Method for preparing silicon dioxide with large pore volume and large aperture

A silicon dioxide and large pore size technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of difficult control of pore size and its distribution, unstable powder properties, etc., and achieve improved sedimentation stability, low cost, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

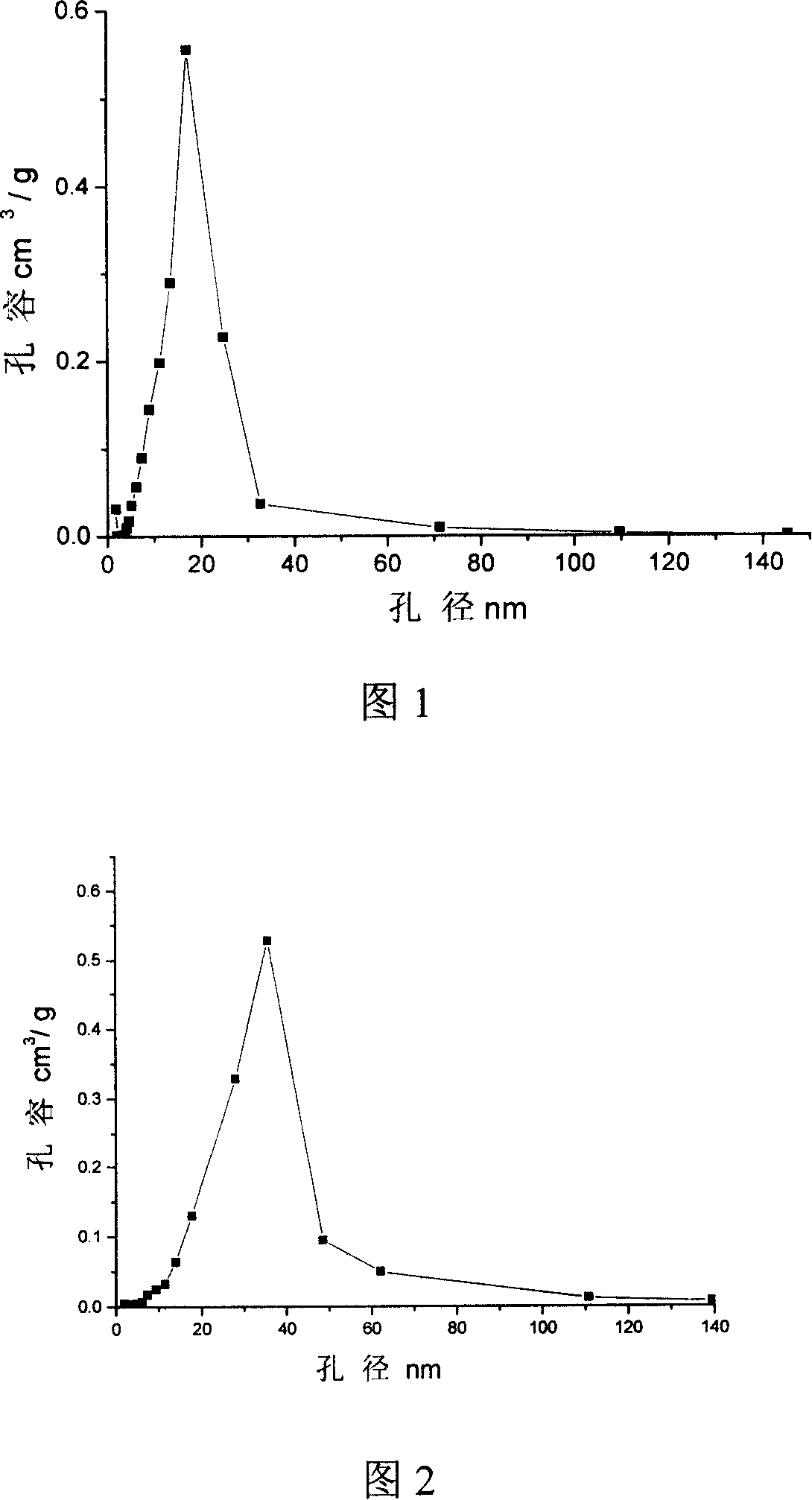

Embodiment 1

[0023] Embodiment 1: In 10 liters of reactors with agitator, add diluted 2000mLSiO 2 Concentration is 6% industrial water glass solution and 33g content is the polyethylene glycol-200 of 29%, is heated to initial temperature 50 ℃, with 0.5mol / lH 2 SO 4 Adjust the pH value to 10.8, stir for 1 h after the gel appears, and then continue to add H 2 SO 4 Until the pH is 3, the temperature is raised to 85° C., and after aging for 4 hours, vacuum filtration is carried out, and water is washed twice, the filter cake is beaten for spray drying, and the product is obtained after jet crushing.

Embodiment 2

[0024] Example 2: Silica was prepared by the method described in Example 1, the difference from Example 1 was that the initial temperature was 85°C.

Embodiment 3

[0025] Example 3: Silica was prepared according to the method described in Example 1, except that the initial temperature was 85° C., and the molecular weight of polyethylene glycol was 400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com