A non-damaging dry overetching preparation method of Schottky junction

A technology of Schottky junction and dry etching, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, semiconductor devices, etc., can solve the problems of etching damage epitaxial materials and uncontrollable process accuracy, and achieve Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

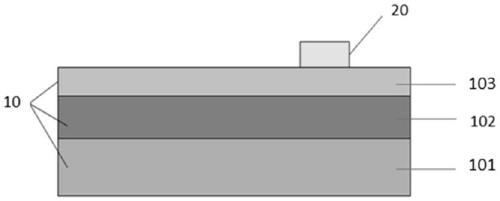

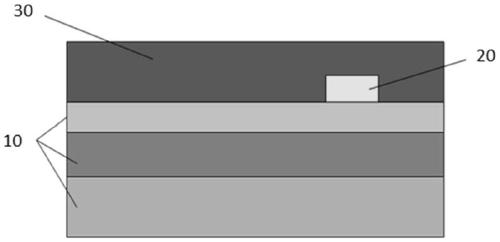

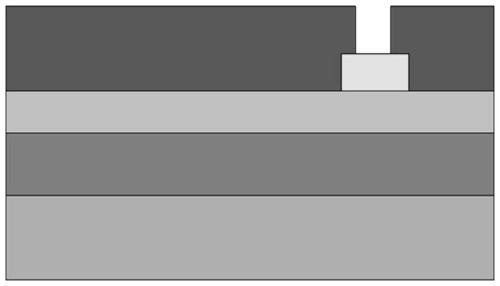

[0032] In an exemplary embodiment of the present invention, a non-destructive dry over-etching preparation method of Schottky junction is provided, which includes the following steps: First, lift is used at the position where the Schottky junction is prepared on the upper surface of the epitaxial wafer. -off method to form a metal barrier layer; then, an insulating dielectric layer is grown on the upper surface of the epitaxial wafer and the upper surface of the metal barrier layer; then, dry etching is used to conduct the insulating medium at the position where the Schottky junction is prepared Etching to form Schottky holes, in which, the scanning electron microscope SEM is used to observe whether over-etching is achi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com