Battery, battery cathode, battery cathode material and preparation method thereof

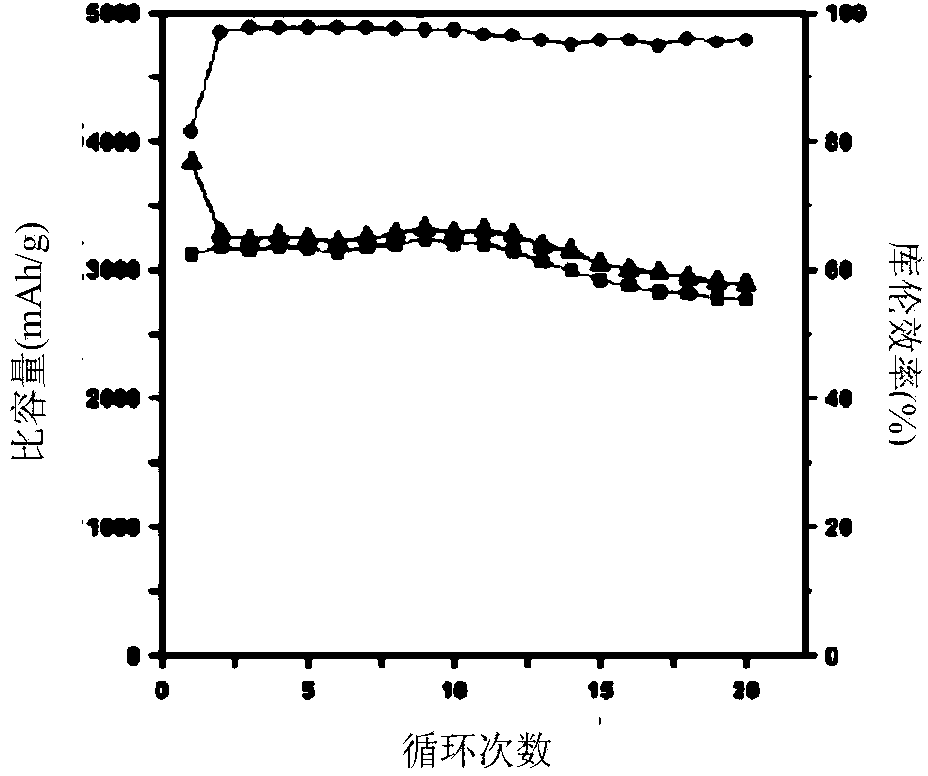

A negative electrode material and battery negative electrode technology, applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of capacity fading and unsatisfactory cycle performance of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

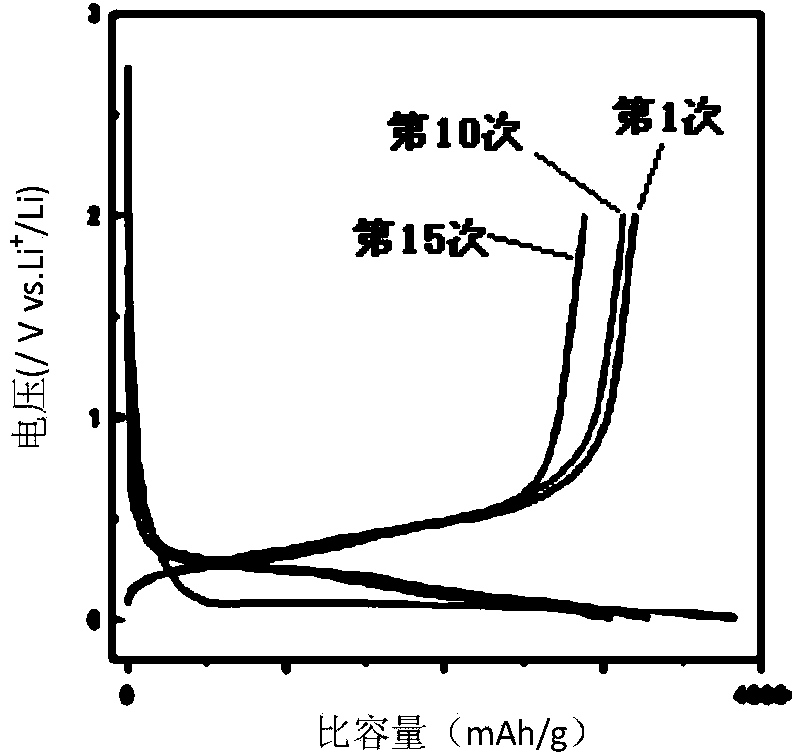

[0055] The invention also discloses a method for preparing the negative electrode material of the battery. The negative electrode material includes active material elemental silicon (Si), reduced graphene oxide (RGO), and polyaniline (PANi).

[0056] Specifically, the preparation method mainly adopts an in-situ polymerization method to prepare polyaniline and reduced graphene oxide double-coated silicon-based composite materials. In-situ polymerization is a kind of adding reactive monomer (or its soluble prepolymer) and catalyst into the dispersed phase (or continuous phase), and the core material is the dispersed phase. Since the monomer (or prepolymer) is soluble in a single phase, and its polymer is insoluble in the whole system, the polymerization reaction occurs on the core material of the dispersed phase. At the beginning of the reaction, the monomers are prepolymerized, and the prepolymers are polymerized. When the size of the prepolymers gradually increases, they are d...

Embodiment 1

[0077] Preparation of n-Si / PANi / RGO

[0078] First, add 0.3 g of nano-silicon (n-Si) particles, 0.5 g of surfactant dodecyltrimethylammonium bromide (DTBA) and 0.375 ml of n-butanol to 100 ml of deionized water, and ultrasonically disperse the above mixture for 30 minutes to obtain Homogeneous brown suspension.

[0079]A solution of 0.3 ml (3.3 mmol) of aniline monomer in 30 ml of HCl (pH=1) was then added dropwise to the brown suspension while stirring. The above mixture was stirred in an ice bath, and at the same time, 10 ml of deionized water in which 0.19 g (0.825 mmol) of ammonium persulfate was dissolved was slowly added dropwise thereto, which as an oxidizing agent could enable in-situ polymerization of aniline monomers. The polymerization process lasted for 12 hours, and a mixture of green and brown mixed colors of polyaniline and nano-silicon (n-Si / PANi) solution was obtained.

[0080] Take a reaction container, add 0.8g natural graphite and 23ml concentrated sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com