Preparation method of modified silicon dioxide obtained via super-hydrophobic modification

A technology of superhydrophobic modification and silicon dioxide, which is applied in the field of coatings, can solve the problems of inability to meet the continuous requirements of industrialized large-scale production, many processing procedures, and high energy consumption, and achieve extinction performance, high purity, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

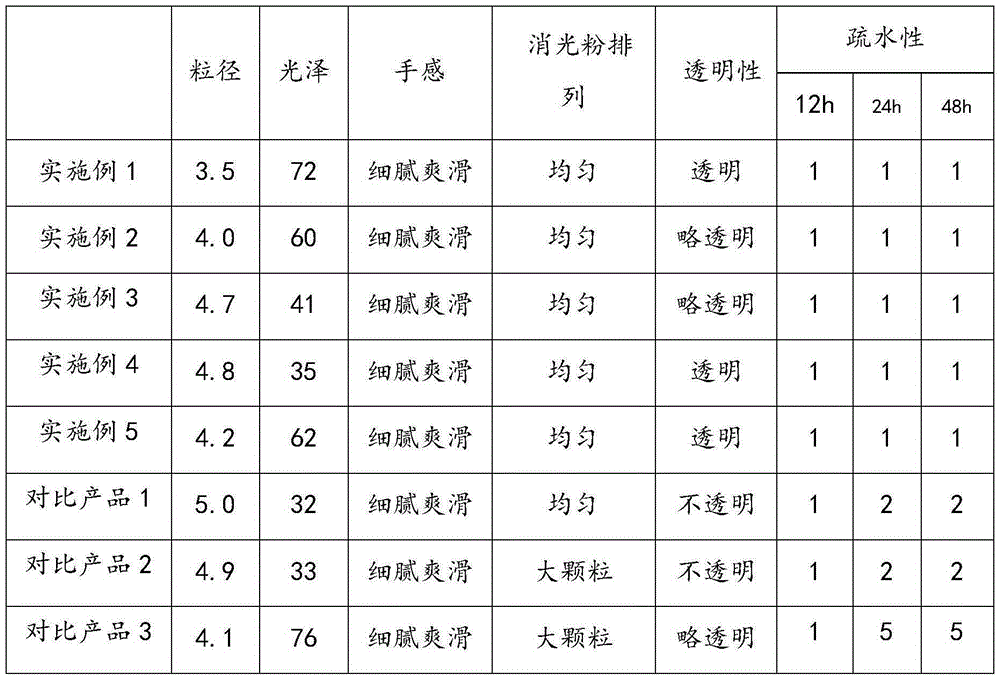

Examples

preparation example Construction

[0038] The present invention mainly adopts the silica substrate in dry powder state to carry out the hydrophobic modification operation. The preparation method of superhydrophobic modified silica includes:

[0039] (1) Raw materials:

[0040] Raw material A: Silica base material, in dry powder state; the silica base material can be precipitation silica, gel silica or gel silica with surface organic modification; such as surface organic modification The treatment can be modified with polyethylene peroxide wax.

[0041] Raw material B: hydrophobic modifier, using organosilane coupling agent, the organosilane coupling agent using methyltrimethoxysilane, methyltriethoxysilane, propyltrimethoxysilane, propyltriethoxysilane Silane, octyltrimethoxysilane, octyltriethoxysilane, decyltrimethoxysilane, decyltriethoxysilane, dodecyltrimethoxysilane, dodecyltriethoxysilane Silane, cetyltrimethoxysilane, cetyltriethoxysilane, octadecyltrimethoxysilane or octadecyltriethoxysilane.

[00...

Embodiment 1

[0062] Add raw material A in dual power mixer JHX-P600, 100kg, precipitation method silica dry powder, origin Shandong, keep mixed state, will mix good raw material C, 10kg, wherein 1.5% acetic acid aqueous solution: isopropanol=1: 4. Add raw material A in the form of atomization through the atomization reactor, mix for 10 minutes, add raw material B, octyltriethoxysilane, 19.8kg, keep mixing for 0.5h, keep at 100 °C for 4h, and process it into The average particle size is 3.5 μm.

Embodiment 2

[0064] In the mixer, add raw material A, 80kg, precipitated silica dry powder, origin in Fujian, keep the mixed state, mix the good raw material C, 13.2kg, wherein 1.5% acetic acid aqueous solution: isopropanol=3:8, through the mist Atomization reactor was added to raw material A in the form of atomization, mixed for 10 min, added raw material B, dodecyl triethoxysilane, 13.7 kg, kept mixing for 1 h, kept at 100 ° C for 3 h, and processed into an average particle size by ultra-fine jet pulverization 4.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com