Liquid crystal display device and manufacturing method therefor

A technology of a liquid crystal display device and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., and can solve the problems of uneven liquid crystal molecular alignment restriction force, reduced light transmittance, and uneven response speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

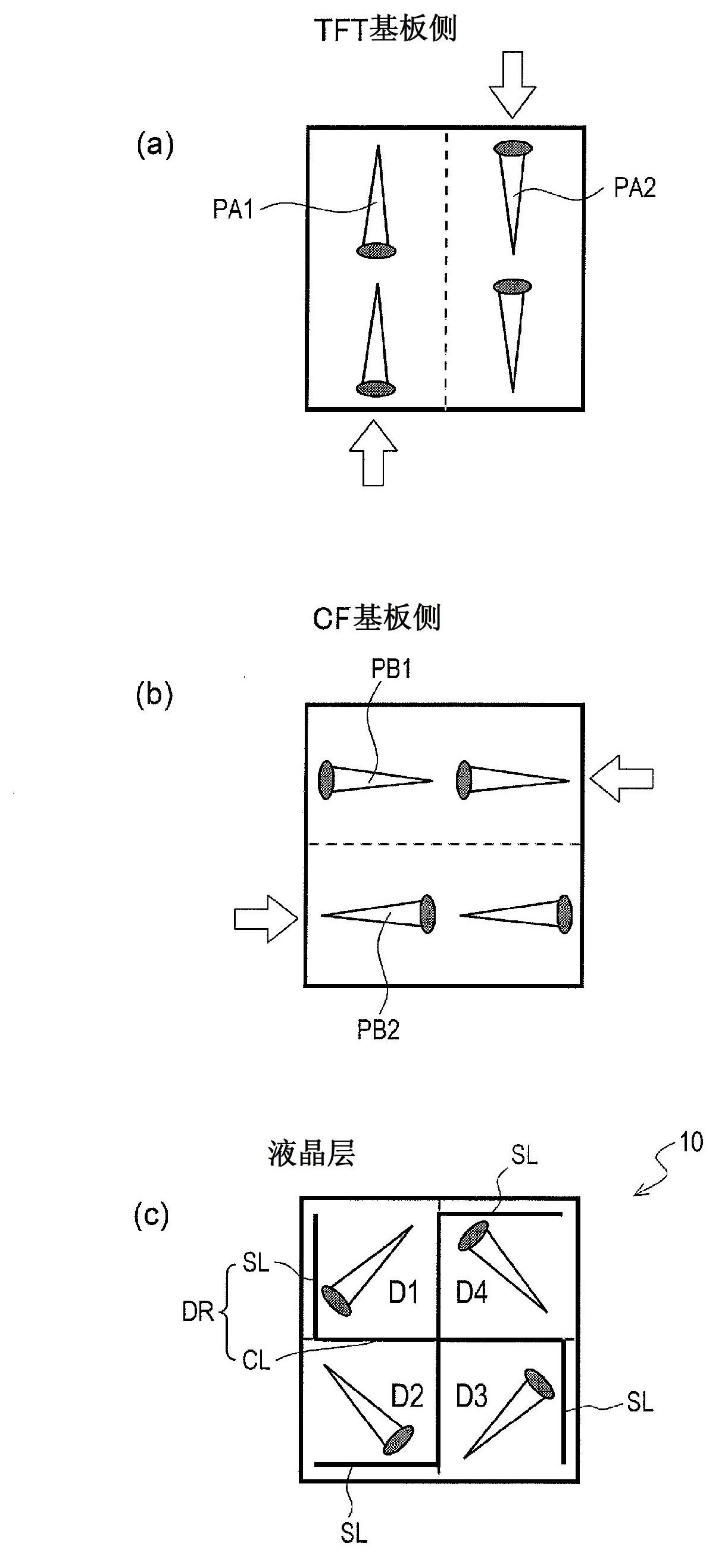

[0162] Before describing the present embodiment, a method for orientationally dividing picture elements in a general 4D-RTN mode and problems in the case of adopting the 4D-RTN mode in a multi-primary-color liquid crystal display device will be described.

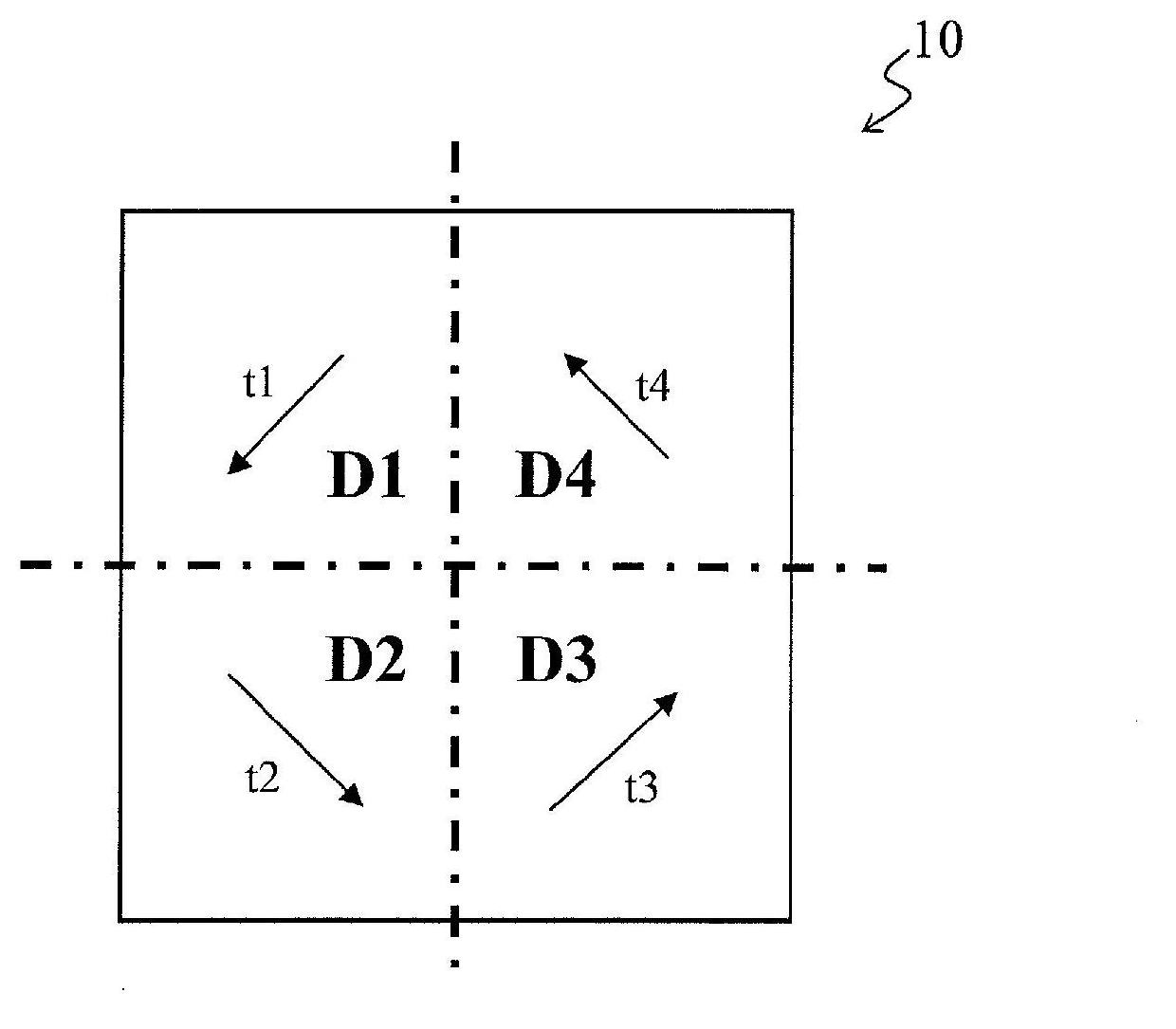

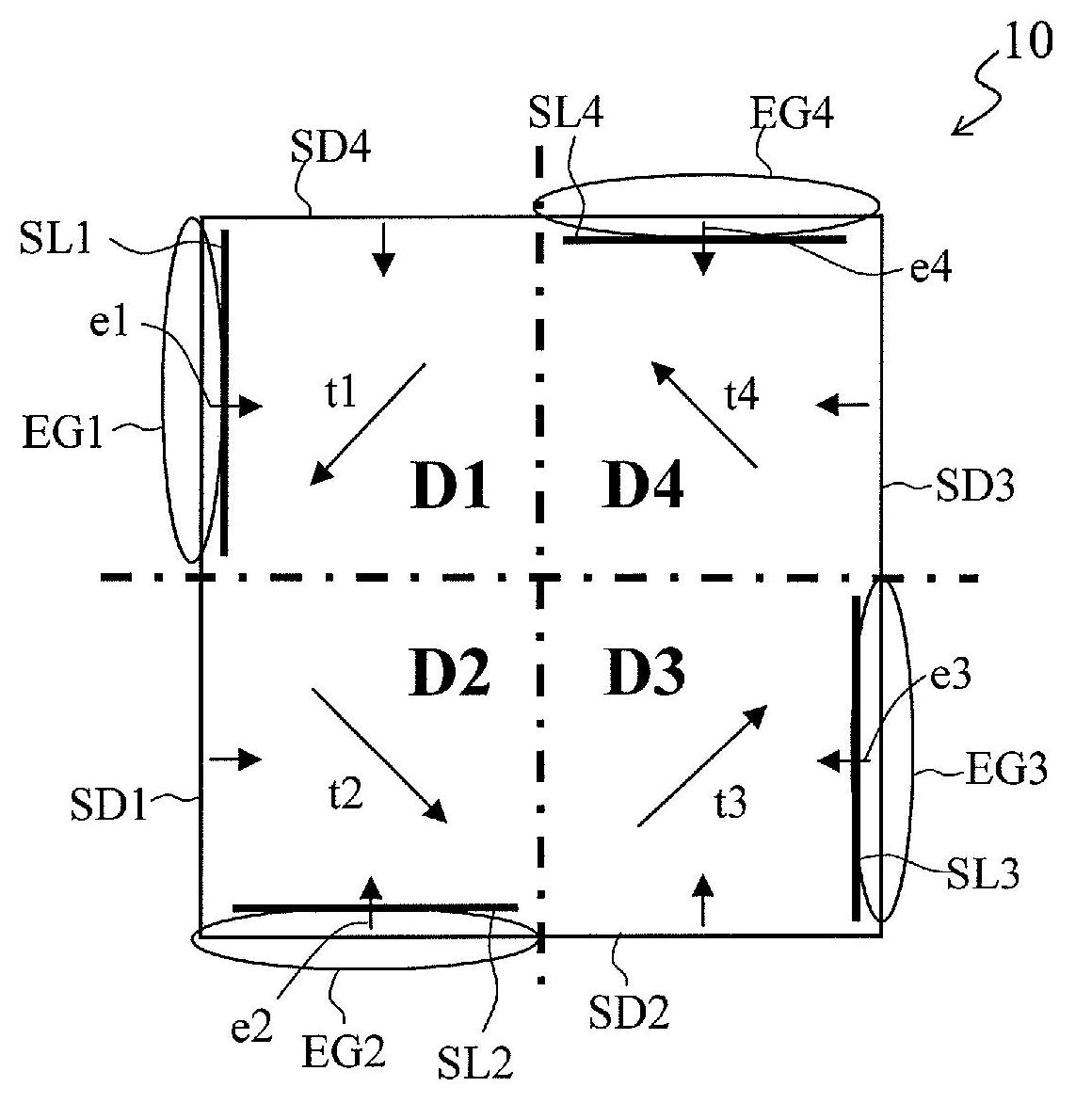

[0163] figure 1 Represents a picture element 10 with a 4-segmented orientation structure (4D structure). Also, for simplicity of illustration, figure 1 A substantially square picture element 10 corresponding to a substantially square picture element electrode is shown, but the shape of the picture element is not limited. For example, the image element 10 may be substantially rectangular.

[0164] like figure 1 As shown, the picture element 10 has four liquid crystal domains D1, D2, D3 and D4. exist figure 1 Among them, the areas of the liquid crystal domains D1, D2, D3 and D4 are equal to each other, figure 1 The illustrated example is an example of the most preferable 4D structure in view angle characteristics. ...

Embodiment approach 2

[0275] exist Figure 44 In , the liquid crystal display device 200 in this embodiment is shown. Figure 44 (a) and (b) are plan views schematically showing four pixels P continuous in the row direction of each liquid crystal display device 200 .

[0276] like Figure 44As shown in (a) and (b), it is defined that the lengths of the four picture elements of each pixel P in the row direction are all different. Specifically, the length L1 of the red image element R along the row direction, the length L2 of the blue image element B along the row direction, the length L3 of the yellow image element Y along the row direction, and the length of the green pixel G along the row direction L4 is from large to small in this order (ie L1>L2>L3>L4). In contrast, the lengths in the column direction of all the picture elements are the same length L5. In this way, in the pixel P of the liquid crystal display device 200 of the present embodiment, there is one type of length of picture elemen...

Embodiment approach 3

[0305] Figure 51 The liquid crystal display device 300 in this embodiment is shown. Figure 51 It is a plan view schematically showing six pixels P continuous in the row direction of the liquid crystal display device 300 .

[0306] like Figure 51 As shown in , it is specified that the lengths along the row direction of the four picture elements of each pixel P are all different. Specifically, the length L1 of the red image element R along the row direction, the length L2 of the blue image element B along the row direction, the length L3 of the yellow image element Y along the row direction, and the length of the green pixel G along the row direction L4 is from large to small in this order (ie L1>L2>L3>L4). In contrast, the lengths in the column direction of all the picture elements are the same length L5. In this way, in the pixel P of the liquid crystal display device 300 of the present embodiment, there is one type of length of picture elements in the column direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com