Preparation method of hydrophobic ultrafine silicon dioxide for coating agent

A technology of ultra-fine silica and silica, applied in chemical instruments and methods, coatings, dyeing organosilicon compound treatment, etc., can solve problems such as inability to bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

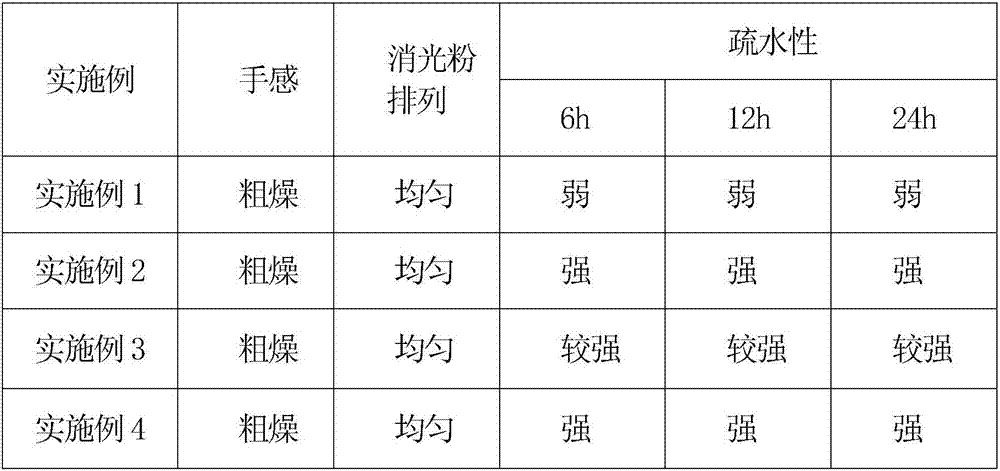

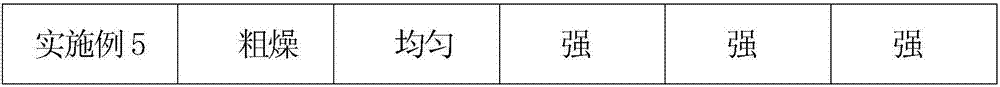

Examples

Embodiment 1

[0020] A kind of preparation method of the hydrophobic superfine silicon dioxide that is used for coating agent, this preparation method comprises the steps:

[0021] (1) Put 5Kg of dry powdered precipitated silica with a particle size of 8 μm to 12 μm and 5 Kg of dry powdered precipitated silica with a particle size of 3 μm to 7 μm in a glass container and mix evenly;

[0022] (2) Mix 2% formic acid aqueous solution and methanol according to the ratio of 2:5 by weight to obtain a formic acid-methanol mixture, slowly pour the formic acid-methanol mixture into a glass container, the weight of the formic acid-methanol mixture is two different particle sizes 15% by weight of the silicon oxide mixture, kept stirring for 30 minutes;

[0023] (3) The hydrophobically modified silane coupling agent 3-aminopropyltriethoxysilane is atomized, and then evenly sprayed into the glass container by the atomization reactor, and the addition amount of the hydrophobically modified silane couplin...

Embodiment 2

[0028] A kind of preparation method of the hydrophobic superfine silicon dioxide that is used for coating agent, this preparation method comprises the steps:

[0029] (1) Put 10Kg of dry powdered sol-gel method silica with a particle size of 8 μm to 12 μm and 5 Kg of dry powdered sol-gel method silica with a particle size of 3 μm to 7 μm in a glass container and mix evenly;

[0030] (2) Mix 2% formic acid aqueous solution and methanol according to the weight ratio of 1:6 to obtain a formic acid-methanol mixture, slowly pour the formic acid-methanol mixture into a glass container, the weight of the formic acid-methanol mixture is two different particle sizes 20% by weight of the silicon oxide mixture, kept stirring for 20 minutes;

[0031] (3) Atomize the hydrophobically modified silane coupling agent N-(2-aminoethyl-3-aminopropyl)methyldimethoxysilane, and then evenly spray it into the glass container through the atomization reactor, The addition amount of the hydrophobically...

Embodiment 3

[0036] A kind of preparation method of the hydrophobic superfine silicon dioxide that is used for coating agent, this preparation method comprises the steps:

[0037] (1) Put 5Kg of dry powdered precipitated silica with a particle size of 8 μm to 12 μm and 10 Kg of dry powdered sol-gel silica with a particle size of 3 μm to 7 μm in a glass container and mix evenly;

[0038] (2) Mix 2% formic acid aqueous solution and methanol according to the ratio of 1:8 by weight to obtain a formic acid-methanol mixture, slowly pour the formic acid-methanol mixture into a glass container, the weight of the formic acid-methanol mixture is two different particle sizes 25% by weight of the silicon oxide mixture, kept stirring for 40 minutes;

[0039] (3) Atomize the hydrophobically modified silane coupling agent 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane, and then evenly spray it into the glass container through the atomization reactor, and then hydrophobically modify The amount of the silane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com