Temperature control method based on phase-transition energy-accumulation material

A temperature control method and phase change energy storage technology, which is applied in the field of temperature control of precision molding product processing devices, to achieve the effects of eliminating temperature rise, solving large fluctuations in temperature changes, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

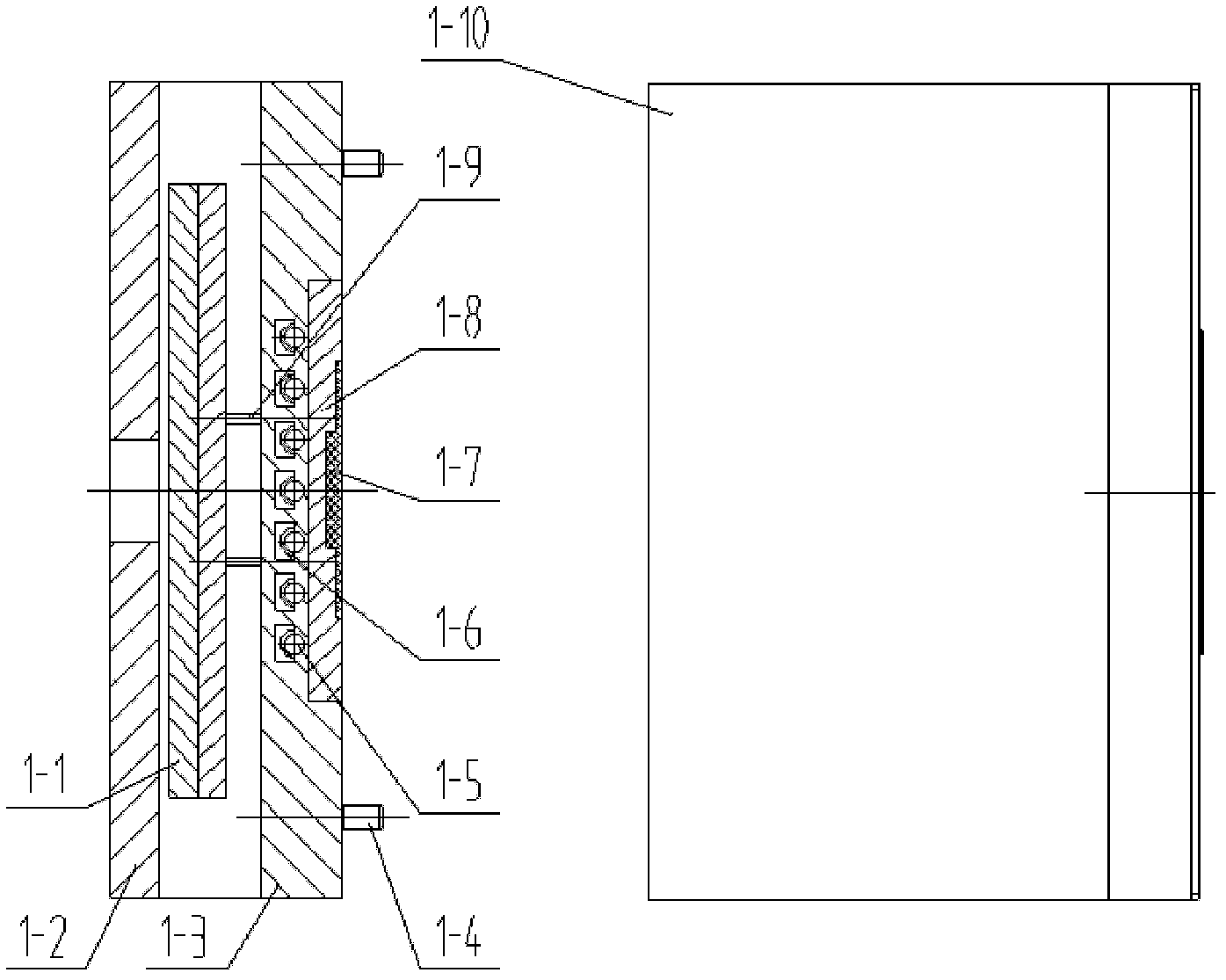

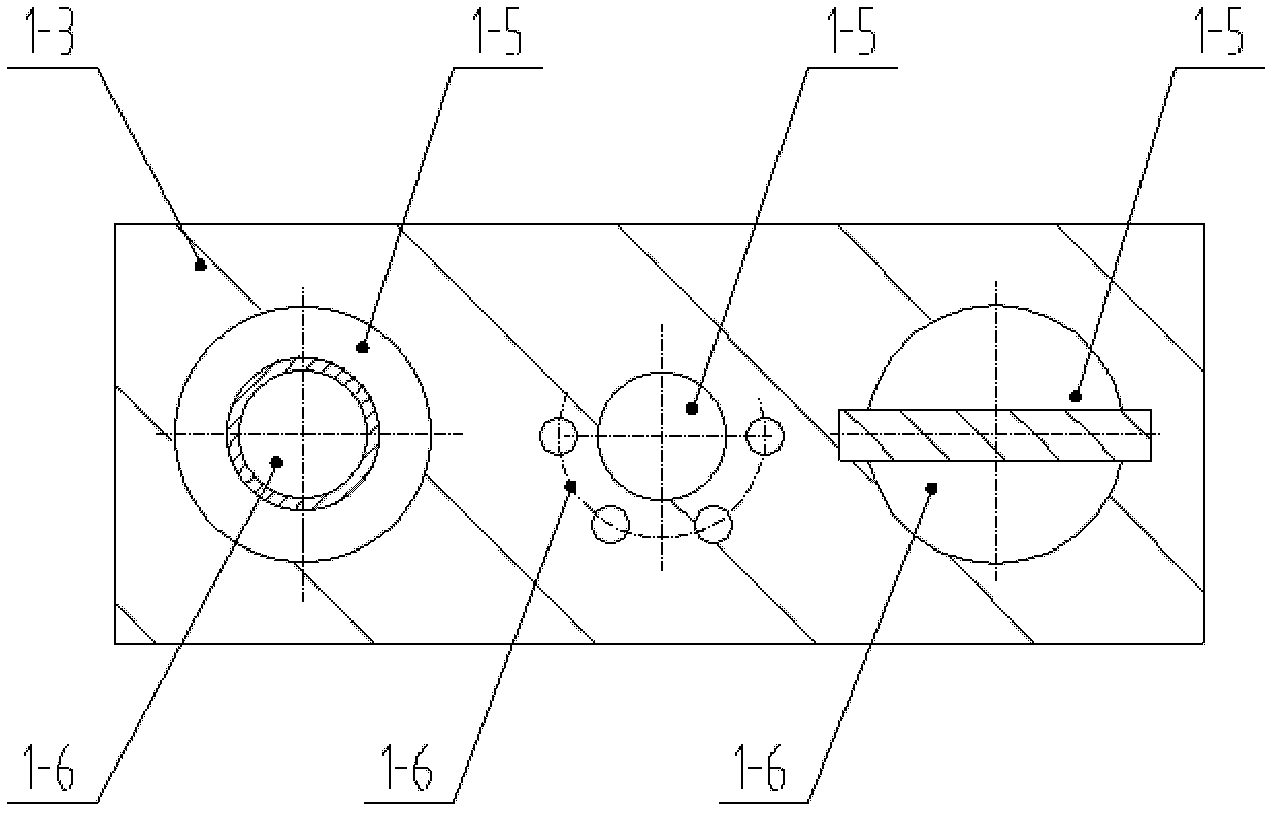

[0022] Such as figure 1 Shown is the precision injection molding method of Embodiment 1 using the temperature control method based on the phase change energy storage material of the present invention. The molding device is mainly composed of an ejector push plate 1-1, a fixed plate 1-2, a movable mold part 1-3, Guide pillar 1-4, phase change energy storage material channel 1-5, circulating cooling water channel 1-6, cavity plate 1-8, ejector pin 1-9, fixed mold part 1-10, ejection push plate 1- 1 is fixedly connected with the thimble 1-9, and can move horizontally to complete the ejection action of the plastic product 1-7; the cavity plate 1-8 is installed on the movable mold part 1-3, and several rear ends of the cavity plate 1-8 are arranged Cooling channels, phase change energy storage material channels 1-5 and circulating cooling water channels 1-6 are arranged in front of and behind, phase change energy storage material channels 1-5 realize cooling and shaping of products...

Embodiment 2

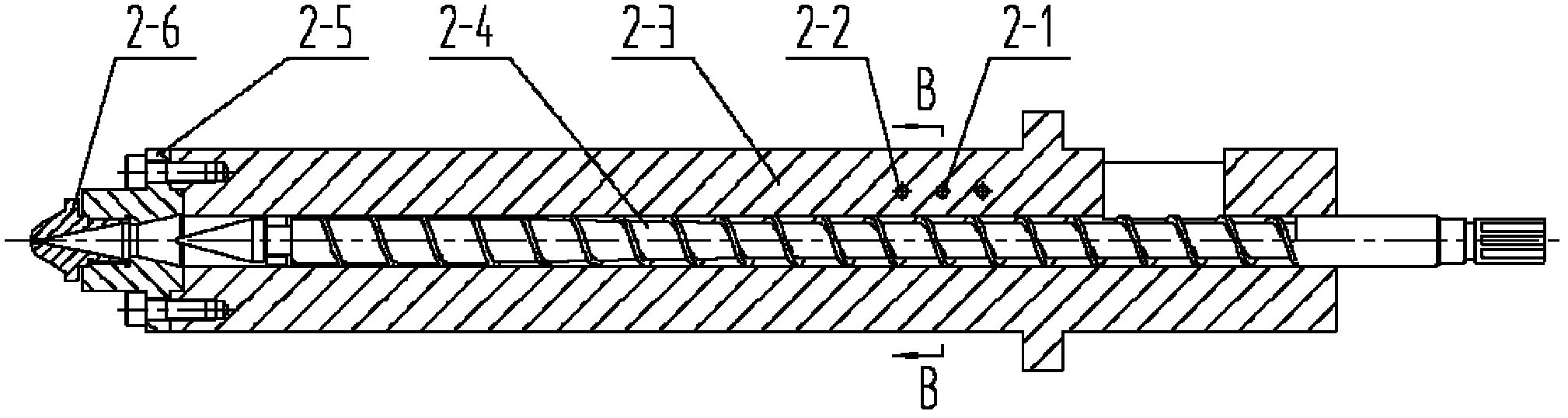

[0033] see image 3 The temperature control method of the present invention based on the phase change energy storage material is used to control the temperature of the feeding barrel of the plasticizing injection device of the injection molding machine. The working principle and effect of this embodiment are basically the same as those of Embodiment 1. The diameter of the hopper near the feeding port of the feeding system of the injection device gradually decreases. If the temperature of the solid conveying area is too high, the material at the bottom of the feeding port will melt under the action of heat transfer, and the material will form a compacted solid, preventing the raw material from entering the plasticizing system. This is The so-called bridging phenomenon. Appropriately increasing the cooling system at the feeding port can effectively solve the bridging phenomenon. Therefore, in this embodiment, the phase change energy storage material channel 2-1 and the circulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com