Method for producing coke by replacing part of coal by sawdust

A technology to replace parts and wood chips, applied in coke ovens, biofuels, special forms of dry distillation, etc., can solve problems such as huge costs, and achieve the effects of protecting the environment, reducing inorganic impurities and increasing carbon content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

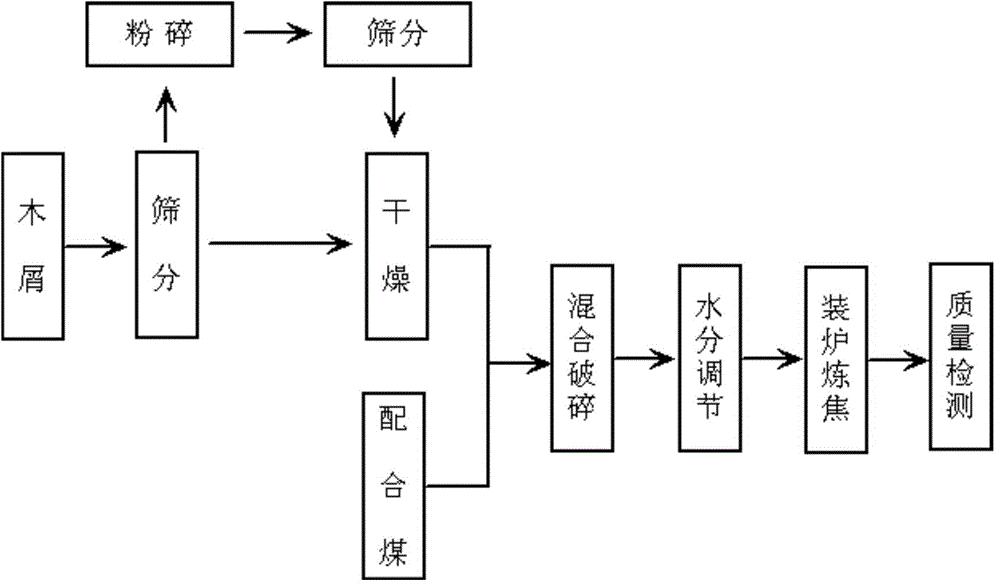

Image

Examples

Embodiment 1

[0018] Sieve the sawdust from the sawmill. The sawdust with a particle size of less than 3mm is used for the test. The sawdust with a particle size of more than 3mm is crushed by a crusher. The crushed sawdust is used as a sample. Dry in an oven at 105°C for 15 hours to ensure that the moisture content of the sawdust after drying is below 3%. After drying, it is cooled in the air. The base coal used is the blended coal of the production plant (A d = 6%, VM d = 28%), the particle size is less than 6mm, the sawdust and basic coal accounting for 6% of the weight of the basic coal are added to the crusher for mixing and crushing, and the particle size after crushing is less than 1mm; a certain amount of Ensure that the moisture content of the mixture is 5%, and then put the mixture into a 40kg coke oven and carry out a coking test under a certain heating system to obtain qualified coke, and then carry out quality inspection of the coke. The test results of coke products are: M40 ...

Embodiment 2

[0020] Sieve the sawdust from the sawmill. The sawdust with a particle size of less than 3mm is used for the test. The sawdust with a particle size of more than 3mm is crushed by a crusher. The crushed sawdust is used as a sample. Dry in an oven at 105°C for 17 hours to ensure that the moisture content of the sawdust after drying is below 3%. After drying, it is cooled in the air. The base coal used is the blended coal of the production plant (A d = 7%, VM d = 27%), the particle size is less than 6mm, the sawdust and basic coal accounting for 7% of the weight of the basic coal are added to the crusher for mixing and crushing, and the particle size after crushing is less than 1mm; a certain amount of Ensure that the moisture content of the mixture is 5.5%, and then put the mixture into a 40kg coke oven and carry out a coking test under a certain heating system to obtain qualified coke, and then carry out a quality inspection of the coke. The test results of coke products are: ...

Embodiment 3

[0022] Sieve the sawdust from the sawmill. The sawdust with a particle size of less than 3mm is used for the test. The sawdust with a particle size of more than 3mm is crushed by a crusher. The crushed sawdust is used as a sample. Dry in an oven at 105°C for 18 hours to ensure that the moisture content of the sawdust after drying is below 3%. After drying, it is cooled in the air. The base coal used is the blended coal of the production plant (A d = 8%, VM d = 25%), the particle size is less than 6mm, the sawdust and basic coal accounting for 8% of the weight of the basic coal are added to the crusher for mixing and crushing, and the particle size after crushing is less than 1mm; Ensure that the moisture content of the mixture is 6%, and then put the mixture into a 40kg coke oven and carry out a coking test under a certain heating system to obtain qualified coke, and then carry out a quality inspection of the coke. The test results of coke products are: M40 is 59.7%, M10 is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com