Nitrogen-doped porous hollow carbon sphere and preparation method and application thereof

A hollow carbon sphere, nitrogen doping technology, applied in active material electrodes, electrical components, electrochemical generators, etc., to achieve the effects of controllable morphology, reduced production costs, and promotion of electron and electrolyte transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

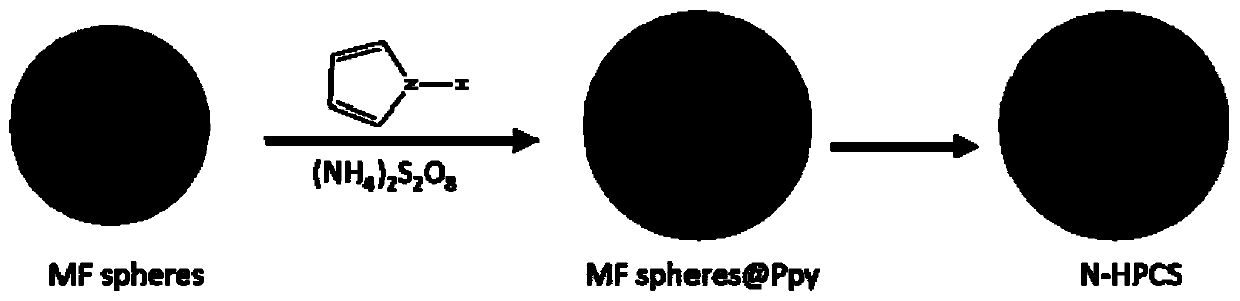

[0038] The preparation method of the nitrogen-doped porous hollow carbon sphere provided by the invention, the specific process is as follows figure 1 Shown:

[0039] a) 2.0g melamine and 6.0g formaldehyde solution (mass fraction is 35%) are added to 200mL deionized water, stirred in 60 ℃ water bath to obtain a clear solution, then add 0.4g hydrochloric acid (mass fraction is 37%), then in Stir in a water bath at 60° C. for 4 hours, separate by filtration, and collect samples to obtain monodisperse melamine resin beads (MFspheres) with an average diameter of about 1500 nm.

[0040] b) Take 1.0 g of monodisperse melamine resin beads as a template, disperse them in 100 mL of deionized water, then add 0.2 g of pyrrole and 0.3 g of ammonium persulfate in sequence, then continue stirring for 24 hours, centrifuge, collect samples, and dry , to obtain melamine resin beads (MF spheres@Ppy) coated with polypyrrole.

[0041] c) Put the melamine resin pellets coated with polypyrrole in...

Embodiment 2

[0049] A preparation method of nitrogen-doped porous hollow carbon spheres: comprising the steps of:

[0050] a) 1.0g melamine and 5.0g formaldehyde solution (35% by mass fraction) were added to 100mL deionized water, stirred in a water bath at 40°C to obtain a clear solution, then 0.8g hydrochloric acid (37% by mass fraction) was added, and then Stir in a water bath at 40°C for 10 h, filter and separate, and collect samples to obtain monodisperse melamine resin pellets (MF spheres).

[0051] b) Take 0.5 g of monodisperse melamine resin beads as templates, disperse them in 50 mL of deionized water, then add 0.1 g of pyrrole and 0.2 g of ammonium persulfate in sequence, then continue to stir for 10 h, centrifuge, and collect samples. After drying, melamine resin pellets (MFspheres@Ppy) coated with polypyrrole were obtained.

[0052] c) Put the melamine resin pellets coated with polypyrrole in a tube furnace, use nitrogen as an inert protective gas, and heat at 1°C min -1 The ...

Embodiment 3

[0056] A preparation method of nitrogen-doped porous hollow carbon spheres: comprising the steps of:

[0057] a) 3.0g melamine and 15g formaldehyde solution (35% by mass fraction) were added to 300mL deionized water, stirred in a water bath at 50°C to obtain a clear solution, then 2.0g hydrochloric acid (37% by mass fraction) was added, and then Stir in a water bath at ℃ for 3 hours, filter and separate, collect samples, and obtain monodisperse melamine resin pellets (MF spheres).

[0058] b) Take 3 g of monodisperse melamine resin beads as templates, disperse them in 150 mL of deionized water, then add 6.0 g of pyrrole and 9.0 g of ammonium persulfate in sequence, then continue to stir for 30 h, centrifuge, collect samples, and dry , to obtain melamine resin beads (MF spheres@Ppy) coated with polypyrrole.

[0059] c) Put the melamine resin pellets coated with polypyrrole in a tube furnace, use nitrogen as an inert protective gas, and heat at 5°C min -1 The heating rate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com