A kind of preparation method of superhydrophobic modified silicon dioxide

A super-hydrophobic modification, silica technology, applied in the field of coatings, can solve the problems of many processing procedures, inability to meet the continuous requirements of industrialized large-scale production, high energy consumption, etc., to achieve high purity, maintain extinction performance, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

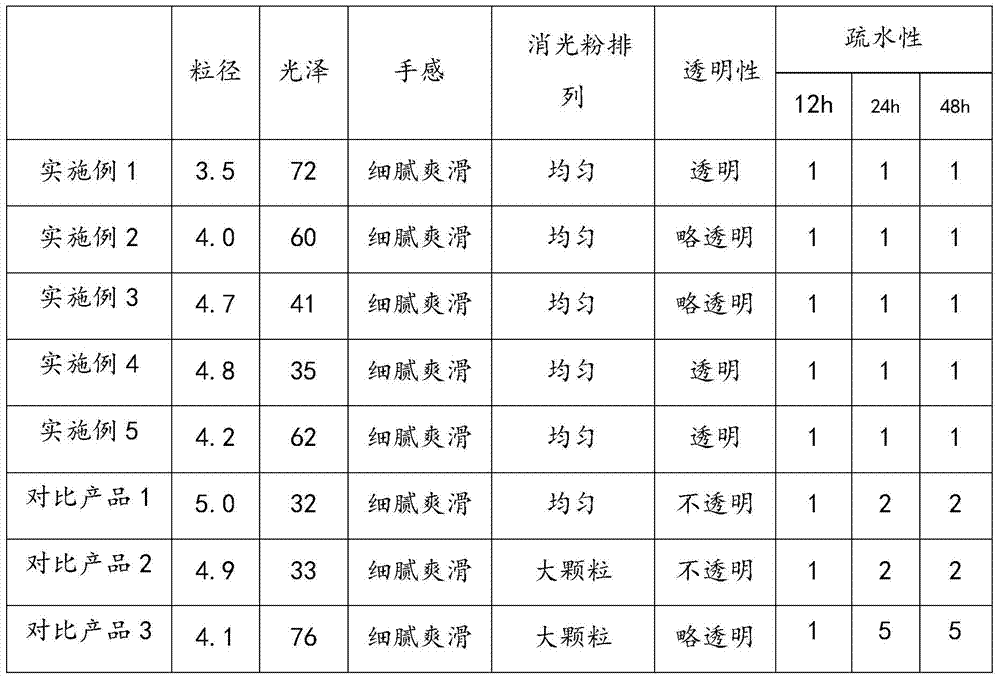

Examples

preparation example Construction

[0038] The present invention mainly adopts the silicon dioxide base material in dry powder state to carry out hydrophobic modification operation. The preparation method of superhydrophobic modified silicon dioxide comprises:

[0039] (1) Raw materials:

[0040] Raw material A: silica substrate, dry powder state; silica substrate can be precipitated silica, gel silica or gel silica with surface organic modification treatment; such as surface organic modification Treatment can be modified with peroxidized polyethylene wax.

[0041] Raw material B: Hydrophobic modifier, using organosilane coupling agent, said organosilane coupling agent using methyltrimethoxysilane, methyltriethoxysilane, propyltrimethoxysilane, propyltriethoxy ylsilane, octyltrimethoxysilane, octyltriethoxysilane, decyltrimethoxysilane, decyltriethoxysilane, dodecyltrimethoxysilane, dodecyltriethoxysilane Silane, cetyltrimethoxysilane, cetyltriethoxysilane, octadecyltrimethoxysilane or octadecyltriethoxysilan...

Embodiment 1

[0062] Add raw material A, 100kg, precipitated silica dry powder in double power mixer JHX-P600, place of production Shandong, keep mixed state, will mix good raw material C, 10kg, wherein 1.5% acetic acid aqueous solution: isopropanol=1: 4. Add raw material A in the form of atomization through the atomization reactor, mix for 10 minutes, add raw material B, octyltriethoxysilane, 19.8kg, keep mixing for 0.5h, keep warm at 100°C for 4h, and process it into The average particle size is 3.5 μm.

Embodiment 2

[0064] Add raw material A, 80kg, precipitated silicon dioxide dry powder in the mixer, the place of origin in Fujian, keep the mixed state, and mix the raw material C, 13.2kg, in which 1.5% acetic acid aqueous solution: isopropanol = 3:8, through the mist Add raw material A to the reactor in the form of atomization, mix for 10min, add raw material B, dodecyltriethoxysilane, 13.7kg, keep mixing for 1h, keep warm at 100°C for 3h, and process it into an average particle by ultra-fine airflow pulverization Diameter 4.0μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com