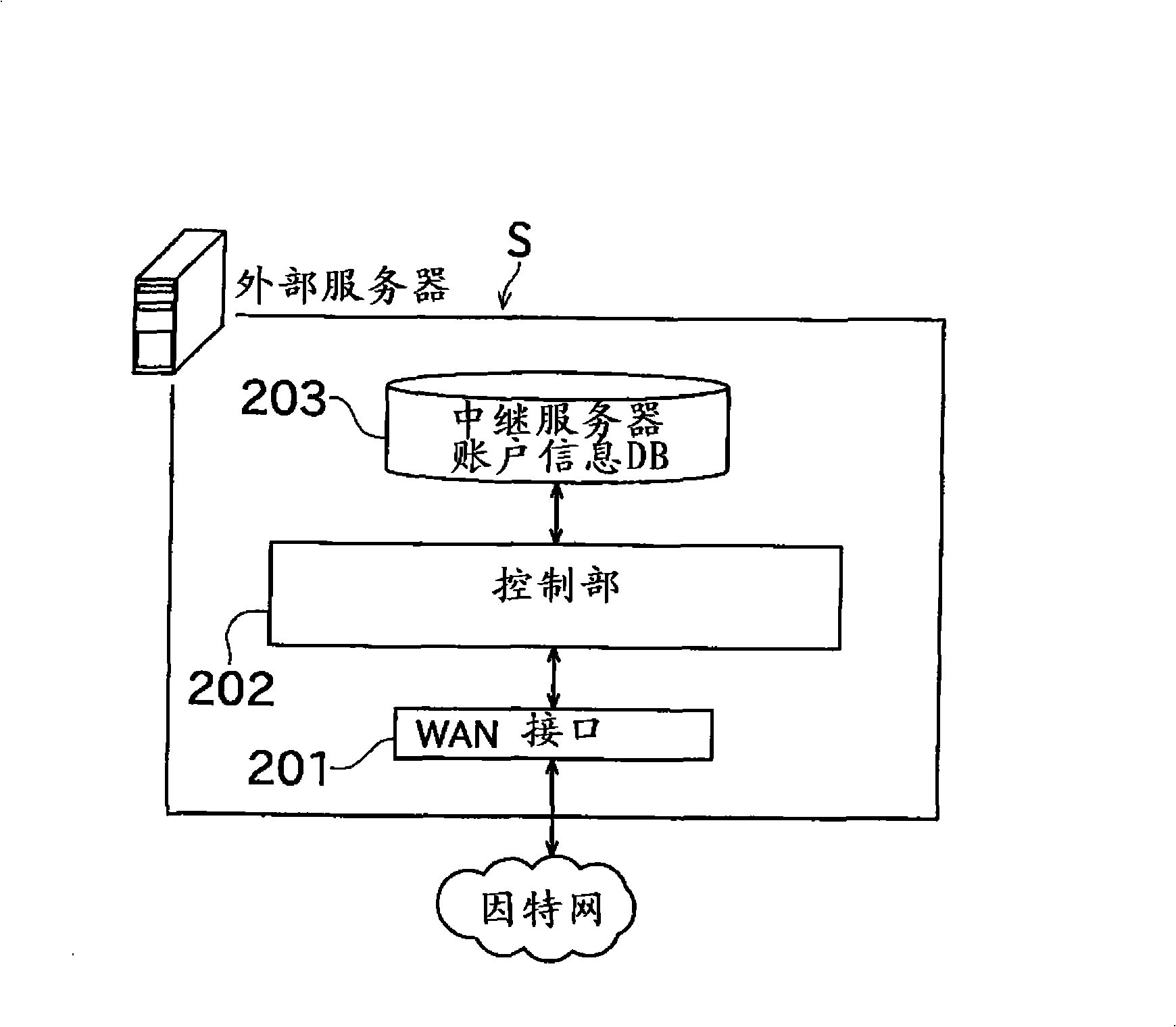

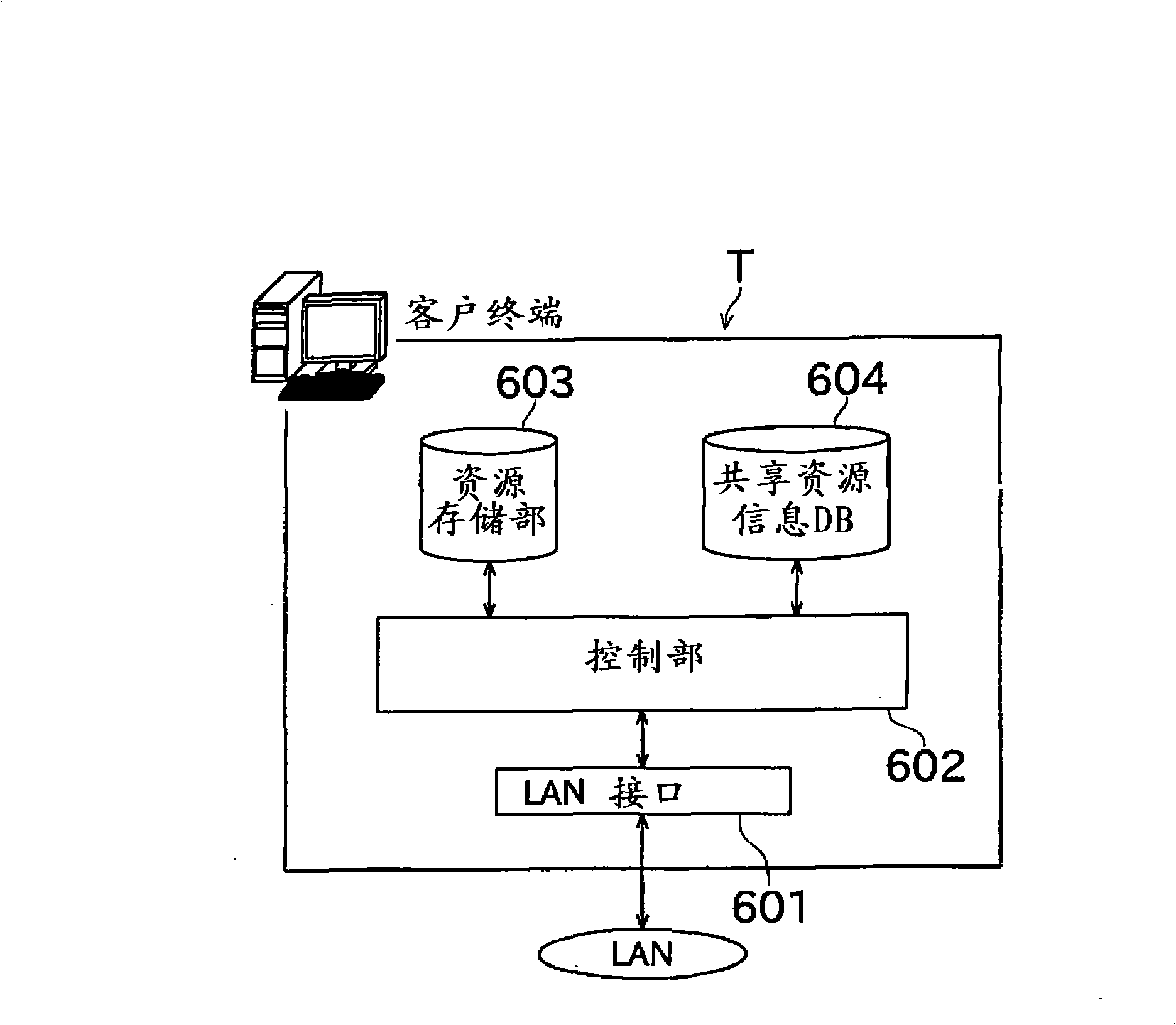

Relay server and relay communication system

ActiveCN101304308APrevent disappearingNetworks interconnectionNetwork connectionsCommunications systemOperating system

A relay server is capable of communicating with other relay servers through an external server arranged on a Wide Area Network. The relay server stores information about a registered terminal, information about the relay servers forming a relay group by permitting connection among each other, and information about a resource and a client terminal sharing the resource. When an operation instruction regarding the resource in another terminal is received, the relay server relays the operation instruction from the registered terminal to another relay server. However, when key information is stored in association with the resource, the relay server relays the operation instruction to the other relay server only when a correct key has been entered.

Owner:MURATA MASCH LTD

Composite skeleton reinforced ceramic based filter material preparation method

InactiveCN109824377ARealize chemical bond connectionImprove pore structureSustainable biological treatmentFiltration separationFiltrationMechanical property

The invention belongs to the technical field of environment-friendly materials and discloses a composite skeleton reinforced ceramic based filter material preparation method. The method includes: uniformly stirring and dispersing modified graphene oxide, macromolecular organic matter dispersion liquid and an antifoaming agent to obtain graphene oxide dispersion liquid; mixing diatomite with strongacid solution, performing hydrothermal reaction, filtering, washing, drying and calcining to obtain pretreated diatomite; subjecting the pretreated diatomite, the graphene oxide dispersion liquid, calcium carbonate, magnesium carbonate, sodium fluoride and nano iron powder to ball milling and mixing, and then standing for aging to obtain an aged material; rubbing the aged material to make balls,naturally drying, performing heat-preservation sintering at different temperatures under the protection of nitrogen while the temperature rise rate is controlled, cooling, and discharging to obtain acomposite skeleton reinforced ceramic based filter material. The ceramic based filter material prepared according to the technical scheme has excellent filtration performances as well as mechanical properties and has a promising prospect in development of the technical industry of environment-friendly materials.

Owner:吕莉

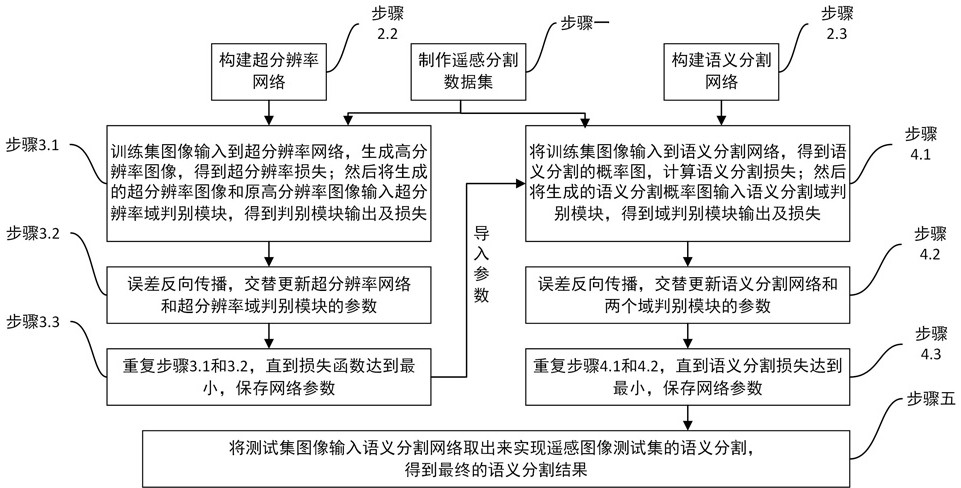

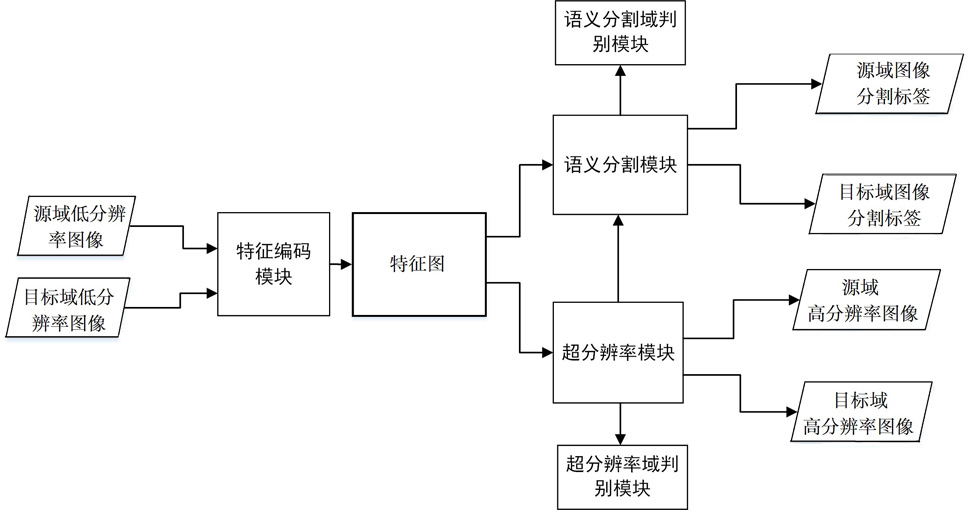

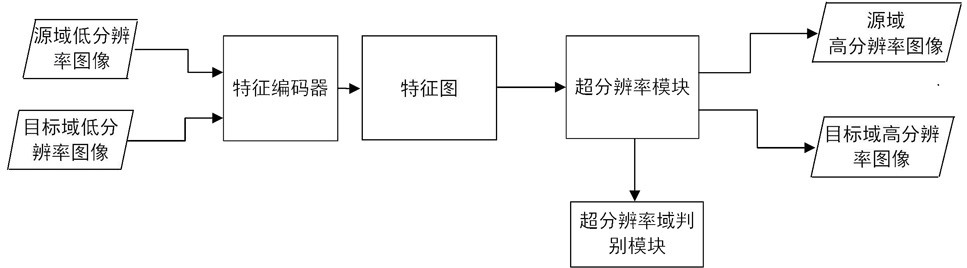

Unsupervised remote sensing image semantic segmentation method based on super-resolution and domain self-adaption

ActiveCN113160234AAvoid explosionPrevent disappearingImage enhancementImage analysisData setImage resolution

The invention discloses an unsupervised remote sensing image semantic segmentation method based on super-resolution and domain self-adaption, and belongs to the technical field of remote sensing image semantic segmentation methods. The technical problem to be solved is to provide the improvement of the unsupervised remote sensing image semantic segmentation method based on super-resolution and domain self-adaption. According to the technical scheme, the method comprises the following steps: obtaining a source domain low-resolution remote sensing image data set and a target domain high-resolution remote sensing image data set, and dividing the obtained target domain image data set into a training image and a test image according to a set proportion; building a remote sensing image semantic segmentation network and a super-resolution network; carrying out network pre-training and parameter optimization on the built super-resolution network; training a remote sensing image semantic segmentation network; inputting the preprocessed test set data into the trained remote sensing image semantic segmentation network, and outputting an accurate segmentation result of the remote sensing image; the invention is applied to remote sensing image processing.

Owner:中国建筑材料工业地质勘查中心山西总队

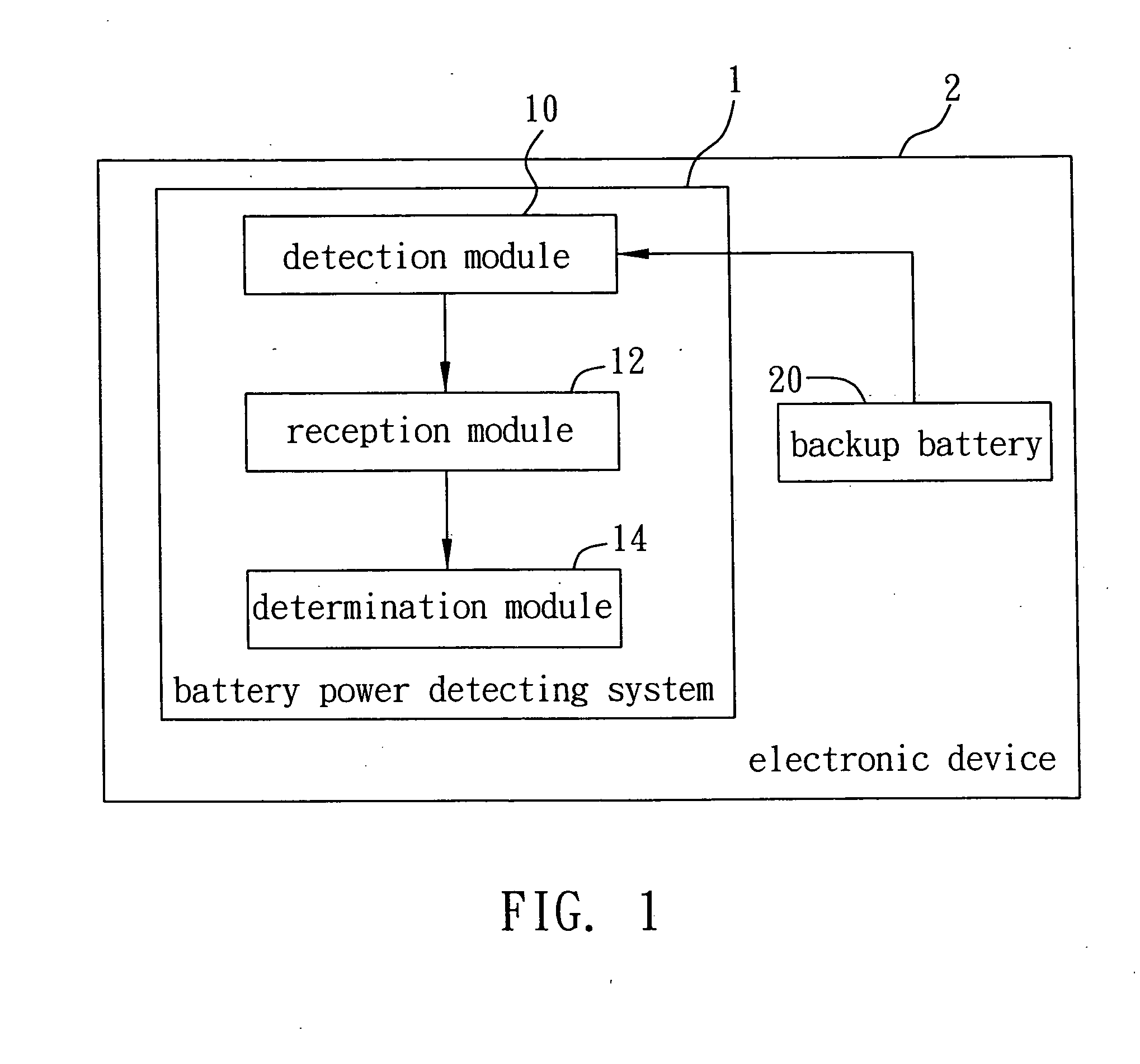

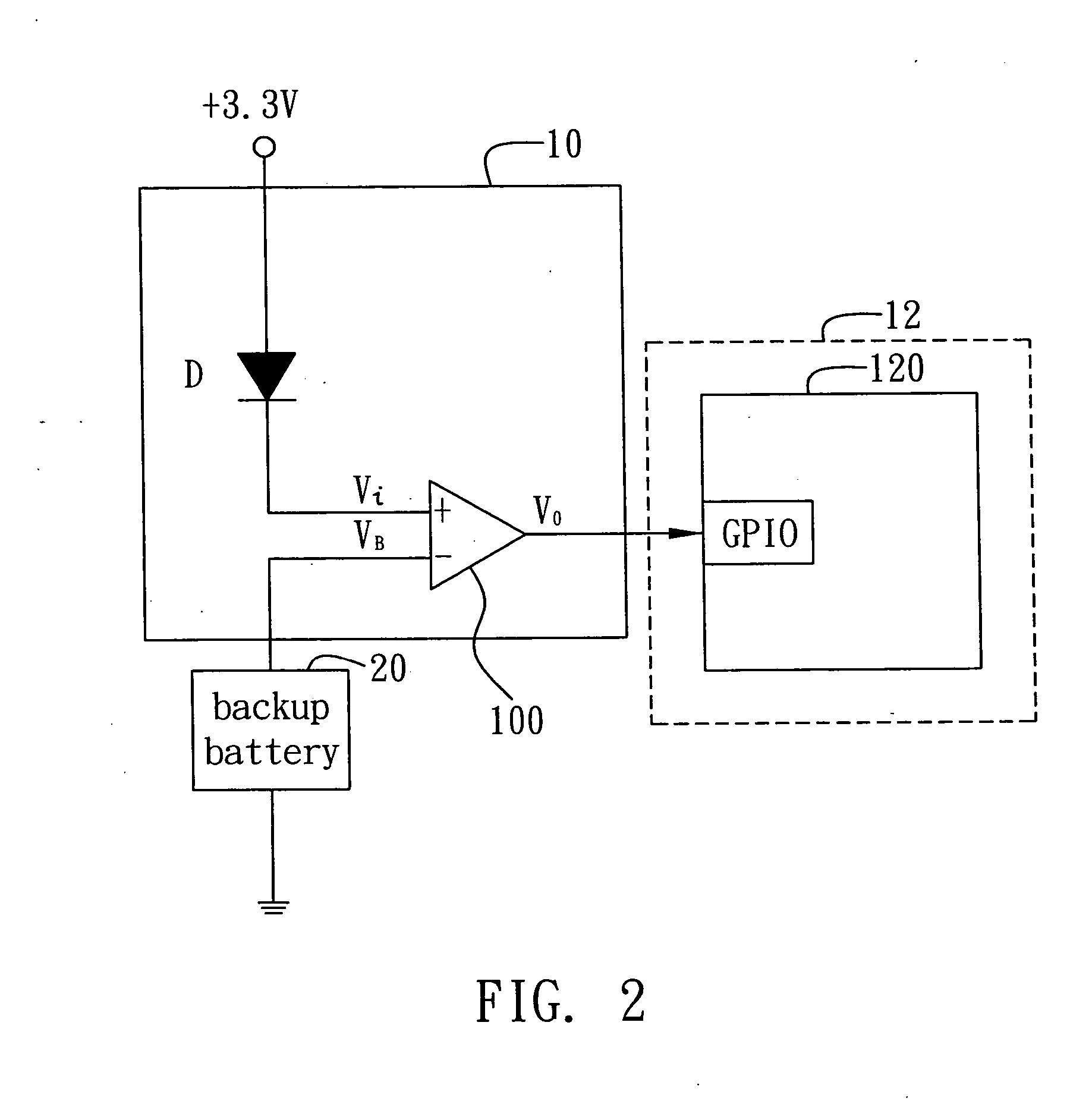

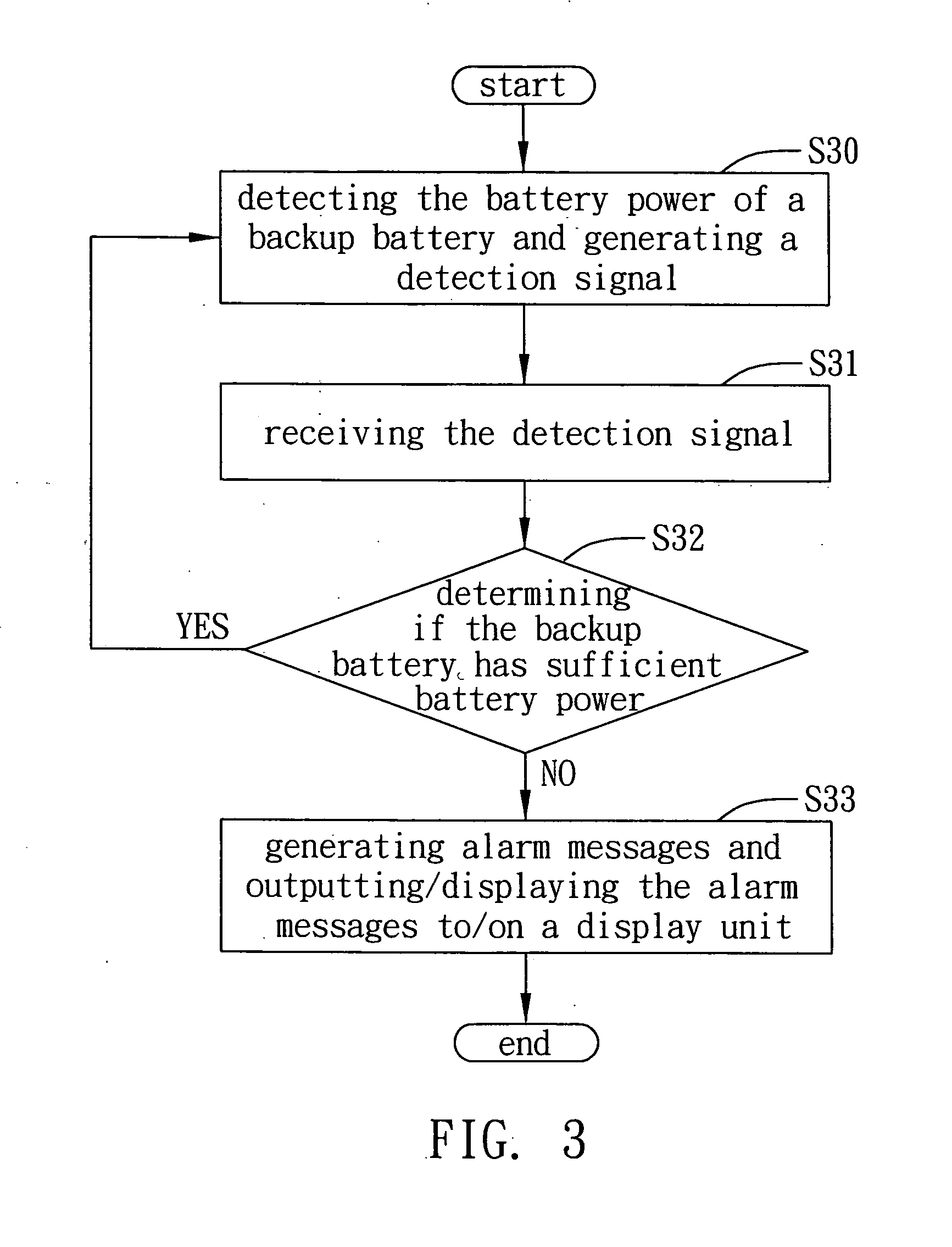

Battery power detecting system and method

InactiveUS20070229029A1Avoid lossEfficient powerCircuit monitoring/indicationDifferent batteries chargingAlarm messageRandom access memory

A battery power detecting system is disclosed applicable to an electronic device having a volatile random access memory (VRAM) for detecting the battery power of a backup battery of the volatile random access memory. The battery power detecting system includes a detection module for detecting the battery power of the backup battery and for generating a detection signal; a reception module for receiving the detection signal; and a determination module for reading a state value of the detection signal received by the reception module, determining the battery power of the backup battery according to the state value, and generating alarm messages to notify a user that the backup battery is lacking in battery power when the backup battery is determined to be have insufficient battery power, so as to prevent data stored in the VRAM from being lost due to the lack of the battery power of the backup battery.

Owner:INVENTEC CORP

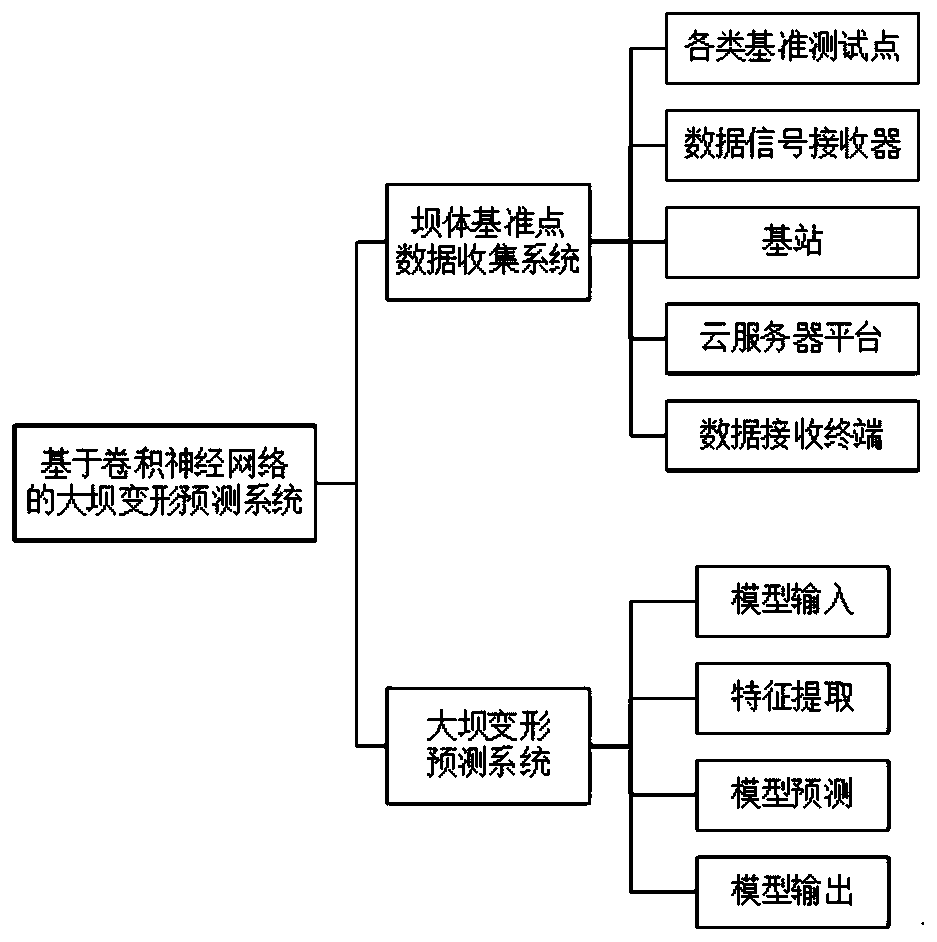

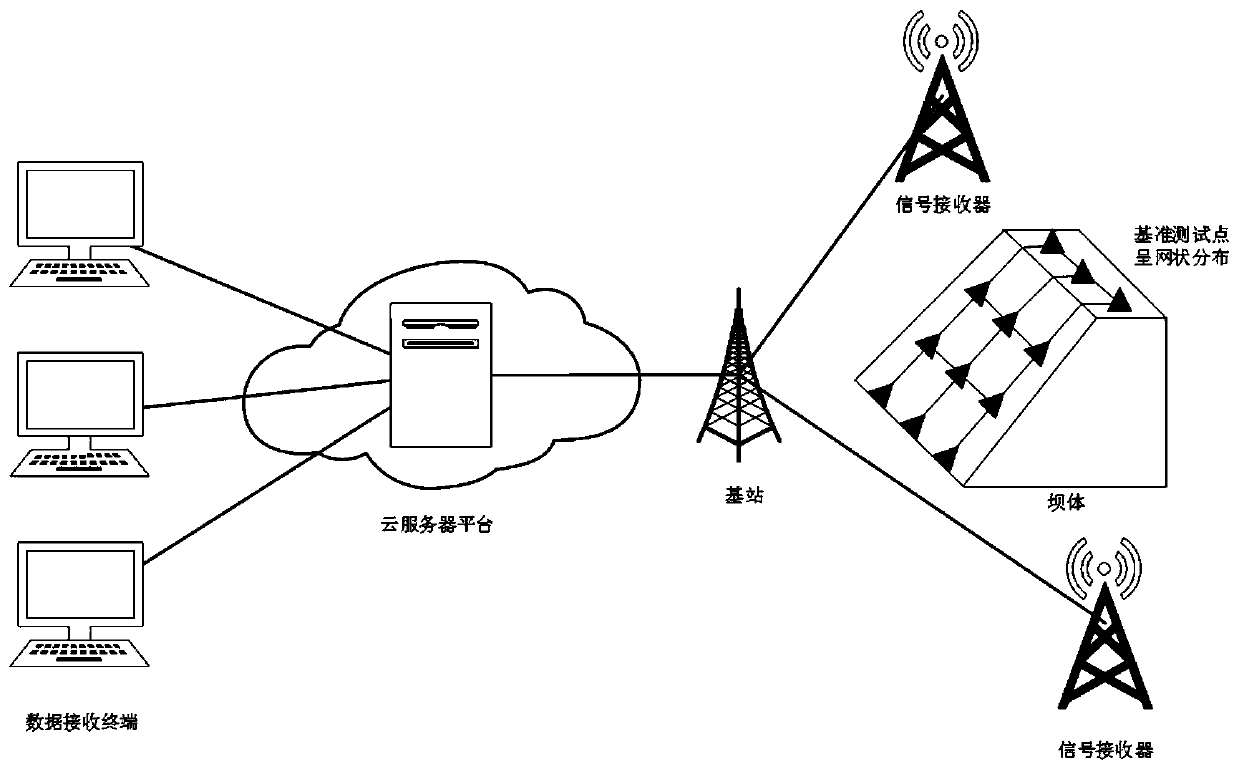

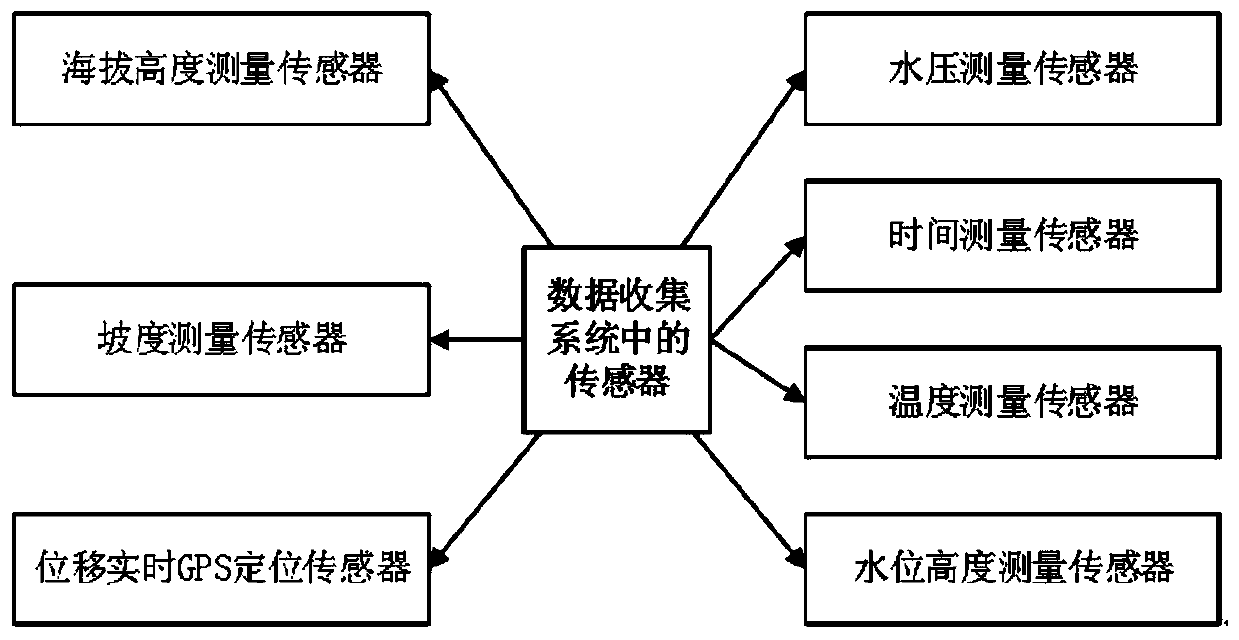

Dam deformation prediction system and method based on convolutional neural network

ActiveCN111105097AReduce the interference of human factorsSimple structureForecastingNeural architecturesConcurrent computationAlgorithm

The invention discloses a dam deformation prediction system and method based on a convolutional neural network. According to the convolutional neural network for dam deformation prediction, the network parallel computing capacity is fully used, two-dimensional data is input into multiple paths in parallel, multiple convolutional layers and pooling layers are alternately cascaded in each path, andin order to obtain more characteristics, different convolutional kernel sizes can be set; a simple path only cascading a convolution layer and a pooling layer is added to extract features different from other paths, and meanwhile, the features extracted by the paths are not necessarily complementary, so that additive operation is used in the system when output results of the paths are combined. According to the method, the automation level of dam deformation prediction is improved, and the efficiency and speed of deformation prediction are improved.

Owner:HOHAI UNIV CHANGZHOU

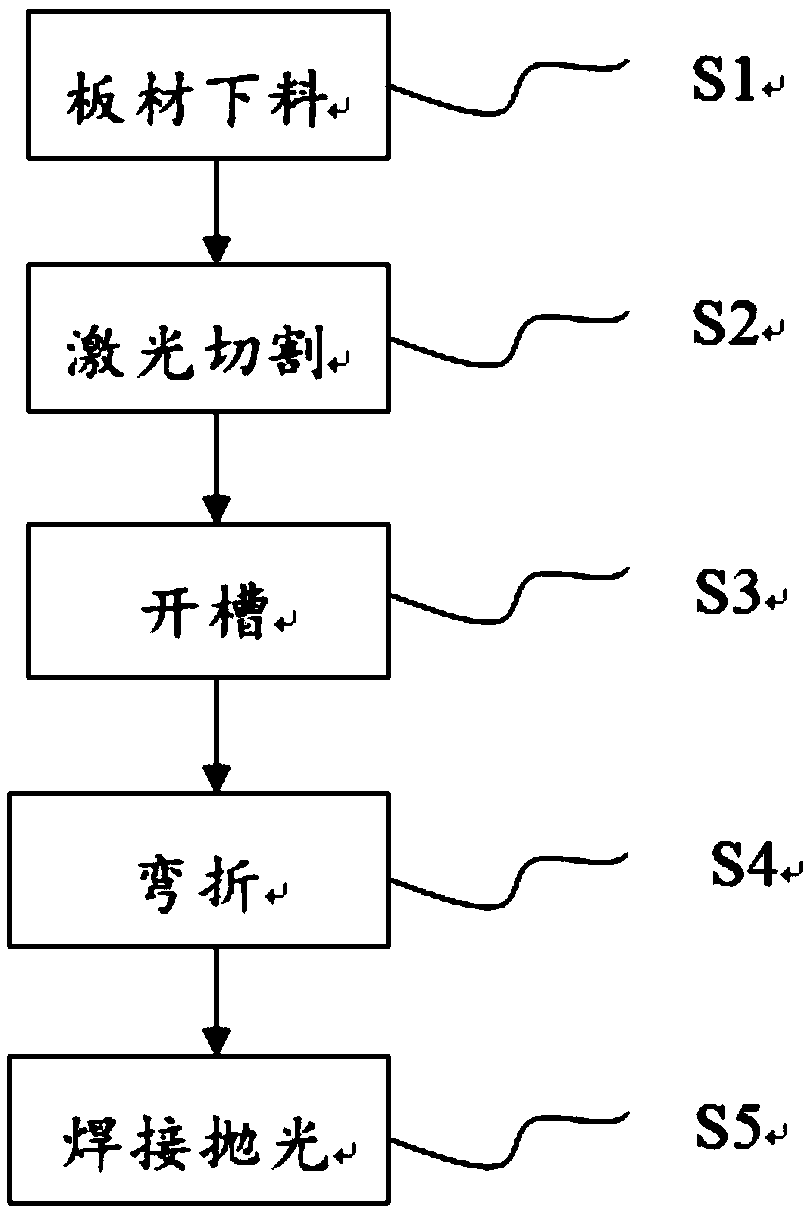

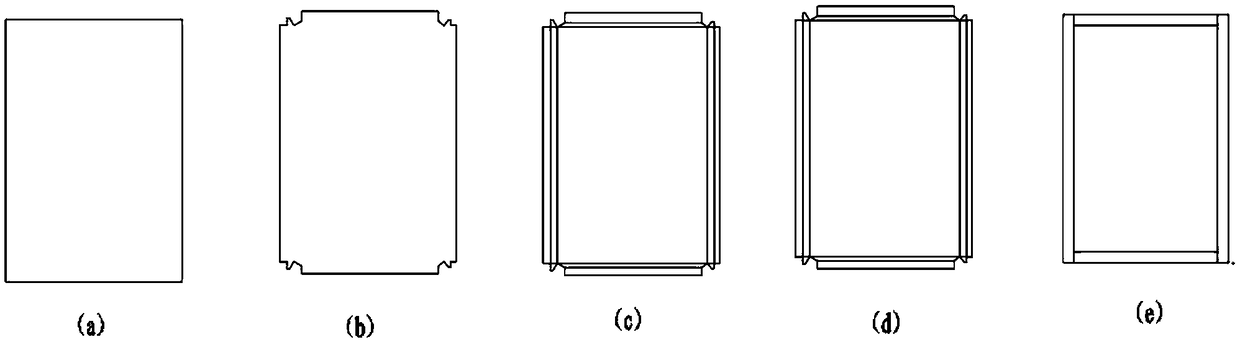

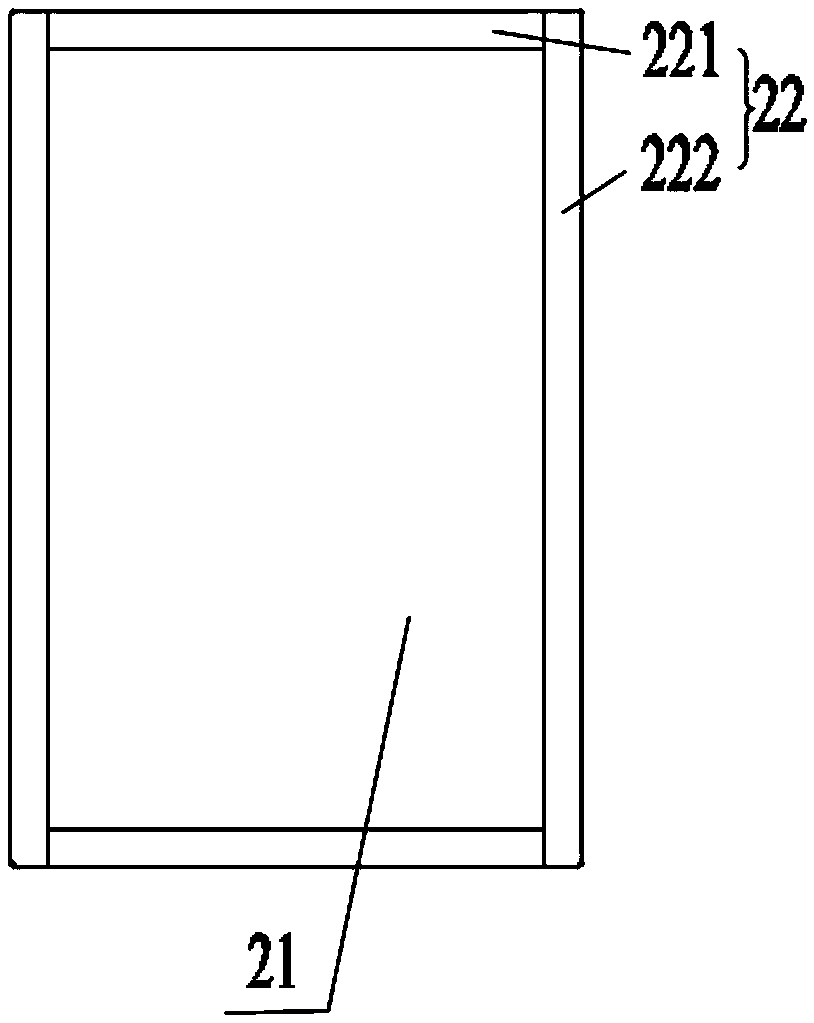

Panel for assembly and machining technology thereof and dryer

InactiveCN108747228APrevent disappearingAvoid chromatic aberrationDrying solid materialsBoundary contourButt joint

The invention relates to a panel for assembly and a machining technology thereof and a dryer. The machining technology comprises the steps that S1, plate blanking is carried out; S2, laser cutting iscarried out, specifically, laser cutting is carried out on a plate according to the boundary contour of a developing drawing of a finished panel; S3, slotting is carried out, specifically, a pluralityof bent lines are drawn on the plate, and slotting is carried out along the bent lines; S4, bending is carried out, specifically, bending treatment is carried out along slotted lines, one opposite sides are bent first, and then the other opposite sides are bend; and S5, welding and polishing are carried out, specifically, butt joints of the edges are subjected to welding and polishing treatment.According to the machining technology, five visible surfaces of the panel have no side seams which need to be welded, all positions which need to be welded are arranged on the inside side surfaces, namely, the invisible surfaces, line disappearance and chromatic aberration of the visible surfaces after welding and polishing are avoided, and an integral attractive effect is achieved. Meanwhile, themachining technology of the panel can effectively simplify the operation steps of bending and effectively ensure the overall flatness and attractive degree of bent parts.

Owner:TRUKING TECH LTD

Technological method of using internal chill for expendable pattern negative pressure casting

ActiveCN105537522AEasy to preparePrevent disappearingFoundry mouldsFoundry coresPressure castingLost-foam casting

The invention belongs to the technical field of casting, and relates to a technological method of using internal chill expendable pattern negative pressure casting for producing a dispersed hot spot shrinkage porosity qualified casting without a shrinkage cavity inside. The method includes the steps of selecting an internal chill material, determining internal chill quality, manufacturing the internal chill, cleaning the internal chill, manufacturing internal chill formed foam model, conducting molding, performing casting and obtaining the casting after solidification. The same material as the casting or a commercially available nickel plated wire structure is adopted in the internal chill, so that the internal chill the same as the casting in shape is manufactured conveniently. The straight rod and winding combined structural form is adopted in the internal chill, the straight rod structure has fixing and supporting functions and can prevent that the internal chill collapses an expendable pattern cavity due to excessive mass. The internal chill is simple in structure, low in cost, easy to operate, high in reliability and applicability and suitable for the casting provided with dispersed hot spots and formed by an expendable pattern.

Owner:JIANGSU GRINKA MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com