Method for manufacturing negative electrode active material for use in non-aqueous electrolyte secondary battery, negative electrode material for use in non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery

A negative electrode active material and non-aqueous electrolyte technology, which is applied in the field of negative electrode active material manufacturing, can solve the problems of inability to maintain the volume expansion rate of silicon oxide, high cost, and difficulty in obtaining it, achieve good cycle characteristics and efficiency, improve electrical conductivity, Effect of suppressing volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

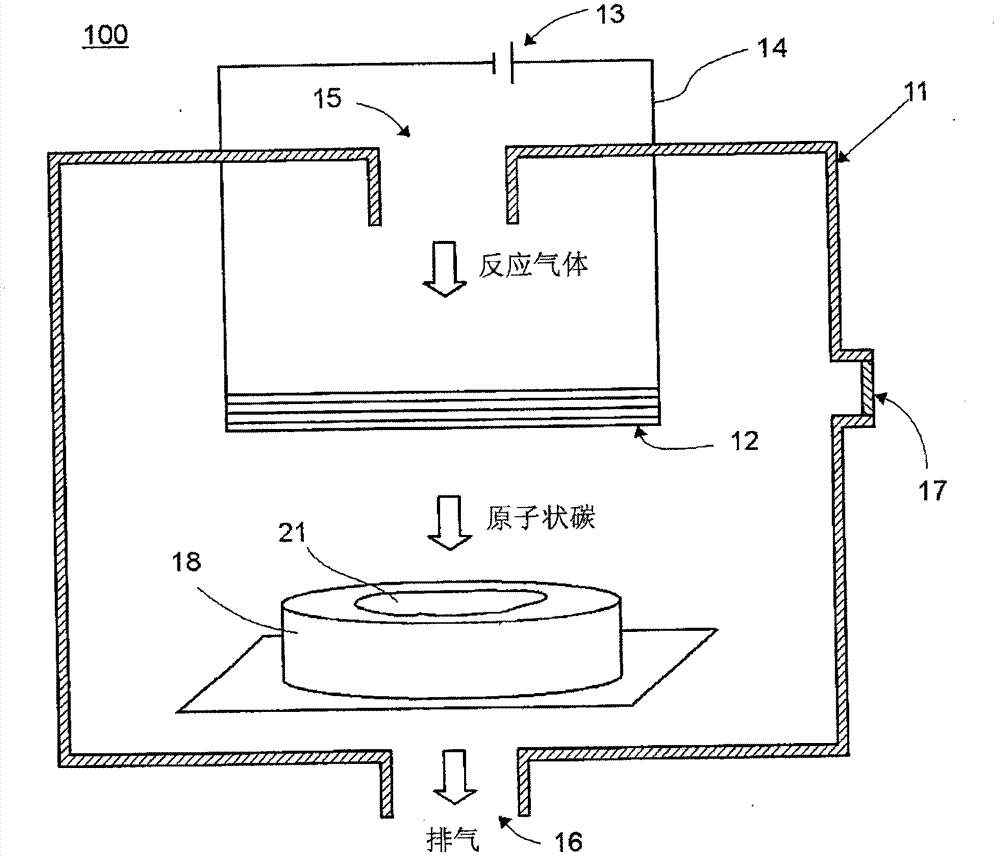

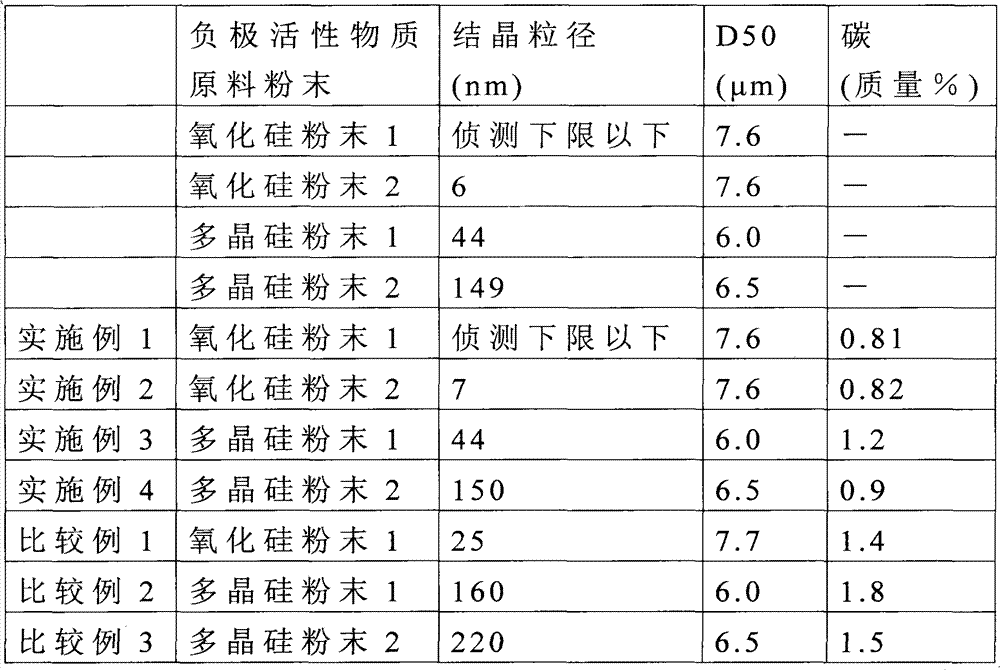

[0133] use as figure 1 In the catalytic CVD apparatus shown, silicon oxide powder 1 is coated with carbon as described below. The silicon oxide powder 1 is placed statically in the reaction chamber 11 of the catalyst CVD apparatus 100, and carbon vapor deposition is carried out in methane / hydrogen / argon = 540 / 60 / 400 sccm as the reaction gas, and the pressure in the reaction chamber is 1000 Pa. The reaction chamber 11 uses a tungsten filament with a diameter of 1 mm as the catalyst body. The temperature of the holder 18 was set at 500° C., and the reaction was performed for 10 hours.

Embodiment 2、3、4

[0135] Carbon-coated silicon oxide powder 2 (Example 2), polycrystalline silicon powder 1 (Example 3), and polycrystalline silicon powder 2 (Example 4) were performed in the same manner as in the case of the silicon oxide powder 1 in Example 1.

Embodiment 5~9、 comparative example 4~6

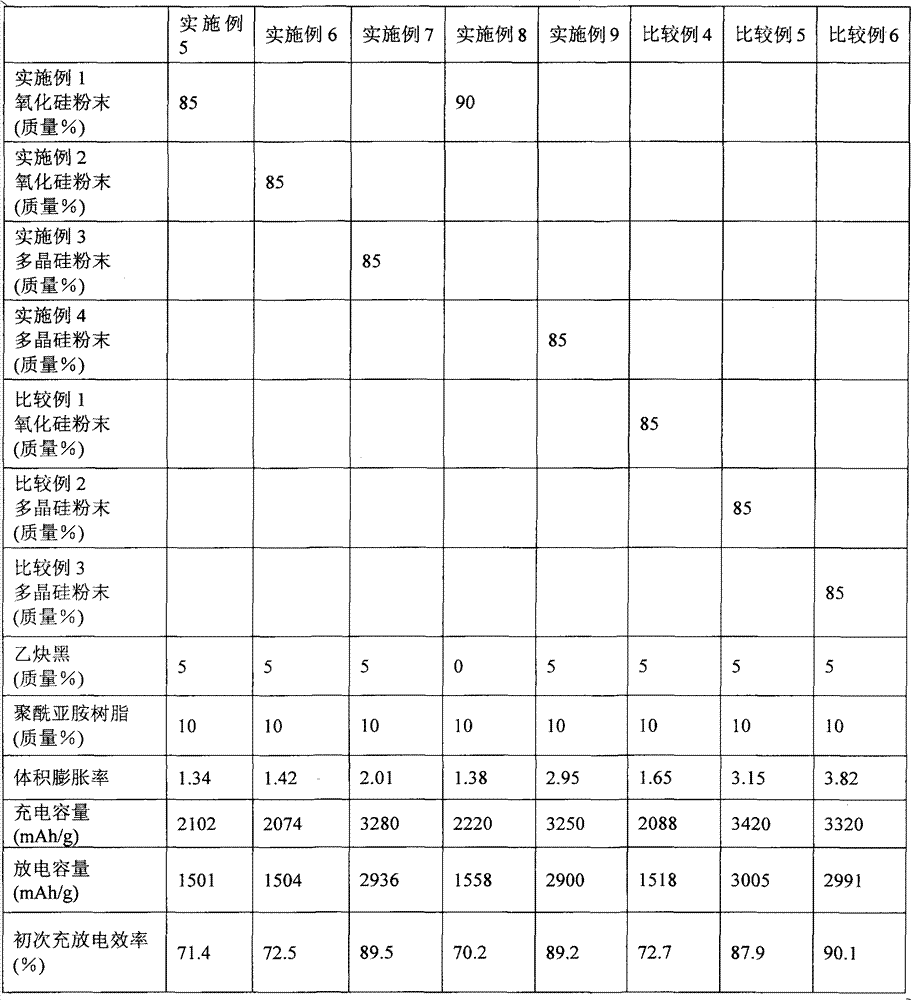

[0148] The negative electrode material in the present invention is obtained by using silicon oxide powder or silicon powder coated with carbon. In order to confirm the usefulness of the negative electrode material in the present invention, as described below, using Examples 1 to 4, comparative Each of the negative electrode active materials prepared in Examples 1 to 3 was used to make negative electrode materials, and after using the negative electrode materials to make lithium-ion secondary batteries for evaluation, the charge-discharge capacity and volume expansion rate were measured.

[0149]

[0150]The following powders were used as negative electrode active materials: silicon oxide powder obtained by coating silicon oxide powder 1 with carbon in Example 1 (Examples 5 and 8), and silicon oxide powder 2 obtained by coating carbon with carbon in Example 2. obtained silicon oxide powder (Example 6), polycrystalline silicon powder obtained by coating polycrystalline silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com