Device and technology for treating exhaust gas of tank ship and preparing inert gas from exhaust gas

A technology for waste gas treatment and waste gas, applied in the direction of inert gas generation, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of high cost of waste gas treatment, small amount of waste gas treatment, increased ship operating costs, etc., and achieve the cost of waste gas treatment Reduce, reduce the effect of exhaust gas purification cost, reduce workload and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

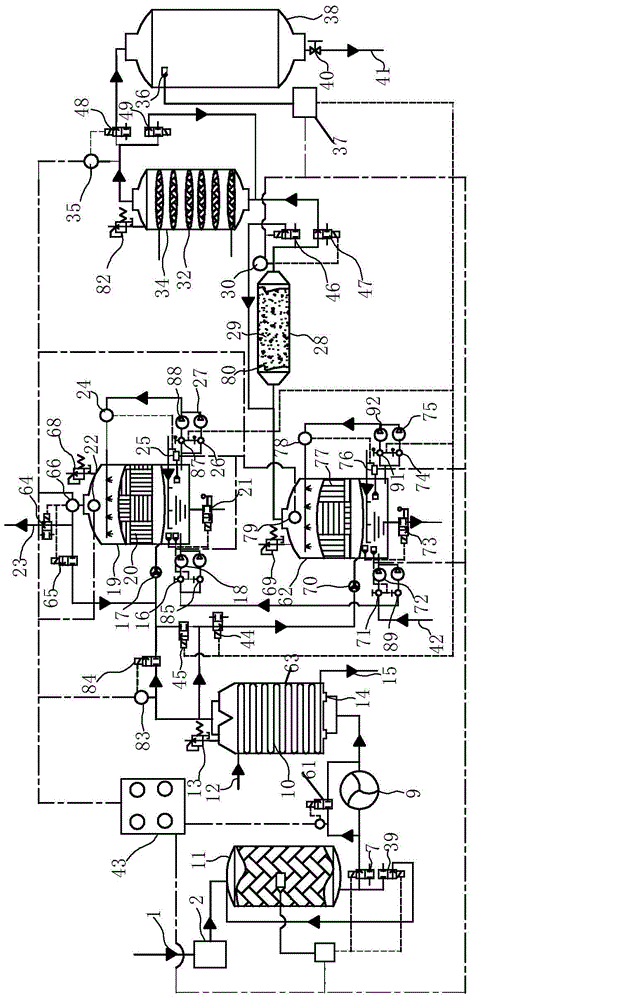

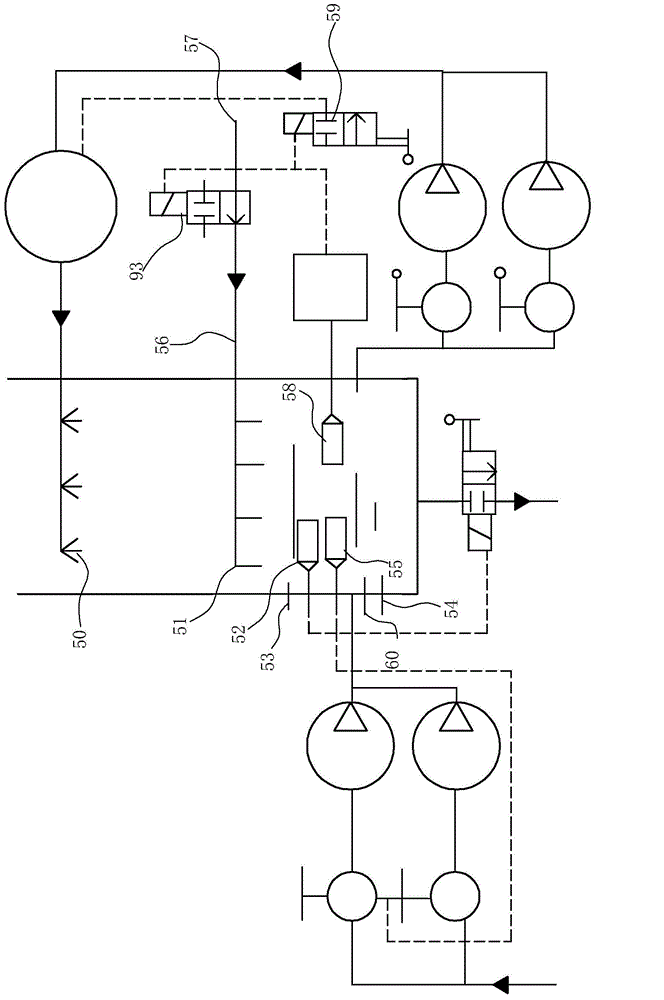

[0027] Such as Figure 1~4 As shown, the device for treating exhaust gas of an oil tanker and utilizing exhaust gas for inerting includes a pipeline burner 2 connected to the exhaust gas inlet, a catalytic conversion device 11 for selectively catalytically reducing the exhaust gas discharged from the pipeline burner 2, The exhaust gas discharged from the catalytic conversion device 11 is cooled by the cooler 63, the pipeline burner 2, the catalytic conversion device 11, and the cooler 63 are connected in sequence through pipelines, and the outlet of the cooler 63 is connected to two branches, one of which is divided into The road connects the CO contained in the exhaust gas to remove the sulfur oxides and carbon oxides 2 Scrubber 19 constitutes a waste gas treatment device, CO 2 The outlet of scrubber 19 is provided with analysis CO 2 Conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com