Solder bump and forming method therefor, and substrate having solder bump and manufacturing method for substrate having solder bump

A technology of solder bumps and substrates, which is applied to substrates with solder bumps and its manufacture, and the field of substrates with solder bumps and its manufacture, which can solve problems such as disappearance of copper patterns, achieve good dimensional accuracy, prevent defects or disappearance, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

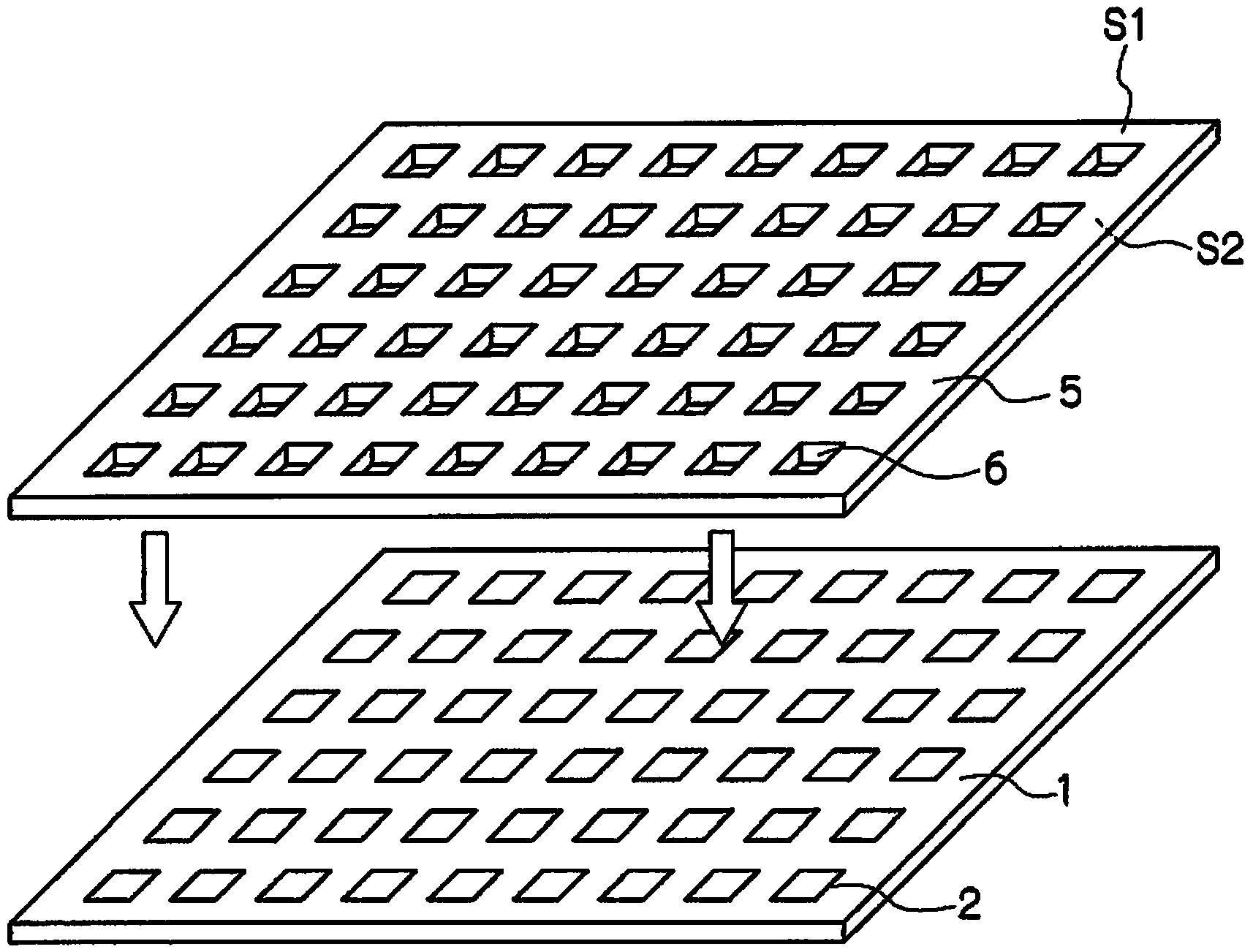

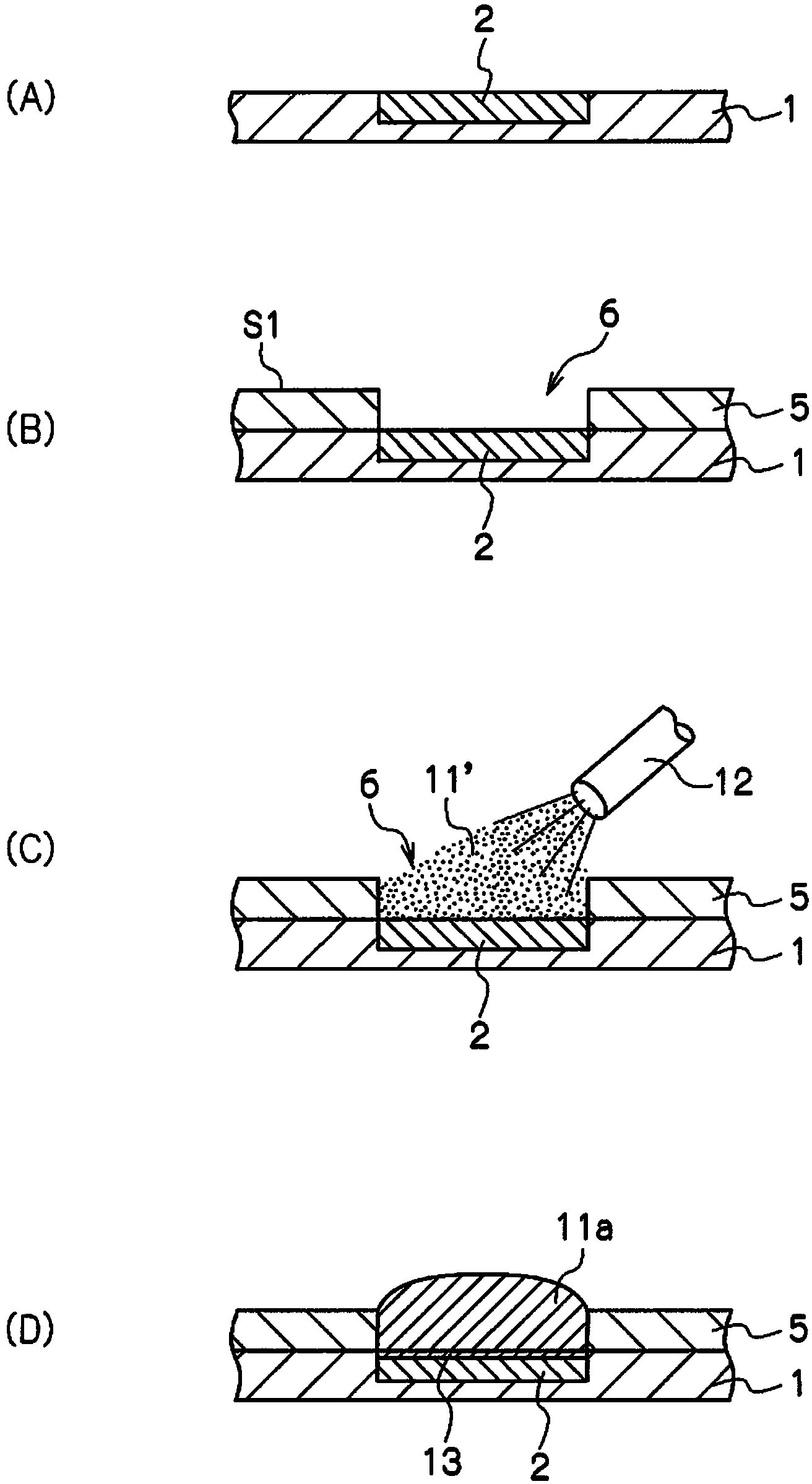

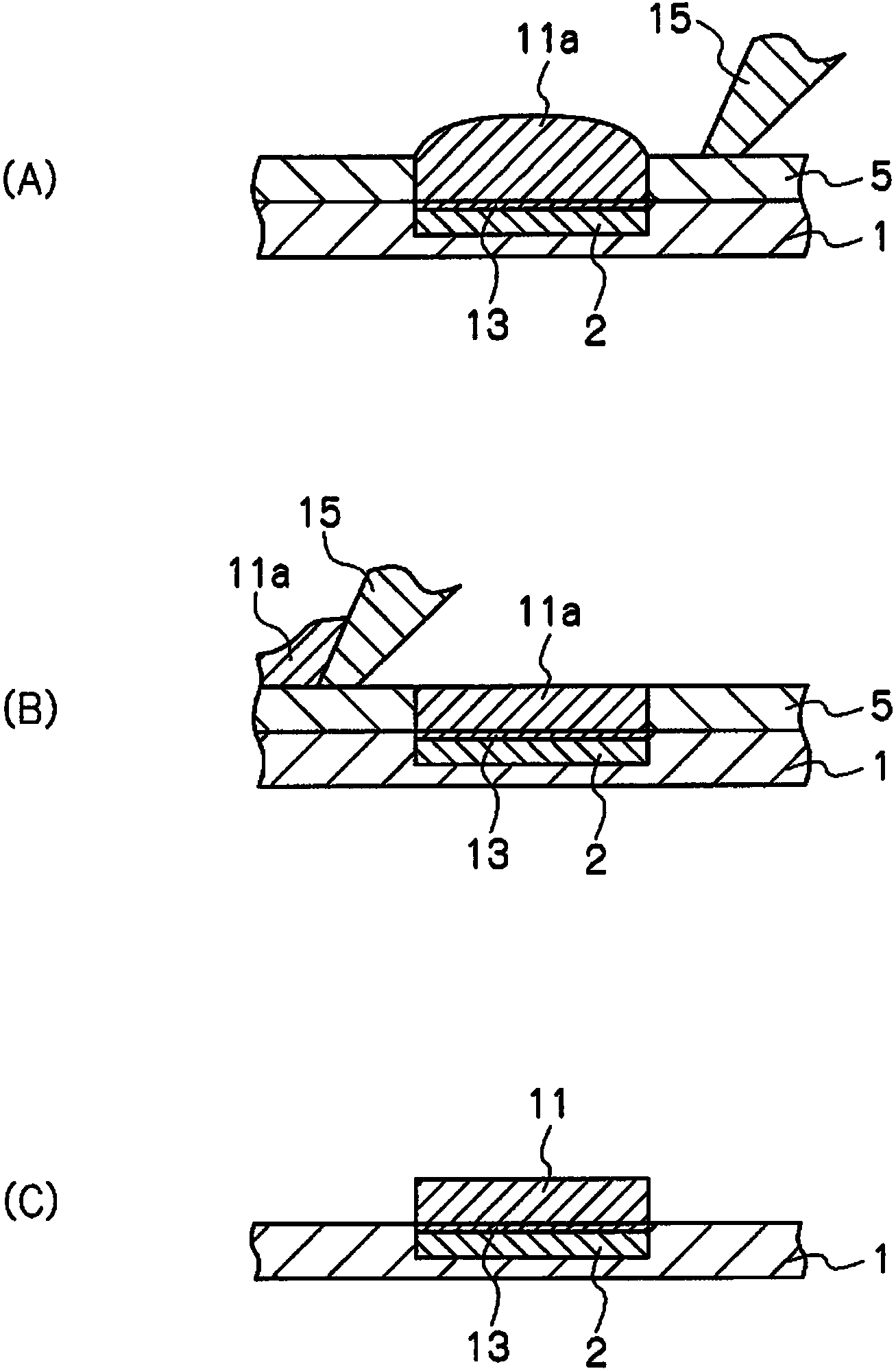

[0113]As an example, a substrate 1 on which a copper wiring pattern having a width of, for example, 200 μm and a thickness of, for example, 10 μm is formed is prepared. In the substrate 1 , only the connecting portion of the copper wiring pattern with a width of, for example, 200 μm and a length of, for example, 50 μm is exposed, and the other copper electrodes 2 are covered with an insulating layer. A mask 5 having openings 6 for forming solder bumps 11 on the above-mentioned connection portions was prepared. After aligning and superimposing the connecting portion where the copper electrode 2 is exposed on the substrate 1 and the opening 6 of the mask 5, use Ni: 0.05% by mass, Ge: 0.005% by mass, Ag: 3% by mass, Cu: 0.5% by mass The quinary system lead-free solder consisting of mass % and the balance of Sn is heated to 250° C. to form molten solder 11 a , and jet 11 ′ of this molten solder is sprayed toward opening 6 . The jet flow 11' of molten solder is performed with the ...

Embodiment 2

[0117] In Example 1, as the solder material, a quinary system lead-free solder consisting of Ni: 0.03% by mass, Ge: 0.005% by mass, Ag: 3% by mass, Cu: 0.5% by mass, and Sn as the balance was used. In addition, the solder bump 11 of Example 2 was formed similarly to Example 1. As in Example 1, it can be seen from the scanning electron micrograph of the cross-section that the CuNiSn intermetallic compound layer 13 a is formed with a thickness of 1 μm although slightly uneven.

Embodiment 3

[0119] In Example 1, as the solder material, a quinary system lead-free solder consisting of Ni: 0.07% by mass, Ge: 0.005% by mass, Ag: 3% by mass, Cu: 0.5% by mass, and Sn as the balance was used. In addition, the solder bump 11 of Example 3 was formed similarly to Example 1. FIG. As in Example 1, it can be seen from the scanning electron micrograph of the cross section that the CuNiSn intermetallic compound layer 13 a is uniformly formed with a thickness of 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com