Patents

Literature

128results about How to "Stable pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for preparing silicon dioxide with large pore volume and large aperture

InactiveCN101112991AImprove precipitation effectOrderly distribution of poresSilicaActive agentWater soluble

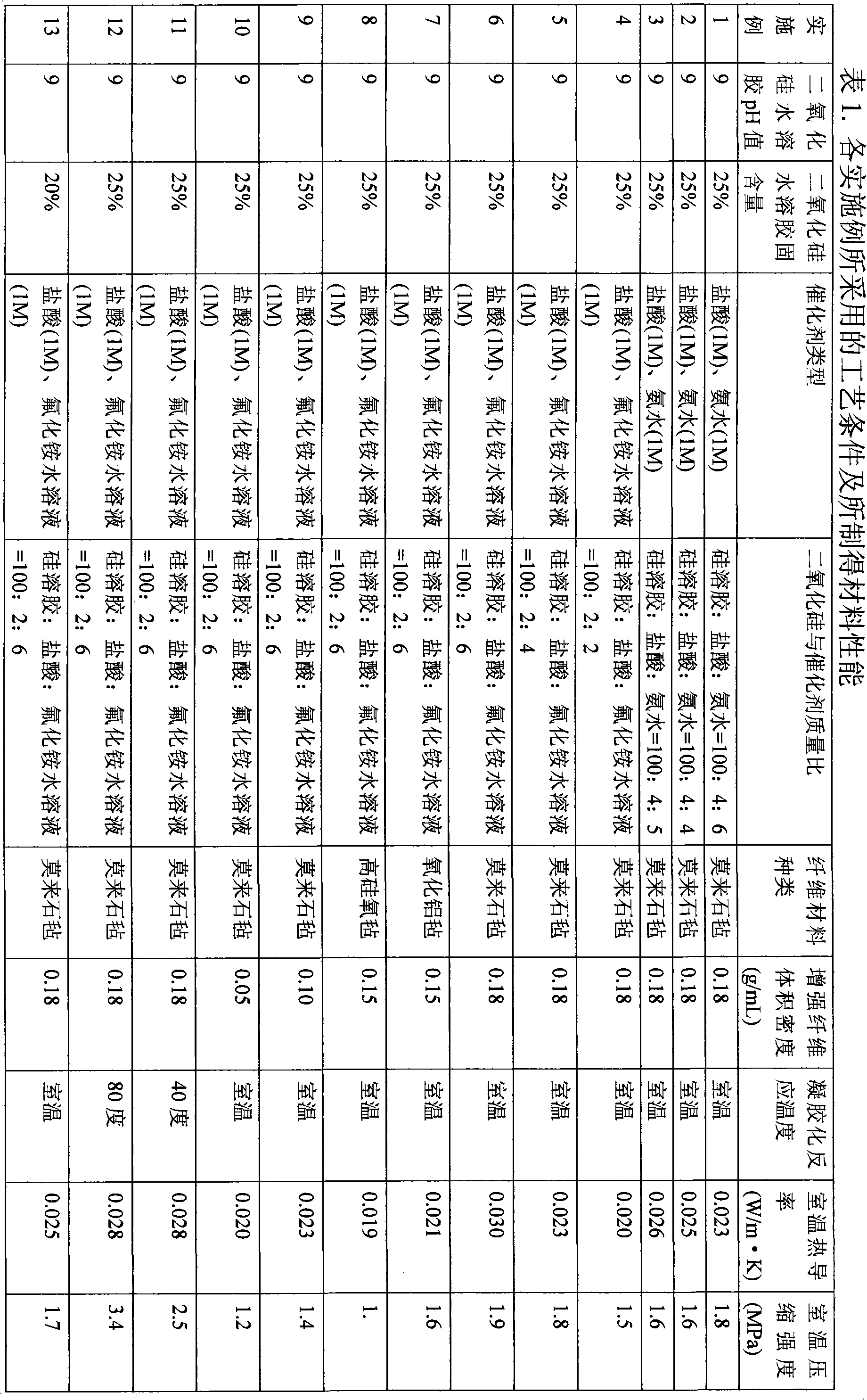

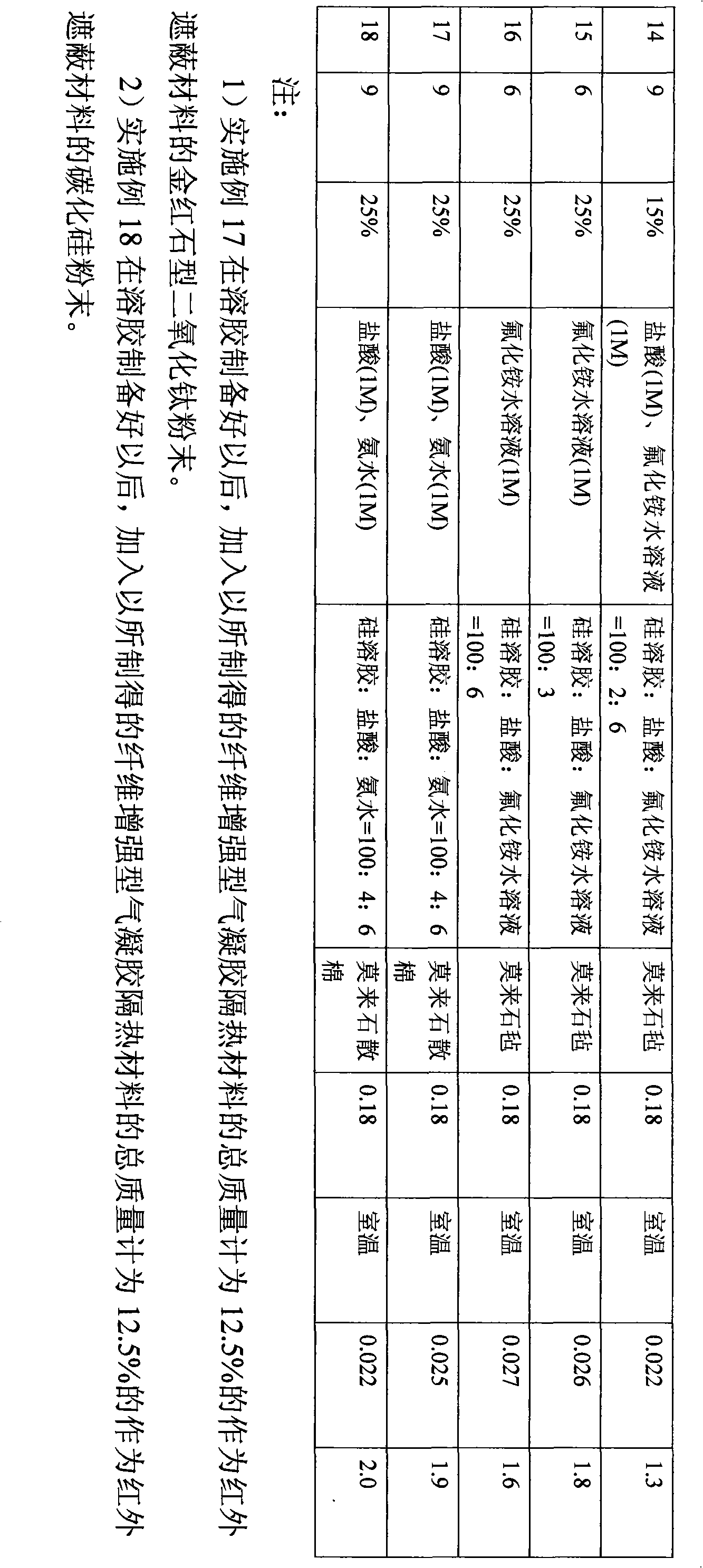

The invention relates to a preparation method of large pore volume and large pore diameter silica. With industrial water glass as silica source, water soluble polymer and surfactant as hydrophobic agent and hole forming template, by controlling reaction conditions such as temperature, hydrophobic agent, final ph value, etc., the large pore volume silica products are produced; the pore diameter is narrowly distributed, the pore volume is between 2-2.5cm3 / g and the average pore diameter is between 18-35 nm. Especially, the more optimal three-step heating regulation is more beneficial to the stability of hole forming and hole structure and that the distribution of pore diameter reaches between 25-35nm is more proper to be used as flatting agent.

Owner:BEIJING UNIV OF CHEM TECH

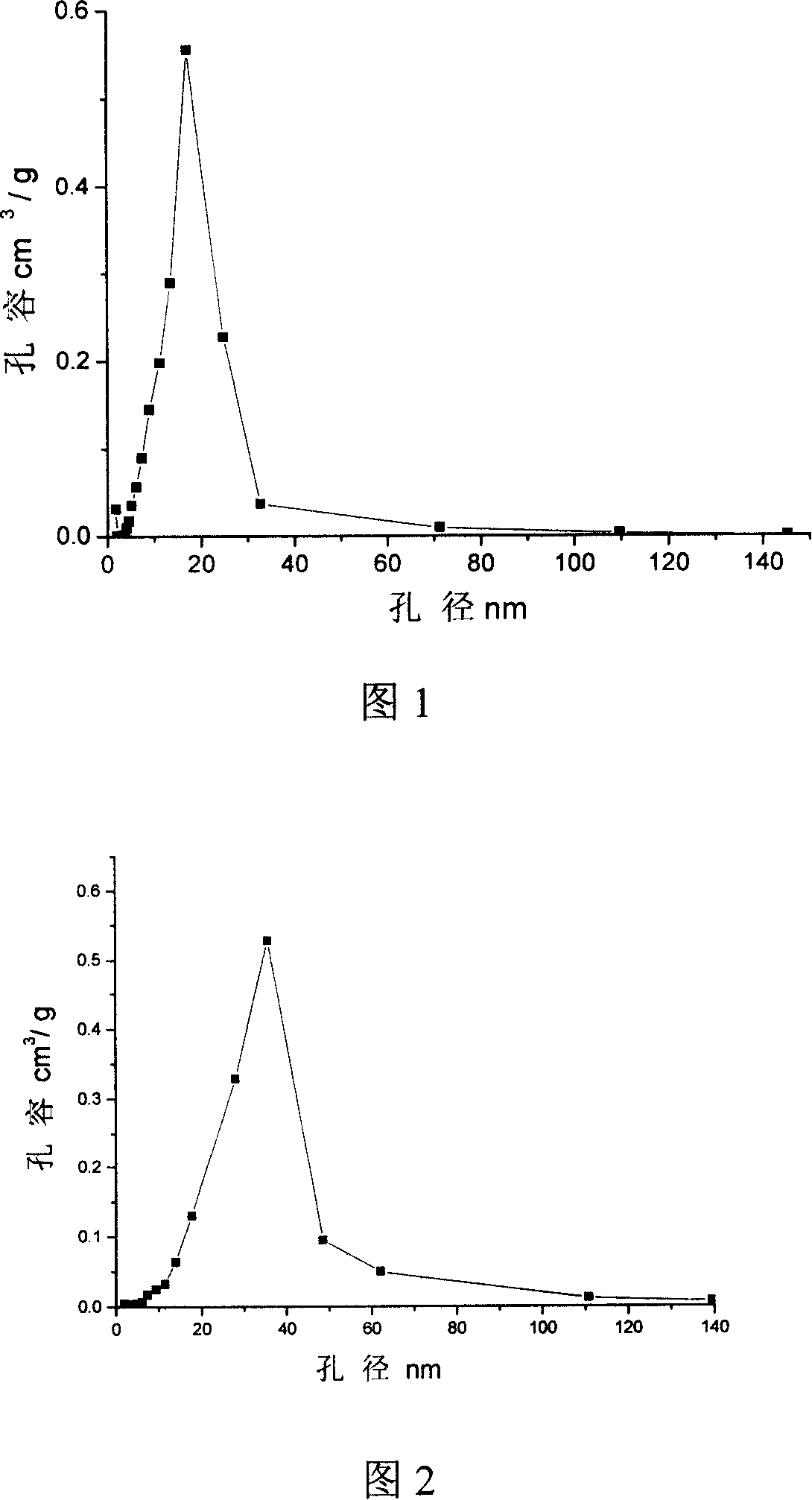

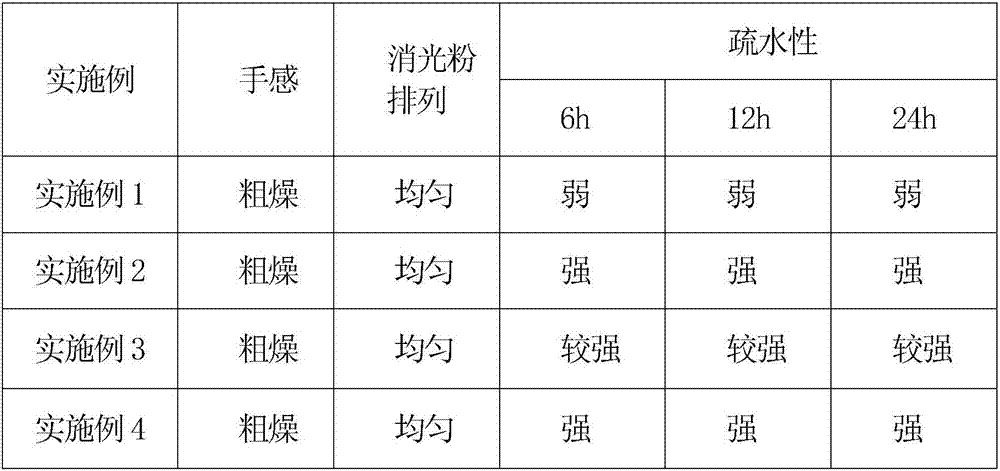

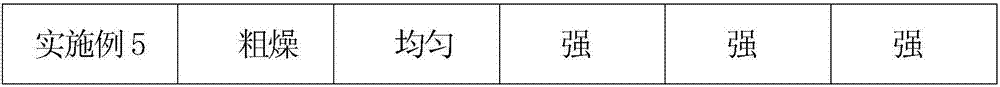

Preparation method of modified silicon dioxide obtained via super-hydrophobic modification

ActiveCN105400239AReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

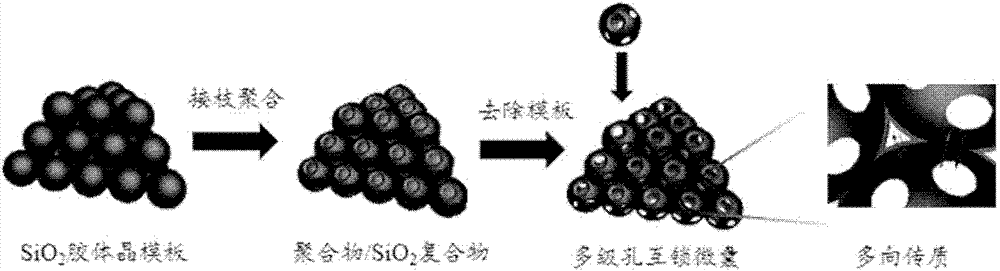

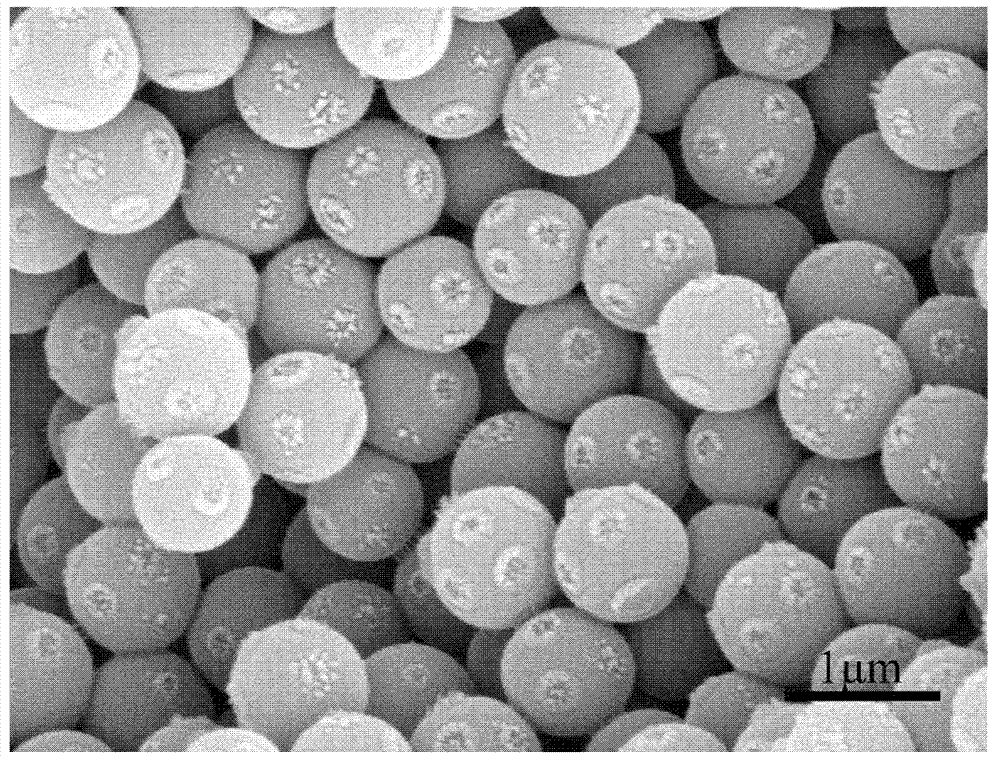

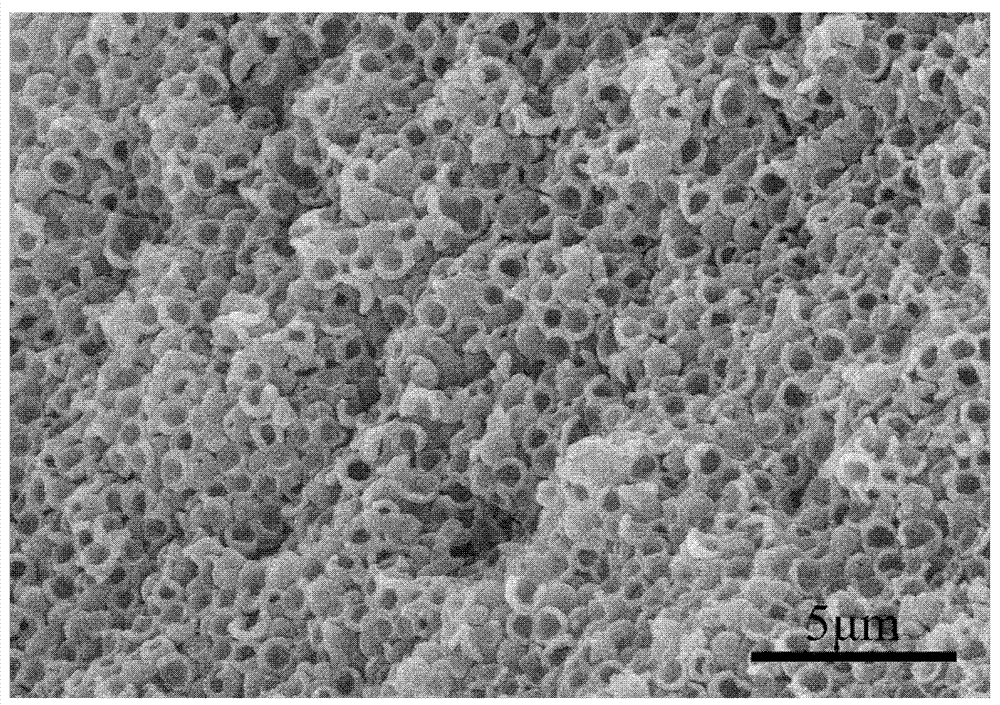

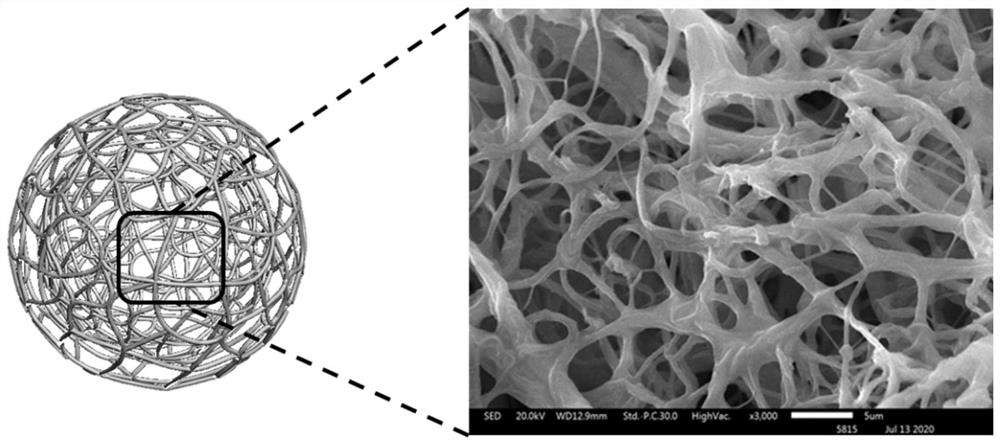

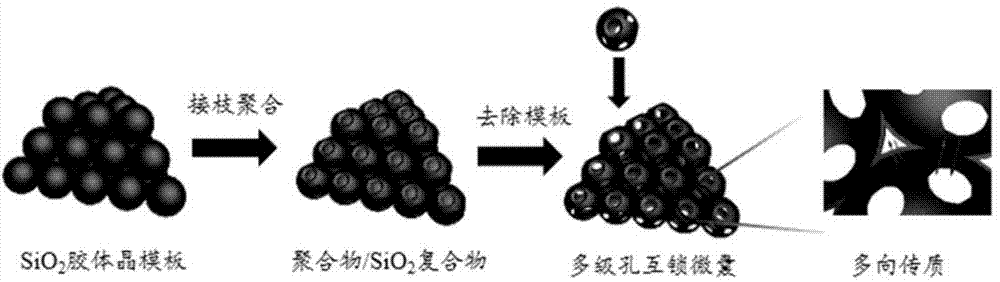

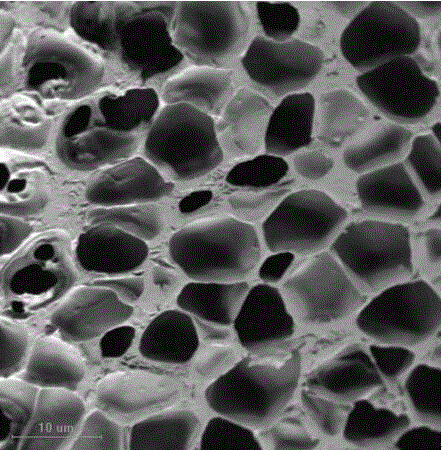

Preparation method for polymer-based hierarchical porous structure interlocking microcapsule

ActiveCN103933911ALarge specific surface areaGood application effectMicroballoon preparationMicrocapsule preparationDouble bondRadical polymerization

The invention discloses a preparation method for a polymer-based hierarchical porous structure interlocking microcapsule. The method comprises the steps of modifying a silicon dioxide colloid crystal template, controllably grafting a polymer by a surface triggering atom transferring free radical polymerization method and a double-bond free radical polymerization method, crosslinking a linear polymer chain section by an Friedel-Crafts crosslinking method for an external crosslinking agent, removing the silicon dioxide colloid crystal template to prepare the polymer-based hierarchical porous structure interlocking microcapsule. Due to the controllably grafted polymer layer, a certain slit is reserved between every two adjacent microcapsules, so that the mass is reduced, and more mass transfer ways are formed; by the adoption of the Friedel-Crafts crosslinking method for the external crosslinking agent, micropores and mesoporous are formed by crosslinking capsule walls made of polymer materials; the apertures of the formed holes and the crosslinking degree are adjusted according to the type of the crosslinking agent; a foundation is laid for the application; communicating windows formed among the micropores, the mesoporous and the interlocking microcapsules in the capsule walls and the slits between the microcapsules adopt classified hole interlocking structures in the mass.

Owner:HEBEI UNIV OF TECH

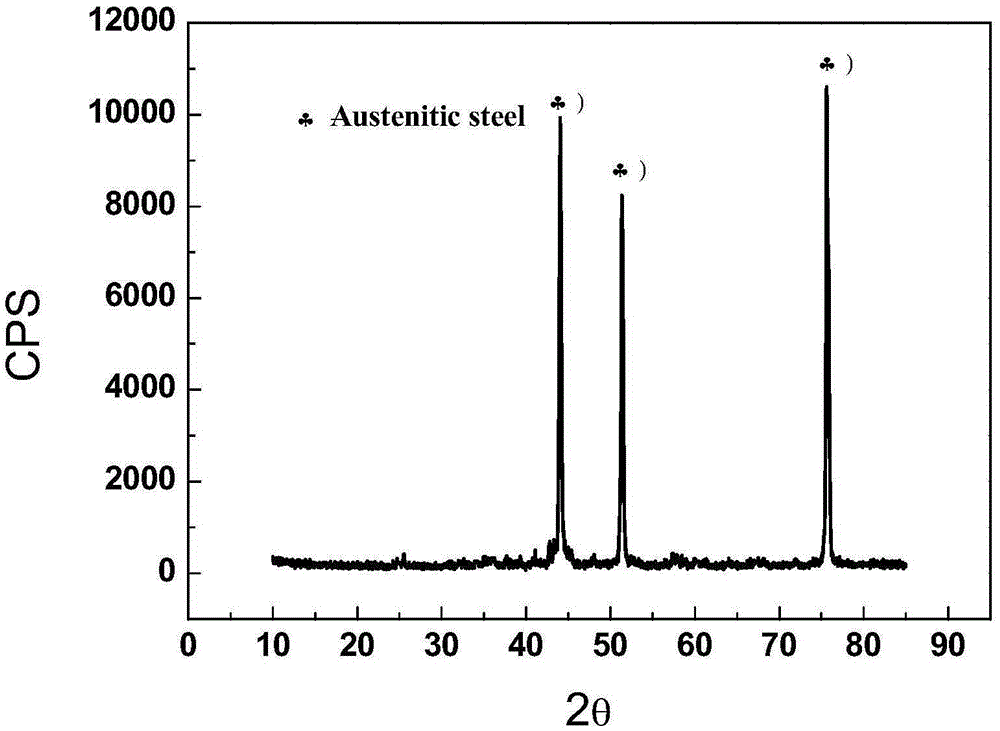

Preparation method for powder-sintered porous metal body resistant to chlorine corrosion

The invention discloses a preparation method for a powder-sintered porous metal body resistant to chlorine corrosion. The preparation method mainly comprises the steps that (1) mixed powder is prepared, that is, 75%-80% by mass of Ni powder, 12%-18% by mass of Cr powder and 2%-13% by mass of Fe powder are mixed; (2) cold press molding is carried out, that is, the mixed powder obtained in the step (1) is pelletized, dried and molded, and a pressed blank is obtained through cold press molding; and (3) sintering is carried out, that is, the pressed blank obtained in the step (2) is sintered in three stages under the vacuum condition of 1*10<-2> to 1*10<-3> Pa. The preparation method is used for the powder-sintered porous metal body which is resistant to chlorine corrosion, has abundant pores and is relatively large in pore diameter. A porous material with abundant pores is made of the Ni powder, the Cr powder and the Fe powder, and filtering in titanium sponge production is achieved by means of the excellent chlorine corrosion resistance of the porous material.

Owner:XIANGTAN UNIV

Porous ceramic composite particle and method for preparing the same

ActiveUS20170166485A1Stable pore structureShape stableMolten spray coatingCeramicwarePorous ceramicsMaterials science

Owner:HYUNDAI MOTOR CO LTD

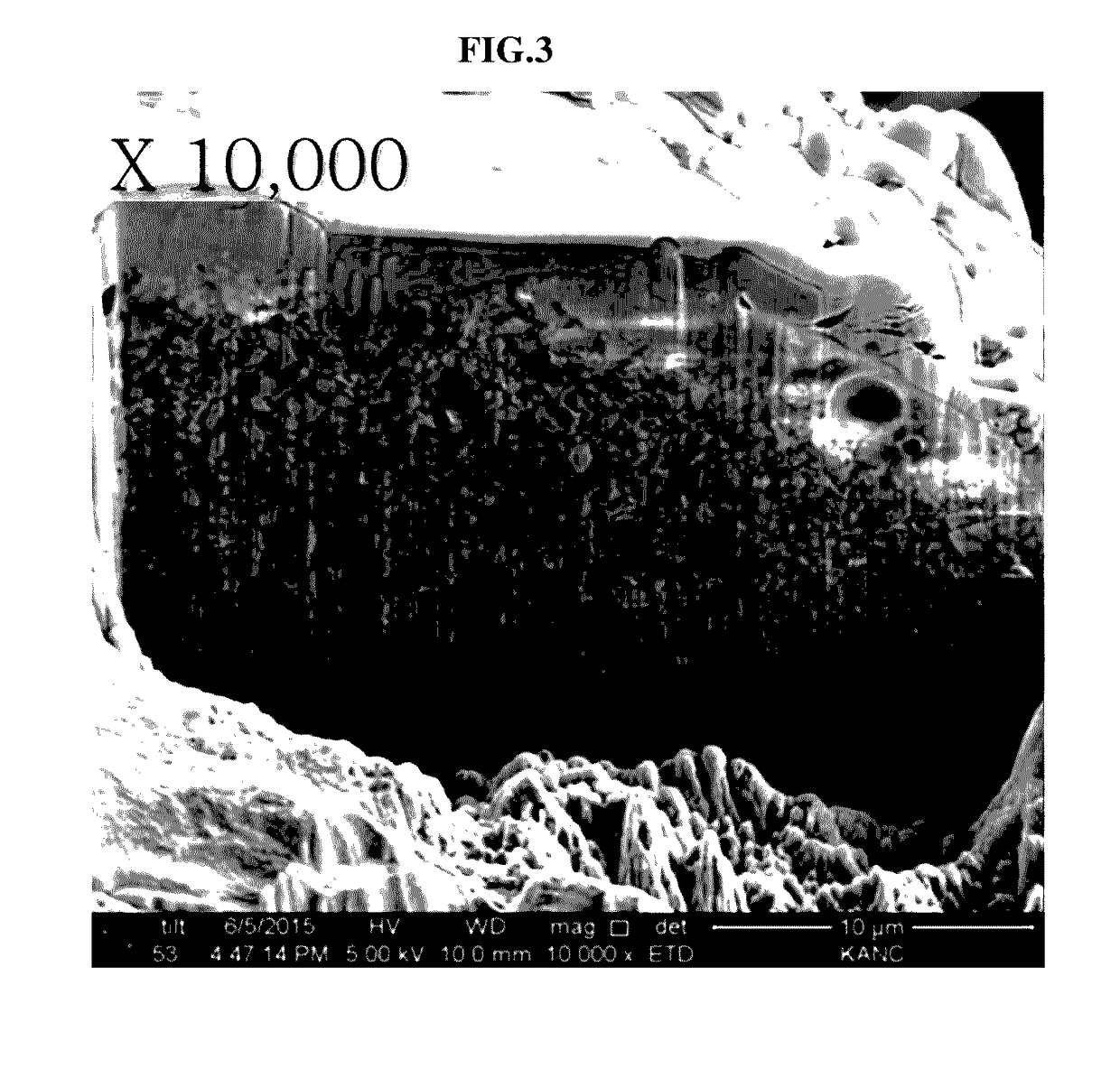

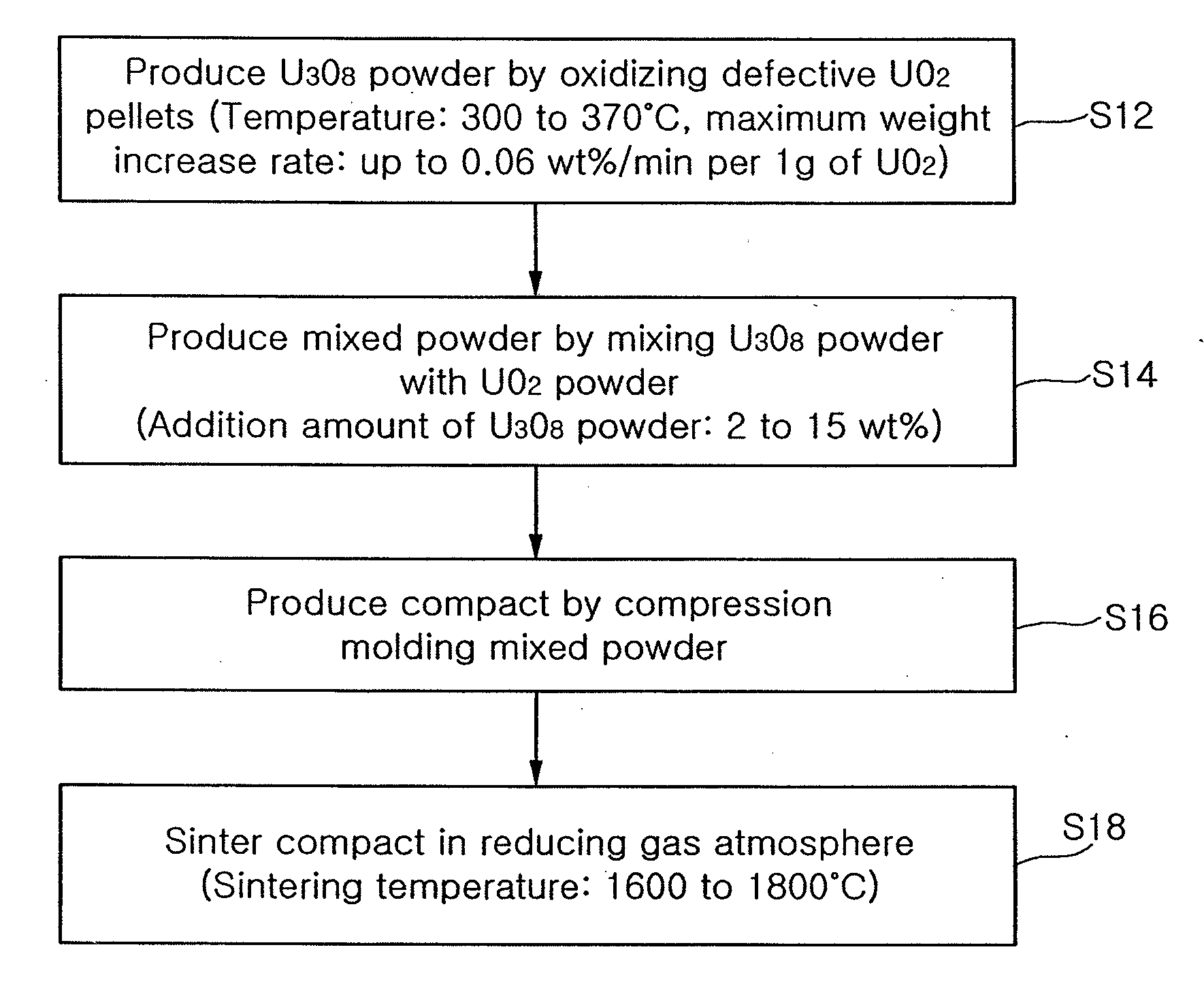

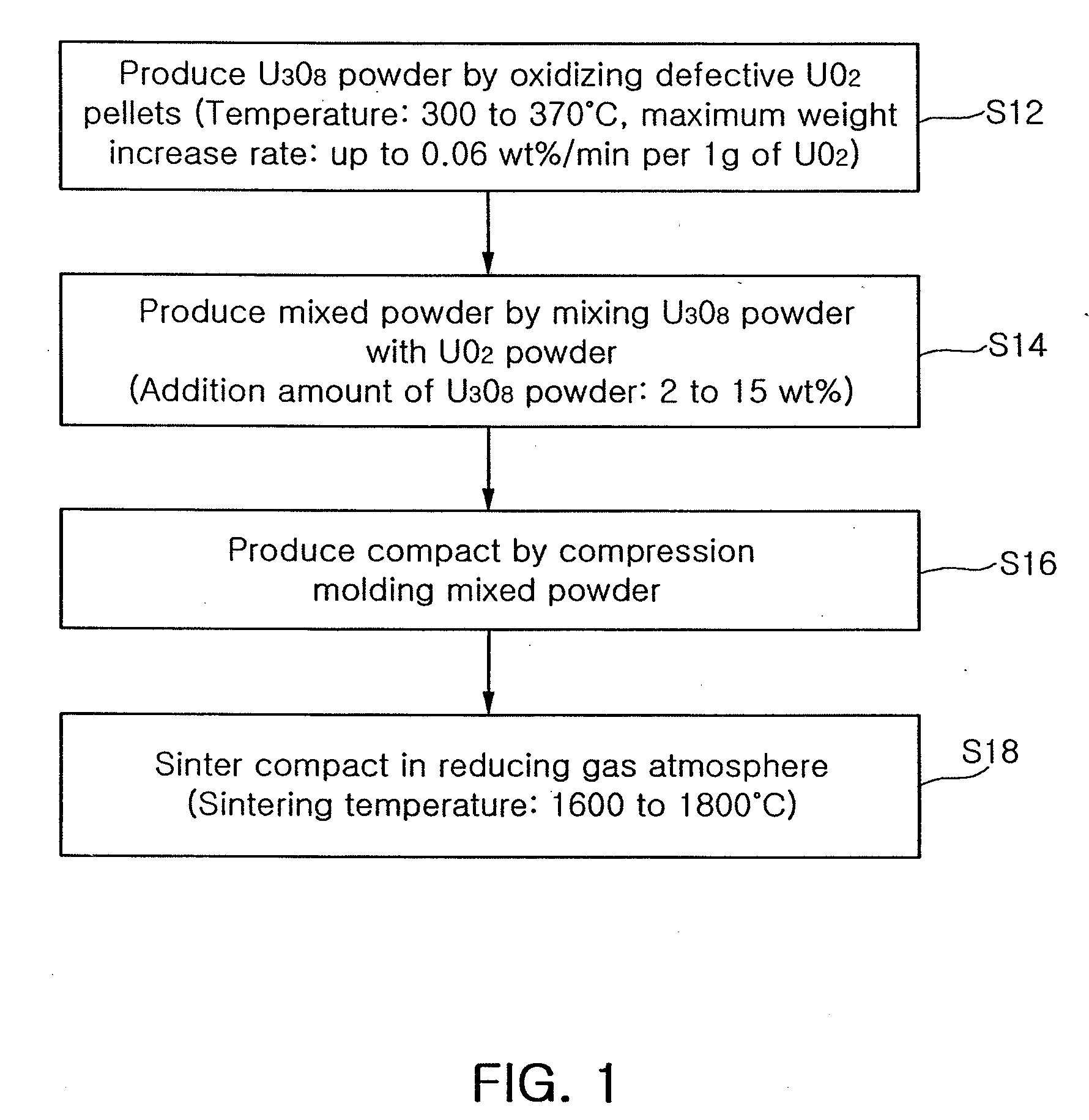

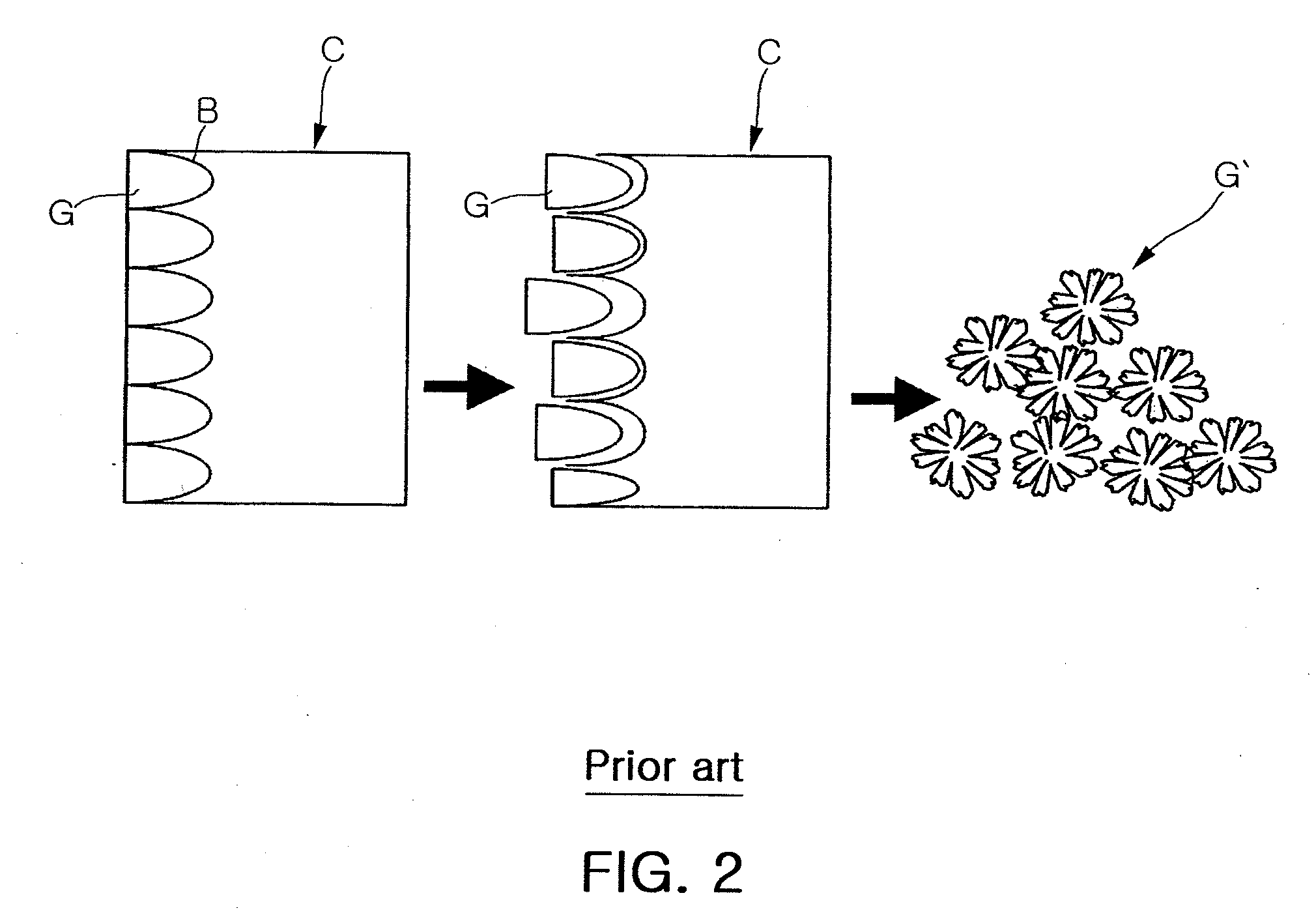

Method of manufacturing sinter-active u3o8 powder and method of producing nuclear fuel pellets utilizing the same

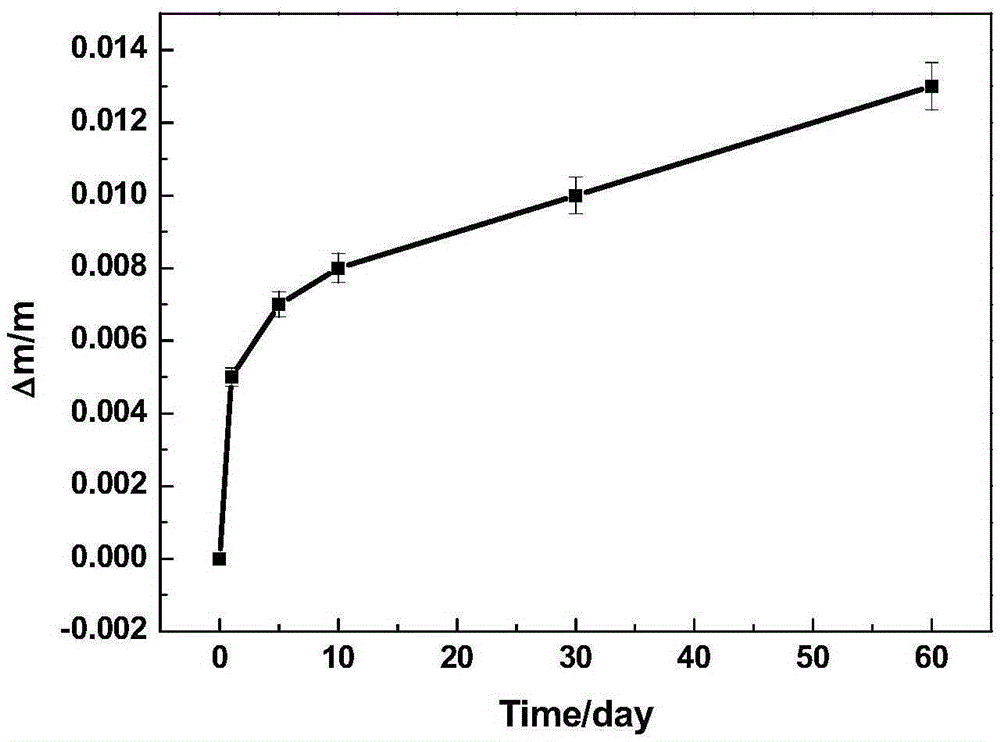

ActiveUS20080185743A1Stable pore structureHigh densityFuel elementsNuclear energy generationCompression moldingHigh density

There is provided a method of producing U3O8 powder having large surface area and small particle size by oxidizing defective UO2 pellets and manufacturing nuclear fuel pellets which are stable in a pore structure and high in density through the use of a mixture comprising UO2 powder and U3O8 powder. The method includes producing an U308 powder having a surface area of at least 1 m2 / g by oxidizing defective UO2 pellets at a temperature of 300 to 370□ in such a way that a maximum weight increase rate per 1 g of the UO2 pellets is up to 0.06 wt % / min; producing a mixed powder by mixing the U3O8 powder with an UO2 powder by 2 to 15 wt %; producing a compact by compression molding the mixed powder; and sintering the compact in a reducing gas atmosphere at a temperature of 1600 to 1800□. In addition, a small amount of an Al-compound may be added to the oxidized U3O8 powder before the U3O8 powder is mixed with the UO2 powder. The additive such as Al is mixed with the U3O8 powder and then mixed with the UO2 powder to produce the pellets by a conventional production method. This ensures a stable pore structure, high density and a considerable increase in a crystal grain size.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

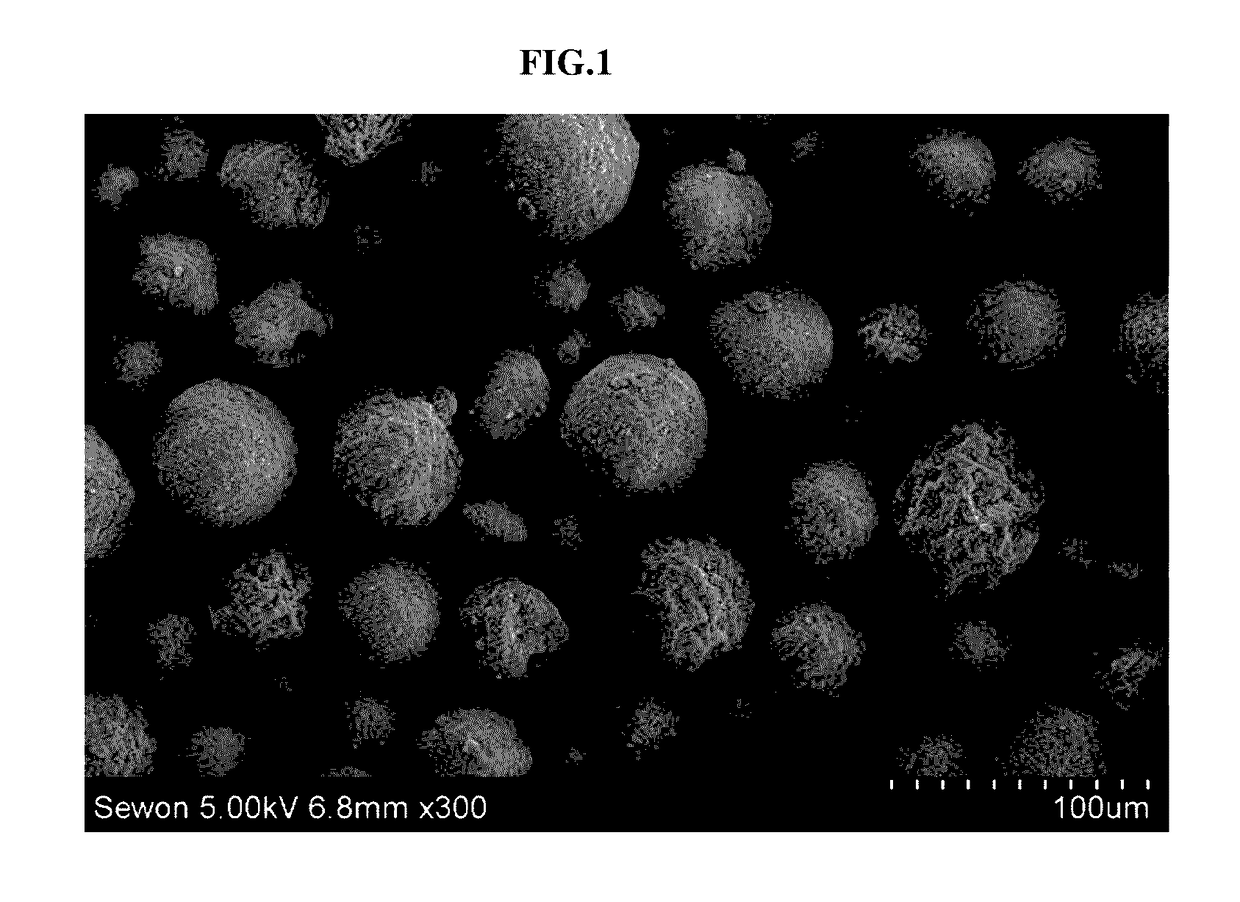

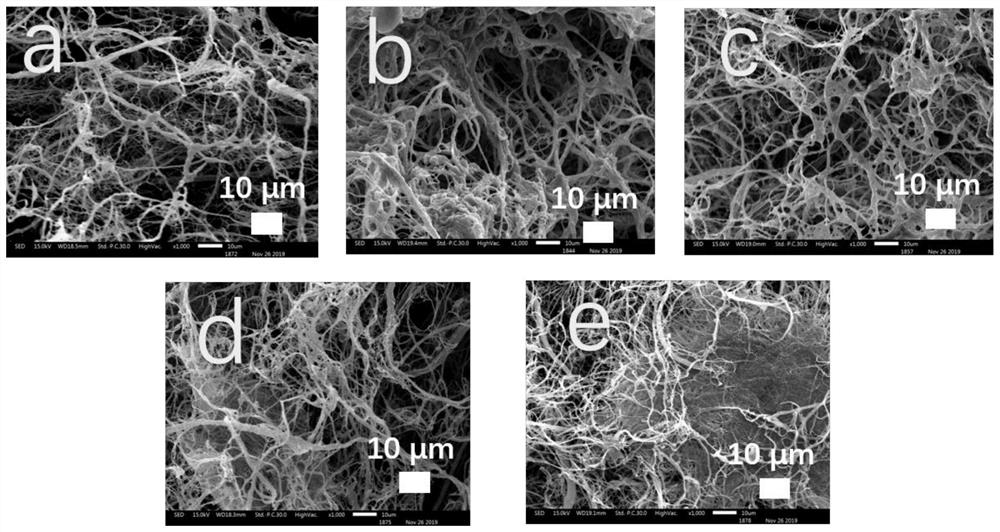

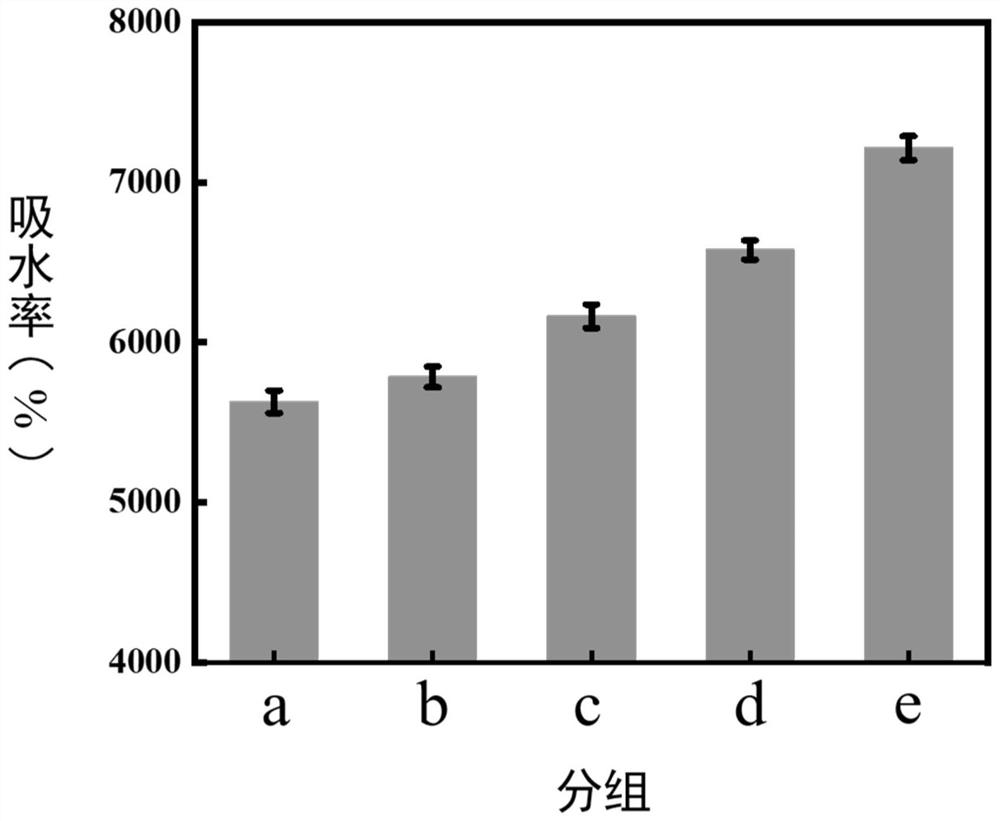

Fibroin micro-nano fiber microsphere as well as preparation method and application thereof

ActiveCN112316914AImprove water absorptionEliminate internal stressOther chemical processesMonocomponent fibroin artificial filamentFiberPolymer science

The invention provides a fibroin micro-nano fiber microsphere as well as a preparation method and application thereof. According to the method, a CaCl2 / ethanol / H2O mixed solution is used for heat andhumidity treatment on silk fibroin, and silk fibroin micro-nano fiber suspension liquid is prepared through physical and mechanical fiber separation effect; and the prepared fibroin micro-nano fiber suspension is blended with a polysaccharide solution, then a cross-linking reaction is conducted, and electrostatic spraying and freeze drying treatment are performed to obtain the fibroin micro-nano fiber microsphere. By means of the above mode, fibroin micro-nano fibers can be prepared while excellent mechanical properties of fibroin fibril are reserved, and covalent bonds are formed between thefibroin micro-nano fibers and polysaccharide molecules through a crosslinking reaction, so the water absorption rate and the morphological stability of the prepared fibroin micro-nano fiber microsphere are greatly improved, and the microsphere is allowed to have a large specific surface area and rich pore structures, thereby faciliating adhesion and proliferation of cells on the surface of the microsphere. The whole preparation process of the microsphere is simple, easy to regulate and control and low in cost, and has higher application value.

Owner:WUHAN TEXTILE UNIV

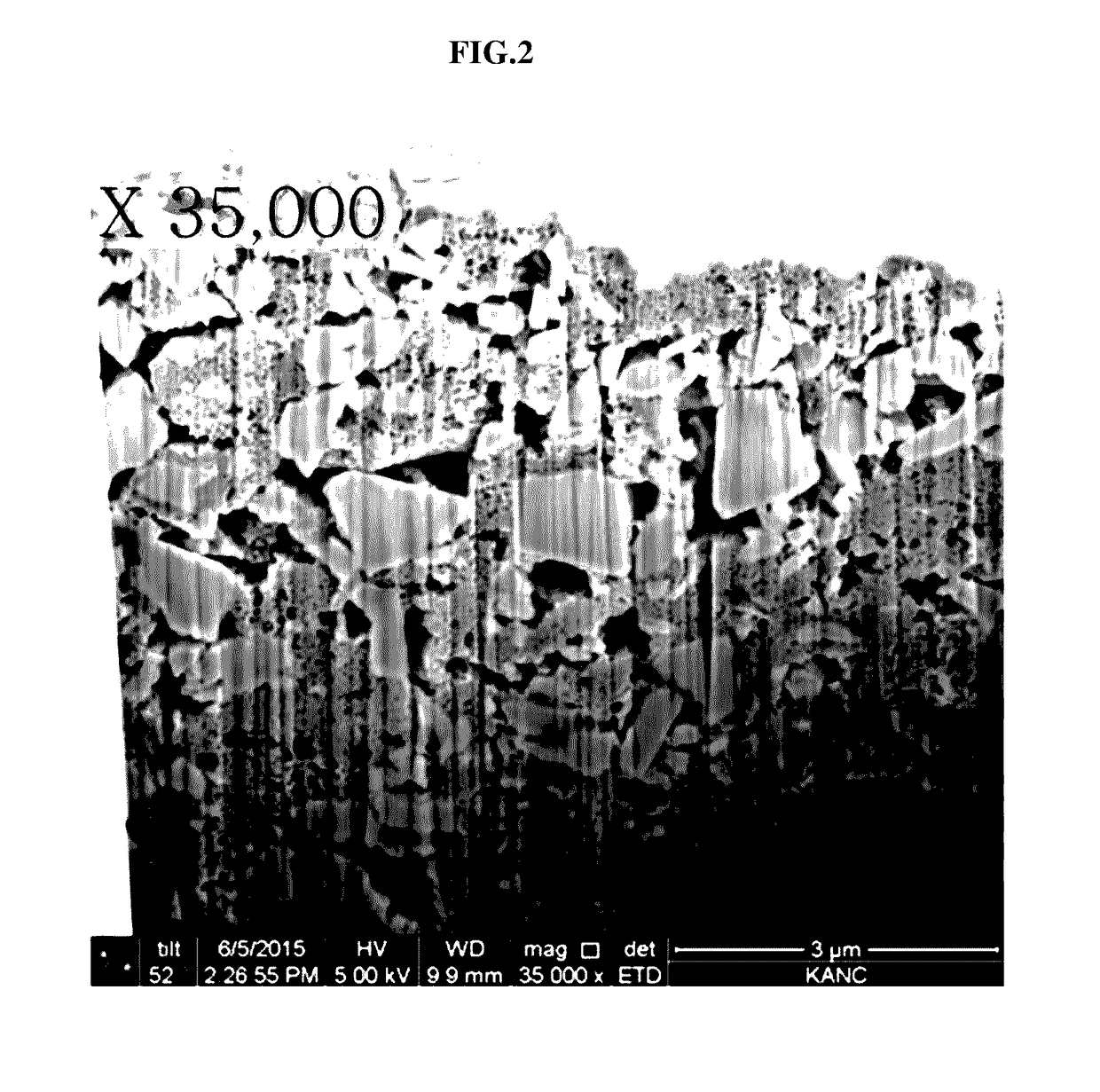

Lithium ion battery negative electrode active material, lithium ion battery negative electrode, lithium ion battery, battery pack and battery power vehicle

ActiveCN109553085AImprove the first discharge capacityImprove discharge rateMaterial nanotechnologyFinal product manufactureAluminium-ion batteryDesorption

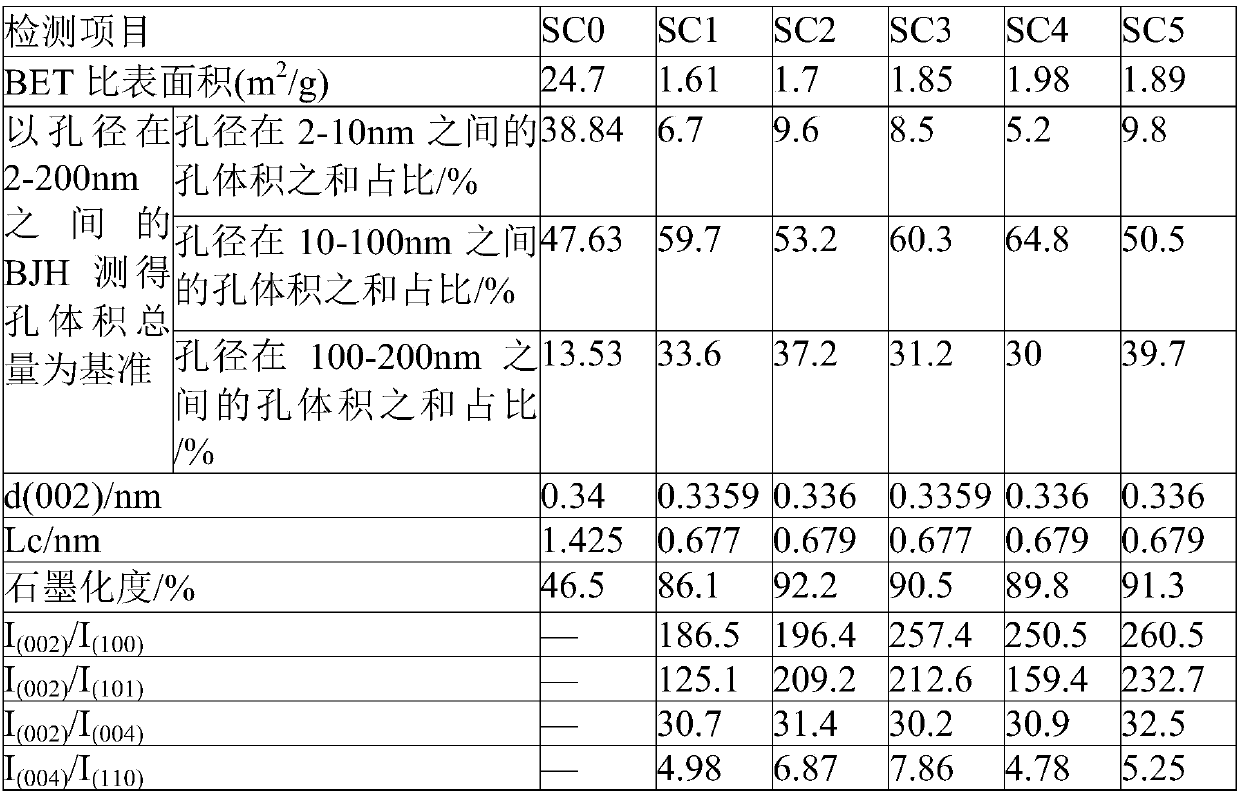

The invention relates to the field of lithium ion battery negative electrode carbon materials, particularly to a lithium ion battery negative electrode active material, a lithium ion battery negativeelectrode, a lithium ion battery, a battery pack and a battery power vehicle. According to the present invention, in the pore structure, measured through N2 adsorption and desorption, of the lithium ion battery negative electrode carbon particles, by using the total pore volume measured by BJH having a pore size of 2-200 nm as the reference, the sum of the volumes of pores with a pore size of 2-10nm is 5-10%, the volumes of pores with a pore size of 10-100 nm account for 50-65%, the volumes of pores with a pore size of 100-200 nm account for 30-40%, and the carbon particles have a BET specific surface area of 1-4 m<2> / g, preferably 1.4-1.9 m<2> / g. According to the present invention, the button cell made of the carbon particles has a charging capacity of 392-403.65 mAh / g and a discharge capacity of 360-373 mAh / g, and the discharge capacity at 5C rate is maintained at 1985.7-2029.8 mAh after the button cell is assembled into the columnar battery.

Owner:HUNAN JINYE HIGH TECH CO LTD

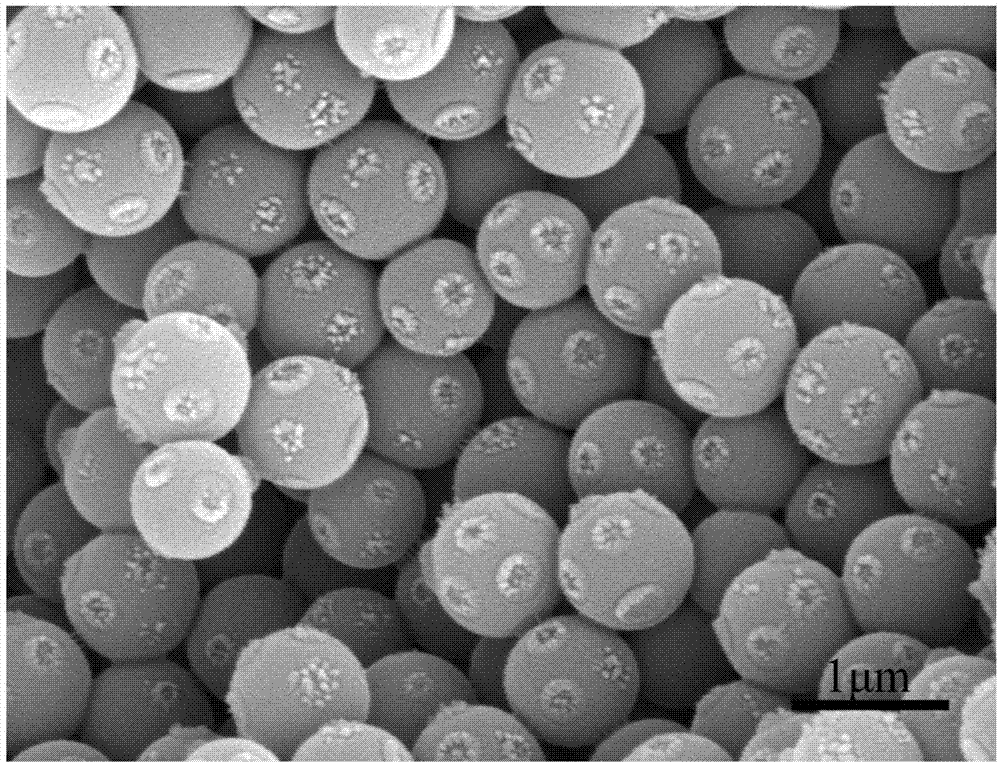

High molecular type reverse chromatography fixing phase and its preparing method

InactiveCN1987453AStable pore structureThe adsorption-desorption process is fastComponent separationOther chemical processesChemical structureChromatographic separation

The invention is especially related to fixed phase of reversed phase chromatography (FPRPC) in macromolecule type of a series of different chemical constitution, and preparation method. Possessing macromolecule micro beads in regular spherical porous type, the disclosed FPRPC in macromolecule type possesses basic property of FPRPC. Using the disclosed FPRPC to carry out verification of chromatographic separation indicates that when macromolecule micro beads in porous type acts as FPRPC, pore structure is steady; under condition of compression elution, micro beads does not break up; adsorption-desorption procedure is quick; comparing with chemical bond silicon ball fixed phase in same granularity, FPRPC possesses closed column performance and closed separation. The disclosed FPRPC is applicable to separating and purifying medical bulk drug, and natural drug as well as applicable to enriching and preparing trace quantity substance in biologic and samples.

Owner:刘开禄

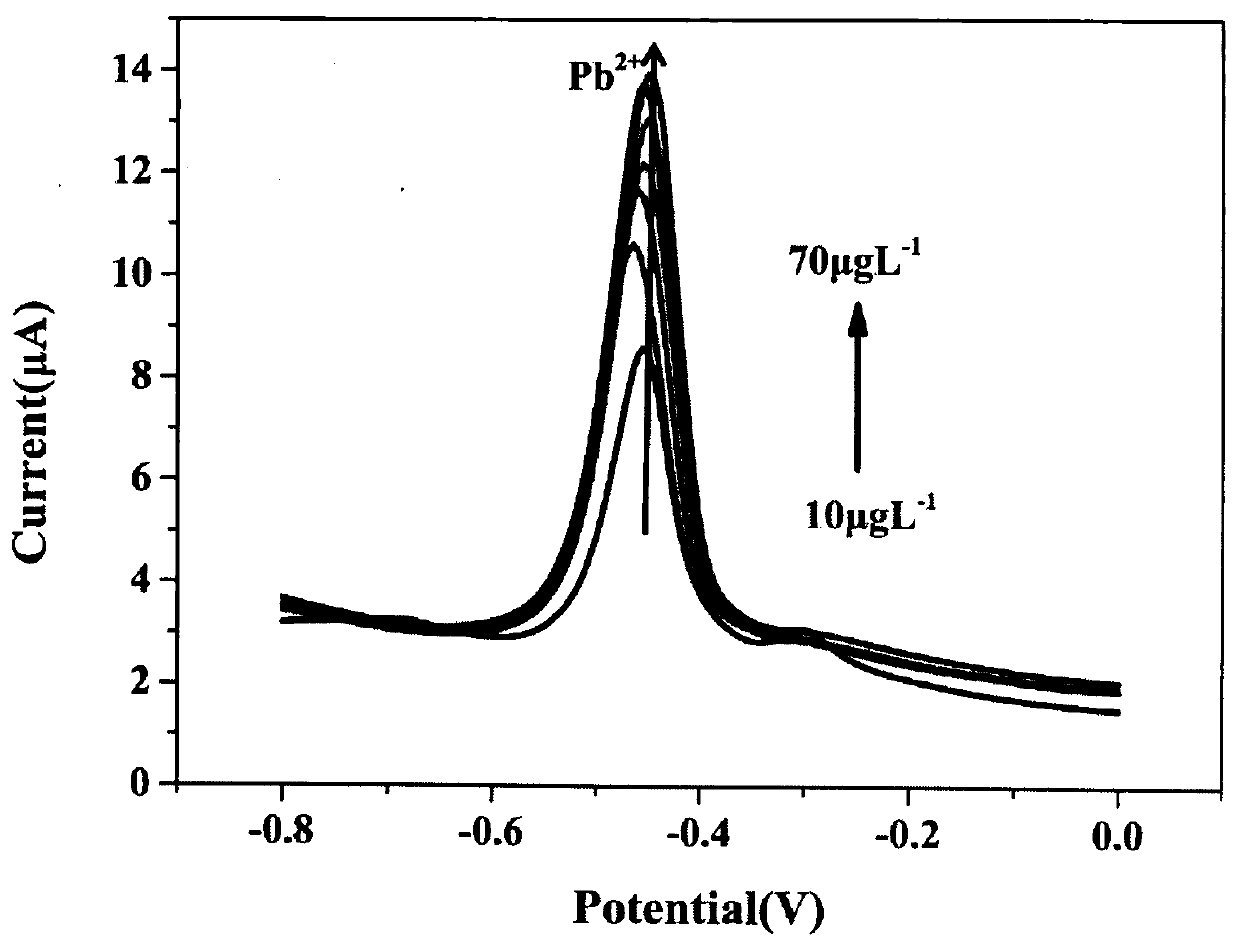

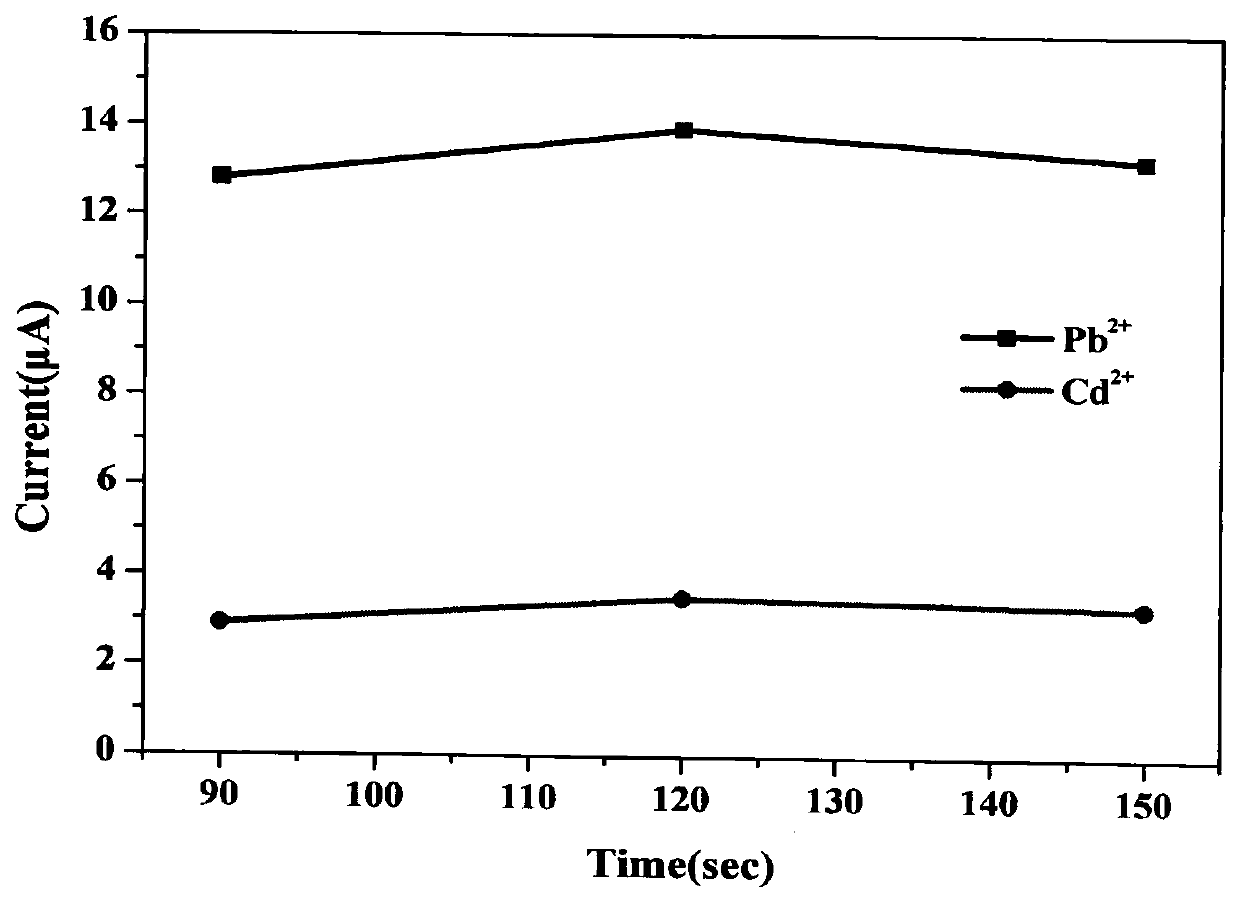

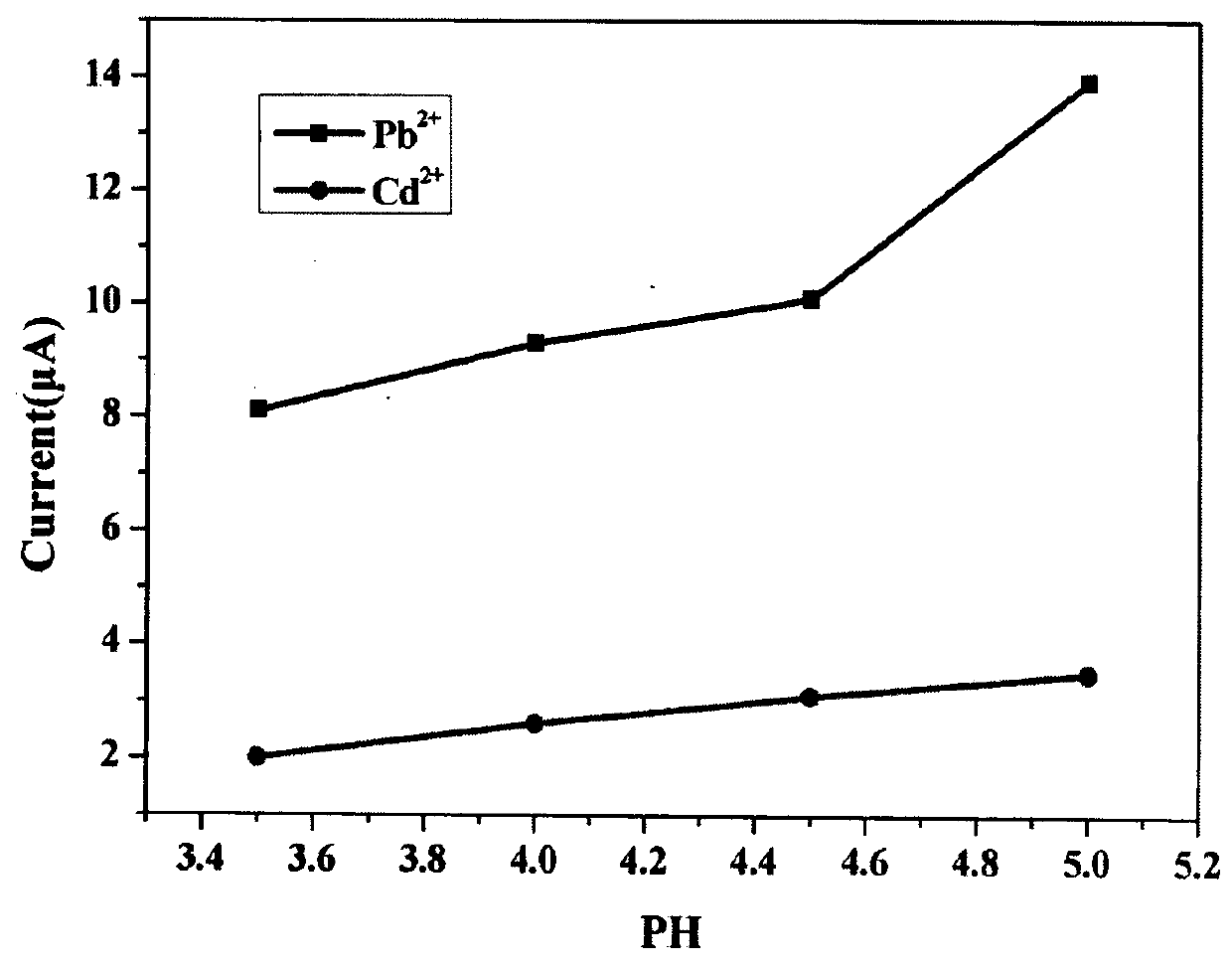

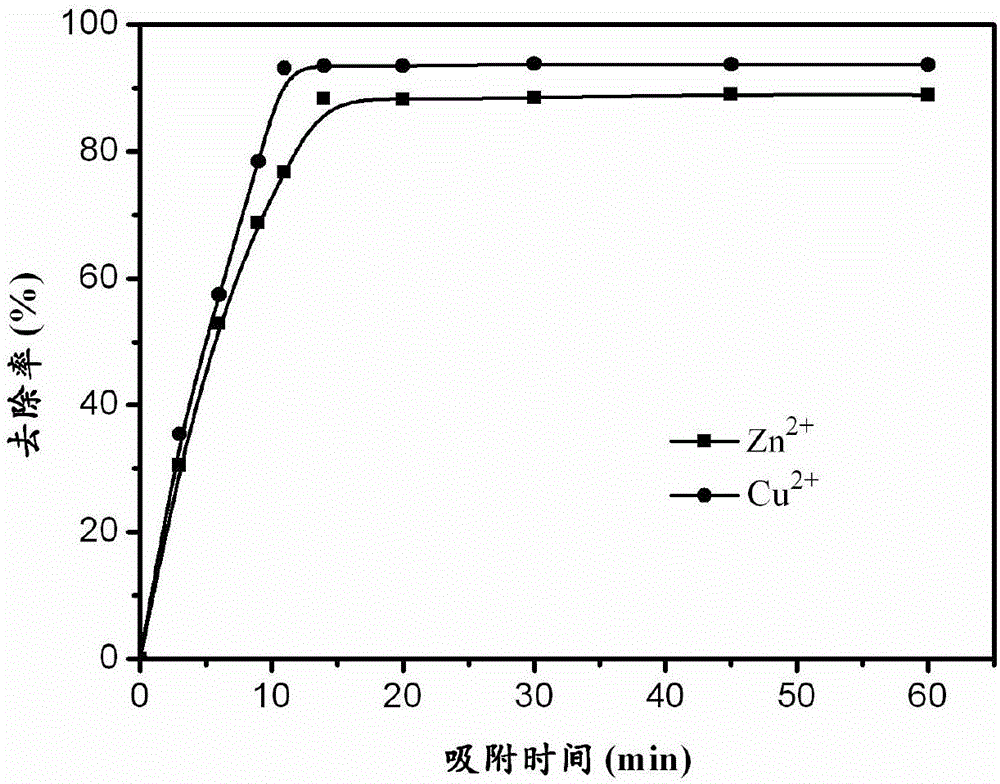

Electrochemical method of detecting trace heavy metal by using walnut shell-based carbon material modified glassy carbon electrode

ActiveCN109884147ALow costWide variety of sourcesMaterial electrochemical variablesPorous carbonCarbonization

The invention discloses an electrochemical method of detecting trace heavy metal by using walnut shell-based carbon material modified glassy carbon electrode. The method comprises steps of preparing biomass porous carbon with walnut shell as a raw material through high temperature carbonization and activation by an activator, modifying the walnut shell-based carbon material on the surface of the glassy carbon electrode, and performing trace detection on heavy metal ions like Cu<2+>, Hg<2+>, Pb<2+> and Cd<2+> by using an electrochemical differential pulse anodic stripping voltammetry method. The biomass porous carbon prepared by the method has advantages of large specific surface area, rich pores, and more surface defects. The method can highly selectively detect heavy metal ions like Cu<2+>, Hg<2+>, Pb<2+> and Cd<2+>, and has advantages of high detection flexibility, high stability, high anti-interference, and wide detection linear range, thereby meeting actual industrial requirements.

Owner:SHIHEZI UNIVERSITY

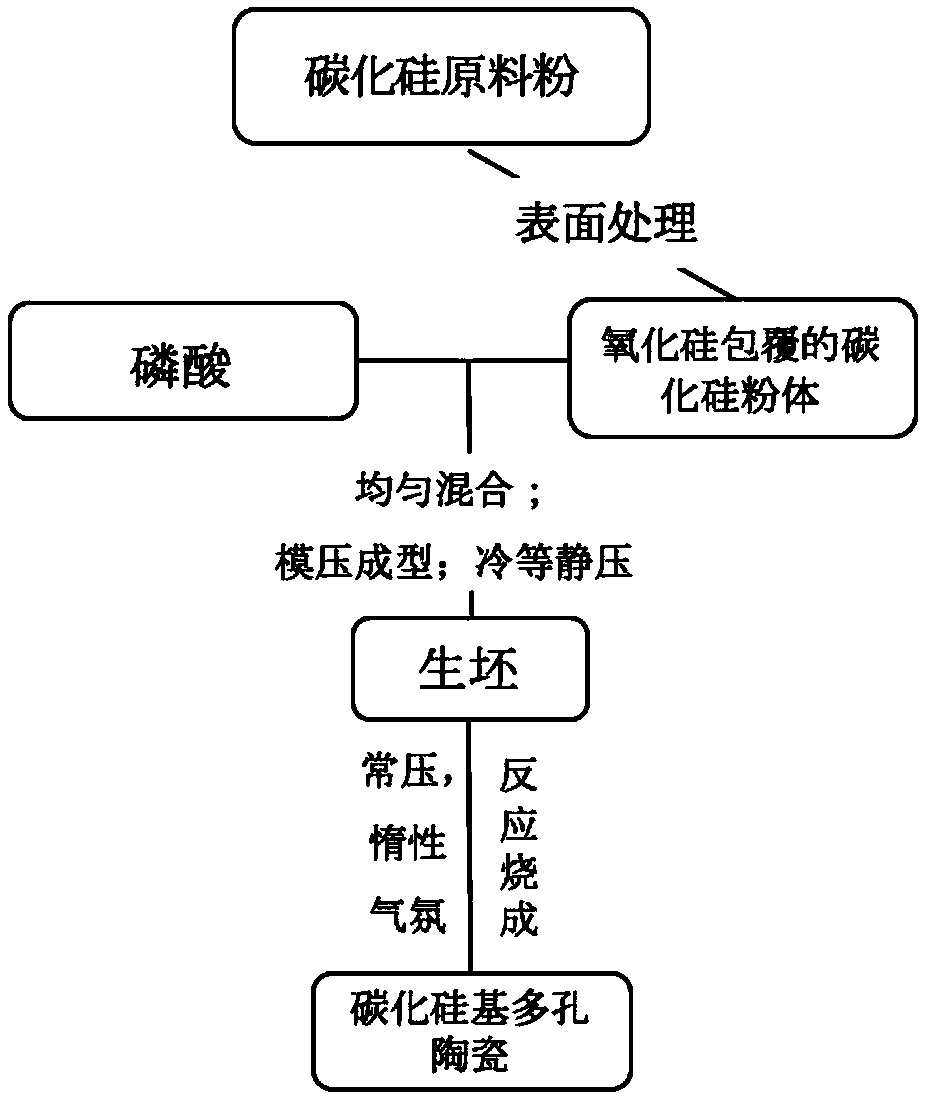

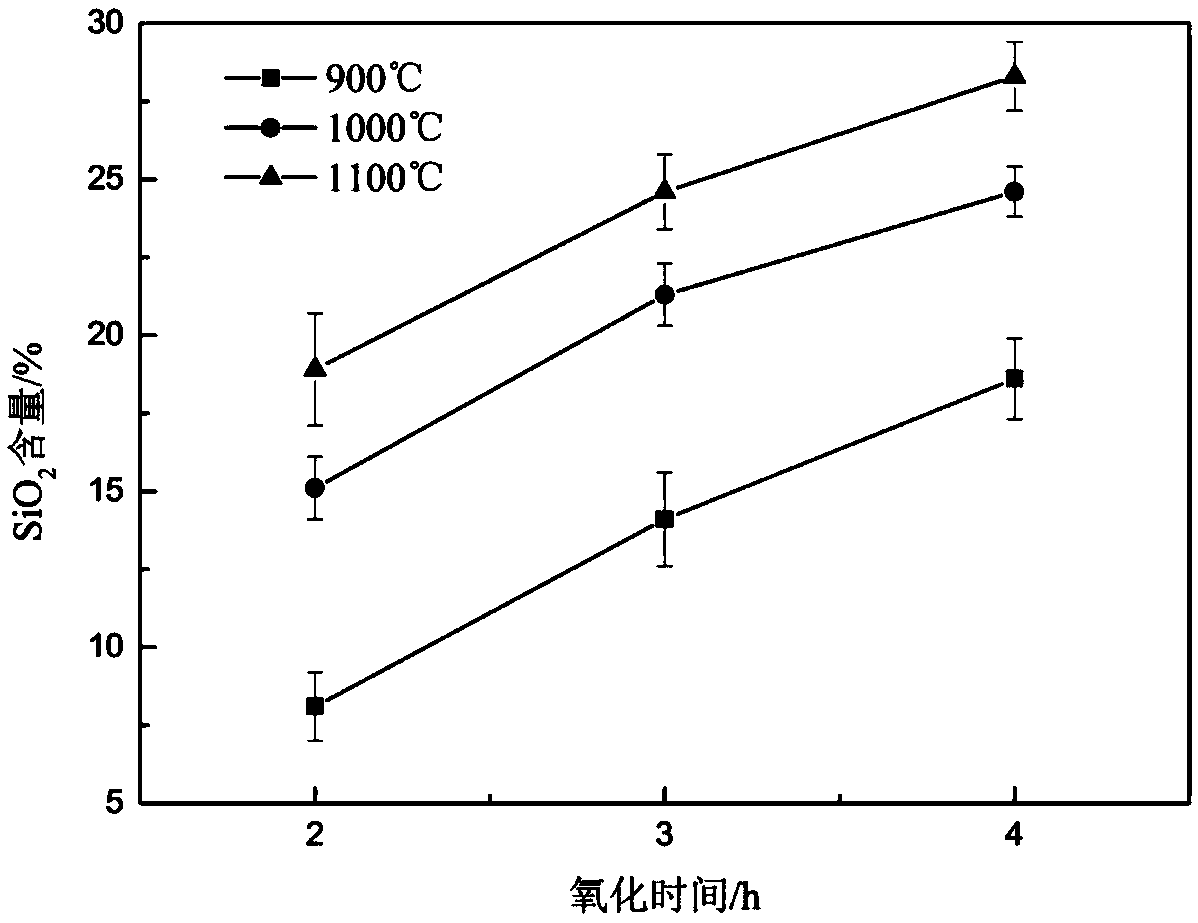

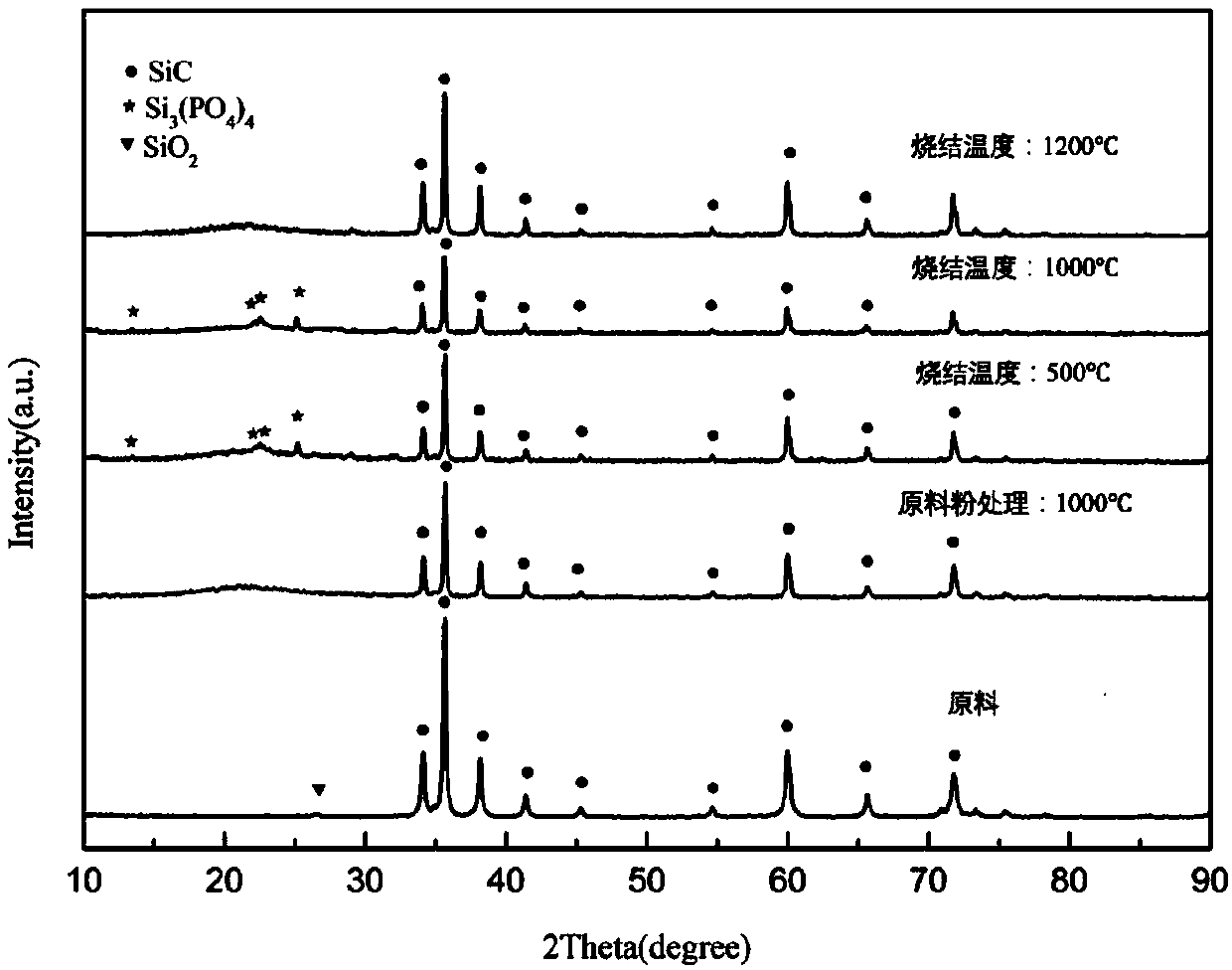

Preparation method of high-porosity silicon carbide-based porous ceramic material

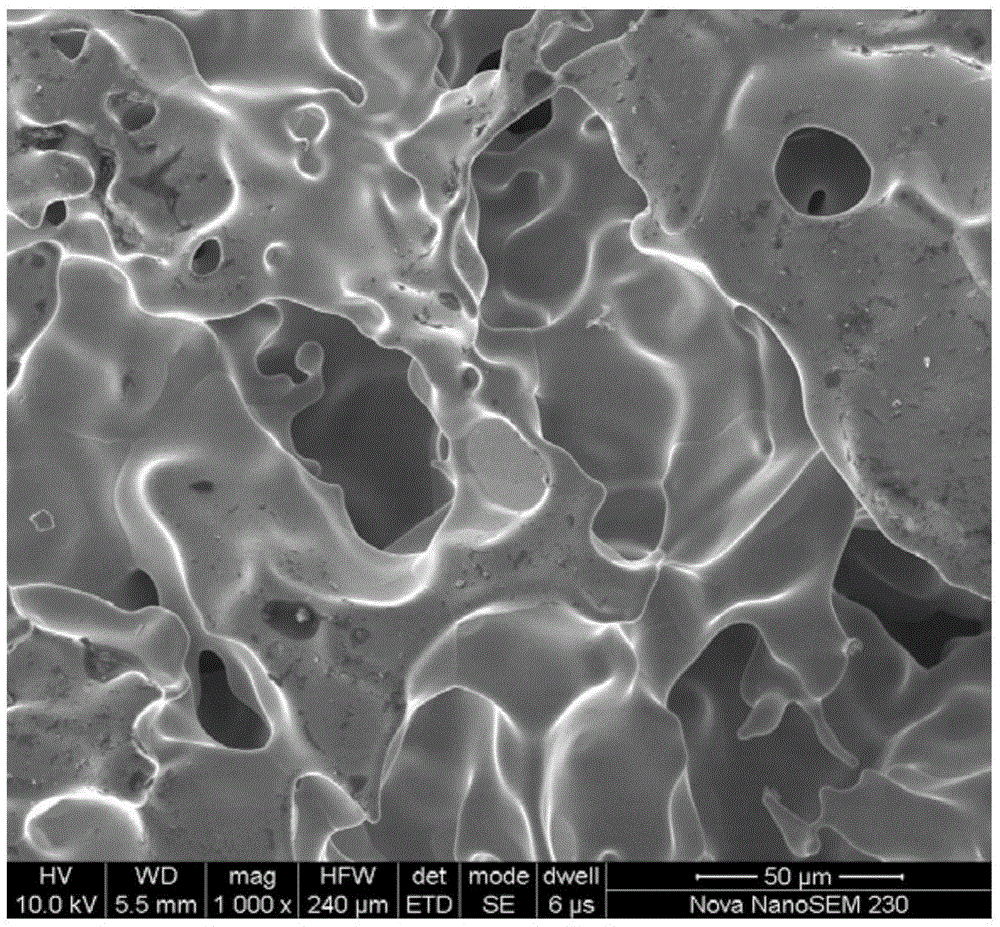

The invention discloses a preparation method of a high-porosity silicon carbide-based porous ceramic material, and the method is a technology for preparing a high-strength porosity-controlled siliconcarbide-based porous ceramic material by reacting phosphoric acid as an additive with a silicon carbide surface oxide layer. Specifically, the method comprises the steps of conducting surface oxidation treatment on a silicon carbide ceramic powder having a particle diameter of 0.5 to 20 [mu]m so as to generate a silicon oxide oxide layer on the surface of the silicon carbide raw material powder, and then directly uniformly mixing liquid phosphoric acid used as an additive with the treated raw material powder, wherein the amount of the phosphoric acid added is 5 to 35 wt%; conducting compression molding on the mixture, and then conducting cold isostatic pressing treatment to obtain a green body; then conducting normal-pressure sintering on the green body in an inert gas atmosphere of 900 to1500 DEG C, and controlling the reaction temperature increase rate to be 0.5-5 DEG C / min and the temperature-keeping time to be 2 to 5 hours. The invention has the advantages of simple process, low cost and high repeatability, and the prepared silicon carbide-based porous ceramic material has stable pore structure and does not easily produce defects.

Owner:淄博赛拉米克陶瓷科技有限公司

Preparation method of interlocking micro-capsules based on polymer with high specific surface area and having hierarchical porous structure

InactiveCN103933912ALarge specific surface areaGood application effectMicroballoon preparationMicrocapsule preparationCross-linkPolymer science

The invention discloses a preparation method of interlocking micro-capsules based on a polymer with a high specific surface area and having a hierarchical porous structure. The method comprises the following steps: modifying a silicon dioxide colloid crystal template, performing controlled graft of a polymer chain segment by surface-initiated atom transfer radical polymerization and double-bond radical polymerization, crosslinking a linear polymer chain segment by using a friedel-crafts crosslinking method, and removing the silicon dioxide colloid crystal template, thus preparing interlocking micro-capsules based on a polymer with a high specific surface area and having a hierarchical porous structure. Through a controlled graft polymer layer, a certain gap is formed in an area which is fully filled before, thereby reducing the mass and forming more mass transfer ways. By adopting a friedel-crafts crosslinking and pore-forming technology, capsule walls made of a polymer material are cross-linked to form micro-pores and meso-pores; the material formed by adopting a friedel-crafts self-crosslinking technology is high in specific surface area, thereby greatly improving the application performance; the capsule cavities at micro-pore, meso-pore and large-pore levels, communication windows formed among interlocking micro-capsules and gaps among the micro-capsules present a hierarchical porous interlocking structure on the whole.

Owner:HEBEI UNIV OF TECH

Preparation of epoxide resin based foam material

The invention discloses a method for preparing an epoxide resin foaming material. The method comprises the following steps that: 1. according to the mass ratio, epoxide resins, foaming agents, foam stabilizing agents and addition agents are respectively picked up and evenly mixed with high-speed stirring; 2. the mixture obtained is put in an oven with a temperature of between 40 and 80 DEG C and pre-heated for 0.5 to 1 hour, and the mixture is taken out and cooled down to a temperature of between 25 and 35 DEG C; 3. The mixture is added with curing agents and evenly mixed; 4. the mixture is put in a stainless steel mold and heated at the temperature of between 40 to 80 DEG C for 0.5 to 2 hours, and the mixture is cooled down to the room temperature and taken out, and finally the finished products are obtained. By controlling reaction conditions, the invention realizes the association control of the chemical foaming and the curing molding of epoxy, and the foaming multiplying factor is as high as 2.7, and products prepared by the method are good in water resistance, chemical corrosion resistance and strength. The method of the invention has the advantages of easy buying of materials, simple operation and easy industrialization, and provides a new path for preparing thermosetting foaming materials.

Owner:SHANGHAI INST OF TECH +1

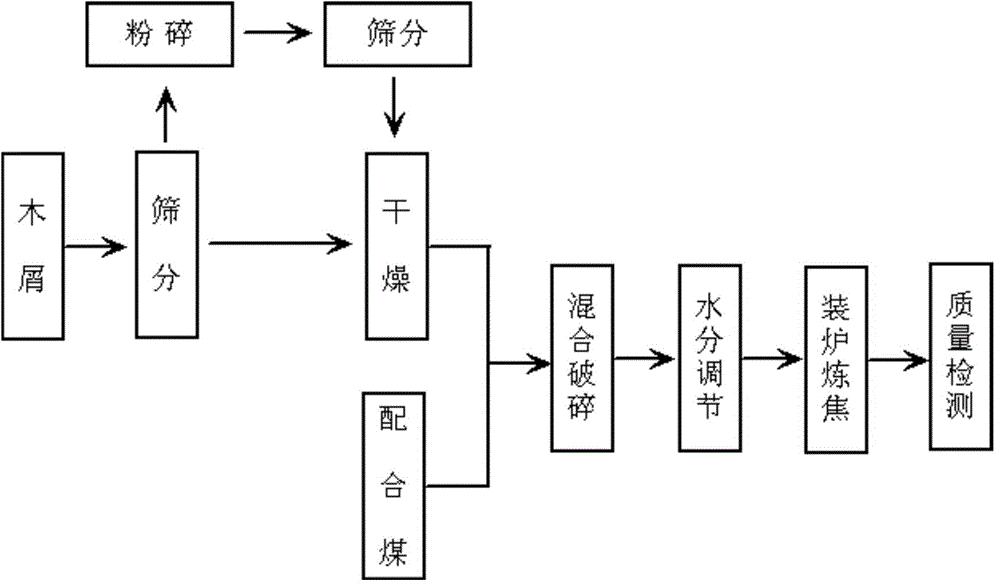

Method for producing coke by replacing part of coal by sawdust

ActiveCN105316013AStable pore structureLarge specific surface areaBiofuelsSpecial form destructive distillationCelluloseSulfur

The invention relates to a method for producing coke by replacing part of coal by sawdust. A sawdust resource and coal blend are mixed and matched in use, so that coke which is relatively high in quality is produced. A manufacturing method and a process course are as follows: I, sawdust screening; II, drying treatment of sawdust; III, mixed crushing of materials; and IV, product preparation. According to the method provided by the invention, by producing coke by matching the sawdust and the basic coal blend with each other, the characteristic that the sawdust contains a large amount of lignocellulose is fully used, thereby finding a novel path for high-value utilization of the sawdust. Meanwhile, part of coking coal can be replaced by sawdust coking, the coking coal shortage problem caused by consumption of a large amount of coking coal can be alleviated, and CO2 emission in a coking process and an iron-making process is reduced. Furthermore, sawdust coking further can reduce sulfur in coke and ash in coke and improve the carbon content in coke, and can reduce inorganic impurities in coke, ensure a stable porous structure and a high specific surface area of coke and can enhance the surface activity of coke.

Owner:BAOSHAN IRON & STEEL CO LTD

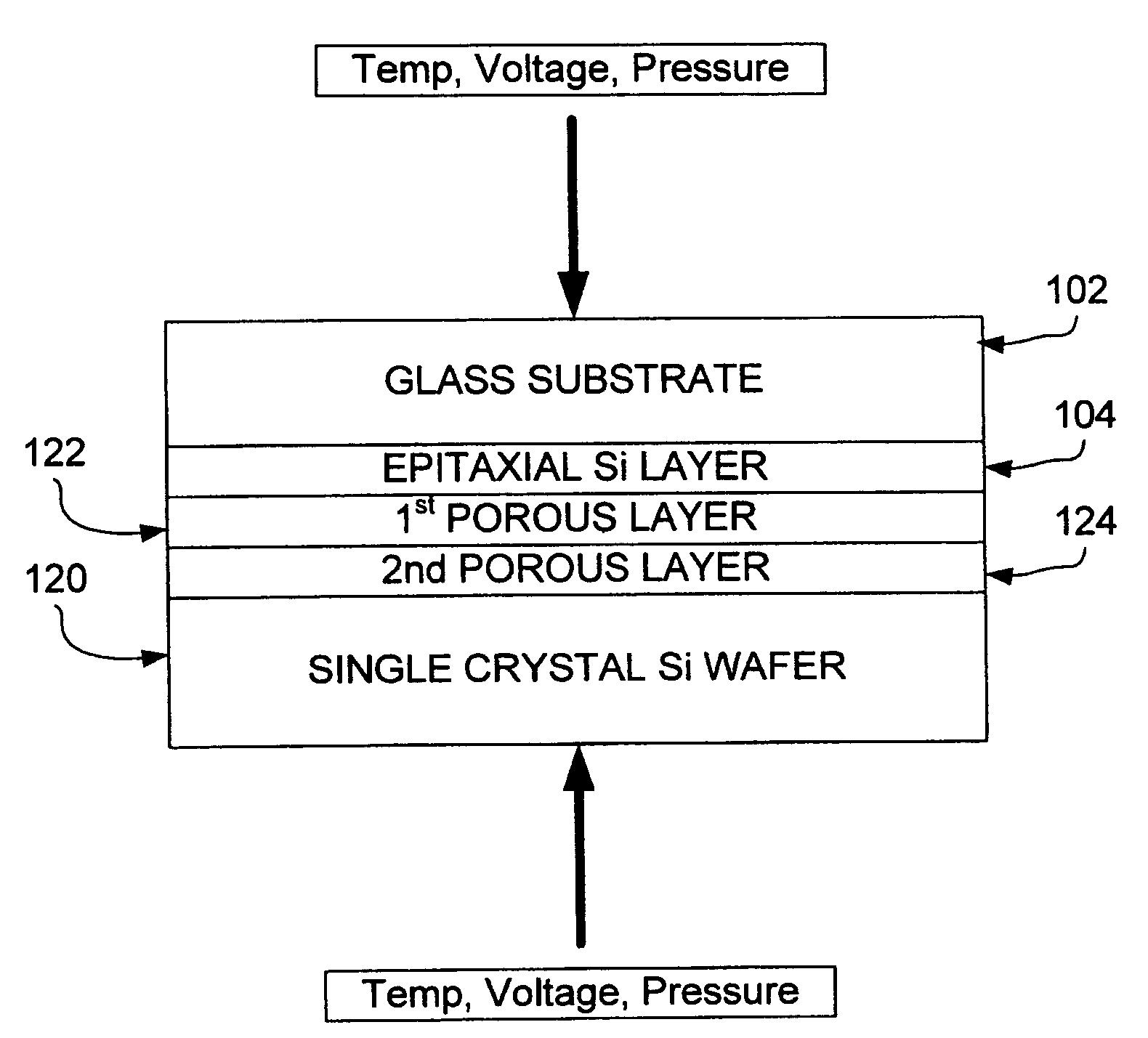

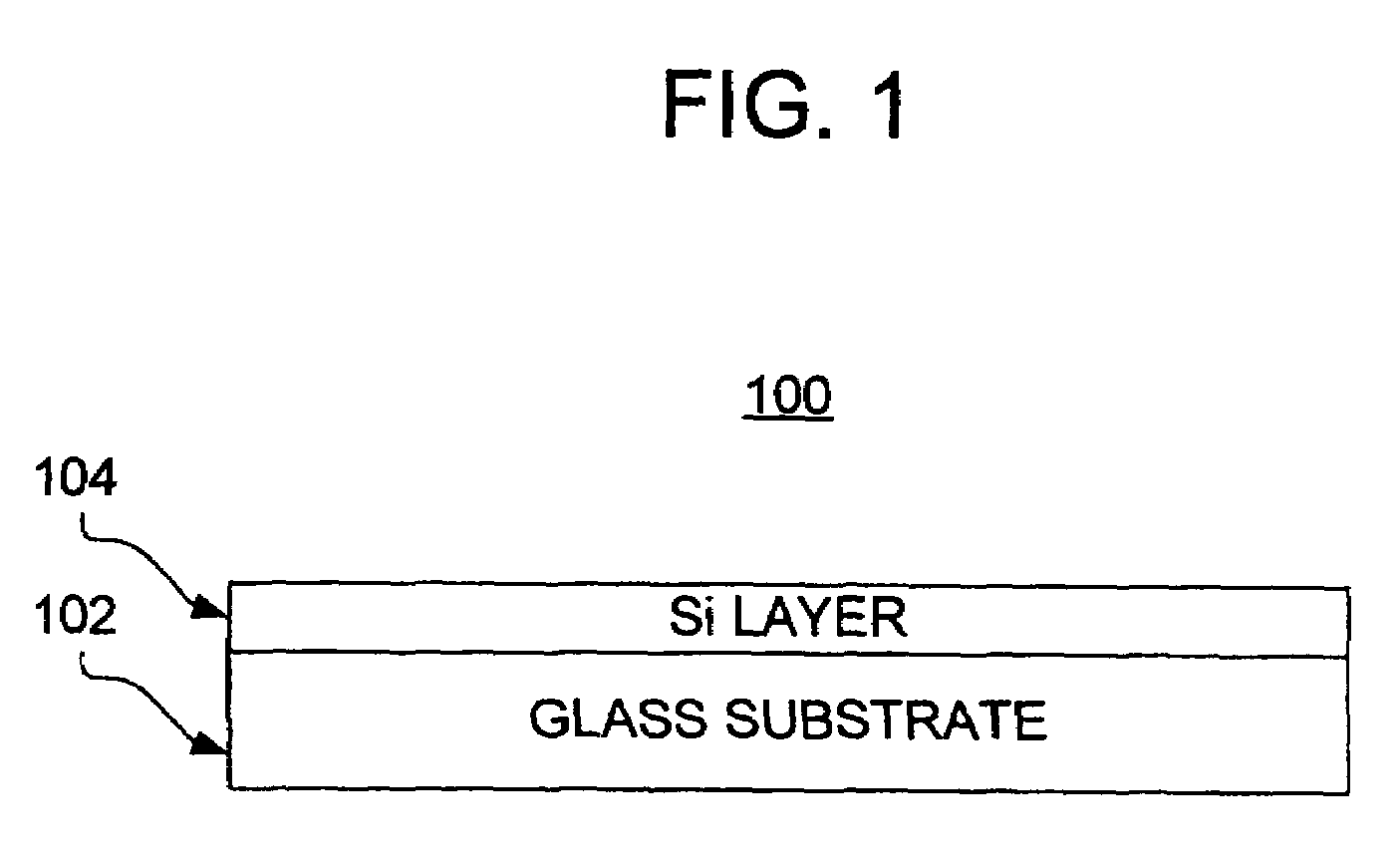

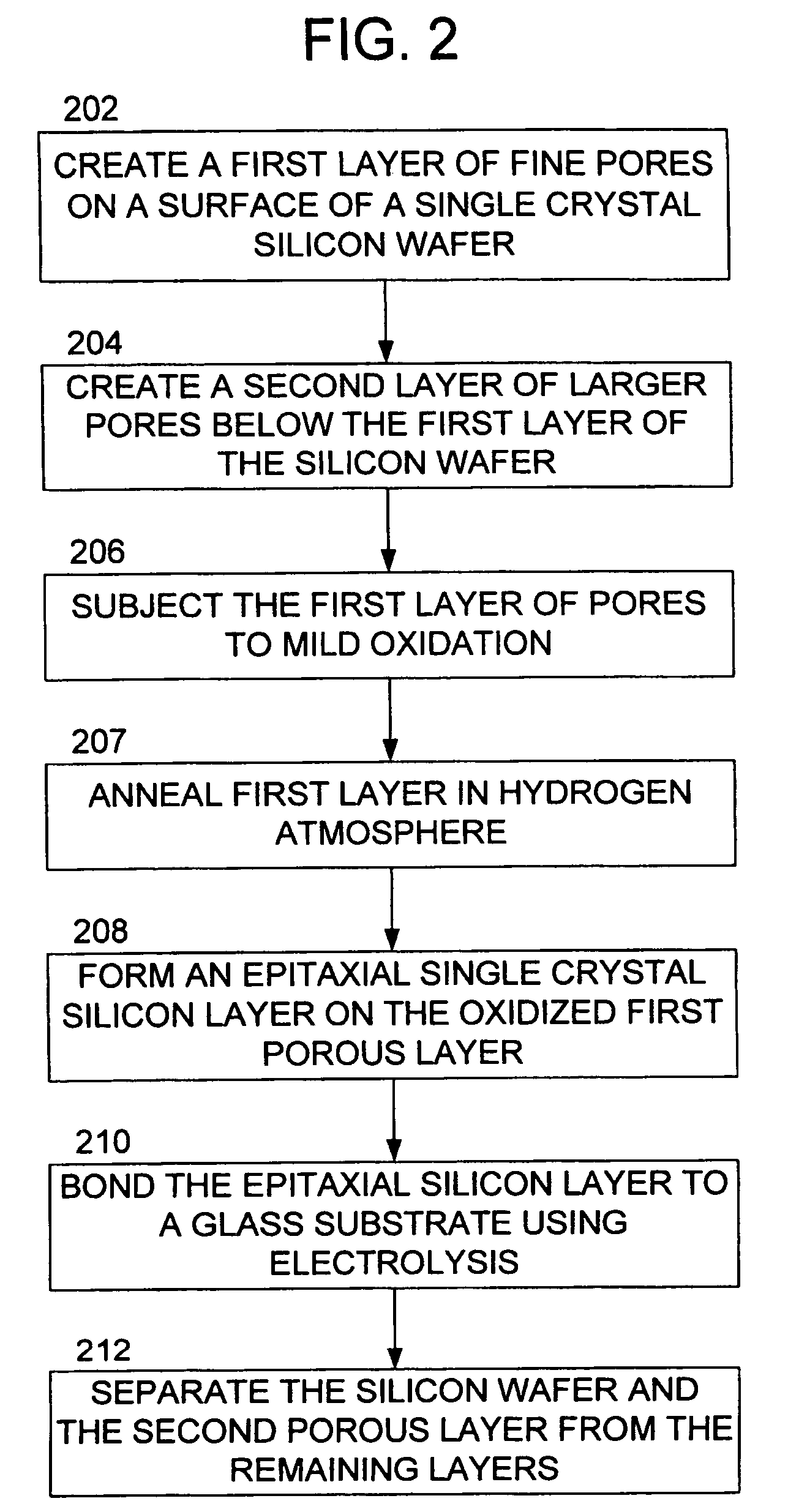

Glass-based semiconductor on insulator structures and methods of making same

InactiveUS7410883B2Minimizing surface defectStable pore structureSemiconductor/solid-state device manufacturingThin material handlingSemiconductor structurePorous layer

Methods and apparatus provide for: a semiconductor wafer; at least one porous layer in the semiconductor wafer; an epitaxial semiconductor layer directly or indirectly on the porous layer; and a glass substrate bonded to the epitaxial semiconductor layer via electrolysis.

Owner:CORNING INC

Efficient mercury-containing wastewater treatment method

InactiveCN106964320AEffective tracking and monitoringStable pore structureOther chemical processesWater contaminantsSorbentSludge

The invention discloses an efficient mercury-containing wastewater treatment method. The method comprises the following steps: preparing a polymer quantum dot from an amino source monomer and a sulfydryl-containing monomer under the existence of an initiator; adding polyethylene glycol into an acetic acid solution of chitosan to prepare a porous chitosan sol, wherein more carboxyl groups are contained on the surface of the sol; and finally blending an active sludge, the porous chitosan sol and the polymer quantum dot, and adding triethylamine, glyoxal and ferroferric oxide to obtain a composite adsorbent. When the mercury-containing wastewater is treated, part of the mercury ion in the water is removed through a metal powder reduction method, then the wastewater is treated by the composite adsorbent, the method effectively removes the mercury ion in the wastewater, and the removal of the mercury ion is also detected.

Owner:付主枝

Prepn of foamed aluminium

The preparation process of foamed aluminum includes the following operation steps: the pre-treatment of foamed base material via deoiling, degreasing and eliminating stress; and the electroplating deposition of aluminum on the conducting treated base material inside electrolyzer with anhydrous organic alkyl aluminum electrolyte and industrial pure aluminum plate as anode. The electroplation is one pulse electrolysis process with pulse DC power source of squared, triangular or sinusoidal waveform, electrolyte temperature 50-95 deg.c, deposition period 1-2 hr, peak current 10-200 A, bread-make ratio of 0.01-1 and pulse frequency 15-2000 Hz. Compared with available technology, the present invention has the advantages of stable foamed aluminum structure, easy controlled production process, fine and homogeneous pores, high porosity, high product quality and low cost. The foamed aluminum may be further heat treated for raised strength and toughness.

Owner:孙伟成

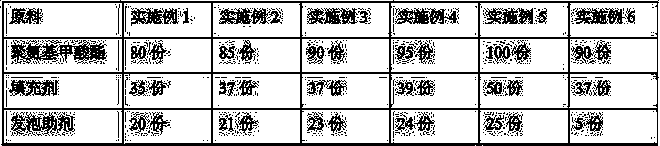

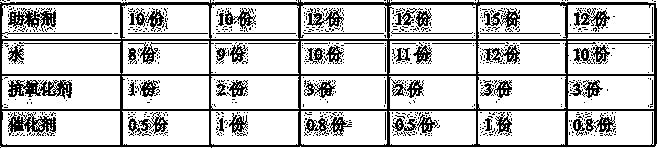

PU sponge with good air permeability and making method thereof

The invention provides PU sponge with good air permeability. A raw material of the PU sponge comprises the following components in part by weight: 80-100 parts of polyurethane, 35-50 parts of fillingagent, 20-25 parts of foaming aid, 10-15 parts of adhesion promoter, 8-12 parts of water, 1-3 parts of antioxidant and 0.5-1 part of catalyst, wherein the foaming aid is a mixture of a foaming agent,benzotriazole, sodium borohydride and P-octyl phenol with a mass ratio of (1-5):(1-3):(3-5):(0.5-2); the adhesion promoter is a mixture of nitrile rubber, polyether polyol and epoxy resin with a massratio of (8-12):(3-7):(1-3). The PU sponge prepared by the raw material and a process provided by the invention has a density of 0.029 / mm<3>, a 25 percent of compression hardness is above 1.9 KPa, a porosity of a above 88 percent and a rebound rate of above 47 percent, thereby being high-quality sponge.

Owner:广汉市新鸿海绵有限公司

Alumino silica gel and preparation method thereof

ActiveCN108046280AUniform structureUniform strengthMaterial nanotechnologyAluminium silicatesMolecular sieveCompressive strength

The invention discloses alumino silica gel and belongs to the technical field of alumino silica gel. In the alumino silica gel, mass content of Al2O3 is 3-8%, and mass content of SiO2 is not lower than 82%; specific surface area of the alumino silica gel is 300-550m2 / g, pore volume is 0.6-1.0mL / g, and compressive strength is not lower than 50N. The invention further discloses a preparation methodof the alumino silica gel. The preparation method includes: subjecting sodium silicate, aluminum salt and raw material acid to sol-gel process, aging, exchange acid treatment, water washing, ammoniumtreatment and drying to obtain the alumino silica gel. The alumino silica gel is wide in silicon-aluminum ratio adjusting range, large in pore volume and specific surface area, high in compressive strength, uniform in framework structure and strength and stable in quality; the preparation method is simple in process and convenient in operation and can be widely used in the field of catalyst and catalyst carriers, adsorption and separation and molecular sieve preparation.

Owner:QINGDAO MAKALL GROUP CO LTD

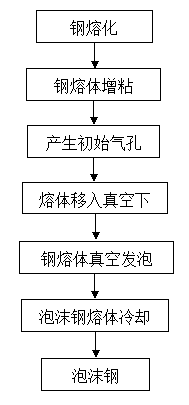

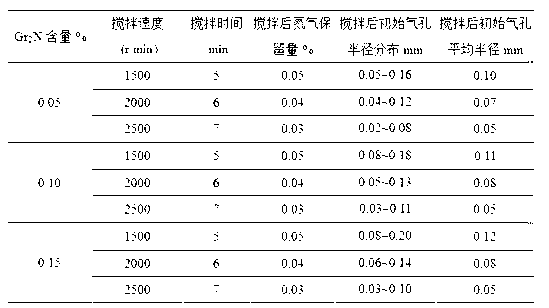

Vacuum foaming preparation method of blister steel

The invention provides a vacuum foaming preparation method of blister steel and belongs to the technical field of a foam metal material. The vacuum foaming preparation method comprises the following steps of: carrying out steel smelting, tackifying a steel melt, generating initial air pores in the steel melt, foaming in vacuum, and cooling a blister steel melt to finally obtain the blister steel with the porosity of 70-85% and the pore diameter of 0.5-5mm. According to the vacuum foaming preparation method disclosed by the invention, SiC is used as a tackifier to carry out tackifying treatment on the steel melt; and a small amount of Cr2N is added into the steel melt tackified by the SiC, and gas is generated by agitating and dispersing the Gr2N and decomposing the Gr2N, so that the initial air pores which are uniformly distributed, great in quantity and fine are generated in the steel melt, and the blister steel is prepared by foaming in the vacuum. The control of the distribution, the quantity, the size, the vacuum degree, the foaming time and the like of the generated initial air pores is carried out so as to control the porosity and the pore structure of the blister steel to prepare the blister steel with the excellent performance in short time. The vacuum foaming preparation method of the blister steel, disclosed by the invention, has the characteristics of high efficiency, simple process, controllable pore structure, stable process and the like, and can realize the industrial production.

Owner:KUNMING UNIV OF SCI & TECH

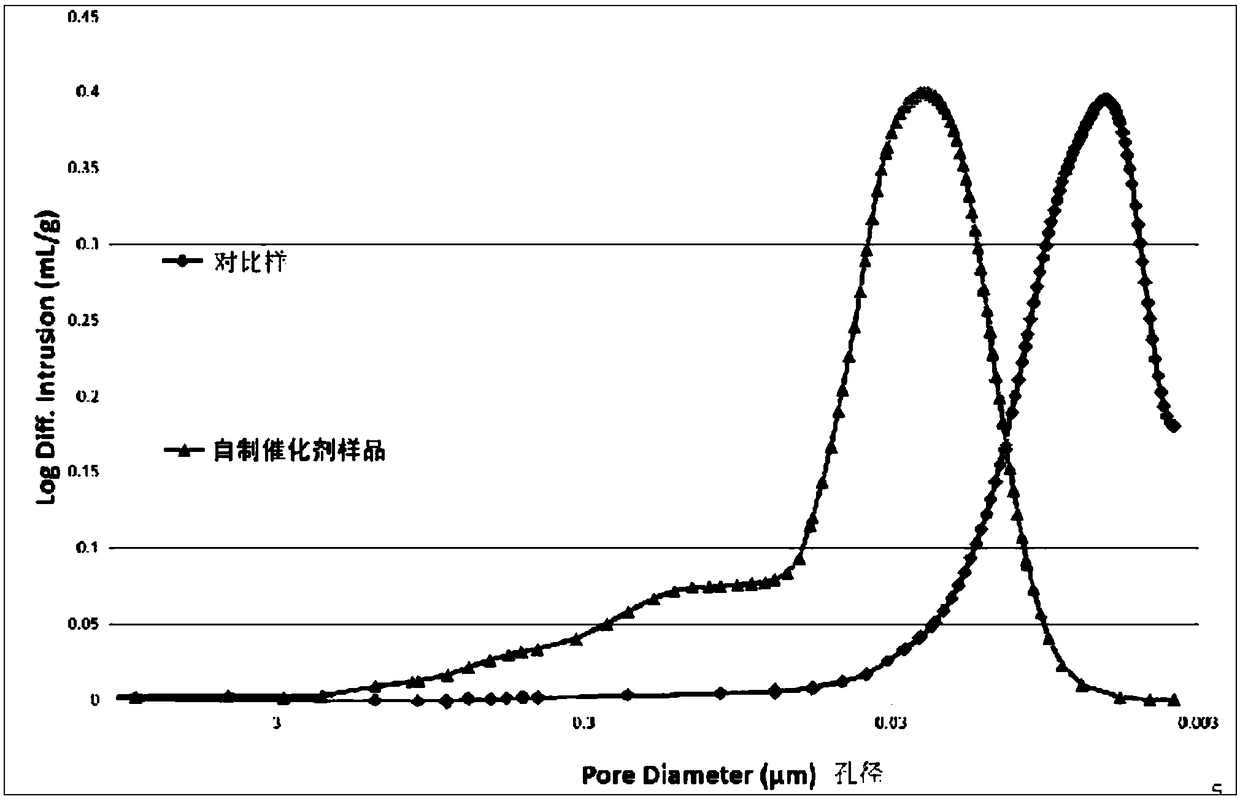

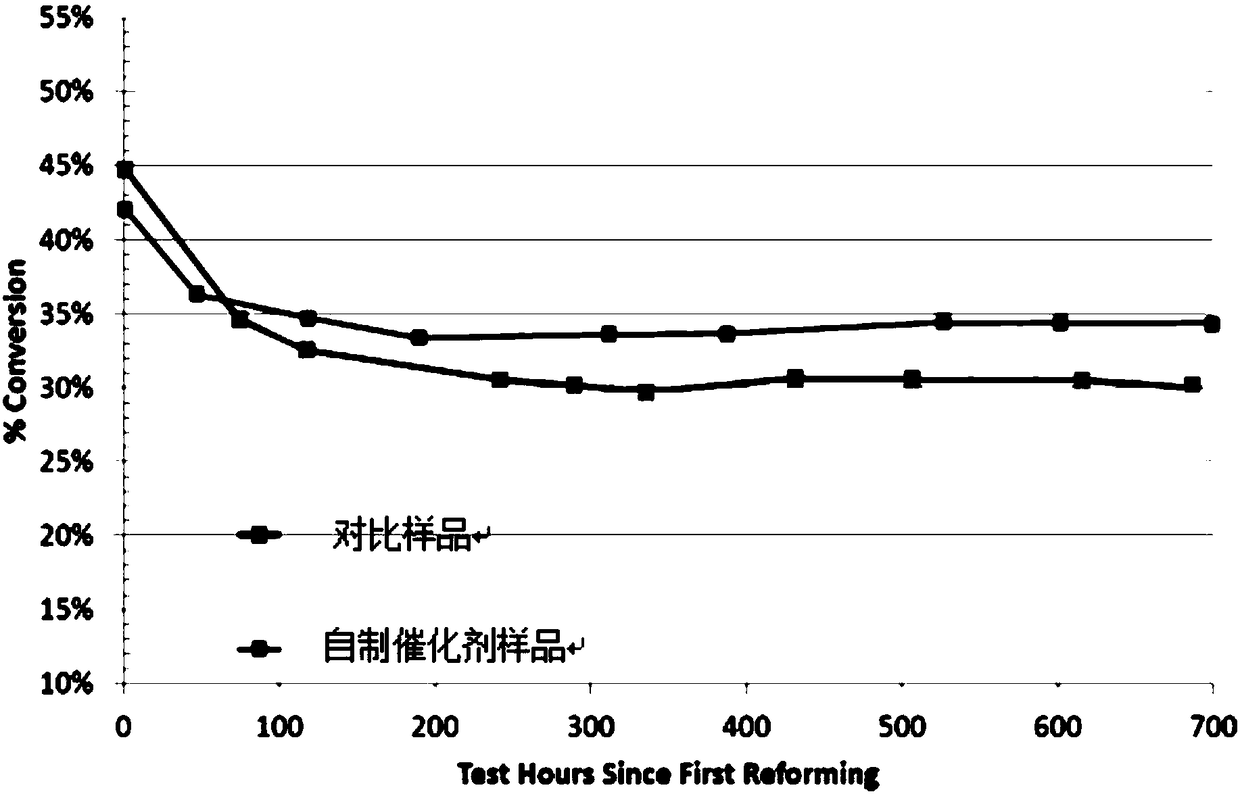

Catalyst for methane steam reforming in fuel cell

The invention belongs to the technical field of catalysts, and particularly relates to a catalyst used in a fuel cell and especially used for methane steam reforming in a molten carbonate fuel cell. The catalyst is characterized by being prepared by a structured granular carrier prepared from oxides of aluminum, zirconium and lanthanum, wherein the structured granular carrier is loaded with oxideof nickel so as to finally form the structured granular catalyst prepared from the oxides of the nickel, the aluminum, the zirconium and the lanthanum. The catalyst provided by the invention is largein pore diameter and stable in pore structure; with large pore diameter, the catalyst cannot be easily blocked by alkali metal of an electrolyte, an active channel of reforming reaction can be continuously provided; the aluminum, the lanthanum (rare earth elements) and zirconium are acted jointly, so that carrier crystal particles are staggered, an active center is increased, and the overall activity of the catalyst is improved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Preparation of epoxide resin based foam material

The invention discloses a method for preparing an epoxide resin foaming material. The method comprises the following steps that: 1. according to the mass ratio, epoxide resins, foaming agents, foam stabilizing agents and addition agents are respectively picked up and evenly mixed with high-speed stirring; 2. the mixture obtained is put in an oven with a temperature of between 40 and 80 DEG C and pre-heated for 0.5 to 1 hour, and the mixture is taken out and cooled down to a temperature of between 25 and 35 DEG C; 3. The mixture is added with curing agents and evenly mixed; 4. the mixture is put in a stainless steel mold and heated at the temperature of between 40 to 80 DEG C for 0.5 to 2 hours, and the mixture is cooled down to the room temperature and taken out, and finally the finished products are obtained. By controlling reaction conditions, the invention realizes the association control of the chemical foaming and the curing molding of epoxy, and the foaming multiplying factor isas high as 2.7, and products prepared by the method are good in water resistance, chemical corrosion resistance and strength. The method of the invention has the advantages of easy buying of materials, simple operation and easy industrialization, and provides a new path for preparing thermosetting foaming materials.

Owner:SHANGHAI INST OF TECH +1

Efficient wood particle active carbon for automobile carbon tank and preparation method thereof

ActiveCN107140636AImprove efficiencyHigh purityNon-fuel substance addition to fuelCarbon compoundsSodium BentoniteDesorption

The invention discloses wood particle active carbon for an automobile carbon tank and a preparation method thereof, and belongs to the fields of active carbon for the automobile carbon tank and the preparation method of the active carbon. The weight ratio of major raw material ingredient of wood active carbon powder to organic sodium-based bentonites to water is 1:(0.2 to 0.25):(0.8 to 1.0); the three kinds of raw materials are uniformly stirred and are then pelleted; after pelleted particles are dried, physical activation is performed to obtain the wood particle active carbon; the wood active carbon powder is formed by mixing aged wood chips and thermal-process food stage phosphoric acid with the concentration being 85 percent according to a weight ratio of 1:(1.2 to 1.5) through fully stirring, still soaking, high-temperature carbonization activation, recovery, rinsing, drying and powder preparation. The preparation method comprises two major work procedures of wood active carbon powder preparation and wood particle active carbon preparation. The product strength is high; the effective aperture pore volume is more developed; the distribution is more uniform; the adsorption and desorption performance is good; the gas flowing resistance is small.

Owner:湖南御洁新材料科技有限公司

Preparation method of prealloyed high-entropy alloy porous material

InactiveCN109622979AOvercome increased energy consumptionOvercoming uneven powder spreadTransportation and packagingMetal-working apparatusHigh entropy alloysOxidation resistant

The invention relates to a preparation method of a prealloyed CrNiFeTiMoW high-entropy alloy porous material. The preparation method mainly comprises the steps that ultrasonically-treated Cr, Ni, Fe,Ti, Mo and W materials are weighed according to an equimolar ratio; the weighed materials are molten through vacuum arc and then are atomized to prepare prealloyed CrNiFeTiMoW high-entropy alloy; stearic acid accounting for 2-4% of the total powder content is added into the powder, and after drying, a pressed blank is obtained through cold press forming; and the pressed blank is placed in a vacuumsintering furnace to be sintered to prepare the high-entropy alloy porous material. According to the prealloyed CrNiFeTiMoW high-entropy alloy porous material prepared through the preparation method,the production process is simple and easy to implement, the sintering period is short, the preparation cost is low, the high open porosity and rich connected pores are obtained, ingredients are uniform, the structure is controllable, and the material can be used for liquid-solid or gas-solid separation conditions of corrosion resistance and high temperature oxidation resistance.

Owner:XIANGTAN UNIV

Diatomite/cellulose inorganic-organic composite filter aid for directly filtering micro-polluted water source as well as preparation method and application of diatomite/cellulose inorganic-organic composite filter aid

InactiveCN103055828AStrong complementarityAchieve optimizationOther chemical processesFiltration separationAnhydrous ethanolCellulose

The invention relates to the technical field of water supply treatment, and specifically relates to a diatomite / cellulose inorganic-organic composite filter aid for directly filtering micro-polluted water source as well as a preparation method and an application of the diatomite / cellulose inorganic-organic composite filter aid. The diatomite / cellulose inorganic-organic composite filter aid is characterized by carrying out pre-hydrolyzing, stirring and reacting on cellulose in the water at 50-90 DEG C; adding anhydrous ethanol dispersion of diatomite and stirring; then adding ammonia water to adjust the pH to an alkaline condition suitable for polycondensation of the cellulose; preserving the heat to carry out the polycondensation; stirring to obtain cellulose-diatomite sol; and ageing to obtain gel and then treating to obtain the diatomite / cellulose inorganic-organic composite filter aid. The diatomite / cellulose inorganic-organic composite filter aid for directly filtering the micro-polluted water source has the characteristics that the turbidity removal rate is high, the turbidity removal rate is only slightly reduced as the increase of the filtration speed, and the reduction is not obviously; and the diatomite / cellulose inorganic-organic composite filter aid can be used for accelerating the filtration speed and increasing the water production efficiency.

Owner:深圳武汉理工大研究院有限公司

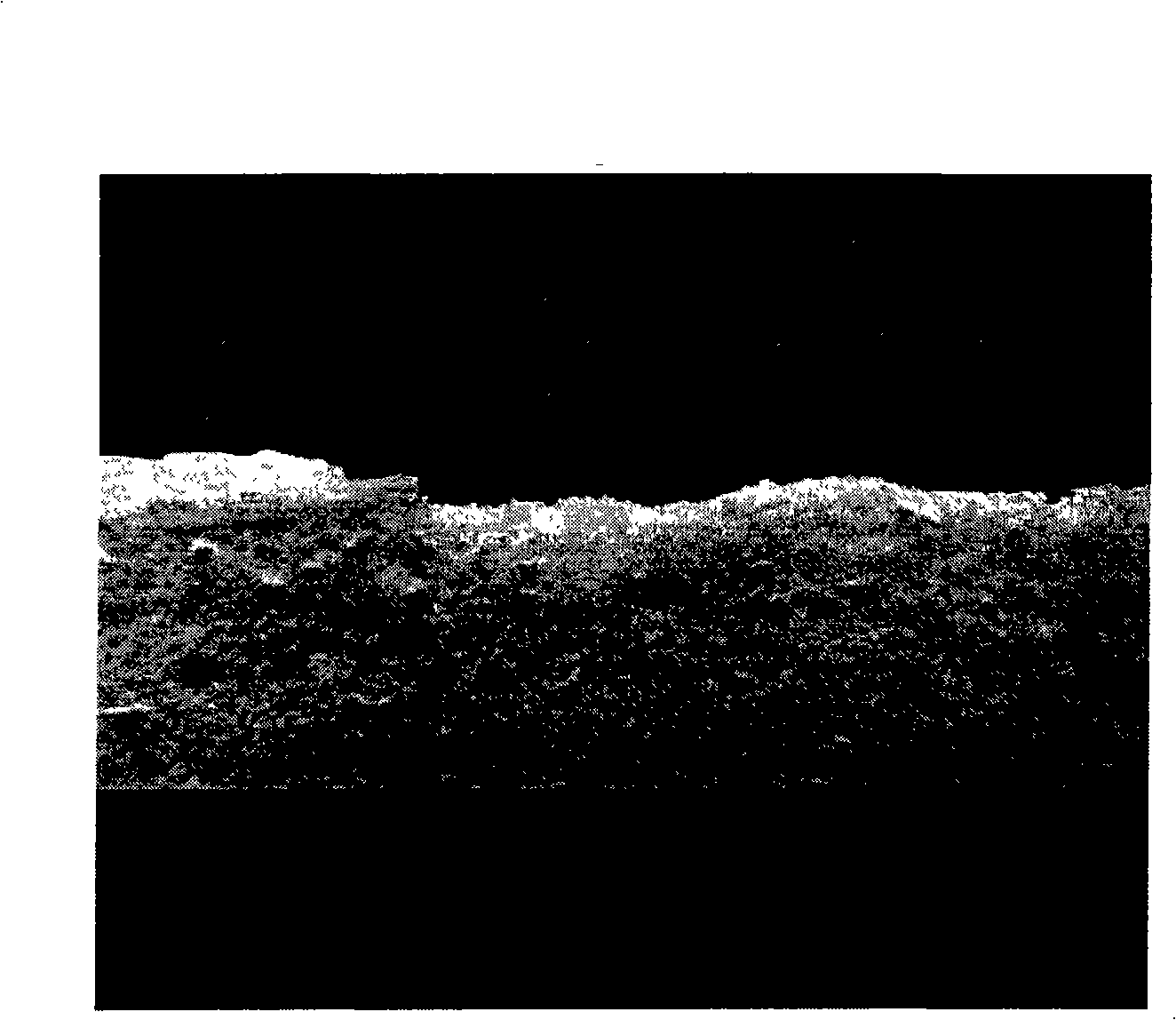

Method for preparing foamed aluminum of uniform pore structure

ActiveCN106756188AStable pore structureThe solution cannot be arbitrarily controlledPorosityMaterials science

The invention relates to a method for preparing foamed aluminum of a uniform pore structure. A foamed aluminum layer material is prepared with calcium carbonate and crushed aluminum skimmings as raw materials. The preparation idea is that the crushed aluminum skimmings and calcium carbonate are dissolved into a sol solution of nanosilicon dioxide, stable turbid liquid is formed, then dispersion liquid obtained after a dispersion agent is dissolved is injected to the turbid liquid dropwise, a preheating reaction is conducted, then a soaking and replacement reaction is conducted, and the foamed aluminum of the uniform pore structure is obtained. The foamed aluminum obtained through the preparation method is low in cost and high in porosity, and the average pore size of pores is small.

Owner:平邑仁安中医药产业发展有限公司

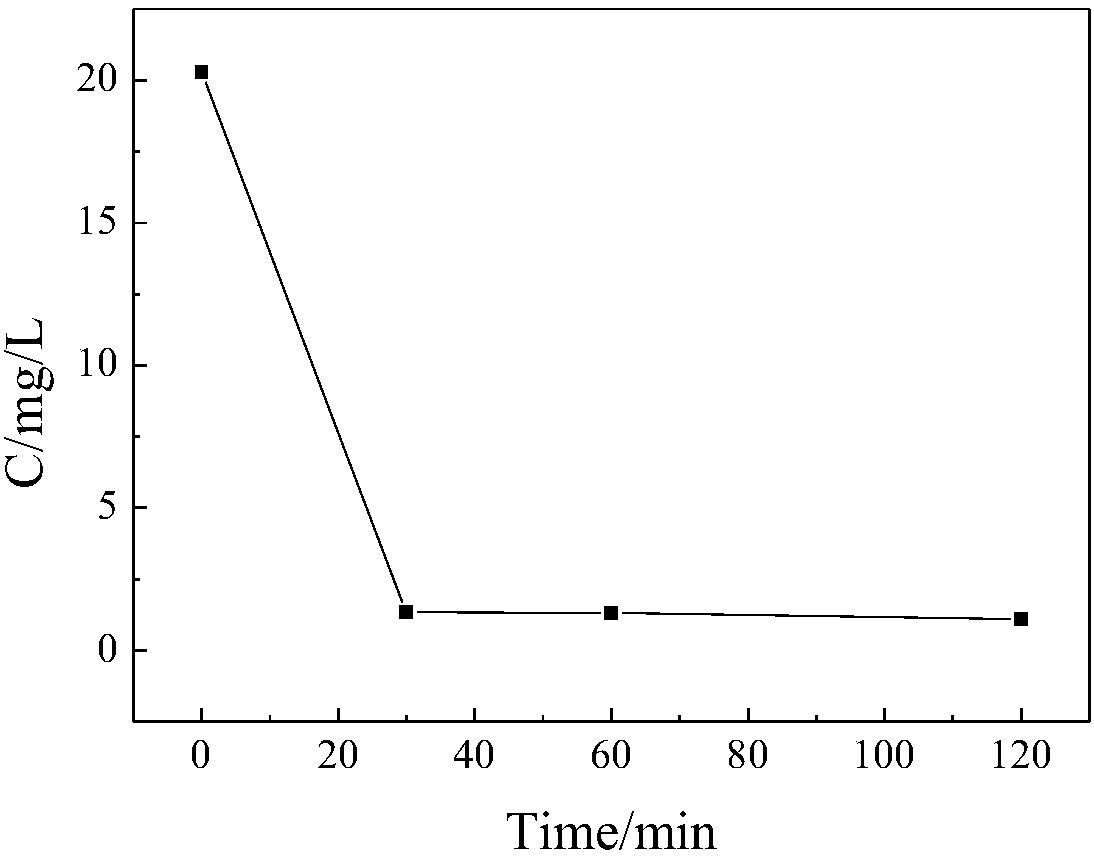

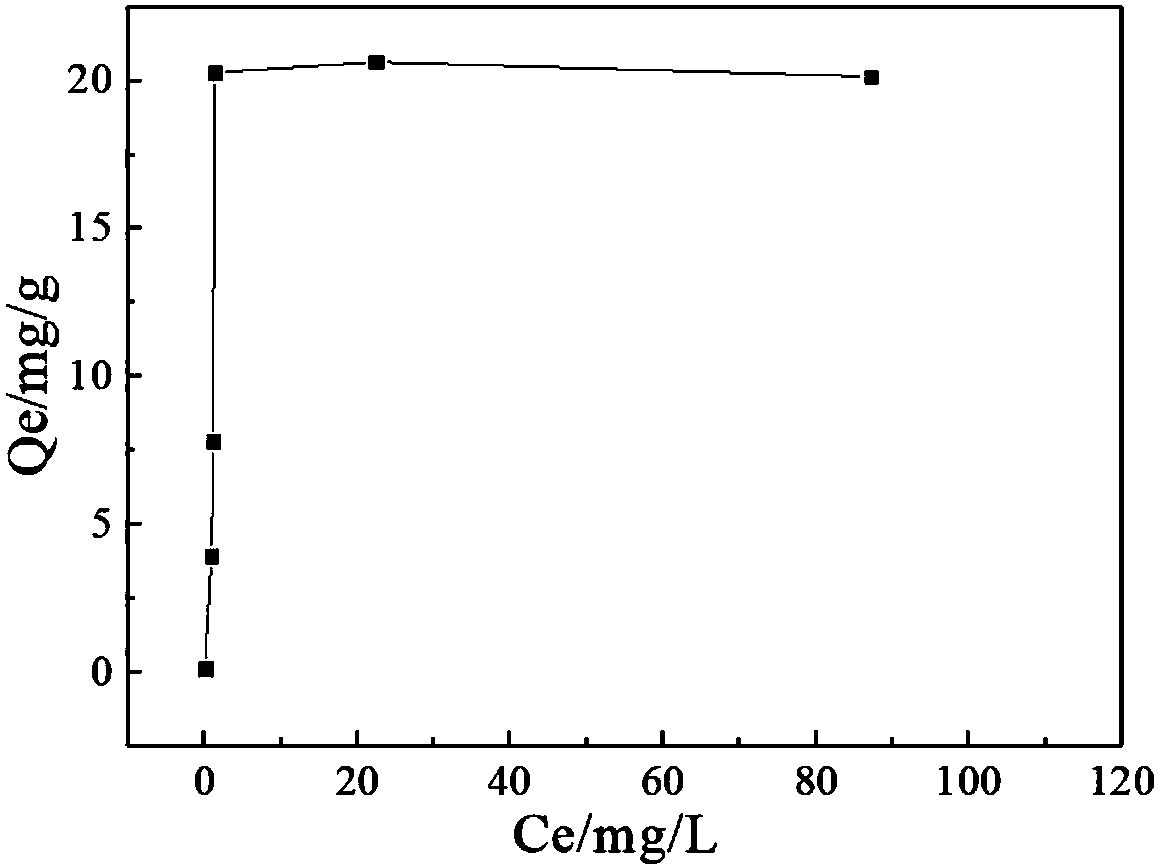

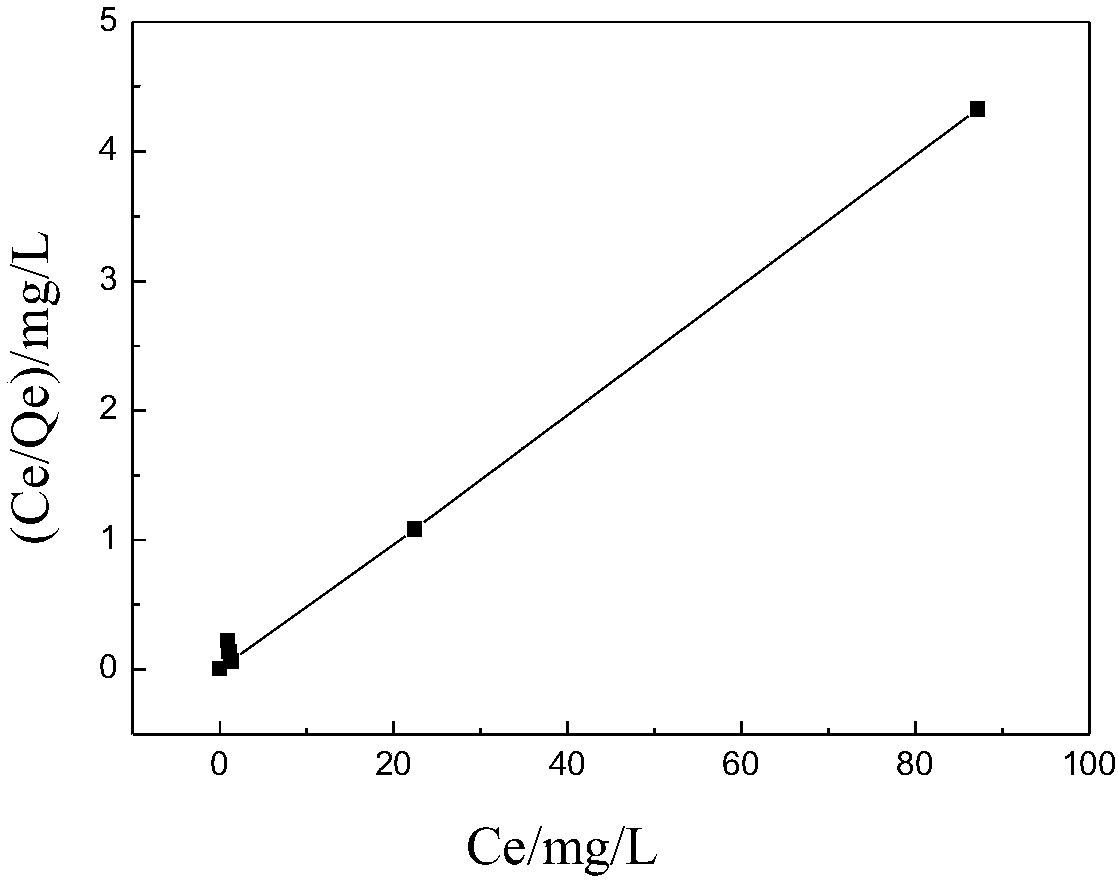

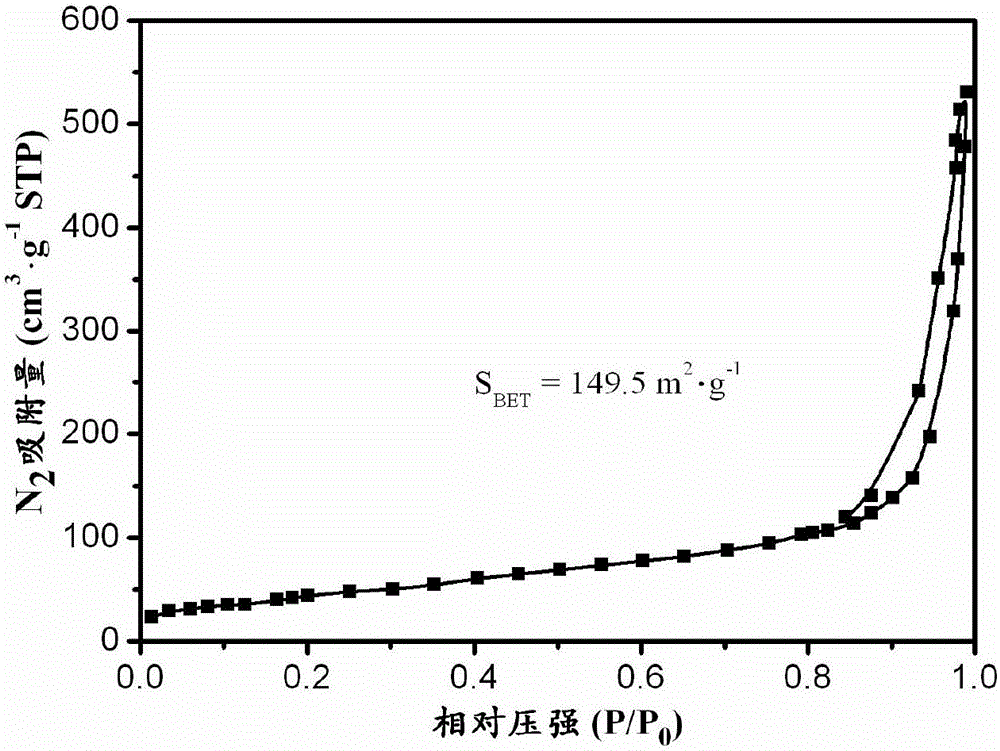

Mesoporous magnetic nanometer iron oxide material, and preparation method and applications thereof

InactiveCN108371938AAchieving controllable equipmentStable pore structureOther chemical processesWater contaminantsSorbentCentrifugation

The invention discloses a mesoporous magnetic nanometer iron oxide material, and a preparation method and applications thereof. According to the preparation method, a precipitating agent and Fe2(SO4)3are dissolved in water so as to obtain a mixed solution; the mixed solution is stirred to be uniform, and is sealed in a drying box for hydro-thermal reaction so as to obtain a nanometer iron oxide precursor precipitate; the nanometer iron oxide precursor precipitate is subjected to distilled water washing, ethanol washing, centrifugation separation, drying, and sintering at room temperature successively so as to obtain the adsorbent. The preparation method is simple; the raw materials are cheap and easily available; the obtained mesoporous magnetic nanometer iron oxide adsorbent possesses excellent adsorption capacity on Cr (VI).

Owner:SHANGHAI UNIV

Method for preparing rapid adsorption material with porous structure

InactiveCN106215884AGood adsorption rateImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesCross-linkCross linker

The invention discloses a method for preparing a rapid adsorption material with a porous structure. The method comprises the steps of firstly, carrying out selective oxidation on microcrystalline cellulose by taking sodium periodate and sodium chlorite as oxidants so as to obtain oxycellulose particles with rigid structures, then, carrying out cross-linking on the oxycellulose particles by using tetrafluoroterephthalonitrile as a rigid cross-linker, forming a microstructure with a stable molecular skeleton, thereby obtaining the rapid adsorption material with the porous structure. The adsorption material prepared by the method contains a large number of adsorption groups such as carboxyl, hydroxyl and ether groups, has a rigid structure, is high in adsorption site density and has more pore structures and a relatively large specific surface area, so that the adsorption material has good adsorption capacity and rapid adsorption rate, is applicable to the treatment of heavy-metal ion polluted wastewater and has an application prospect in the field of environmental protection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

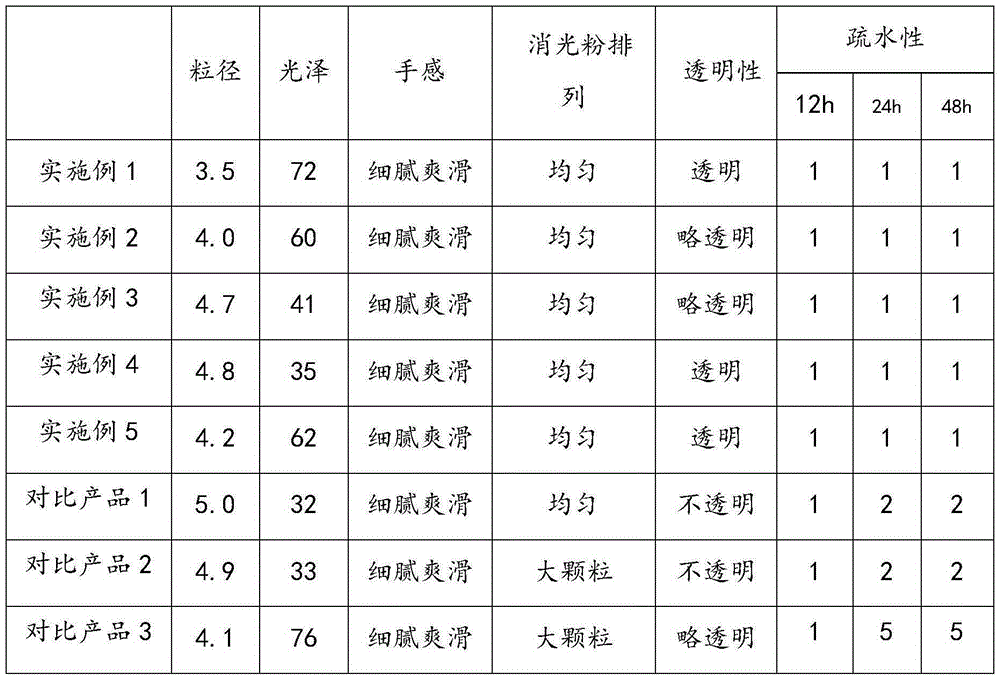

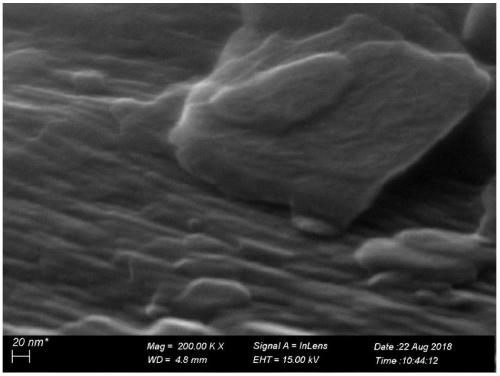

Preparation method of hydrophobic ultrafine silicon dioxide for coating agent

InactiveCN107011719AUniform particle sizeStable pore structureCoatingsPigment treatment with organosilicon compoundsReaction temperatureSilicon dioxide

The invention discloses a preparation method of hydrophobic ultrafine silicon dioxide for a coating agent. The preparation method includes steps: (1) well mixing dry powdered silicon dioxide being 8-12micron in particle size and dry powdered silicon dioxide being 3-7micron in particle size in a glass container; (2) mixing formic acid aqueous solution being 2% in weight percent with methyl alcohol, slowly pouring formic acid and methyl alcohol mixed solution into the glass container, and keeping stirring for 20-40min; (3) atomizing a hydrophobic modified silane coupling agent, uniformly spraying into the glass container, and stirring at a constant speed to allow complete reaction of raw materials for 30-60min at a reaction temperature of 40-70 DEG C; (4) hermetically placing reaction products, and ageing for 3-6h; (5) drying the aged materials, and performing airflow ultrafine grinding to obtain a finished product. The preparation method of hydrophobic ultrafine silicon dioxide for the coating agent has the advantage that an uneven state is achieved while a hydrophobic property of silicon dioxide on the surface of the coating agent is realized.

Owner:德清美联新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com