Catalyst for methane steam reforming in fuel cell

A fuel cell and steam reforming technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unstable catalyst structure, poor activity stability, low activity rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

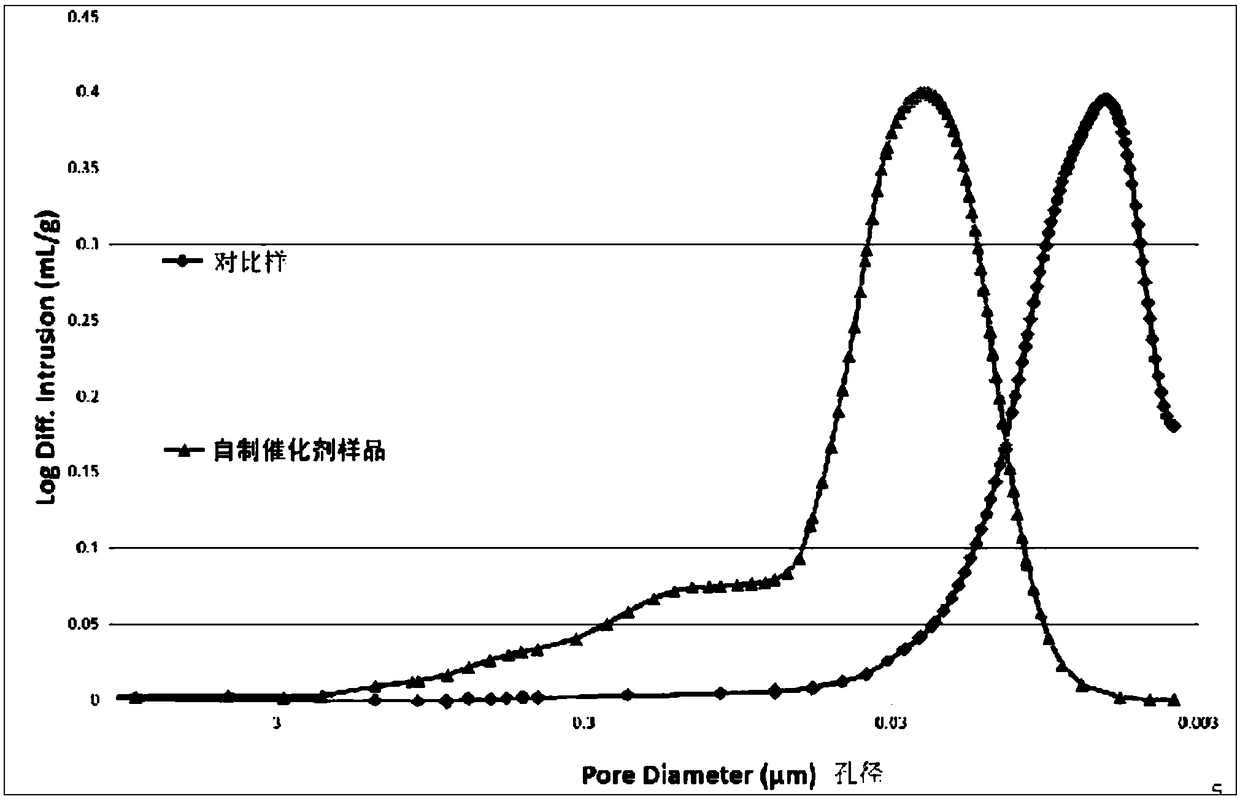

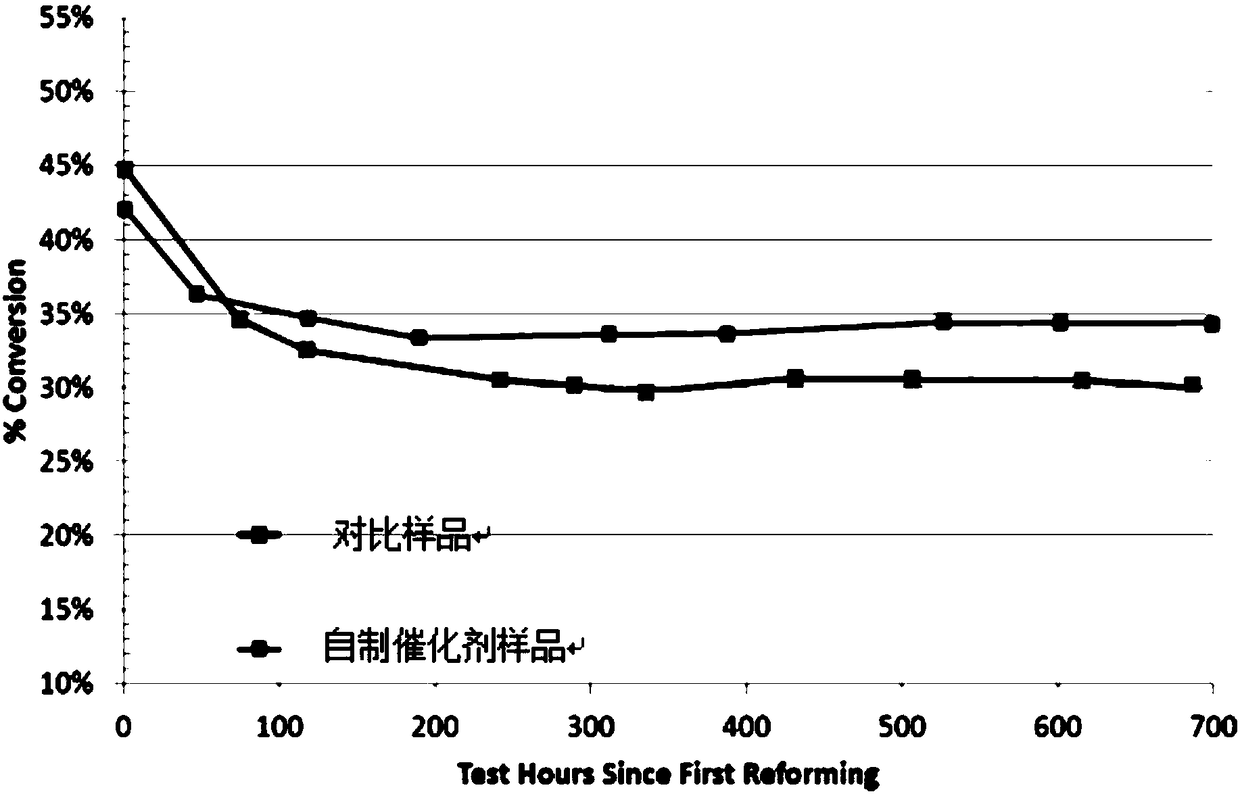

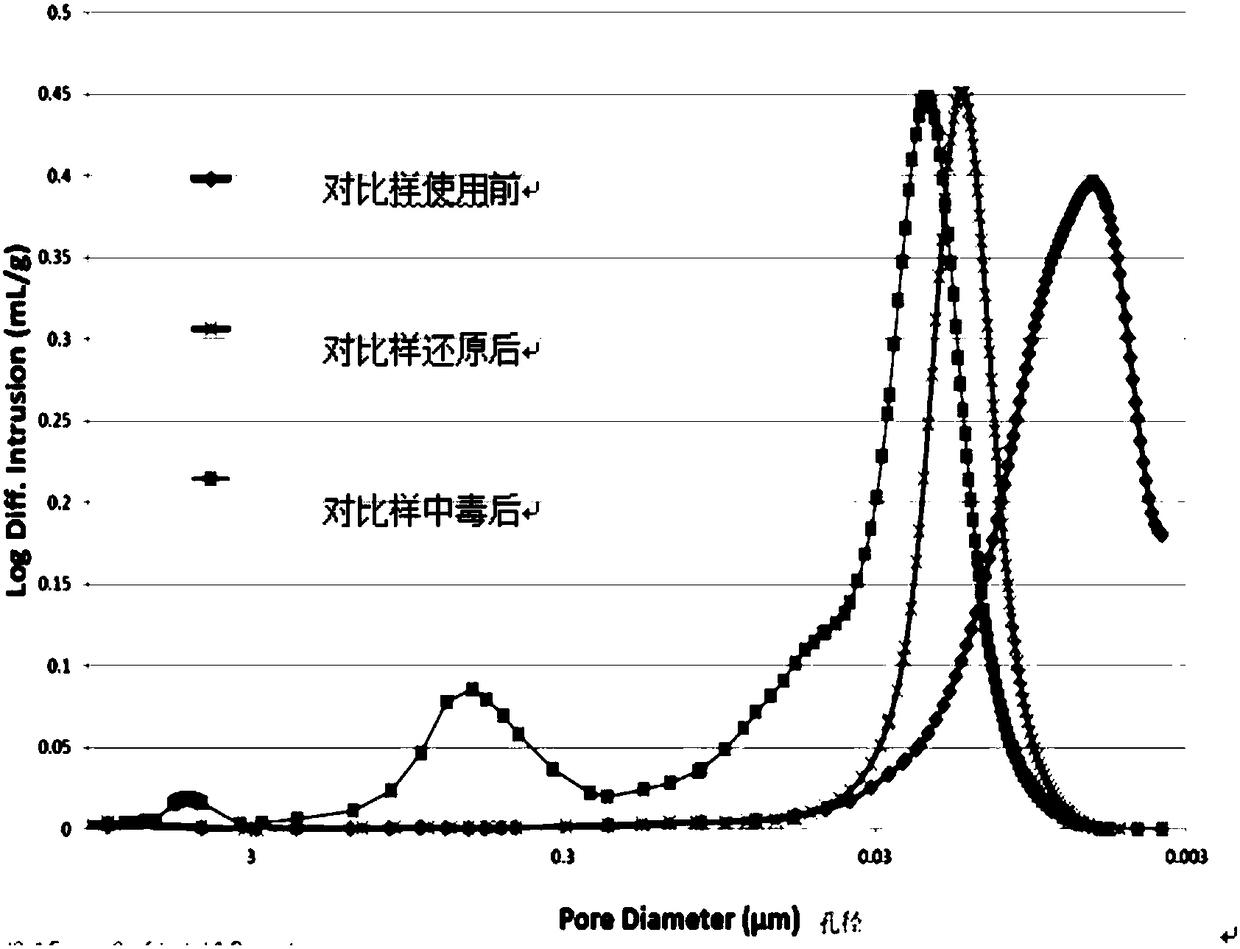

[0047] Catalysts for steam reforming of methane in molten carbonate fuel cells, including regular granular supports made of oxides of aluminum, zirconium and lanthanum (rare earth elements), then loaded with oxides of nickel, and finally formed with nickel, Regular granular catalyst formed from oxides of aluminum, zirconium and lanthanum (rare earth elements). The average pore diameter of the catalyst is 200-500Å, the pore volume is 0.2-0.5ml / g, and the specific surface area is greater than 45 m 2 / g, the loss on ignition at 900°C is less than 5%. The catalyst includes the following components in mass percentage: 37% of nickel oxide, 48% of aluminum oxide, 10% of zirconia, and 5% of lanthanum oxide (rare earth element). The granular catalyst is a cylindrical granular catalyst with a diameter of 1 mm and a height of 0.5 mm.

[0048] Wherein the raw materials of alumina, zirconia, lanthanum oxide and nickel oxide are alumina powder, zirconia powder, lanthanum oxide (rare earth...

Embodiment 2

[0057] Catalysts for steam reforming of methane in molten carbonate fuel cells, including regular granular supports made of oxides of aluminum, zirconium and lanthanum (rare earth elements), then loaded with oxides of nickel, and finally formed with nickel, Regular granular catalyst formed from oxides of aluminum, zirconium and lanthanum (rare earth elements). The average pore diameter of the catalyst is 200-500Å, the pore volume is 0.2-0.5ml / g, the specific surface area is greater than 45m2 / g, and the weight loss on ignition at 900°C is less than 5%.

[0058] The raw materials of alumina, zirconia, lanthanum oxide (rare earth element) and nickel oxide are alumina powder, zirconia powder, lanthanum oxide (rare earth element) powder and nickel nitrate solution, and the concentration of nickel nitrate solution is 0.1mol / L.

[0059] The preparation method is as described in Example 1, wherein the catalyst includes the following components in mass percentage: 42% nickel oxide, 42%...

Embodiment 3

[0062] Catalysts for steam reforming of methane in molten carbonate fuel cells, including regular granular supports made of oxides of aluminum, zirconium and lanthanum (rare earth elements), then loaded with oxides of nickel, and finally formed with nickel, Regular granular catalyst formed from oxides of aluminum, zirconium and lanthanum (rare earth elements). The average pore diameter of the catalyst is 200-500Å, the pore volume is 0.2-0.5ml / g, and the specific surface area is greater than 45m 2 / g, the loss on ignition at 900°C is less than 5%.

[0063] The raw materials of alumina, zirconia, lanthanum oxide (rare earth element) and nickel oxide are alumina powder, zirconia powder, lanthanum oxide (rare earth element) powder and nickel nitrate solution, the concentration of nickel nitrate solution is 0.5mol / L.

[0064] The preparation method is as in Example 1, wherein the catalyst includes the following components in mass percentage: 40% nickel oxide, 46% aluminum oxide, 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com