Mixed fluid uniformization device and mixed fluid feeding apparatus

A technology for mixing fluids and supply equipment, which is applied in the field of homogenizing devices for mixed fluids, which can solve the problems that the mixer cannot be fully mixed, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

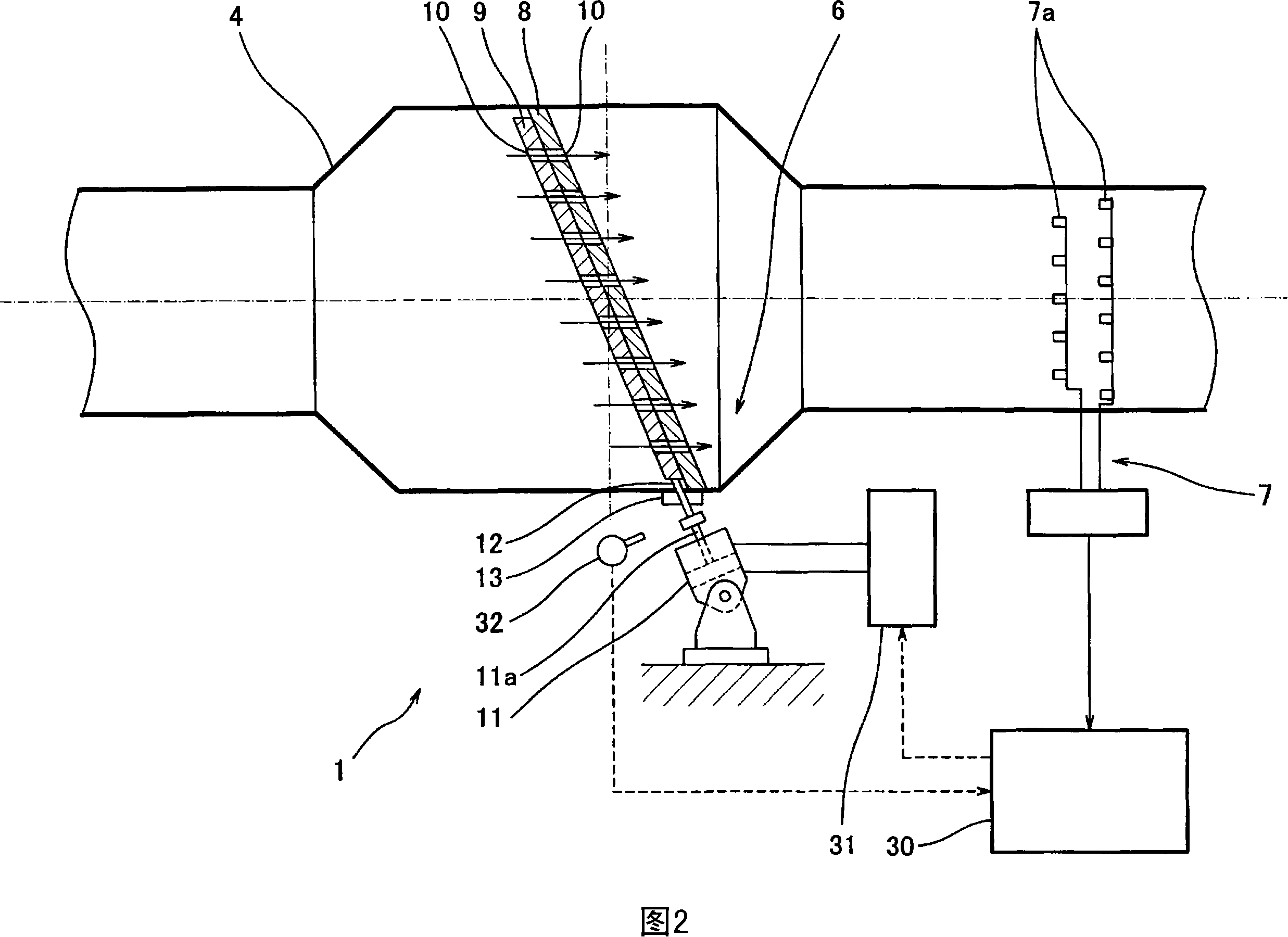

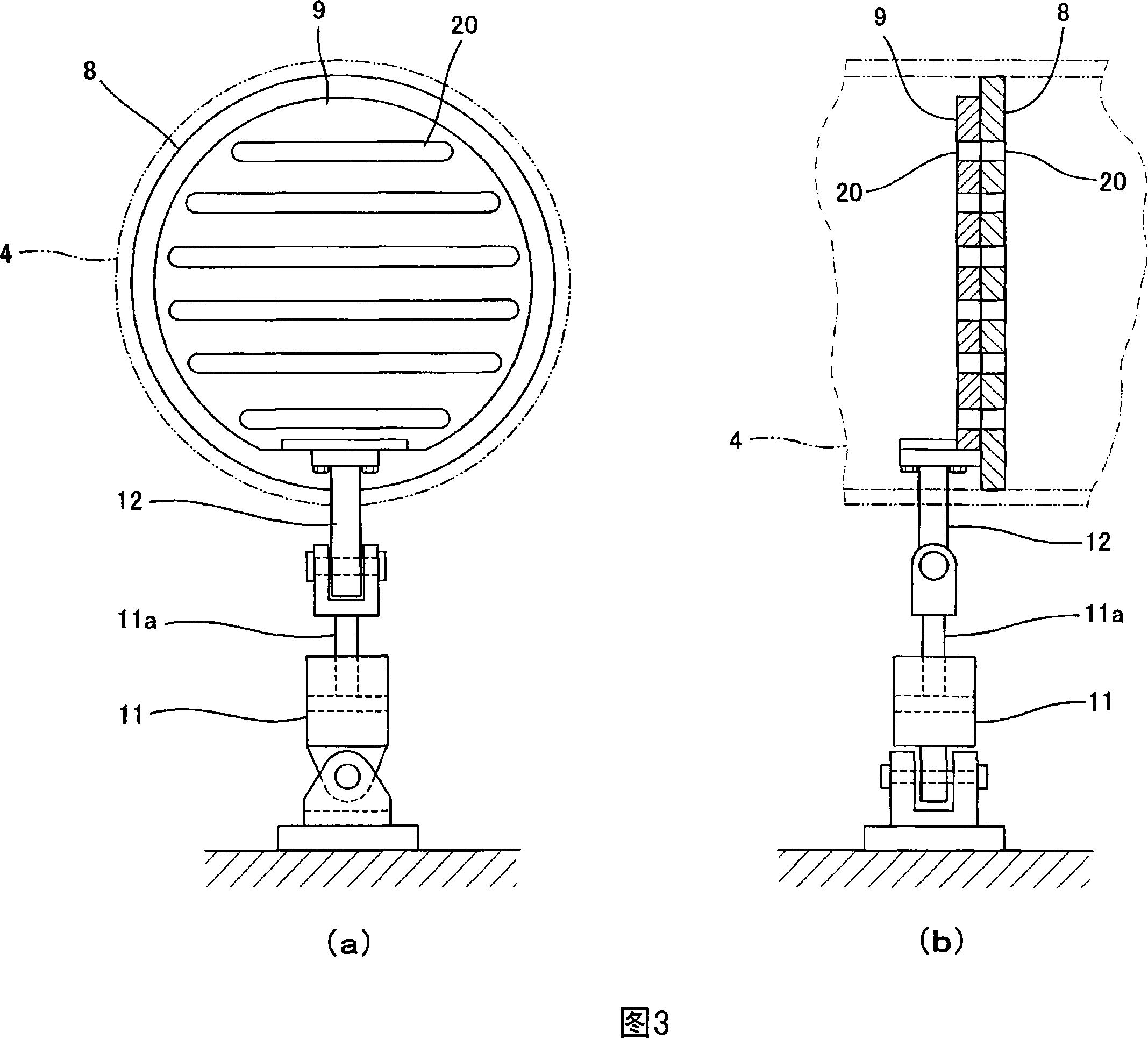

[0089] Next, an embodiment of a mixed fluid homogenizing device and a mixed fluid supply facility including the same according to the present invention will be described with reference to the drawings.

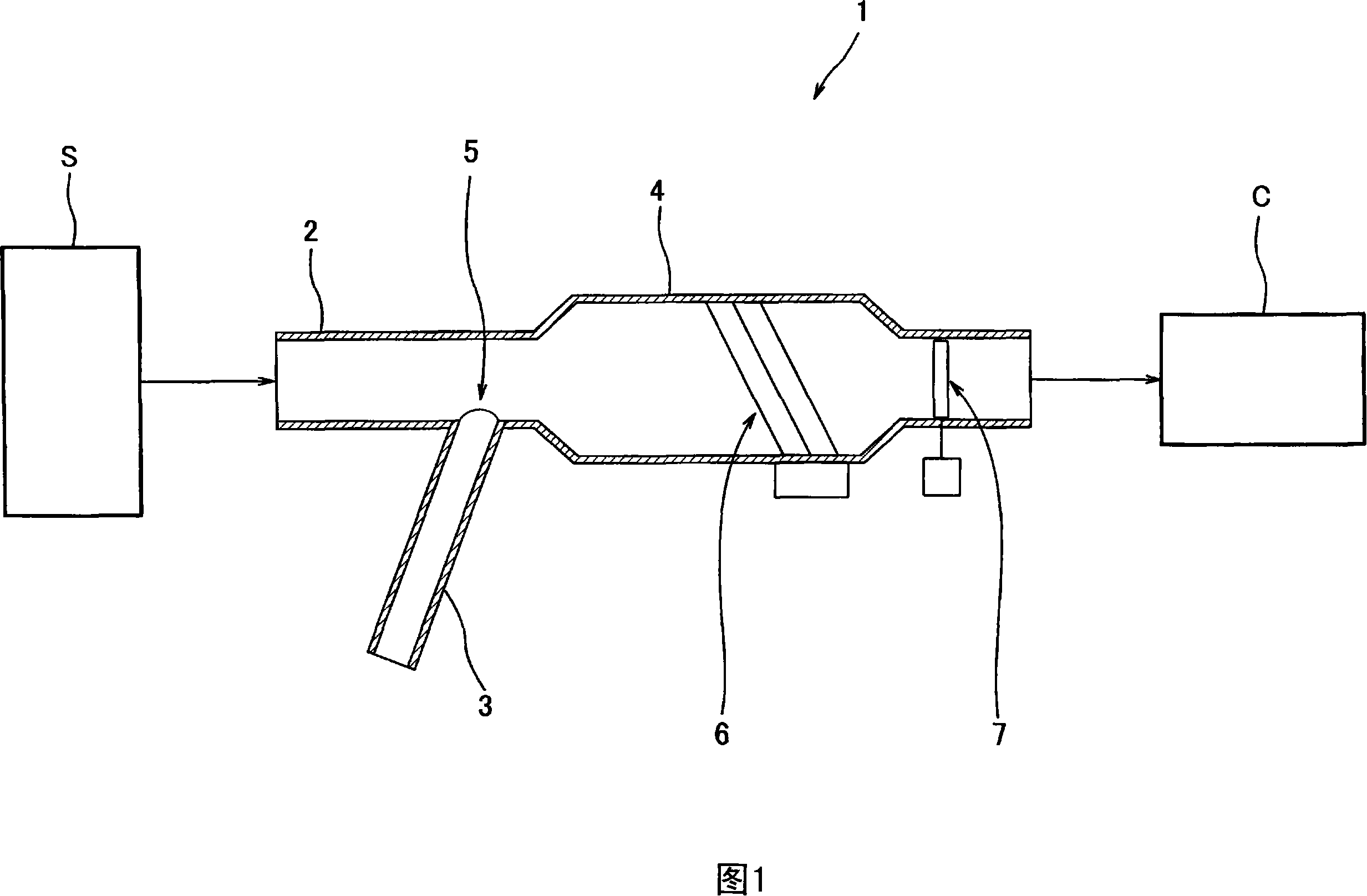

[0090] Fig. 1 is a mixed fluid supply device 1 according to an embodiment of the present invention. As such a supply facility, when using, for example, a by-product gas with fluctuating calorific value generated by a gas supply source S such as a blast furnace or a direct reduction ironmaking facility, as a fuel gas for a gas turbine, there are, for example, various types of by-product gas with different properties. Fuel gas supply equipment supplied after mixing, or fuel gas supply equipment that mixes inert gas as a calorific value reducing gas, or COG as a calorific value increasing gas with these fuel gases. The above-mentioned gas supply source S passes through necessary processing steps including supplying generated gas as fuel, for example, a dust removal step. The flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com