Preparation method of high-porosity silicon carbide-based porous ceramic material

A high-porosity, porous ceramic technology, applied in the field of ceramic materials, can solve the problems of difficult to take into account porosity and mechanical properties, complex preparation process, difficult to obtain ceramics, etc., to achieve the effect of not easy to produce defects, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

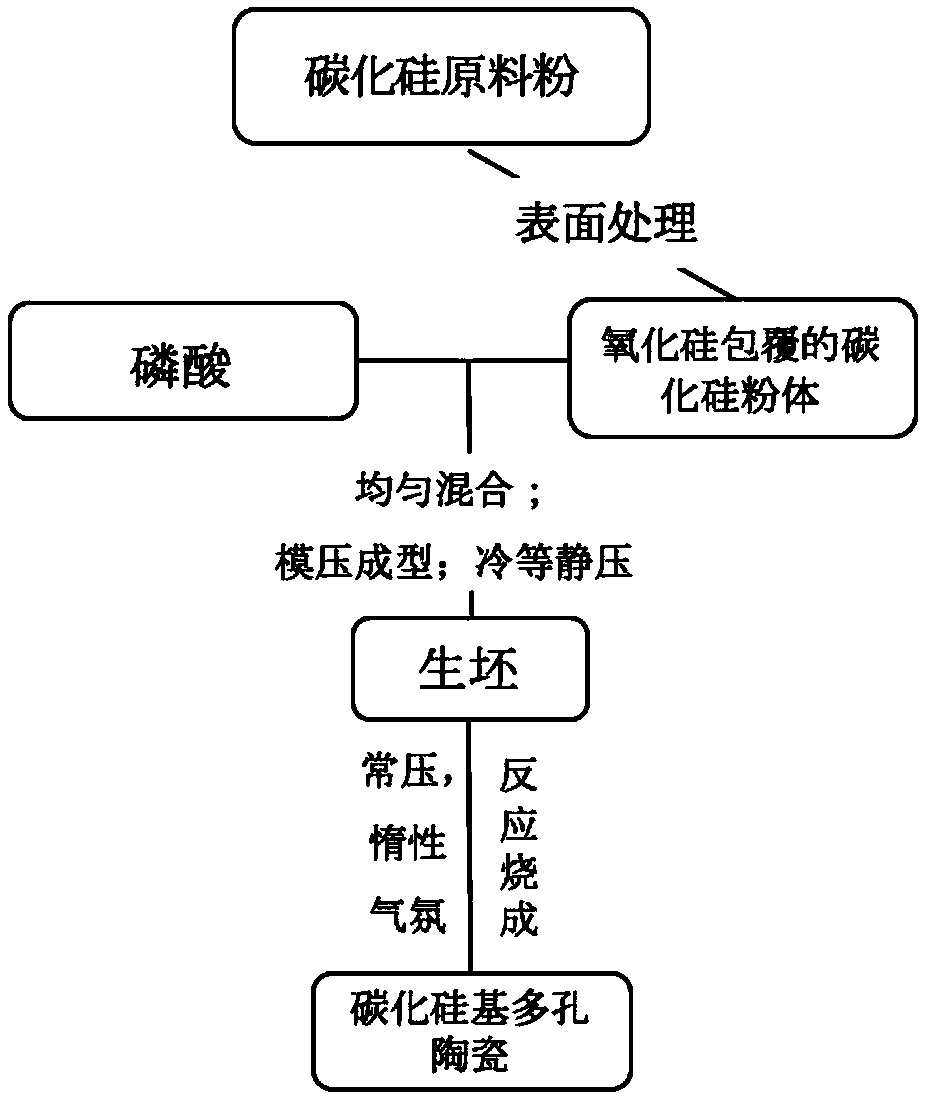

Method used

Image

Examples

Embodiment 1

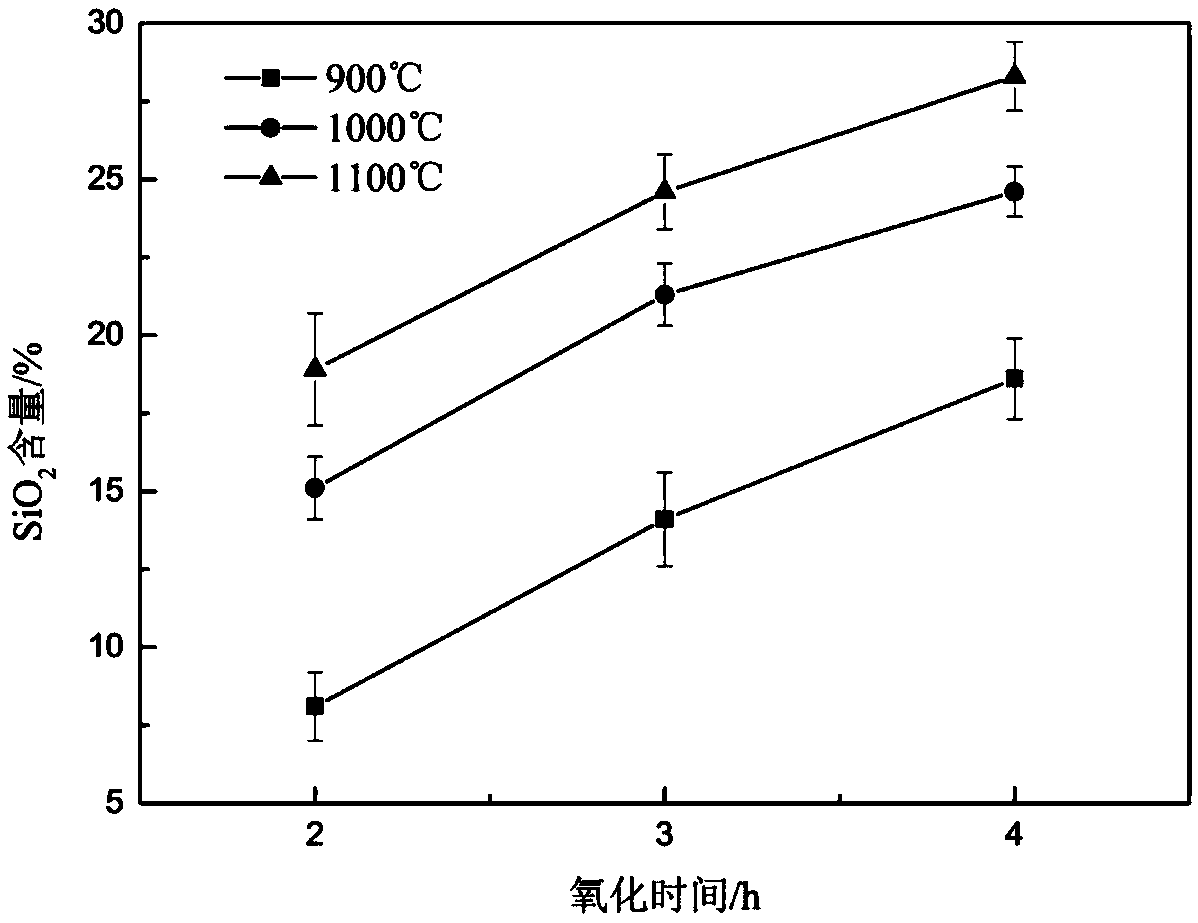

[0044] (1) Heat the silicon carbide ceramic powder with a particle size of 0.5μm to 1000°C in a common box furnace and keep it for 3h;

[0045] (2) The phosphoric acid with a weight concentration of 85% is uniformly mixed with the surface-treated silicon carbide powder, and the amount of phosphoric acid added is 20wt.%;

[0046] (3) Through 10MPa steel mold compression treatment, and then 200MPa cold isostatic pressing treatment, the formed body material is obtained;

[0047] (4) Atmospheric pressure sintering at 1200℃ under the protection of nitrogen atmosphere, the heating rate is 0.5℃ / min, and the heat preservation is 2h. A porous silicon carbide ceramic with an open porosity of 55% and a bending strength of 34.5MPa can be obtained.

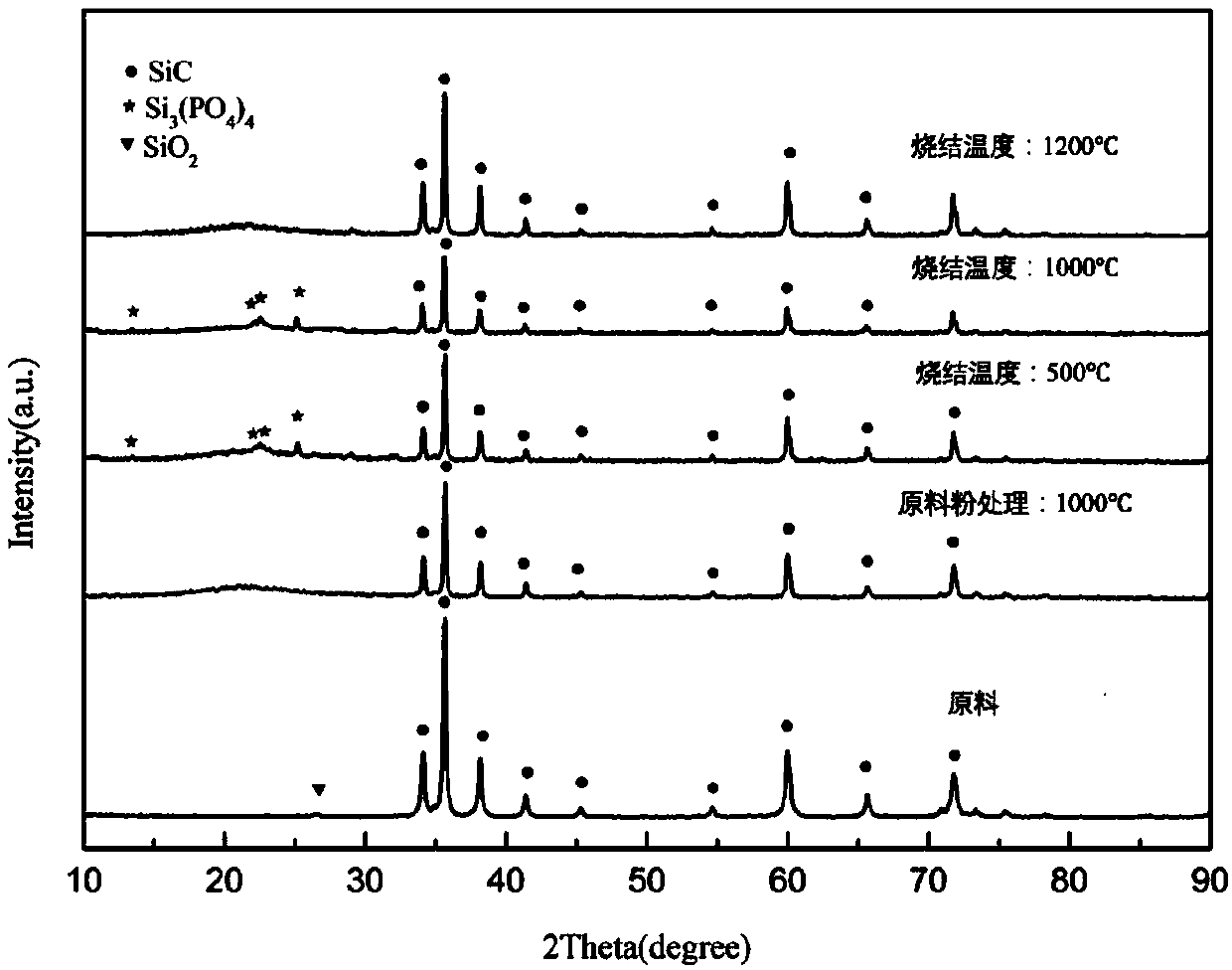

[0048] Analysis and testing show (see image 3 ): The main phase of the raw material powder is silicon oxide. After treatment at 1000°C, the main phase of the product is still silicon carbide and amorphous silicon oxide. The amorphous silicon oxide f...

Embodiment 2

[0050] (1) Heat the silicon carbide ceramic powder with a particle size of 10μm to 1000°C in a common box furnace and keep it for 4h;

[0051] (2) The phosphoric acid with a weight concentration of 75% is uniformly mixed with the surface-treated silicon carbide powder, and the amount of phosphoric acid added is 5 wt.%;

[0052] (3) Through 10MPa steel mold compression treatment, and then 200MPa cold isostatic pressing treatment, the formed body material is obtained;

[0053] (4) Carry out atmospheric sintering at 1000°C under the protection of argon atmosphere, the heating rate is 0.5°C / min, and the heat preservation is 4h. A porous silicon carbide ceramic with an open porosity of 57% and a bending strength of 18.3 MPa can be obtained.

Embodiment 3

[0055] (1) Heat the silicon carbide ceramic powder with a particle size of 0.5μm to 1000°C in a common box furnace and keep it for 2h;

[0056] (2) The phosphoric acid with a weight concentration of 85% and the silicon carbide powder after surface treatment are uniformly mixed, and the amount of phosphoric acid added is 20wt.%;

[0057] (3) Through 10MPa steel mold compression treatment, and then 200MPa cold isostatic pressing treatment, the formed body material is obtained;

[0058] (4) Normal pressure sintering is performed at 900°C under the protection of nitrogen atmosphere, the heating rate is 1°C / min, and the heat preservation is 5h. A porous silicon carbide ceramic with an open porosity of 40.7% and a bending strength of 21.5MPa can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com