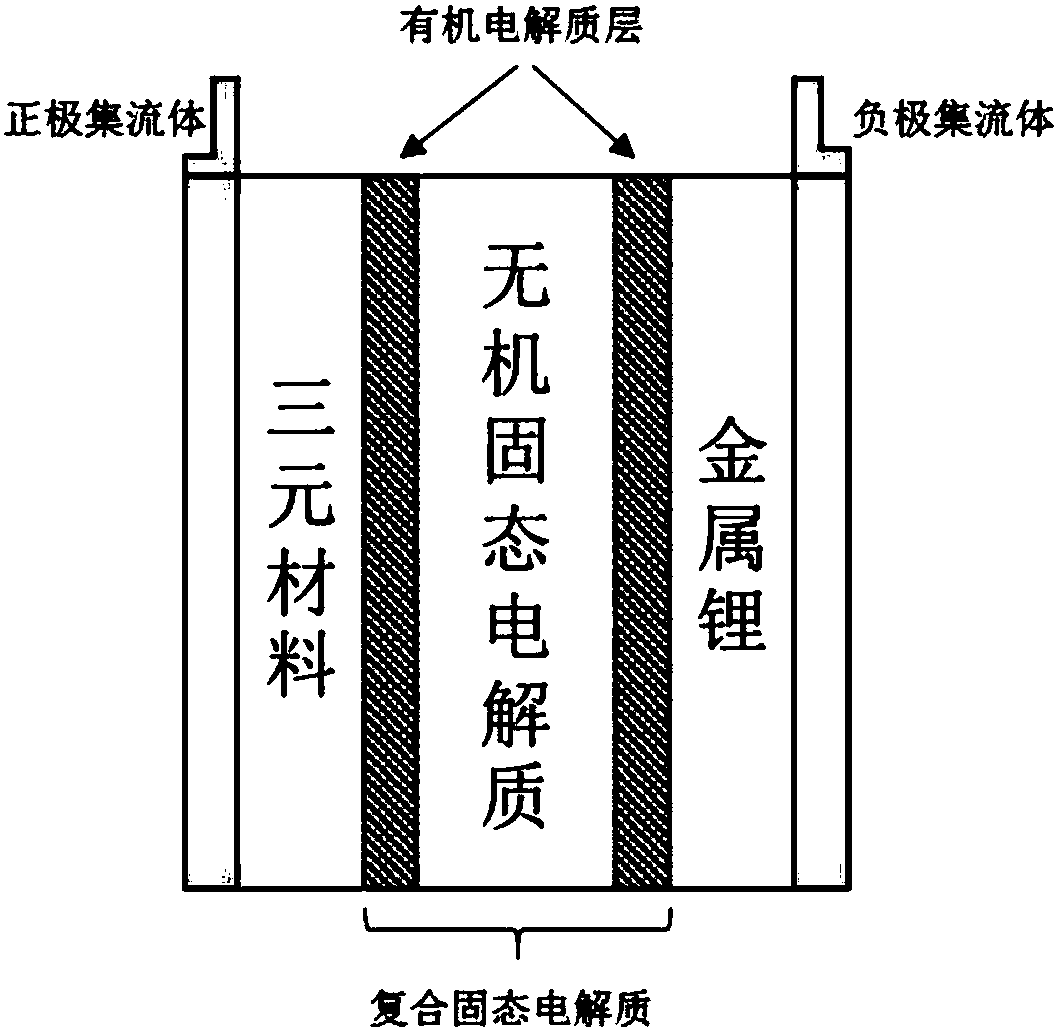

A composite solid-state electrolyte for all-solid-state lithium ion batteries and a preparation method thereof

A solid-state electrolyte, lithium-ion battery technology, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve problems such as rate discharge capacity and cycle performance decline, high conductivity can not be well exerted, and solid-state battery performance is limited. , to achieve the effect of improved conductivity, high energy density, and improved contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: Preparation of composite solid electrolyte

[0076] Composite solid electrolytes were prepared as follows

[0077] i) Preparation of rare metal-doped inorganic electrolyte powder:

[0078] With 7mmol lithium hydroxide, 2.5mmol lanthanum nitrate, 2mmol zirconium nitrate, 0.5mmol niobium nitrate (that is, molar ratio 7:2.5:2:0.5) and pH buffer (barbital-sodium chloride-hydrochloric acid, adjust pH = 7.5) Disperse evenly in 100ml ethanol aqueous solution (mixing ratio of ethanol and water is 1:1), add urea, and conduct heat treatment at 550°C under argon protection to obtain inorganic electrolyte powder with a particle size of 100-4000 nanometers.

[0079] ii) Forming an inorganic electrolyte layer:

[0080] Add 100 mg of powder obtained in step i) to 800 mg of ethanol and butanone mixed solvent (the mixing ratio of ethanol and butanone is 1:1), add SDS dispersant to make a slurry, and ball mill in a high-energy ball mill for 12 hours to obtain a fine powde...

Embodiment 2

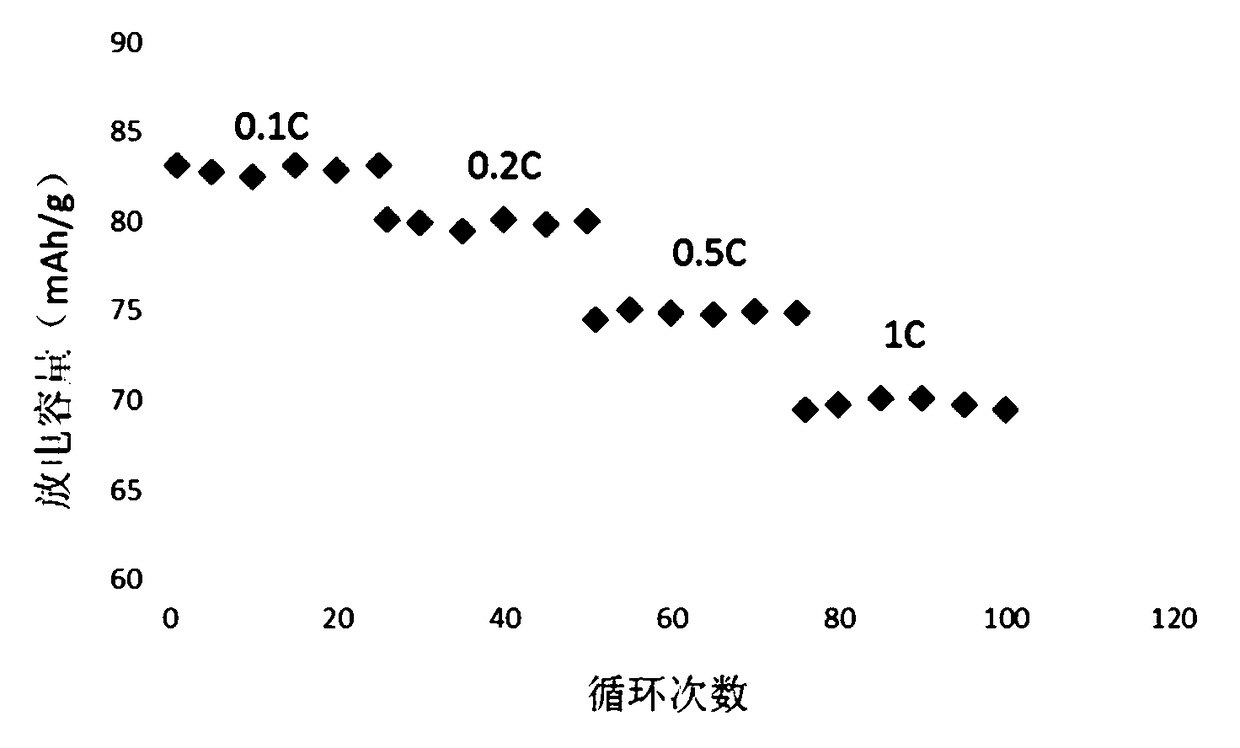

[0086] Embodiment 2: Preparation of all-solid-state lithium-ion battery

[0087] Prepare an all-solid-state lithium-ion battery as follows:

[0088] Cut the aluminum-plastic film into 150*200mm in advance, take the center line of the long side as the axis of symmetry, and punch out two square pits of 102*52mm in the center of the two sides, with a depth of 4mm.

[0089] Put 20 pairs of positive and negative electrodes and electrolytes into the square pit in the order of positive electrode-solid electrolyte layer-negative electrode-solid electrolyte layer, and the laser welding tabs are drawn out of the aluminum-plastic film from above.

[0090] Fold the aluminum-plastic film in half so that all the electrodes fall into the square pit, and vacuumize the edge for the first time.

[0091] The battery is compressed under a pressure of 200kN, and the gas is driven to the first sealing edge.

[0092] The second edge sealing is performed on the inside of the exhausted gas, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com