Surface-modified silicon-carbon composite and preparing method and application thereof

A silicon-carbon composite material and surface modification technology, which is applied in the fields of nanotechnology, active material electrodes, and electrical components for materials and surface science. and other problems, to achieve the effect of improving electrochemical performance, low cost, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

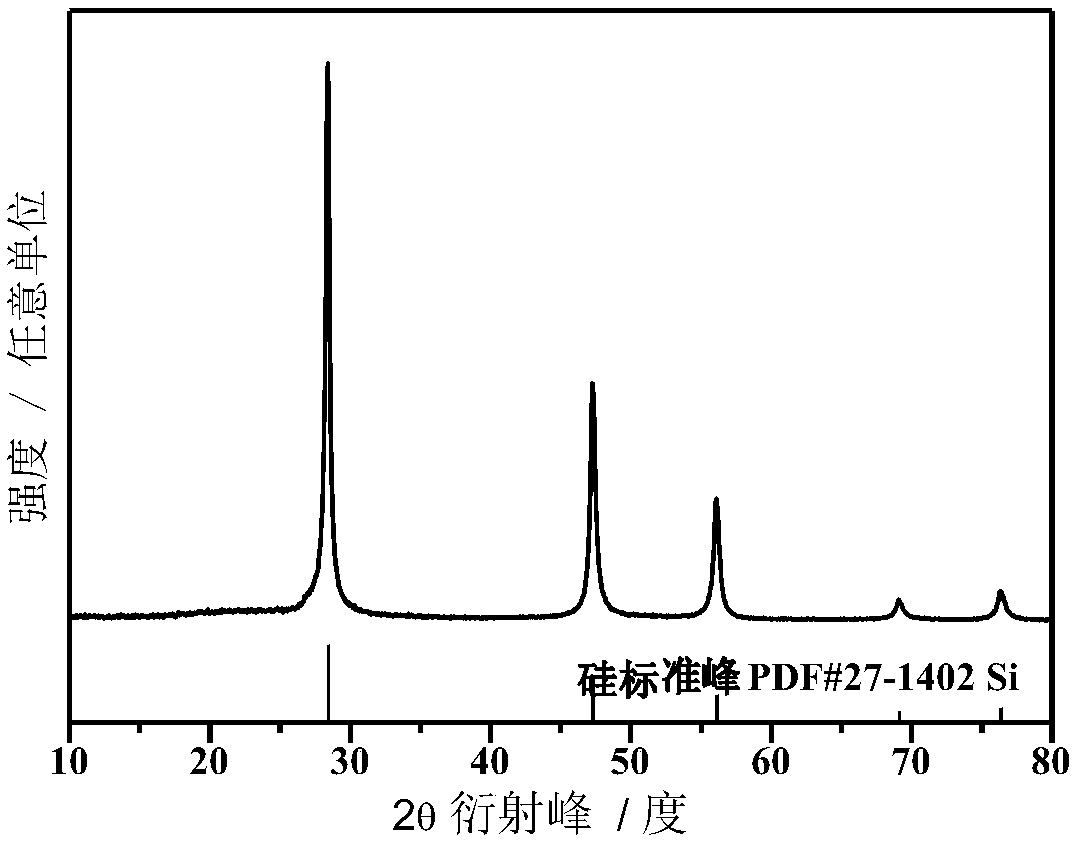

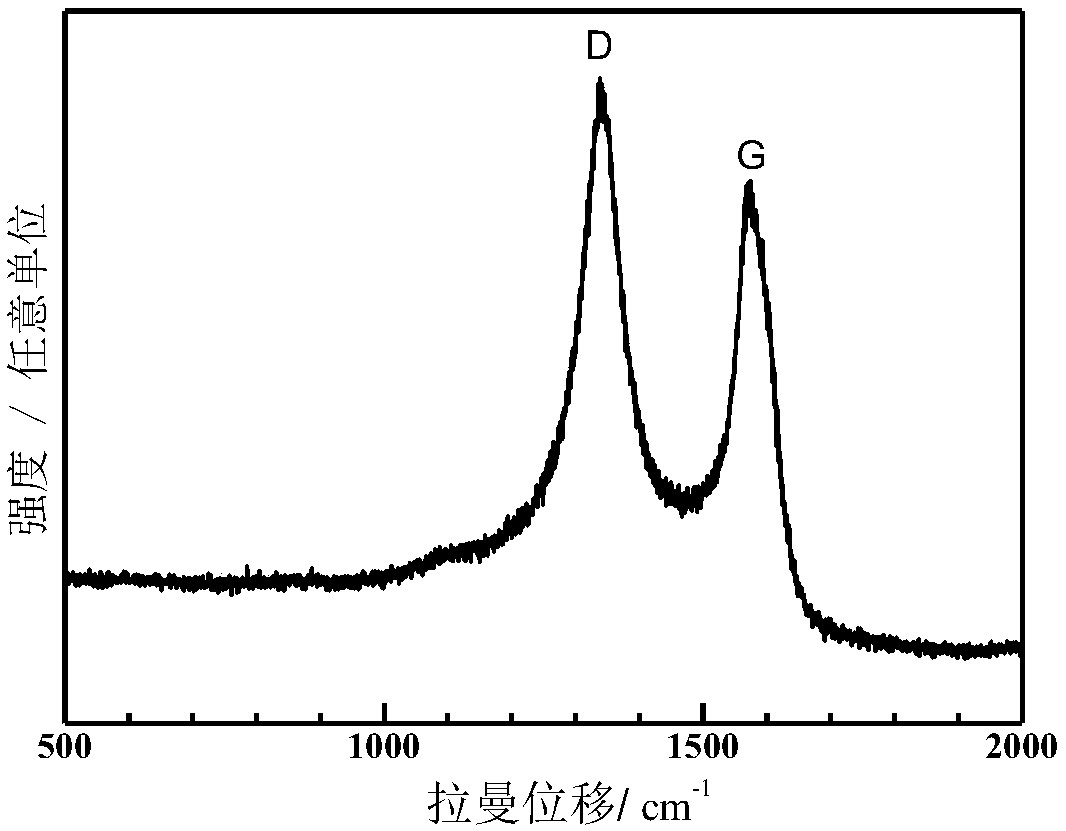

[0044]A method for preparing a surface-modified silicon-carbon composite material, comprising the following steps:

[0045] 1) Calcining diatomite in air at 800°C for 2 hours, then washing the calcined product with 6mol / L hydrochloric acid for 12 hours, and then washing it with water for 5 times to obtain pure silicon oxide;

[0046] 2) Then the pure silicon oxide, magnesium powder and sodium chloride prepared in step 1) are mixed by ball milling, the molar ratio of magnesium powder and pure silicon oxide is 2:1, and the weight ratio of sodium chloride to pure silicon oxide is 6:1; The ball milling speed is 180r / min, and the ball milling time is 10 hours to obtain a mixture;

[0047] 3) Put the mixture prepared in step 2) in a magnetic boat, then put polypropylene in another magnetic boat, the weight ratio of polypropylene to pure silicon oxide is 1:1, and place the two magnetic boats side by side in the tube furnace In the process, argon gas was introduced to carry out simul...

Embodiment 2

[0059] A method for preparing a surface-modified silicon-carbon composite material, comprising the following steps:

[0060] 1) Calcining kaolin in air at 800°C for 2 hours, then washing the calcined product with 6mol / L hydrochloric acid for 12 hours, and washing it with deionized water for 5 times to obtain pure silicon oxide;

[0061] 2) Then the pure silicon oxide, magnesium powder and potassium chloride prepared in step 1) are mixed by ball milling, the molar ratio of magnesium powder and pure silicon oxide is 2.1:1, and the weight ratio of potassium chloride and pure silicon oxide is 8:1; The ball milling speed is 180r / min, and the ball milling time is 10 hours to obtain a mixture;

[0062] 3) Put the mixture prepared in step 2) in a magnetic boat, then put polyethylene in another magnetic boat, the weight ratio of polyethylene to pure silicon oxide is 1:1, and place the two magnetic boats side by side in the tube furnace In the process, argon gas is introduced to carry ...

Embodiment 3

[0068] A method for preparing a surface-modified silicon-carbon composite material, comprising the following steps:

[0069] 1) Diopside was first calcined in air at 800°C for 2 hours, then the calcined product was washed with 6mol / L hydrochloric acid for 12 hours, and then washed 5 times with deionized water until neutral to obtain pure silica;

[0070] 2) Then the pure silicon oxide, magnesium powder and sodium chloride prepared in step 1) are mixed by ball milling, the molar ratio of magnesium powder and pure silicon oxide is 2.1:1, and the weight ratio of sodium chloride to pure silicon oxide is 10:1; The ball milling speed is 180r / min, and the ball milling time is 10 hours to obtain a mixture;

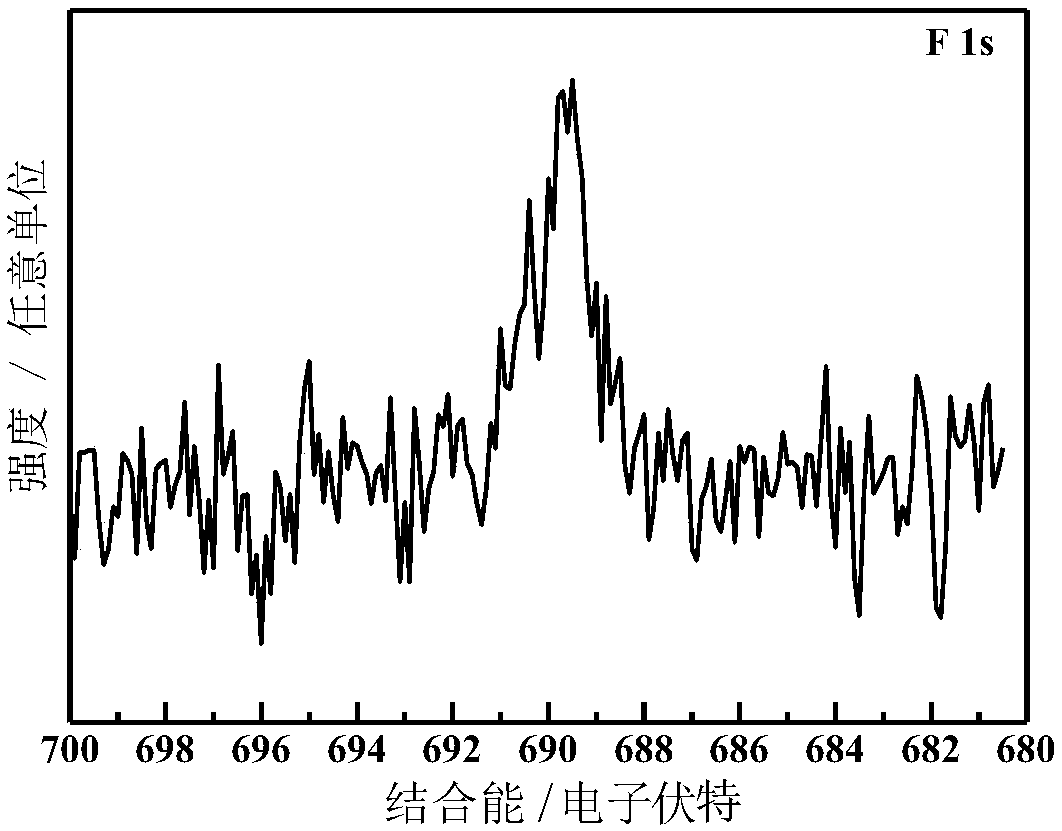

[0071] 3) Place the mixture prepared in step 2) in a magnetic boat, then place polyvinyl chloride in another magnetic boat, the weight ratio of polyvinyl chloride to pure silicon oxide is 1:1, and place the two magnetic boats side by side in the tube In the type furnace, argon ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com