Modified lithium manganate material, and preparation method and application thereof

A technology of permanent lithium manganese oxide and manganese ions, which is applied in the field of modified lithium manganate materials, can solve the problems of low capacity of lithium manganate, influence on material performance, weak binding force, etc., and achieve high current and excellent cycle performance with low cost Inexpensive, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take by weighing aluminum nitrate nonahydrate powder 0.188g, be made into 20ml solution, measure 50wt.% manganese nitrate (Mn(NO 3 ) 2 ) solution, 0.349ml, was dropped into the aluminum nitrate solution, and stirred evenly. Weigh 0.696g of manganese dioxide, put it into the mixed solution, stir evenly, weigh 0.42g of lithium hydroxide monohydrate, dissolve it in 10ml of deionized water, slowly drop it into the mixed solution, and stir for 30 minutes. The above mixed solution was placed in a hydrothermal reactor at 200 o C reacted for 20 hours, filtered, washed and dried to obtain the finished precursor, after 3 hours 750 o C heat treatment to prepare LiMn 1.5 al 0.5 o 3.95 Uniformly coated LiMn 2 o4 Powder, coating element stoichiometry was determined by X-ray photoelectron spectroscopy (XPS).

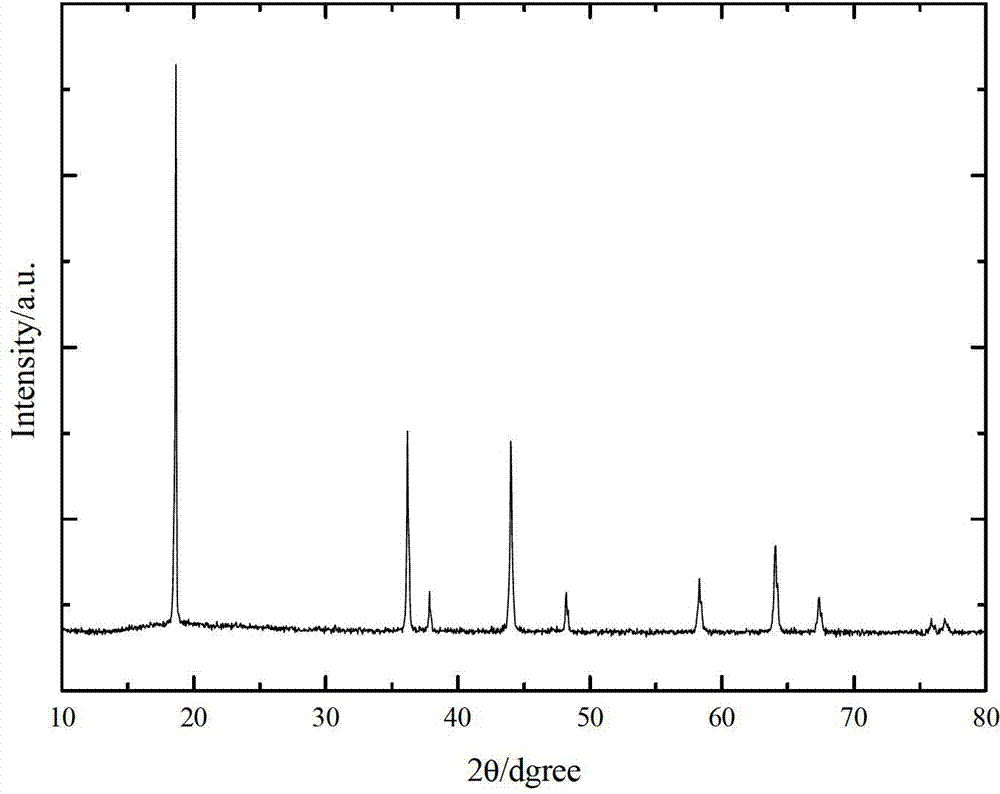

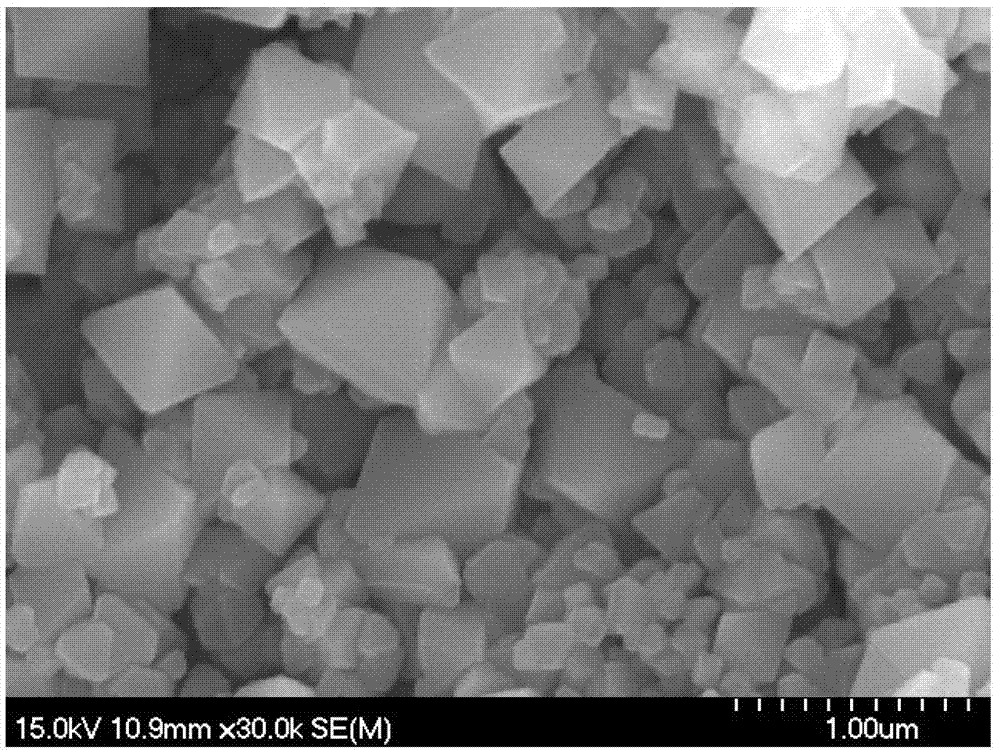

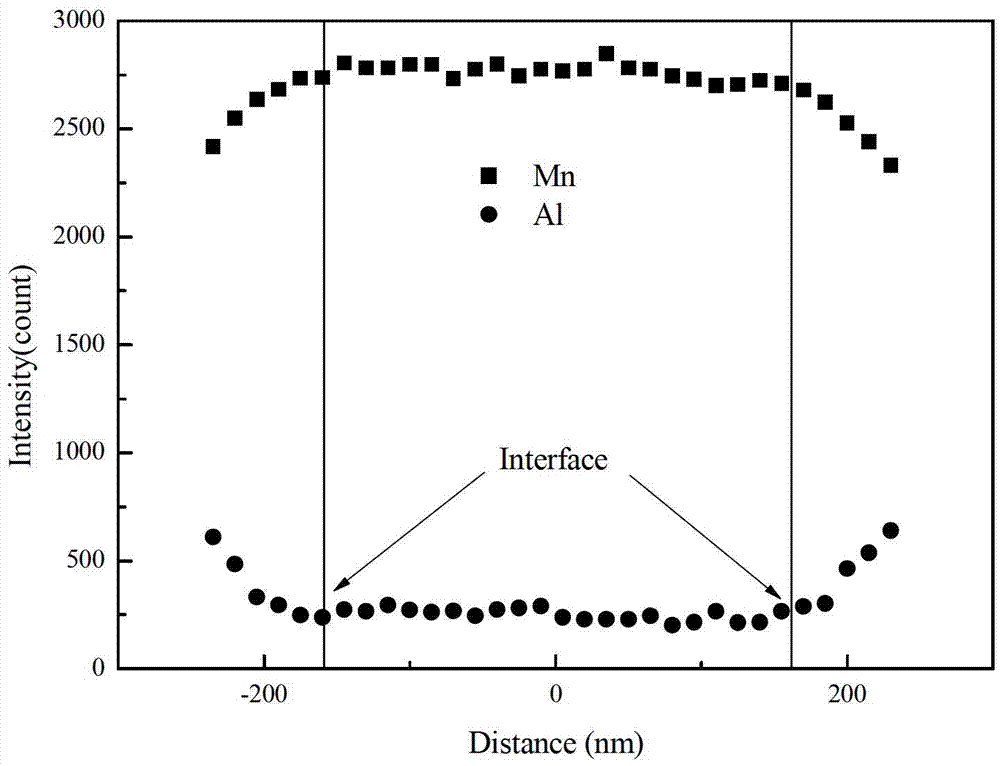

[0033] X-ray diffraction analysis was done to the modified lithium manganate material prepared in this way, by figure 1 It can be seen that the prepared lithium manganat...

Embodiment 2

[0037] Take by weighing nickel nitrate hexahydrate powder 0.145g, be made into 20ml solution, measure 50wt.% manganese nitrate (Mn(NO 3 ) 2 ) solution 0.349ml, drop in the nickel nitrate solution, and stir evenly. Weigh 0.696g of manganese dioxide, put it into the mixed solution, stir evenly, weigh 0.42g of lithium hydroxide monohydrate, dissolve it in 10ml of deionized water, slowly drop it into the mixed solution, and stir for 30 minutes. The above mixed solution was placed in a hydrothermal reactor at 200 o C reacted for 20 hours, filtered, washed and dried to obtain the finished precursor, after 3 hours 750 o C heat treatment to prepare LiMn 1.5 Ni 0.5 o 3.95 Uniformly coated LiMn 2 o 4 Powder, coating element stoichiometry was determined by X-ray photoelectron spectroscopy (XPS).

[0038] Using the prepared modified lithium manganese oxide material as the positive electrode material, assemble it into a 2032 button battery according to the method of Example 1, and ...

Embodiment 3

[0040] Take by weighing cerium nitrate hexahydrate powder 0.217g, be made into 20ml solution, measure 50wt.% manganese nitrate (Mn(NO 3 ) 2 ) solution 0.349ml, drop into the cerium nitrate solution, and stir evenly. Weigh 0.696g of manganese dioxide, put it into the mixed solution, stir evenly, weigh 0.42g of lithium hydroxide monohydrate, dissolve it in 10ml of deionized water, slowly drop it into the mixed solution, and stir for 30 minutes. The above mixed solution was placed in a hydrothermal reactor at 200 o C reacted for 20 hours, filtered, washed and dried to obtain the finished precursor, after 3 hours 750 o C heat treatment to prepare LiMn 1.5 Ce 0.5 o 3.97 Uniformly coated LiMn 2 o 4 Powder, coating element stoichiometry was determined by X-ray photoelectron spectroscopy (XPS).

[0041] Using the prepared modified lithium manganese oxide material as the positive electrode material, assemble it into a 2032 button battery according to the method of Example 1, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com