Aqueous emulsion solution, coloring agent composition containing said aqueous solution, aqueous inkjet ink, and method for producing aqueous emulsion solution

A manufacturing method and aqueous solution technology, applied in ink, coating, organic dyes, etc., can solve the problems of inability to achieve resolubility, insolubility, poor redispersibility, etc., and achieve excellent inkjet printing adaptability and simple yield , Improve the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

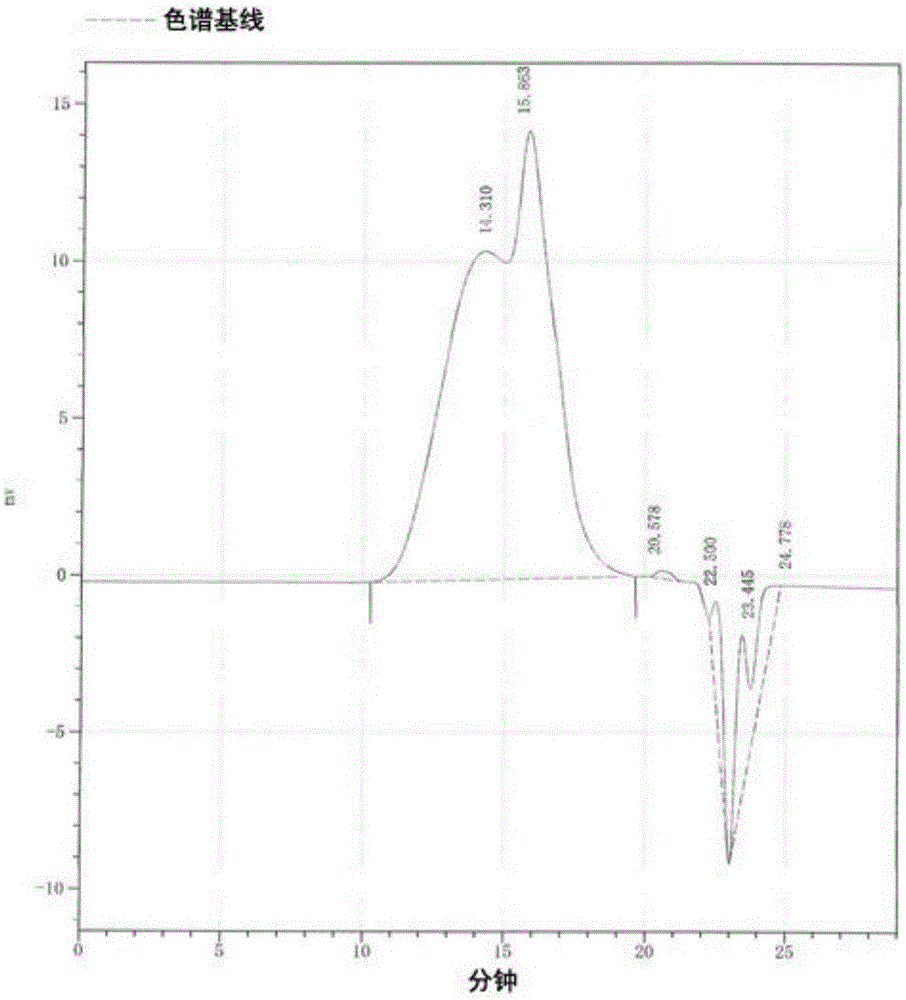

Image

Examples

Embodiment 1

[0135] [Example 1] Synthesis of polymer I-1 and emulsion (Em-1) using it

[0136] [Synthesis of Polymer I-1]

[0137] First, add the following substances to a reaction device of a 2-liter detachable flask equipped with a stirrer, a countercurrent condenser, a thermometer, and a nitrogen gas introduction tube, and proceed as follows to synthesize A-B used to constitute the polymer I specified in the present invention. A polymer block of the block copolymer. Specifically, 828.4 parts of diethylene glycol monobutyl ether (hereinafter abbreviated as BDG) as an organic solvent, 3.8 parts of iodine for obtaining iodide as a polymerization initiating compound, and 2,2'- 14.0 parts of azobis(4-methoxy-2,4-dimethylvaleronitrile) (hereinafter abbreviated as V-70), 0.22 parts of N-iodosuccinimide as a catalyst, and benzyl methacrylate 213.9 parts of ester (hereinafter abbreviated as BzMA) and 19.8 parts of 2-hydroxyethyl methacrylate (hereinafter abbreviated as HEMA) were stirred and h...

Embodiment 2~5

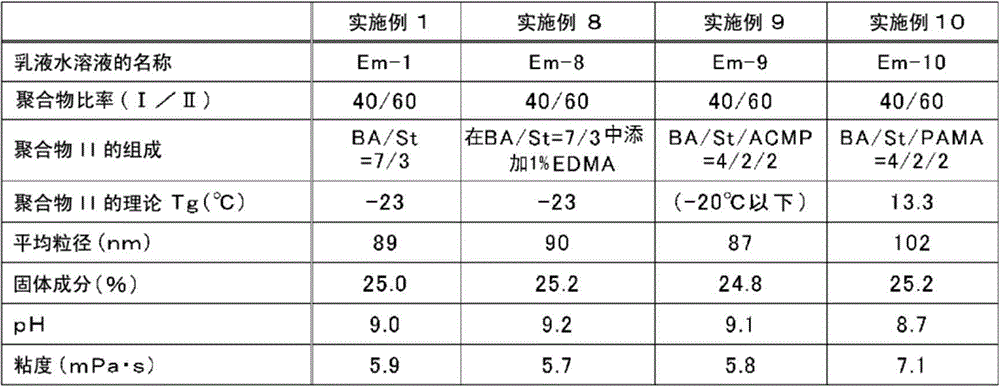

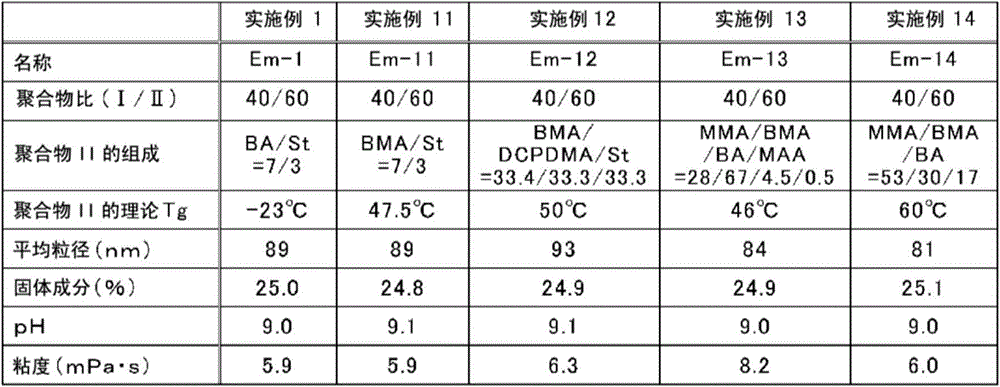

[0148] [Examples 2 to 5] Emulsions using polymer I-1 (Em-2 to Em-5)

[0149] With the respective polymer compositions, compounding amounts, etc., the same operations as in the aforementioned Example 1 were carried out to obtain aqueous emulsion solutions Em-2 to Em-5 of Examples 2 to 5 of the present invention, respectively. Specifically, the ratios of polymer I-1 and polymer II were changed in the manner shown in Table 1 with the ratio of polymer I as the protective colloid and polymer II as the coating component to obtain the examples of the present invention, respectively. 2-5 aqueous emulsion solutions Em-2-Em-5. The properties and the like of these aqueous emulsion solutions were obtained in the same manner as in Example 1, and are summarized in Table 1. In addition, in Table 1, the correlation value of the emulsion aqueous solution Em-1 of Example 1 is shown together.

[0150] Table 1: Properties, etc. of each emulsion aqueous solution

[0151]

[0152] As c...

Embodiment 6、7

[0153] [Example 6, 7] Emulsions (Em-6, Em-7) using polymer I-1

[0154] Except changing the ratio of BA and St, which are the forming components of polymer II, as shown in Table 2, the emulsion aqueous solution Em-6 and Em-7 of the present invention were obtained in the same manner as Em-1 in Example 1. . These examples were used to study the effect of Tg on Polymer II by varying the ratio of BA and St to vary the Tg of Polymer II. In the same manner as in Example 1, properties and the like of these aqueous emulsion solutions were obtained and are shown in Table 2. In addition, in Table 2, the correlation value of the emulsion aqueous solution Em-1 of Example 1 is shown together.

[0155] Table 2: Properties, etc. of each emulsion aqueous solution

[0156]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com