Preparation method of porous metal doped lithium manganate/graphene lithium battery positive electrode material

A technology of lithium heteromanganate and porous metal, which is applied in the field of electrochemistry, can solve the problems of unfavorable electrode reaction pulverization, difficulty in controlling the uniformity of the carbon layer, and limited inhibition, so as to inhibit the dissolution of manganese and improve electrochemical stability performance, excellent rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

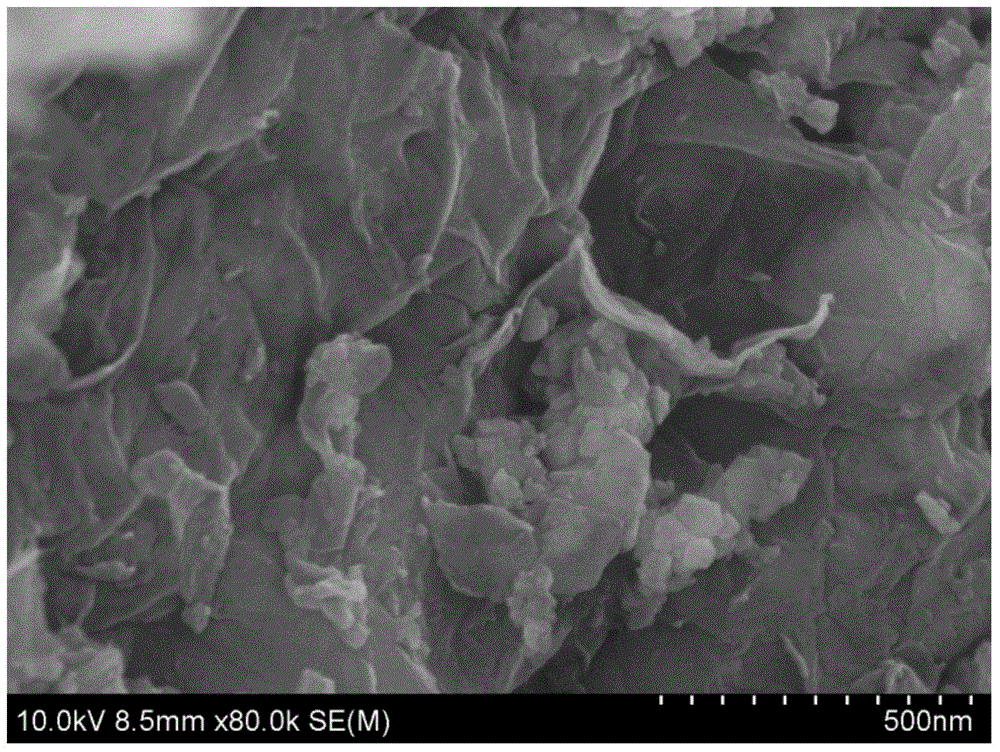

Image

Examples

Embodiment 1

[0031] In the first step, the polymer P123 with a molar mass of 5800 was dissolved in an appropriate amount of absolute ethanol, and stirred continuously at room temperature to obtain 20 mL of P123 gel with a uniform dispersion concentration of 0.05 g / mL.

[0032] In the second step, solid Mn(NO 3 ) 2 4H 2 O, LiNO 3 , Fe(NO 3 ) 3 9H 2 O is added in a molar ratio of 9:5:1, LiNO 3 The amount is 0.05mol.

[0033] In the third step, the above mixture was magnetically stirred at a medium speed for 12 h at room temperature.

[0034] In the fourth step, the uniformly mixed sol is air-dried at 60° C. for 24 hours in an air-blast drying oven.

[0035] In the fifth step, the dried mixture is heated in a muffle furnace at 2° C. / min to 500° C. in an air atmosphere, and kept for 2 hours.

[0036] Step 6: Add 1g NaNO3 and 2g flake graphite to 40ml of concentrated sulfuric acid solution; add 3g of potassium permanganate, heat up to 10°C, stir for 1h; heat up to 35°C, keep for 1h; ad...

Embodiment 2

[0043] In the first step, the polymer P123 with a molar mass of 5800 was dissolved in an appropriate amount of absolute ethanol, and stirred continuously at room temperature to obtain 20 mL of P123 gel with a uniform dispersion concentration of 0.08 g / mL.

[0044] In the second step, solid Mn(NO 3 ) 2 4H 2 O, LiNO 3 , Fe(NO 3 ) 3 9H 2 O is added in a molar ratio of 9:5:1, LiNO 3 The amount is 0.1mol.

[0045] In the third step, the above mixture was magnetically stirred at a medium speed for 16 h at room temperature.

[0046] In the fourth step, the uniformly mixed sol was air-dried at 70° C. for 36 hours in an air-blast drying oven.

[0047] In the fifth step, the dried mixture is heated in a muffle furnace at 3° C. / min to 600° C. in an air atmosphere, and kept for 3 hours.

[0048] Step 6: Add 1.5g NaNO3 and 3g flake graphite to 60ml of concentrated sulfuric acid solution; add 6g of potassium permanganate, heat up to 10°C, stir for 1h; heat up to 35°C, keep for 1h; ...

Embodiment 3

[0054] In the first step, the polymer P123 with a molar mass of 5800 was dissolved in an appropriate amount of absolute ethanol, and stirred continuously at room temperature to obtain 20 mL of P123 gel with a uniform dispersion concentration of 0.1 g / mL.

[0055] In the second step, solid Mn(NO 3 ) 2 4H 2 O, LiNO 3 , Fe(NO 3 ) 3 9H 2 O is added in a molar ratio of 9:5:1, LiNO 3 The amount is 0.5mol.

[0056] In the third step, the above mixture was magnetically stirred at a medium speed for 24 h at room temperature.

[0057] In the fourth step, the uniformly mixed sol is air-dried at 80° C. for 48 hours in an air-blast drying oven.

[0058] In the fifth step, the dried mixture is heated up to 700° C. in a muffle furnace at 5° C. / min in an air atmosphere, and kept for 4 hours.

[0059] Step 6: Add 2g NaNO3 and 4g flake graphite to 60ml of concentrated sulfuric acid solution; add 9g of potassium permanganate, heat up to 15°C, stir for 1h; heat up to 35°C, keep for 1h; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com