Patents

Literature

174 results about "Mixed states" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mixed quantum state is a statistical ensemble of pure states (see quantum statistical mechanics). Mixed states inevitably arise from pure states when, for a composite quantum system H 1 ⊗ H 2 {\displaystyle H_{1}\otimes H_{2}} with an entangled state on it, the part H 2 {\displaystyle H_{2}} is inaccessible to the observer.

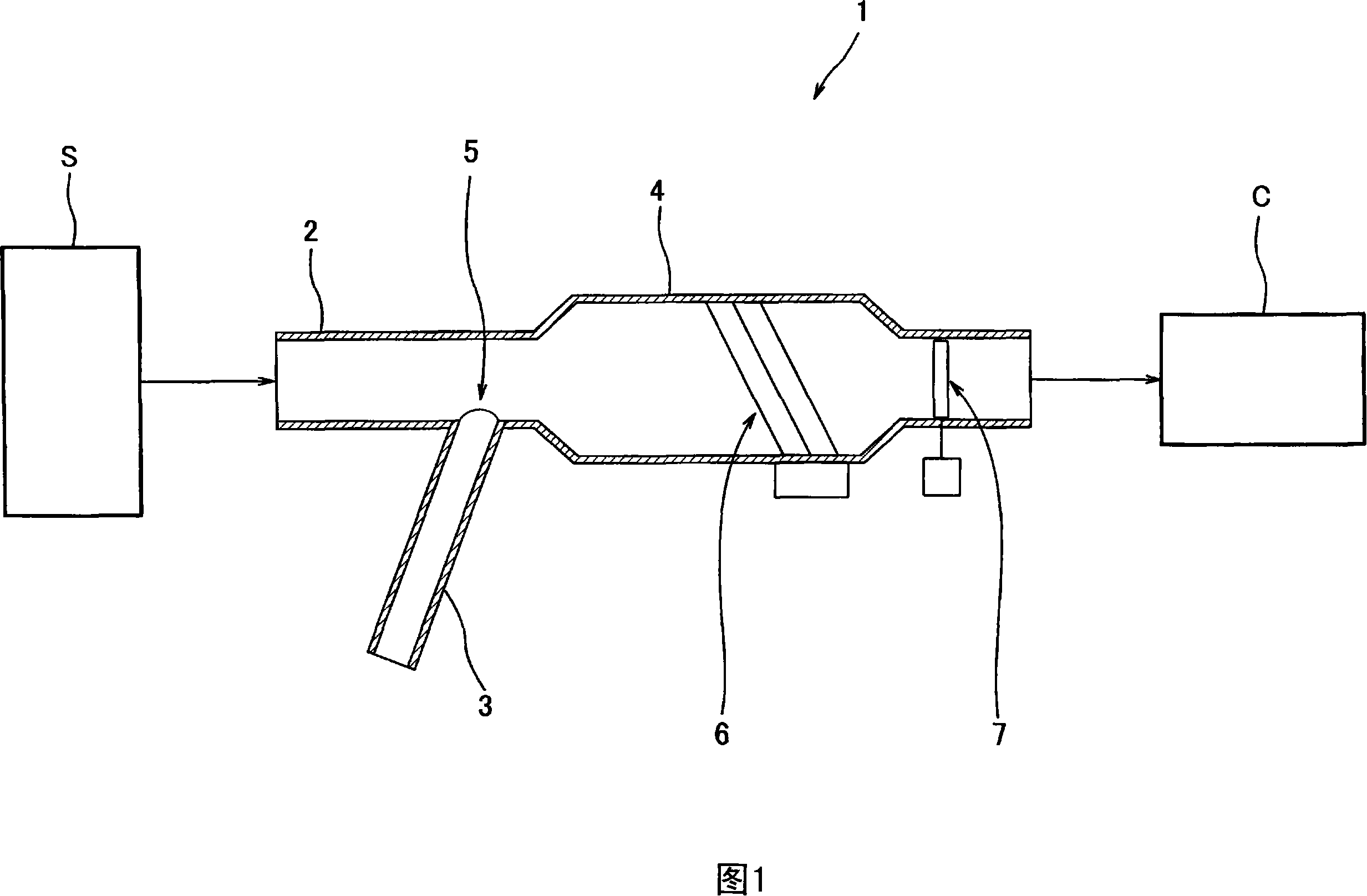

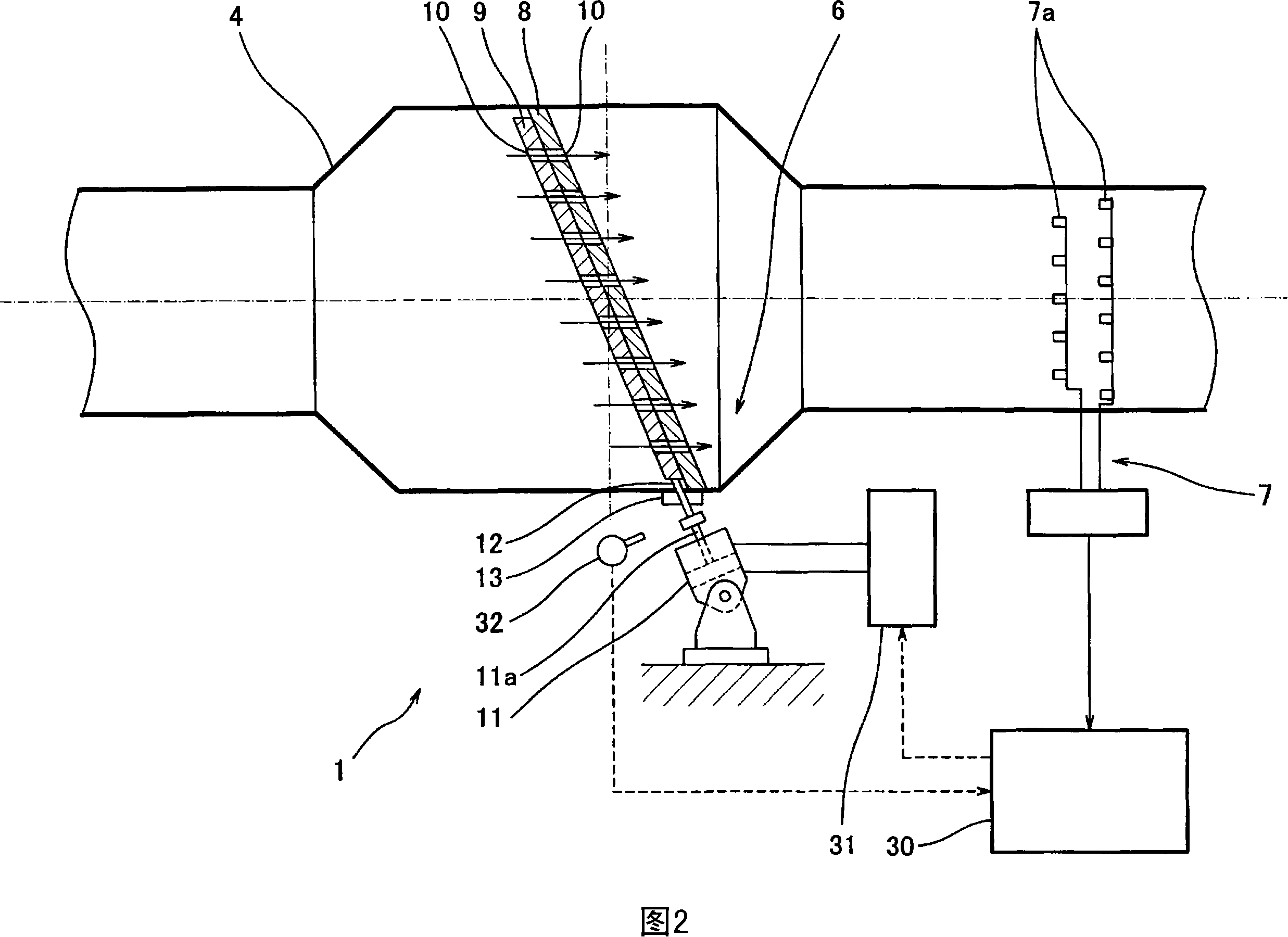

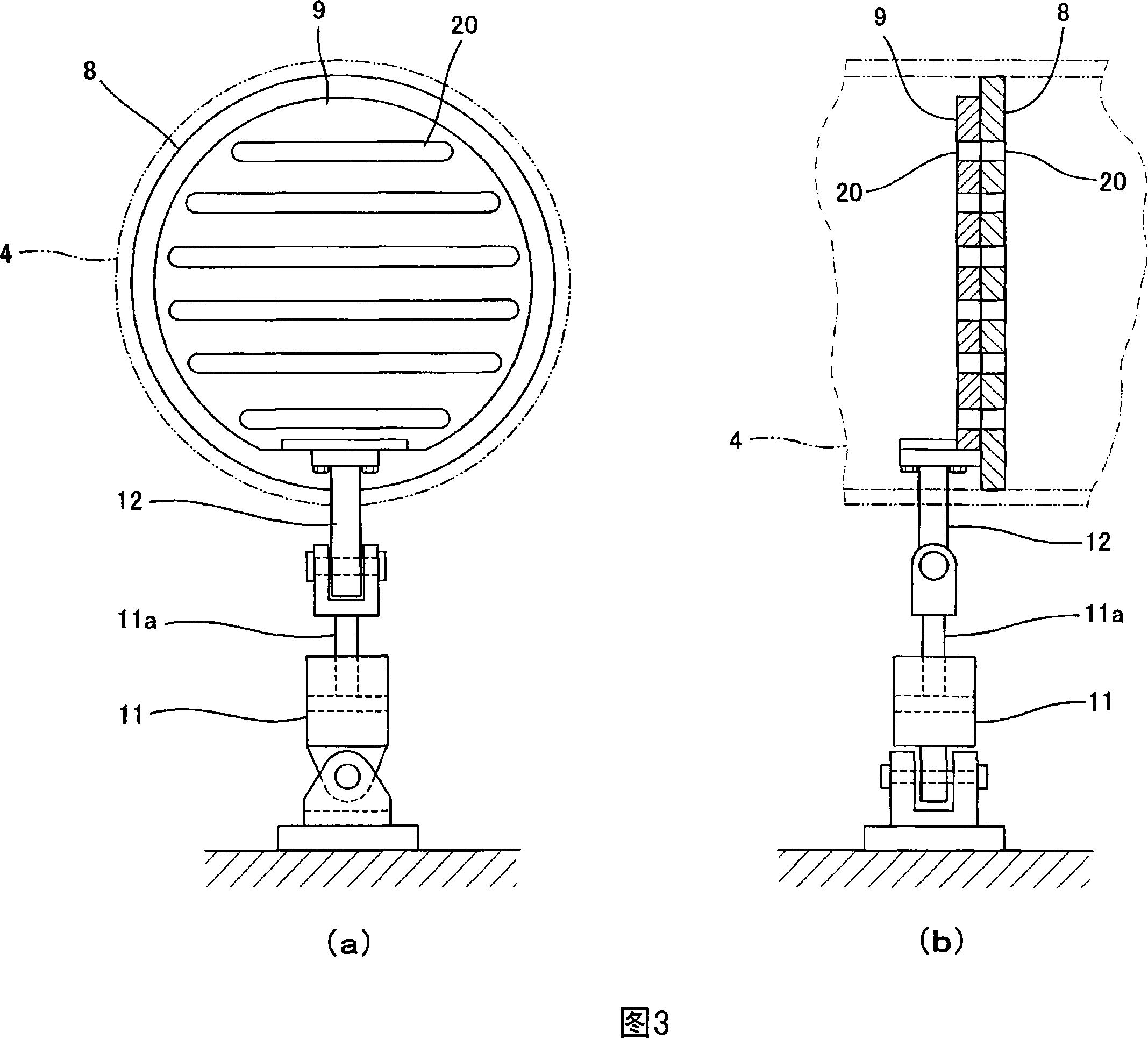

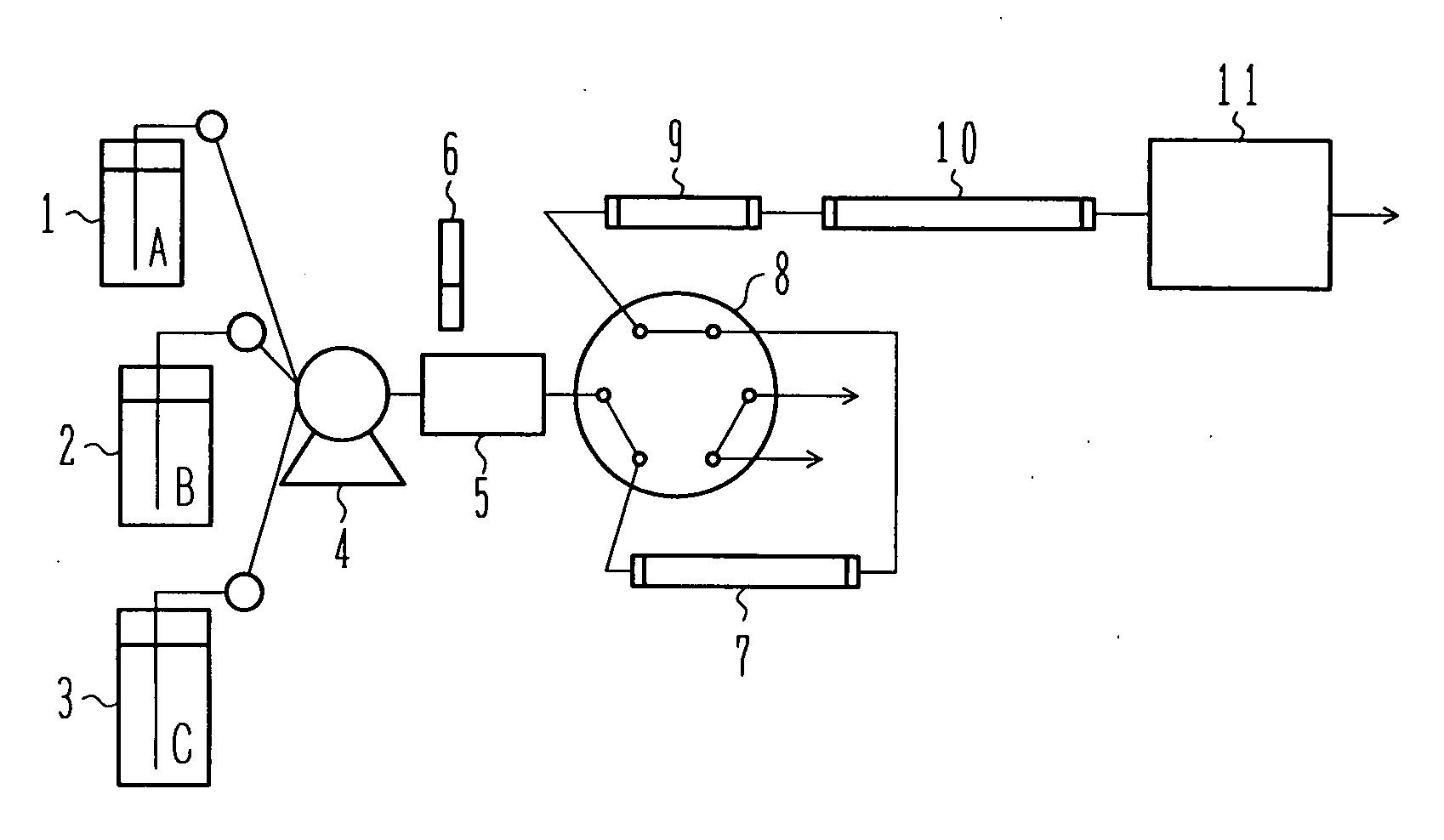

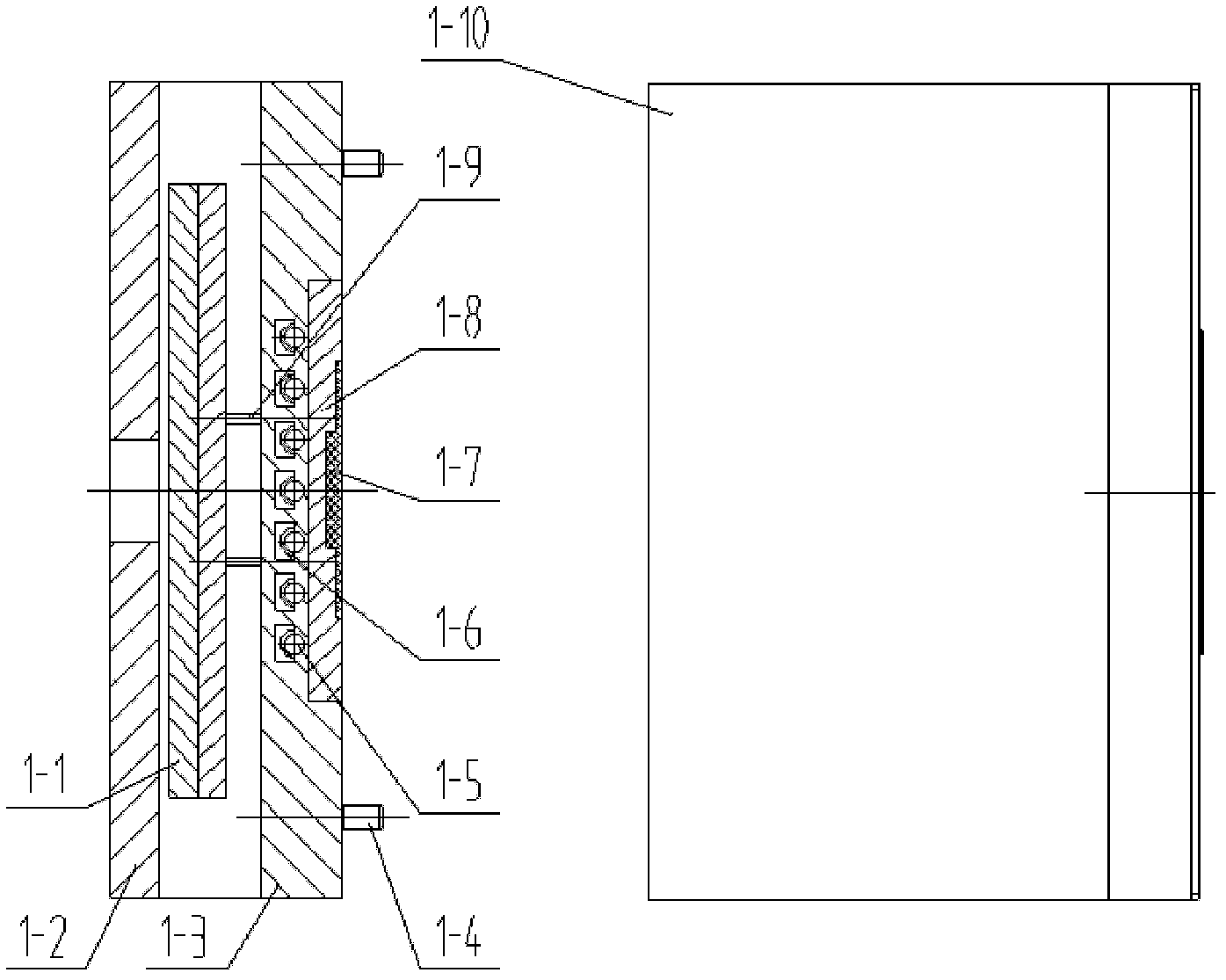

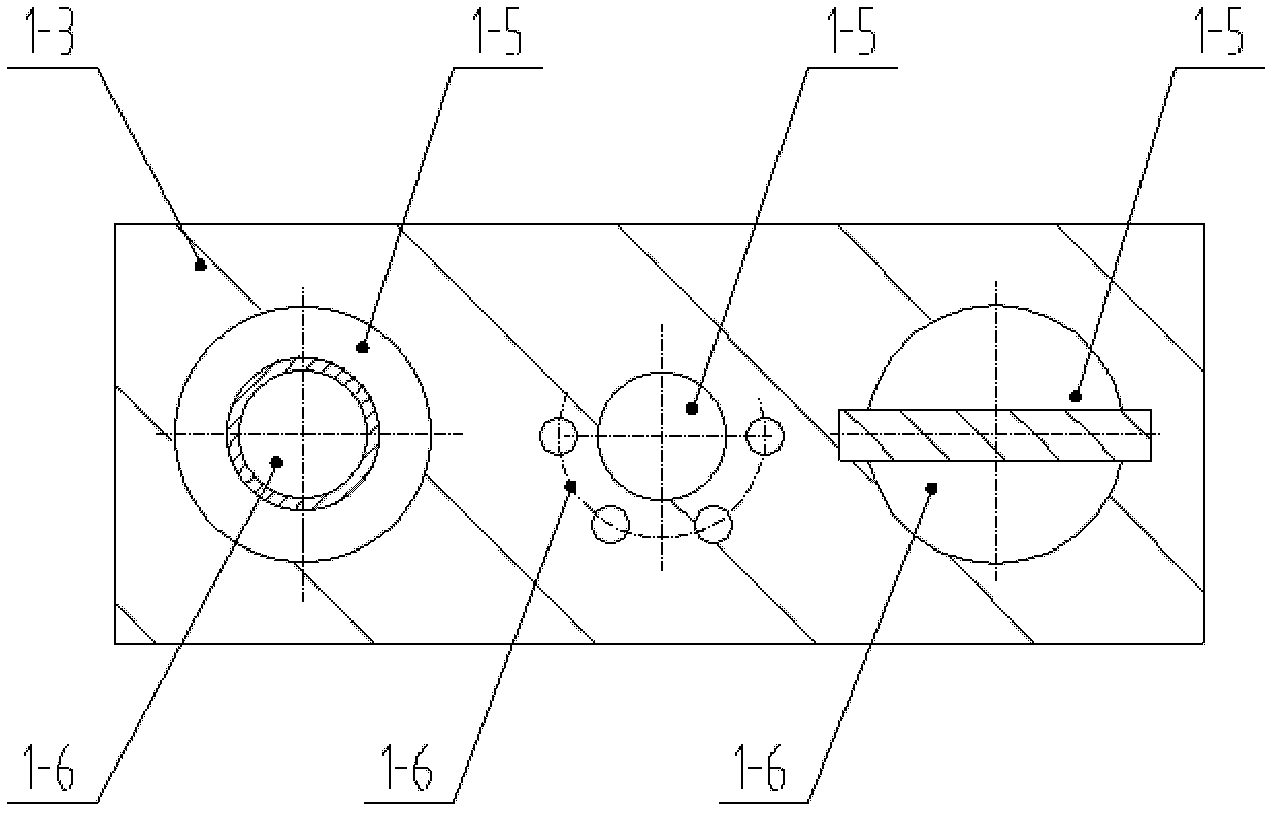

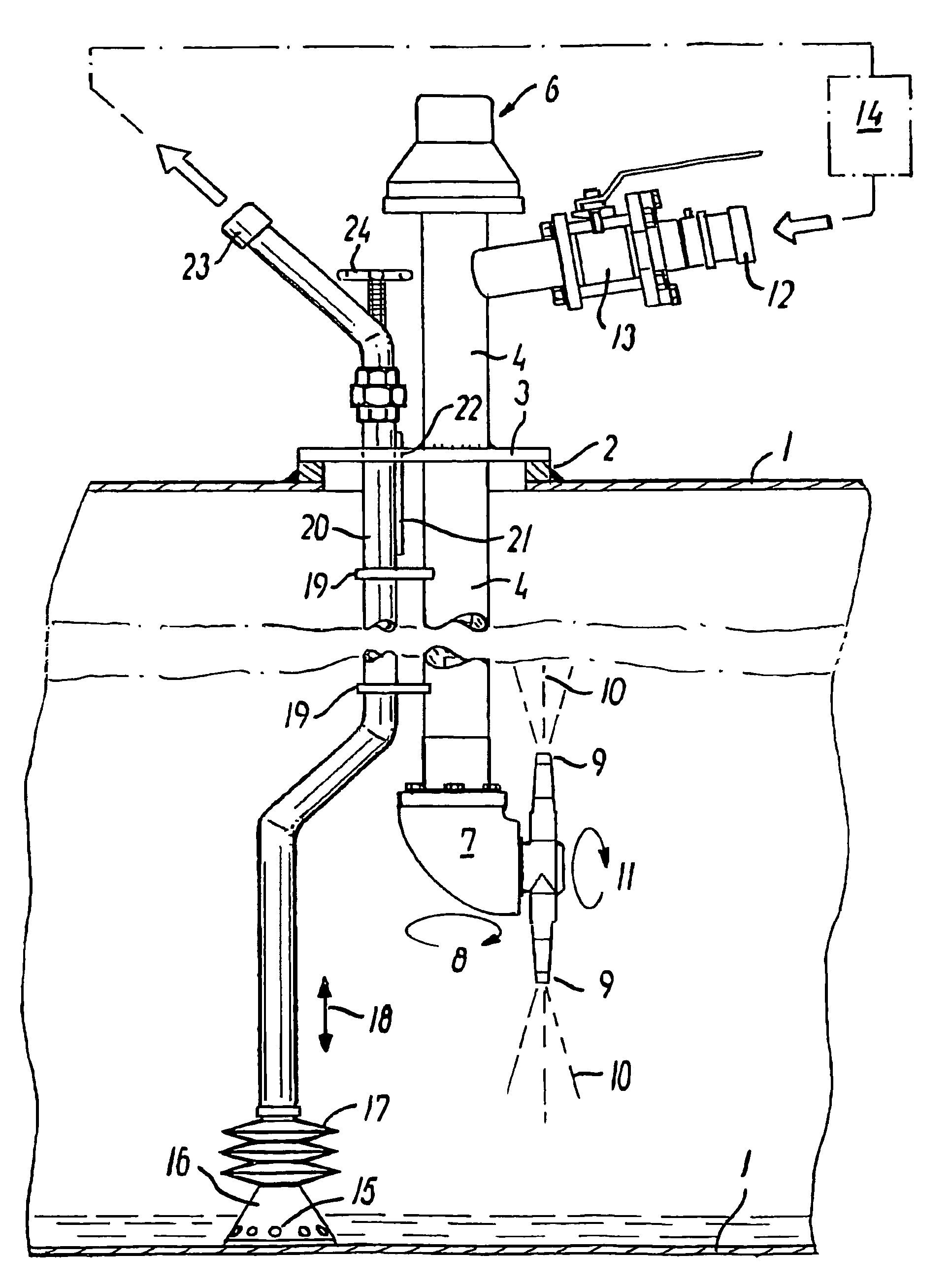

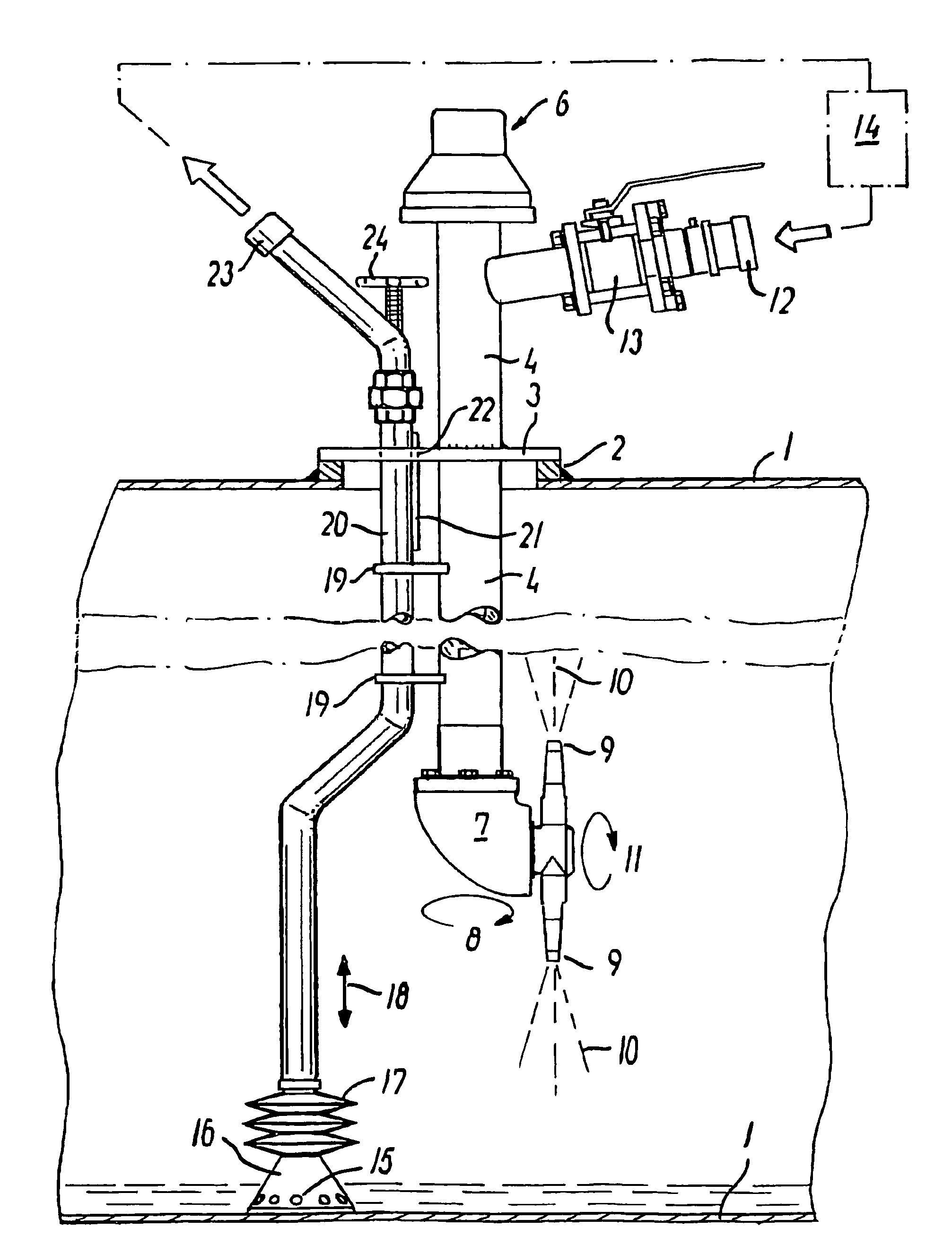

Mixed fluid uniformization device and mixed fluid feeding apparatus

InactiveCN101142012AImprove uniformityFlow mixersTransportation and packagingMixed statesEngineering

Owner:KAWASAKI HEAVY IND LTD

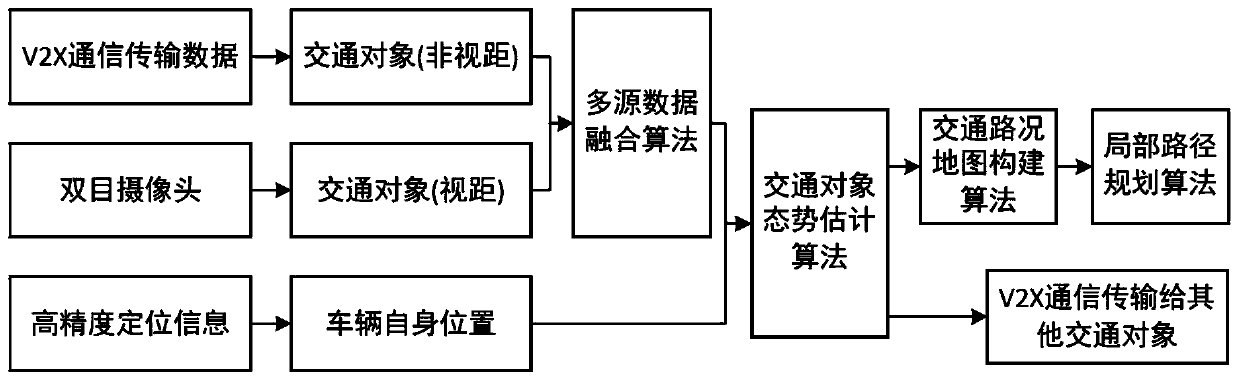

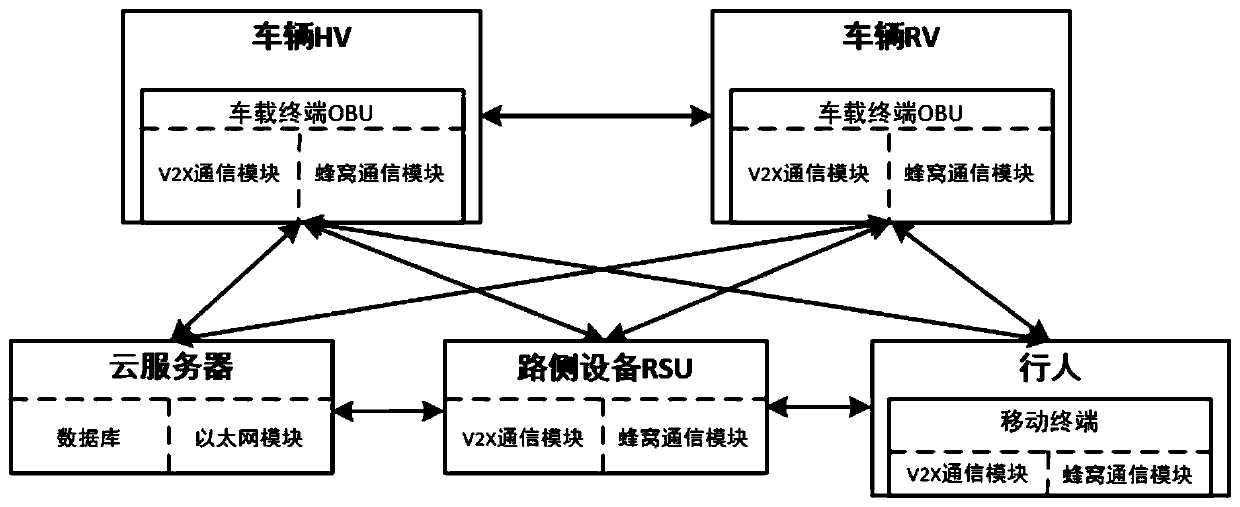

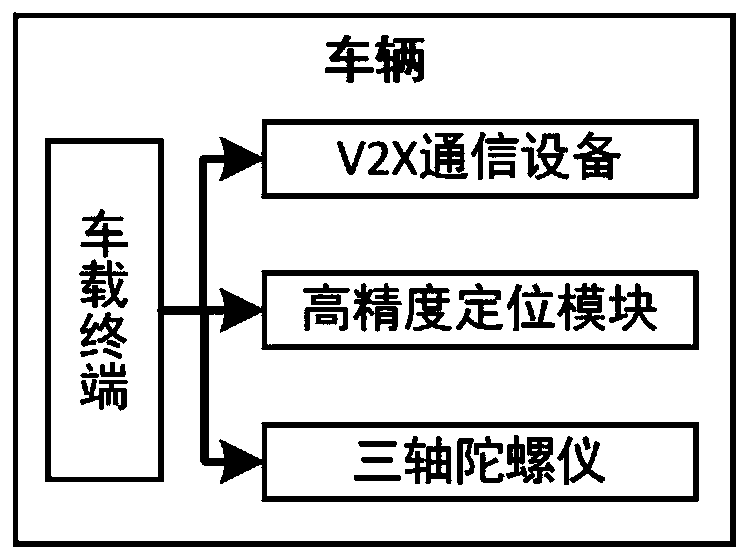

Coordinated local path planning method based on V2X communication and binocular vision

ActiveCN109920246AExpand the range of perceptionImprove driving safetyInstruments for road network navigationNavigational calculation instrumentsRoad mapState prediction

The invention claims for protection of a coordinated local path planning method based on V2X communication and binocular vision. An OBU acquires vehicle body information and environmental informationthrough a binocular preposed camera, OBD equipment and V2X communication and the information is transmitted to a coordinated local path planning controller; with a traffic object mixed state estimation model, state prediction is carried out on a traffic object state, spatio-temporal data fusion is carried out on the traffic object information and traffic rules after state estimation based on a multi-source data fusion algorithm, a traffic road map with high credibility is constructed by the fused traffic data according to a coordinate mapping model, an own vehicle state is calculated by combining own vehicle information according to an own vehicle state estimation model, and then an optimal smooth driving path of the current vehicle is calculated based on an improved local path planning algorithm; and then the path is transmitted to the OBU and the information is broadcasted to other vehicles through V2X. According to the invention, the accuracy of vehicle environment perception and local path planning is improved by combining visibility-range and non-visibility-range traffic object sense sensing.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

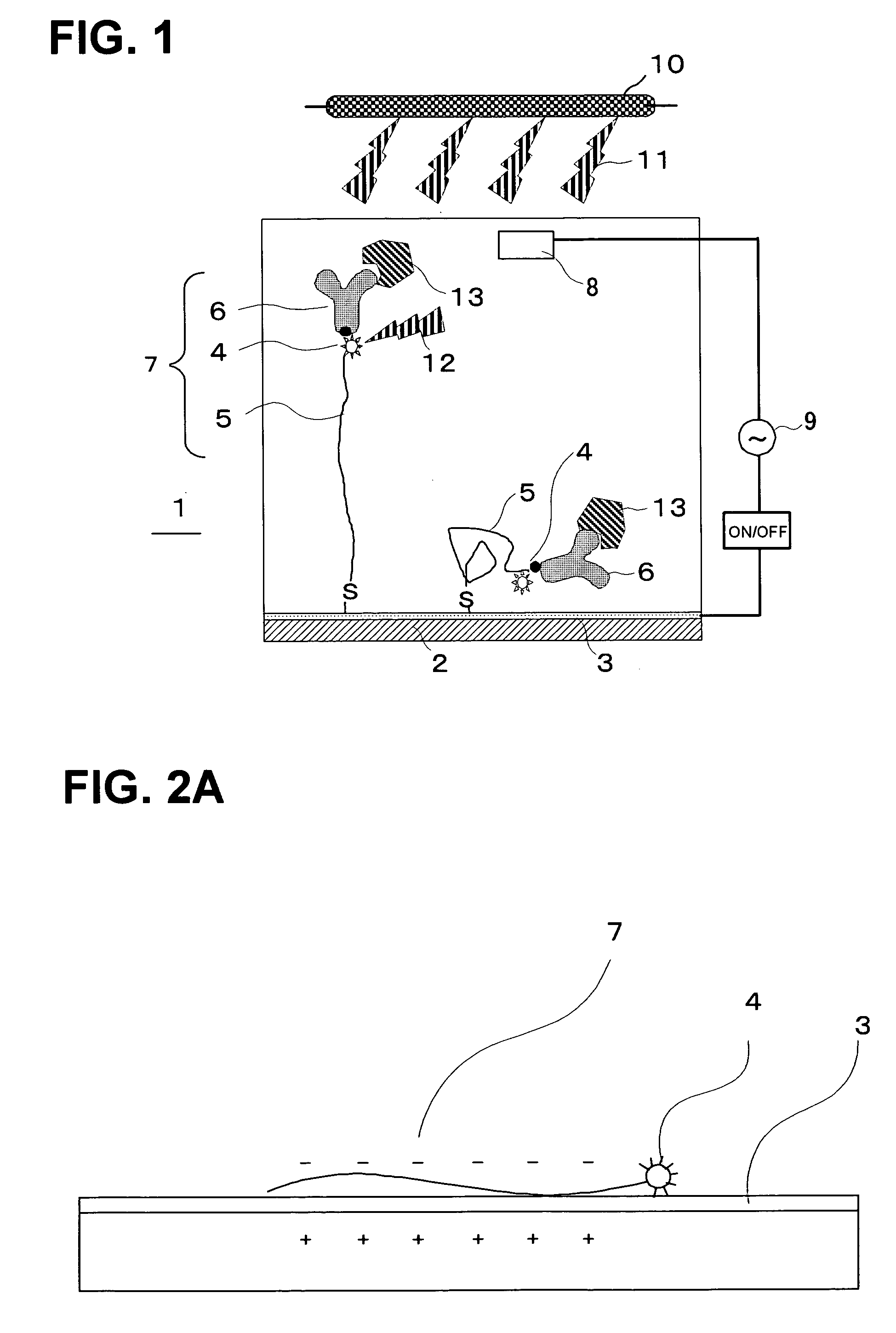

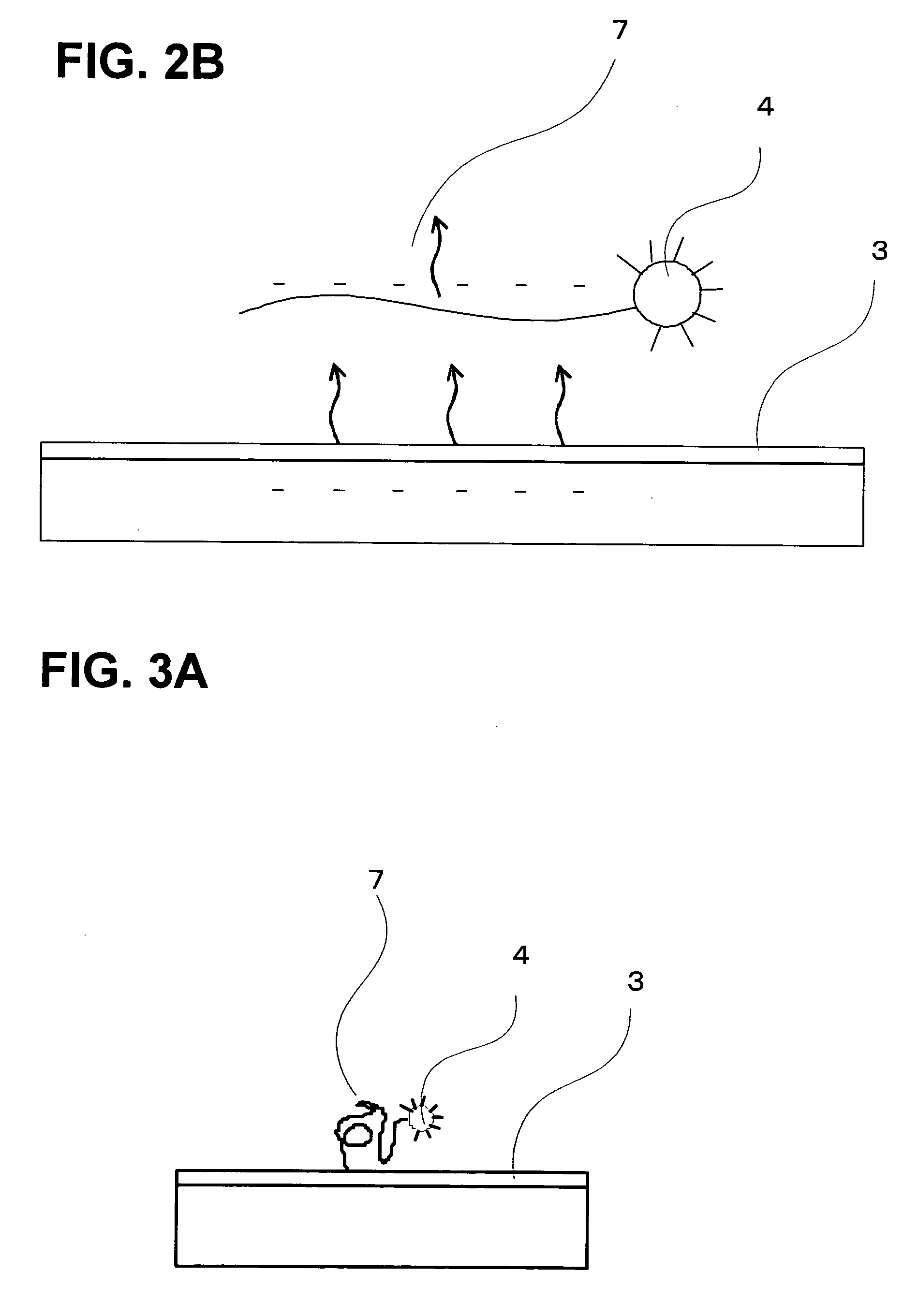

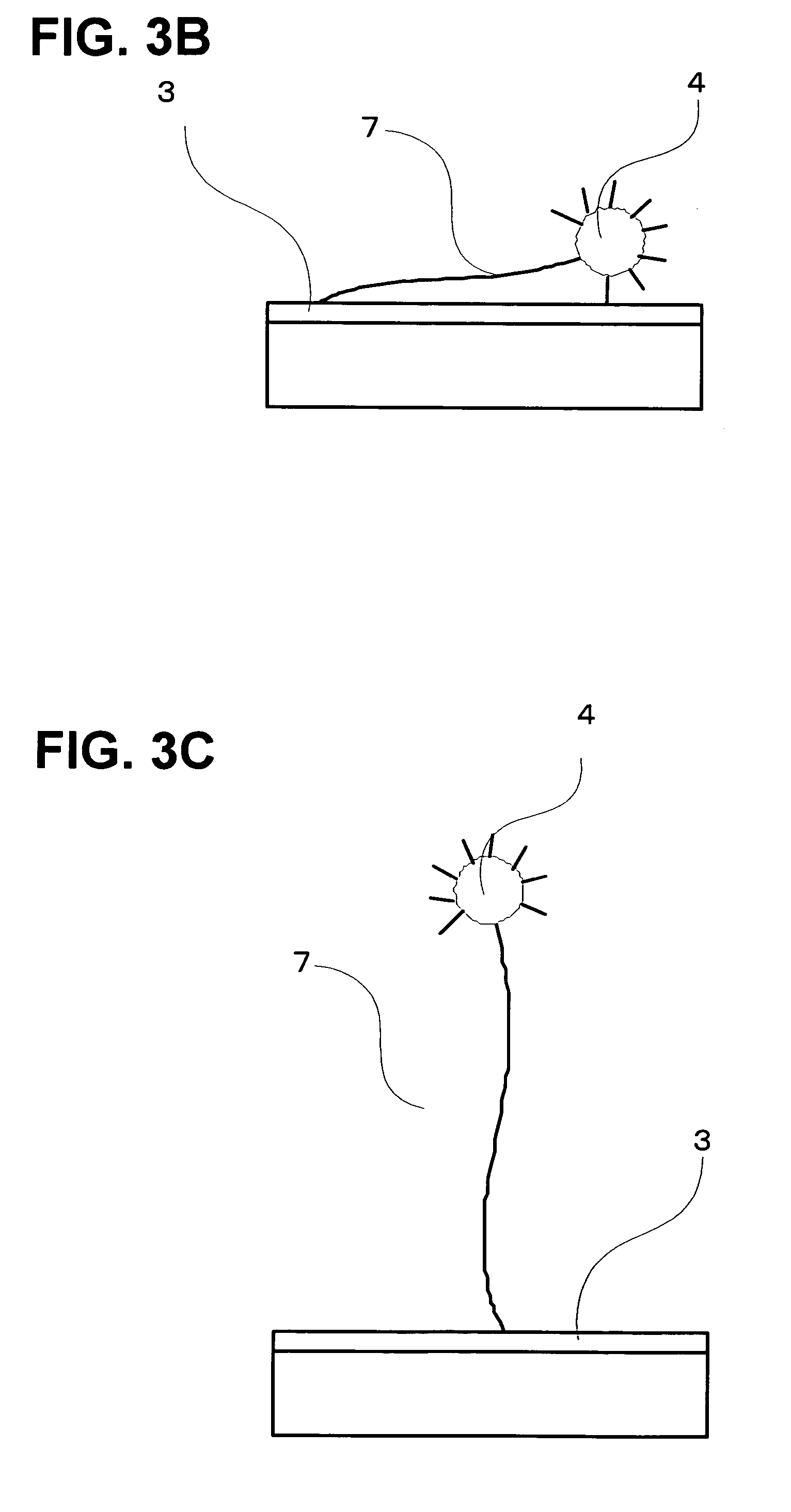

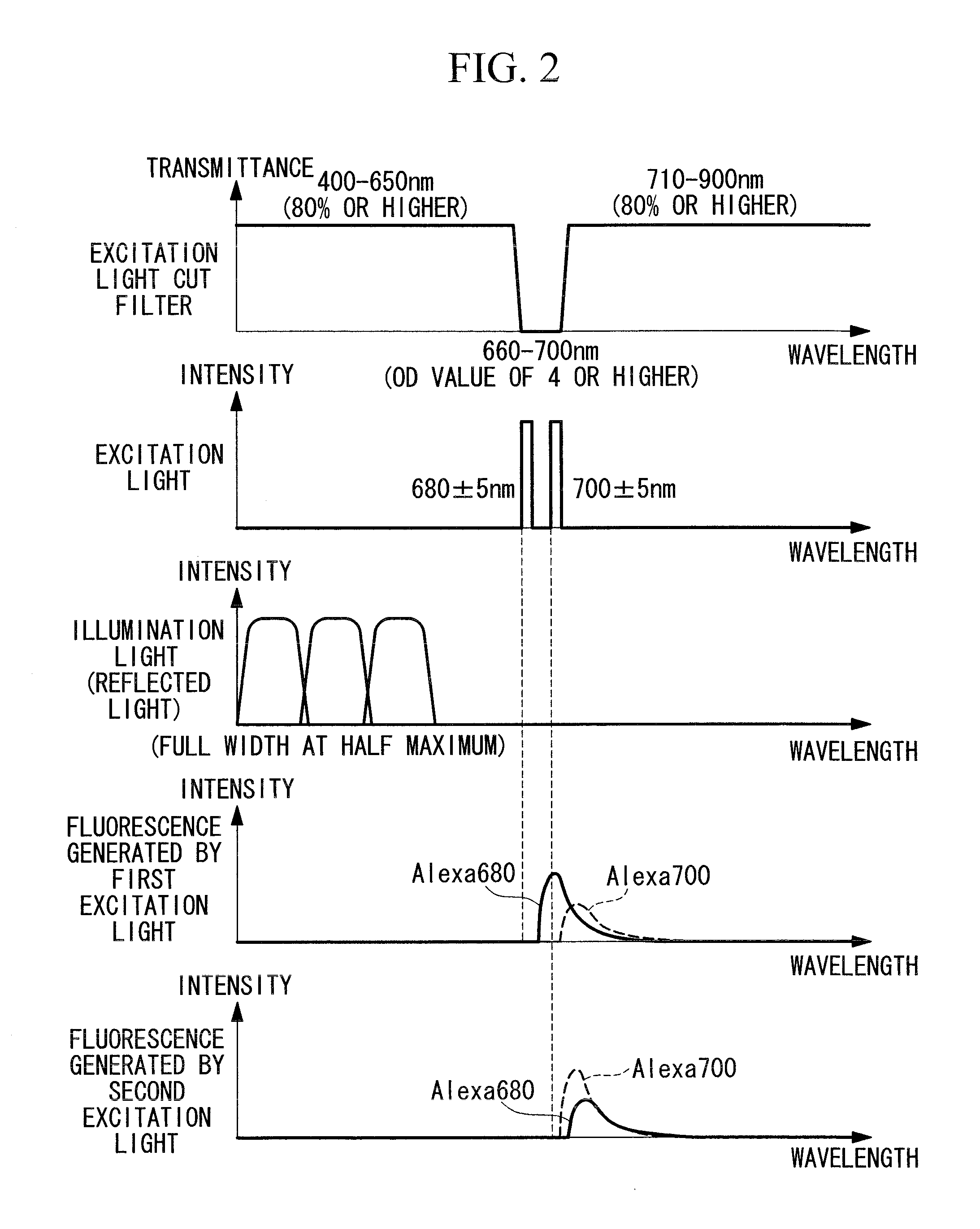

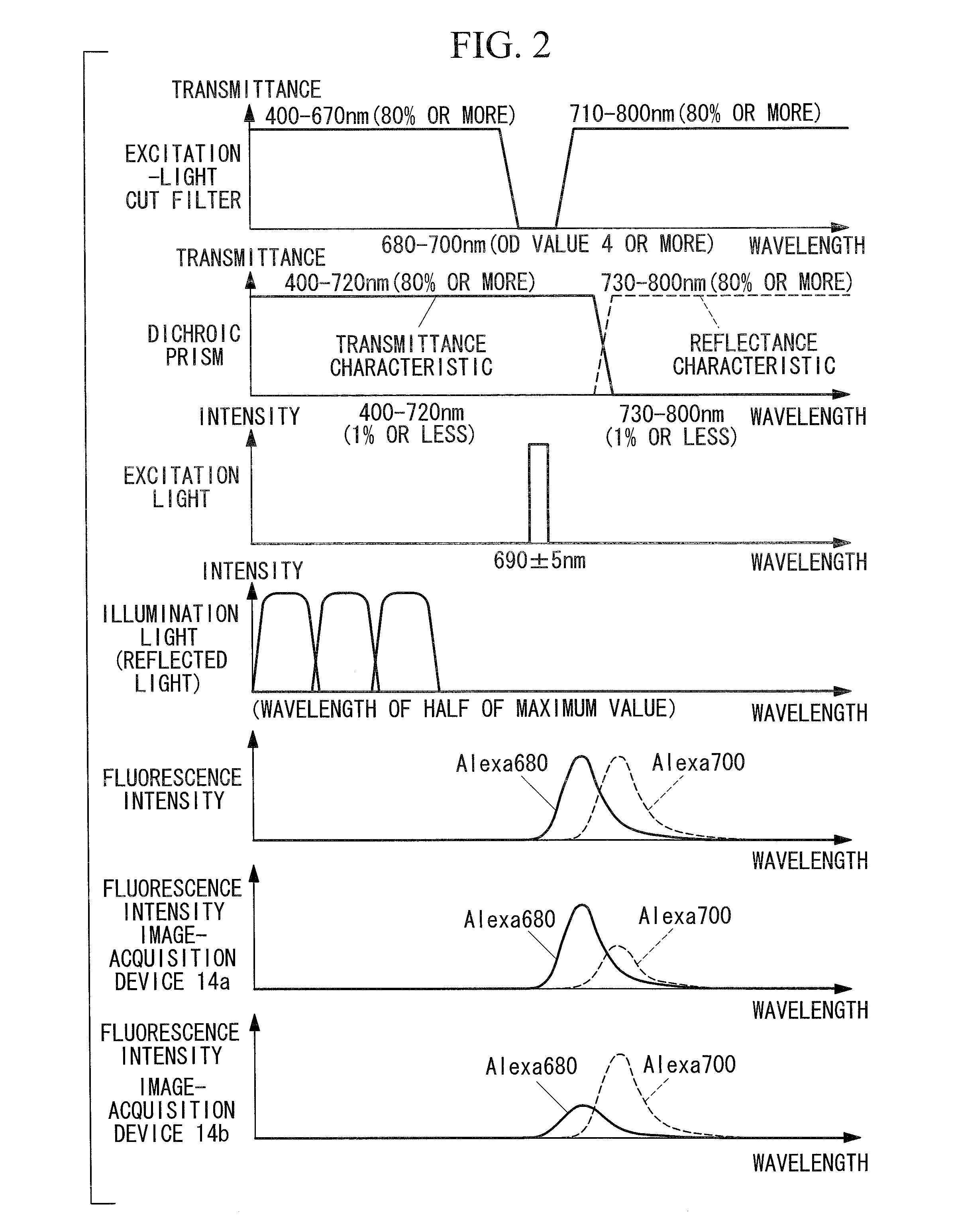

Analyte evaluating device, and method for evaluating analyte

InactiveUS20050069932A1High sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteLight irradiation

In an analyte evaluating device comprising a carrier body that can be bound with an analyte having a fluorescence-labeled part that can emit fluorescence by light received when the distance between the fluorescence-labeled part and the carrier body is enlarged, at least one factor selected from the group consisting of a light irradiation angle, a light irradiation intensity, a light irradiation area, a fluorescence detection angle, a fluorescence detection area, the shape of the carrier body, the surface area of the carrier body, a salt concentration in a medium for use in the detection, and the adhesion density of analytes on the carrier body, is made to be adjustable. A high sensitivity is realized. Evaluation is possible without introducing fluorescence-labeled parts. Evaluation for a tiny amount of sample is possible. It is also possible to evaluate objects in a mixed state. Miniaturized, complex, and integrated devices are possible.

Owner:XDYNAMIC BIOSENSORS GMBH

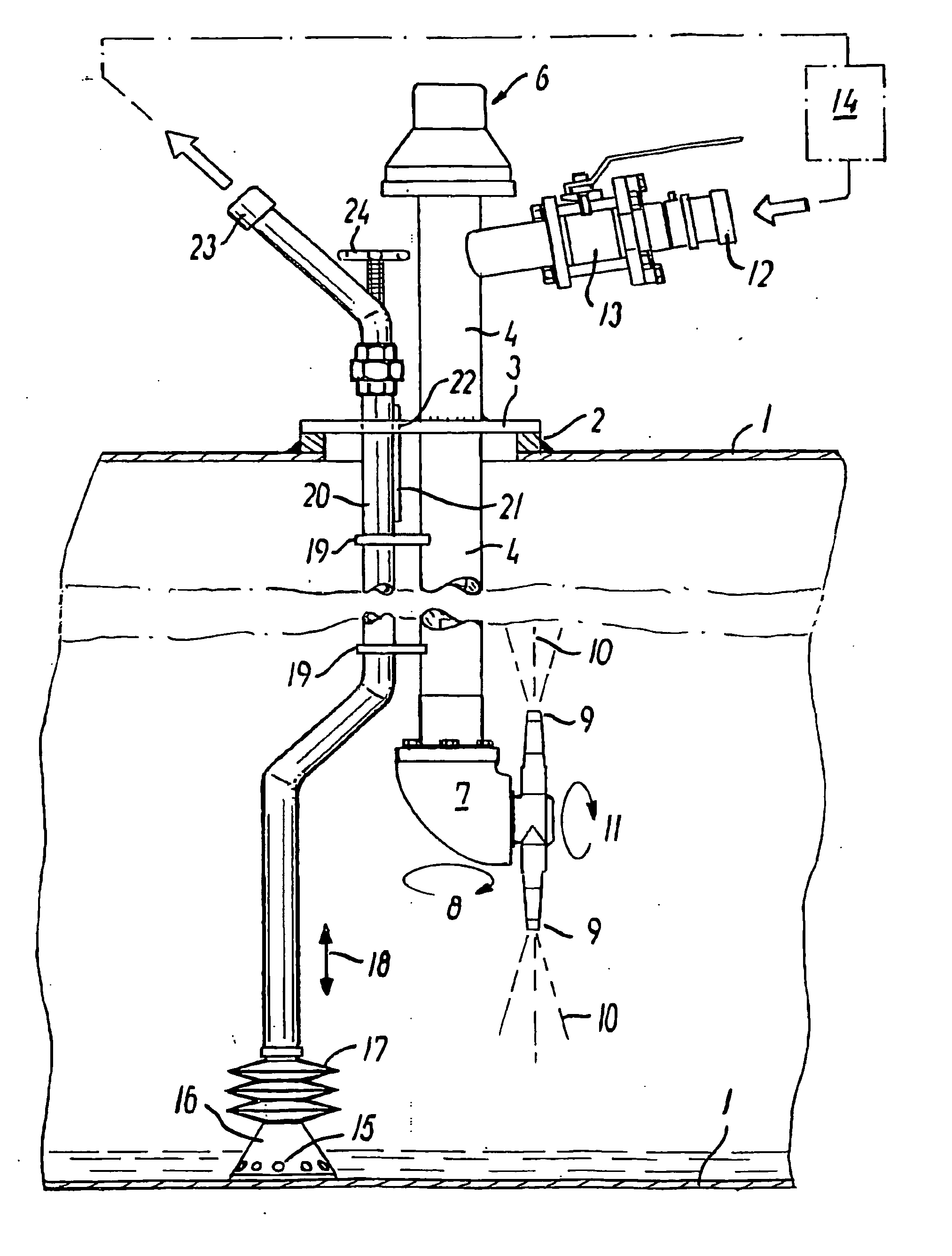

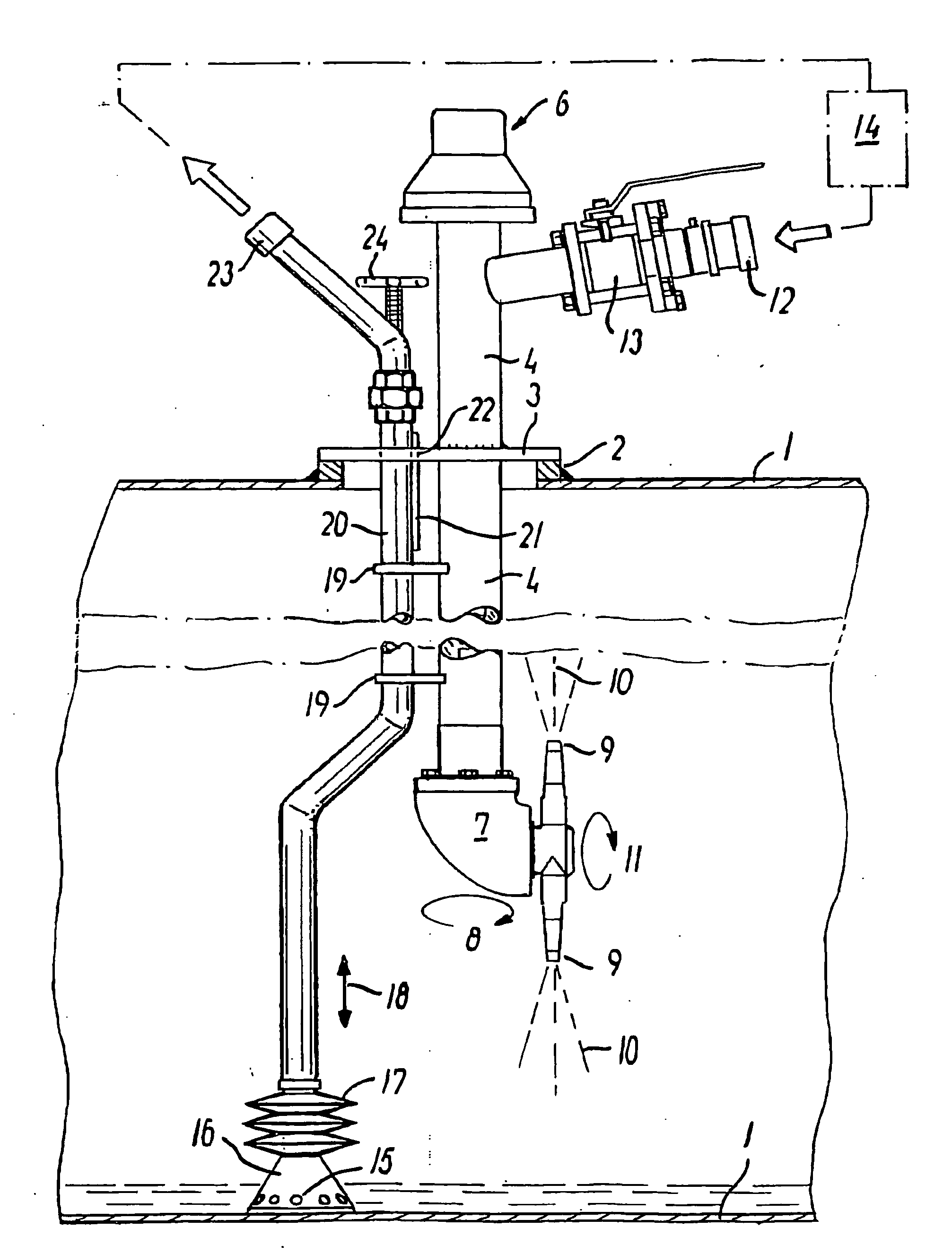

Cleaning equipment and use thereof

InactiveUS20040238009A1Compact installationLimited amountTank vesselsHollow article cleaningReady to useMixed states

By constructing tank cleaning equipment according to the invention such that it comprises a cleaning jetting part (7, 9) as well as a suction part (4), the equipment can work with the same cleaning medium which is recirculated. This saves supply of fresh cleaning medium, and since used medium is thus not discharged, it is not necessary to establish deposit facilities to avoid pollution. Furthermore, this equipment according to the invention may advantageously be used for keeping so-called drilling mud in a mixed and thus ready-to-use state, even when left to stand for an extended period of time in a tank. The nozzle jets (10) thus keep the mud in the tank in a constantly mixed state, and the mud can therefore be sucked through the suction pipe (20) for pumping in the drill pipe, it being ensured that the mud is homogeneous and has a suitable viscosity.

Owner:ALFA LAVAL TANK EQUIP

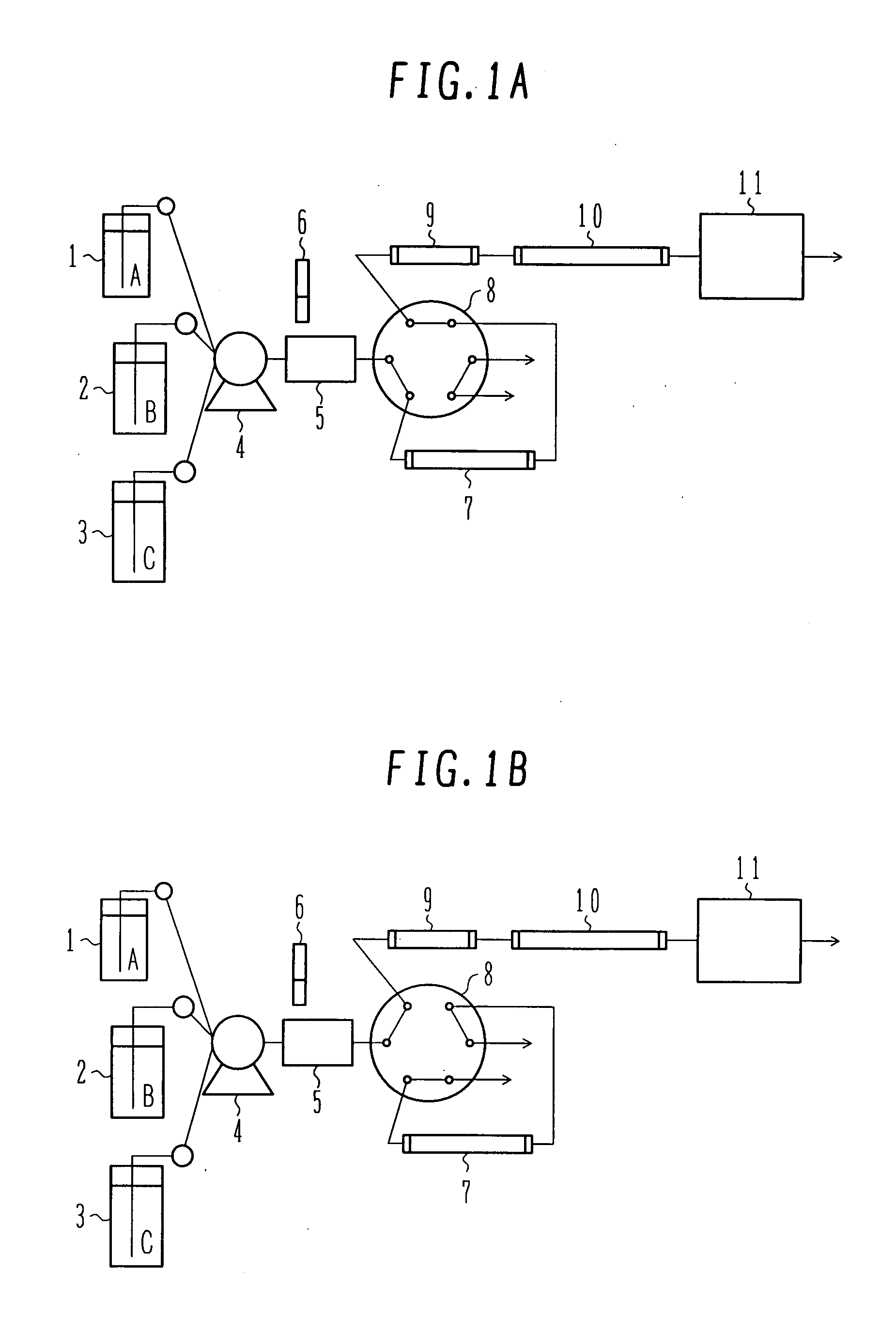

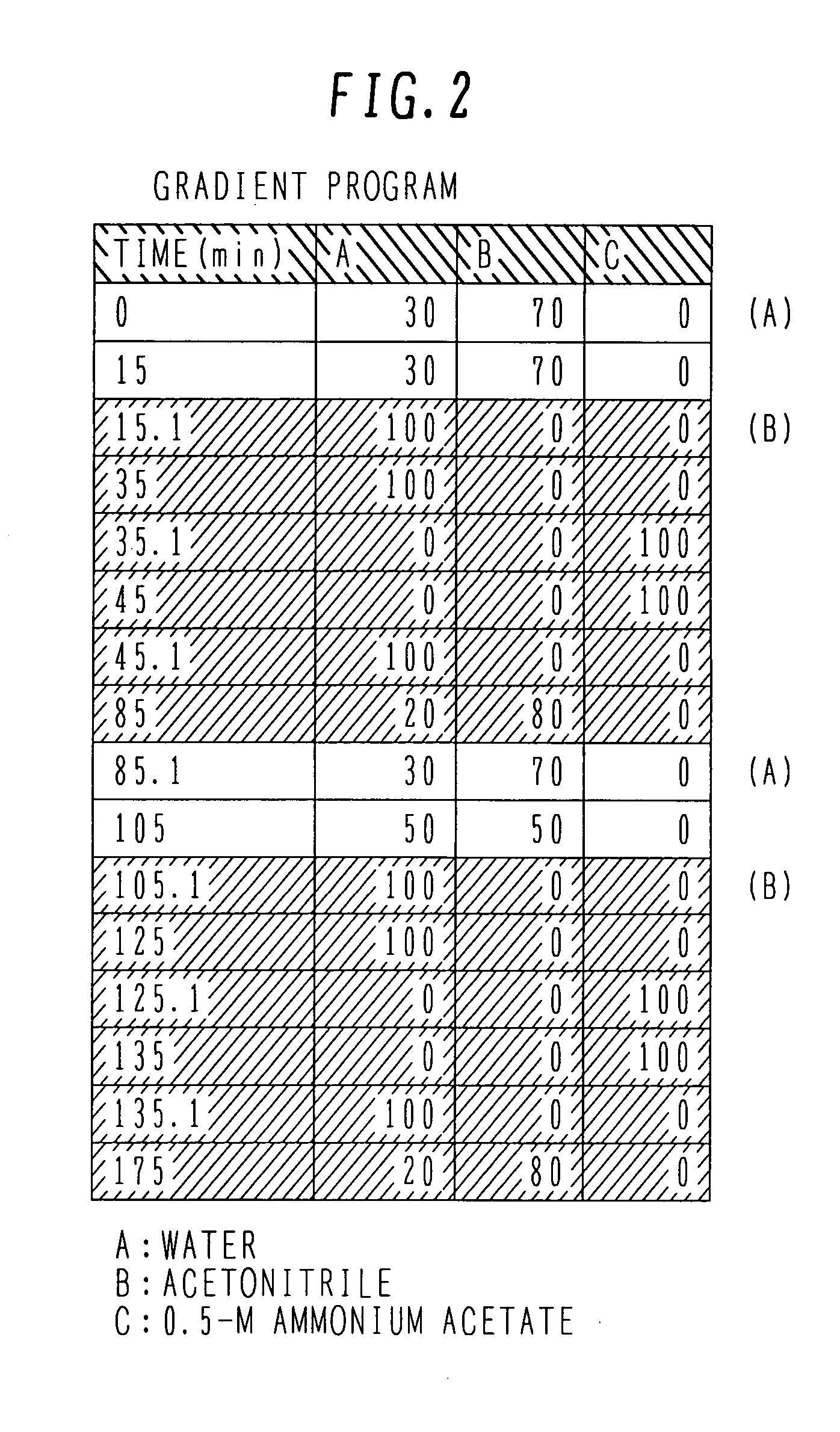

Three-dimensional liquid chromatography

InactiveUS20070199874A1Easy to separateIon-exchange process apparatusAnalysis using chemical indicatorsIntermediate stageMixed states

In a liquid chromatography apparatus, a separation column of intermediate stage is additionally connected between a separation column of first stage and a separation column of second stage. Preferably, a switching unit and a liquid feed unit for mixing and feeding a plurality of solutions are added to improve a separation capability. A three-dimensional liquid chromatography apparatus capable of avoiding the “solution interference” can be realized. Even a complex sample containing a hydrophilic component and a hydrophobic component in a mixed state can be separated and analyzed satisfactorily on-line.

Owner:HITACHI HIGH-TECH CORP

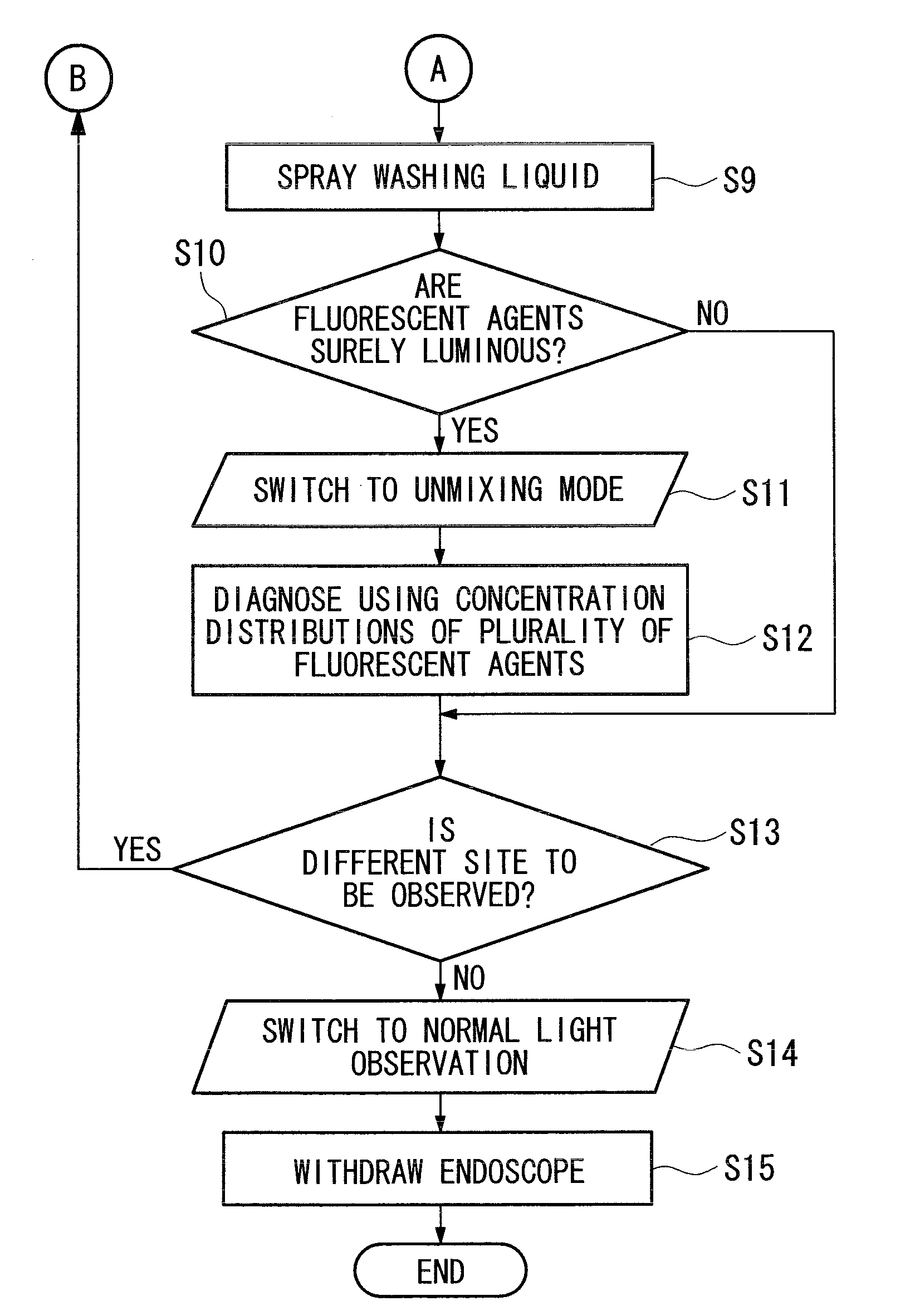

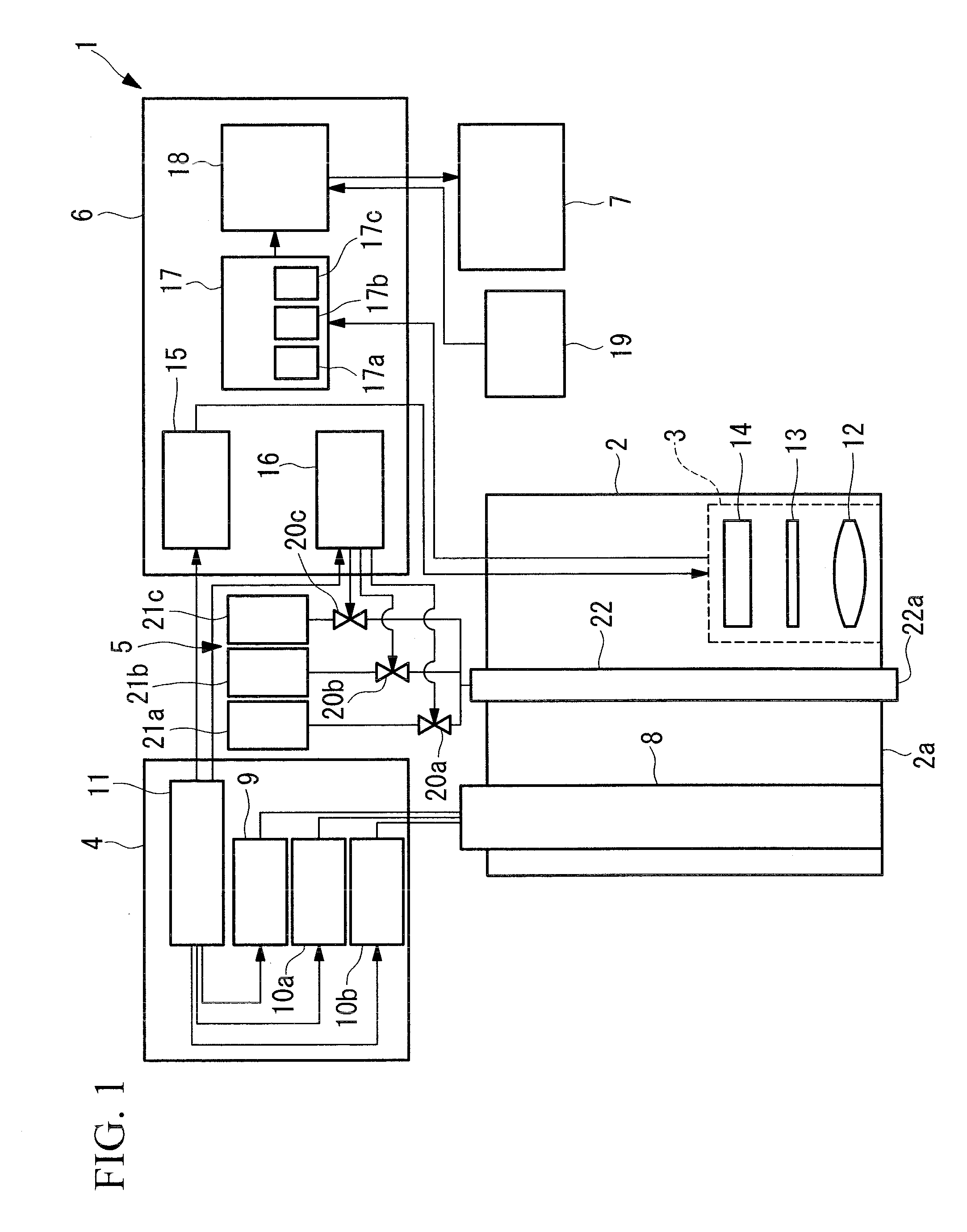

Endoscope system

ActiveUS20100094136A1Diagnosability can be improvedDiagnosability of cancer cells can be improvedRaman/scattering spectroscopySurgeryCancer cellMixed states

A fluorescence distribution image of each fluorescent agent can be acquired from a fluorescence image that has been captured in a mixed state so as to improve the diagnosability of cancer cells. An endoscope system comprises: a light source section for selectively irradiating two or more types of excitation lights having different spectral characteristics so as to excite two or more types of fluorescent agents having different optical characteristics; an imaging section provided on a part to be inserted into a body cavity, and having a light-receiving sensitivity in the wavelength bands of the two or more types of fluorescence radiated from the observation target by respective types of excitation lights; a storage section for storing relation information between the fluorescence intensity and the concentration of each of the fluorescent agents; a concentration information computing section for computing concentration information of each of the fluorescent agents on the basis of the fluorescence intensities of two or more images captured by the imaging section and the relation information stored in the storage section, and outputting the concentration information; and a mode switching section capable of switching between a first fluorescence observation mode in which at least one of the fluorescence intensity images acquired by the imaging section is presented, and a second fluorescence observation mode in which the concentration information of each of the fluorescent agents computed by the concentration information computing section is presented.

Owner:OLYMPUS CORP

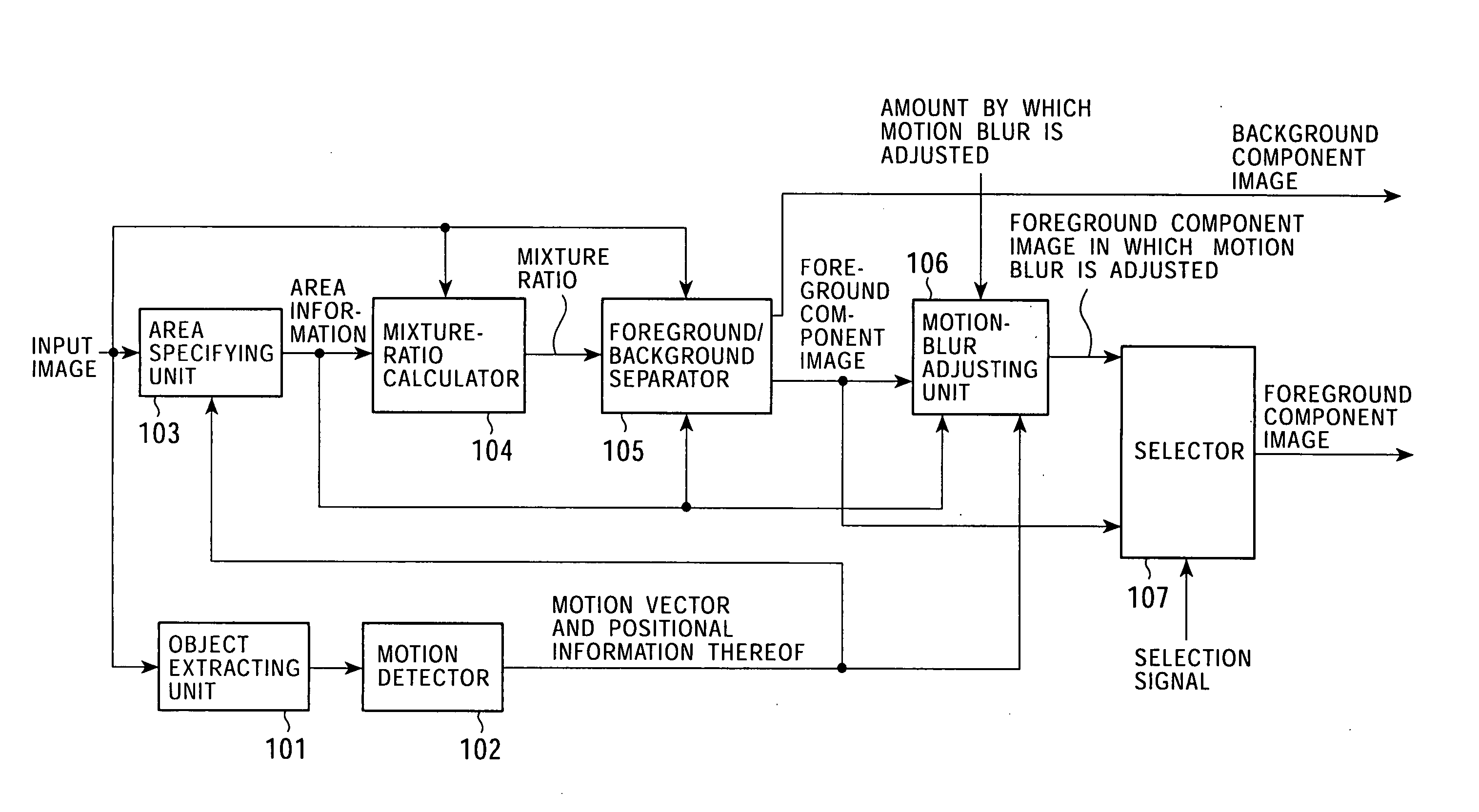

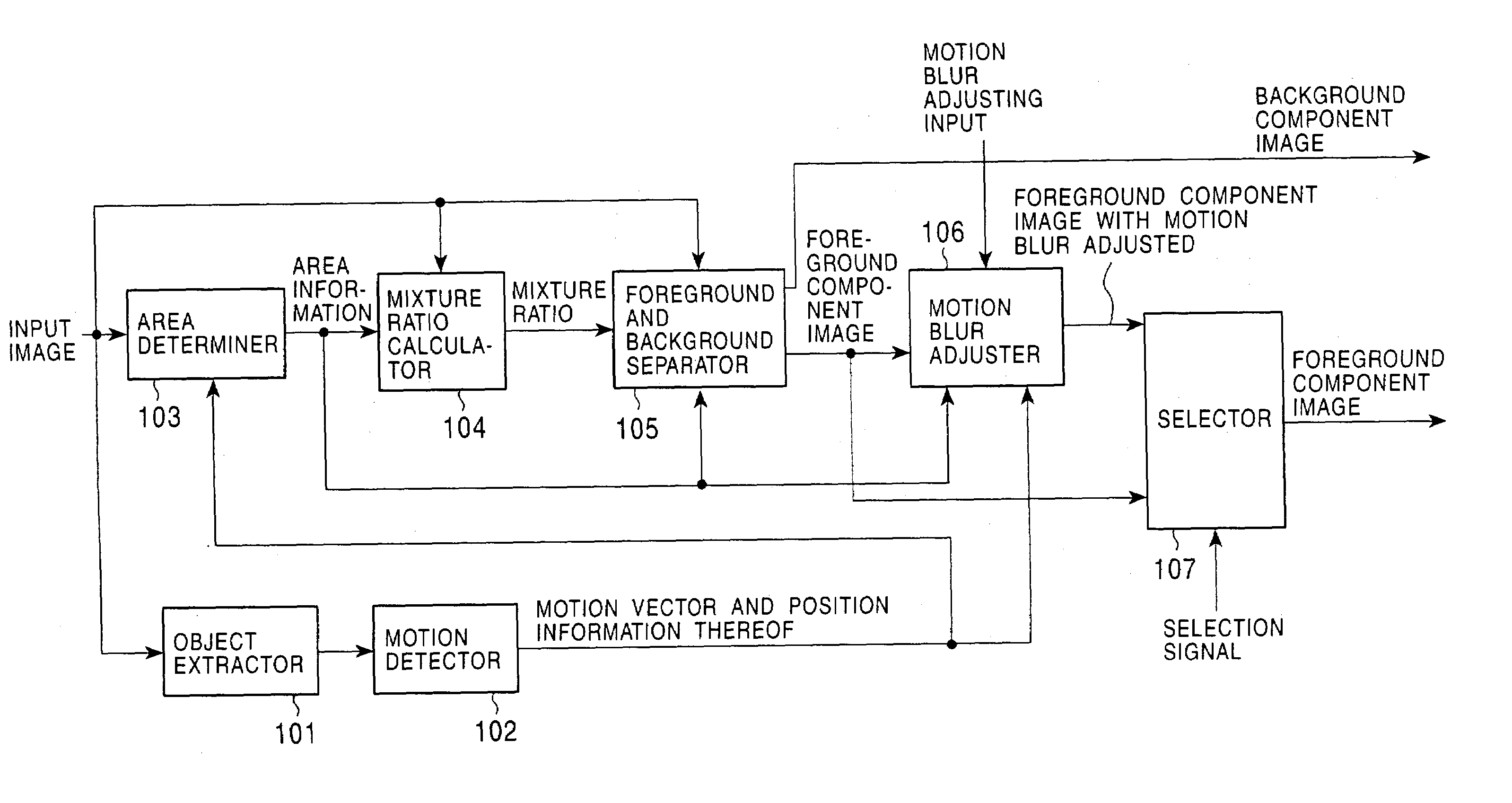

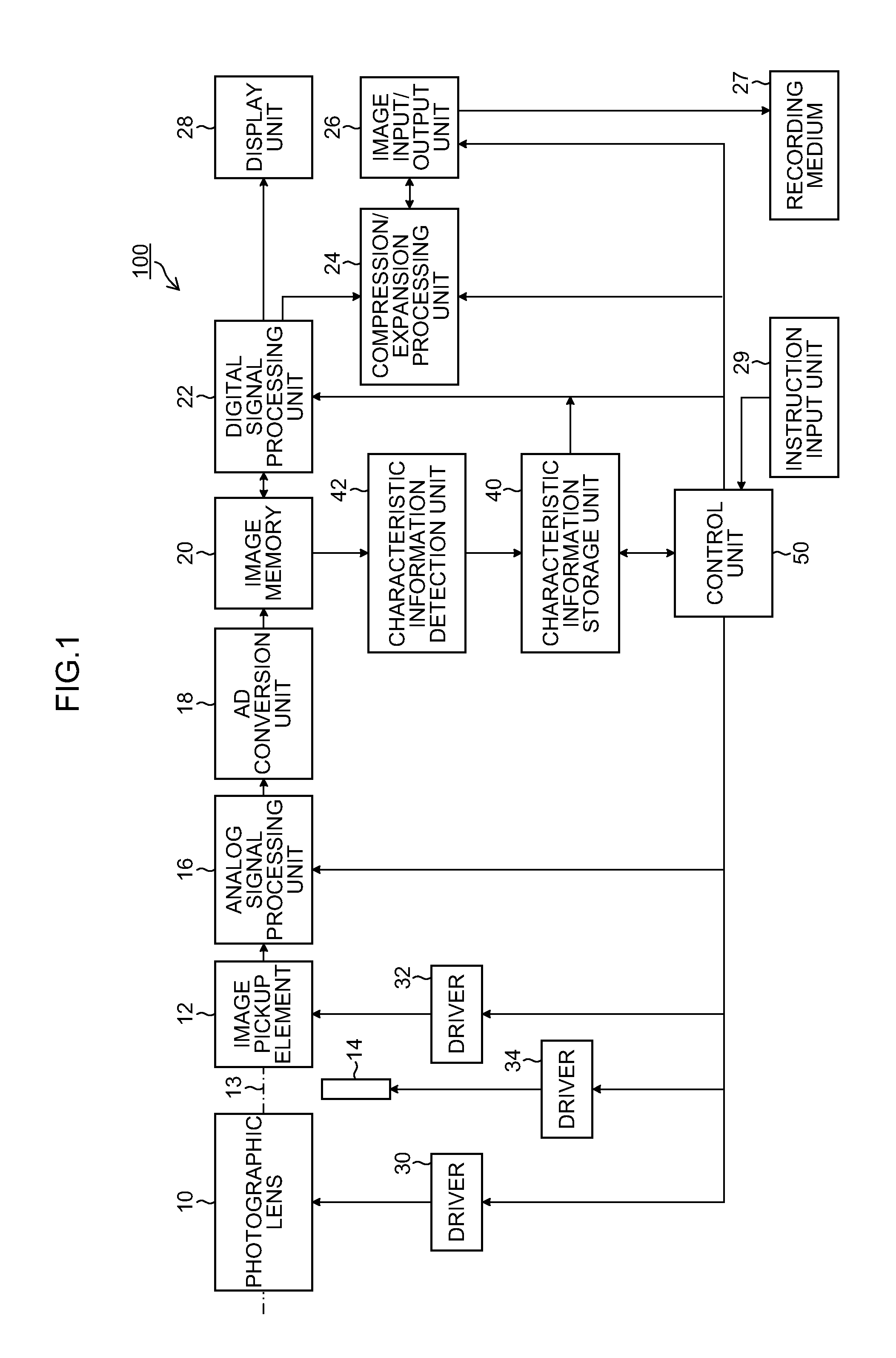

Image processing apparatus and method, and image pickup apparatus

An object of the present invention is to enable the detection of a mixture ratio indicating the mixture state of a plurality of objects, such as a background image and a moving object image. A normal-equation adder 541 extracts mixed pixel data according to a motion, and also extracts background pixel data corresponding to the mixed pixel data so as to generate relational expressions for a designated pixel. A normal-equation calculator 542 detects the mixture ratio indicating the mixture state of the objects based on the relational expressions. The normal-equation adder 541 generates the plurality of relational expressions based on a first approximation in which foreground object components change substantially linearly, and a second approximation in which the mixture ratio changes substantially linearly. The present invention is applicable to a signal processing apparatus for processing images.

Owner:SONY CORP

Method for preparing low temperature solder sheets

ActiveCN107486651AImprove uniformityHigh strengthWelding/cutting media/materialsSoldering mediaLiquid stateMixed states

The invention discloses a method for preparing low temperature solder sheets. The method comprises the following steps: firstly, carrying out chemical cleaning on stains and oxide films on the surface of a foam metal skeleton; filling metal foam with low-melting point solder in an infiltration way; and finally heating the metal foam filled with the low-melting point solder to a solid-liquid mixed state and rolling to obtain composite sheets with certain thicknesses. According to the method disclosed by the invention; the foam metal-reinforced solder is rolled in the solid-liquid mixed state, so that the problems that the foam metal skeleton is stretched to form a thin strip-type fiber structure and is fractured during normal temperature rolling are effectively solved; meanwhile, during rolling in the solid-liquid mixed state, low-melting point metal which is in a liquid state is good in fluidity and can be uniformly filled in the foam metal skeleton, so that the mass percentage of the foam metal skeleton can be increased, the porosity of the foam metal is reduced and the uniformity and the strength of the foam metal-reinforced low melting point solder are increased.

Owner:CHINA NAT ELECTRIC APP RES INST

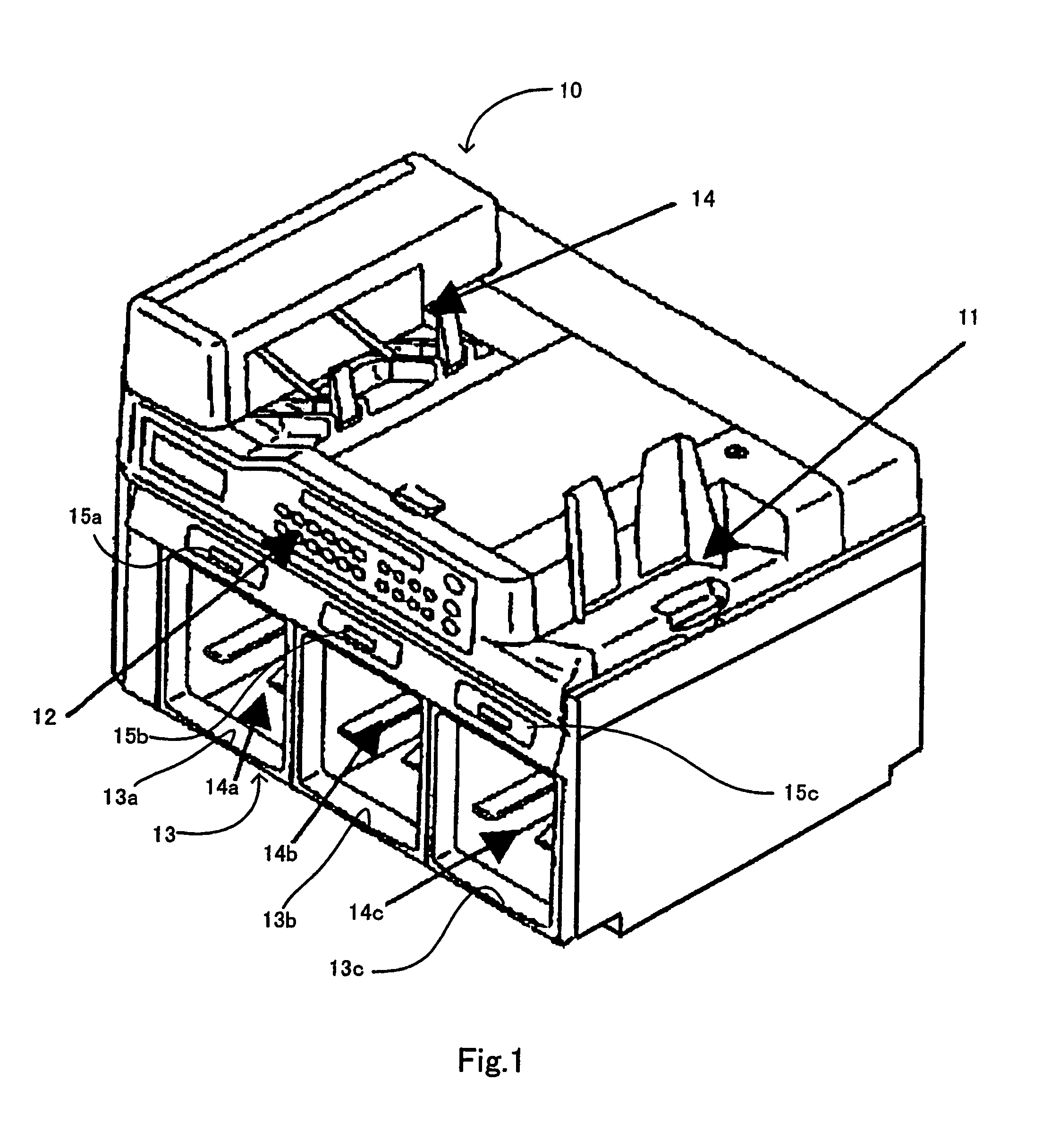

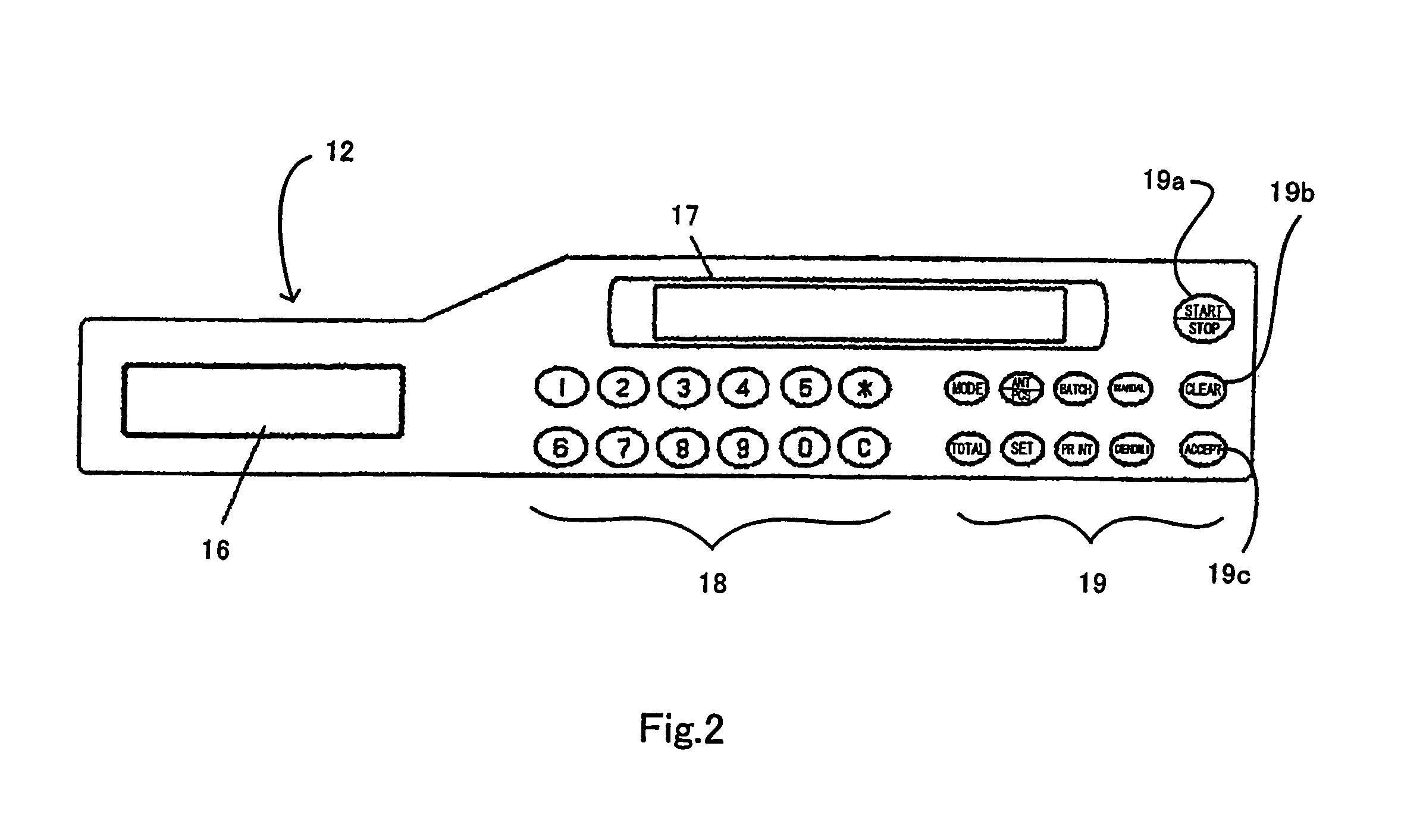

Apparatus for sorting mixed bills and barcoded tickets and method therefor

ActiveUS7040476B2Efficient implementationConveying record carriersPaper-money testing devicesBarcodeMixed states

In an apparatus and a method capable of sorting and counting bank notes and barcoded tickets by a single apparatus, the apparatus includes an insertion receptacle disposed to an upper portion of the apparatus for placing the bank notes and the barcoded tickets thereon, three stacker units disposed to lower portions of the apparatus, a conveying path interposed between the insertion receptacle and the stacker units, and first and second identification units disposed midway in the conveying path for identifying the bank notes and the barcoded tickets, respectively. The bank notes and the barcoded tickets placed on the insertion receptacle in a mixed state are drawn out to the conveying path one by one, identified by both the identification units, sorted according to results of identification of both the identification units, and stacked in the respective stacker units. The results of both the identification units are stored in a host computer.

Owner:GLORY KOGYO KK

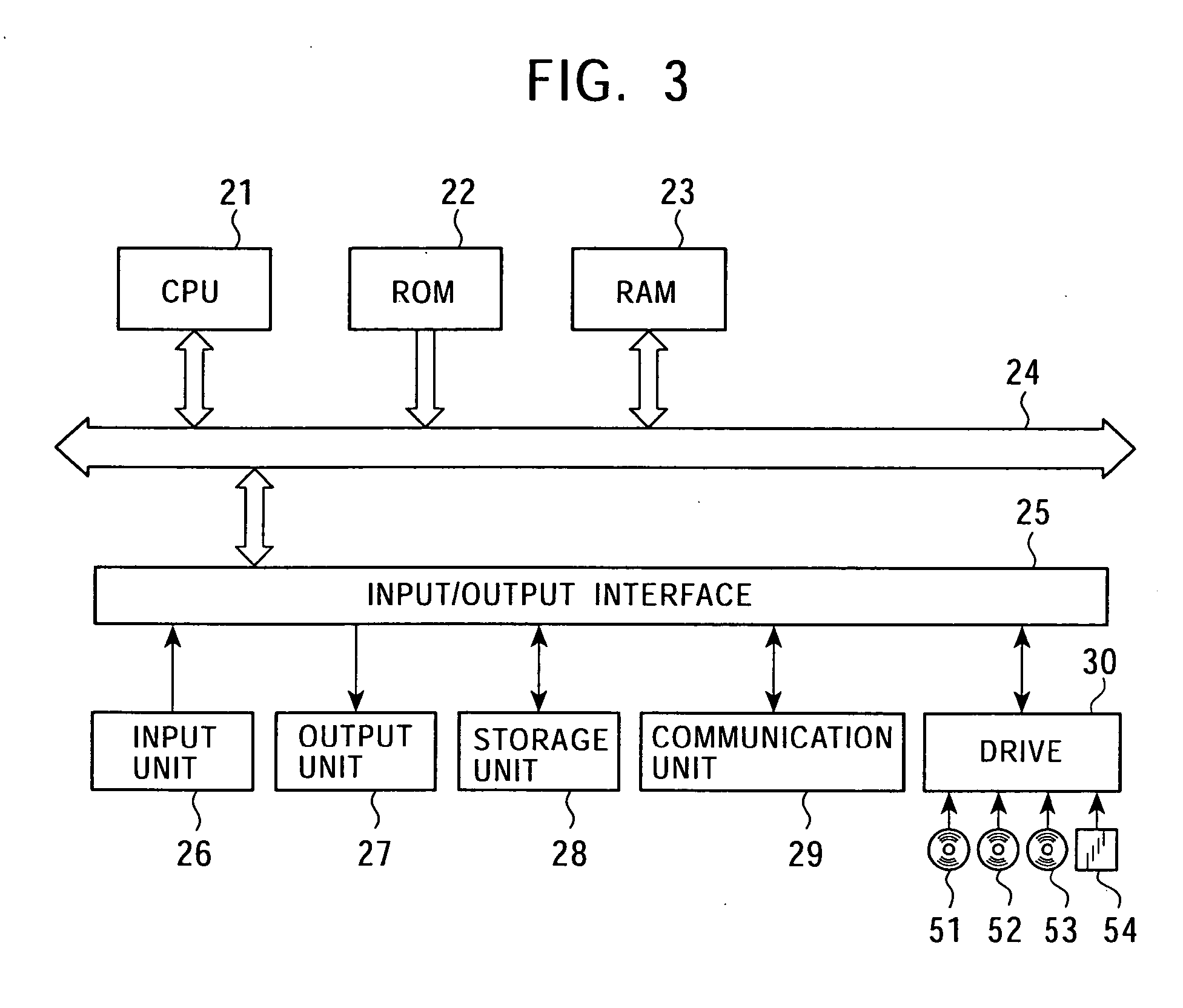

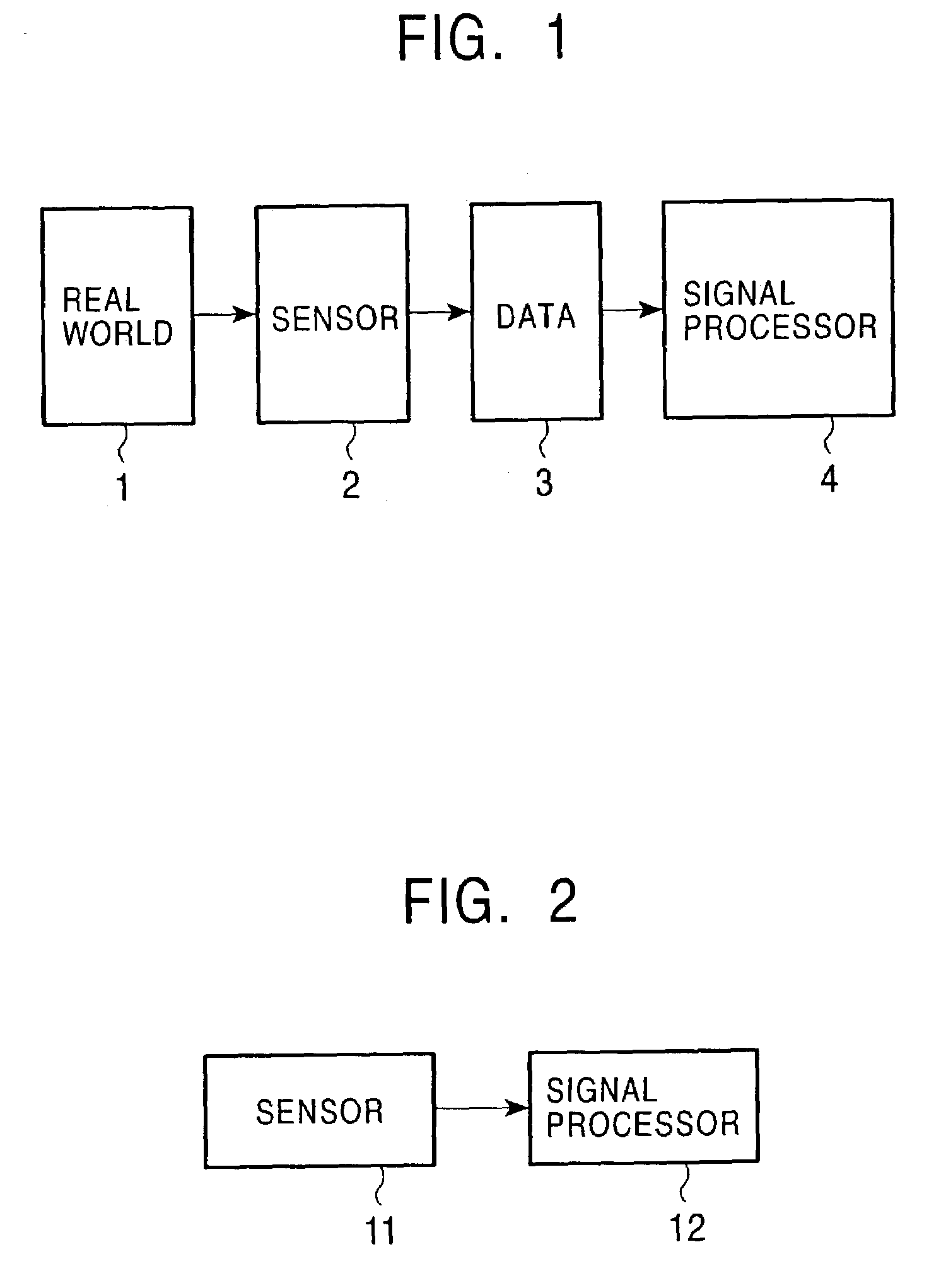

Image processing device

In accordance with the present invention, a mixture ratio indicating the state of mixture of a plurality of objects such as a background image and the image of an object is detected. A pixel value setter 502 extracts background pixel data while also extracting the date of a target pixel and a pixel in the vicinity of the target pixel. The pixel value setter 502 generates a plurality of relational equations indicating data of the target pixel and the pixel in the vicinity of the target pixel and the background pixel data. An arithmetic unit 503 calculates a mixture ratio indicating a mixed state of the plurality of objects in the real world with respect to the target pixel based on the relational equations. The present invention is applicable to an image processing apparatus that accounts for a difference between a signal detected by a sensor and the real world.

Owner:SONY CORP

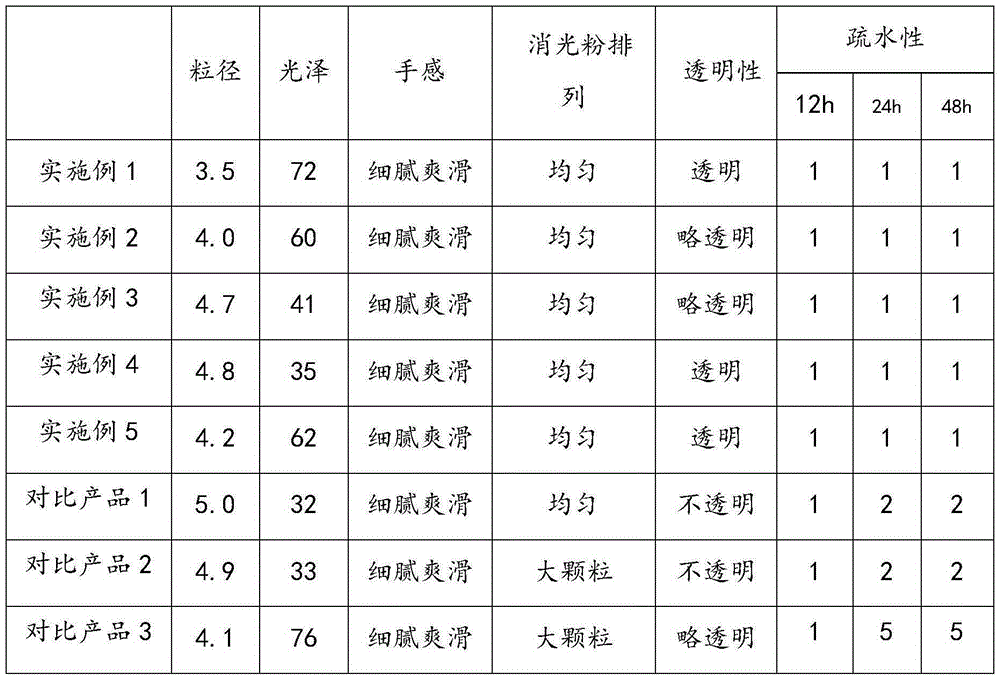

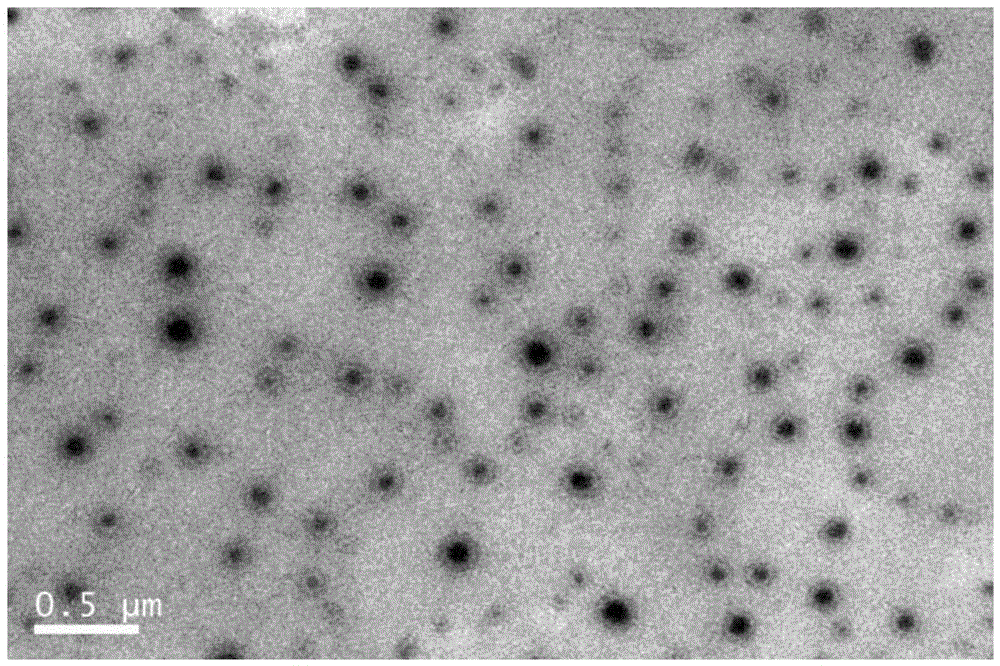

Preparation method of modified silicon dioxide obtained via super-hydrophobic modification

ActiveCN105400239AReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

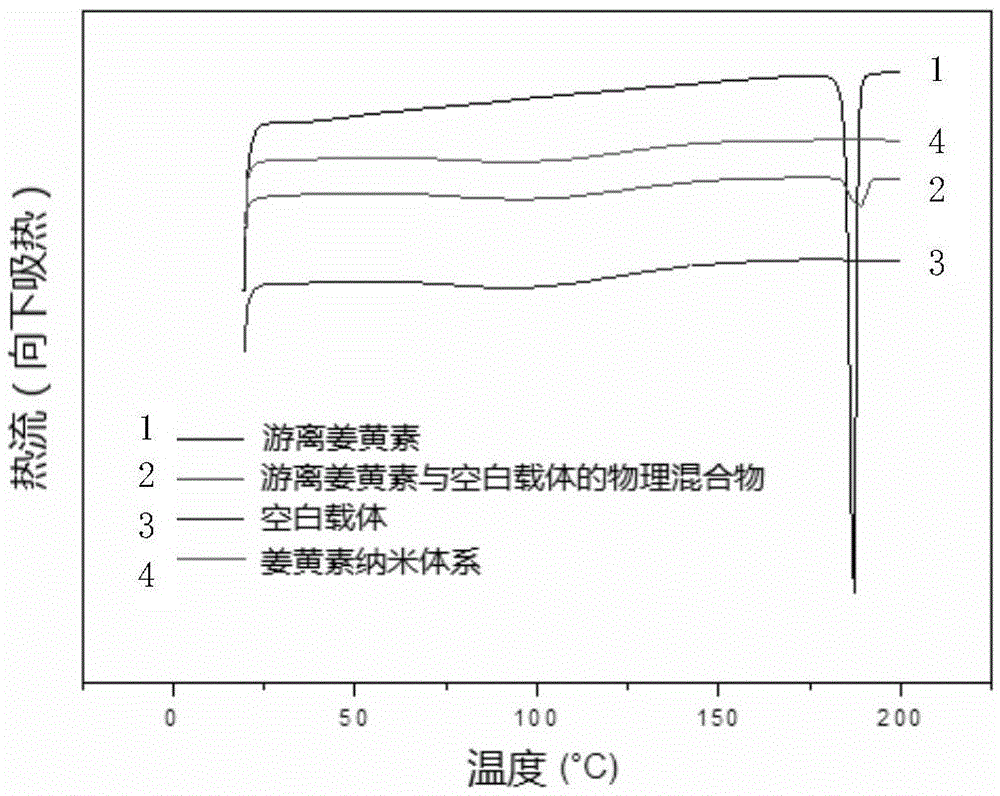

Curcumin composite particle and preparation method and application thereof

The invention provides a curcumin composite particle and a preparation method and application thereof. In particular, the curcumin composite particle comprises component (a) curcumin, component (b) prolamin and component (c) casein or caseinate or casein derivative. The component (a) and the component (b) are in a mixed state and wrapped by the component (c). The curcumin composite particle can remarkably improve the water solubleness, bioavailability and stability of the curcumin, and has good application prospects in the field of functional food and medicine.

Owner:SHANGHAI JIAO TONG UNIV

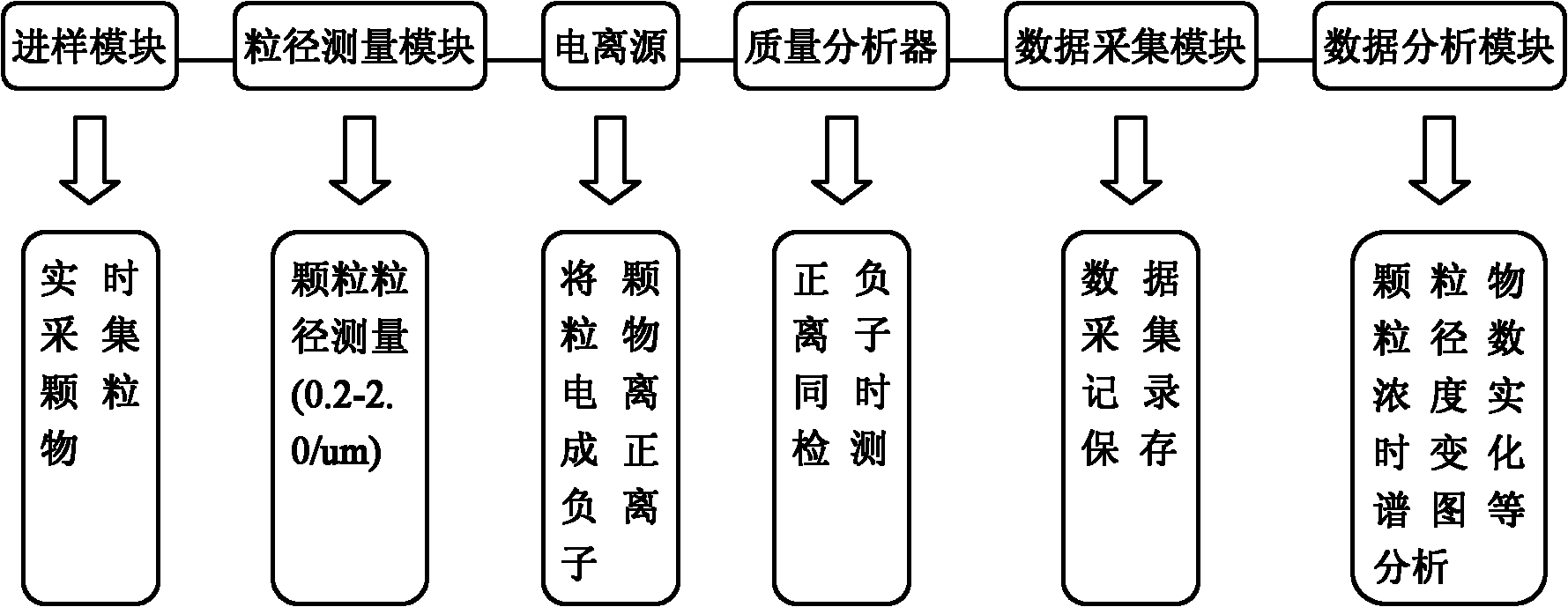

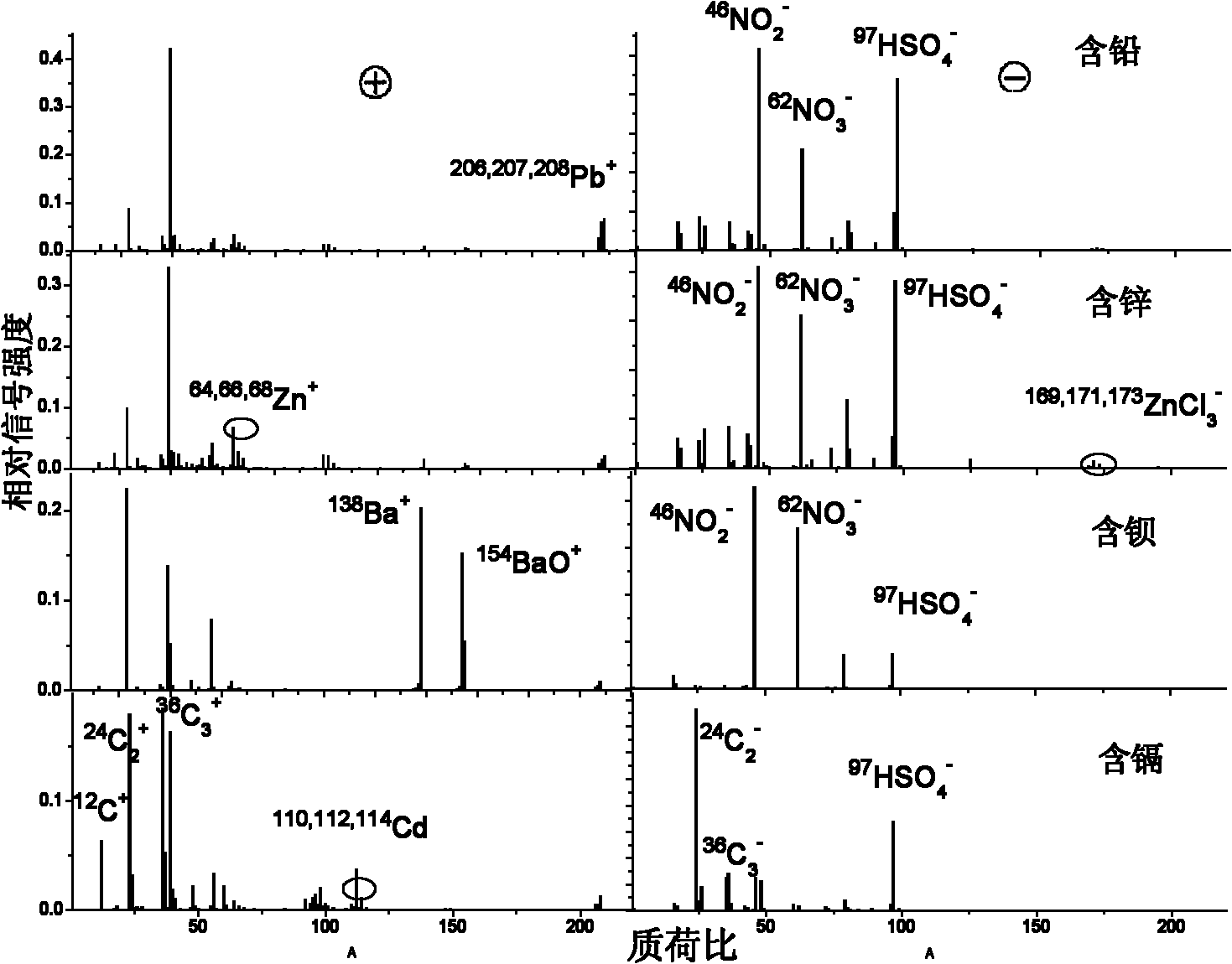

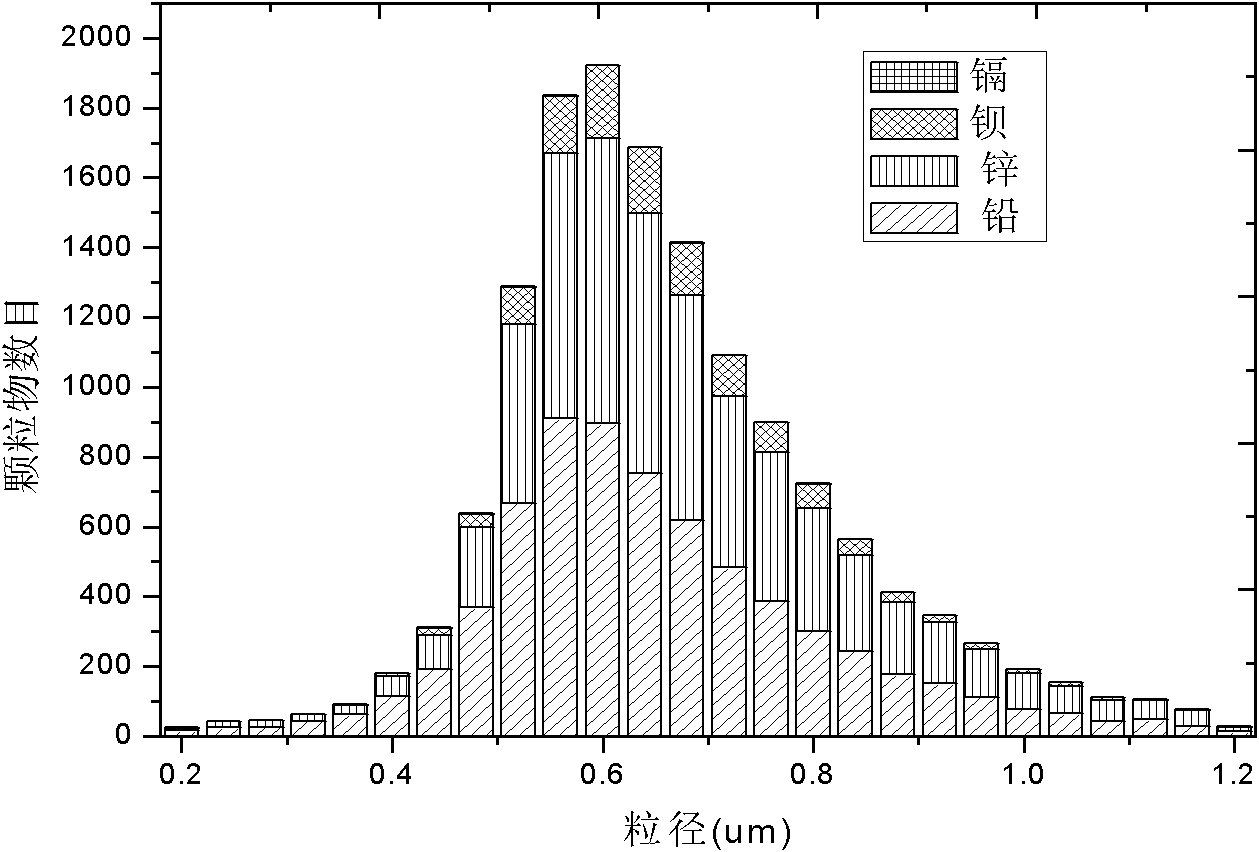

Method and device for detecting indoor heavy metal pollution by single particle aerosol mass spectrometry

InactiveCN102262039AAvoid Analytical ErrorsReal-time online collectionMaterial analysis by electric/magnetic meansParticle size analysisReal time analysisPolystyrene bead

The invention discloses a method and device for detecting indoor heavy metal pollution by single-particle aerosol mass spectrometry. The method is as follows: firstly, a polystyrene ball is used to perform a particle size calibration experiment on the instrument, and then a standard solution of known metal ions is used Carry out the mass number correction experiment. After the calibration is completed, use SPAMS to collect indoor atmospheric aerosols in different areas and heights in real time, and then use SPAMS to analyze and collect various parameters and status information of heavy metal particles in the samples in real time. The SPAMS in the device includes a sequentially connected sampling module, a particle size measurement module, an ionization source module, a mass analyzer module, a data acquisition module and a data analysis module. The invention can quickly, sensitively, accurately and real-time online detect the particle number concentration, particle size distribution, mass spectrum characteristics, mixing state, etc. of indoor heavy metal particles, and judge its possible source.

Owner:SHANGHAI UNIV +1

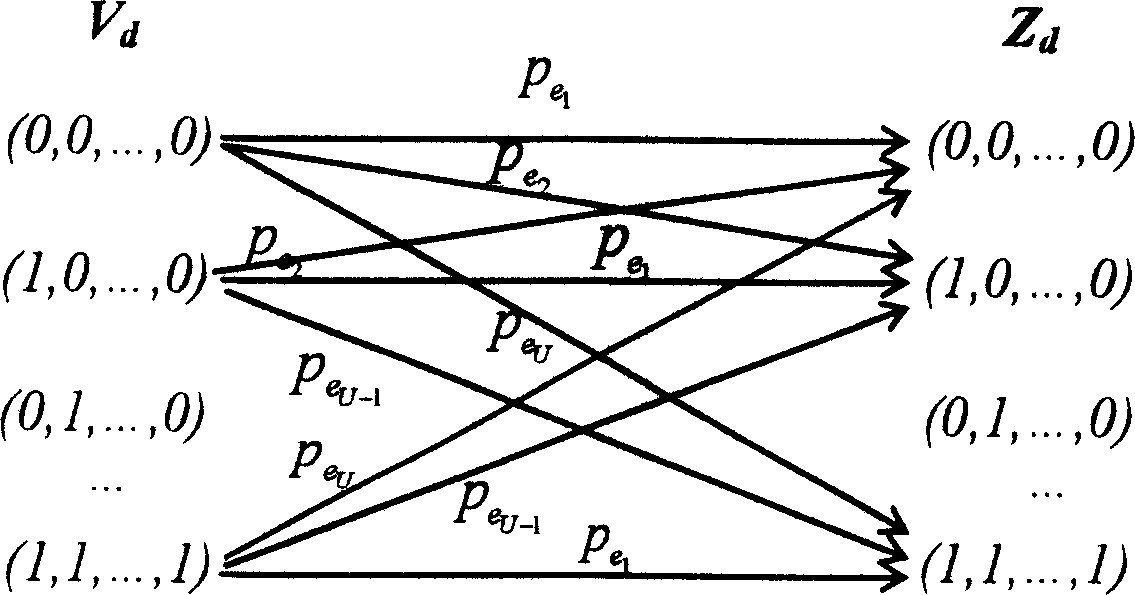

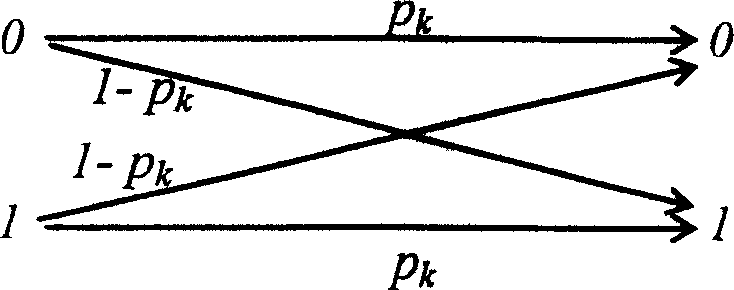

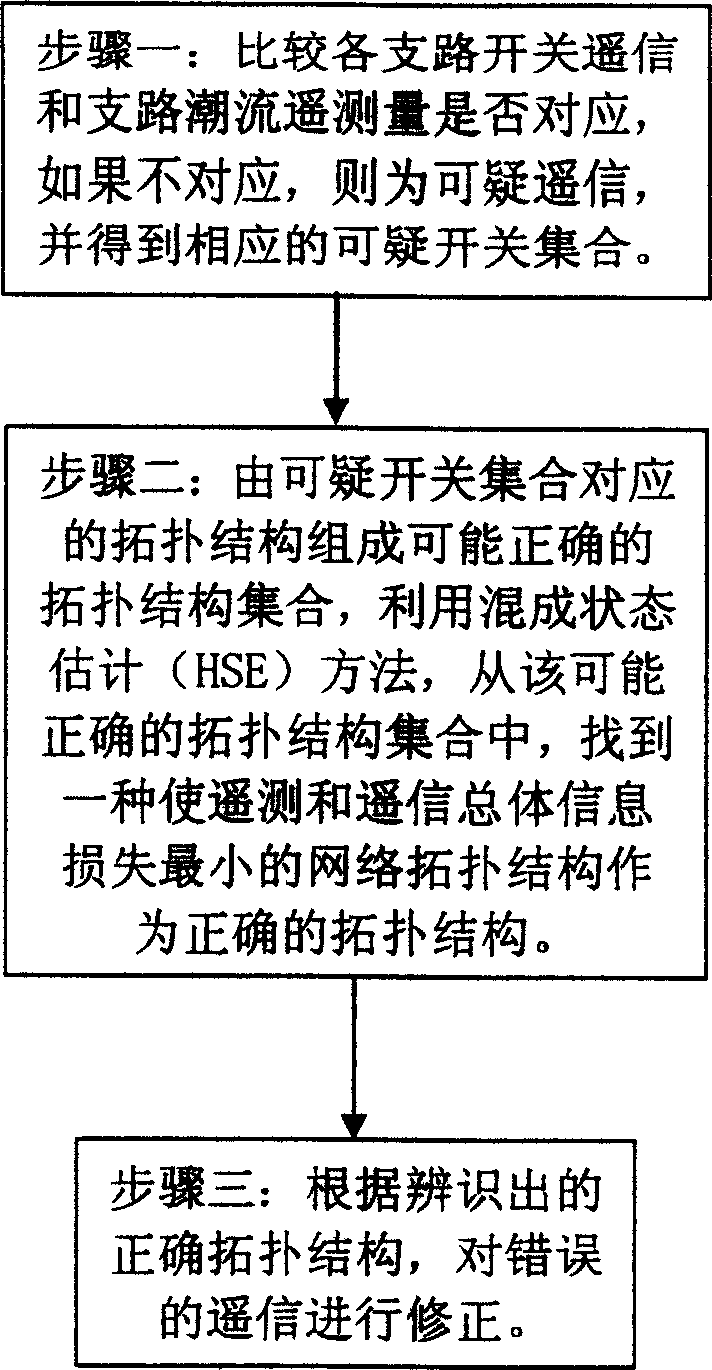

Power network topology error identification method based on mixed state estimation

InactiveCN1738143ATake advantage ofImprove accuracyAc network circuit arrangementsElectric power systemPower grid

The invention relates to electrical network topological error identification method based on mixed evaluation, belonging to the network topological error identification technique of evaluating the condition of electrical system. Said method comprises: detection: checking the correspondence between each branch switch telemetry and branch current measurement, attaining relative suspected switch integration when they are not corresponding; evaluation and identification: using the topological structure corresponded to the suspected switch integration to form a possible correct topological structure integration, utilizing mixed evaluation method to find a network topological structure which can make the remote measurement and telemetry total information be damaged least, as a correct topological from said possible topological structure integration; correcting the switch telemetry: correcting the fault telemetry according to said correct topological structure. The invention can integrated take regard of network topological information of remote measurement and telemetry, to improve the accuracy of topological error identification.

Owner:TSINGHUA UNIV

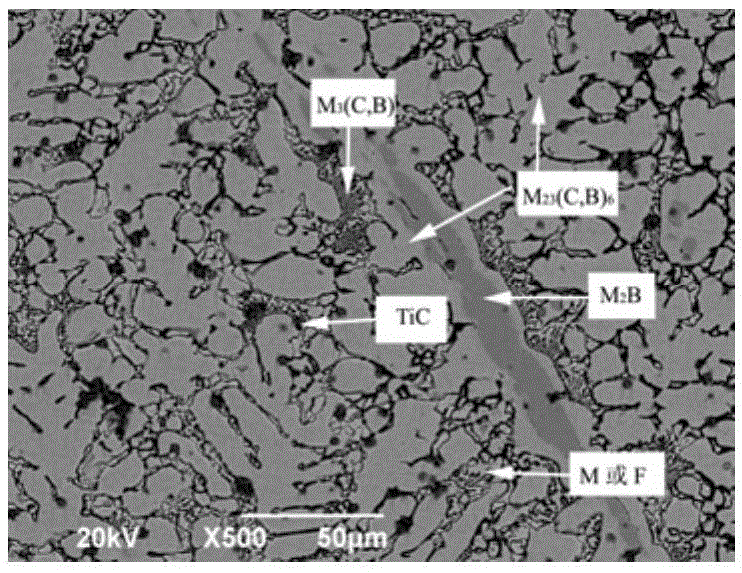

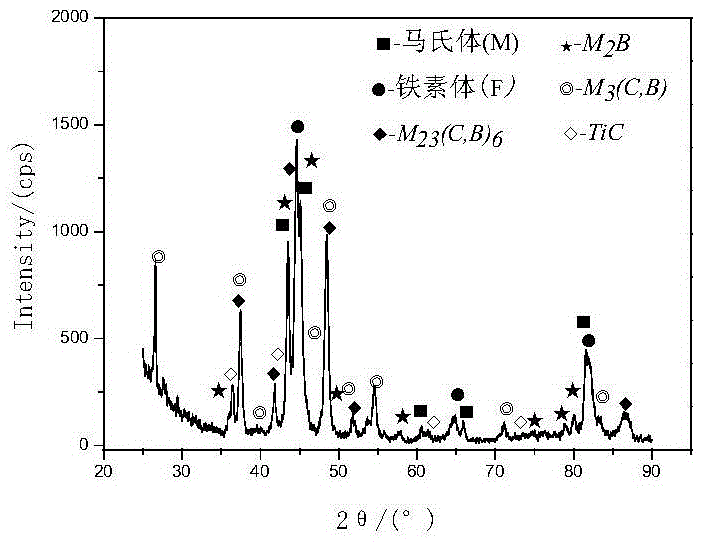

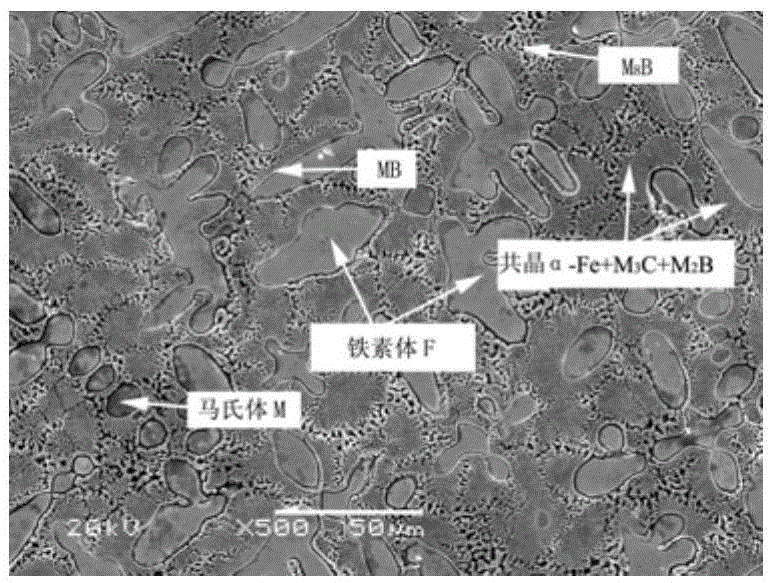

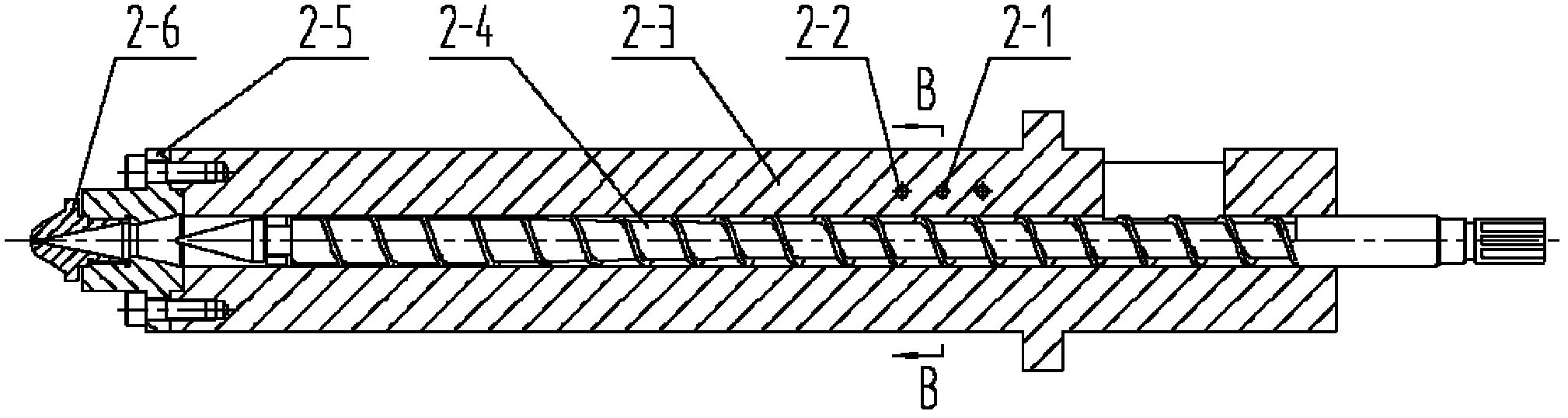

Carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire

InactiveCN105537797ARealize carbon control and tougheningReduce carbon contentWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire. According to the technical scheme, a low-carbon-steel H08A cold-rolled thin steel strip is adopted as an outer sheath, and an alloy, graphite and other metal powder are mixed in the sheath to form a powder core, wherein the surfacing alloy is alloy powder obtained by adding high-content ferro-boron, high-carbon ferrochrome and ferrotitanium with different melting properties into the flux-cored wire; by virtue of open-arc surfacing current control, a high-boron surfacing melt with the alloy component in an incompletely-molten and unevenly-mixed state is formed, so that an alloy element phase structure is selectively optimized and configured; the powder core mainly consists of the following components: ferro-boron, high-carbon ferrochrome, ferrotitanium, graphite, medium-carbon ferromanganese, ferrosilicon and reduced iron powder. The carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire overcomes the defect that a current high-boron surfacing alloy is great in brittleness due to microstructure characteristics of the high-boron surfacing alloy, can be widely applied to surfacing manufacturing or repairing of parts with abrasive wear resistance, for example, a concrete cement conveying tube, and is especially suitable for surfacing manufacturing or paring of the parts with low-stress abrasive wear resistance.

Owner:XIANGTAN UNIV

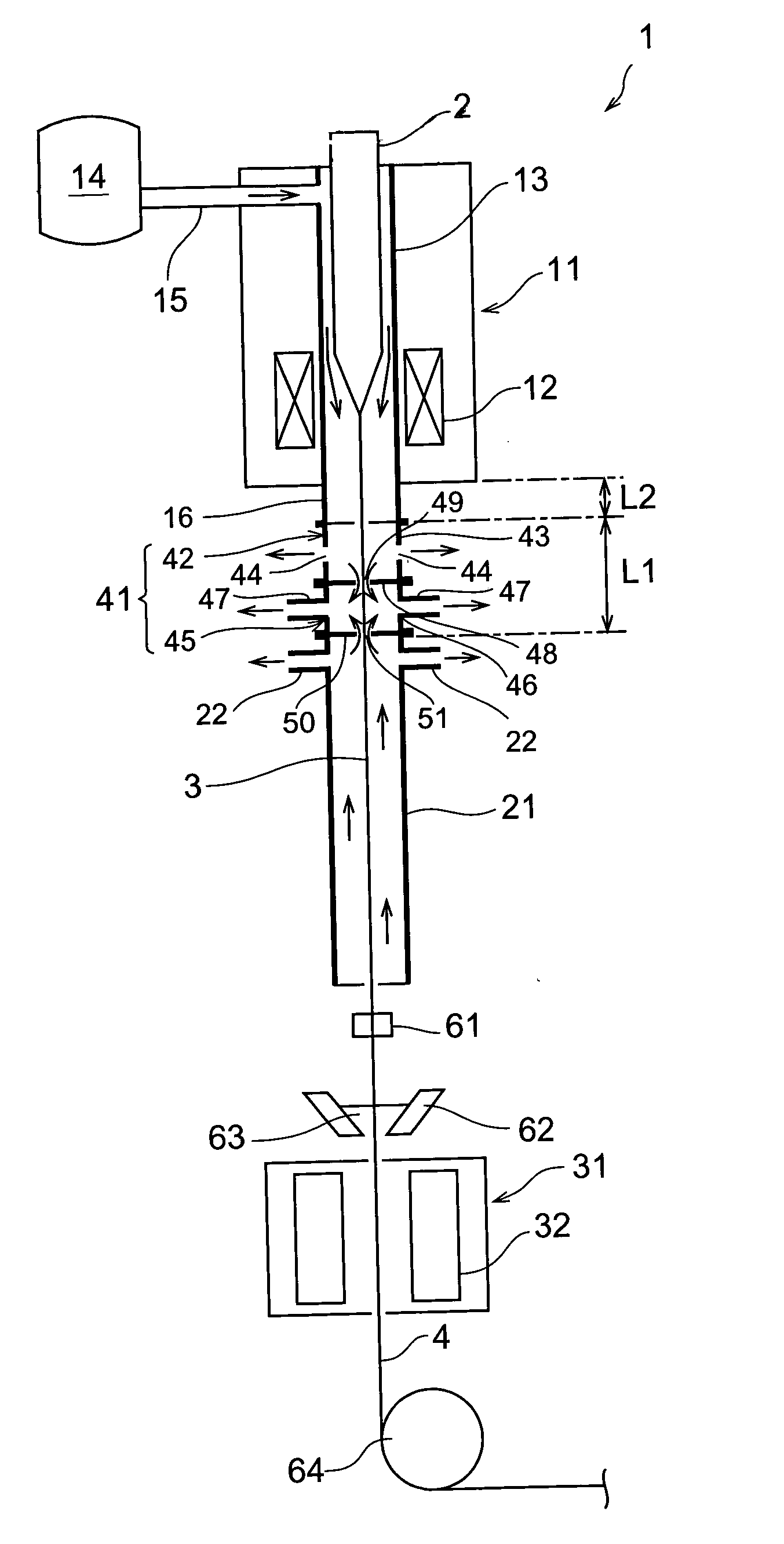

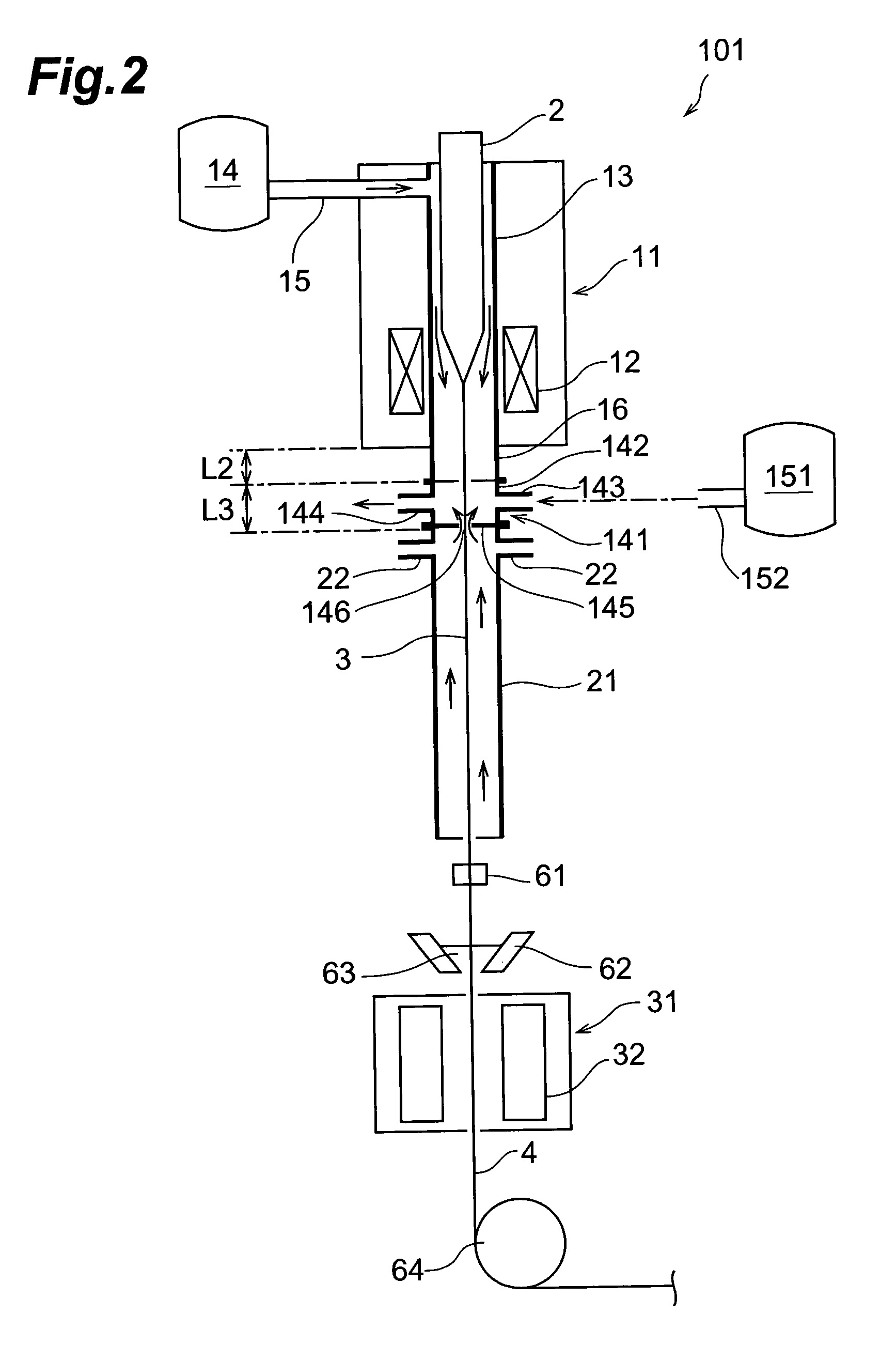

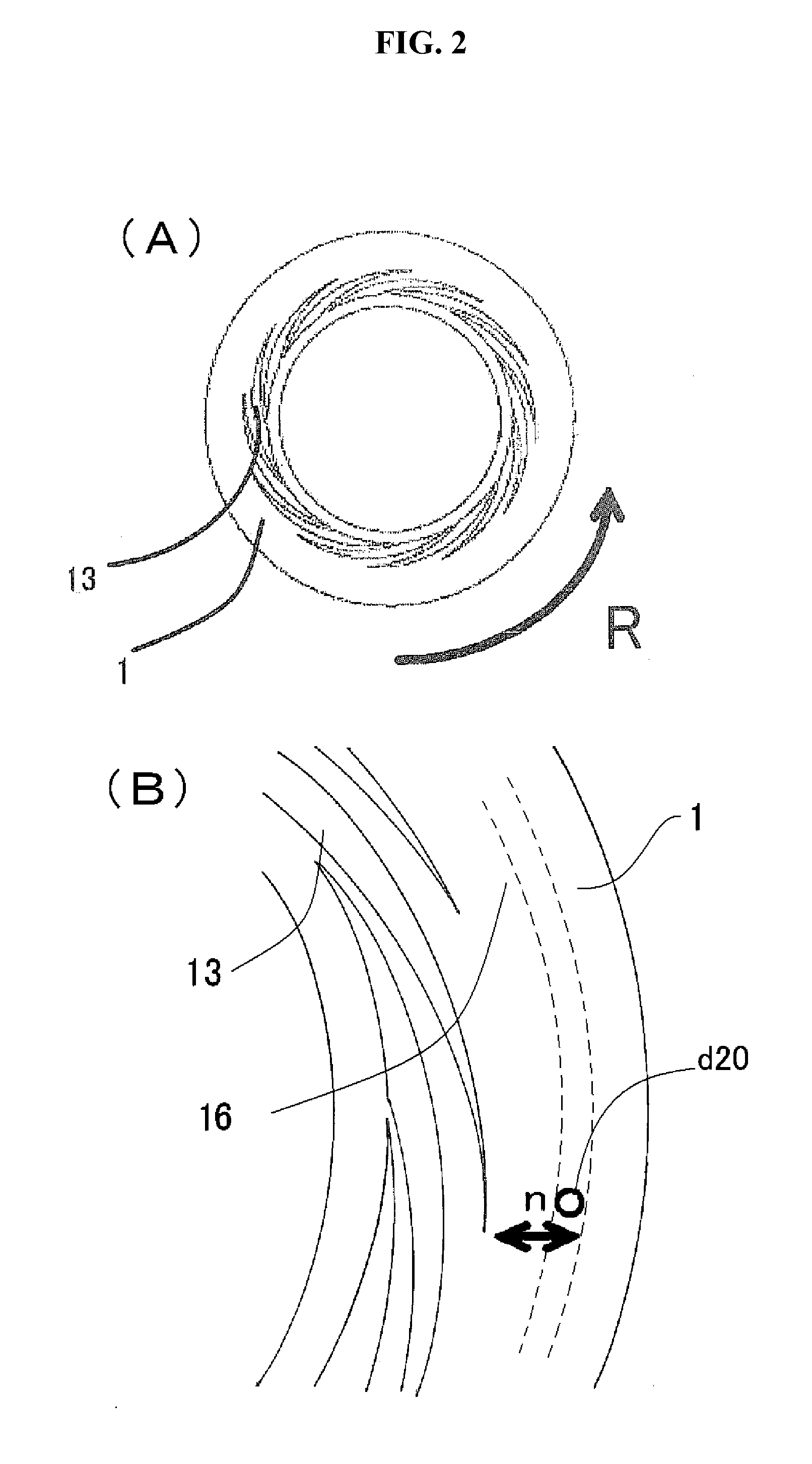

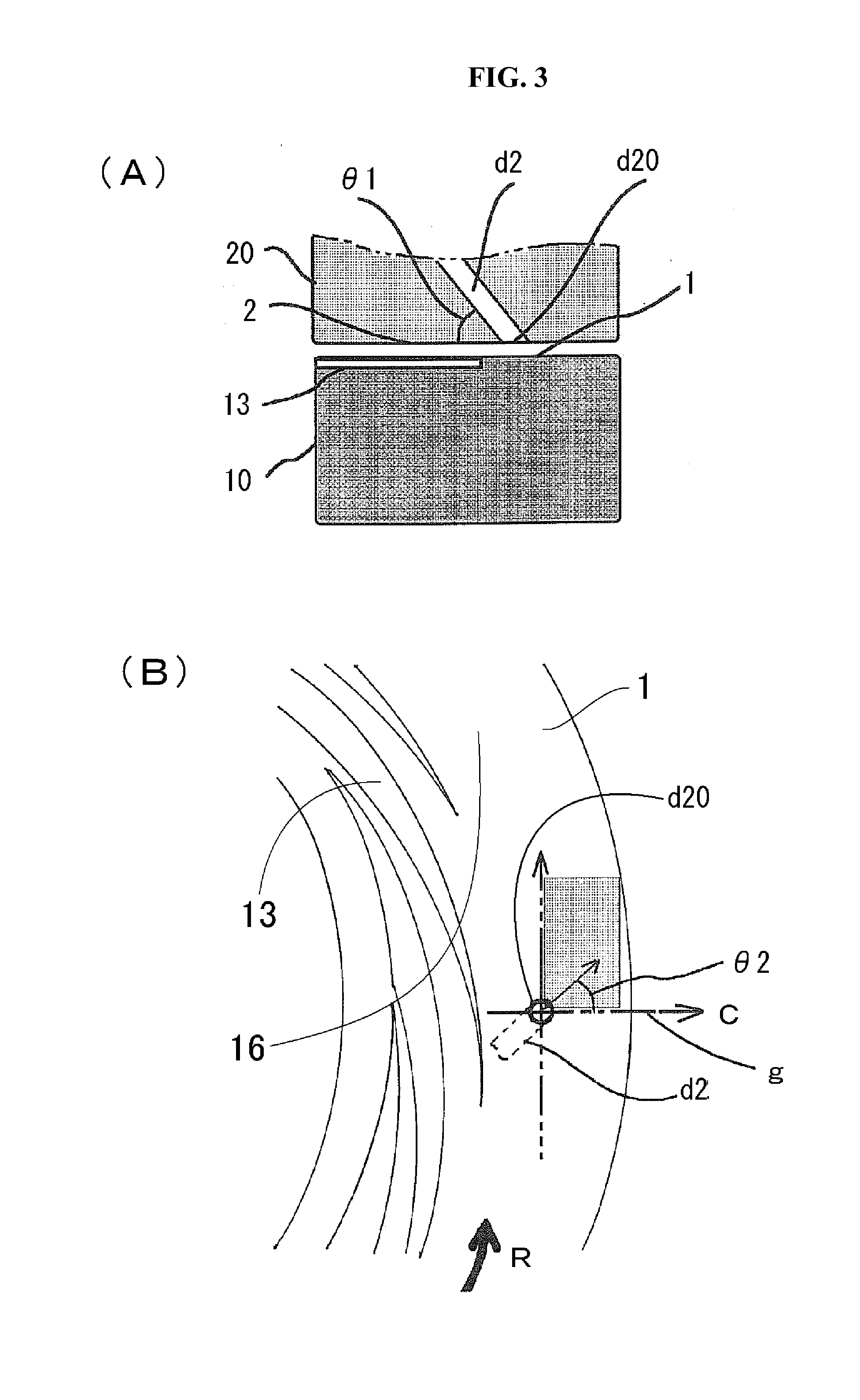

Optical fiber producing method

InactiveUS6928840B1Reduce transmission lossReduce intensityGlass furnace apparatusGlass fibre drawing apparatusMixed statesEngineering

A drawing apparatus 1 comprises a drawing furnace 11, a protecting tube 21, and a resin curing unit 31. A buffer chamber 41 is disposed between the drawing furnace 11 and the protecting tube 21, and has a length L1 in the drawing direction of the optical fiber 3. The buffer chamber 41 is constituted by a first buffer cell 42 and a second buffer cell 45. In the space within the buffer chamber 41, an He gas, which is an atmosphere gas within the drawing furnace 11, and the air, which is an atmosphere gas within the protecting tube 21, exist in a mixed state. The optical fiber 3 drawn upon heating in the drawing furnace 11 is fed to the protecting tube 21, and a predetermined part of the optical fiber 3 is annealed at a predetermined cooling rate. Thereafter, a coating die 62 coats the optical fiber 3 with a UV resin solution 63, and the resin curing unit 31 cures the UV resin 63, whereby a coated optical fiber 4 is obtained.

Owner:SUMITOMO ELECTRIC IND LTD

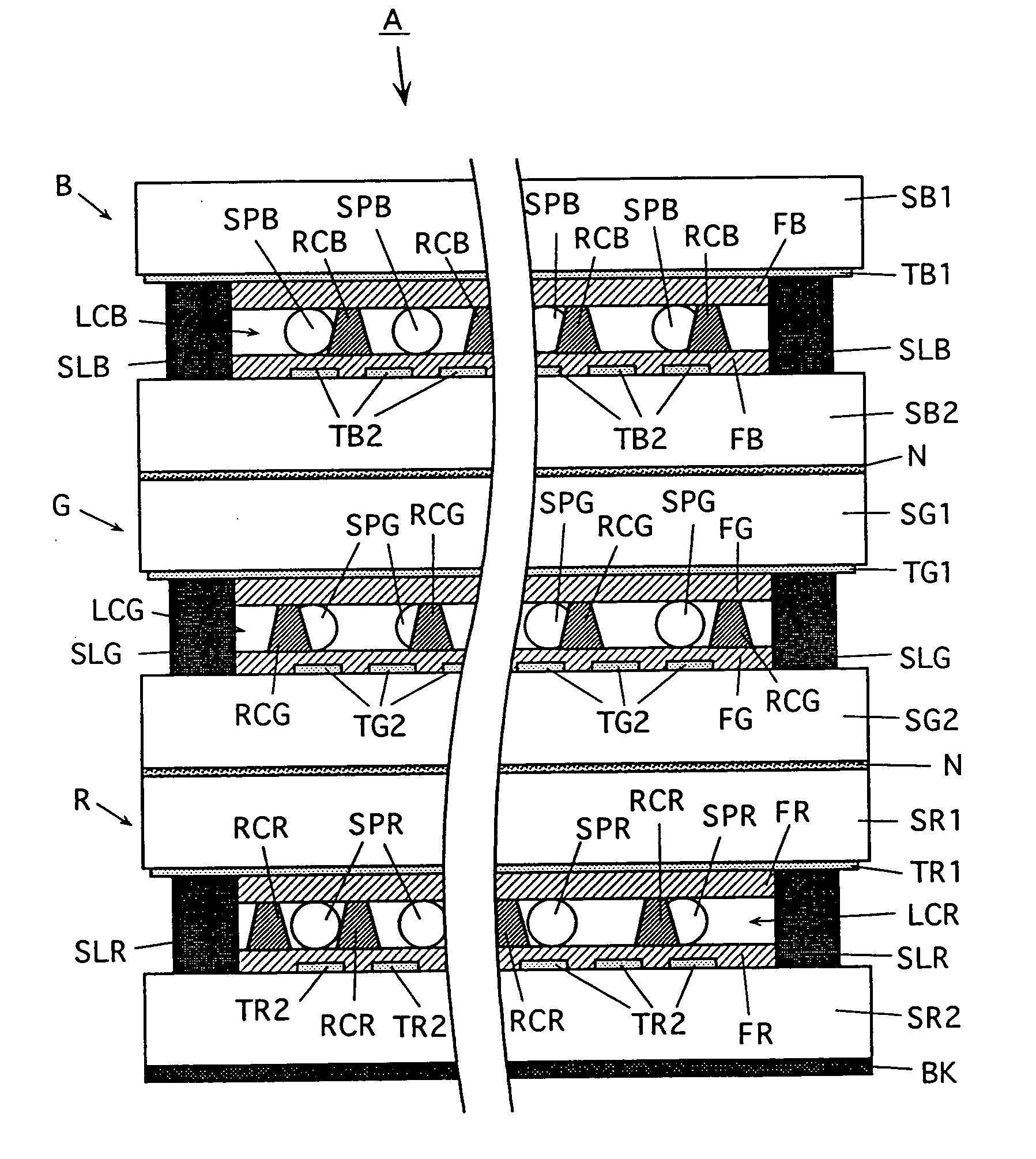

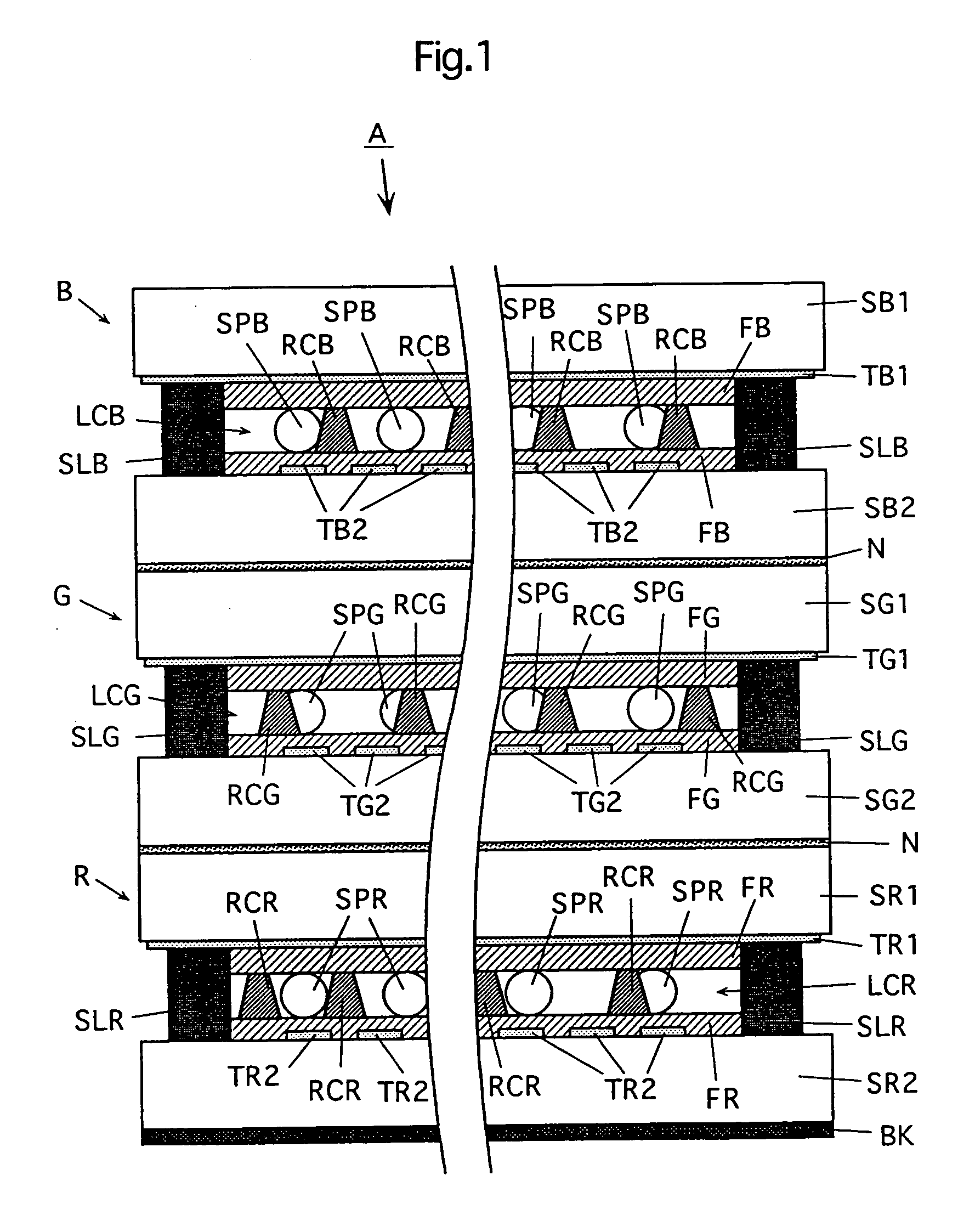

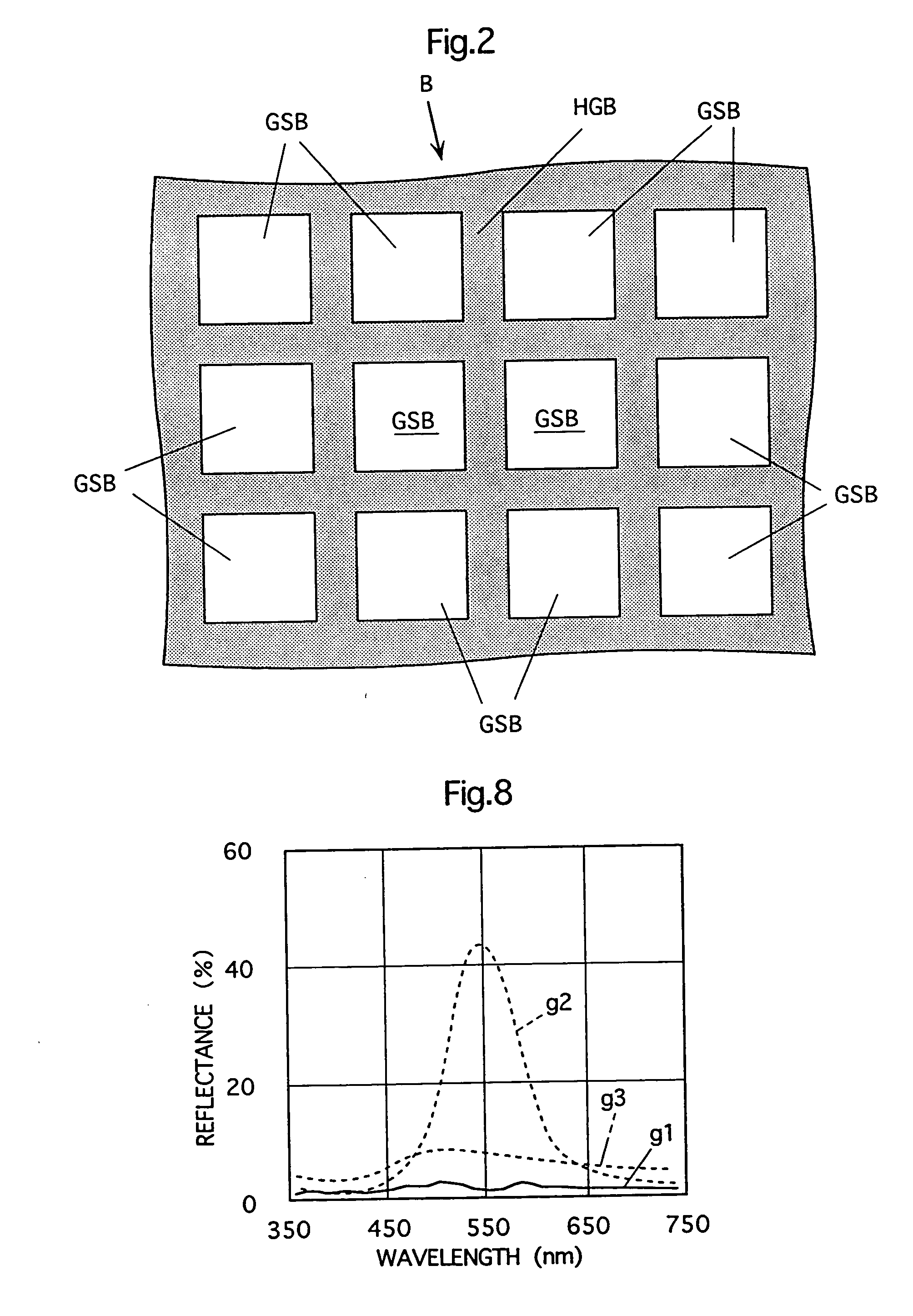

Liquid crystal display element and method of producing the same

InactiveUS20050007531A1Quality improvementIncrease contrastLiquid crystal compositionsNon-linear opticsLiquid-crystal displaySelective reflection

(1) A liquid crystal display element including a liquid crystal layer including liquid crystal contained between a pair of substrates and exhibiting a cholesteric phase, wherein an orientation film is arranged on at least one of the paired substrates, and is in contact with the liquid crystal layer, and liquid crystal molecular orientation processing for portions of each orientation film corresponding to pixel regions are effected in a manner different from that effected on at least a portion of a portion corresponding to non-pixel region of the orientation film on at least one of the substrates. (2) A liquid crystal light modulation element including a liquid crystal layer held between a pair of substrate and including a liquid crystal material exhibiting a cholesteric phase in a room temperature and having a peak of a selective reflection wavelength in a visible wavelength range, wherein the liquid crystal layer in the selective reflection state has pixel regions neighboring to the opposite substrates, respectively, and liquid crystal domains in the pixel regions neighboring to at least one of the substrates are in a mixed state of a polydomain state and a monodomain state.

Owner:MINOLTA CO LTD

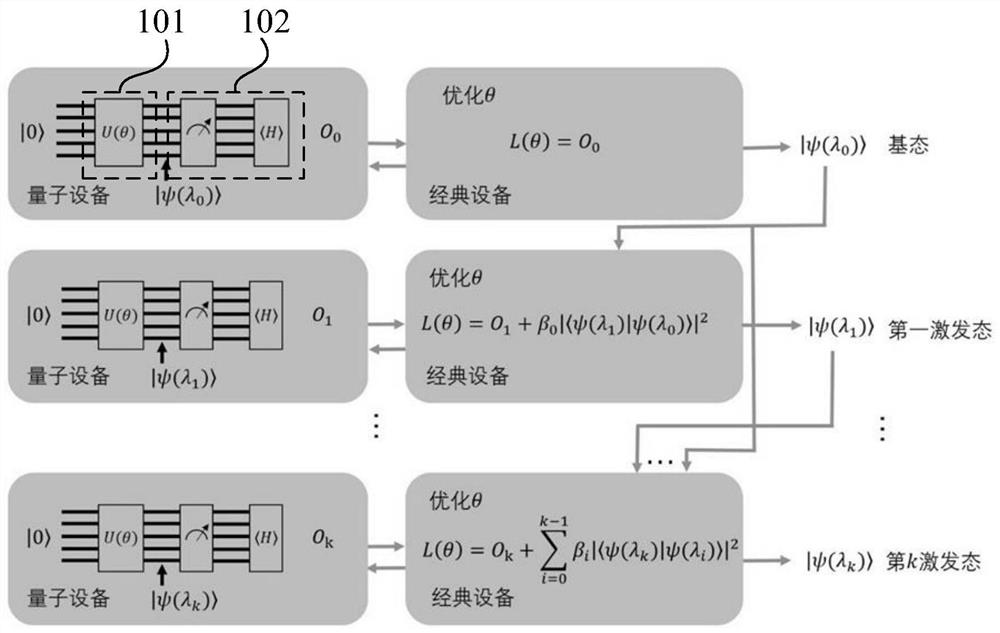

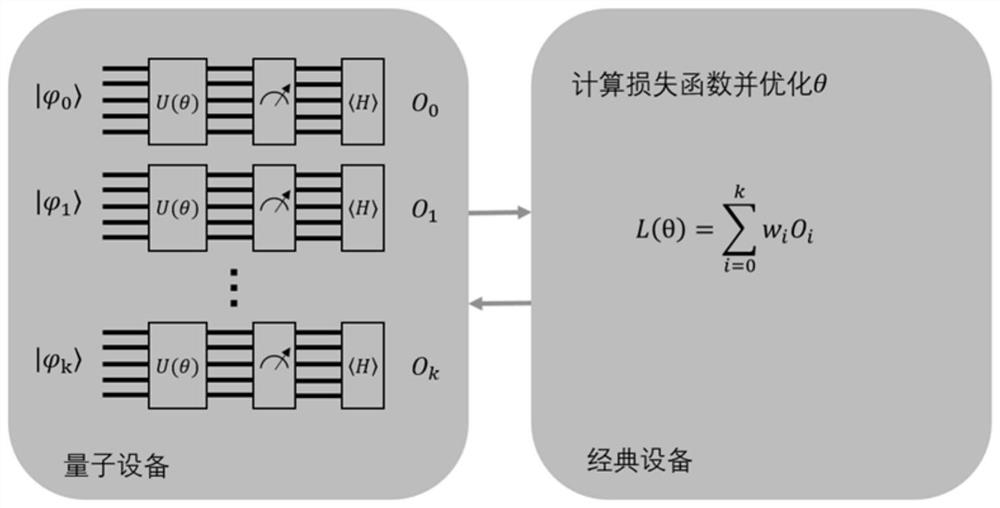

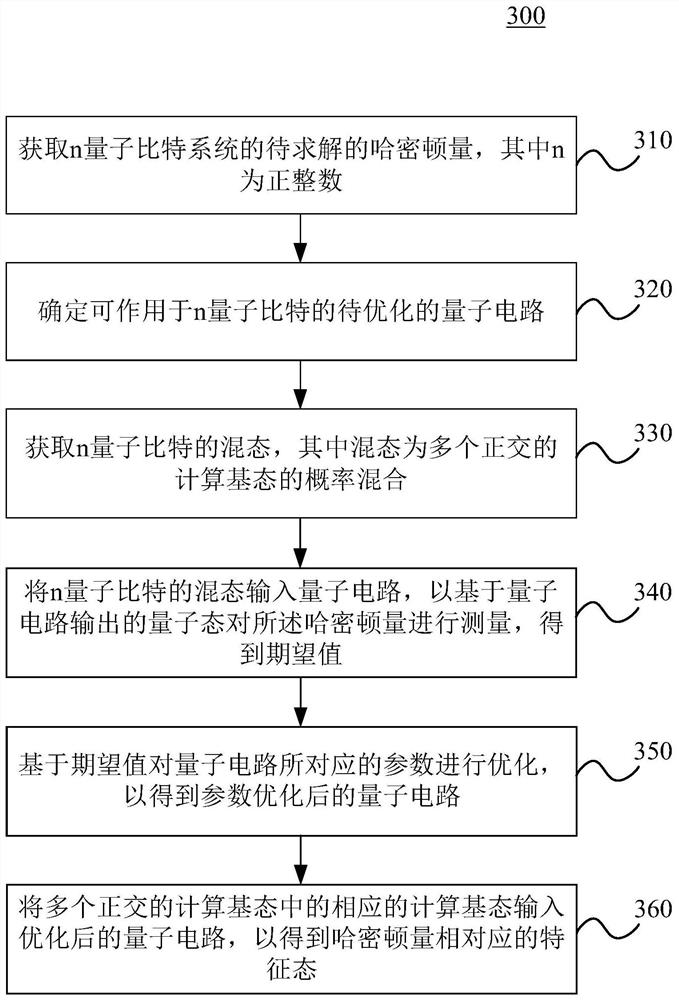

Data processing method and device based on quantum circuit, electronic equipment and medium

PendingCN113496285ASave resourcesQuick extractionQuantum computersCharacter and pattern recognitionHemt circuitsEngineering

The invention provides a data processing method and device based on a quantum circuit, electronic equipment, a computer readable storage medium and a computer program product, and relates to the field of quantum computing, in particular to the technical field of data processing. According to the implementation scheme, the method includes obtaining a to-be-solved Hamiltonian of an n quantum bit system, wherein n is a positive integer; determining a to-be-optimized quantum circuit capable of acting on the n quantum bits; obtaining a mixed state of n quantum bits, wherein the mixed state is a probability mixture of a plurality of orthogonal calculation ground states; inputting the mixed state of the n quantum bits into a quantum circuit, and measuring the Hamiltonian based on the quantum state output by the quantum circuit to obtain an expected value; optimizing the parameters corresponding to the quantum circuit based on the expected value to obtain the quantum circuit after parameter optimization; and inputting a corresponding calculation ground state in a plurality of orthogonal calculation ground states into the optimized quantum circuit to obtain a characteristic state corresponding to the Hamiltonian.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Solid metal alloy

ActiveUS20140308158A1Fully characterizedSuppress migration of silverMaterial nanotechnologyTransportation and packagingMetal alloyMixed states

The present invention addresses the problem of providing a novel, sold metal alloy. Provided is a metal alloy containing two or more types of metal, wherein an equilibrium diagram of the metal alloy shows the two or more types of metal in a finely mixed state at the nanolevel in a specific region where the two types of metal are unevenly distributed. This metal alloy has a substitutional solid solution of the two or more types of metal as the principal constituent thereof. This metal alloy is preferably one obtained by precipitation after mixing ions of two or more types of metal and a reducing agent in a thin-film fluid formed between processing surfaces, at least one of which rotates relative to the other, which are arranged so as to face one another and are capable of approaching and separating from one another.

Owner:M TECHN

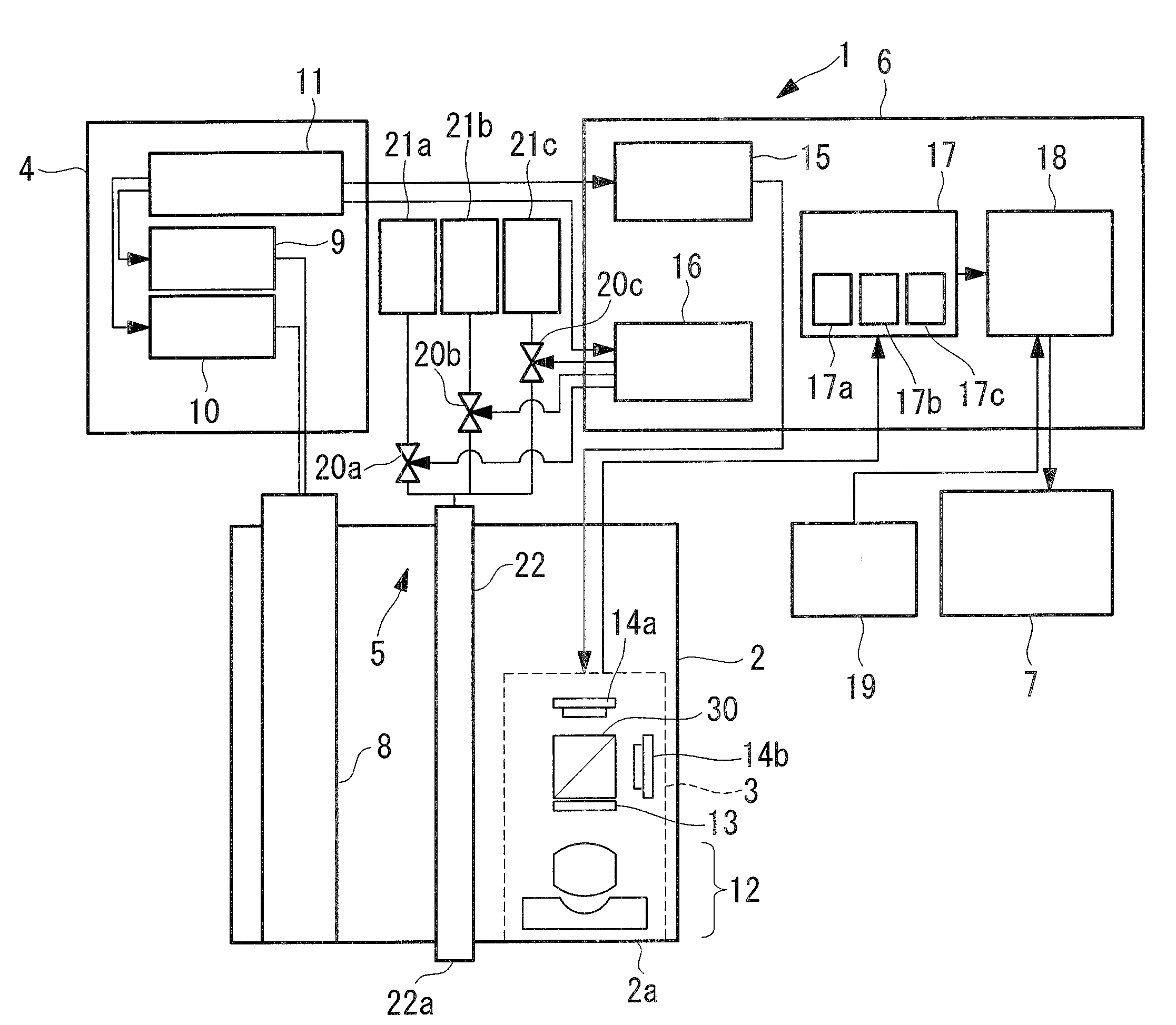

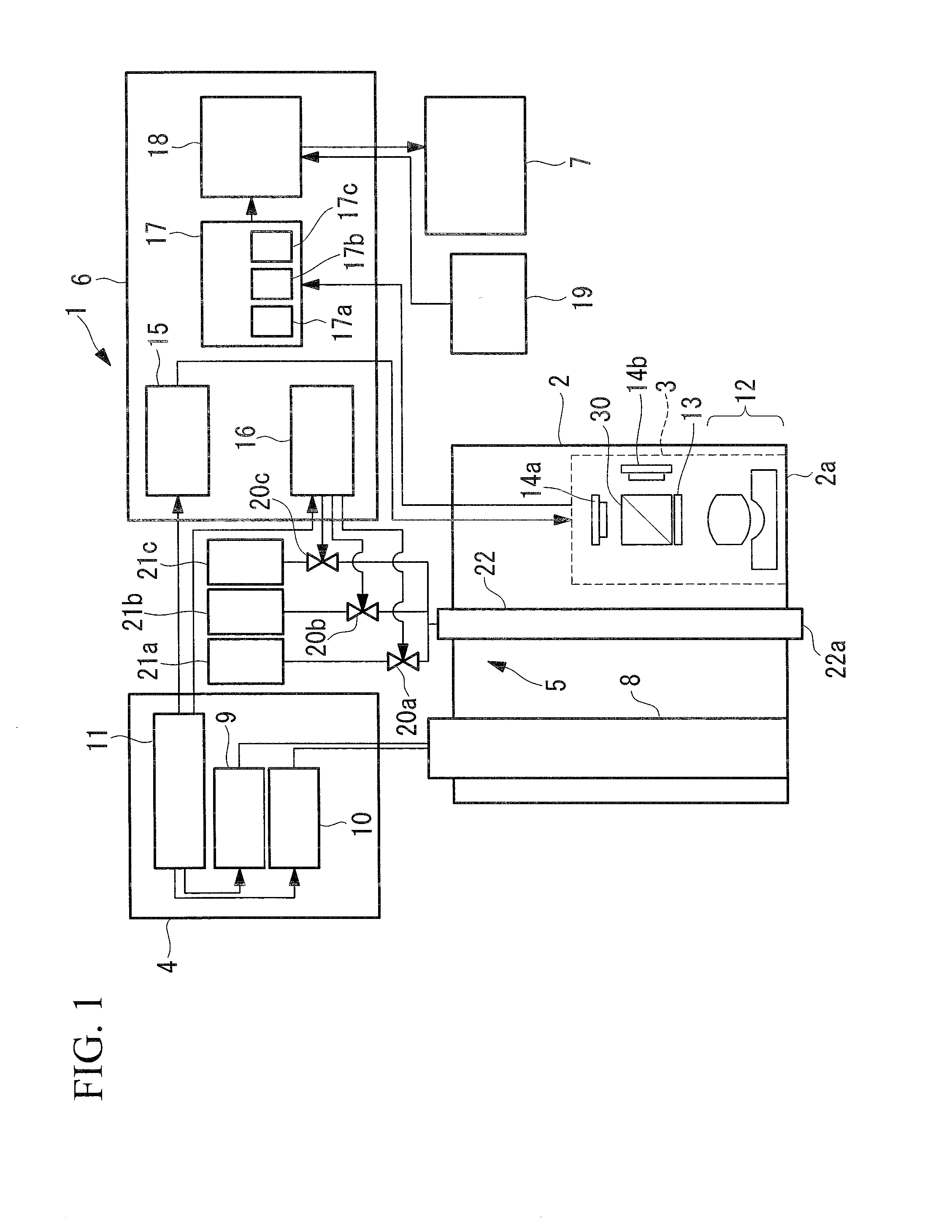

Endoscope system

It is possible to acquire a fluorescence distribution image for each fluorescent agent from a fluorescence image acquired in a mixed state, thus improving the diagnostic performance of cancer cells. There is provided an endoscope system (1) configured to insert at least a part into a body cavity of a living body and to acquire an image of an image-acquisition subject in the body cavity, the endoscope system including a light source unit (10) configured to emit excitation light for exciting two or more different types of fluorescent agents having different optical characteristics; two or more image-acquisition units (14a, 14b) provided in a section inserted in the body cavity and configured to simultaneously capture fluorescence emitted from the image-acquisition subject as fluorescence in two or more different wavelength bands; a storage unit configured to store information associated with the relative relationship between the intensity of fluorescence generated when excited by the excitation light and the concentrations of the fluorescent agents; and a concentration-information calculating unit (18) configured to calculate and output concentration information of the fluorescent agents on the basis of fluorescence intensity of images in two or more wavelength bands captured by the image-acquisition units and the information associated with the relative relationship stored in the storage unit.

Owner:OLYMPUS CORP

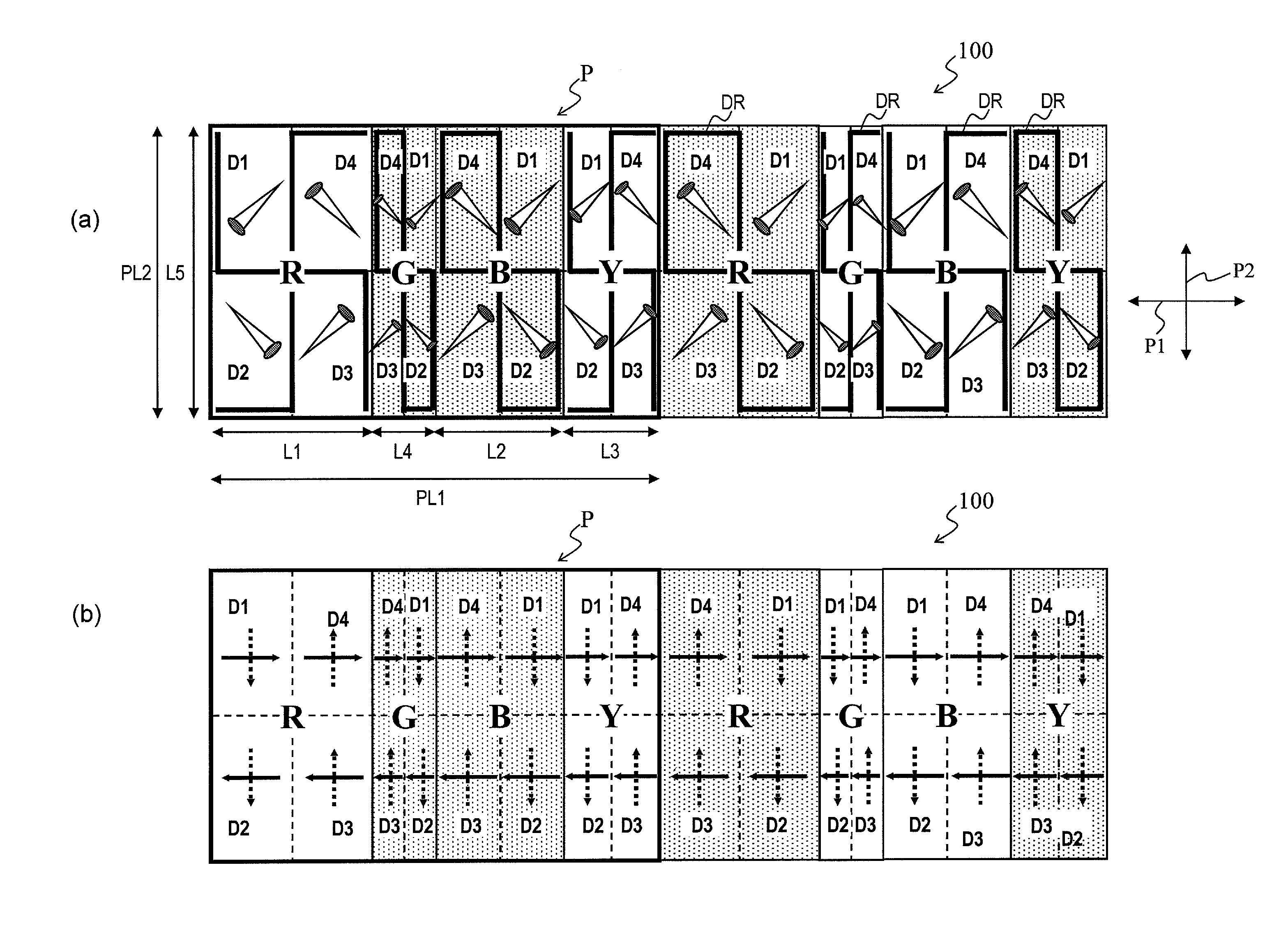

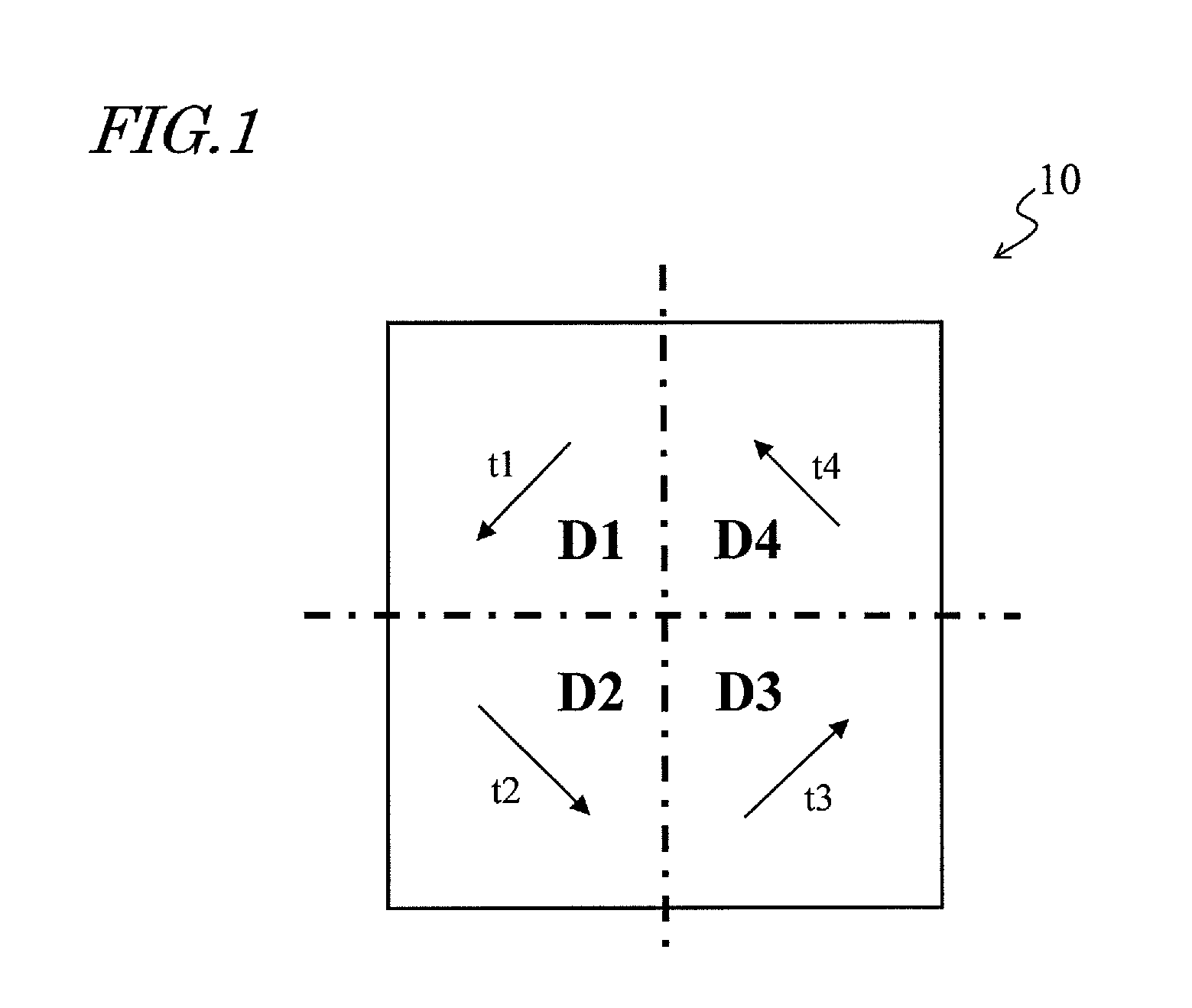

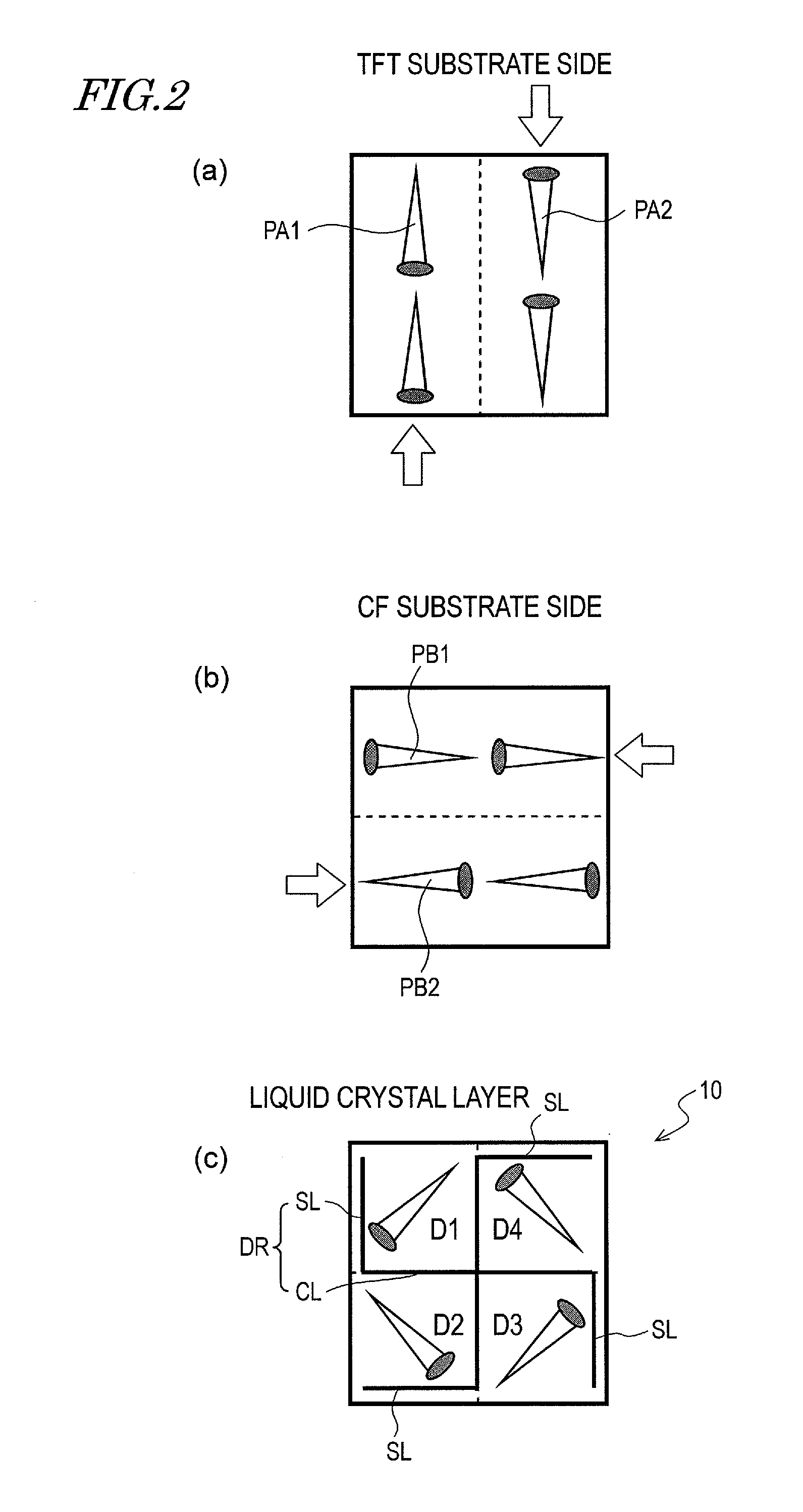

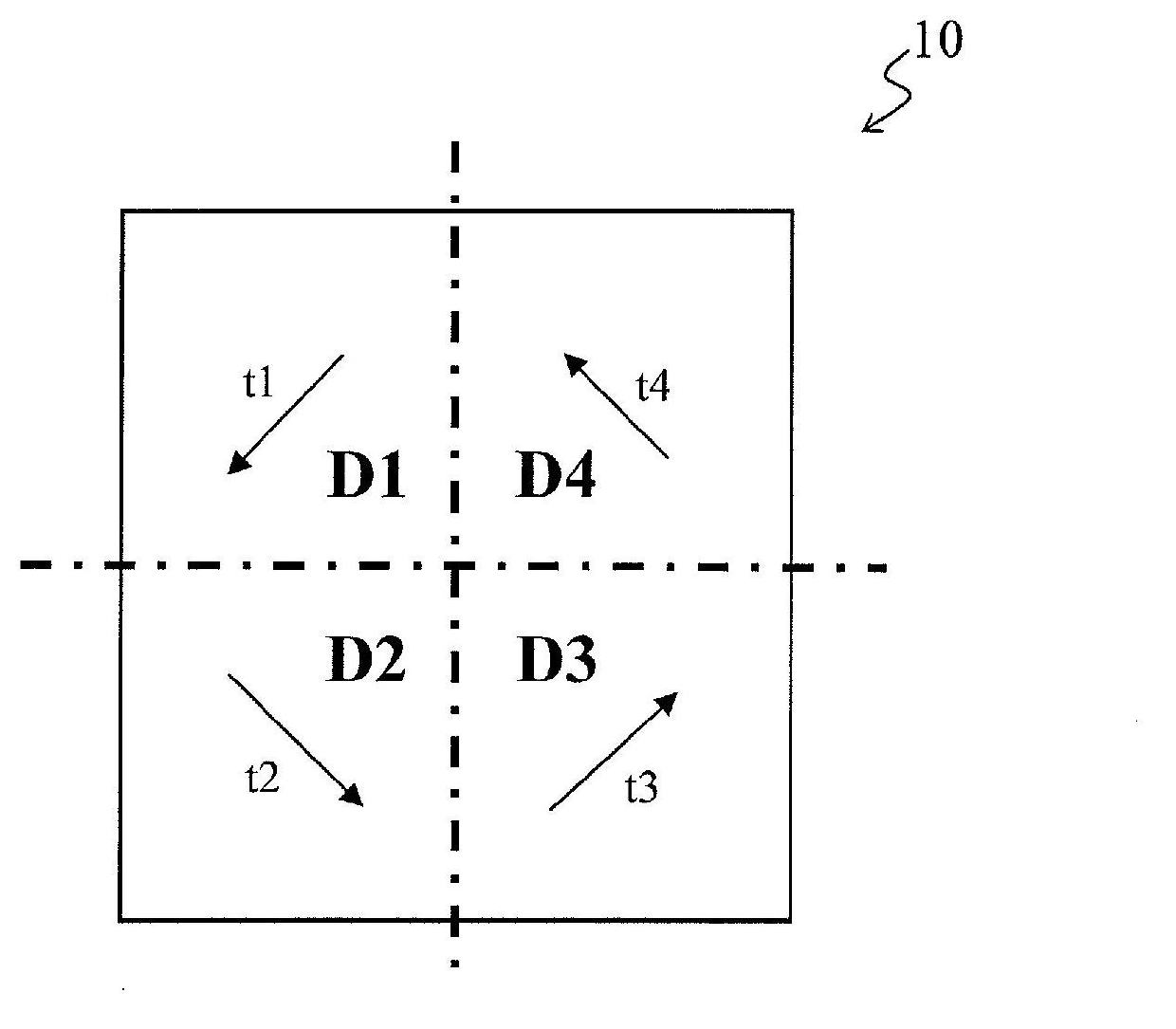

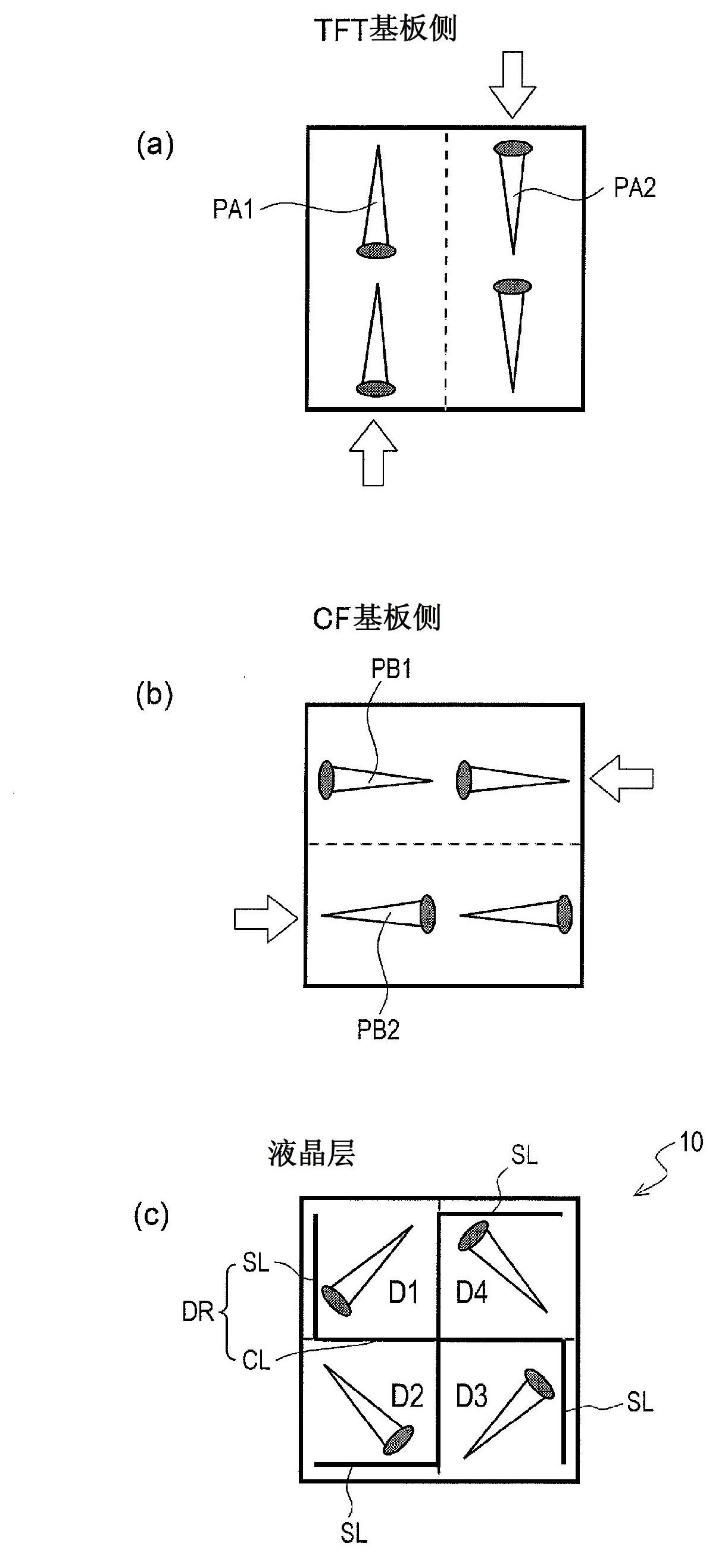

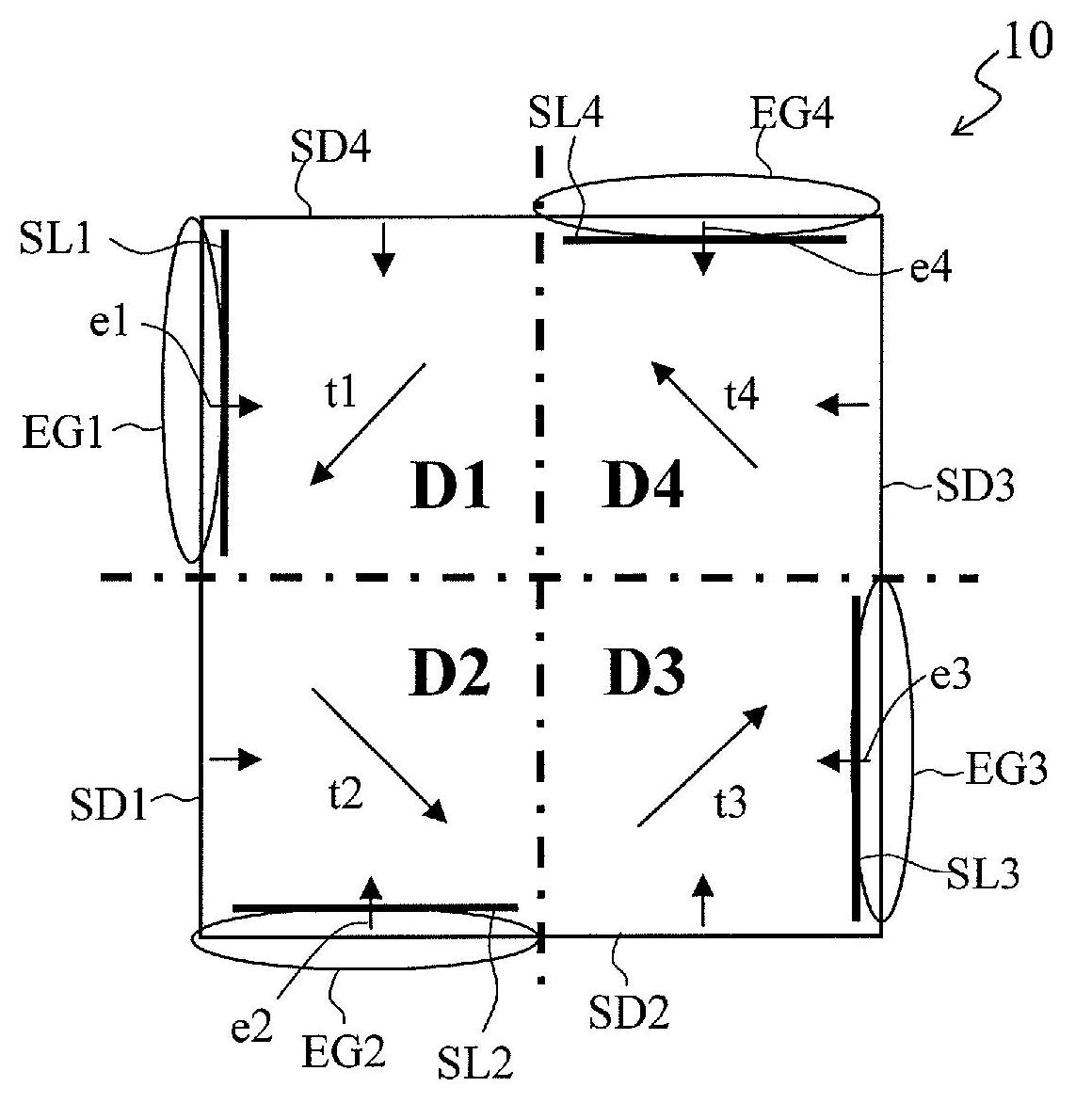

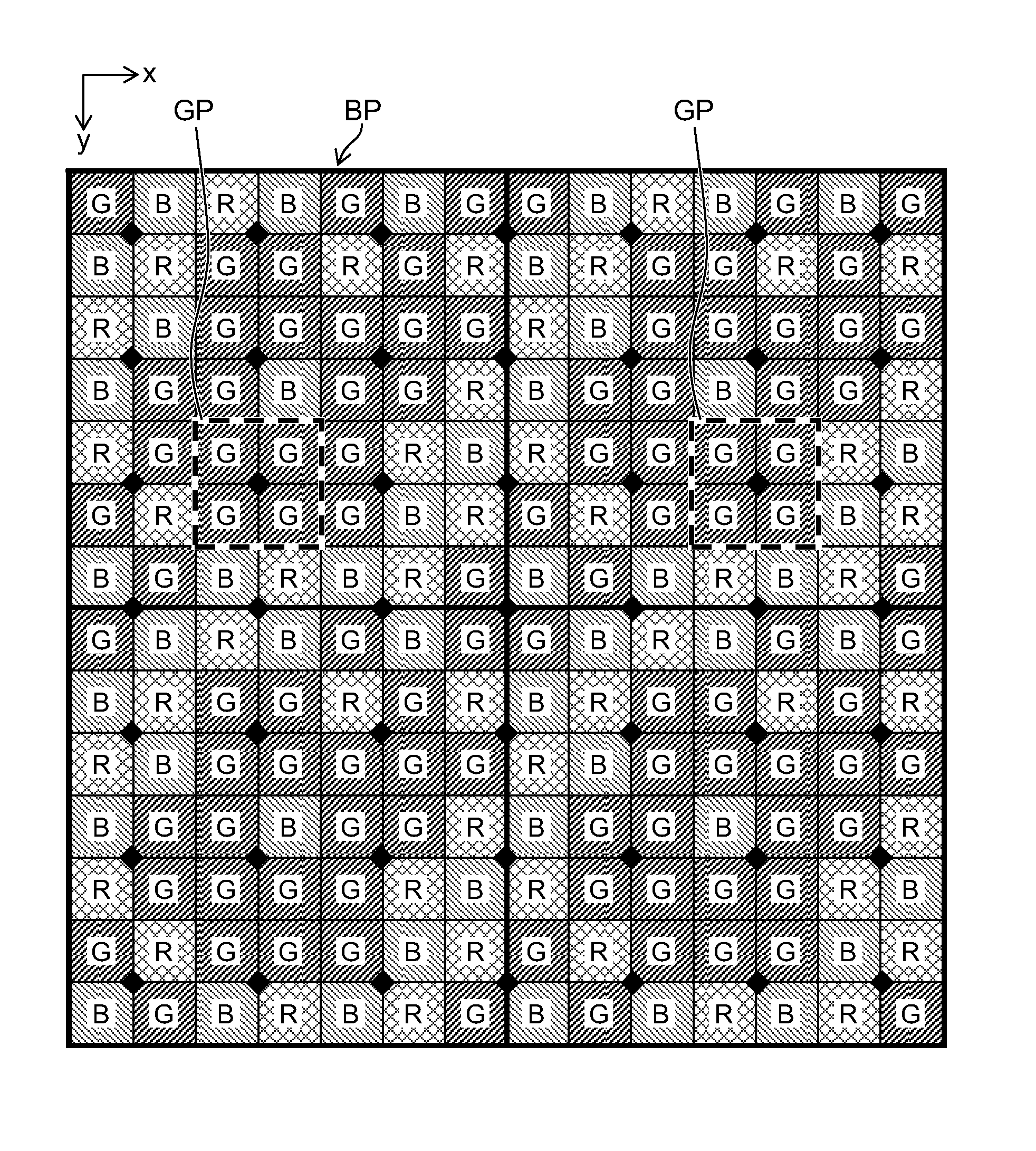

Liquid crystal display device and manufacturing method therefor

InactiveUS20120229739A1Low costIncrease of timeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusVertical alignmentMixed states

A liquid crystal display device (100) according to the present invention includes a vertical alignment type liquid crystal layer (3); and a pair of optical alignment films (12, 22). A plurality of picture elements (R, G, B, Y) each include four liquid crystal domains (D1 through D4) in which tilt directions of liquid crystal molecules when a voltage is applied are different. The four liquid crystal domains are located in a matrix of 2 rows×2 columns. The pair of optical alignment films have such an alignment regulation force that causes an identical alignment pattern to appear in repetition in the liquid crystal layer along a first direction which is parallel to one of a row direction and a column direction, with 2n pixels (n is an integer of 1 or greater) being a minimum unit. In the 2n pixels which form the repeat unit of alignment pattern, there are first picture elements and second picture elements in a mixed state, the first picture elements each including the four liquid crystal domains located in a first order, and the second picture elements each including the four liquid crystal domains located in a second order which is different from the first order. According to the present invention, when the 4D-RTN mode is adopted for a liquid crystal display device in which one pixel includes a picture element having a different size from that of another picture element, increase of the cost and the time which are required for optical alignment processing can be suppressed.

Owner:SHARP KK

Temperature control method based on phase-transition energy-accumulation material

The invention discloses a temperature control method based on a phase-transition energy-accumulation material. In the method, the phase-transition energy-accumulation material is selected according to a required control temperature, so that the phase-transition temperature of the phase-transition energy-accumulation material can be a set control temperature of a device; in a product processing process, the selected phase-transition energy-accumulation material in a solid-liquid mixed state is introduced into an energy-accumulation material channel, a temperature-control area is close to the phase-transition energy-accumulation material channel, and a constant-temperature temperature-control medium is provided by utilizing the energy-accumulation property of the phase-transition energy-accumulation material. By adopting the temperature control method based on the phase-transition energy-accumulation material, the temperature around a cavity is stably controlled under the phase-transition temperature of the selected material, the phase-transition material is molten from the solid state to the liquid state at a fixed temperature after absorbing heat so as to form a heat-absorption mechanism, and large heat absorption amount ensures that the temperature around the cavity is relatively balanced; after being properly cooled, the phase-transition material is solidified from the liquid state to the solid state so as to form a heat release mechanism at the fixed temperature, so that the temperature around the cavity is relatively balanced and continuously recycled.

Owner:BEIJING UNIV OF CHEM TECH

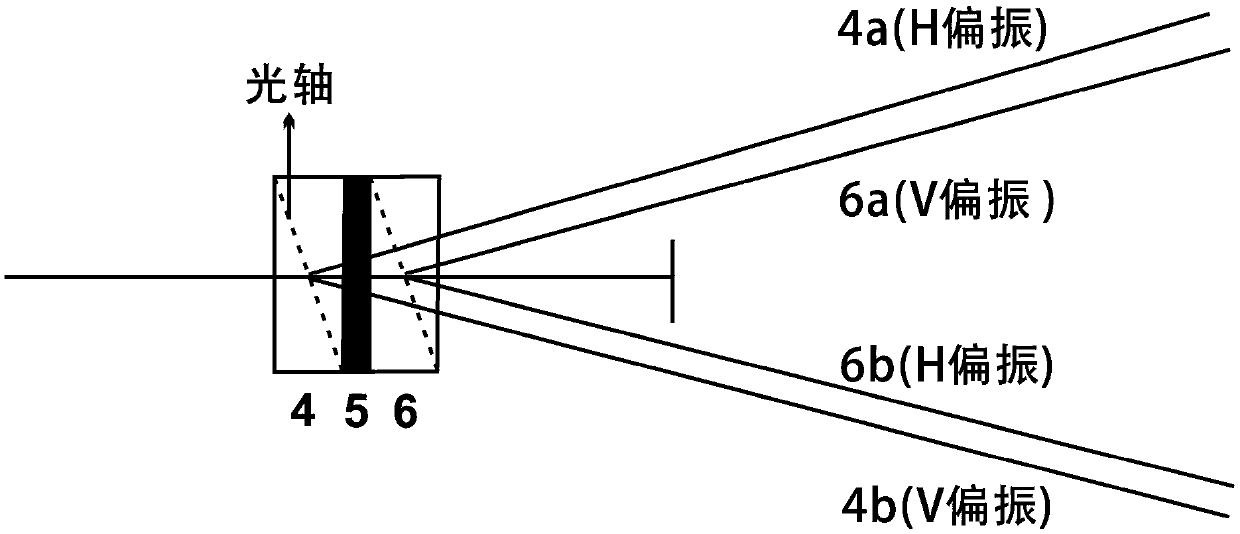

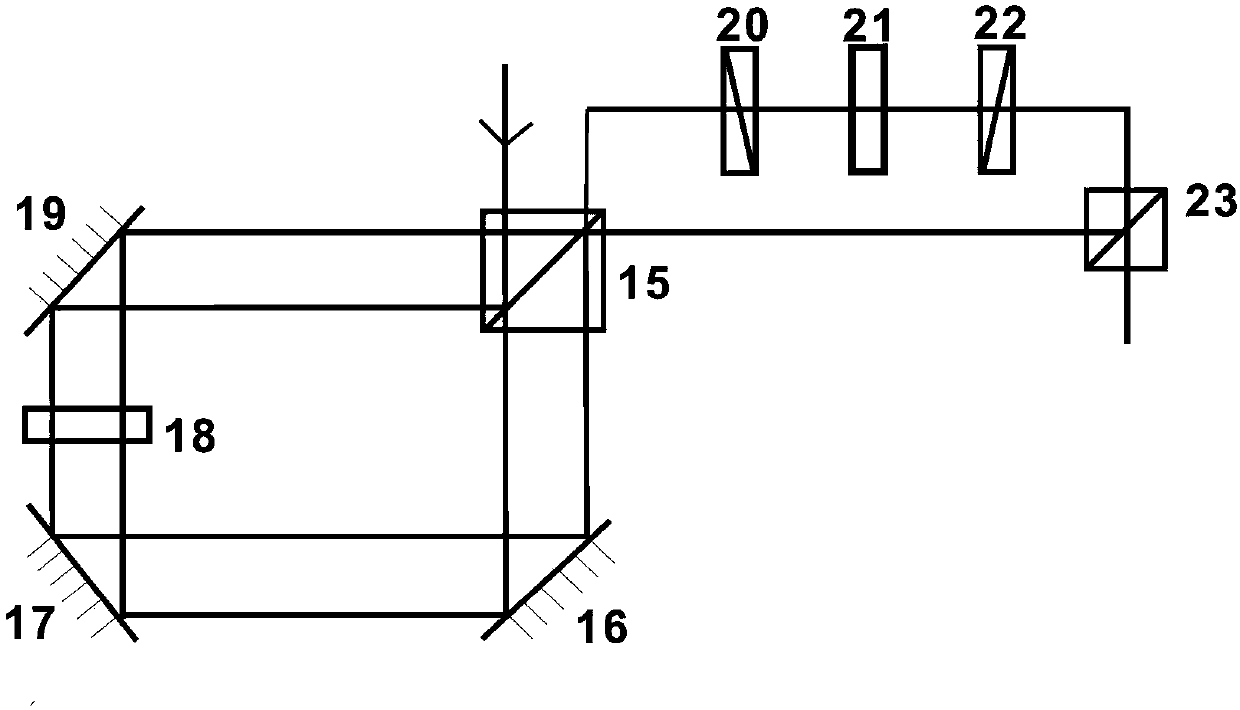

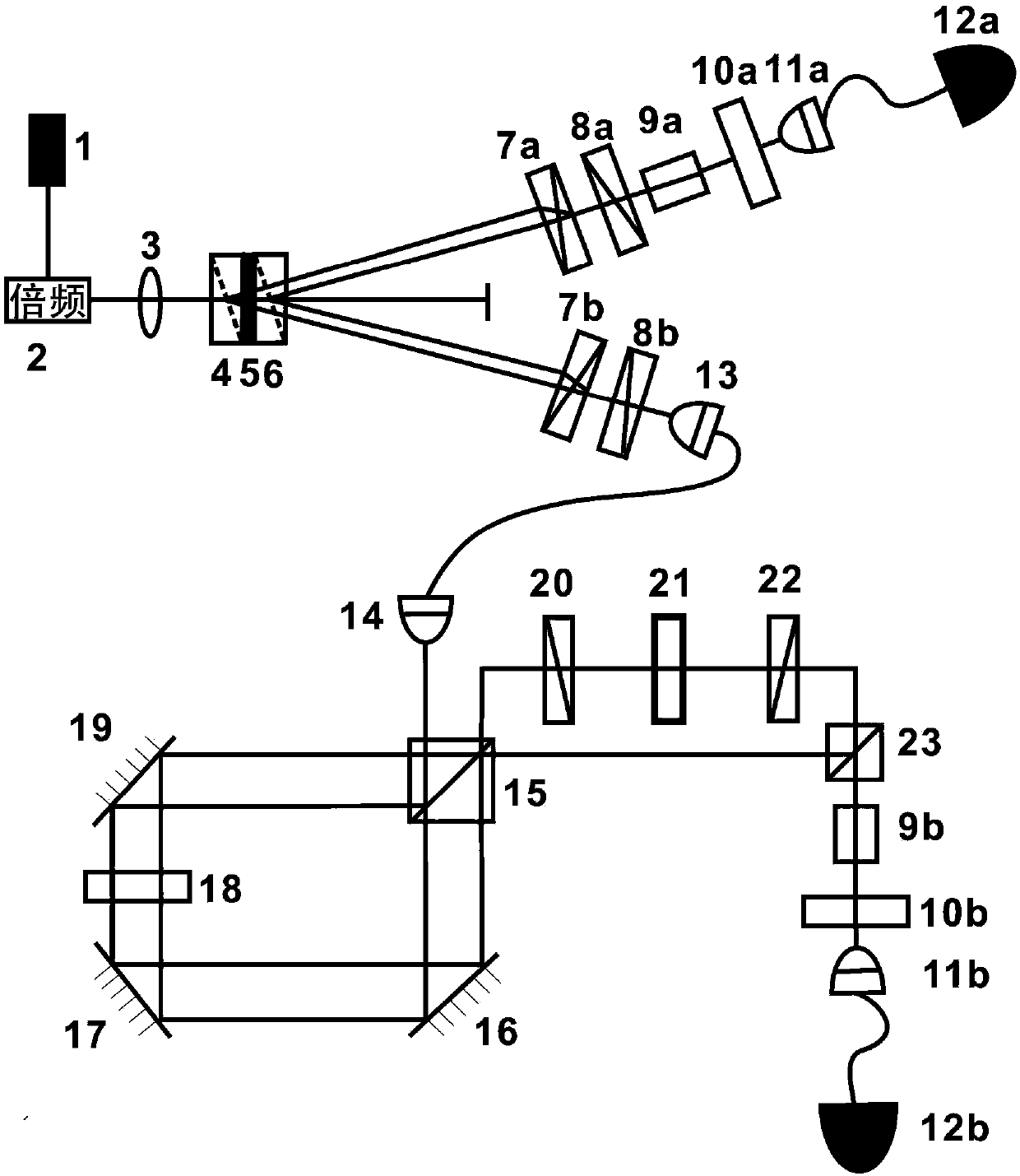

Simple and reliable method for preparing any Werner state

ActiveCN107608158AEasy to adjustHighly integratedNon-linear opticsOptical elementsMixed statesSpontaneous parametric down-conversion

The invention discloses a simple and reliable method for preparing any Werner state, comprising a step of preparing an entanglement light source, in which photon pairs are entangled by using laser topump nonlinear crystals to generate a spontaneous parametric down conversion process, and a step of constructing a controllable depolarized channel, in which a completely mixed state is introduced byacting the controllable depolarized channel on one photon. Sandwich-shaped crystals are adopted for the nonlinear crystals and comprise two BBO crystals and a real zero-order half-wave plate disposedbetween the two BBO crystals. The controllable depolarized channel is composed of a Sagnac ring, a complete destructive phase channel and a state superposition portion, the Sagnac ring is of a rectangular structure, and a half-wave plate is disposed between two reflectors thereof; the complete destructive phase channel is composed of two destructive phase crystals and a half-wave plate therebetween; and the state superposition portion comprises a BS. The simple and reliable method is convenient to adjust and high in feasibility, and can be applied to the fields of quantum information processing and quantum communication.

Owner:NANJING UNIV OF POSTS & TELECOMM

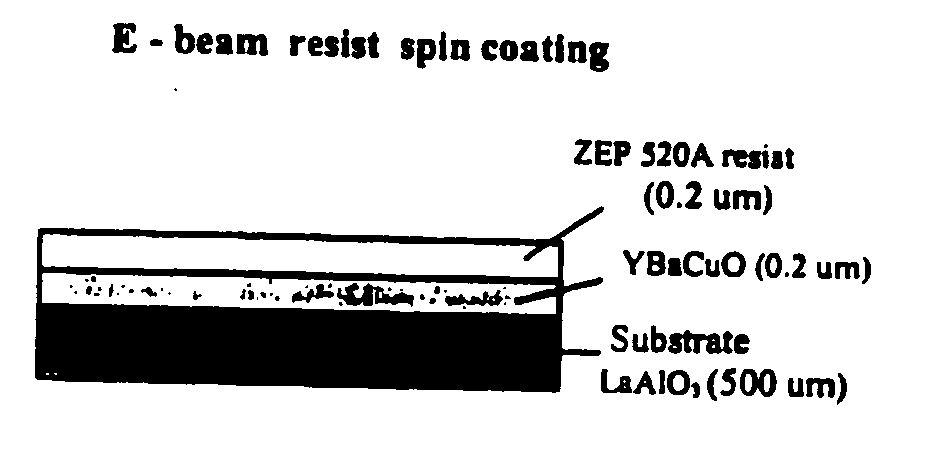

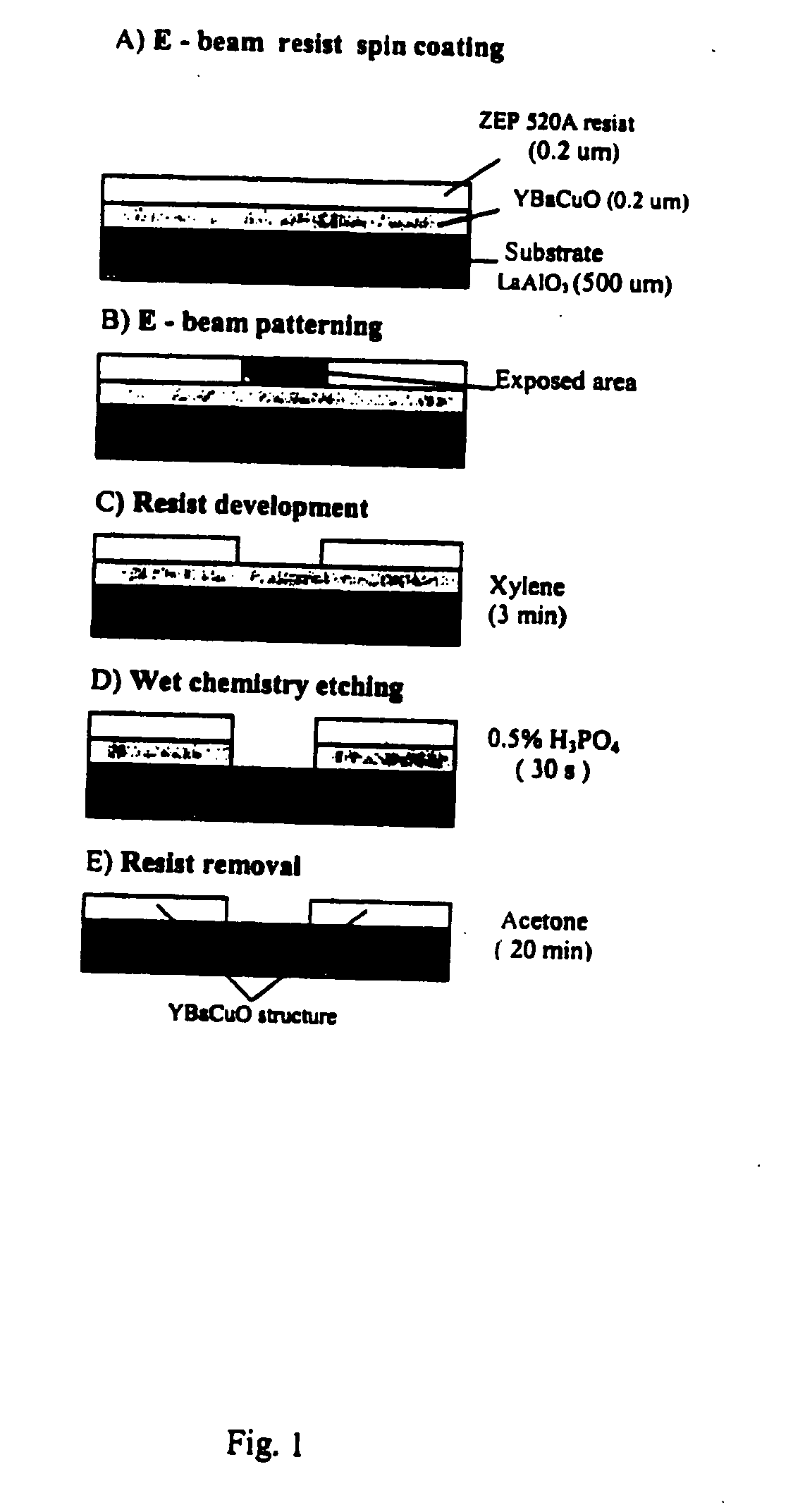

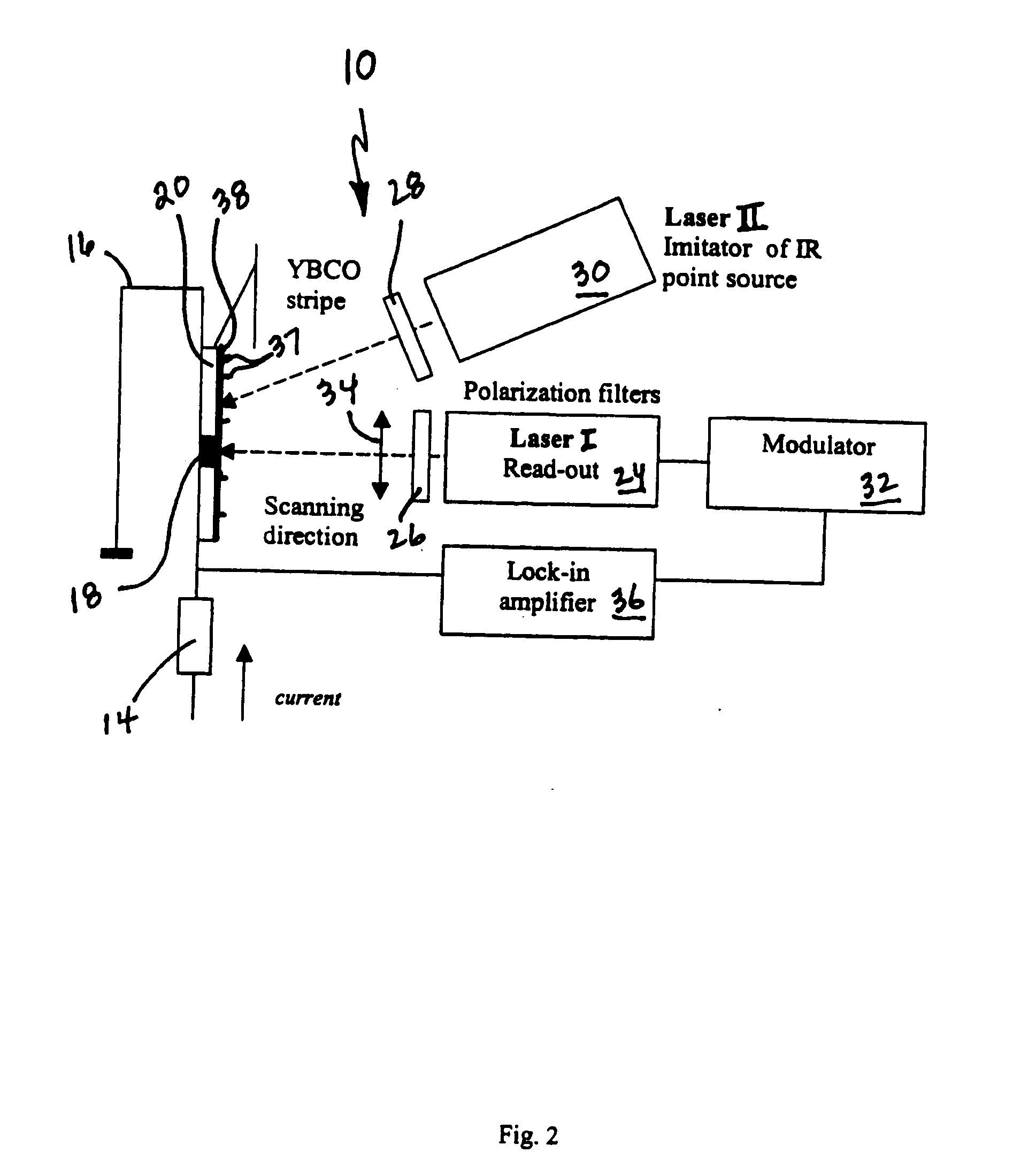

Method for detection and imaging over a broad spectral range

InactiveUS20060058196A1Wide spectral rangeLow costSuperconductors/hyperconductorsSemiconductor/solid-state device detailsEtchingTwo dimensional detector

A method of controlling the coordinate sensitivity in a superconducting microbolometer employs localized light, heating or magnetic field effects to form normal or mixed state regions on a superconducting film and to control the spatial location. Electron beam lithography and wet chemical etching were applied as pattern transfer processes in epitaxial Y—Ba—Cu—O films. Two different sensor designs were tested: (i) a 3 millimeter long and 40 micrometer wide stripe and (ii) a 1.25 millimeters long, and 50 micron wide meandering-like structure. Scanning the laser beam along the stripe leads to physical displacement of the sensitive area, and, therefore, may be used as a basis for imaging over a broad spectral range. Forming the superconducting film as a meandering structure provides the equivalent of a two-dimensional detector array. Advantages of this approach are simplicity of detector fabrication, and simplicity of the read-out process requiring only two electrical terminals.

Owner:UCHICAGO ARGONNE LLC +1

Liquid crystal display device and manufacturing method therefor

A liquid crystal display device (100) according to the present invention includes a vertical alignment type liquid crystal layer (3); and a pair of optical alignment films (12, 22). A plurality of picture elements (R, G, B, Y) each include four liquid crystal domains (D1 through D4) in which tilt directions of liquid crystal molecules when a voltage is applied are different. The four liquid crystal domains are located in a matrix of 2 rows 2 columns. The pair of optical alignment films have such an alignment regulation force that causes an identical alignment pattern to appear in repetition in the liquid crystal layer along a first direction which is parallel to one of a row direction and a column direction, with 2n pixels (n is an integer of 1 or greater) being a minimum unit. In the 2n pixels which form the repeat unit of alignment pattern, there are first picture elements and second picture elements in a mixed state, the first picture elements each including the four liquid crystal domains located in a first order, and the second picture elements each including the four liquid crystal domains located in a second order which is different from the first order. According to the present invention, when the 4D-RTN mode is adopted for a liquid crystal display device in which one pixel includes a picture element having a different size from that of another picture element, increase of the cost and the time which are required for optical alignment processing can be suppressed.

Owner:SHARP KK

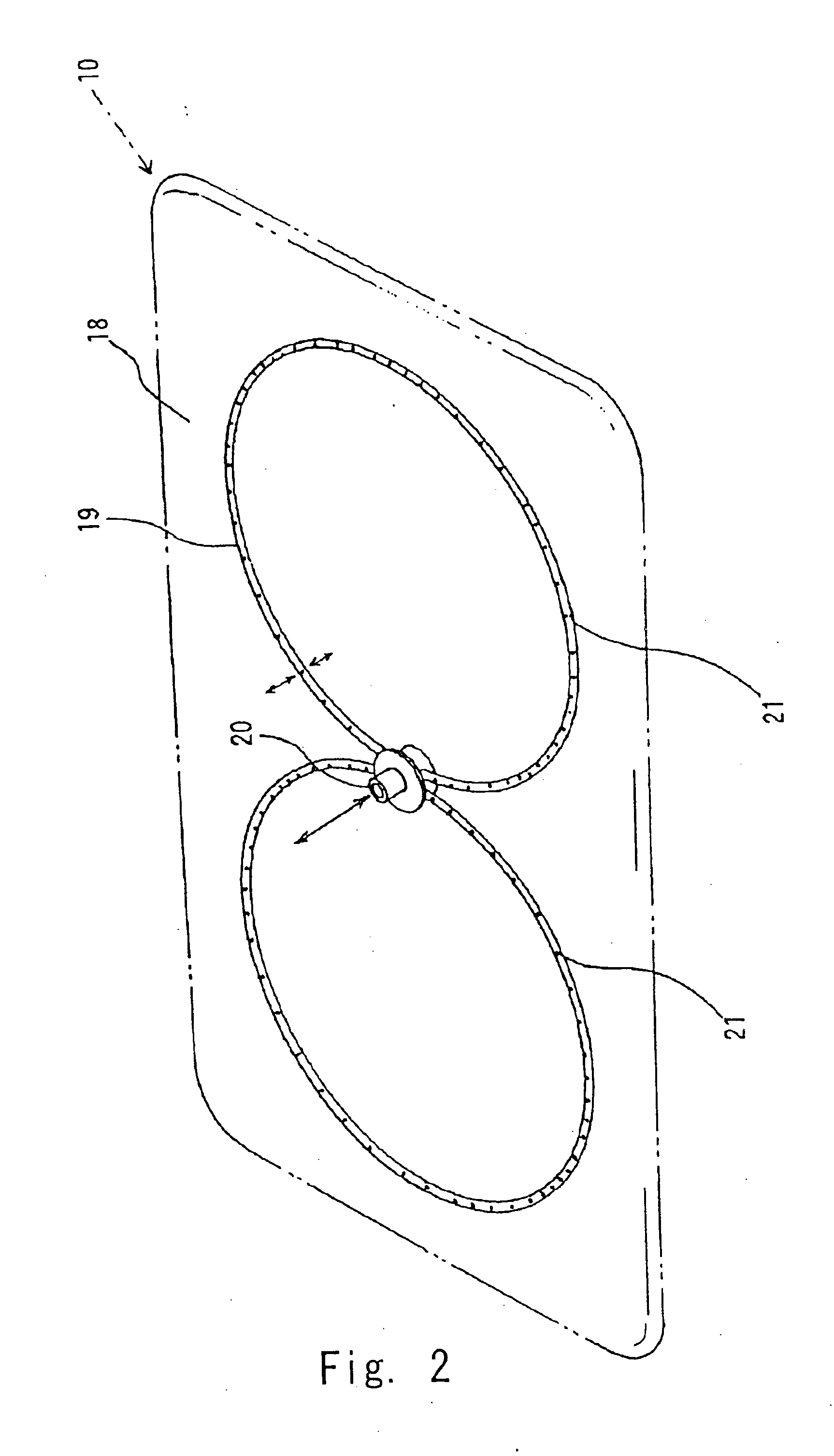

Cleaning equipment and use thereof

InactiveUS7507298B2Limited amountMountingTank vesselsHollow article cleaningMixed statesReady to use

By constructing tank cleaning equipment according to the invention such that it comprises a cleaning jetting part (7, 9) as well as a suction part (4), the equipment can work with the same cleaning medium which is recirculated. This saves supply of fresh cleaning medium, and since used medium is thus not discharged, it is not necessary to establish deposit facilities to avoid pollution. Furthermore, this equipment according to the invention may advantageously be used for keeping so-called drilling mud in a mixed and thus ready-to-use state, even when left to stand for an extended period of time in a tank. The nozzle jets (10) thus keep the mud in the tank in a constantly mixed state, and the mud can therefore be sucked through the suction pipe (20) for pumping in the drill pipe, it being ensured that the mud is homogeneous and has a suitable viscosity.

Owner:ALFA LAVAL TANK EQUIP

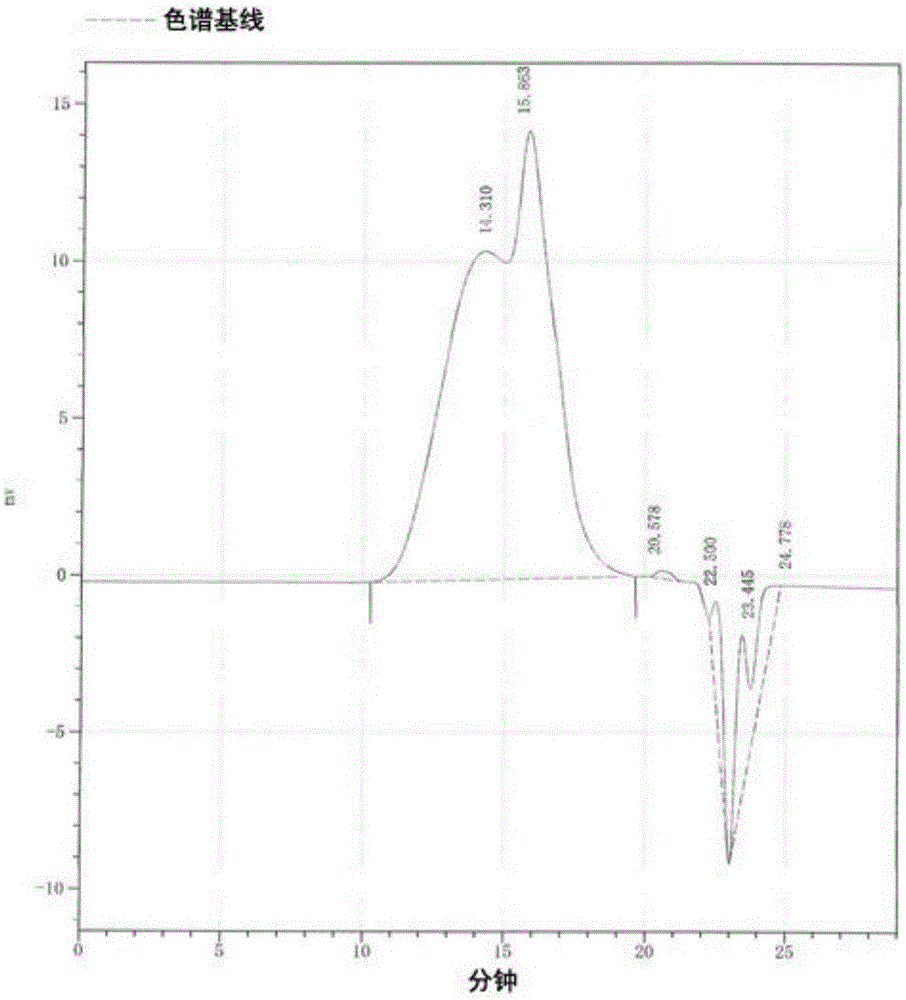

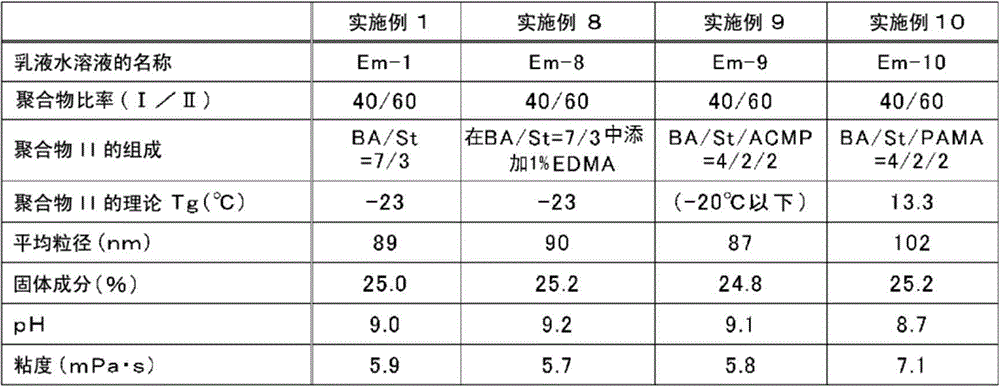

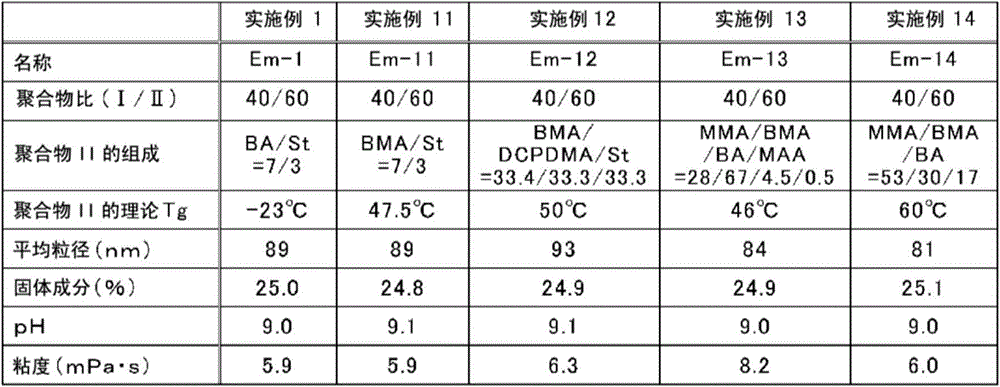

Aqueous emulsion solution, coloring agent composition containing said aqueous solution, aqueous inkjet ink, and method for producing aqueous emulsion solution

Provided is a novel aqueous emulsion solution that can be formed into a binder for coating film formation purposes which is suitable for an inkjet printing mode. An aqueous emulsion solution comprising a polymer (I) and a polymer (II) in a mixed state, wherein the polymer (I) is an A-B block copolymer containing 90% or more of a methacrylate monomer and is neutralized with an alkali agent, the chain A is substantially insoluble in water and has a number average molecular weight of 1000 to 10000 and a dispersion degree of 1.5 or less, the chain B is synthesized using a monomer containing methacrylic acid and has an acid value of 30 to 250 mgKOH / g, the A-B block copolymer has a number average molecular weight of 5000 to 20000, a chain A content of 5 to 60% and an entire dispersion degree of 1.6 or less, the polymer (II) is produced by polymerizing a hydrophobic addition-polymerizable monomer and has a Tg value of 70˚C or lower, and the ratio of the amount of the polymer (I) to the amount of the polymer (II) is (5 to 80):(95 to 20) by mass.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

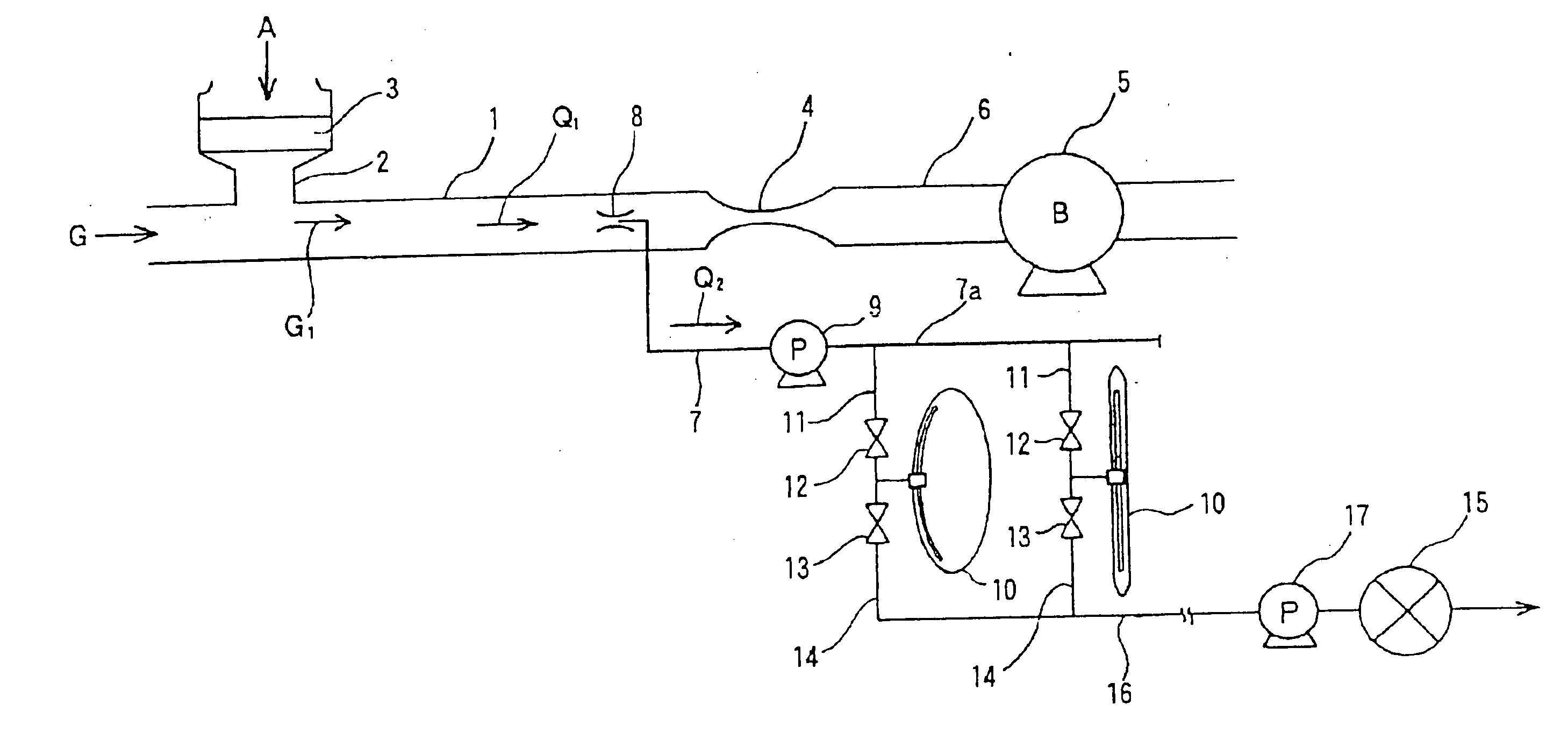

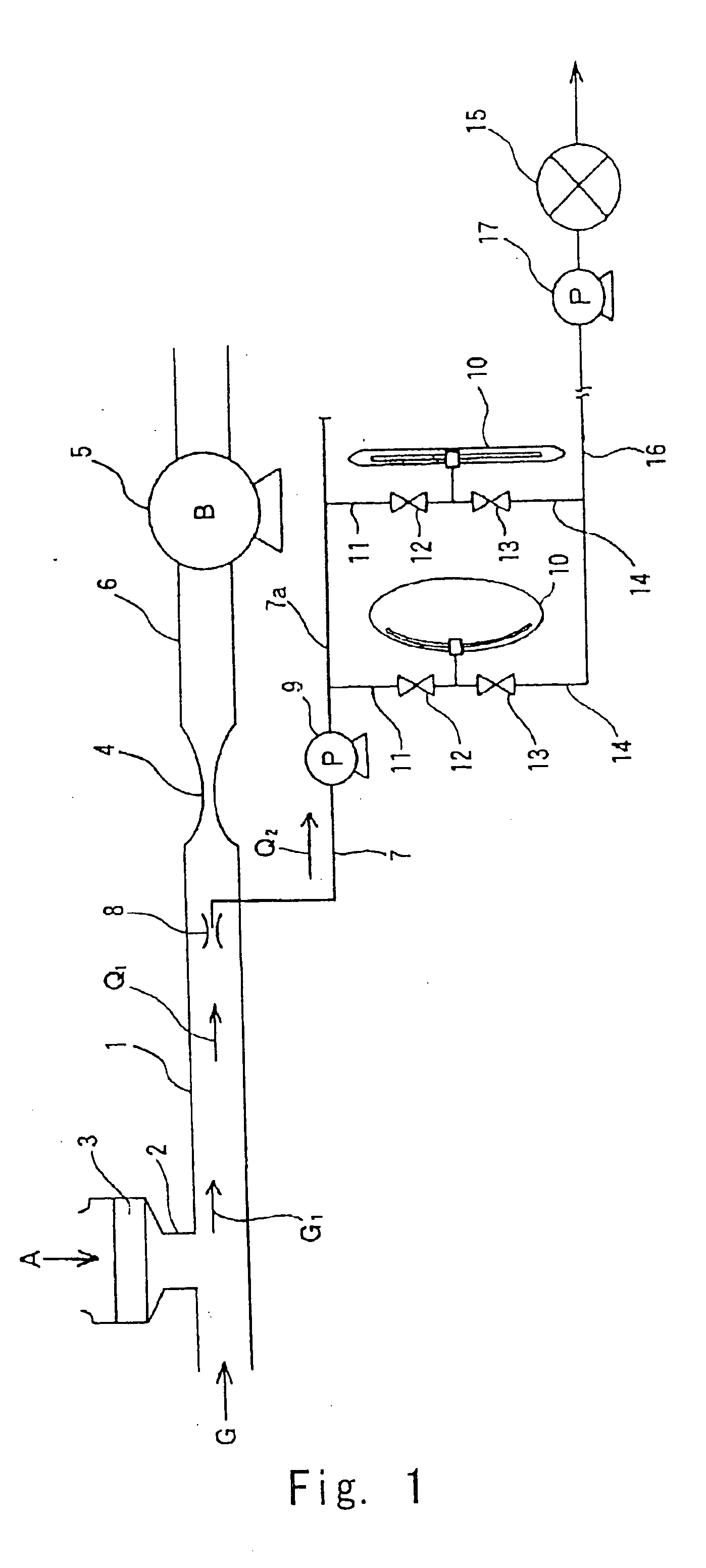

Gas sampling bag

ActiveUS20050056103A1Suppress pressure lossIncrease flow rateWithdrawing sample devicesProduct gasEngineering

A gas sampling bag is capable of blowing out the gas uniformly into the bag main body, and filling the bag main body with gas in a securely mixed state. A gas sampling bag that is connected to a constant volume sampling passage, contains a pipe, on which a plurality of gas inlet / outlet holes are formed, in a bag main body, and allows the gas to flow into / out of the bag main body through the gas inlet / outlet holes. The opening of the plurality of gas inlet / outlet holes is formed in such a manner that the size is minimized while the pressure loss is suppressed so as not to increase as far as possible.

Owner:HORIBA LTD

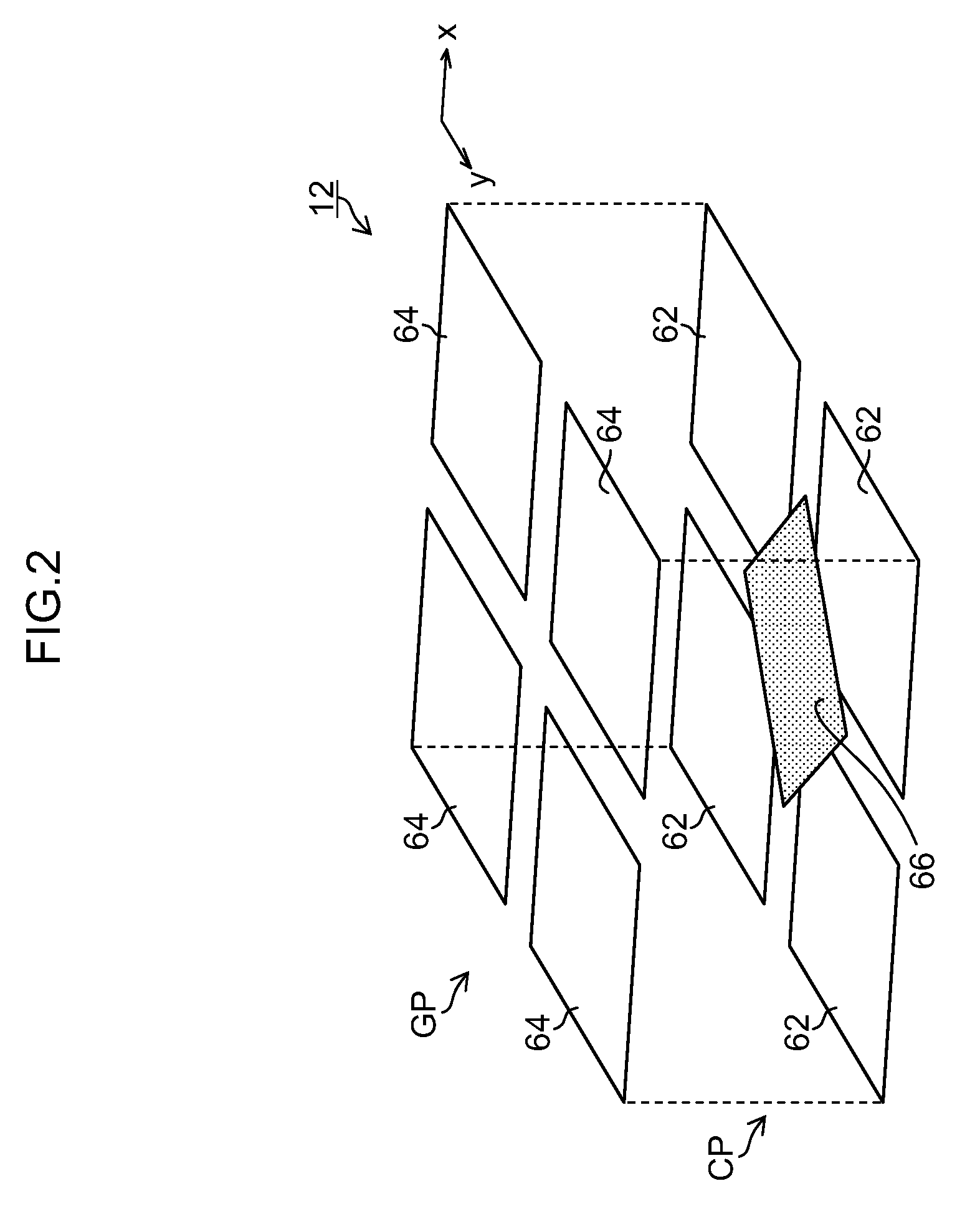

Image pickup apparatus, image pickup element, and method for correcting sensitivity difference

InactiveUS8810697B2Improve accuracySufficient color reproducibilityTelevision system detailsTelevision system scanning detailsSquare arrayDigital signal processing

In an image pickup element, basic array patterns are repeatedly arranged in a horizontal direction and a vertical direction, each of the basic array patterns being made of I×J color filters, the color filters of each of three or more colors being arrayed in a mixed state, an arrangement cycle (I×J) of a basic array pattern is different from an arrangement cycle (2×2) of a sharing configuration pattern, the basic array pattern includes at least one same-color square array pattern which is made of 2×2 color filters of a same color respectively arranged on the 2×2 pixels of the sharing configuration pattern, a characteristic information storage unit stores information on sensitivity calculated from output values of the 2×2 pixels, and a control unit and a digital signal processing unit correct a sensitivity difference between all the pixels of the image pickup element with use of the information on the sensitivity.

Owner:FUJIFILM CORP

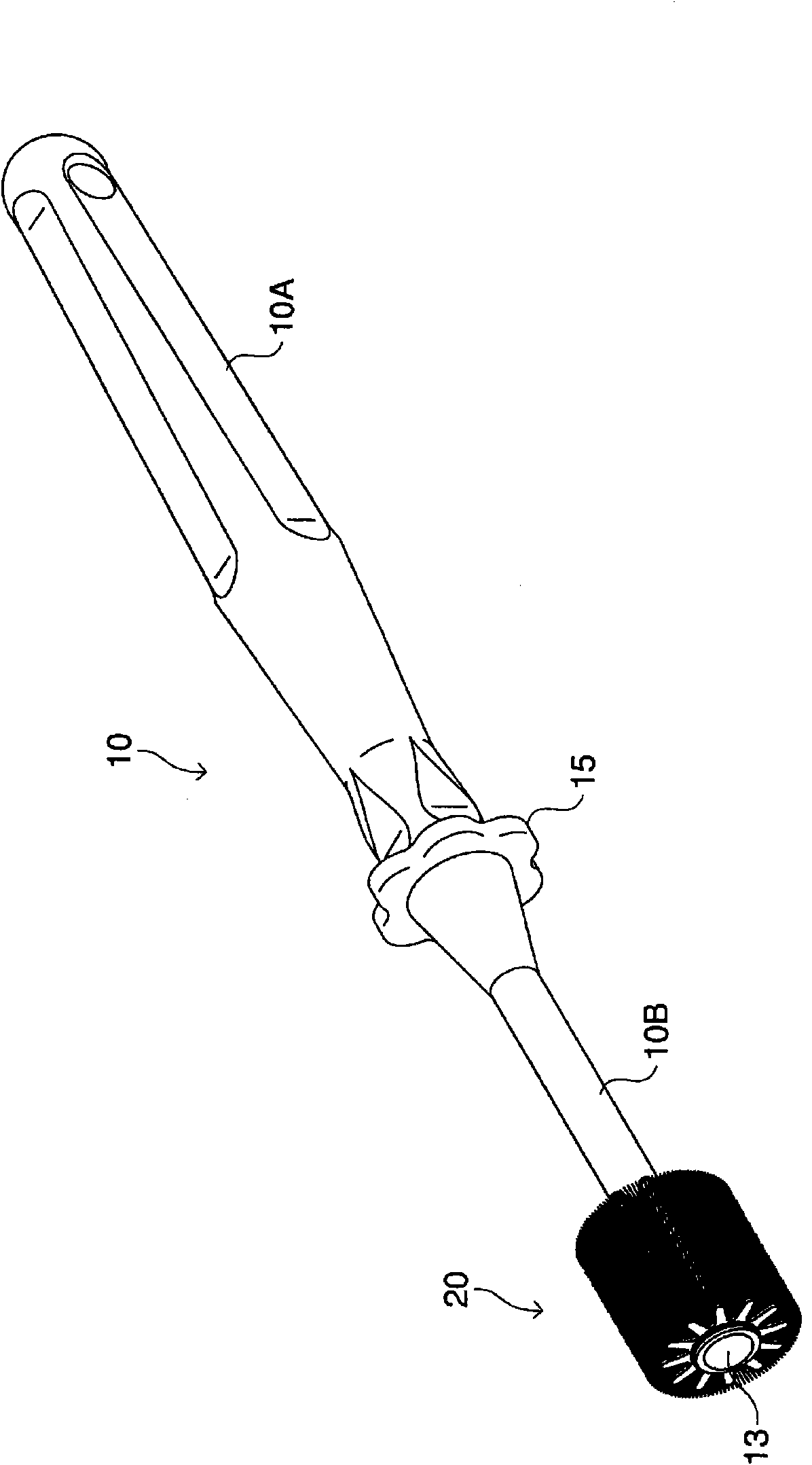

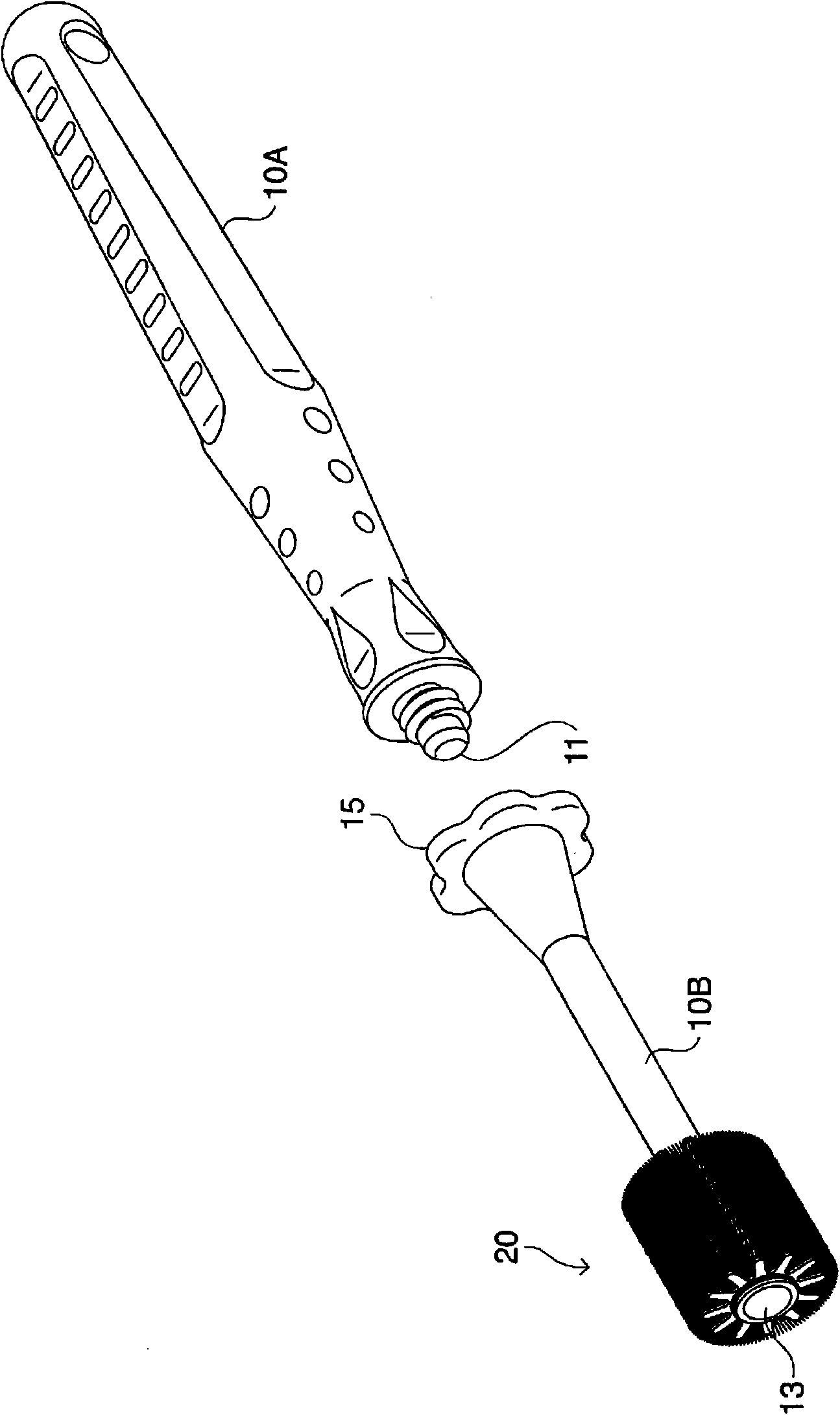

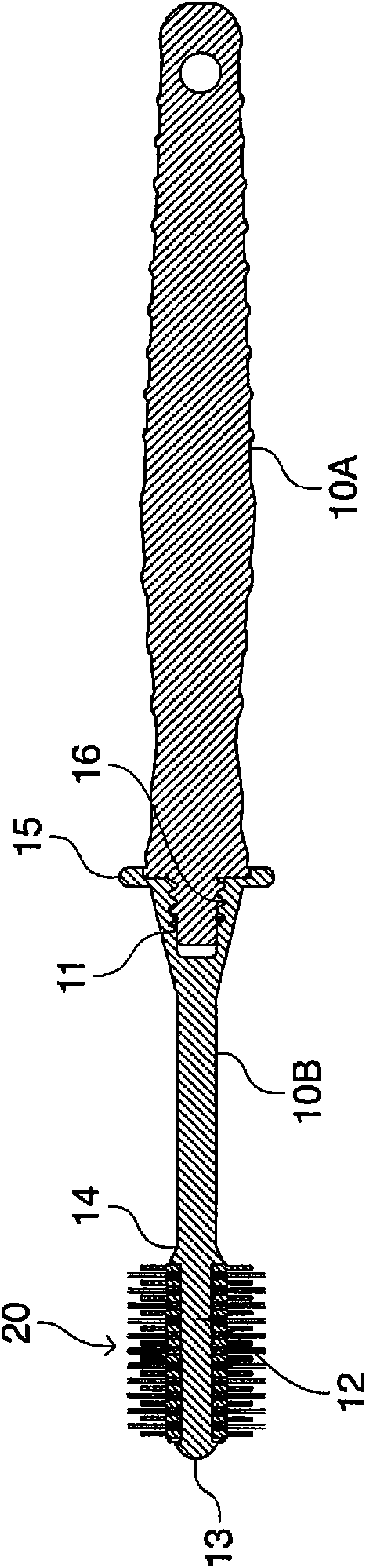

Circular tubular toothbrush

A circular tubular toothbrush having bristles implanted with an appropriate implant density distribution in the direction of the axis of a handle. The structure allows a user to comfortably use the toothbrush and provides the toothbrush with excellent massage performance in addition to excellent brushing performance. A circular tubular brush head (20) provided to the front end of a handle (10) has a hybrid structure in which hard round brush elements (20A) and soft round brush elements (20B) are arranged in the axial direction in a mixed state. The hard round brush elements (20A) each consist of a large number of nylon threads used for the bristles of toothbrushes and are each formed as a thin radial blade in which the nylon threads project radially outward. The soft round brush elements (20B) are each formed as an integral part consisting of an SEBS resin used for toothpicks etc. and each have a petaline shape in which tongue-shaped planar projections project radially outward.

Owner:NARUTOYA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com