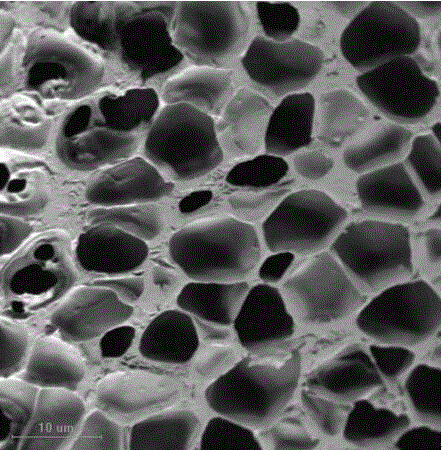

Method for preparing foamed aluminum of uniform pore structure

A technology of foamed aluminum and pore structure, applied in the field of aluminum materials, can solve the problems of inability to arbitrarily control and adjust structural parameters of foamed aluminum, poor uniformity of pore structure, etc., and achieve the effects of stable and uniform pore structure, stable performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing aluminum foam with uniform pore structure, the preparation steps are as follows:

[0029] Step 1, put nano silicon dioxide into absolute ethanol, stir evenly to form a sol;

[0030] Step 2, adding calcium carbonate and crushed aluminum scraps to the sol solution in step 1 to form a suspension;

[0031] Step 3, put the dispersant into isopropanol, stir until completely dissolved, and obtain a dispersion;

[0032] Step 4, drop the dispersion liquid into the suspension gel and stir slightly to form a viscous shape;

[0033] Step 5, put the viscous reaction liquid into the preheated metal mold for preheating, and obtain the foamed aluminum precursor after cooling;

[0034] Step 6, soaking the foamed aluminum precursor in a saturated ammonium chloride aqueous solution to obtain a foamed aluminum material.

[0035] The formula in the preparation method is as follows:

[0036] 10 parts of calcium carbonate, 20 parts of crushed aluminum chips, 3 parts...

Embodiment 2

[0045] A method for preparing aluminum foam with uniform pore structure, the preparation steps are as follows:

[0046] Step 1, put nano silicon dioxide into absolute ethanol, stir evenly to form a sol;

[0047] Step 2, adding calcium carbonate and crushed aluminum scraps to the sol solution in step 1 to form a suspension;

[0048] Step 3, put the dispersant into isopropanol, stir until completely dissolved, and obtain a dispersion;

[0049] Step 4, drop the dispersion liquid into the suspension gel and stir slightly to form a viscous shape;

[0050] Step 5, put the viscous reaction liquid into the preheated metal mold for preheating, and obtain the foamed aluminum precursor after cooling;

[0051] Step 6, soaking the foamed aluminum precursor in a saturated ammonium chloride aqueous solution to obtain a foamed aluminum material.

[0052] The formula in the preparation method is as follows:

[0053] 15 parts of calcium carbonate, 30 parts of crushed aluminum chips, 5 parts...

Embodiment 3

[0062] A method for preparing aluminum foam with uniform pore structure, the preparation steps are as follows:

[0063] Step 1, put nano silicon dioxide into absolute ethanol, stir evenly to form a sol;

[0064] Step 2, adding calcium carbonate and crushed aluminum scraps to the sol solution in step 1 to form a suspension;

[0065]Step 3, put the dispersant into isopropanol, stir until completely dissolved, and obtain a dispersion;

[0066] Step 4, drop the dispersion liquid into the suspension gel and stir slightly to form a viscous shape;

[0067] Step 5, put the viscous reaction liquid into the preheated metal mold for preheating, and obtain the foamed aluminum precursor after cooling;

[0068] Step 6, soaking the foamed aluminum precursor in a saturated ammonium chloride aqueous solution to obtain a foamed aluminum material.

[0069] The formula in the preparation method is as follows:

[0070] 12 parts of calcium carbonate, 28 parts of crushed aluminum chips, 4 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com