Technological method of using internal chill for expendable pattern negative pressure casting

A process method and negative pressure casting technology, applied in the field of casting, can solve the problems of thermal joint dispersion, scrapped castings, inability to perform centralized feeding, etc., and achieve the effects of strong applicability, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The process of using internal cooling iron in lost foam negative pressure casting mainly includes the following steps:

[0025] (1) Selection of inner cooling iron material: the material of inner cooling iron 3 can be the filament 4 of the same material as the casting, and commercially available nickel-plated iron wire can be used for less demanding castings or parts that can be processed.

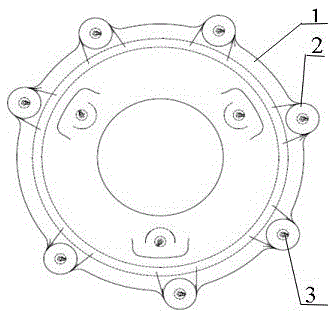

[0026] (2) Determination of the quality of the inner cooling iron: the quality of the inner cooling iron 1 can be determined according to the quality of the hot joint. Generally, the quality of the inner cooling iron is 2~3.5% of the mass of the hot joint.

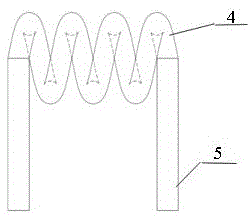

[0027] (3) Preparation of inner cooling iron: preparation of inner cooling iron 3, with a cross-sectional area of 1~7mm 2 Commercially available nickel-plated iron wire or castings of the same

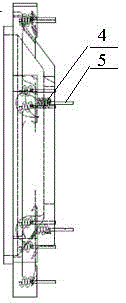

[0028] The filament 4 of the material is prepared by winding the inner cooling iron 3 with the same shape as the casting, and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com