Fibroin micro-nano fiber microsphere as well as preparation method and application thereof

A technology of micro-nano fiber and silk fibroin, applied in biochemical equipment and methods, rayon manufacturing, general cultivation methods, etc., can solve the problem of residual specific surface area of harmful chemical reagents, poor mechanical properties of silk fibroin microspheres, and difficulty in controlling particle size To achieve the effect of optimizing hole shape stability, excellent mechanical properties and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

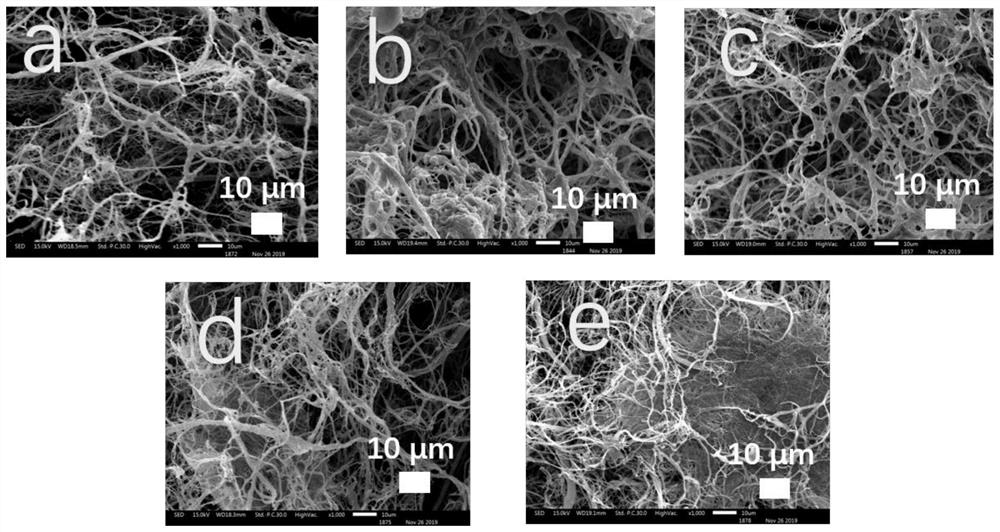

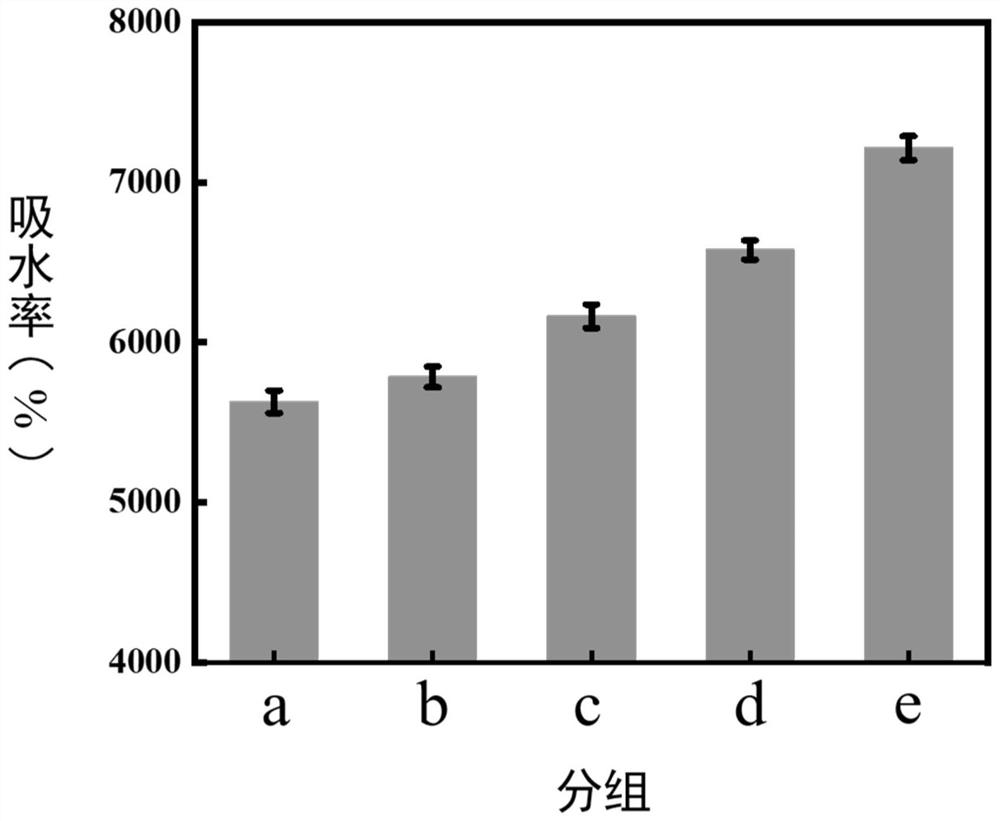

Examples

preparation example Construction

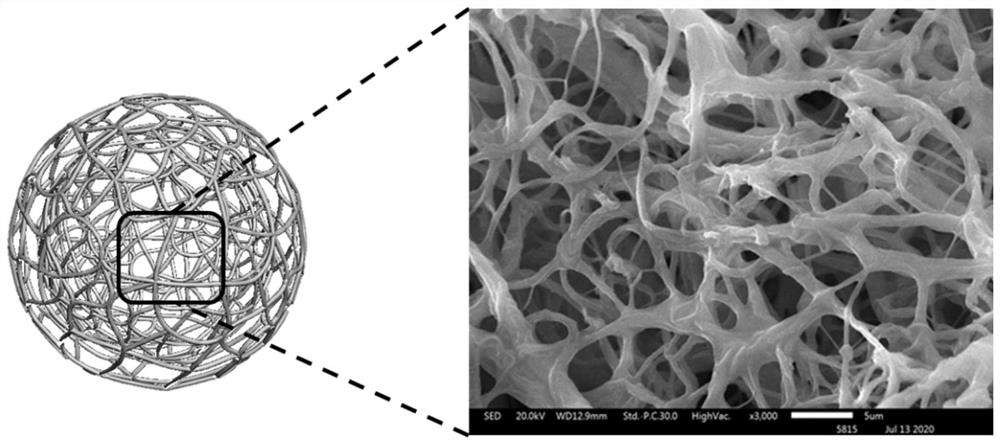

[0037] The invention provides a method for preparing silk fibroin micronano fiber microspheres, comprising the following steps:

[0038] S1, prepare the silk fibroin micro-nano fiber suspension for standby;

[0039] S2, preparing the polysaccharide solution for subsequent use;

[0040] S3. Mix the silk fibroin micro-nanofiber suspension prepared in step S1 with the polysaccharide solution prepared in step S2 according to the preset solute mass ratio, and mix thoroughly to obtain a mixed solution; then add the mixed solution to the mixed solution Add morpholineethanesulfonic acid, N-hydroxysuccinimide and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride successively to obtain the reaction solution after fully reacting;

[0041] S4. Inject the reaction solution obtained in step S3 into a push injection mold, push out the reaction solution by electrostatic spraying, collect it with liquid nitrogen, and obtain silk fibroin micro-nanofiber microspheres after freeze-dryi...

Embodiment 1

[0050] This embodiment provides a method for preparing silk fibroin micro-nano fiber microspheres, comprising the following steps:

[0051] S1. Preparation of silk fibroin micronanofiber suspension

[0052] Calcium chloride, ethanol and water were mixed according to the molar ratio of 1:2:8 to prepare a ternary mixed solution, and then the degummed silk was placed in the ternary mixed solution according to the bath ratio of 1:250g / mL. Treat at ℃ for 6 hours; then add water to the treated silk fiber and place it in a physical fiber splitter with a power of 1000W. After treating for 15 minutes, collect the resulting solution, filter and dry it to make silk micro-nano fiber suspension solution and stored at 4°C for later use.

[0053] S2. Preparation of silk fibroin micro-nano fiber microspheres

[0054] Take 30mL of the silk fibroin micro-nanofiber suspension with a concentration of 0.3wt% prepared in step S1, fully stir it and inject it into the injection mold, form the micro...

Embodiment 2

[0056] This embodiment provides a method for preparing silk fibroin micro-nano fiber microspheres, comprising the following steps:

[0057] S1. Preparation of silk fibroin micronanofiber suspension

[0058] This step is the same as that in Embodiment 1, and will not be repeated here.

[0059] S2, preparing polysaccharide solution

[0060] Take 0.5 g of hyaluronic acid powder, add it to 50 mL of deionized water, and stir slowly for 6 hours to obtain a hyaluronic acid solution with a mass fraction of 1 wt%, which is sealed and stored at 4°C as a polysaccharide solution for later use.

[0061] S3. Preparation of silk fibroin micro-nano fiber microspheres

[0062] Mix the silk fibroin micro-nanofiber suspension prepared in step S1 with the polysaccharide solution prepared in step S2 at a solute mass ratio of 99:1, and stir thoroughly to obtain a mixed solution in which the mass percentage of the total solute is 0.3 wt%. Add predetermined amount of morpholinoethanesulfonic acid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com