Patents

Literature

238results about How to "Inhibition of volume change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

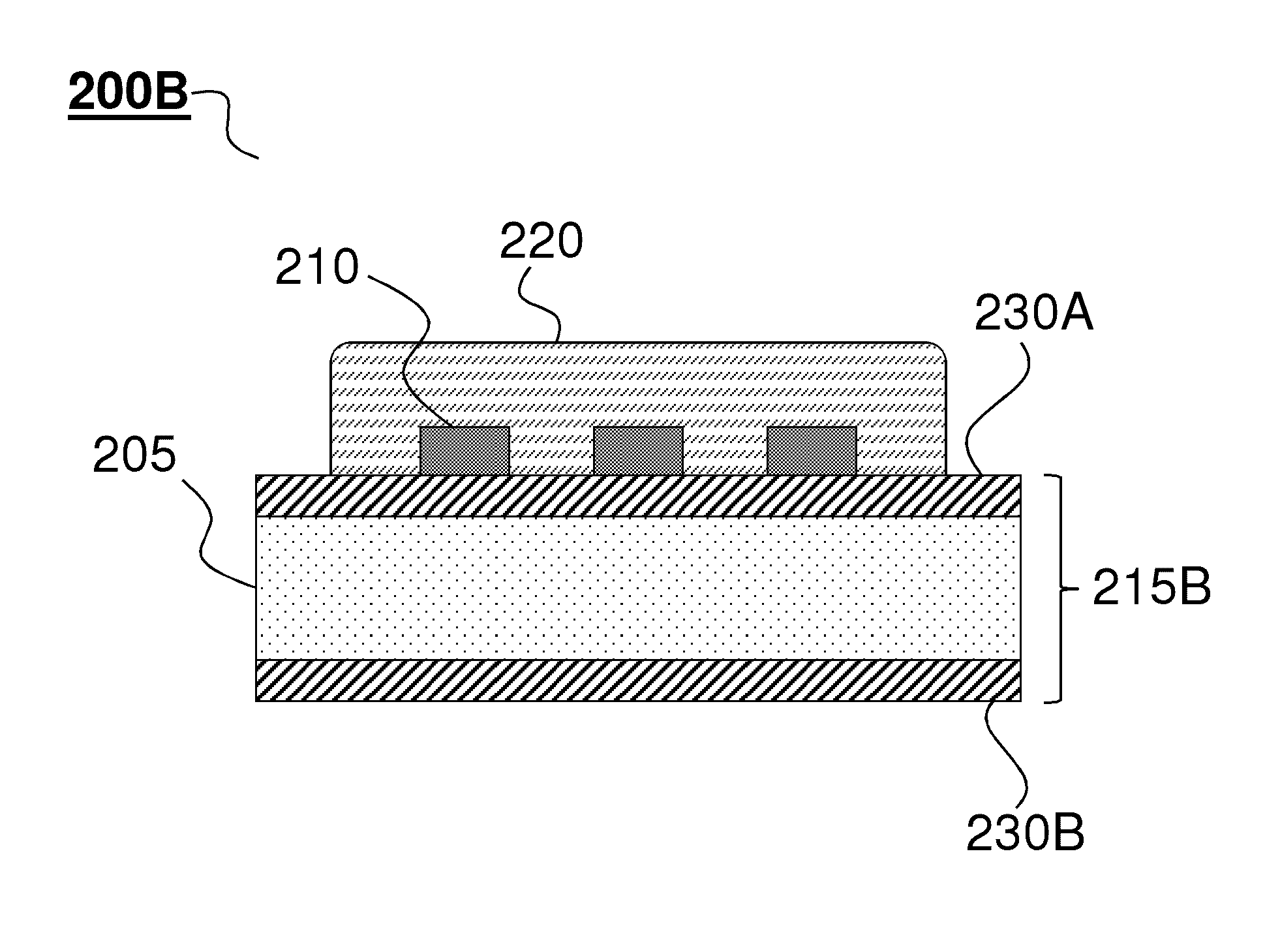

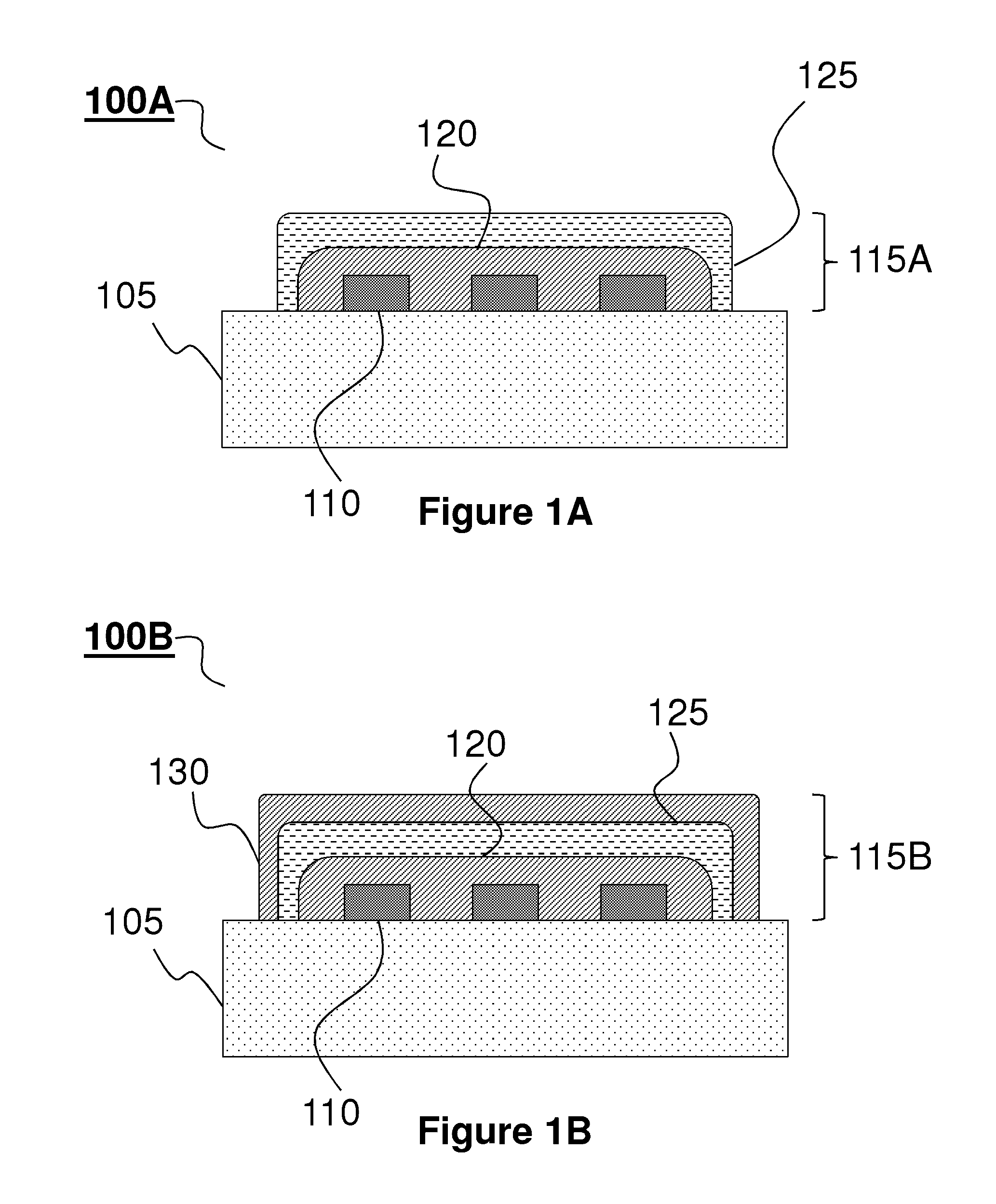

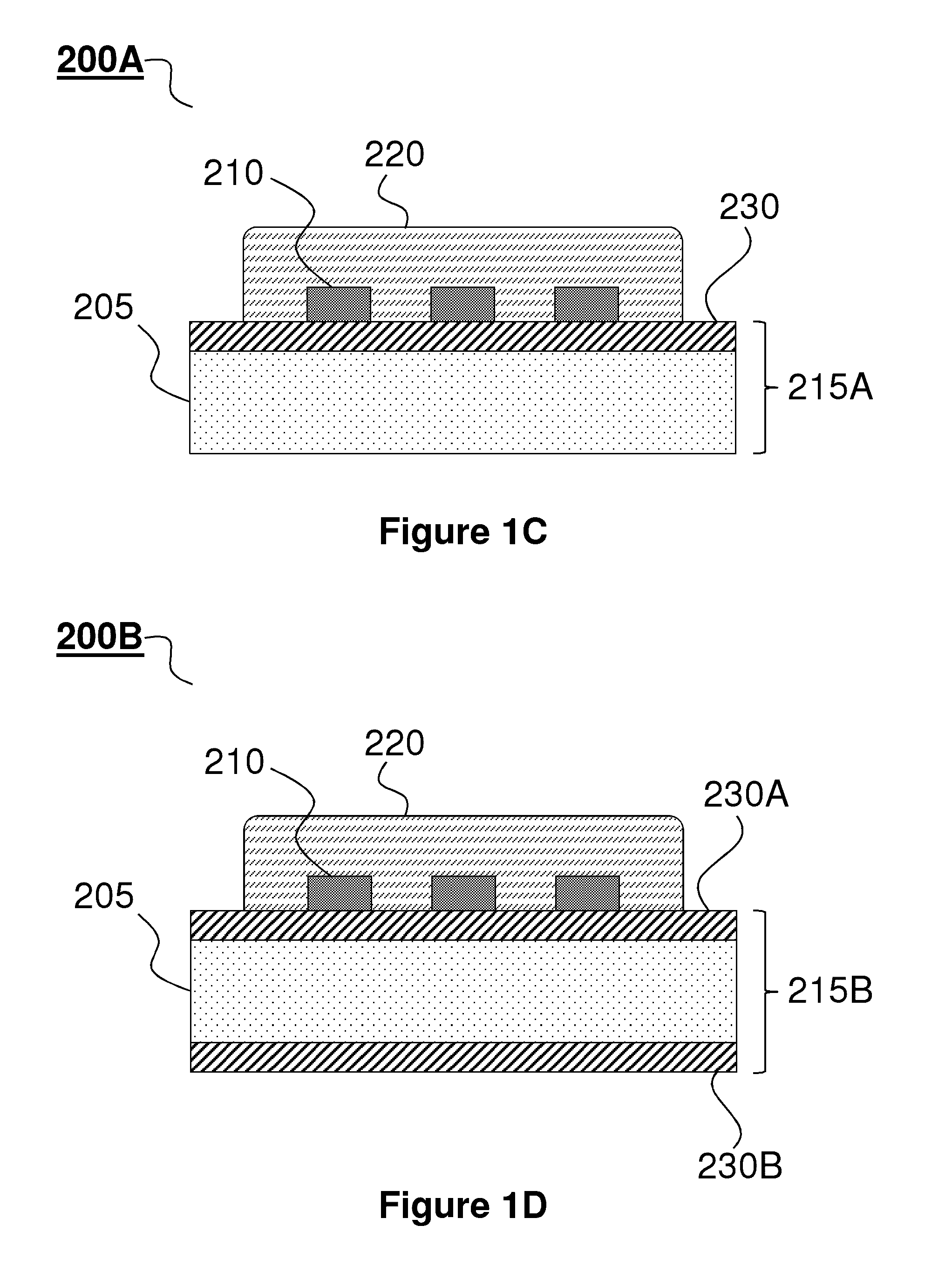

Transient electronic devices comprising inorganic or hybrid inorganic and organic substrates and encapsulates

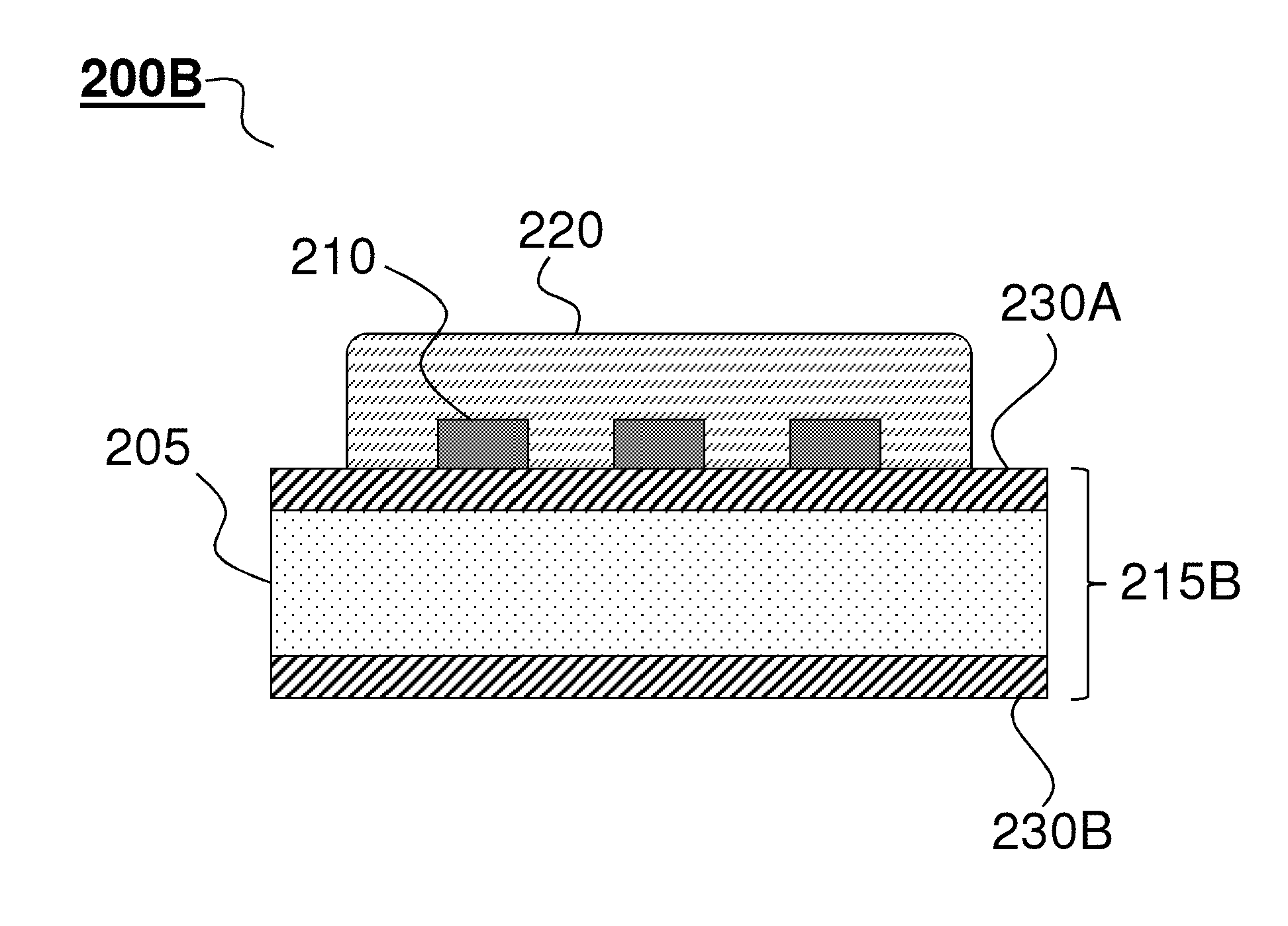

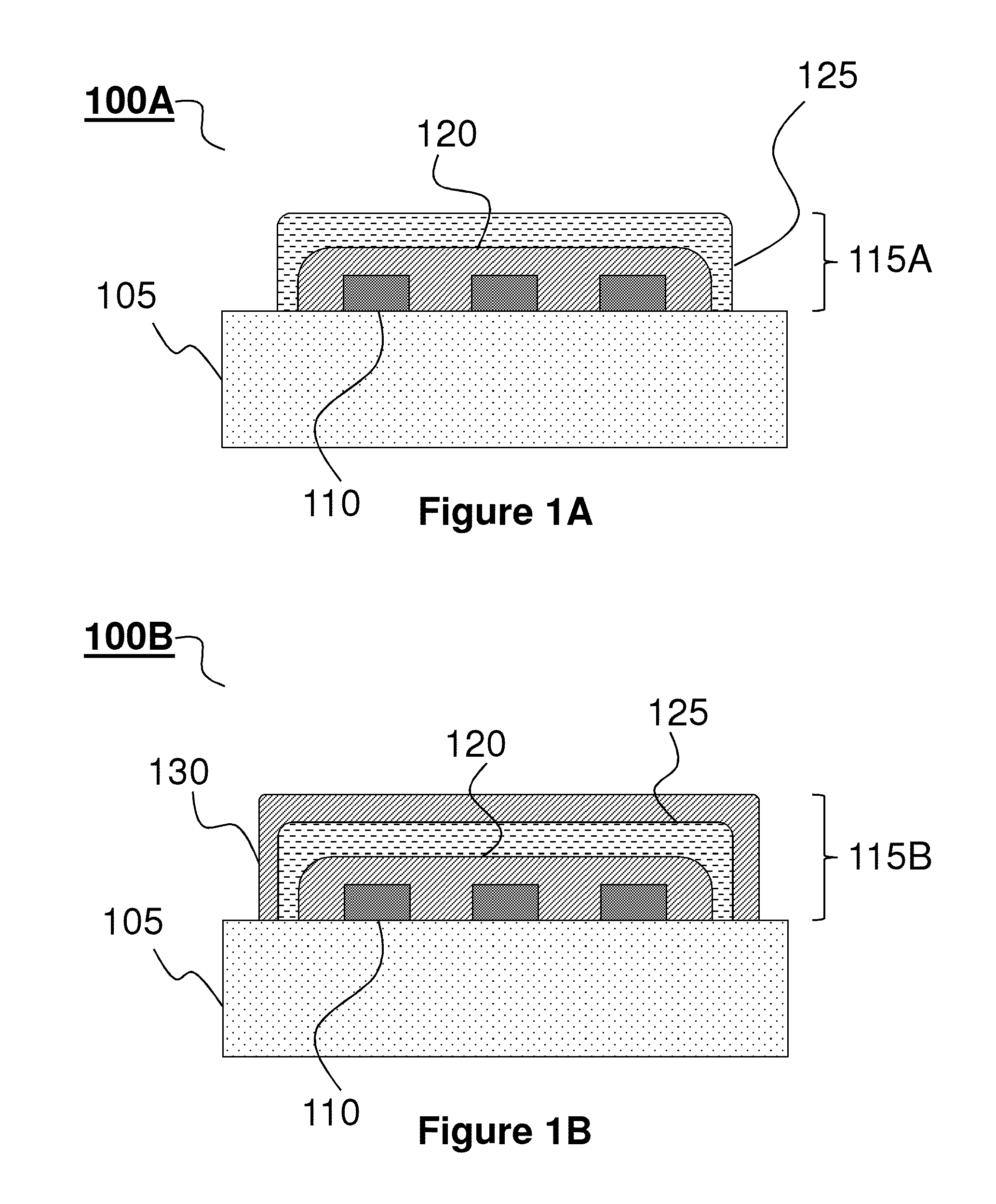

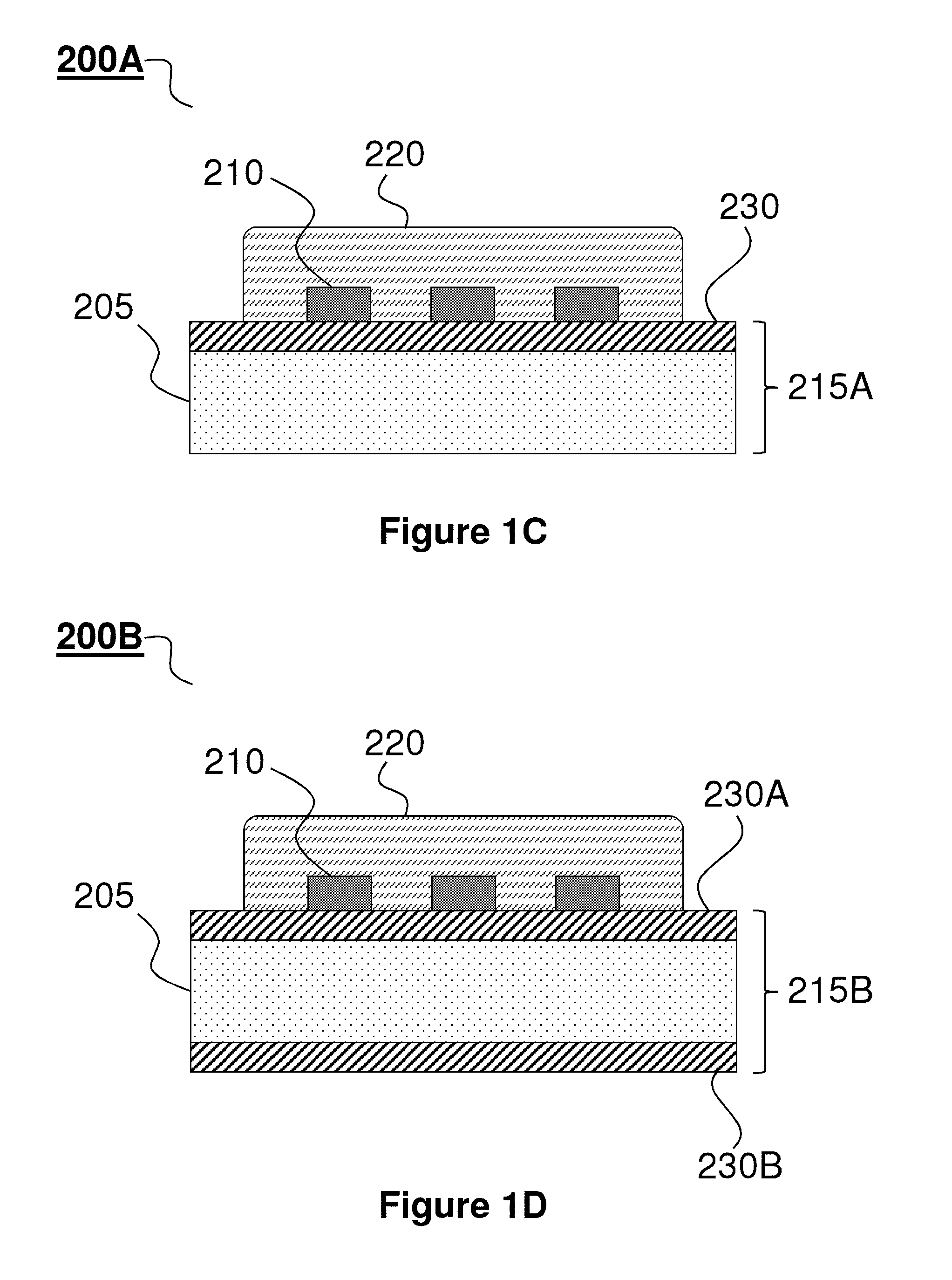

ActiveUS20140305900A1Effective fabrication of deviceUseful overall permeabilityLayered productsFinal product manufactureSingle crystalInorganic materials

The invention provides transient devices, including active and passive devices that physically, chemically and / or electrically transform upon application of at least one internal and / or external stimulus. Incorporation of degradable device components, degradable substrates and / or degradable encapsulating materials each having a programmable, controllable and / or selectable degradation rate provides a means of transforming the device. In some embodiments, for example, transient devices of the invention combine degradable high performance single crystalline inorganic materials with selectively removable substrates and / or encapsulants.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

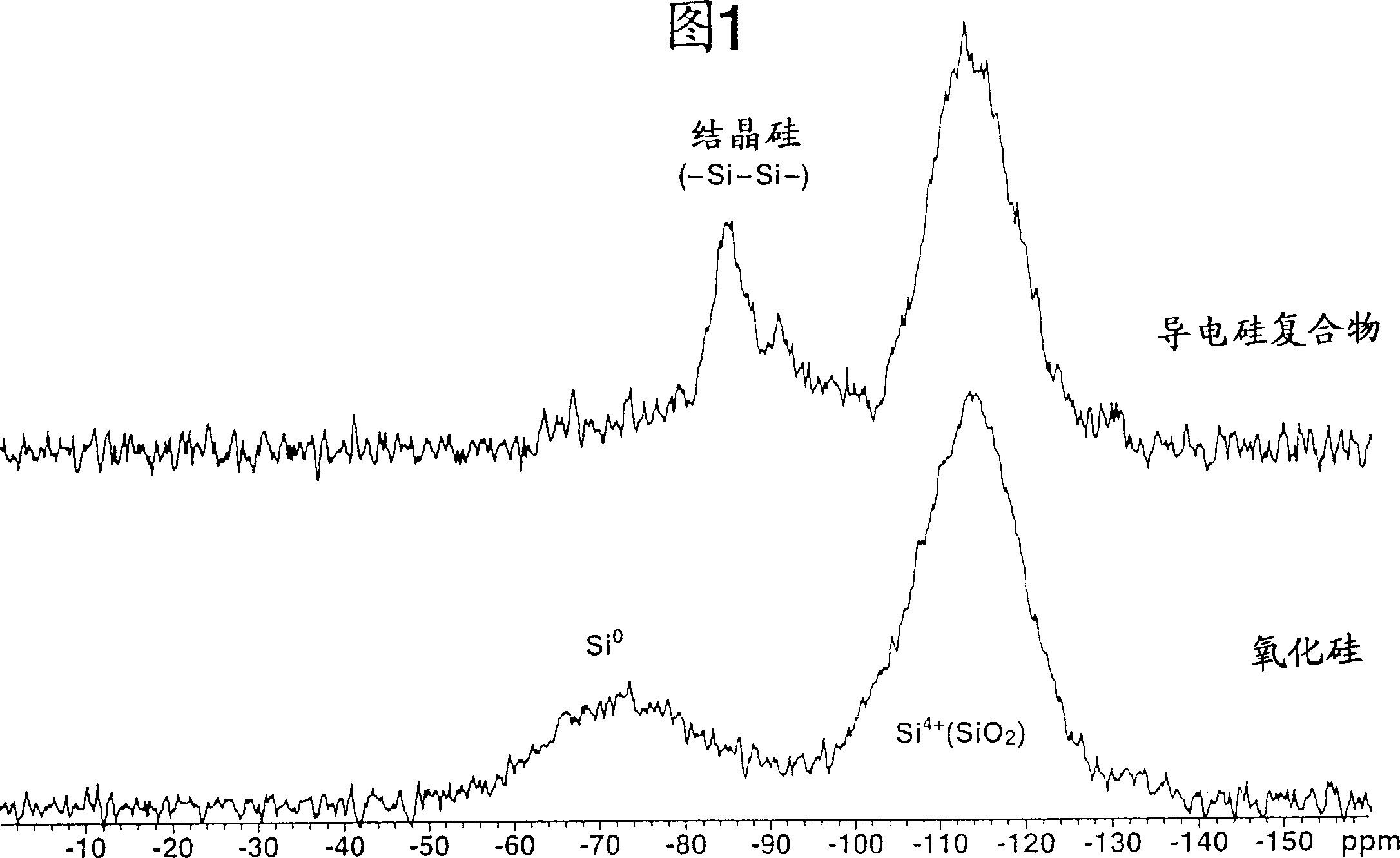

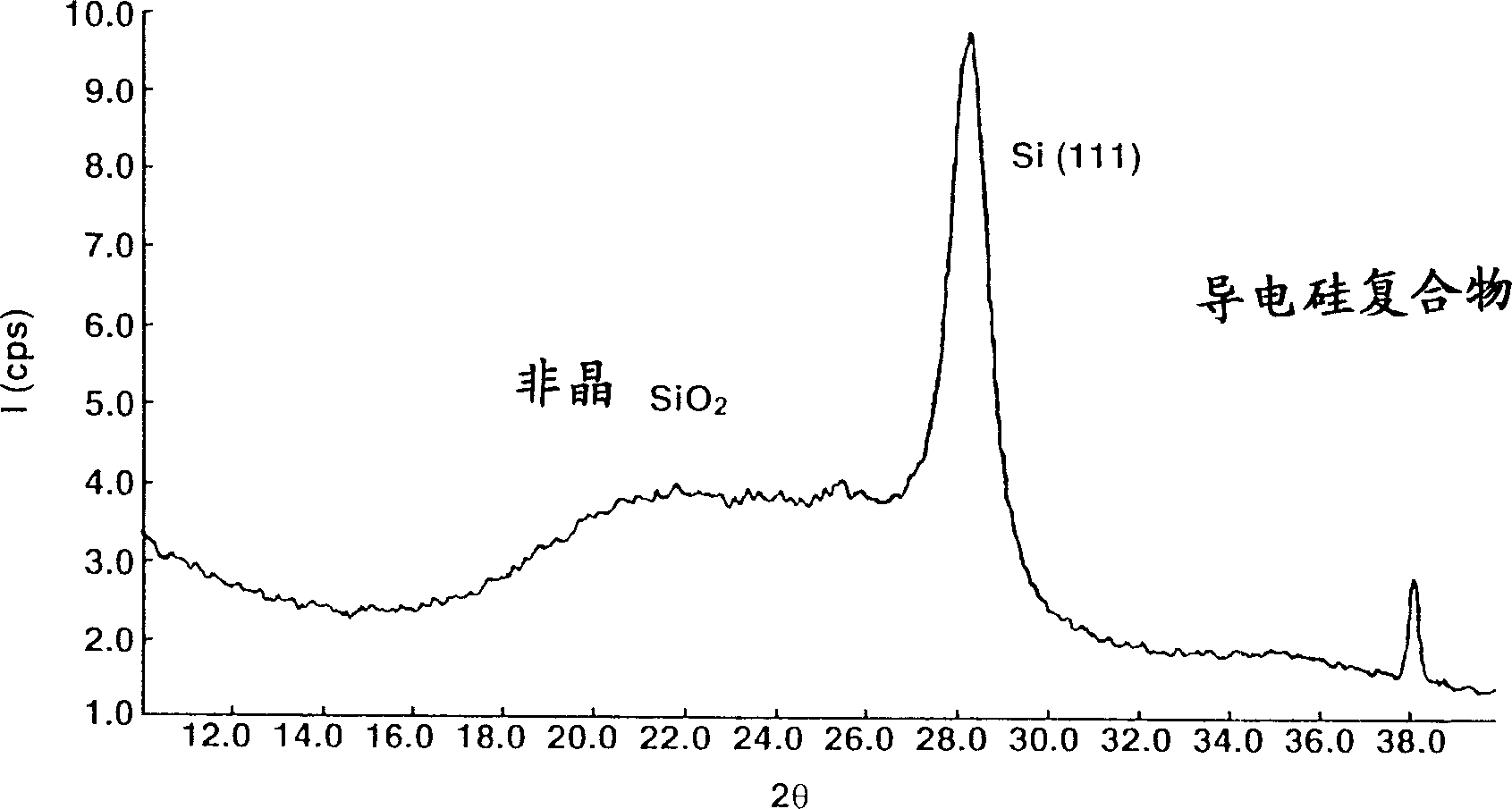

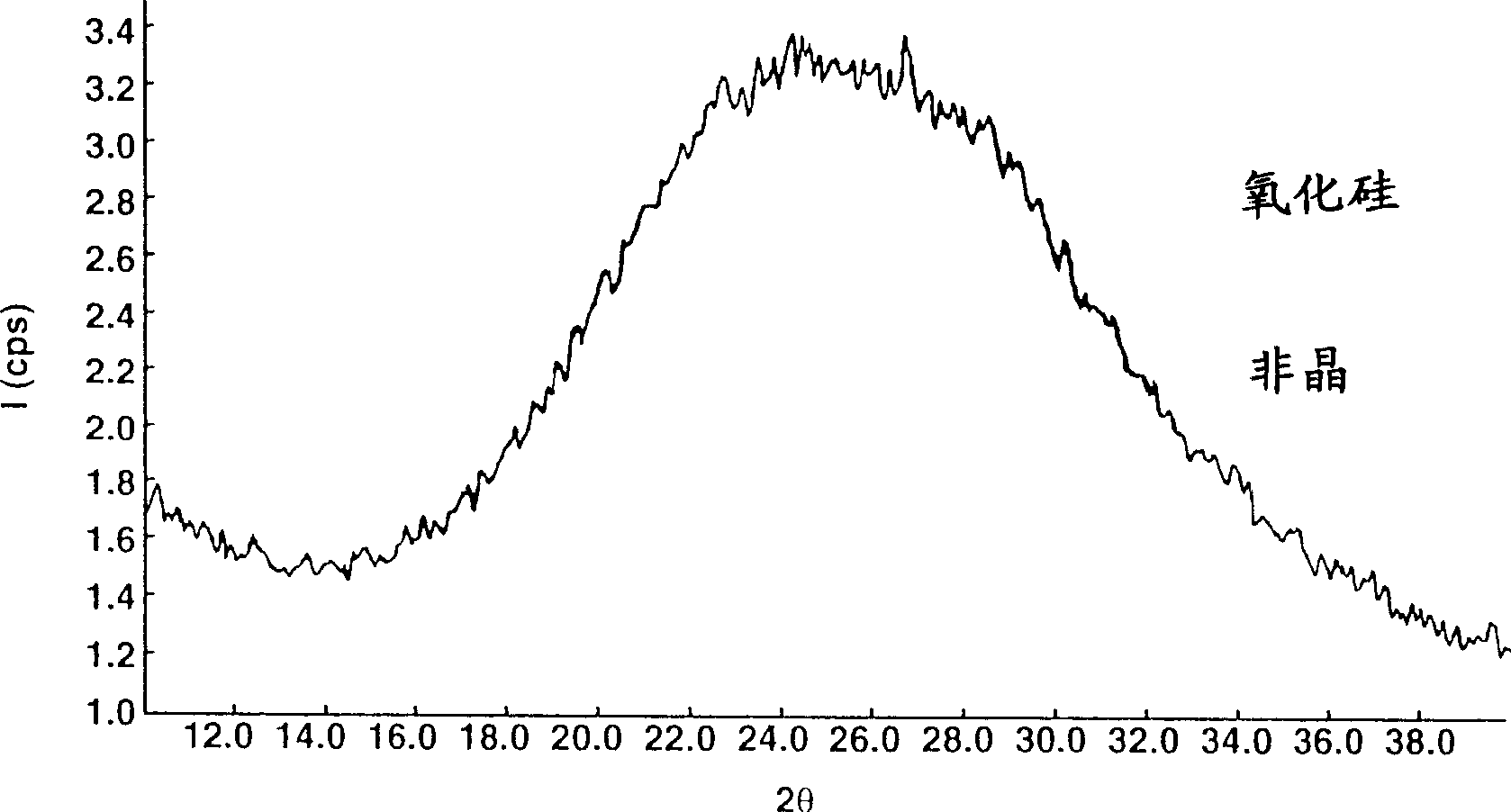

Conductive silicon compound, its preparation and negative electrode material of non-aqueous electrolyte secondary battery

InactiveCN1513922AImprove cycle performanceAvoid defectsMaterial nanotechnologyInorganic pigment treatmentSilicon dioxideSilicon

A conductive silicon composite in which particles having a structure in which crystallites of silicon are dispersed in silicon dioxide are coated on their surfaces with carbon affords satisfactory cycle performance when used as the negative electrode material in a non-aqueous electrolyte secondary cell.

Owner:SHIN ETSU CHEM IND CO LTD

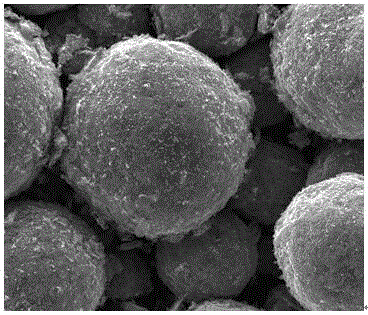

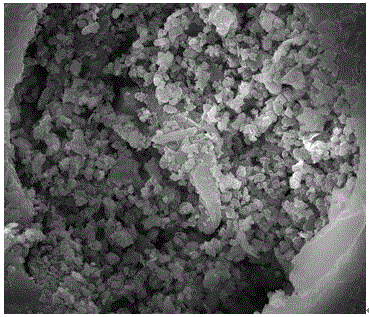

Spherical porous silicon/carbon composite material as well as preparation method and application thereof

InactiveCN106711461AHigh specific capacityPromote circulationCell electrodesCarbon compositesAdhesive

The invention discloses a spherical porous silicon / carbon composite material as well as a preparation method and application thereof. The spherical porous silicon / carbon composite material is structurally characterized in that a SiOx / C matrix, graphite with small particle size and a conductive agent are dispersed in porous amorphous carbon, wherein the average particle diameter is 12-25mu m; the method comprises the following steps of carrying out first coating on a SiOx raw material with powder pitch, and performing heat treatment so as to obtain a SiOx / C material; then performing ball milling by use of a wet method so as to reduce the particle diameter of powder, adding a carbon source adhesive, the graphite with the small particle diameter and the conductive agent, and performing high-speed dispersion, thereby obtaining pulp; and finally performing spray granulation and sintering on the pulp, thereby obtaining the final spherical porous silicon / carbon composite material. According to the invention, SiOx is dispersed in cracking carbon, the graphite and the conductive agent, so that SiOx volume expansion during a charge / discharge process is buffered, and the conductibility is enhanced; by virtue of the porous structure, the imbibition rate and cycle performance of the material can be effectively improved; by virtue of bitumencarb coating and high-heat treatment performed in advance, SiOx is prevented from being directly contacted with an electrolyte, and furthermore, the stability and first efficiency of the silicon / carbon material are improved.

Owner:ZHONGTIAN ENERGY STORAGE TECH

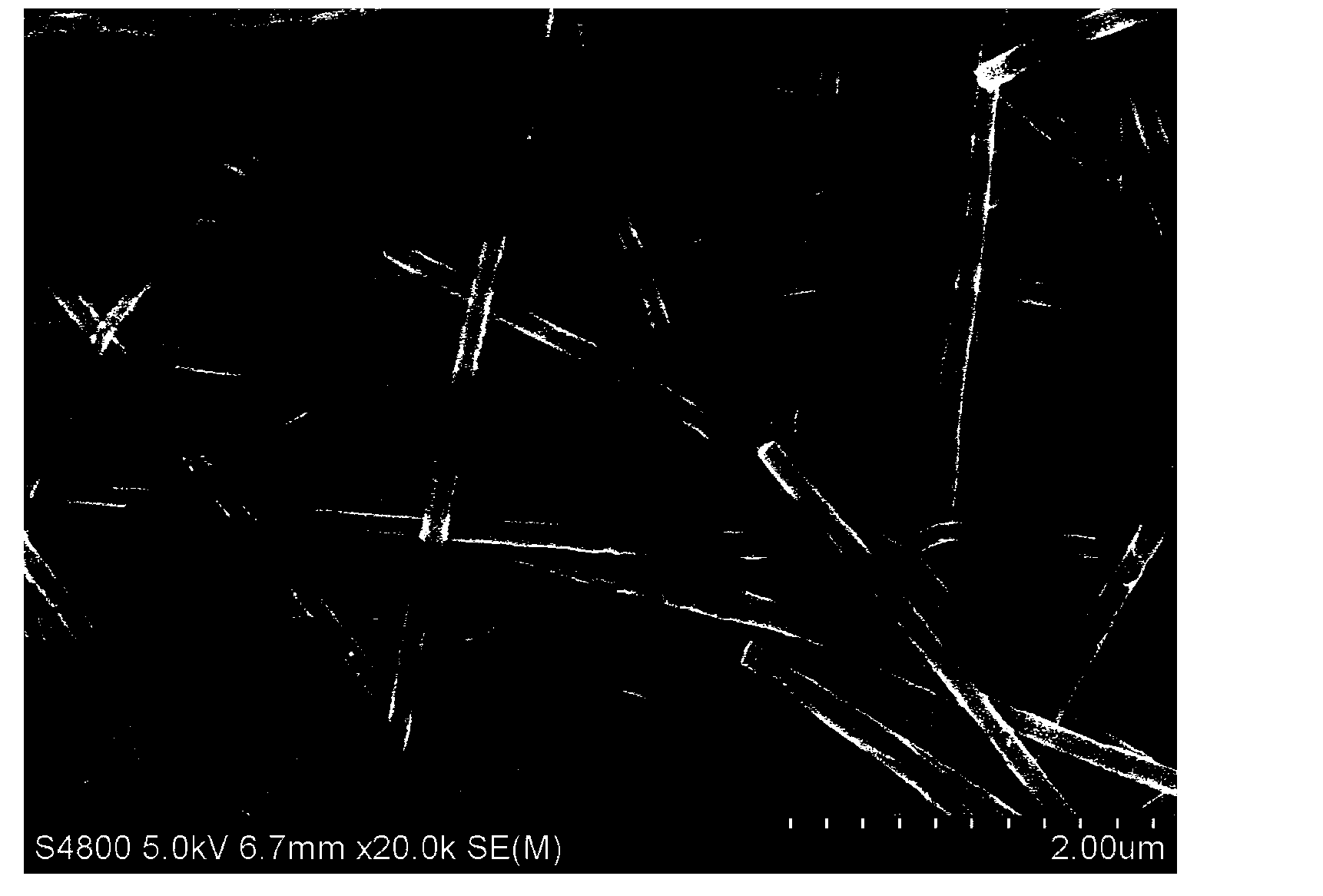

Convenient method for preparing binder-free stannic oxide/carbon fibrofelt for negative pole of high-performance lithium ion battery

InactiveCN104319372AImprove mechanical stabilityInhibition of agglomerationCell electrodesCarbon fibersElectrospinning

The invention discloses a convenient method for preparing binder-free stannic oxide / carbon fibrofelt for a negative pole of a high-performance lithium ion battery. The method disclosed by the invention comprises the following steps: dissolving polyacrylonitrile and stannous chloride which have certain concentrations to a N'N-dimethyl formamide solution, magnetically stirring the solution of polyacrylonitrile, the stannous chloride and the N'N-dimethyl formamide solution until the solution is clarified, electrostatically spinning the solution, and finally annealing the obtained solution which is obtained at a high temperature twice to obtain Sn-SnOx uniformly loaded nanometer composite materials of the carbon fibrofelt. For a compound which is prepared by the method disclosed by the invention, since the electrostatic spinning method is adopted, nanometer particles of metal-metallic oxide are uniformly dispersed into buffer substrate carbon fiber, and the circulation specific capacity and the stability of materials for the negative pole of the lithium ion battery are effectively improved. The preparation technology disclosed by the invention has the advantages that the operation is simple, the cost is low, the efficiency is high, the large-scale and industrial production is easy to realize, and the application range is broad.

Owner:HUNAN UNIV

Preparation method of lithium ion battery porous silicon carbon composite negative material

InactiveCN102709565AInhibition of volume changeSmall volume changeCell electrodesAcid etchingCarbon composites

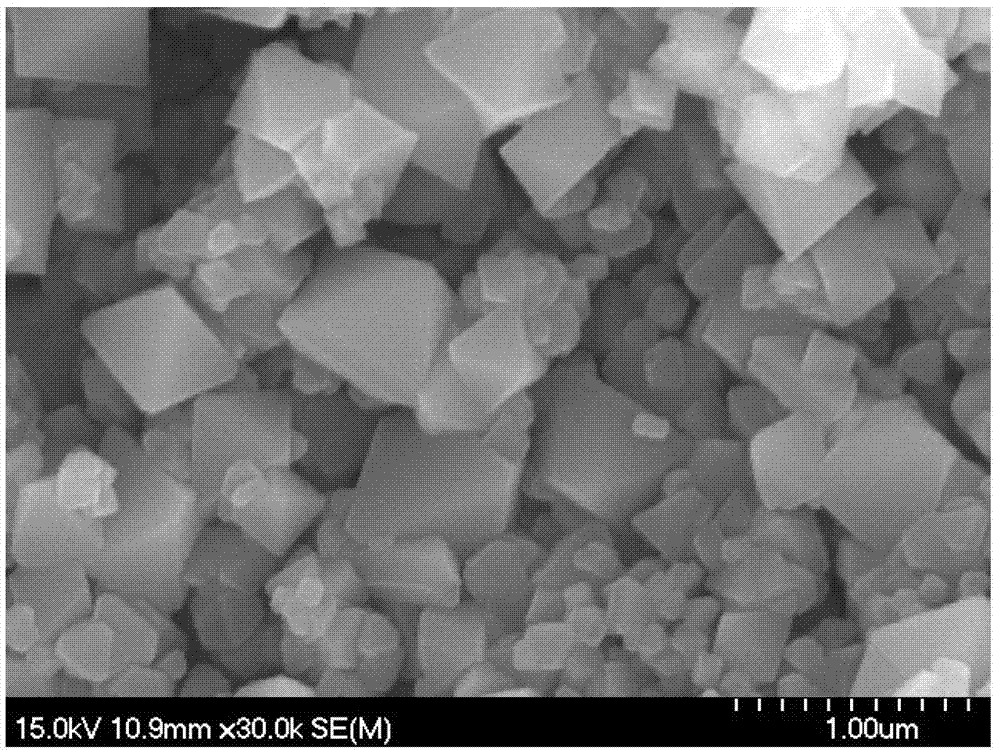

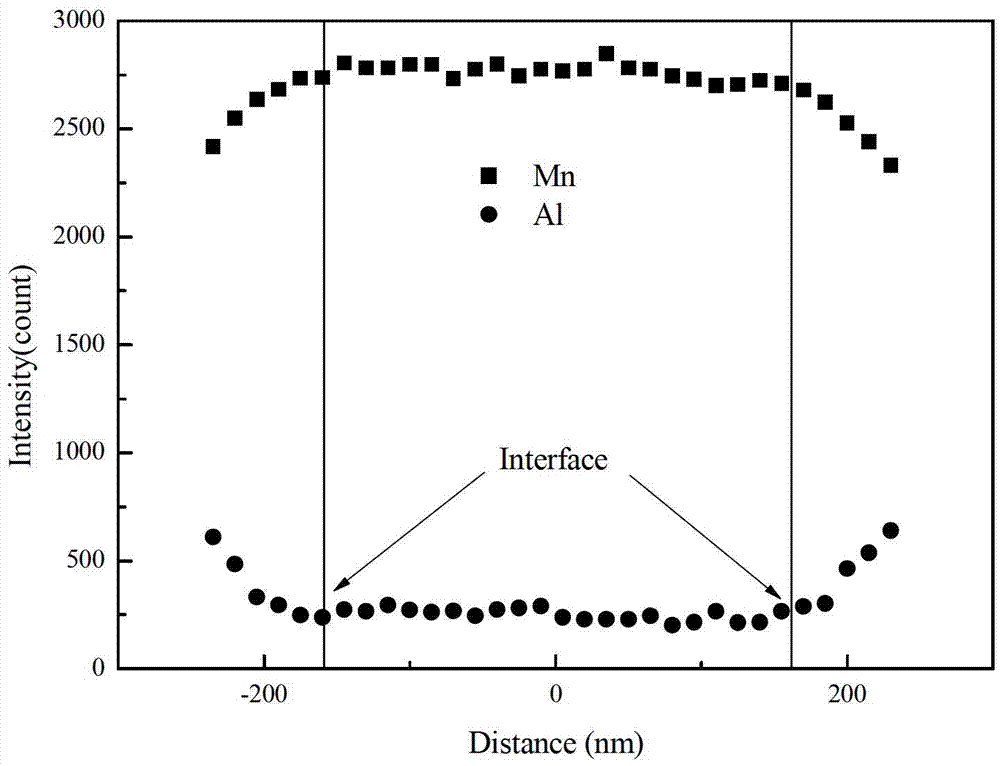

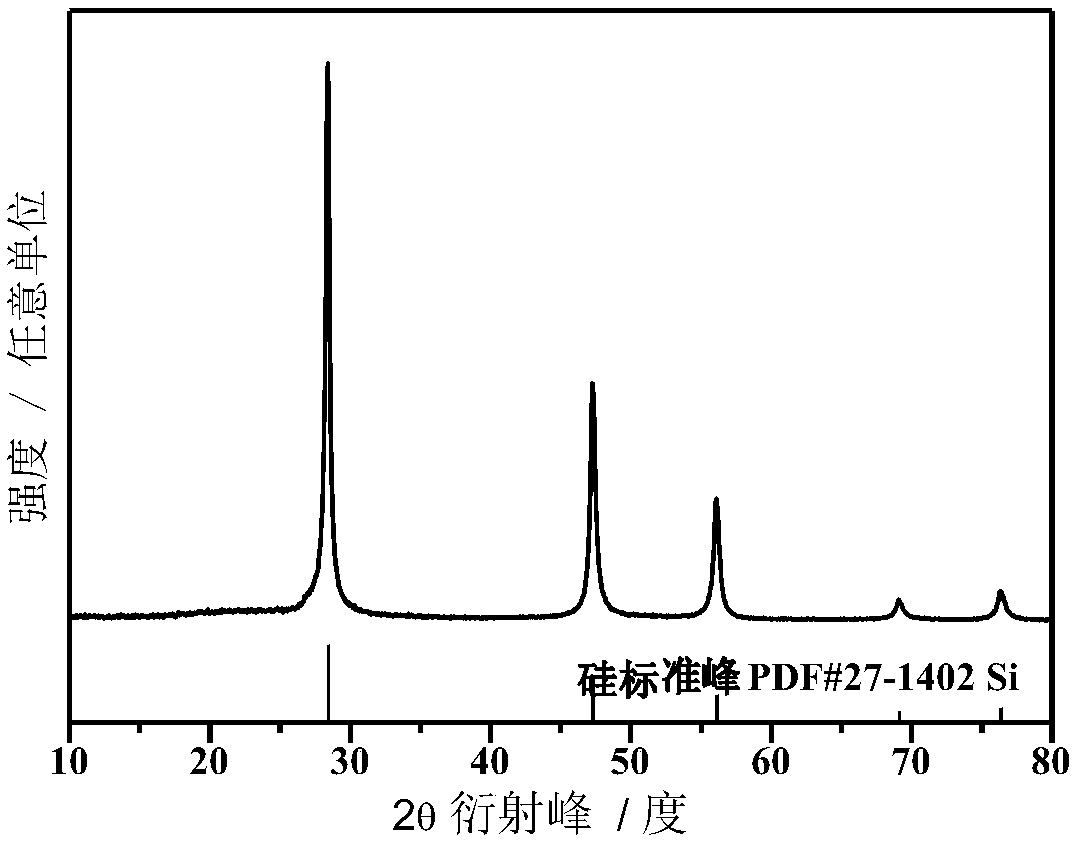

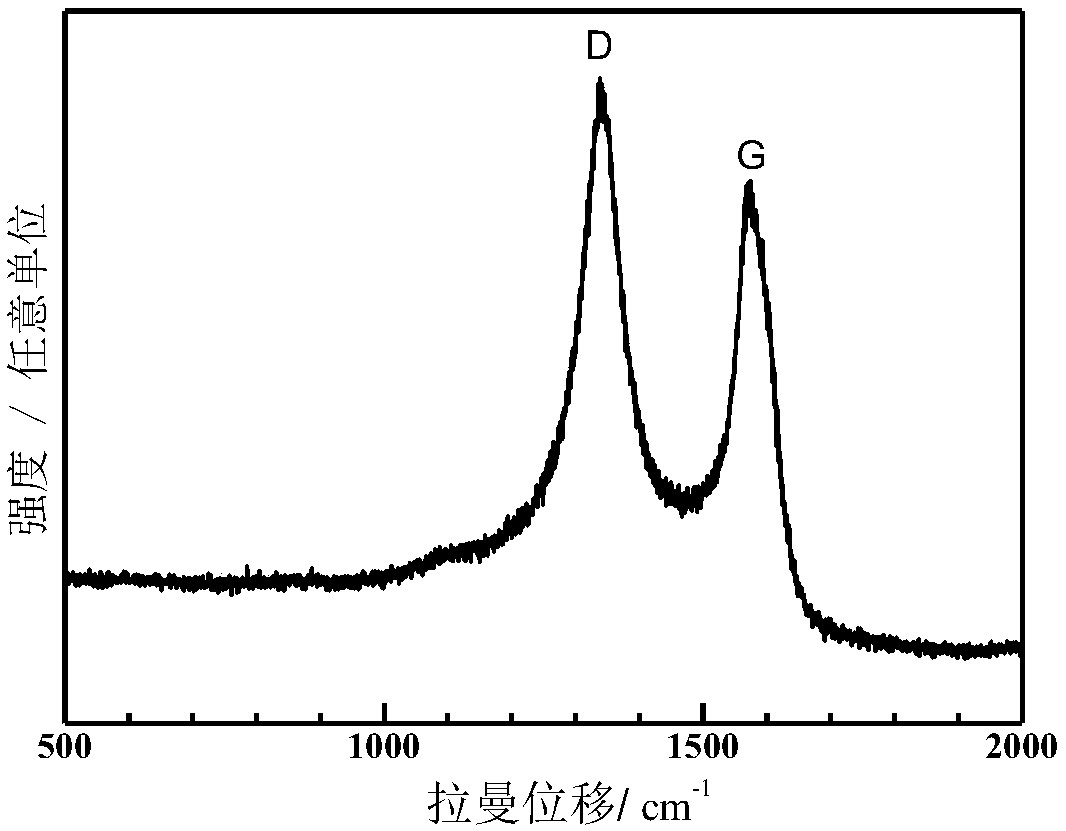

The invention puts forwards a preparation method of a lithium ion battery porous silicon carbon composite negative material. The prepared porous silicon carbon composite material simultaneously has the characteristics of high capacity and excellent circulating stability. Micron silicon and nanometer aluminum powder are promoted to be compounded by utilizing a high-energy ball milling method, a porous silicon material can be formed through acid etching, and through a porous structure, the volume change of silicon in the discharging process is relieved to a great extent. Meanwhile, the stress generated by the volume change of the silicon can be effectively buffered through taking graphite as a dispersion matrix and in combination with a secondary surface amorphous carbon coating technology of the composite material, so that the circulating stability of the material is improved. The preparation method of the material has the advantages of simplicity, low cost and easiness in industrial production.

Owner:力芯(青岛)新能源材料有限公司

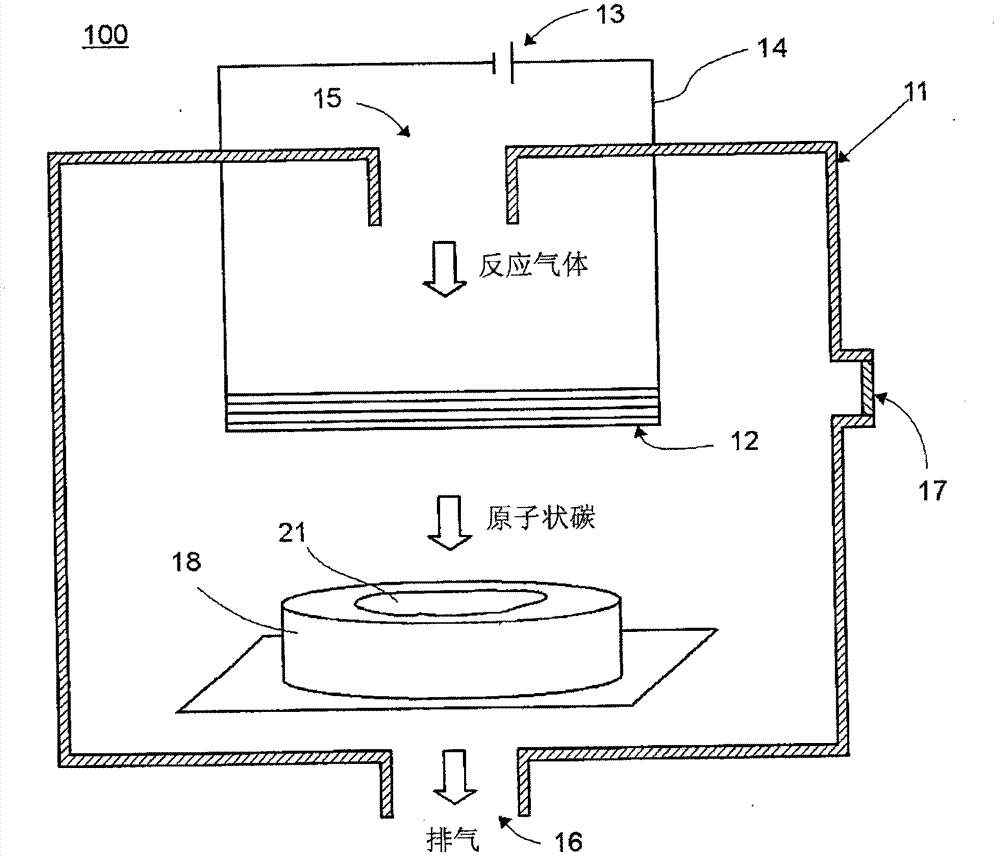

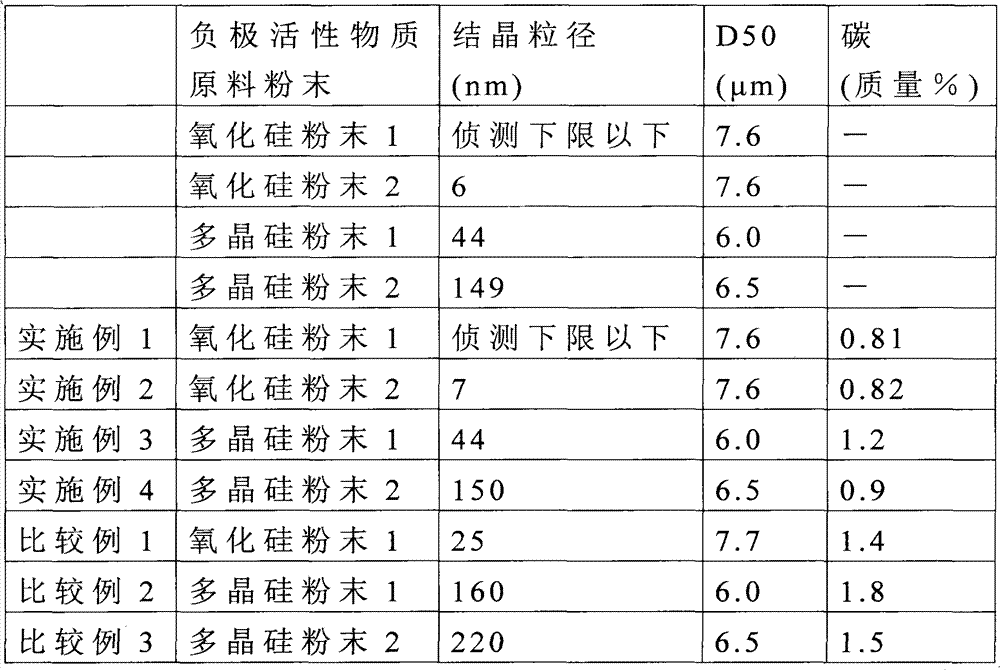

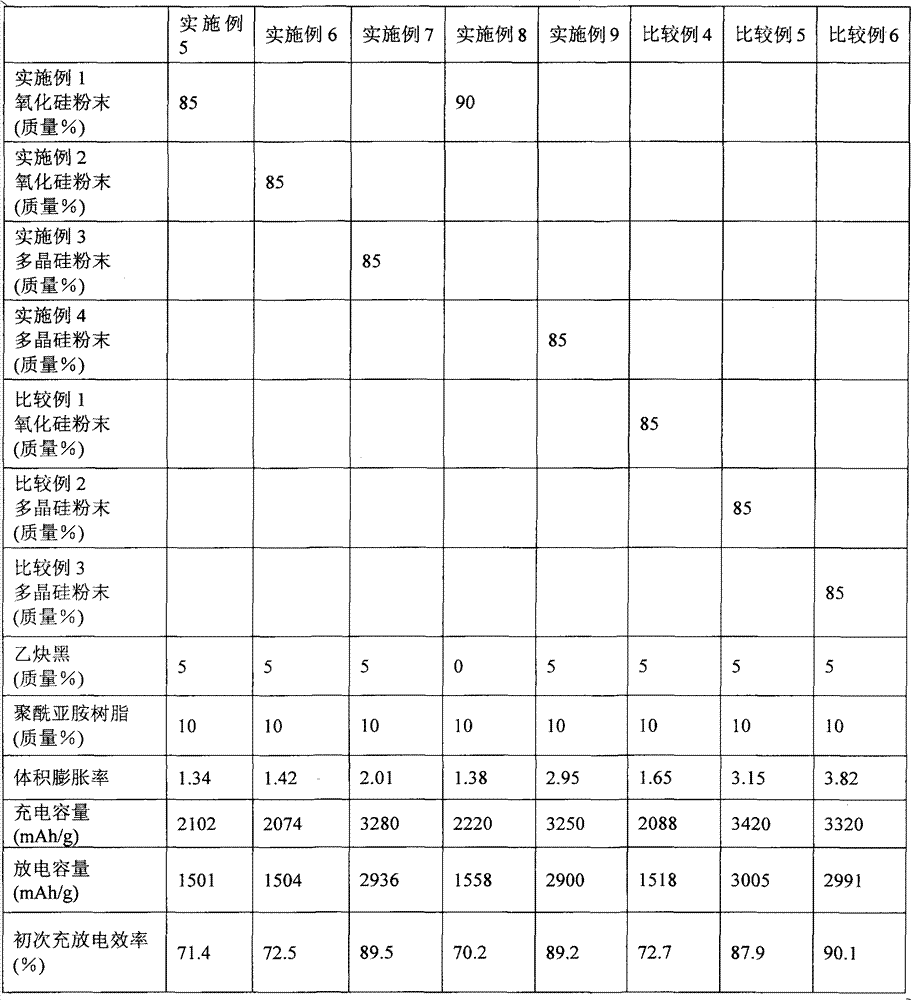

Method for manufacturing negative electrode active material for use in non-aqueous electrolyte secondary battery, negative electrode material for use in non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery

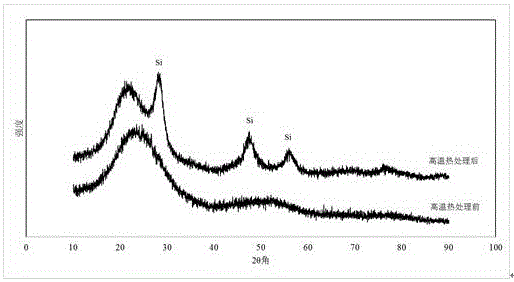

ActiveCN102738440AImprove conductivityIncreased crystal sizeElectrode manufacturing processesSiliconSilicon oxideCarbon coated

The present invention provides a method for manufacturing a carbon-coated negative electrode active material for use in a non-aqueous electrolyte secondary battery, wherein a negative electrode active raw material including at least one of silicon oxide powder and silicon powder is coated with carbon by a catalytic CVD method. The present invention also provides a negative electrode material for use in a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery using the negative electrode active material. As a result, there is provided a method for manufacturing a negative electrode active material for use in a non-aqueous electrolyte secondary battery in which high battery capacity given by the silicon-based active material is maintained and a volume expansion and a break in the active material are suppressed.

Owner:SHIN ETSU CHEM CO LTD

Tin cobalt alloy/ graphene composite material and preparation method thereof

InactiveCN104064739AInhibition of volume changeAlleviate volume changesCell electrodesSecondary cellsSolventGlycol synthesis

The invention discloses a tin cobalt alloy / graphene composite material and a preparation method of the tin cobalt alloy / graphene composite material. The preparation method of the tin cobalt alloy / graphene composite material includes the following steps that firstly, graphene oxide is dispersed into methyl alcohol or ethylalcohol or ethylene glycol or diethylene glycol, and then suspension liquid is prepared; secondly, cobalt salt and tin slat of which the mass ratio of the sum of mass to the mass of graphene oxide ranges from 60:1 to 30:1 dissolve in the suspension liquid prepared through the first step, wherein the molar ratio of a cobalt element to a tin element ranges from 1: 0.66 to 1:3; thirdly, a sodium borohydride alcoholic solution of which the concentration ranges from 1 mol / L to 2.5 mol / L is prepared, alcohol used in the first step is used in this step, the sodium borohydride alcoholic solution is mixed with the suspension liquid obtained through the second step, nitrogen is injected, and after 10 minutes of bubbling, solvent heat treatment is conducted, wherein solvent heat treatment refers to the process that a mixture reacts for 6 h to 12 h at the temperature of 100 DEG C to 160 DEG C in a closed reaction kettle and then is cooled to the room temperature, and the molar ratio of the cobalt element in sodium borohydride to the cobalt element in the cobalt salt is 6-13 to 1; fourthly, a sample obtained in the third step is repeatedly washed centrifugally in ethyl alcohol and deionized water, and a product is obtained after vacuum drying.

Owner:CHANGSHA GUORONG NEW ENERGY

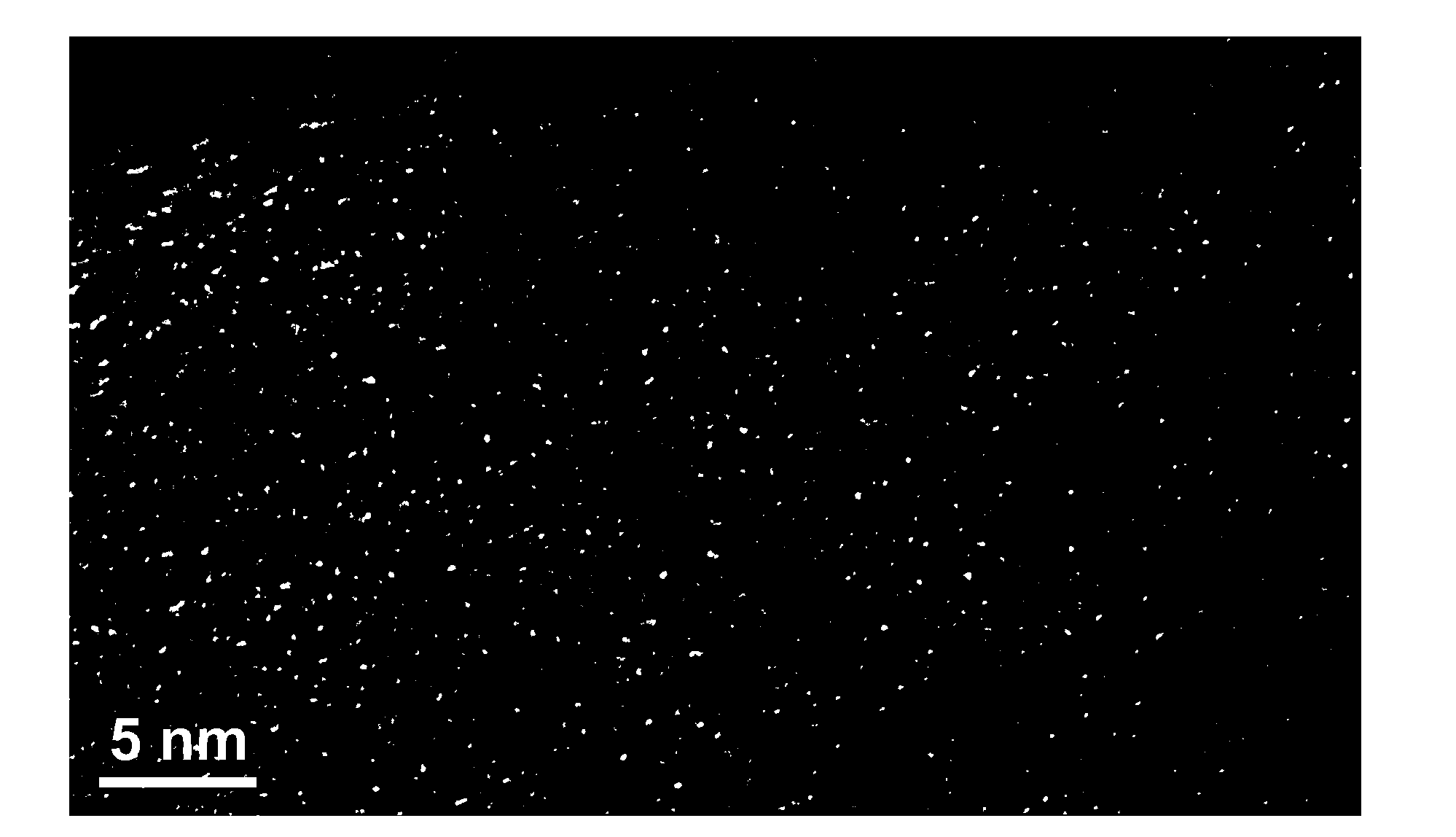

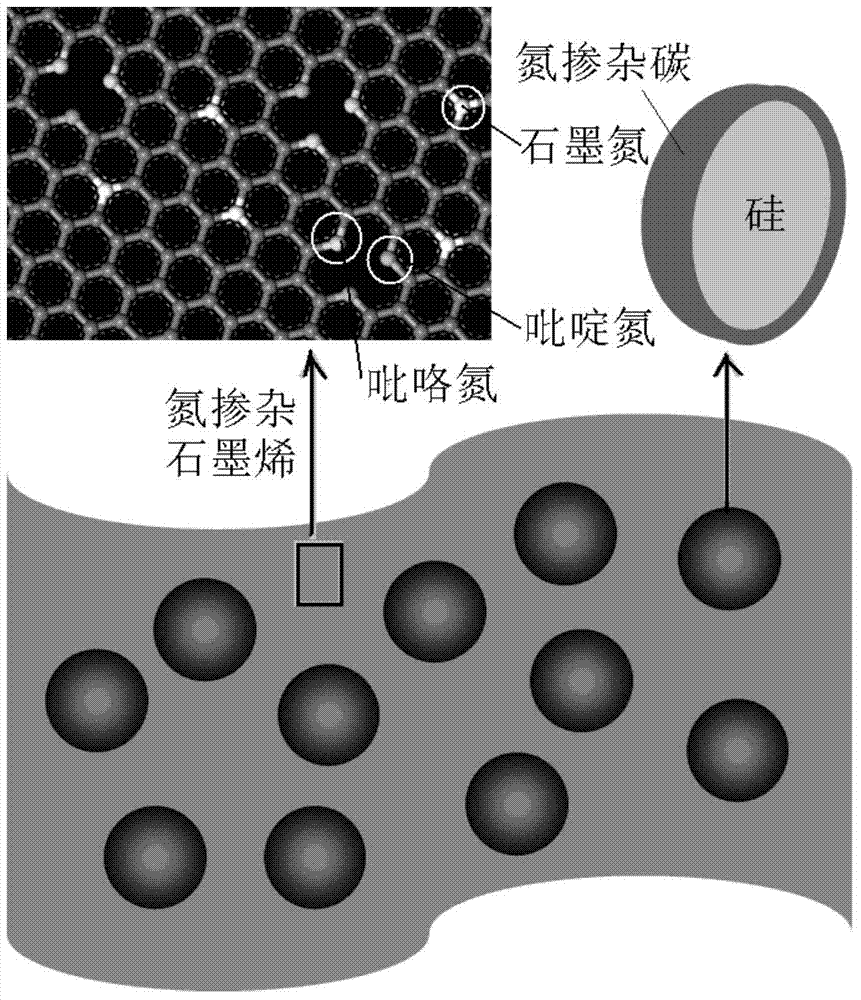

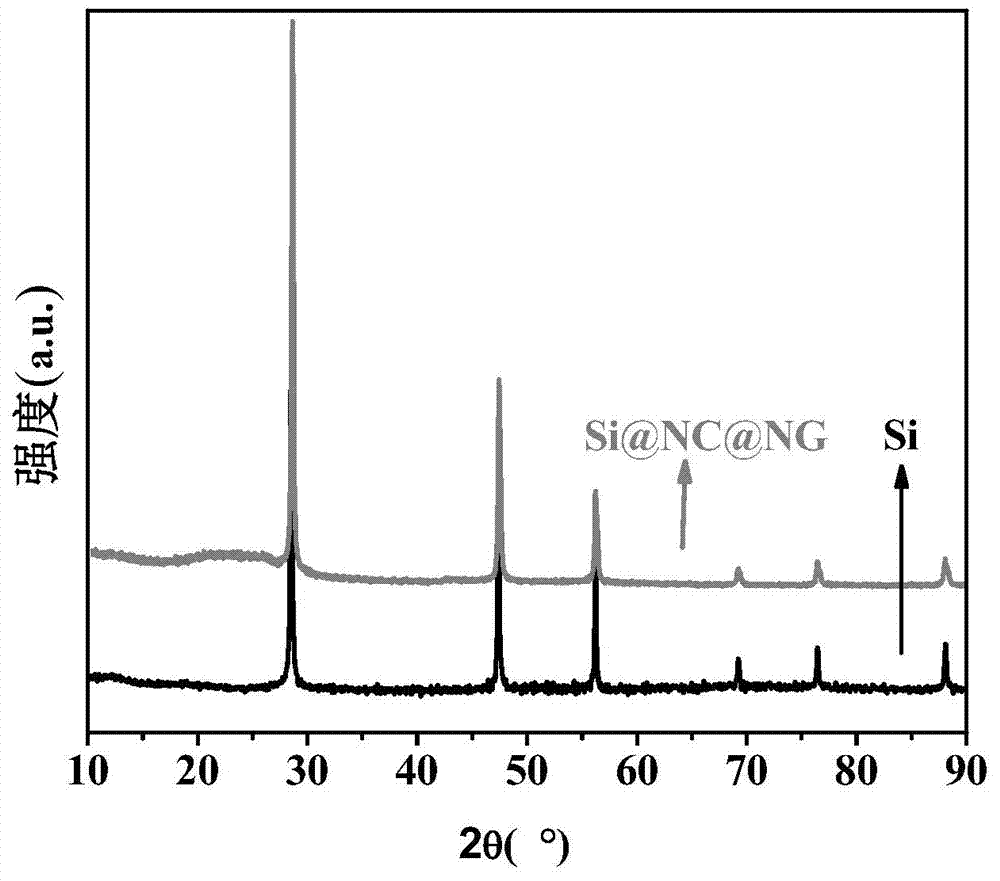

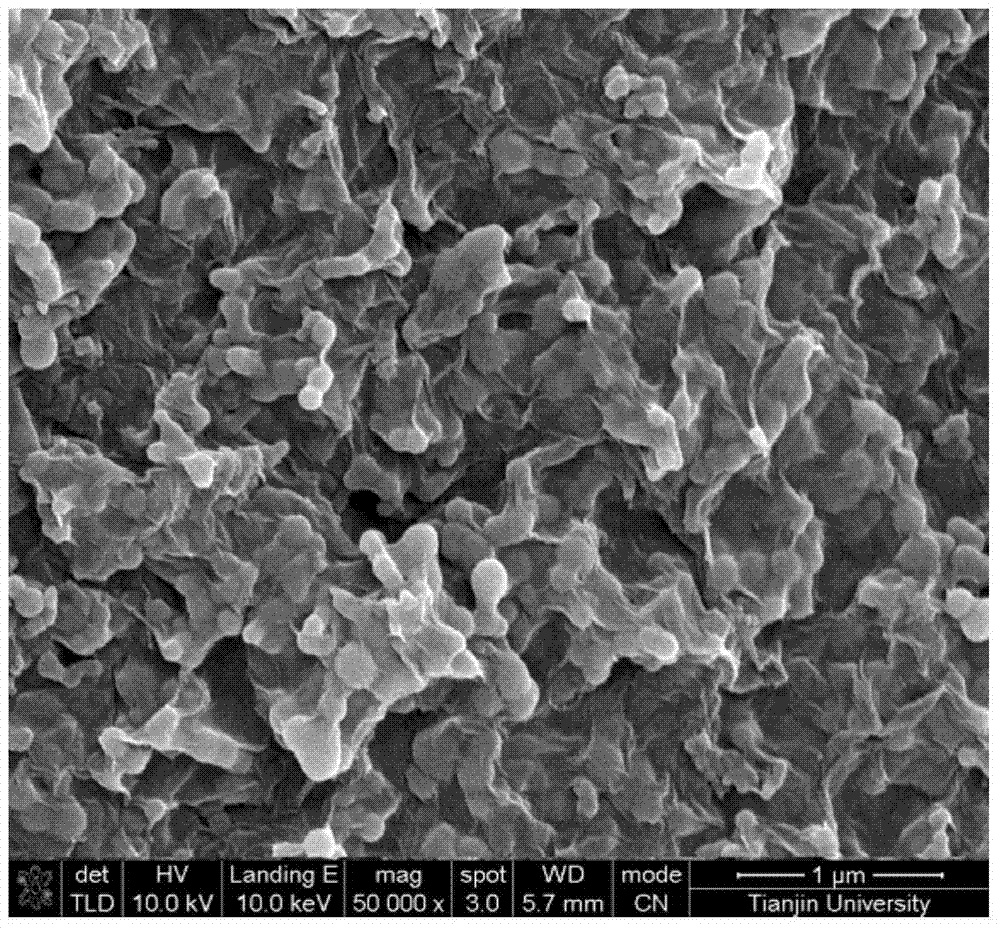

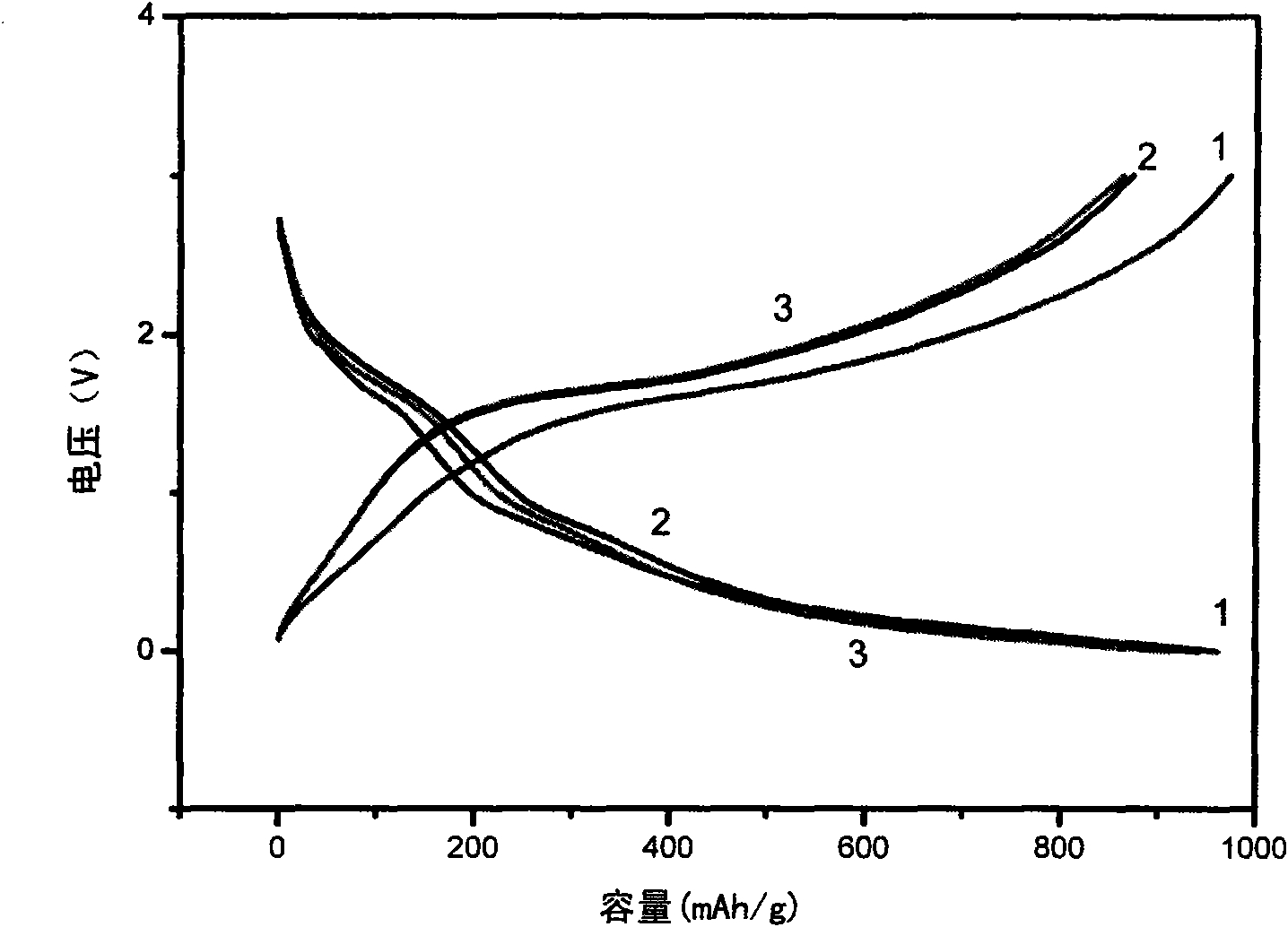

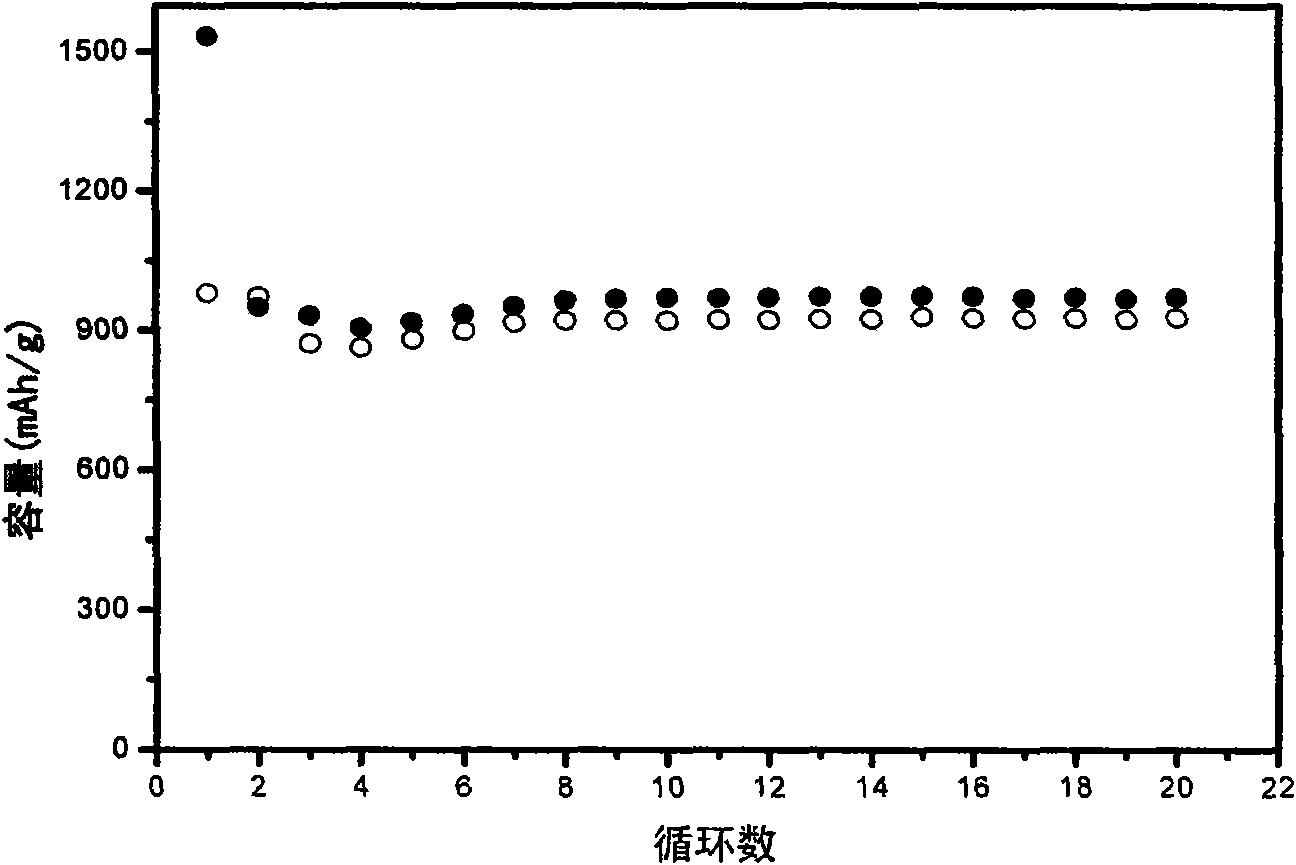

Silicon-nitrogen doped carbon-nitrogen doped graphene composite material, and preparation method and application thereof

InactiveCN104716321AAvoid reunionInhibition of volume changeCell electrodesSecondary cellsCarbon layerDoped graphene

The invention discloses a silicon-nitrogen doped carbon-nitrogen doped graphene composite material. The silicon-nitrogen doped carbon-nitrogen doped graphene composite material is formed by graphene oxide, a nitrogen-containing carbon source and silicon, wherein a mass ratio of graphene oxide to the nitrogen-containing carbon source to silicon is 1-4:2:2-6; and nitrogen doped carbon with a core-shell structure is obtained through a solution mixing process and a high temperature charring process, and coats silicon particles, and the nitrogen doped carbon coated silicon particles are uniformly inlaid in nitrogen doped graphene interlayer. A preparation method of the composite material comprises the following steps: adding a nitrogen-containing carbon source solution into a silicon dispersion, and carrying out stirring ultrasonic treatment; adding a graphene oxide dispersion solution to the above obtained mixed solution in the ultrasonic process; and carrying out stirring heating, evaporation pulping, freeze drying and high temperature charring in order to obtain the silicon-nitrogen doped carbon-nitrogen doped graphene composite material. The nitrogen-containing carbon source is used to form a carbon layer on the surface of silicon particles and realize nitrogen doping of the carbon layer and graphene, the preparation process is simple, controllable and environmentally-friendly, and the composite material greatly improves the integral electrochemical performances.

Owner:TIANJIN UNIV

Anode material for lithium ion battery and preparation method thereof

ActiveCN102044674AImprove electrochemical performanceAlleviate volume changesCell electrodesCopper organic compoundsAluminium-ion batterySodium-ion battery

The invention relates to an anode material for a lithium ion battery, which is a complex formed by an organic compound and a metal or metalloid material. The invention also provides a preparation method of the anode material, comprising the steps of: uniformly mixing the metal or metalloid material and the organic compound under an atmospheric pressure within a temperature range of 0-25 DEG C andadding an oxidizing agent to obtain the required complex of the organic compound and the metal or metalloid material. According to the invention, the complex compound can be directly used as the anode material of a lithium ion battery and can be also mixed with other lithium storing materials in a proportion of 1-99 wt%; the anode material has very high lithium storing capacity and good circulating performance without being subjected to a plurality of circulations, can improve the electrical contact and adhering performances among electrode material particles as well as between an electrode material and a current collector, can effectively restrain the volume change of the electrode material in a charge-discharge process, can slow down the capacity attenuation of the electrode material, and can prolong the circulating life of the constituted battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

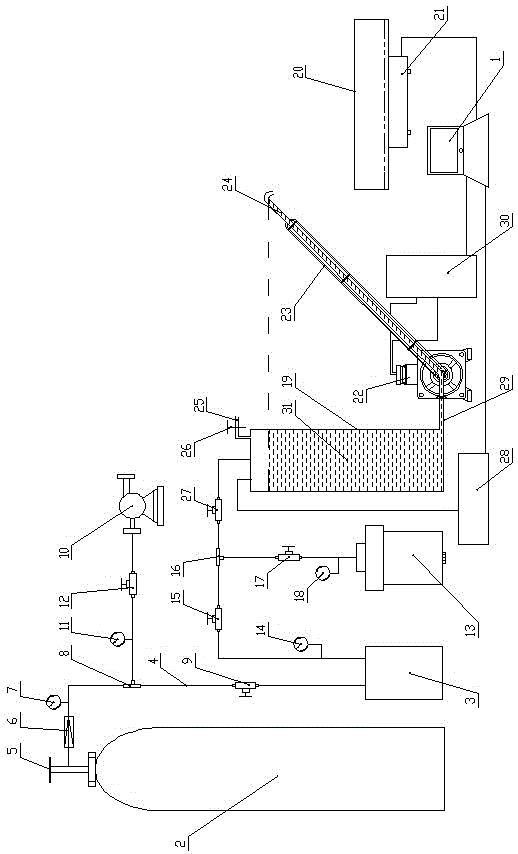

Servo measuring testing system and method for coal sample gas adsorption and desorption

ActiveCN105547907AShow desorptionDisplay ratePermeability/surface area analysisMeasurement deviceLiquid water

Provided are a servo measuring testing system and method for coal sample gas adsorption and desorption. The system comprises a gas supply device, a vacuumizing device, a gas adsorption device, a gas desorption measurement device and an electric control device; the gas supply device comprises a high-pressure gas tank and a gasing tank; the vacuumizing device comprises a vacuum pump and a vacuum meter; the gas adsorption device comprises a coal sample tank, and the gas desorption measurement device comprises a water storage container, a water collection container, an electronic balance, a servo motor, a fixed support and a water guide pipe. According to the servo measuring testing system and method for coal sample gas adsorption and desorption, volume measurement of desorbed gas is converted into volume measurement of liquid water, test operation is easy and convenient, test data is accurate, and real-time precise automatic collection and real-time display of the test data are achieved; in addition, it is guaranteed that the gas desorbed from a coal sample is under the condition of one atmospheric pressure, and a more reliable data basis is provided for researching the coal-mass gas adsorption and desorption rule.

Owner:HENAN POLYTECHNIC UNIV

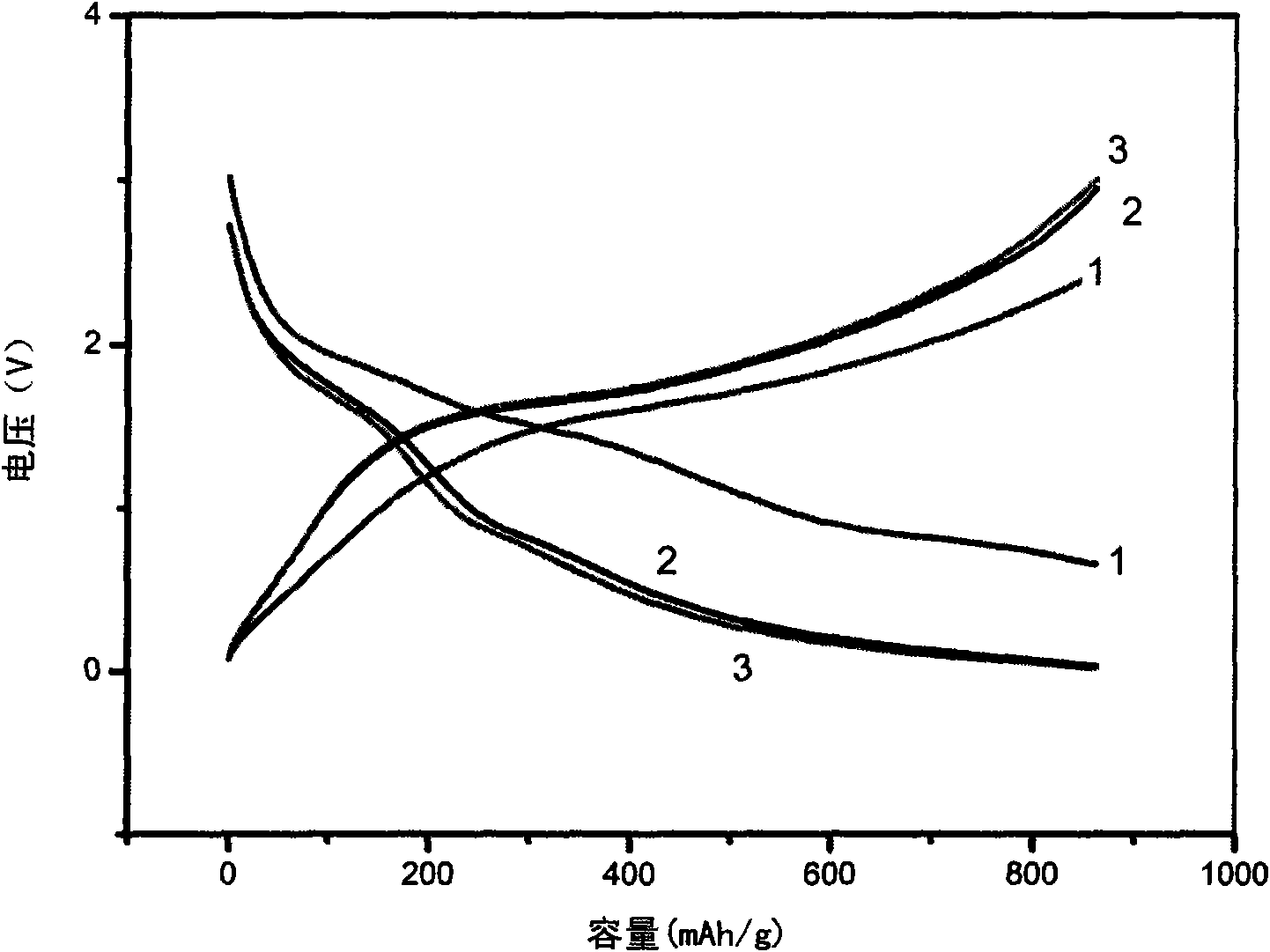

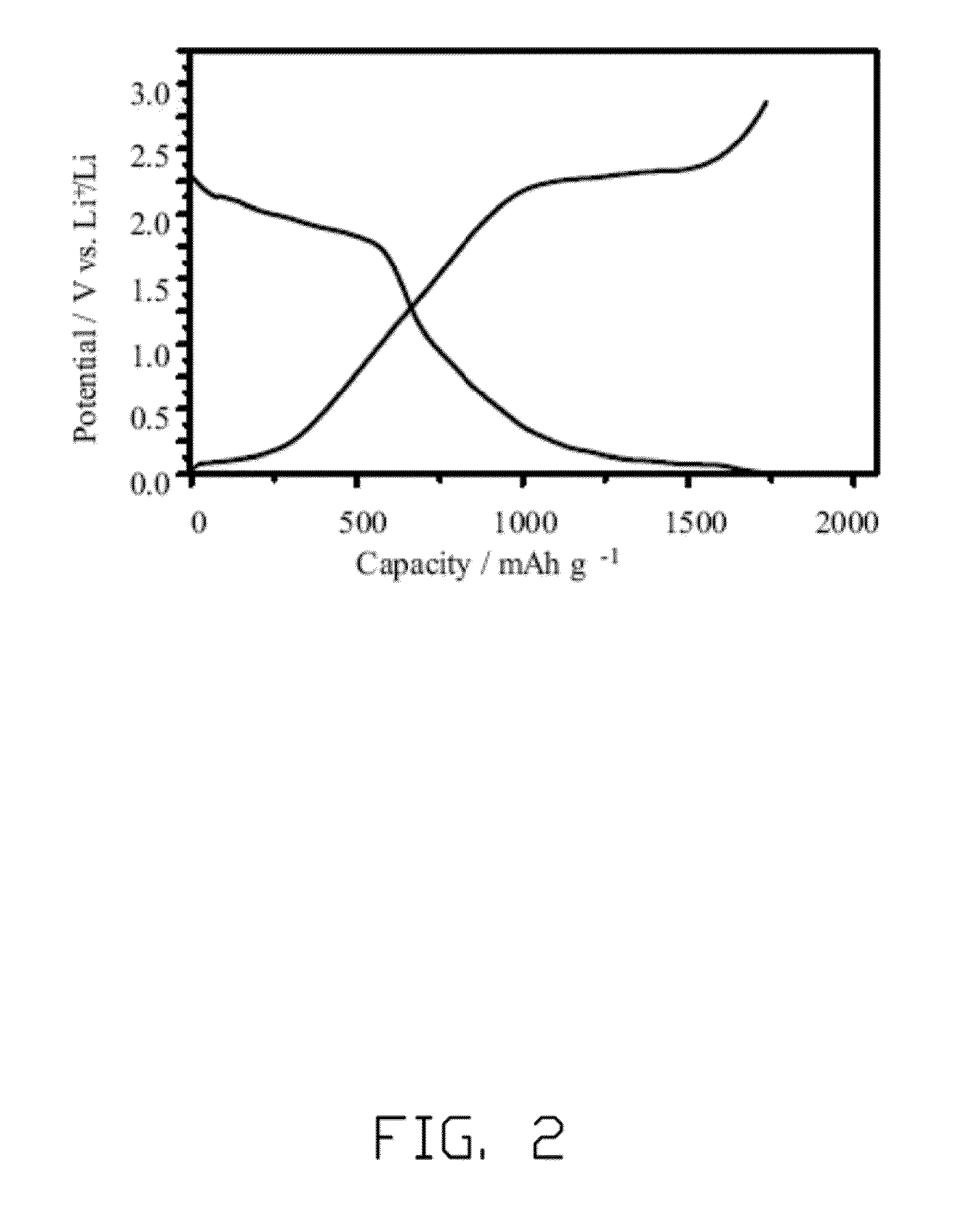

Cycling method for sulfur composite lithium ion battery

ActiveUS20130307485A1Improve efficiencyImprove retentionBatteries circuit arrangementsCell electrodesVoltage rangeCharge and discharge

A method for cycling a sulfur composite lithium ion battery includes a step of charging and discharging the sulfur composite lithium ion battery at a first voltage range between a predetermined highest voltage and a predetermined lowest voltage. The lithium ion battery includes an electrode active material. The electrode active material includes a sulfur composite. The step of charging and discharging satisfies at least one conditions of (1) and (2): (1) the predetermined lowest voltage of the first voltage range is larger than a discharge cutoff voltage of the sulfur composite; and (2) the predetermined highest voltage of the first voltage range is smaller than a charge cutoff voltage of the sulfur composite. A method for using a sulfur composite as an electrode active material of a lithium ion battery is also disclosed.

Owner:TSINGHUA UNIV +1

Transient electronic devices comprising inorganic or hybrid inorganic and organic substrates and encapsulates

ActiveUS9496229B2Useful overall permeabilityInhibition of volume changeFinal product manufactureSemiconductor/solid-state device detailsElectricitySingle crystal

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

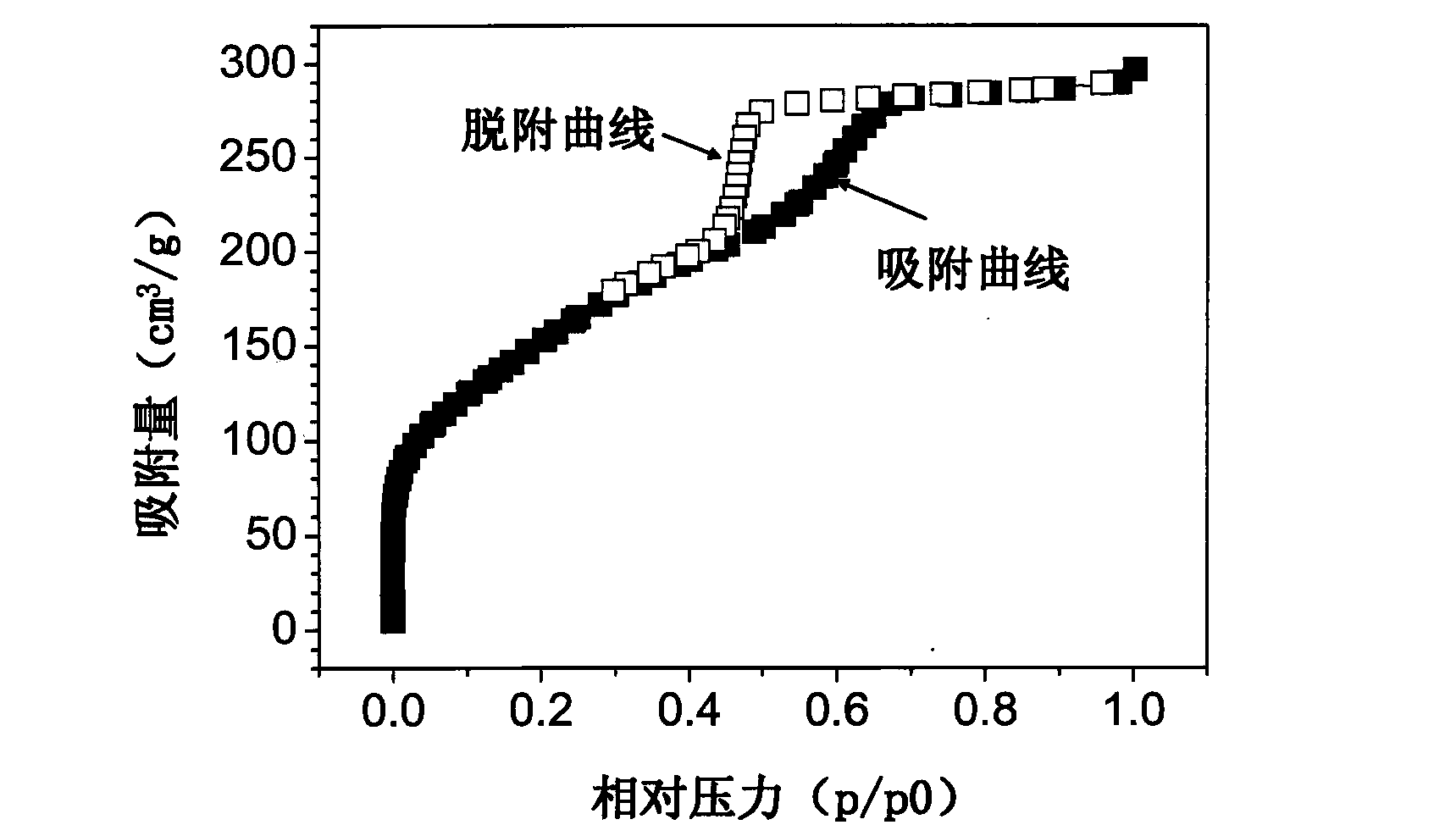

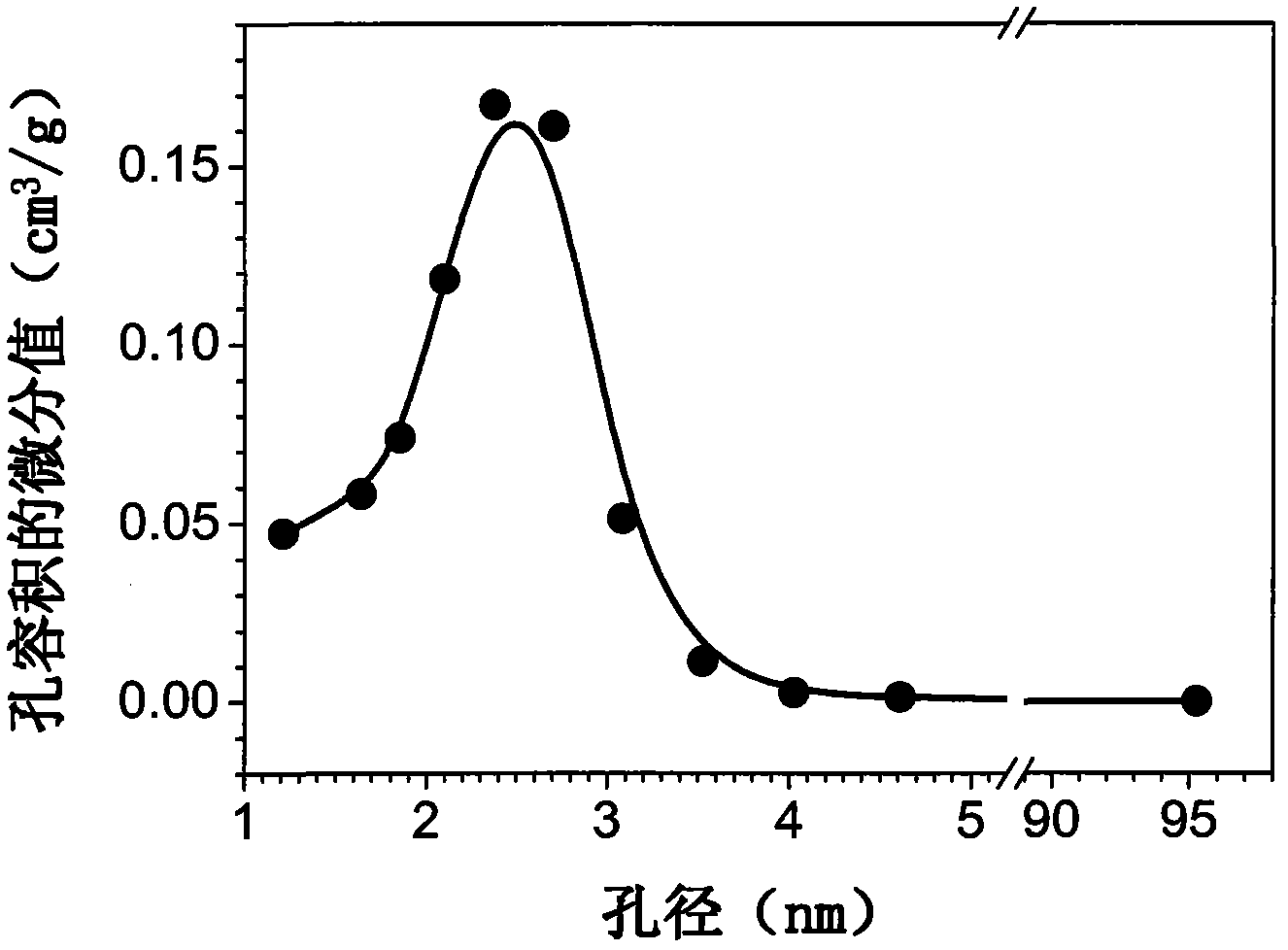

Mesoporous carbon/silicon composite anode material and preparation method thereof

InactiveCN102867944AIncrease capacityInhibition of volume changeCell electrodesElectrical batteryElectric vehicle

The invention discloses a novel mesoporous carbon / silicon composite anode material and a preparation method thereof. The mesoporous carbon / silicon composite anode material is provided with a mesoporous structure, the molar ratio of carbon to silicon in the composite material ranges from 1:99-99:1, and the silicon is one or more of Si or SiOx (0<x<2). The carbon and the silicon in the material are horizontally compounded, ultrahigh theoretical capacity of the silicon is effectively used, and huge volume change of silicon atoms in repeated charge-discharge process is avoided. The capacity of the anode material is increased, and the cycle performance is importantly improved. The material can be used as an electrode material with high capacity and excellent cycle performance for a lithium ion secondary battery, and development of an electric vehicle can be promoted.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

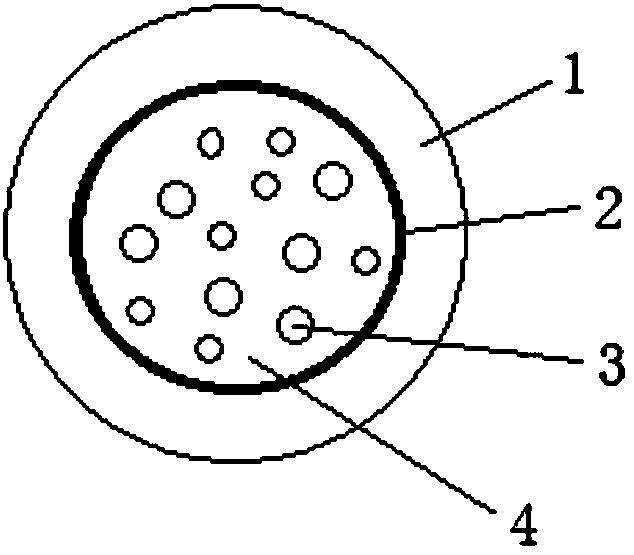

Core-shell-structured silicon carbon negative electrode material and preparation method therefor

ActiveCN107863512ASolve the disadvantages of low first-time Coulombic efficiencyInhibition of volume changeCell electrodesSecondary cellsCarbon dotCoating

The invention discloses a core-shell-structured silicon carbon negative electrode material and a preparation method therefor. The silicon carbon negative electrode material comprise a core, a buffer layer and a shell from inside to outside in sequence; the core material consists of SiO, Si, SiO<2> and silicate; the buffer layer material comprises carbon dots or graphene quantum dots; and the shellmaterial is a hard carbon material. The core material disclosed in the invention comprises a modified SiO material; through a high-temperature reaction between SiO and NaOH, nanometer silicon and sodium silicate are generated, so that the shortcoming of low initial coulombic efficiency caused by a reaction between SiO and Li in the initial charging process can be solved; meanwhile, by taking thegenerated sodium silicate as a buffer medium, volume change of the material in the lithium de-intercalation process can be suppressed effectively, and cycle performance of the electrode can be improved; and by taking conductive carbon as a coating layer and by introducing the carbon dots or graphene quantum dots, the material conductivity is improved and a buffer effect can be played, thereby realizing stable cycle performance and high reversible capacity of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

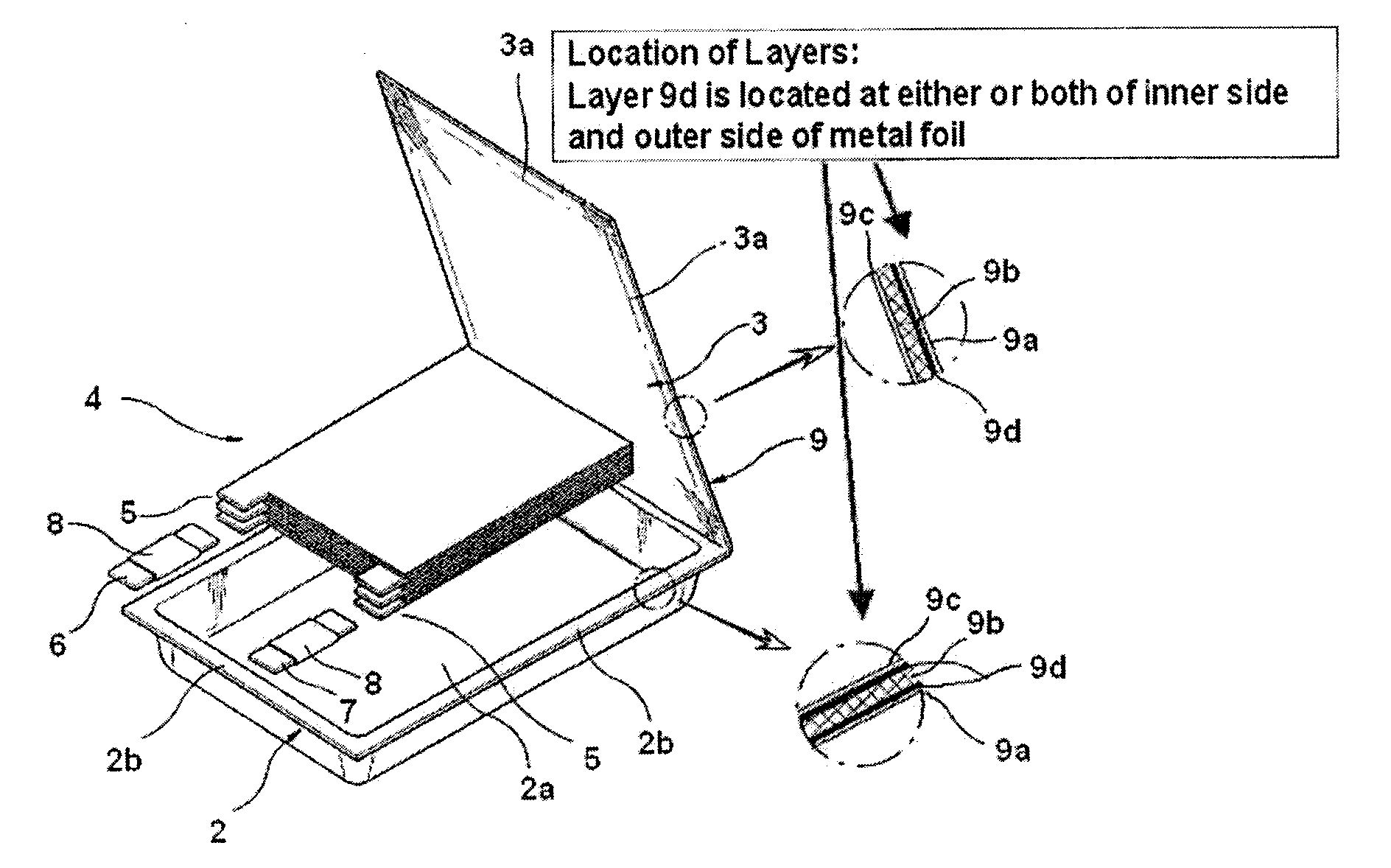

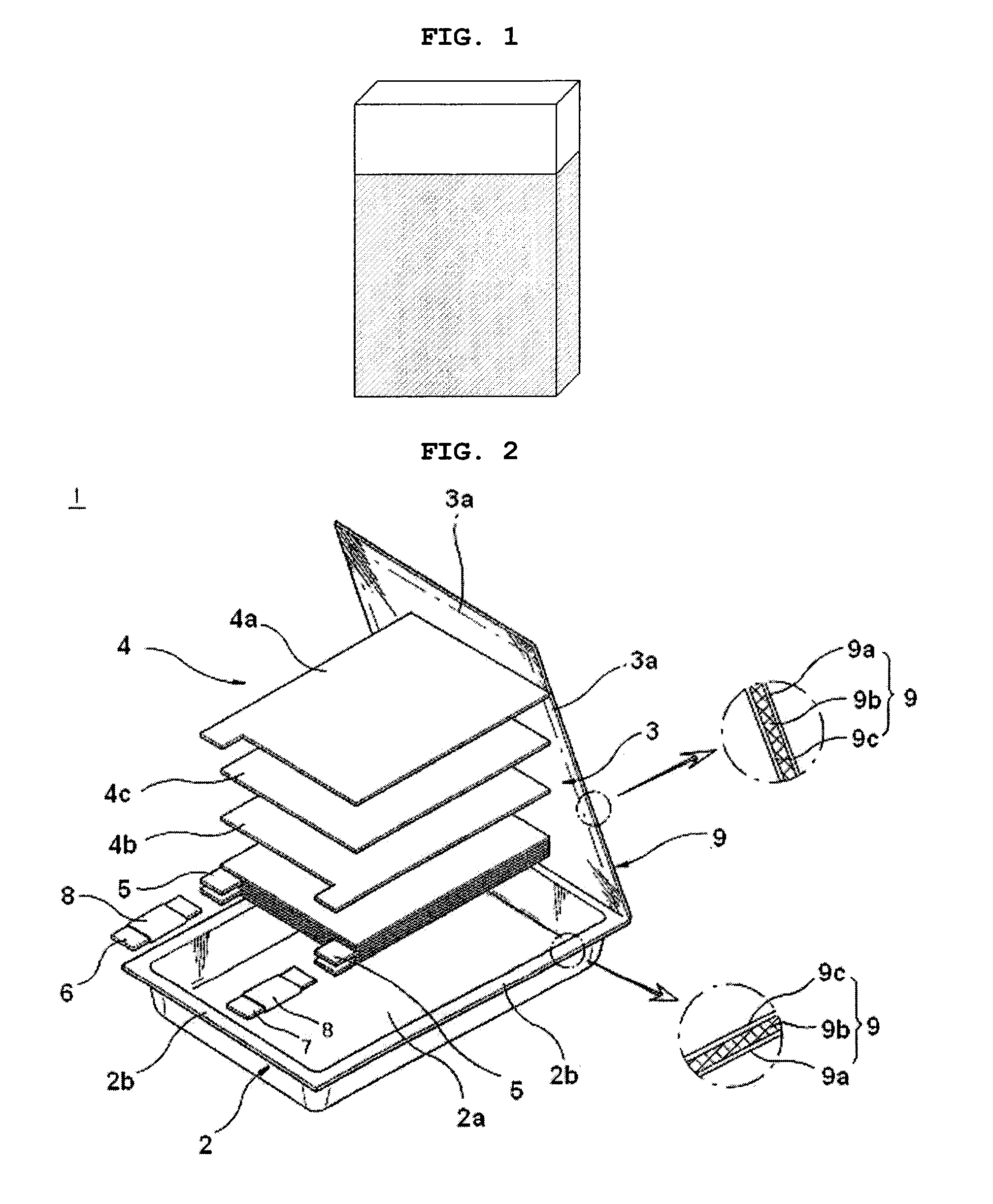

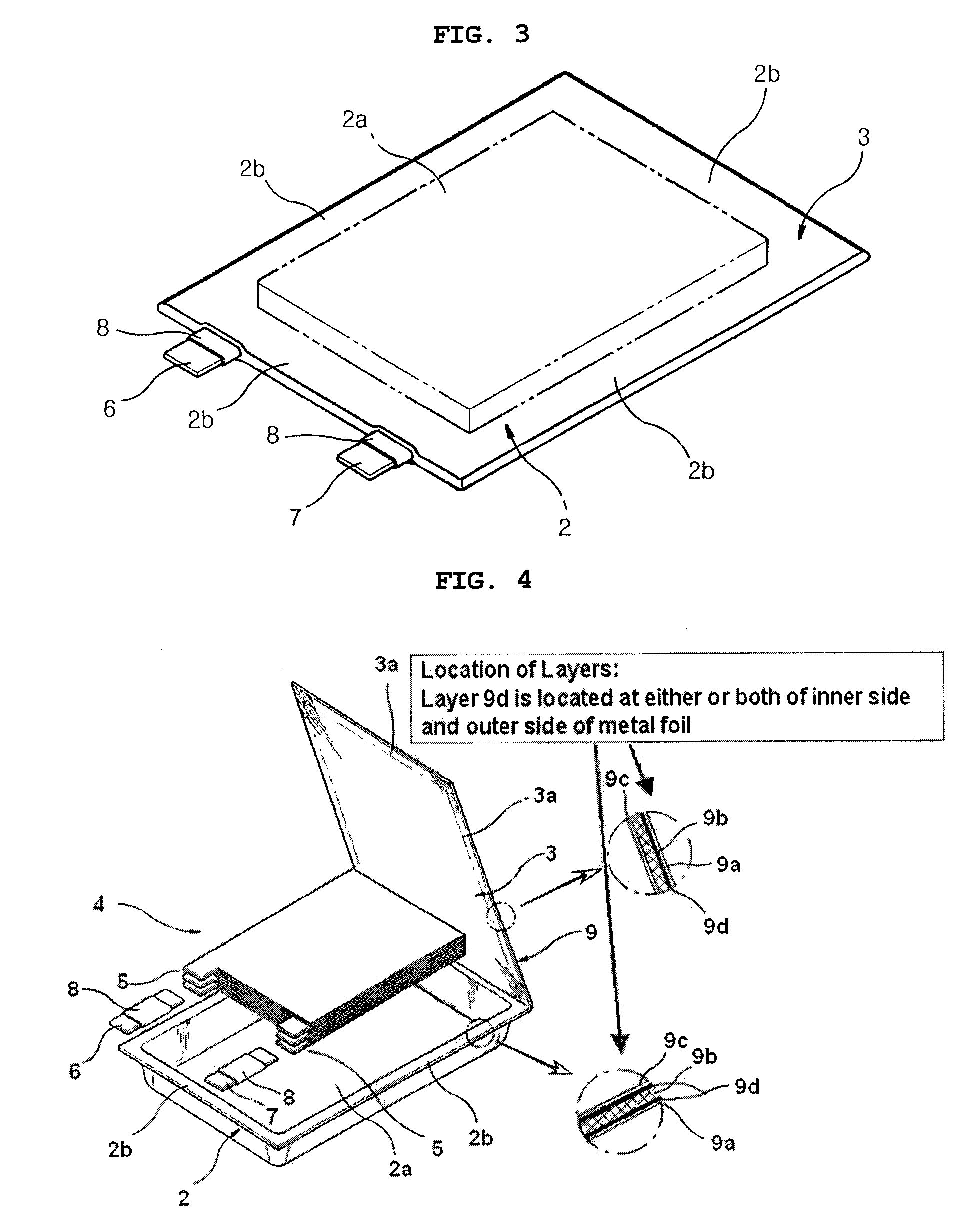

Case For Batteries And Preparation Method Thereof

Disclosed is a battery casing, comprising one or more sub-layers as constitutional elements, wherein at least one region selected from the group consisting of a surface of the casing and the sub-layers of the casing is coated partially or totally with a metal having a grain size of 50 nm or less. A battery comprising the same casing is also disclosed. The casing efficiently inhibits degradation of the safety of a battery, caused by internal or external factors, and thus provides a battery with excellent safety.

Owner:LG ENERGY SOLUTION LTD +1

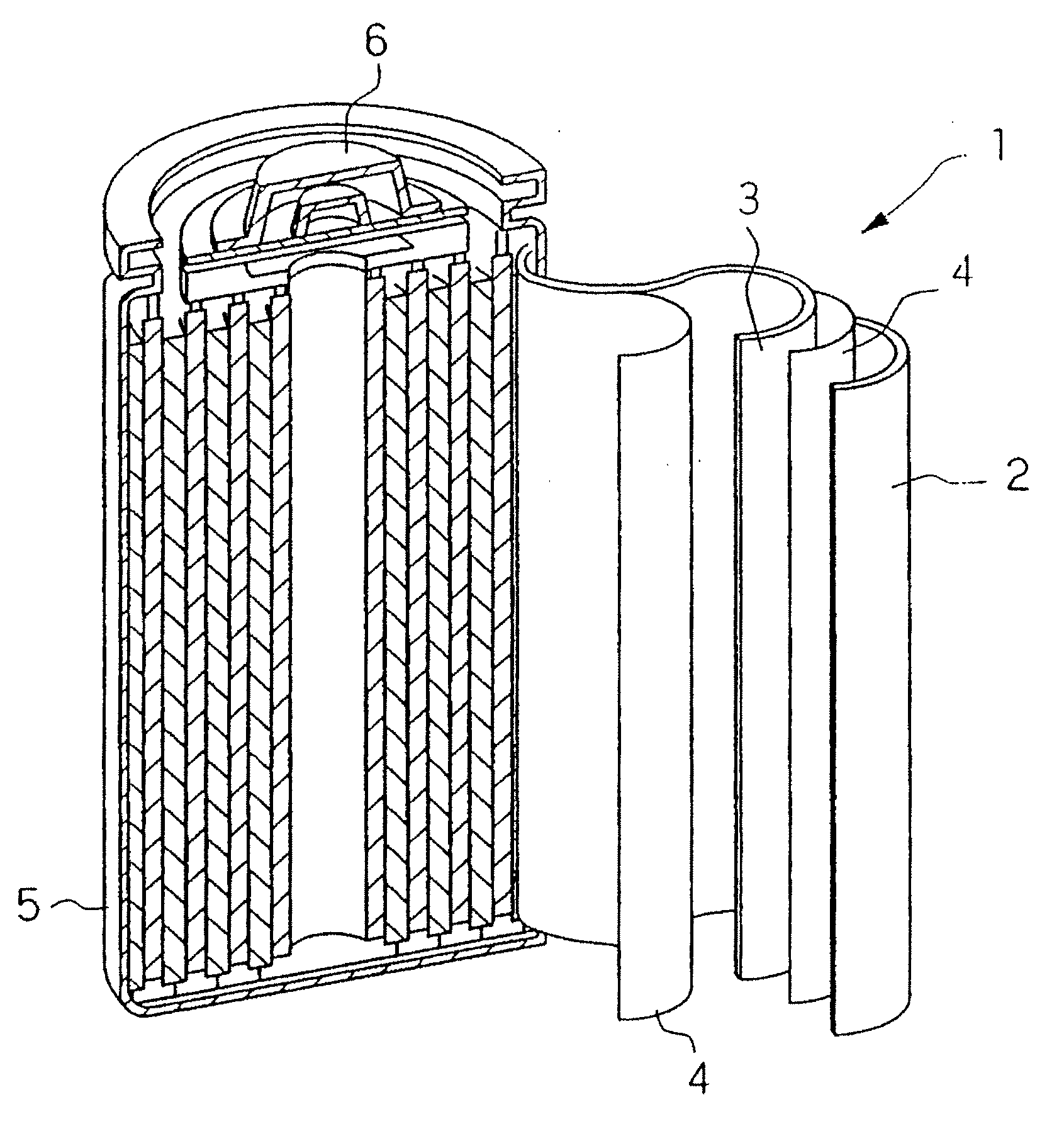

Negative electrode material for nonaqueous electrolyte secondary battery and method for manufacturing the same

InactiveUS20130334468A1Large capacityExcellent cycle characteristicsElectrode manufacturing processesNon-aqueous electrolyte accumulatorsDischarge efficiencyCarbon composites

The present invention provides a method for manufacturing a negative electrode material for a nonaqueous electrolyte secondary battery, which includes the steps of: preparing silicon nanoparticles; manufacturing the silicon-carbon composite material that contains the silicon nanoparticles and a carbonaceous material; and heat-compressing the silicon-carbon composite material. As a result, there is provided a negative electrode material for a nonaqueous electrolyte secondary battery, which has a high capacity and excellent initial charge / discharge efficiency and cycle characteristics and a method for manufacturing the same, and a nonaqueous electrolyte secondary battery that uses the negative electrode material for a nonaqueous electrolyte secondary battery.

Owner:SHIN ETSU CHEM IND CO LTD +1

Battery, battery cathode, battery cathode material and preparation method thereof

InactiveCN104300129AImprove electronic conductivityGood dispersionMaterial nanotechnologySecondary cellsCharge dischargeSilicon particle

The invention relates to a battery cathode material and a preparation method thereof. The cathode material at least comprises the active material elemental silicon and reduced graphene oxide, and also includes polyaniline. Also, the elemental silicon has the double cladding layer of polyaniline and reduced graphene oxide. On the one hand, the special internal structure of polyaniline can well inhibit huge volume change of silicon particles in a charge-discharge process, thus improving the cycle performance of the battery; and on the other hand, both polyaniline and graphene have excellent electrical conductivity, and can significantly improve the charge-discharge capacity of the material. The invention also relates to a battery cathode and a battery containing the cathode material. The battery cathode and the battery provided by the invention have high charge-discharge capacity and good cycle performance, thus being suitable for various mobile electronic equipment.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

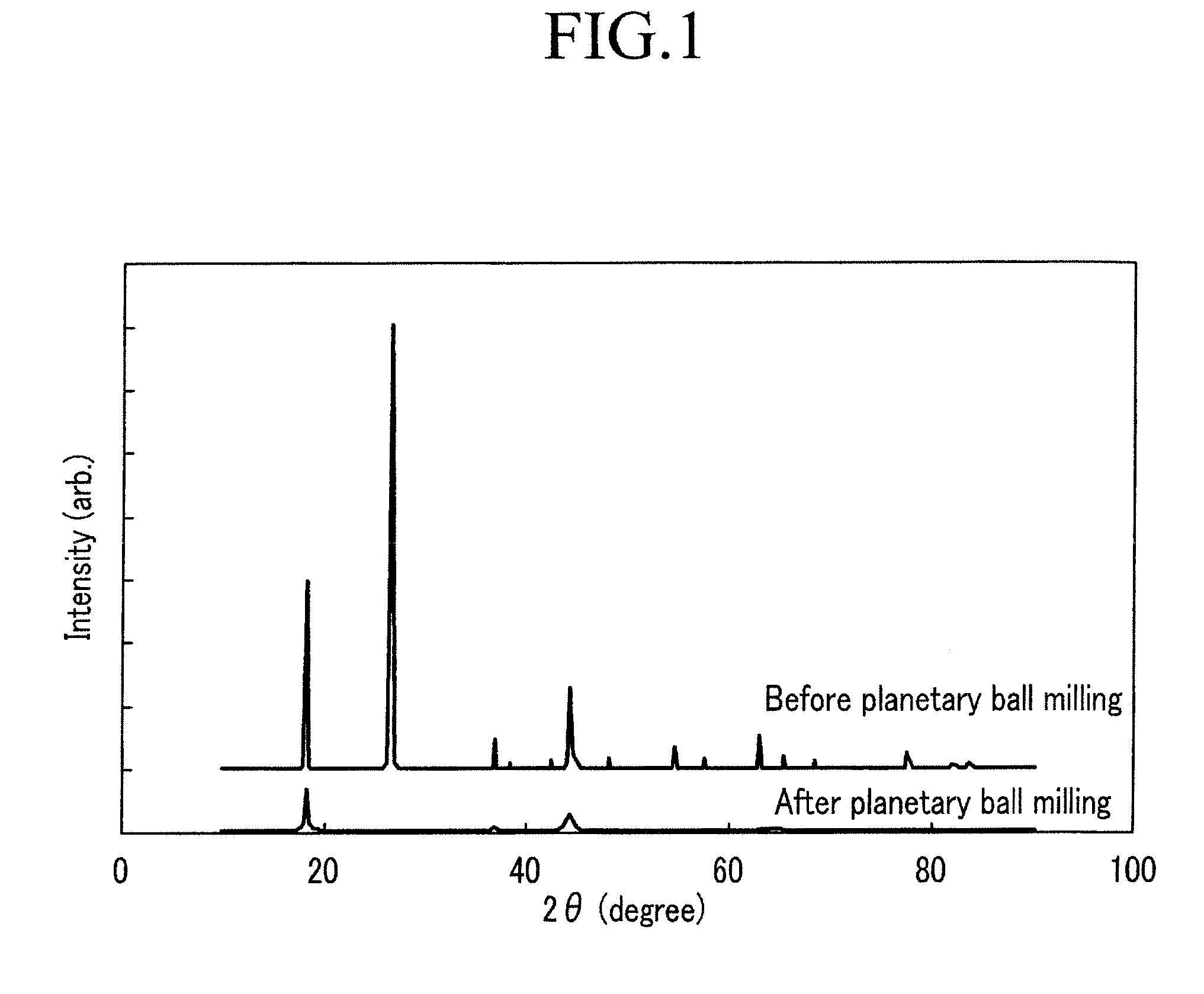

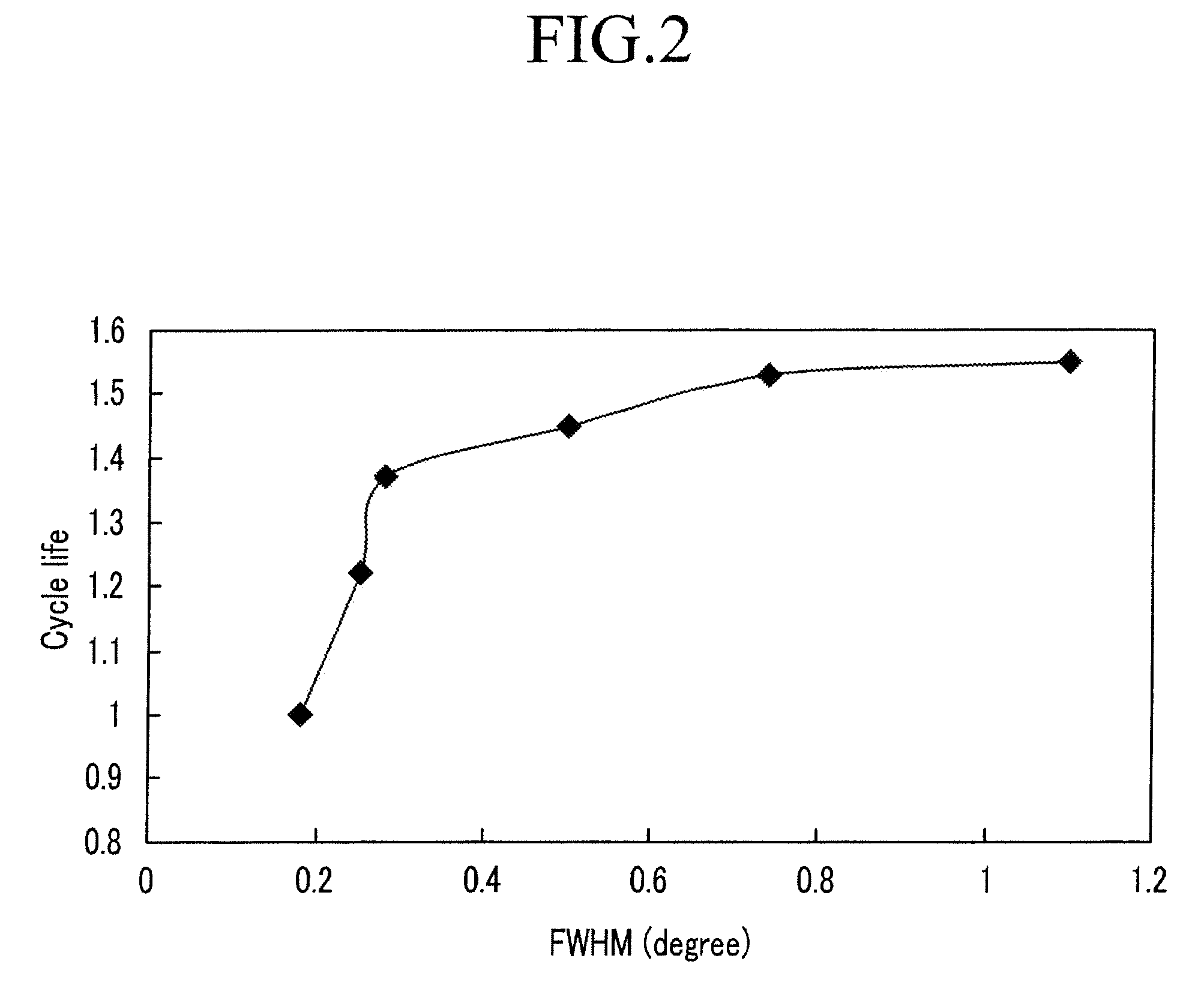

Negative active material for lithium secondary battery, and lithium secondary battery including same

InactiveUS20080305397A1Improve featuresImproved capacity and cycle-life characteristicElectrode manufacturing processesNegative electrodesX-rayFull width at half maximum

The present invention relates to negative electrode materials for rechargeable lithium batteries and to rechargeable lithium batteries including the same. The negative electrode materials improve the capacity characteristics and cycle-life characteristics of the rechargeable lithium batteries. The negative electrode material includes a negative active material capable of intercalating and deintercalating lithium ions, and the negative active material includes an oxide particle represented by LixMyVzO2+d and having a full width at half maximum of a X-ray diffraction angle (2θ) at a (003) plane of 0.2 degrees or more as measured by X-ray diffraction analysis using a CuKαray.

Owner:SAMSUNG SDI CO LTD

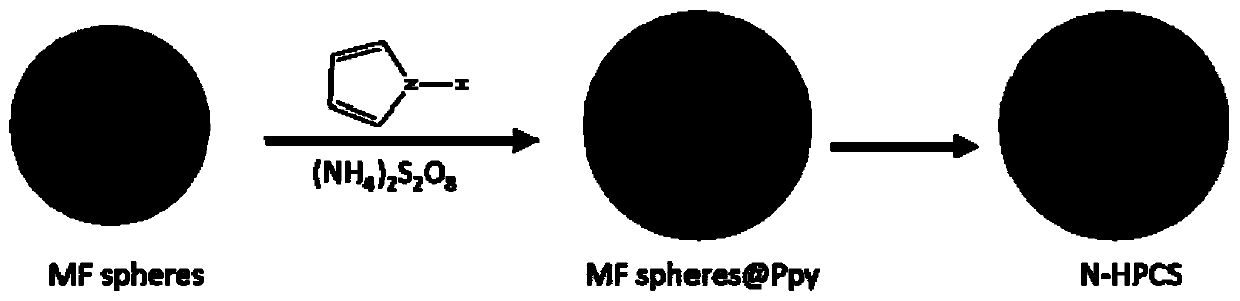

Nitrogen-doped porous hollow carbon sphere and preparation method and application thereof

PendingCN110729480AEliminate the etching stepFewer etch stepsSecondary cellsNegative electrodesPtru catalystPolypyrrole

Melamine resin pellets are obtained through one-step condensation of melamine and formaldehyde, the melamine resin pellets used as templates are coated with polypyrrole by using pyrrole as a nitrogensource and a carbon source and ammonium persulfate as a catalyst; the melamine resin pellets are gradually decomposed in the roasting process by controlling roasting to obtain nitrogen-doped porous hollow carbon spheres; and finally, the material is used in a lithium ion battery negative electrode. By using the melamine resin pellets instead of traditional silicon dioxide pellets, the problem of environmental pollution caused by etching of a silicon dioxide hard template with use of toxic reagents such as hydrofluoric acid in a traditional hard template method is avoided. Because the melamineresin pellets can generate a large amount of gas in the decomposition process, pores can be further formed in the pore walls of the hollow carbon spheres. Because the material is uniform in morphology, large in specific surface area and of a hollow structure, volume expansion can be relieved, and high specific capacity and cycle stability are shown in the lithium ion battery.

Owner:NANKAI UNIV

Composite anode material for a lithium ion battery and preparation method thereof

InactiveUS20150064552A1High mechanical strengthSimple technologyElectrode thermal treatmentPretreated surfacesSilicon alloyNetwork structure

The present invention belongs to the technical field of lithium ion batteries and in particularly relates to a composite anode material for a lithium ion battery. The composite anode material for a lithium ion battery comprises an anode active material and a coating layer coating the surface of the anode active material, wherein the anode active material is at least one selected from the group of Si, SiOx or a silicon alloy, the coating layer, which is a polymer of a network structure, accounts for 1-20% by mass of the anode material.

Owner:DONGGUAN AMPEREX TECH +1

Preparation method of hydro-thermal coupling spray pyrolysis MnO2/graphene electrode material

InactiveCN103915613AStable structureWide variety of sourcesMaterial nanotechnologyHybrid capacitor electrodesActive agentGraphene electrode

The invention discloses a preparation method of a hydro-thermal coupling spray pyrolysis MnO2 / graphene electrode material, belonging to the technical field of electrode materials for energy storage systems. The preparation method comprises the following steps: uniformly mixing graphene oxide (GO) prepared by using a Hummer method with an aqueous solution of bivalent manganese salt and a doped metal ion compound, adding a dispersing agent, an oxidant and a surfactant, and ultrasonically dispersing for a certain period of time; putting the mixed solution into a hydrothermal kettle, adjusting the temperature, and keeping for a certain period of time; filtering and washing a reaction product to obtain a precursor; adding the dispersing agent and the surfactant into the precursor, uniformly stirring for mixing, and adjusting the solid-liquid ratio, inlet temperature and outlet temperature to perform spray pyrolysis in order to obtain a metal ion-doped MnO2 / graphene nanometer composite electrode material. According to the nanometer composite electrode material prepared by using the method, components are uniform and the batch stability is high.

Owner:SHANDONG RUNSHENG POWER TECH +1

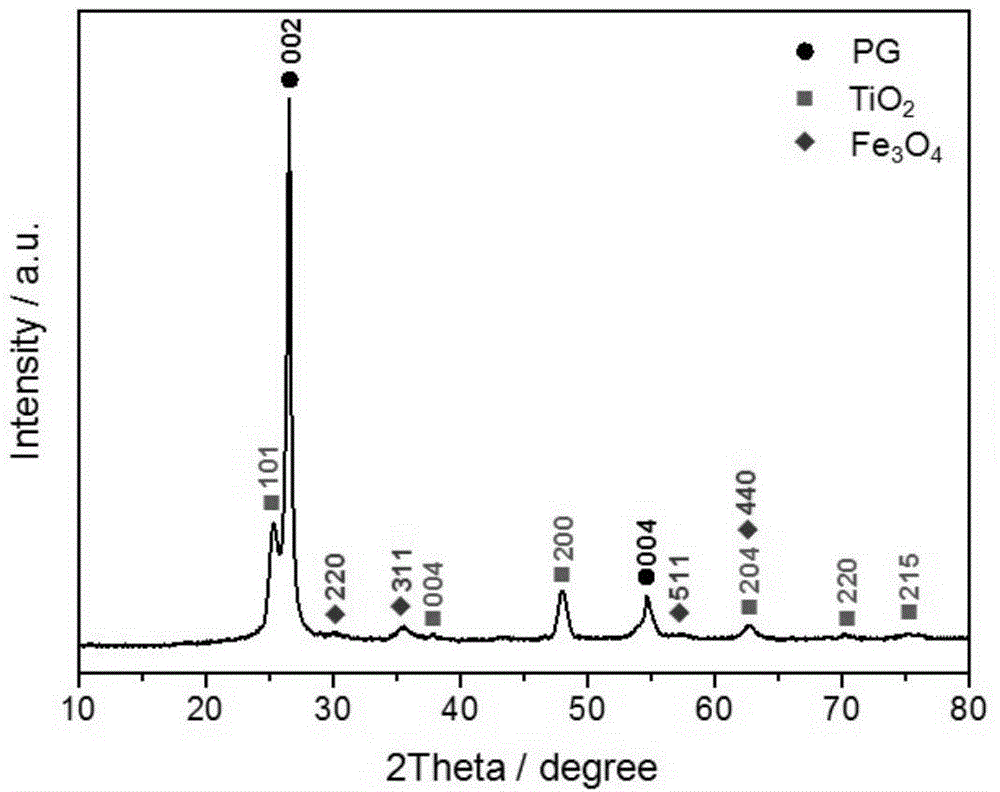

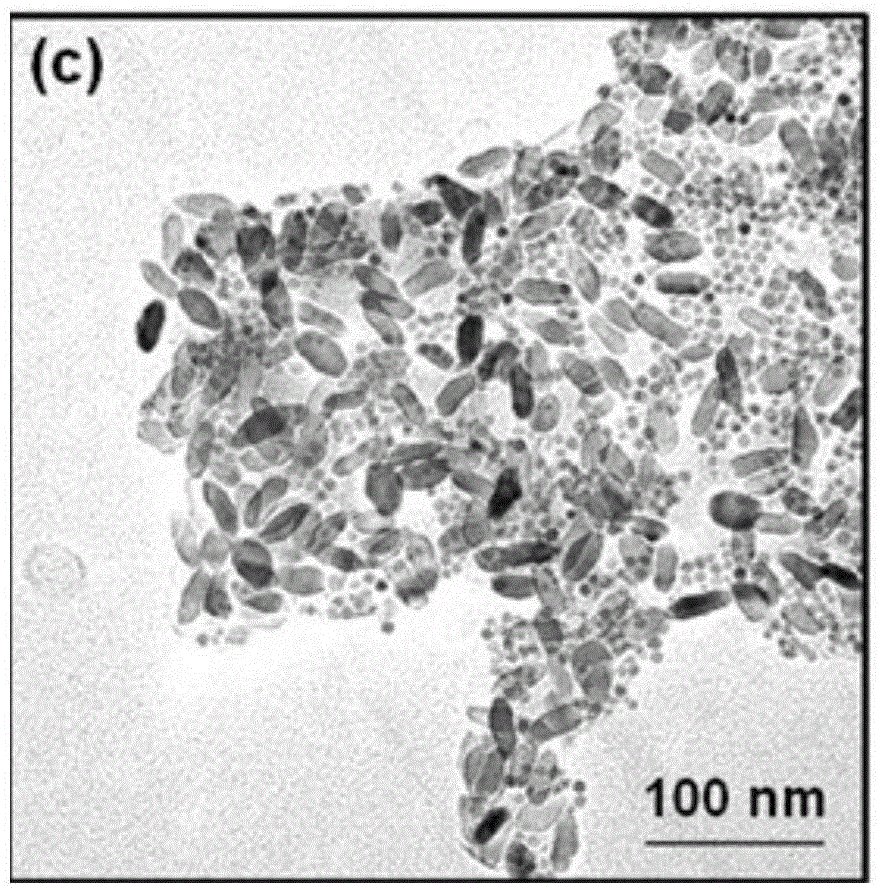

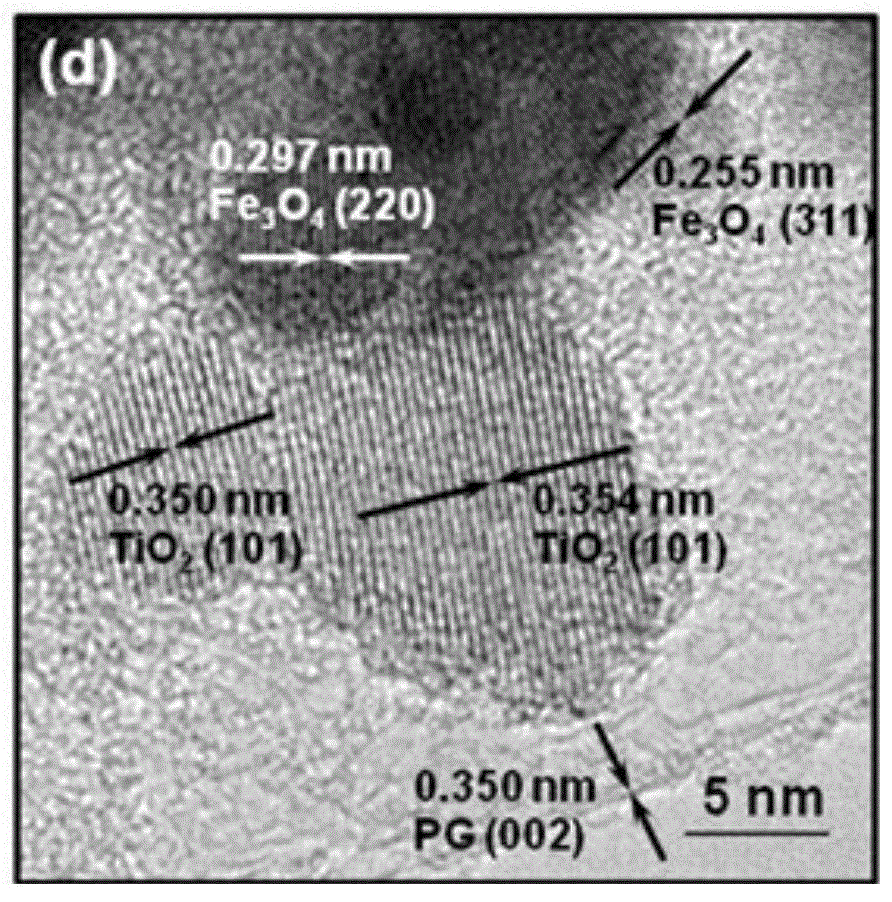

Ternary multilevel multi-dimensional structure composite material and preparation method thereof

ActiveCN104319377AImprove conductivityPromote circulationCell electrodesSecondary cellsNano structuringElectrochemistry

The invention discloses a ternary multilevel multi-dimensional structure composite material and a preparation method thereof. The excellent electrochemical comprehensive performance can be exerted by utilizing the remarkable synergistic effect and unique multilevel multi-dimensional structure. The composite material is formed by TiO2 of a low-dimensional nano structure and second-phase high-specific-capacity metal oxide as well as two-dimensional micrometer (x-y plane direction) high-conductivity plain graphene. Drive force for lowering the total surface free energy of the solution system is utilized to uniformly load and compactly combine TiO2 of the nano structure and high-specific-capacity metal oxide to an exposed surface of the plain graphene nanosheet by virtue of a tetrahydrofuran solution mixing method. The ternary multilevel multi-dimensional structure composite material effectively integrates the remarkable function of each ingredient, including excellent circulating property and outstanding safety of TiO2, high specific capacity of the second-phase metal oxide, and good conductivity of the plain graphene.

Owner:HARBIN INST OF TECH

Gas generator composition

InactiveUS6623574B1Low toxicityImprove securityPedestrian/occupant safety arrangementExplosivesCelluloseCombustion

A gas generating composition which is excellent in a combustion efficiency and a gas output and in which amounts of residues generated are reduced in the combustion is obtained.A gas generating composition comprising (a) 5 to 40% by weight of at least one high polymer selected from the group consisting of a polyacrylic derivative resin, a polyacetal, a urea resin, a melamine resin, a ketone resin and a cellulose-based high polymer, and (b) 60 to 95% by weight of ammonium nitrate or phase-stabilized ammonium nitrate. It is suitable as a gas generating agent for an air bag of automobiles.

Owner:DAICEL CHEM IND LTD

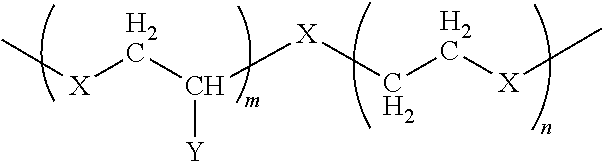

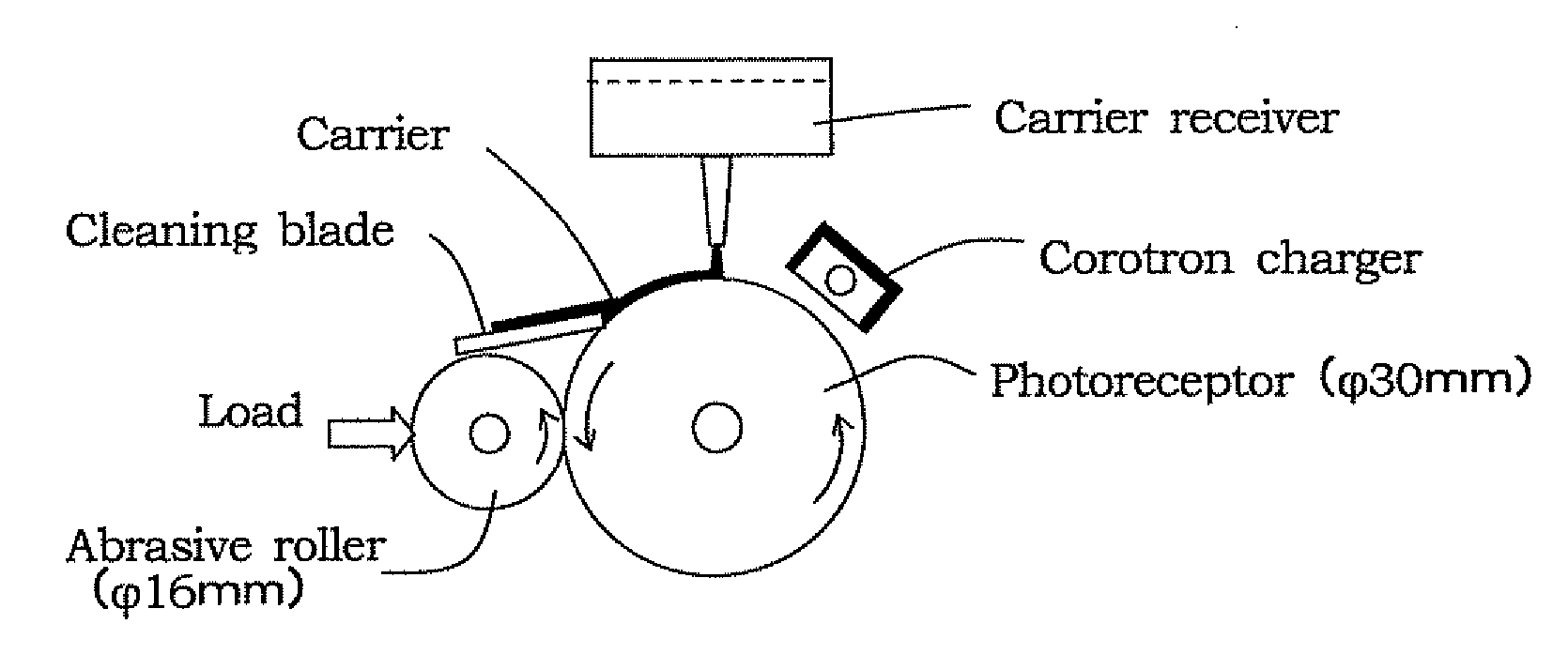

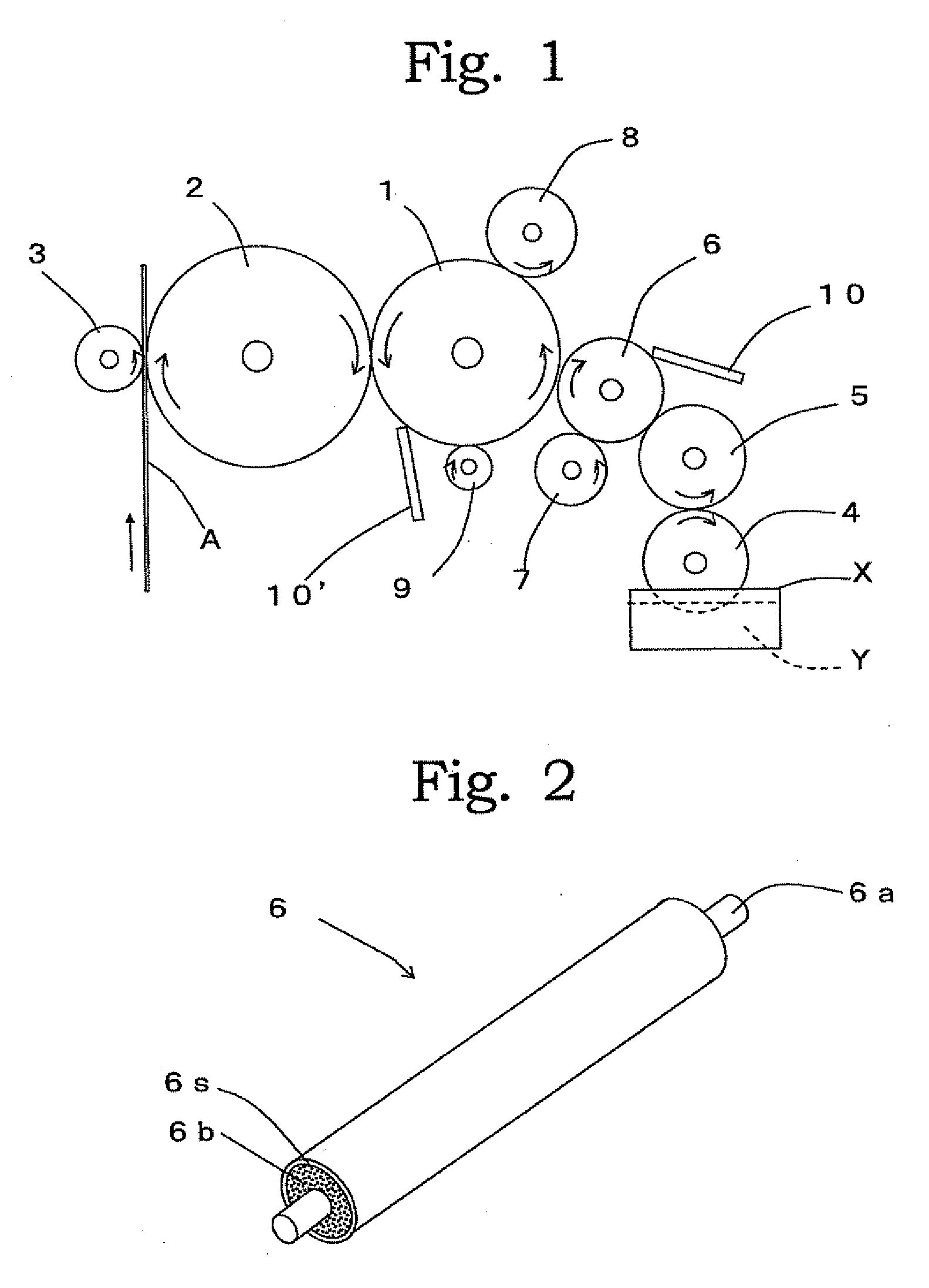

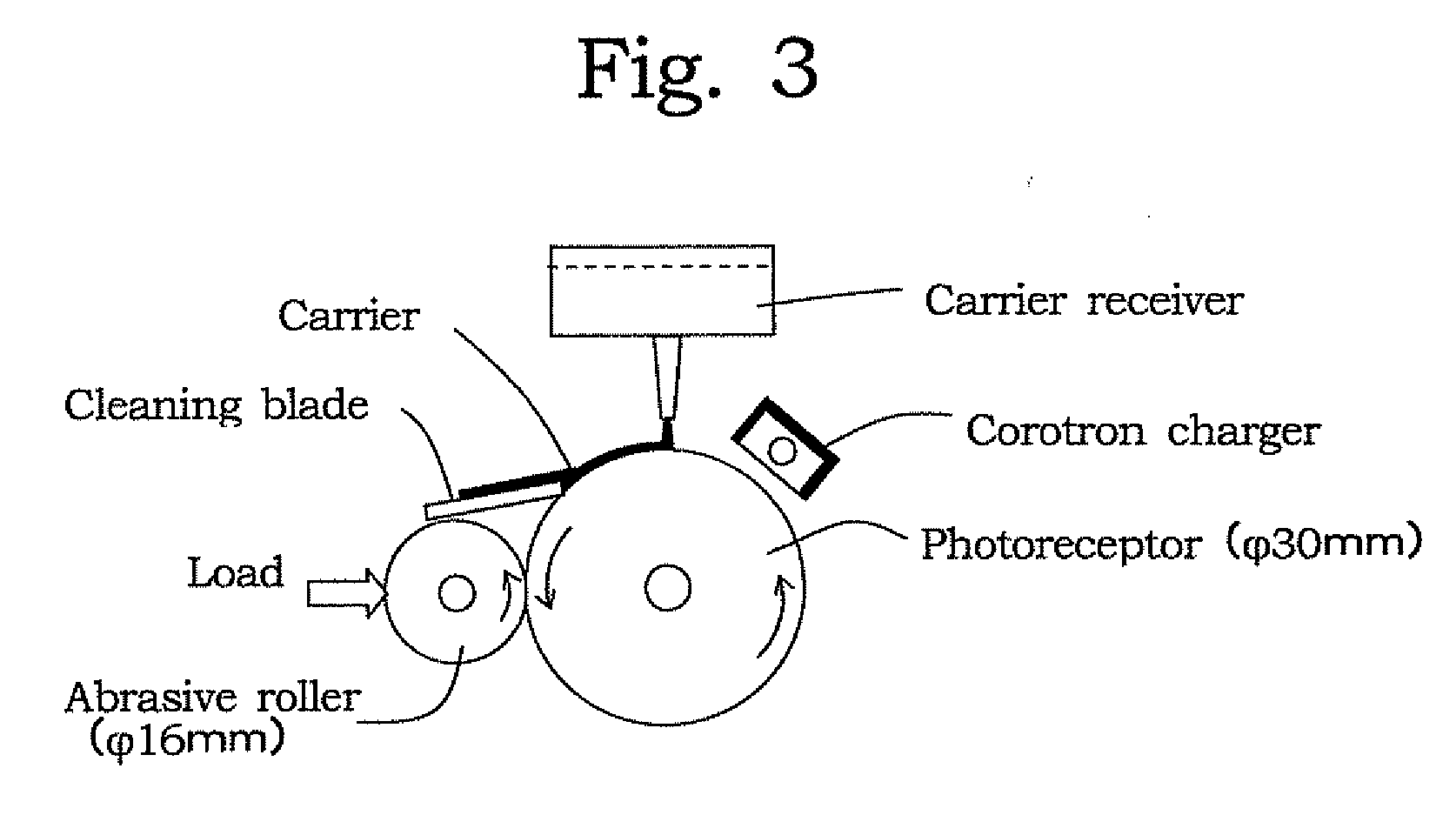

Liquid Developing Electrophotographic Device Roller and Liquid Developing Electrophotographic Device

InactiveUS20090290909A1Resistant to volumetric variationInhibition of volume changeElectrographic process apparatusPolyesterPolyol

An object of the present invention is to provide a liquid developing electrographic device roller suppressed in volumetric variation caused by a carrier. As a means for solving the problems, the present invention provides a liquid developing electrophotographic device roller including a shaft and an elastic material layer provided around the outer peripheral side of the shaft, wherein the elastic material layer is formed by using a polyurethane obtained by reacting a polyester polyol with a difunctional isocyanate.

Owner:BANDO CHEM IND LTD

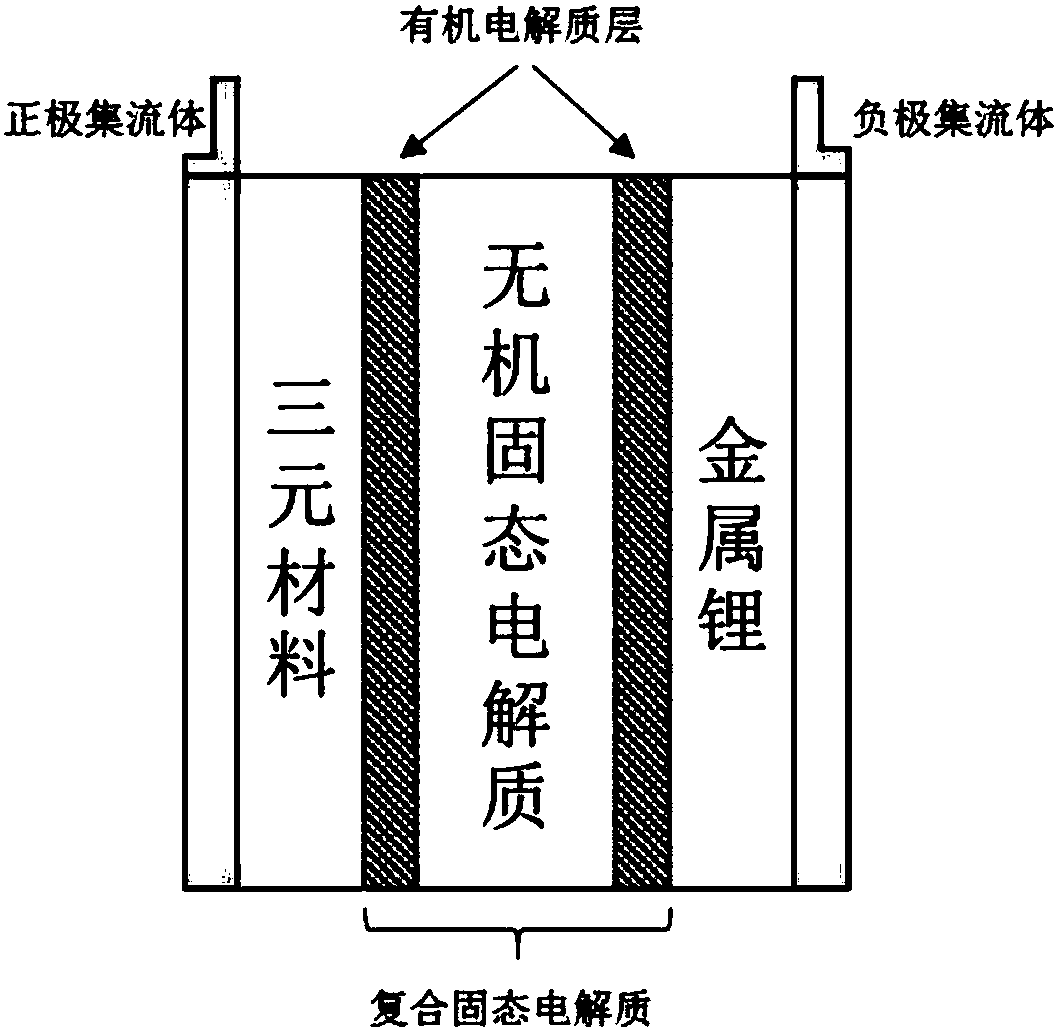

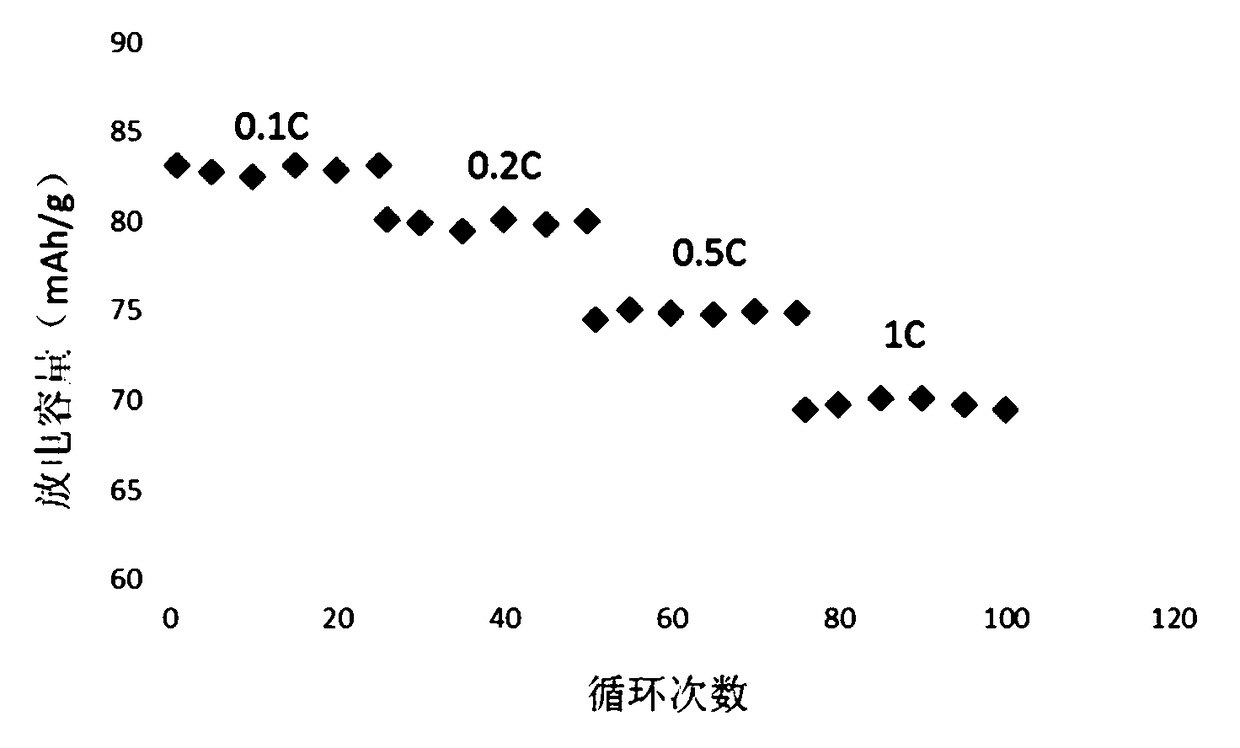

A composite solid-state electrolyte for all-solid-state lithium ion batteries and a preparation method thereof

InactiveCN109256582AImprove ionic conductivityIncrease contactSolid electrolytesSecondary cellsSolid state electrolyteAll solid state

The invention relates to a composite solid-state electrolyte for an all-solid-state lithium ion battery and a preparation method thereof. The composite solid electrolyte comprises an inorganic electrolyte layer and two organic electrolyte layers attached to both surfaces of the inorganic electrolyte layer, the organic electrolyte layer comprising a lithium salt and an organic electrolyte, and theinorganic electrolyte layer is formed of rare metal doped inorganic electrolytes. The battery containing the composite solid electrolyte of the present invention has high energy density and high safety.

Owner:SAIC GENERAL MOTORS +1

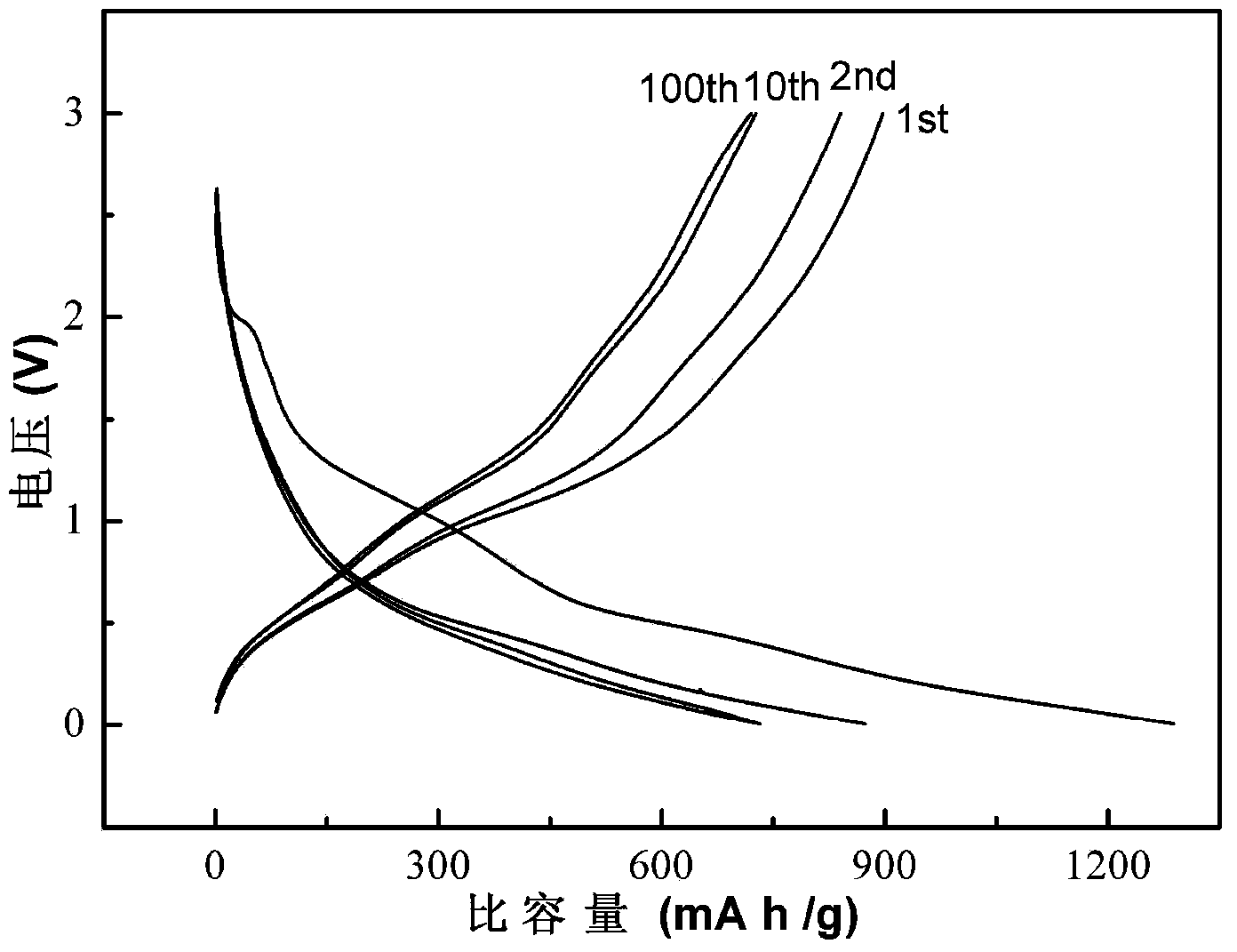

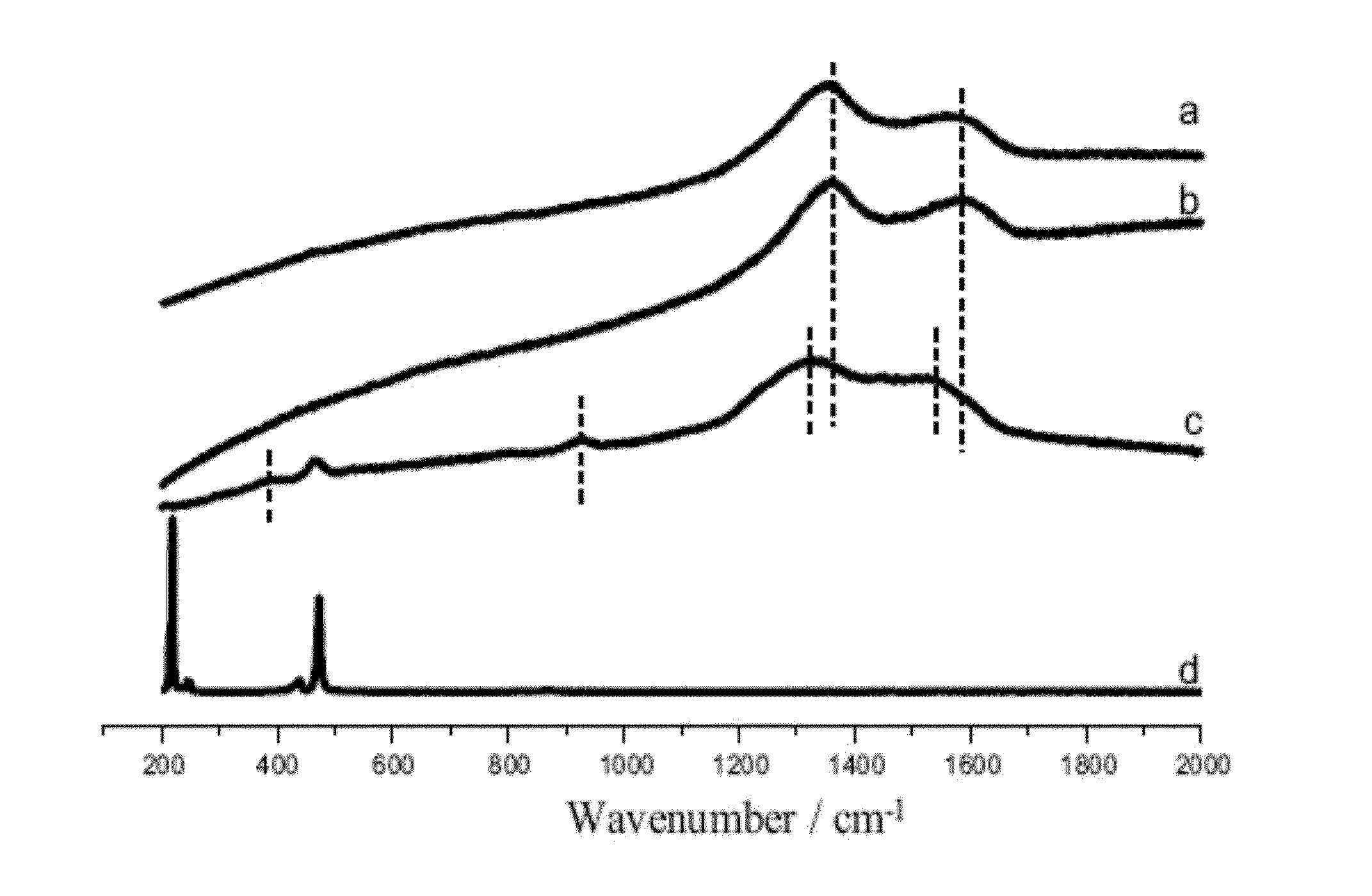

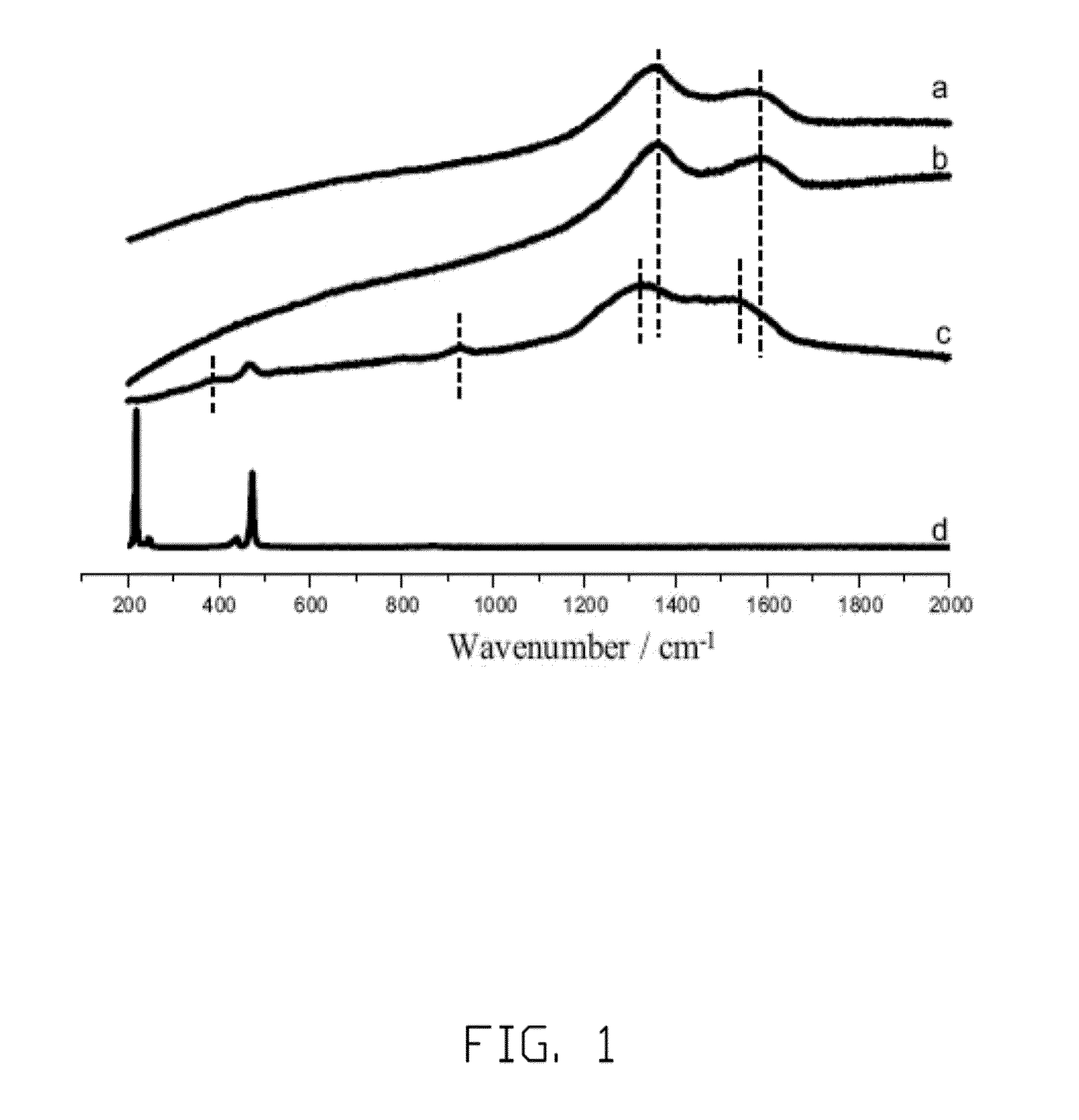

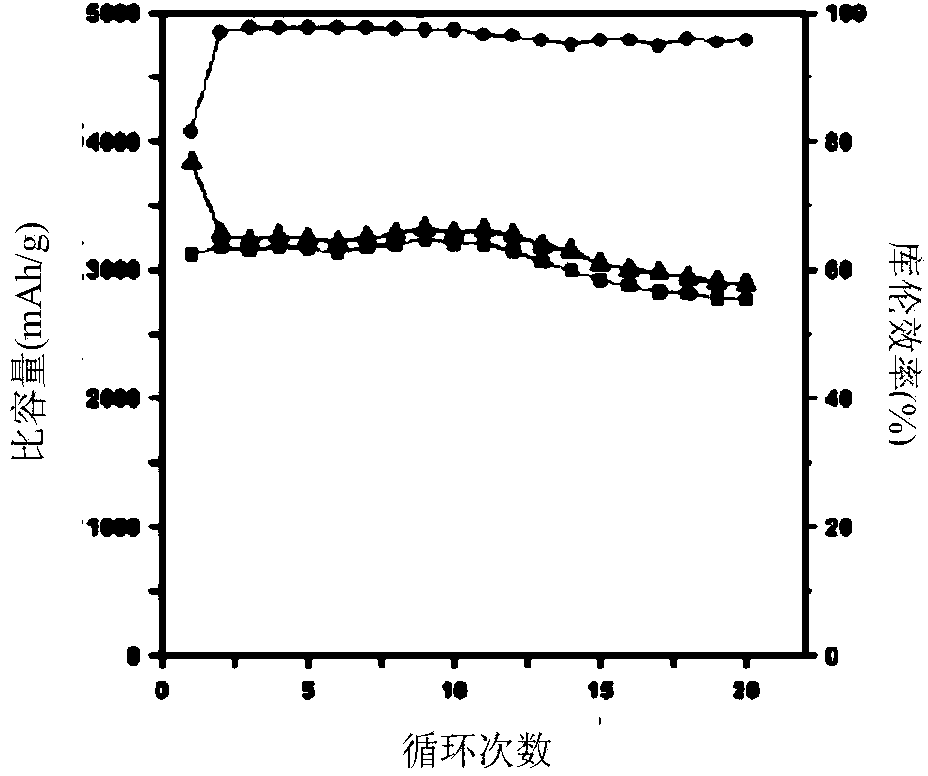

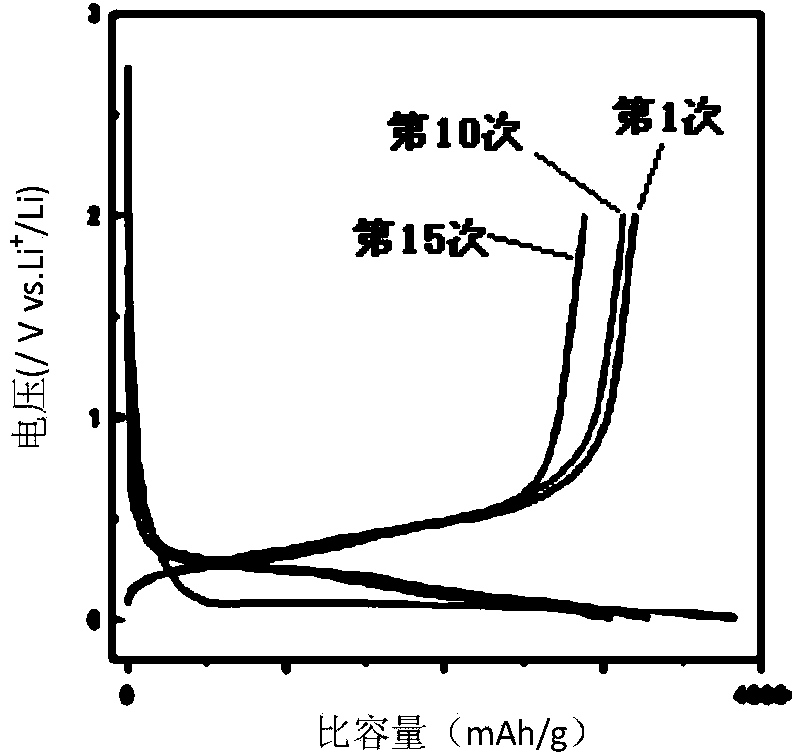

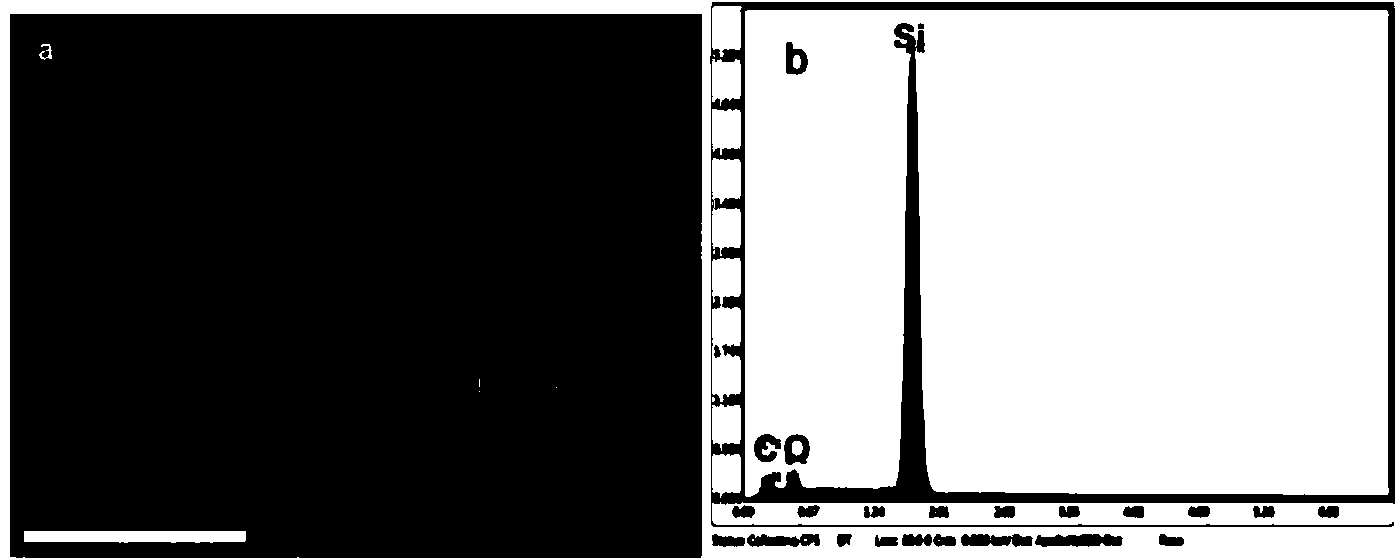

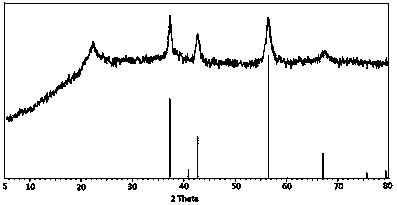

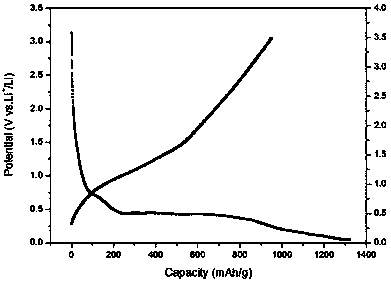

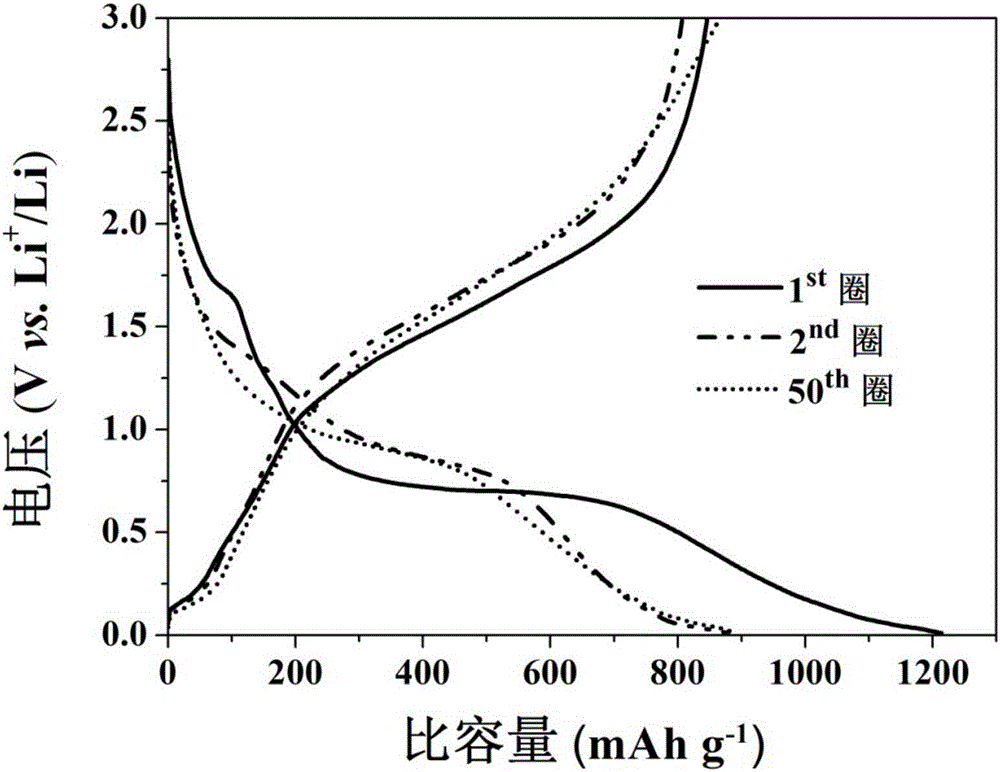

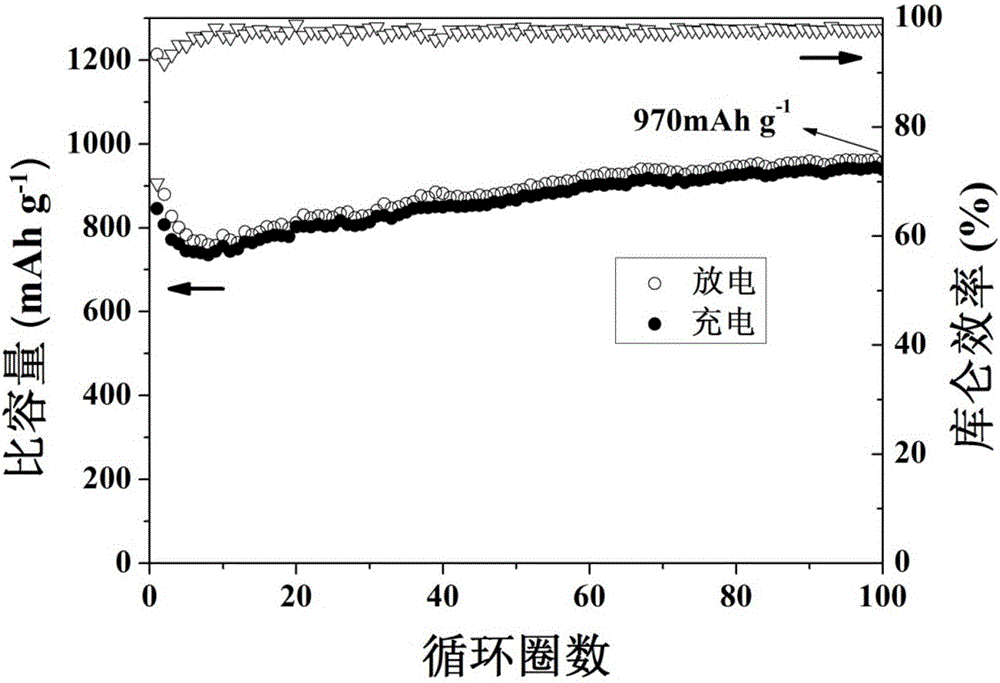

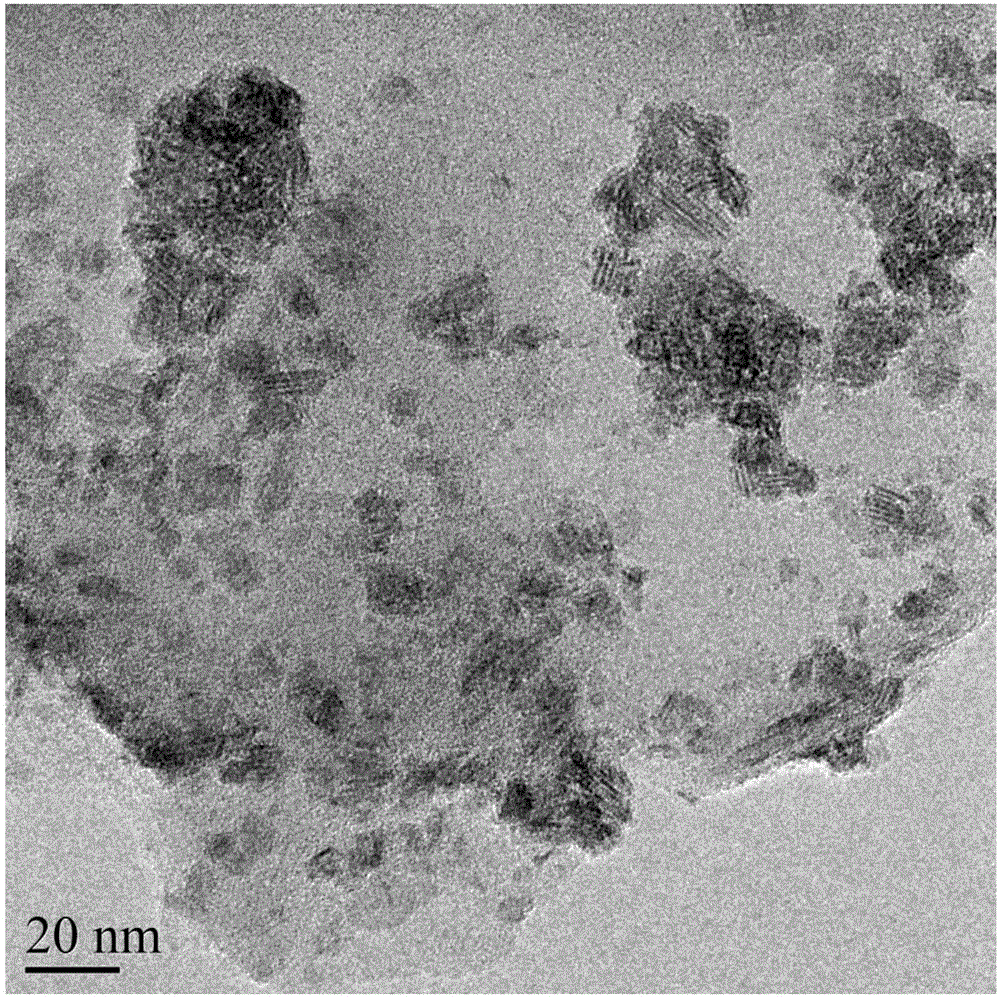

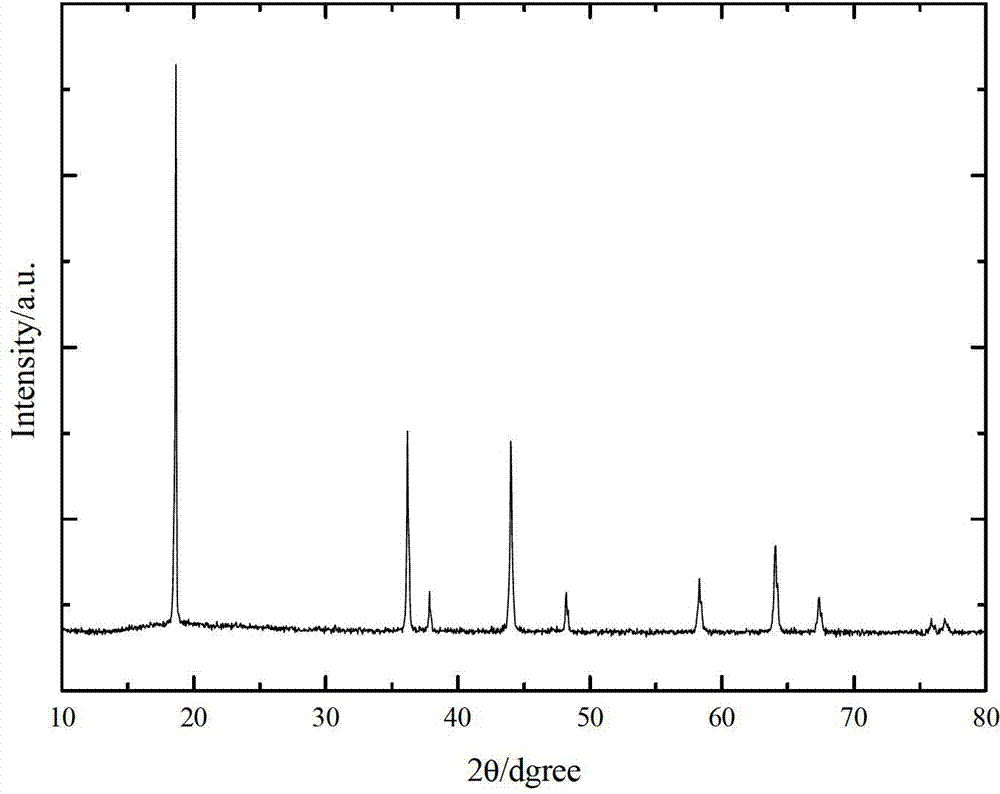

Fe3O4-graphite composite nanometer material and preparation method thereof and application of Fe3O4-graphite composite nanometer material in lithium ion battery

ActiveCN106450210AInhibition of volume changeImprove structural stabilityMaterial nanotechnologyCell electrodesFiltrationPotassium ferrate

The invention discloses a Fe3O4-graphite composite nanometer material and a preparation method thereof and application of the Fe3O4-graphite composite nanometer material in a lithium ion battery, and belongs to the technical field of lithium ion battery electrode materials. The preparation method includes the following steps: using graphite and potassium ferrate as raw materials, and then adding zirconium balls in the raw materials; at a speed of 300-500rpm, conducting ball milling by a planetary ball mill for 12-60 hours; conducting product separation, filtration, washing and drying to obtain the Fe3O4-graphite composite nanometer material. The material is applied in a lithium ion battery cathode and has excellent electrical properties; under the condition of the current density of 200 mA g<-1>, the material can keep a reversible capacity of 970 mAh g<-1> after circulation for 100 turns, the reversible capacity reaches 1132 mAh g<-1)> after circulation for 250 turns, and under the condition of large current density (1000 mA g <-1>), the reversible capacity can still keep at about 650 mAh g<-1> after circulation for 200 turns.

Owner:GUANGDONG ORIENT RESIN

Modified lithium manganate material, and preparation method and application thereof

ActiveCN103035904ADissolution inhibitionMaintain capacity performanceCell electrodesManganateCore shell

The invention discloses a modified lithium manganate material, and a preparation method and application thereof. The modified lithium manganate material adopts a core-shell structure taking LiMn204 as a core and LiMn2-xMxO4-delta as a coating layer, wherein M is one of Al, Ti, Ce, Co and Ni, the value of x ranges from 0.05 to 0.5, and delta ranges from 0.01-0.1. The modified lithium manganate material is prepared by co-precipitation coating, hydro-thermal reaction and high-temperature heat treatment, and used as the cathode material of a lithium ion battery. The preparation process is simple and feasible, the components and the proportion of the raw materials are easy to control, the stability from batch to batch is good, the cost is low, and the synthesized lithium manganate material is high in specific capacity, high in current and excellent in cycle performance, and is expected to be applied in the field of power cells.

Owner:嘉善县国创新能源研究院

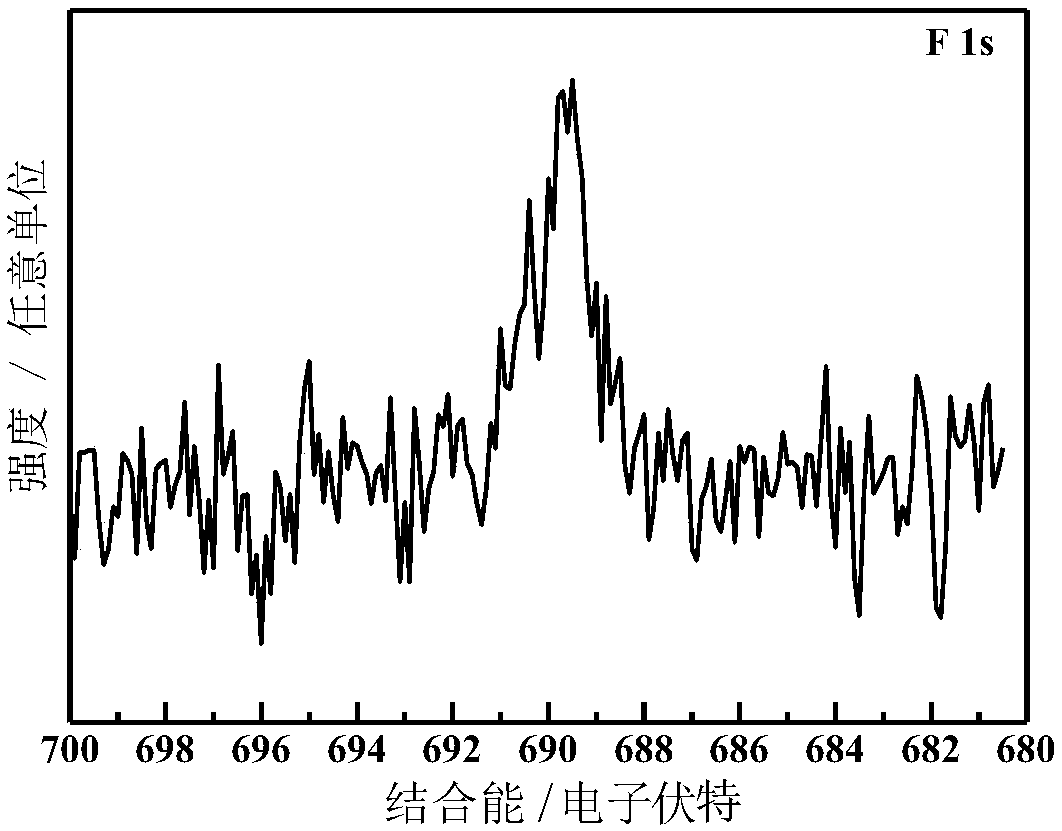

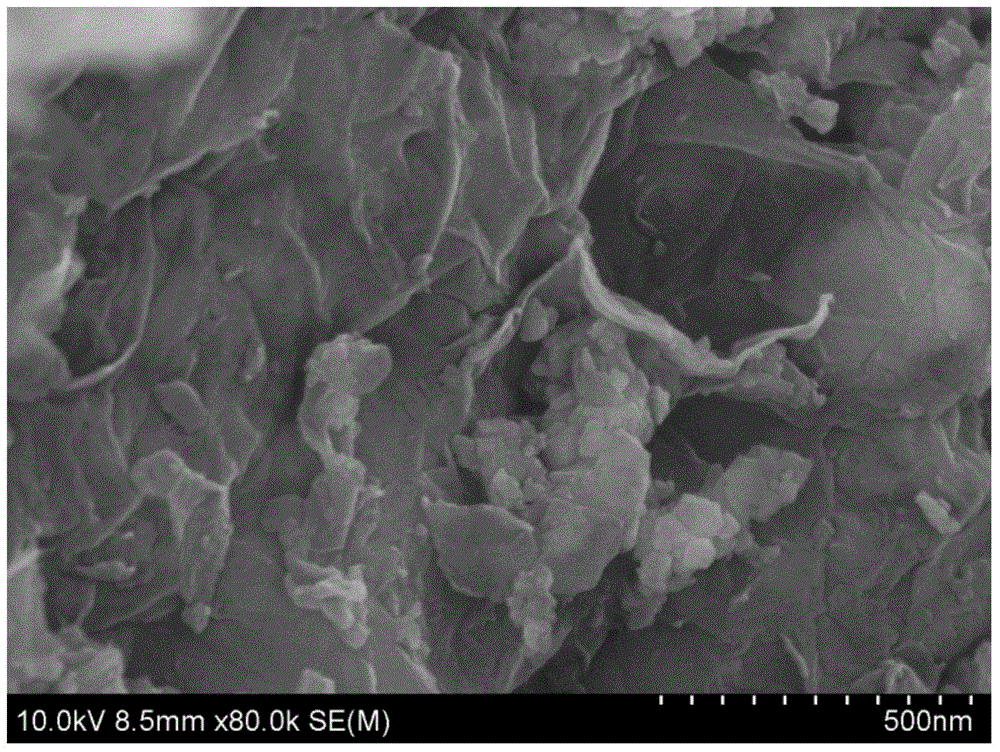

Surface-modified silicon-carbon composite and preparing method and application thereof

InactiveCN109286014AImprove conductivityAvoid contactMaterial nanotechnologyNegative electrodesCarbon compositesSilicon oxide

The invention discloses a surface-modified silicon-carbon composite and a preparing method and application thereof. The method includes the steps of firstly, conducting high-temperature treatment on commercial raw materials containing silicon oxide, and conducting pickling to clean away impurities to obtain silicon oxide; secondly, conducting magnesium thermal reduction reaction on the silicon oxide to obtain nanometer silicon, synchronously conducting carbon wrapping to obtain a silicon-carbon nanometer material, and combining the nanometer silicon carbon and fluoride through ball-milling toobtain the silicon-base composite. Compared with the prior art, the method is simple in process, low in energy consumption and beneficial for industrial production. The silicon-carbon composite modified by the prepared surface fluoride has high capacity, high primary coulombic efficiency and excellent circulating performance.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

Preparation method of porous metal doped lithium manganate/graphene lithium battery positive electrode material

InactiveCN105206799AImprove conductivityAvoid reunionMaterial nanotechnologyCell electrodesCvd grapheneMuffle furnace

The invention relates to a preparation method of a porous metal doped lithium manganate / graphene lithium battery positive electrode material. The method includes the steps that 1, a sol-gel method is adopted for preparing a precursor of porous LiM0.2Mn1.8O4, and the precursor is put into a muffle furnace to be calcined at constant temperature to obtain porous LiM0.2Mn1.8O4; 2, graphene oxide is taken and added into deionized water to prepare a graphene oxide solution with the mass concentration of 0.05-0.1 g / mL; 3, porous LiM0.2Mn1.8O4 is put into the graphene oxide solution, the mixture is subjected to magnetic stirring, ultrasonic dispersion and drying and then transferred into a tube furnace to be calcined at constant temperature, and the porous metal doped lithium manganate / graphene lithium battery positive electrode material is obtained. Compared with the prior art, the preparation method is simple, and the raw materials are easy to get; the prepared material is good in crystallinity and uniform in particle size, and the size is about 30 nm; serving as a lithium battery positive electrode material, the prepared material is good in electrochemical stability, high in specific discharge capacity and good in rate performance and cycle performance.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of nanosheet self-assembled three-dimensional nano flower tin sulfide/graphitized carbon nitride lithium ion battery anode material

ActiveCN109286009AControllable growthUniform size distributionMaterial nanotechnologyCell electrodesVacuum dryingMaterials science

The invention discloses a preparation method of a nanosheet self-assembled three-dimensional nano flower tin sulfide / graphitized carbon nitride lithium ion battery anode material. Melamine is kept at450-650 DEG C for 2-6 hours, is naturally cooled to room temperature, is ground for prepare use, and is dispersed in ethanol to obtain a suspension, the suspension is centrifuged and washed several times with deionized water and absolute ethanol, vacuum drying is conducted to obtain a product g-C3N4, the product g-C3N4 is dissolved in the deionized water, after stirring, the product g-C3N4 is ultrasonically dispersed to form a suspension A, PVP is added to the suspension A, stirring is conducted until the product g-C3N4 is completely dissolved to form a solution B, TAA and SnCl4 2H2O are addedto the solution B, stirring is uniformly conducted to form a solution C, the solution C is subjected to a microwave hydrothermal reaction, after the reaction is completed, a precursor is obtained, the precursor is centrifuged and washed several times with the deionized water and the absolute ethanol, and vacuum drying is conducted to obtain a nanosheet self-assembled three-dimensional nano flowerSnS2 / g-C3N4 battery material.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com