Spherical porous silicon/carbon composite material as well as preparation method and application thereof

A silicon-carbon composite material and carbon composite material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of high cost, unsuitable for industrialization, complicated operation, etc., and achieve low cost, easy to enlarge, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

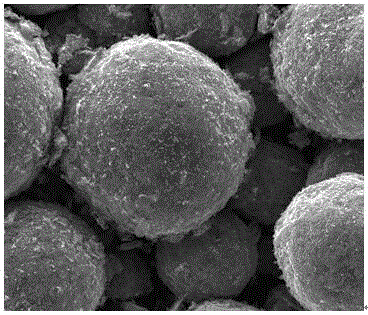

[0032] A method for preparing a spherical porous silicon-carbon composite material, the specific steps are as follows:

[0033] (1) A certain proportion of SiO x The powder and asphalt powder are added to the VCJ heating mixer and stirred for a period of time, and then the temperature is raised under an inert atmosphere for coating; SiO x The average particle size of the powder is 5-20μm; the asphalt powder is petroleum pitch or coal tar pitch, the average particle size is 2-10μm; SiO x The mass percentage of powder and pitch powder is 60-90:1-40; the stirring speed is 60-100rpm, and the stirring time is 0.5-3h; the inert gas is one of nitrogen, argon, helium, and neon; the heating rate is 1- 5°C / min, the heating end point is 200-500°C, and the holding time is 1-5h.

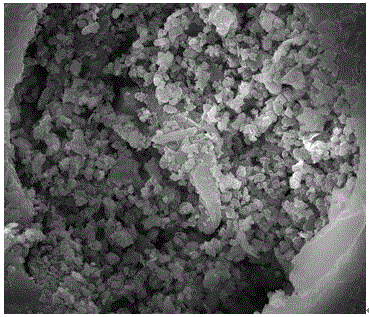

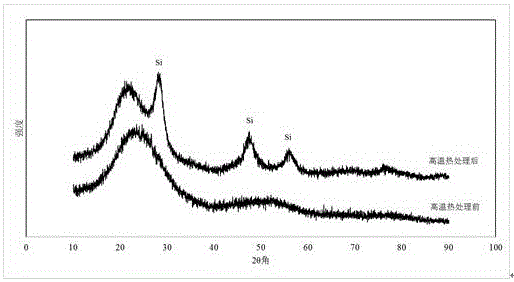

[0034] (2) The coated material is heat-treated at high temperature for a period of time under an inert atmosphere and sieved to obtain SiO x / C matrix; the inert atmosphere is one of nitrogen, argon, helium, an...

Embodiment 1

[0040] Preparation of silicon-carbon composite materials: Add 2.4 kg of SiOx powder with an average particle size D50 of 6 μm and 0.6 kg of petroleum pitch powder with an average particle size D50 of 2.5 μm into the VCJ heating mixer, start stirring and pass high-purity nitrogen to remove the air , the rotating speed is 80rpm, the time is 1h, keep stirring, and then raise the temperature to 400°C at a heating rate of 3°C / min for 2h, and collect the asphalt-coated SiOx material. The asphalt-coated SiOx was heat-treated in a nitrogen atmosphere in a box furnace, and the temperature was raised to 1000°C for 5 hours at a rate of 10°C / min and then sieved to obtain the heat-treated SiOx / C material. Get 500g of heat-treated SiOx / C material and wet grind it with a stirring ball mill, using ethanol as a solvent, with a solid content of 15%, a rotating speed of 260rpm, and a grinding time of 3h. μm artificial graphite, 30g of conductive agent Super-p and 3000g of ethanol were added into...

Embodiment 2

[0047] Embodiment 2 Change "0.6kg petroleum asphalt powder" in embodiment 1 to "0.3kg petroleum asphalt powder", and the others remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com