Conductive silicon compound, its preparation and negative electrode material of non-aqueous electrolyte secondary battery

A composite and conductive silicon technology, applied in secondary batteries, secondary battery components, battery electrodes, etc., can solve problems such as insufficient use of secondary batteries, insufficient carbon coating structure, and reduced cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] To illustrate the structure of the conductive silicon composite of the present invention, refer to an exemplary conductive silicon composite made of silicon oxide (SiOx) as a raw material.

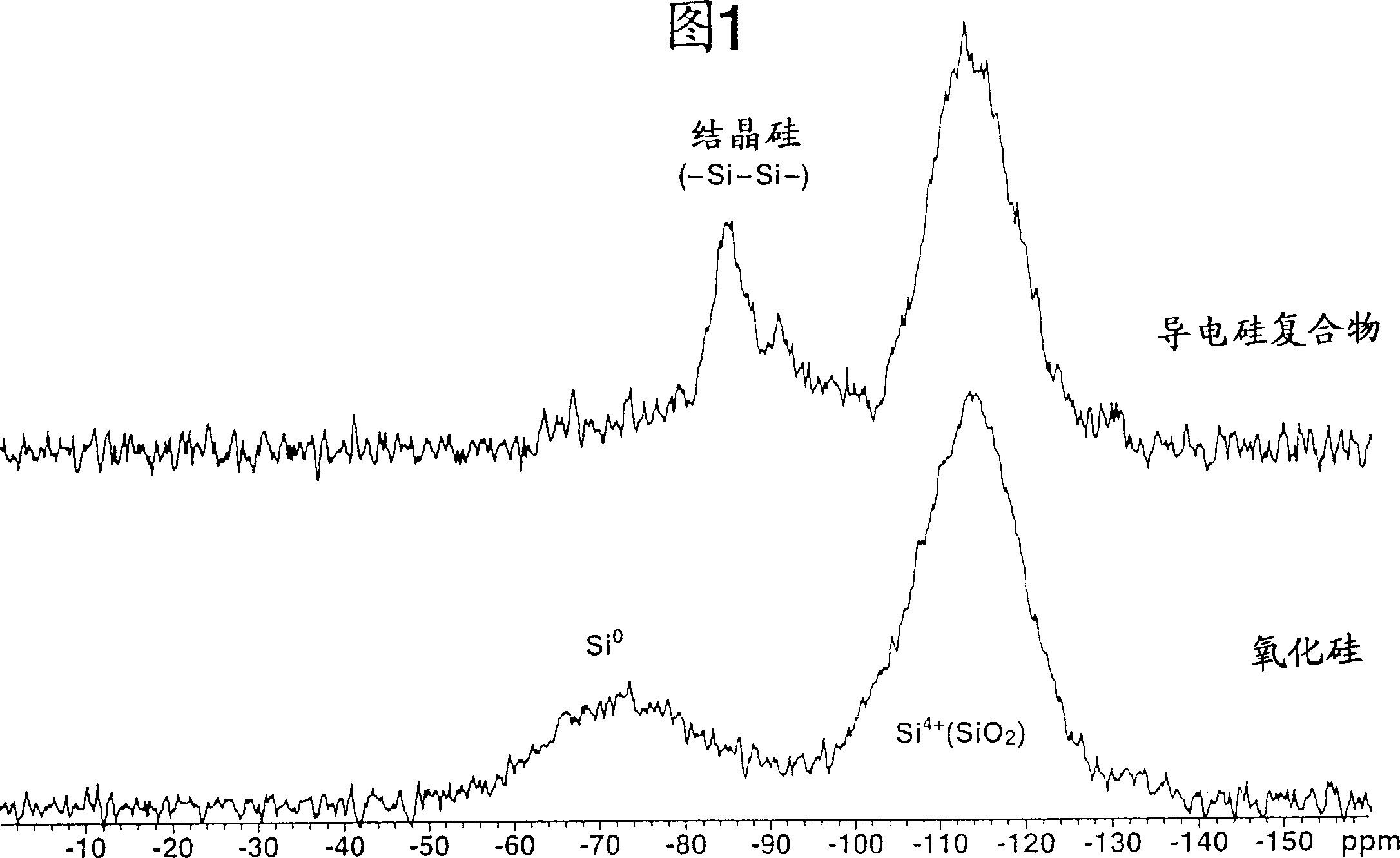

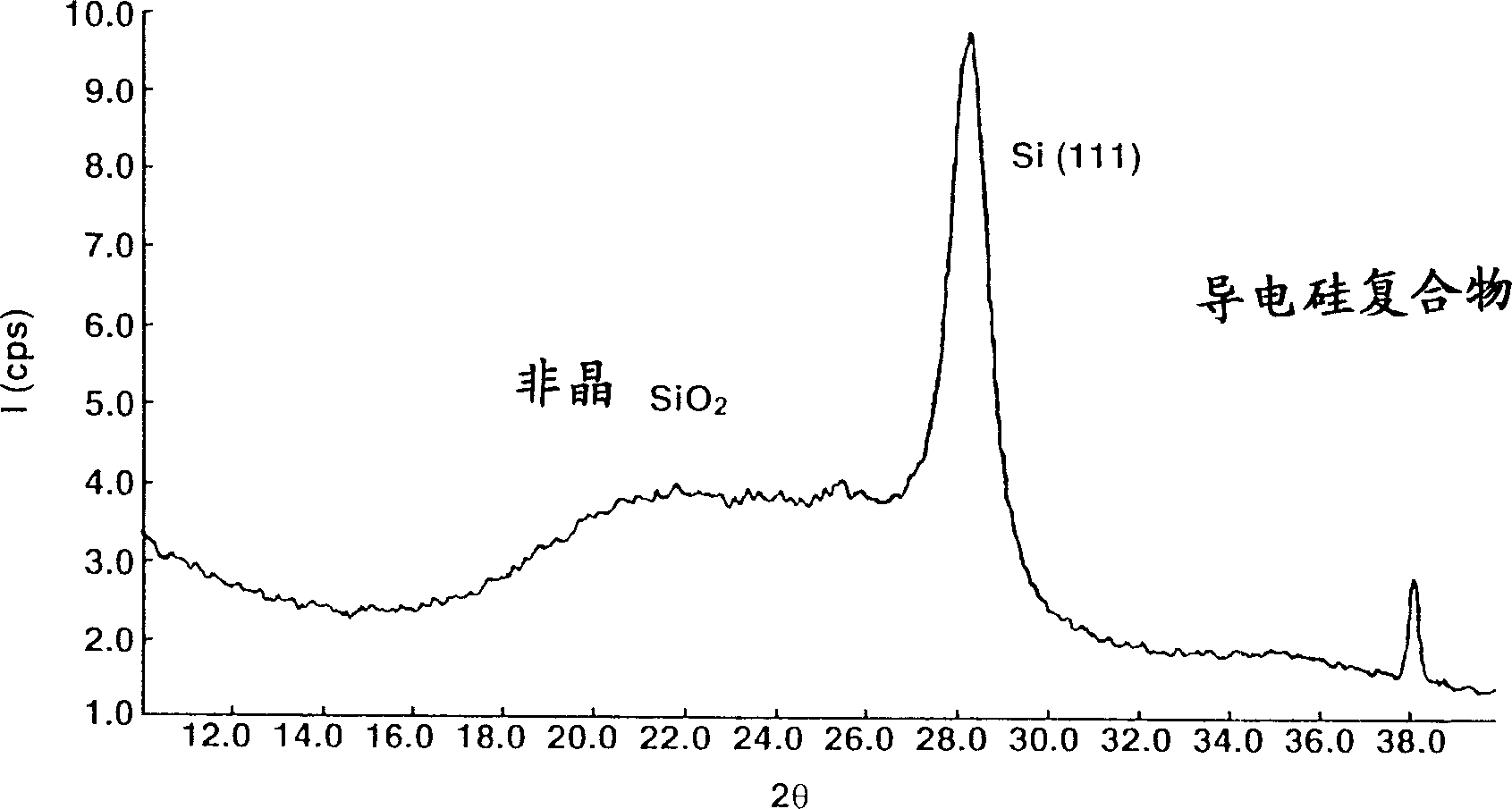

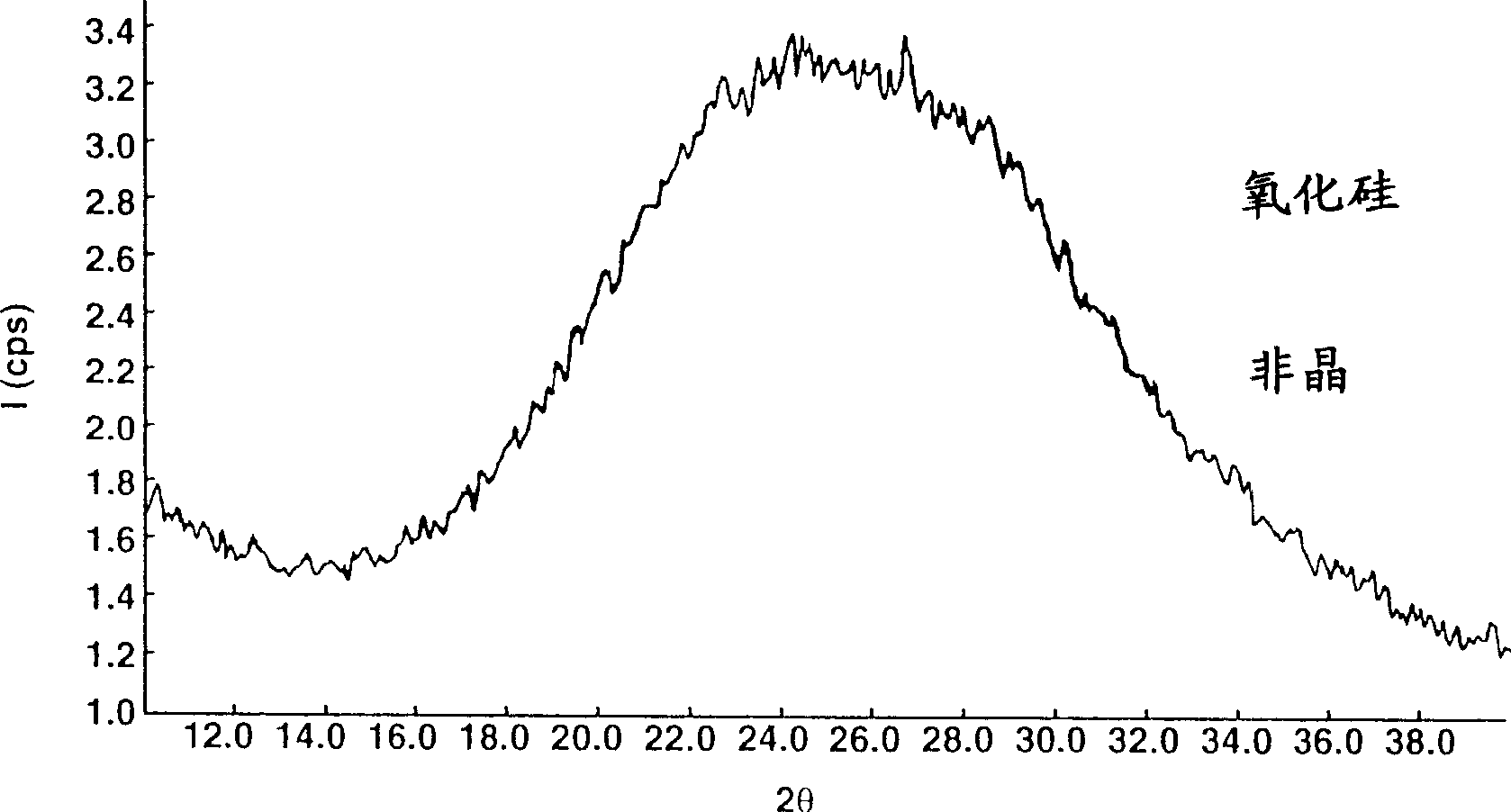

[0061] Silicon oxide (SiOx, x=1.02) was ground in a ball mill using hexane as a dispersion medium. The silicon oxide powder thus obtained was put into a rotary kiln-type reactor. In this reactor, the disproportionation of silicon oxide and thermal CVD were carried out simultaneously in a mixed flow of methane-argon gas at 1150°C and the average residence time was about 2 hour. The powder thus obtained was analyzed by solid-state NMR, x-ray diffractometry, TEM microphotography, and Raman spectroscopy (excitation light 532 nm), and the results are shown in FIGS. 1 to 4, respectively. From the solid state of silicon oxide as the raw material and conductive silicon composite as the final product 29 From the results of Si-NMR analysis, it can be seen that on the curve of a conductive silicon...

Embodiment 2

[0067]Using hexane as a dispersion medium, silicon oxide (SiOx, x=1.02) was ground in a ball mill. By filtering the suspension thus prepared in a nitrogen atmosphere and removing the solvent, a powder with an average particle size of about 0.8 μm is obtained. The silicon oxide powder is placed in a rotary furnace-type reactor, in which a methane-argon mixed gas stream is simultaneously subjected to disproportionation and thermal CVD of silicon oxide with an average residence time of approximately 2 hours at 1150°C. The product thus obtained had a carbon content of 16.5%, and the amount of active silicon or zero-valent silicon determined from the amount of hydrogen generated by the reaction with the potassium hydroxide aqueous solution was 26.7%. Analyzed by x-ray diffractometry (Cu-Kα), silicon crystals dispersed in silicon dioxide had a size of approximately 11 nm determined by the Scherrer method from the half-width of the Si(111) diffraction line at 2θ=28.4°. At the end of ther...

Embodiment 3

[0074] In an inert gas (argon) environment, heat block or flake silicon oxide at 1300°C for one hour to disproportionate into silicon and silicon dioxide. The analysis was performed by x-ray diffractometry (Cu-Kα), and the silicon crystals in the product had a size of approximately 55 nm determined by the Scherrer method from the half-width of the Si(111) diffraction line at 2θ=28.4°. The heat-treated silicon-silica composite was then ground in a ball mill using hexane as a dispersion medium. In a nitrogen environment, by filtering the suspension thus obtained and removing the solvent, a powder with an average particle size of approximately 0.8 μm is obtained. The silicon composite powder was placed in a vertical tube furnace (inner diameter ~ 50 mm), and in the furnace, thermal CVD was performed for 3 hours at 1100°C under a mixed gas flow of methane and argon. The conductive silicon composite powder thus obtained is pulverized in an automatic grinding body. The conductive silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com