Patents

Literature

57results about How to "Overcome purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-purity hyodeoxycholic acid by pig bile

InactiveCN101037463AReduce the difficulty of purificationLow impurity contentDigestive systemUnknown materialsBenzeneHyodeoxycholic acid

The invention relates to a method for extracting the hyodeoxycholic acid from the leftovers of pig bile or extracted bilirubin, including saponify the leftovers with alkali, adjusting pH value, acetic ester extraction, decoloring with active carbon; concentrating the mother liquid to a proper volume, precipitating deposit, separating the deposit and drying to get coarse hyodeoxycholic acid; esterifying the coarse product, then doing an addition reaction with benzene, separating the methylhyodeoxycholanate-benzene addition compound; decomposing the addition compound with alkali, adjust pH value, getting the purified deoxycholic acid. The obtained mother liquid can be further extracted to get precious chenodeoxycholic acid. The craft has a lot of material, a low pollution, safety and no poison, a low cost, a high product purity and is suitable for industry production in a large scale.

Owner:JIANGSU UNIV

Preparation and application of human-stem-cell-secreted bioactive factor and lysis solution

InactiveCN102586182APromote proliferationPromote differentiationCosmetic preparationsToilet preparationsOrganismHigh activity

The invention discloses preparation and application of human-stem-cell-secreted bioactive factors and a lysis solution. The process comprises the following steps of: extracting stem cells of the umbilical cord or the placenta tissue of a health human person; performing in-vitro culture and amplification; and preparing high-purity and high-activity stem-cell-secreted bioactive factors and bioactive substances in the stem cell (namely, high-purity stem cell lysis solution) by the modern biological technologies of low-temperature separation, purification and the like. According to the invention, the bioactive factors or the substances do not contain any animal component, and can be developed into a product with a cell biological activity; after acting on the human body, the product can activate the stem cell of the organism and repair or replace damaged, lesion and old cells; and the product has the functions of regulating the cell metabolism function of the organism, enhancing the immunity of the organism, delaying the aging and the like. The human bioactive factors or the substances have great application prospect in the fields of medical science, healthcare and beauty.

Owner:ANHUI HUIEN BIOTECH

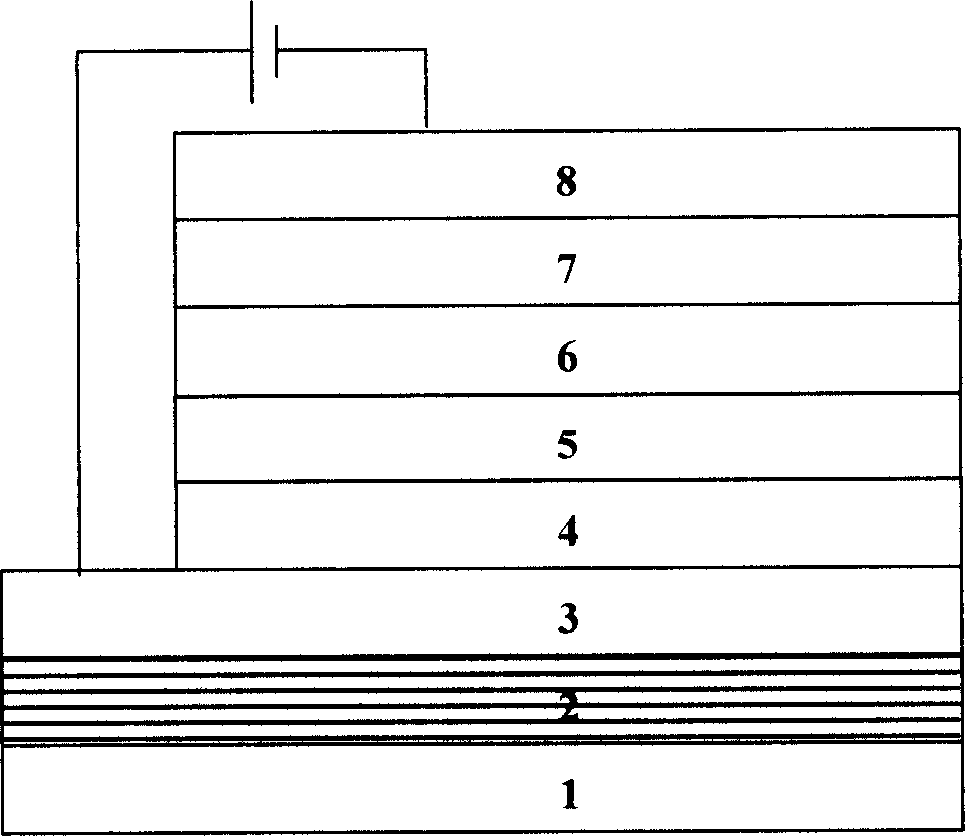

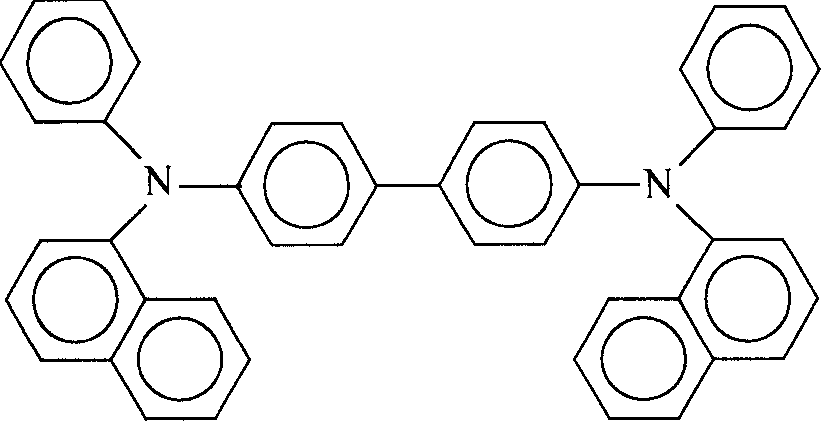

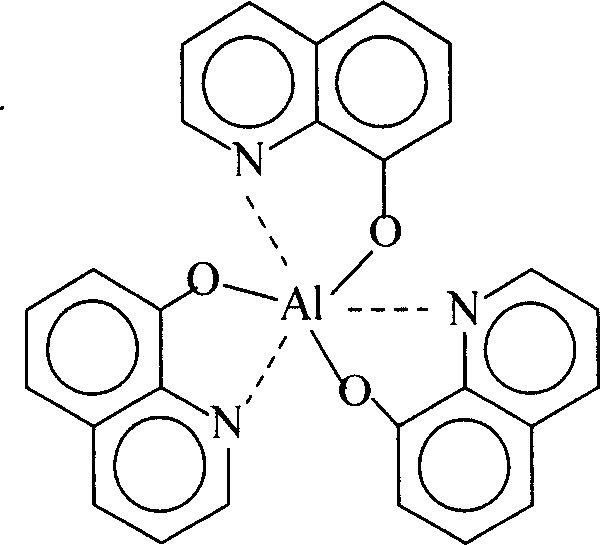

Organic white light emitting diode in tiny cavity type

InactiveCN1728413AHigh luminous intensityImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLuminous intensityHole transport layer

The invention solves issues of color purity of white color, stability of color and luminous efficiency. The disclosed diode includes substrate, Bragg reflection mirror, anode, hole transport layer, luminous layer, cavity barrier layer, electron transport layer, and cathode. Through structure of micro cavity, changing luminous characters of broadband of organic material, the invention realizes irradiance in two modes of resonance in visible range, making match of spectrum generate white light. Since luminous layer is positioned near to antinode of stationary field intensity in two modes of resonance in micro cavity, luminous intensities in two modes are enhanced, and luminous efficiency is increased. Under condition of not changing length of cavity, adjusting relative position of luminous layer changes relative luminous intensities between two modes to optimize color purity. Features are: stable white light and raised luminous efficiency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

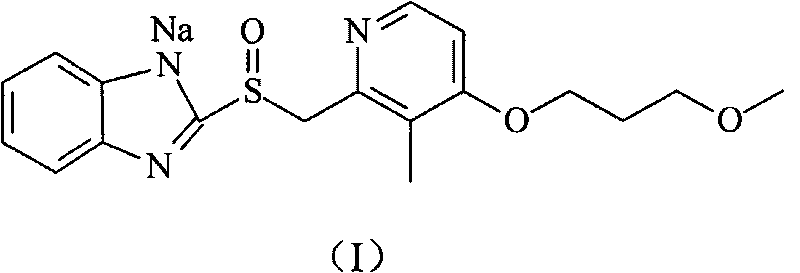

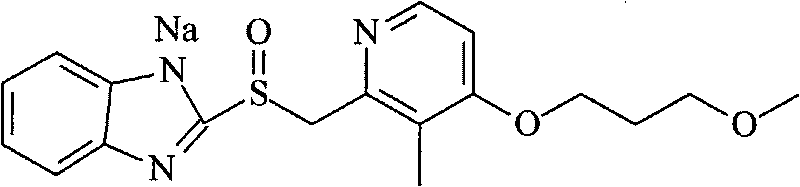

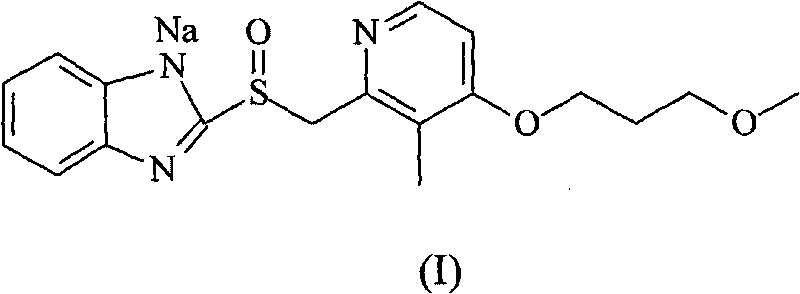

High-purity sodium rabeprazole compound

InactiveCN101704811AOvercome purityOvercome the disadvantages of difficult purificationOrganic chemistryOrganic solventRabeprazole

The invention relates to a high-purity sodium rabeprazole compound, belonging to the technical field of medicine. The method includes the following steps: dissolving crude sodium rabeprazole synthesized by the reaction of rabeprazole and sodium hydroxide in water, adjusting pH value to be faintly acid to neutral by using solid acid salt, and collecting precipitated solid; after dissolving the solid with organic solvent, conducting elution and purification by using eluting agent through macroporous adsorption resin, and collecting eluent; and adjusting the pH value of the eluent to be alkaline, and collecting the precipitated solid to obtain the pure sodium rabeprazole.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

Method for enriching and purifying cannabidiol

PendingCN110156568ALow costPromote regenerationOrganic chemistryOrganic compound preparationChemical industryMicrowave

The invention belongs to the technical field of chemical industry, relates to a method for enriching and purifying cannabidiol, and particularly relates to a method for purifying cannabidiol by usingmicrowave countercurrent extraction, macroporous adsorption resin adsorption and column chromatography. The method has the following advantages: 1, the microwave extraction is adopted, ethanol is usedas a solvent, a part of fat oils is removed, the extraction time is greatly reduced, the production efficiency is improved, and the method is simple; 2, the macroporous resin regeneration is convenient and rapid, and is suitable for large production, the cost is greatly reduced, most impurities are removed by water elution, and the operation is simple; and 3, the macroporous resin and silica gelcolumn chromatography are combined, the separation and purification effect is good, and the product purity is greatly improved. The method adopts microwave countercurrent extraction, macroporous resinseparation and purification, and column chromatography to carry out further purification, the product purity is greatly improved, and finally the cannabisdiol with a content of more than 65% and thecannabisdiol final product with a content of more than 90% are obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Process for producing thiourea dioxide

The present invention belongs to the field of peroxide preparing technology in organic chemistry. Into reactor, water is added in advance, thiourea is thrown in batches and hydrogen peroxide solution containing stabilizer is dripped to produce thiourea dioxide. After finishing the reaction, thiourea dioxide is filtered and stoved to obtain crystallized thiourea dioxide powder. The added amountof the stabilizer is 0.1-5 wt% of thiourea and crystal habit modifier in 0..005-2 wt% of thiourea may be also added into water. The improved thiourea dioxide producing process has improved crystal state of thiourea dioxide and raised product purity and is suitable for industrial production in large scale.

Owner:陶华西

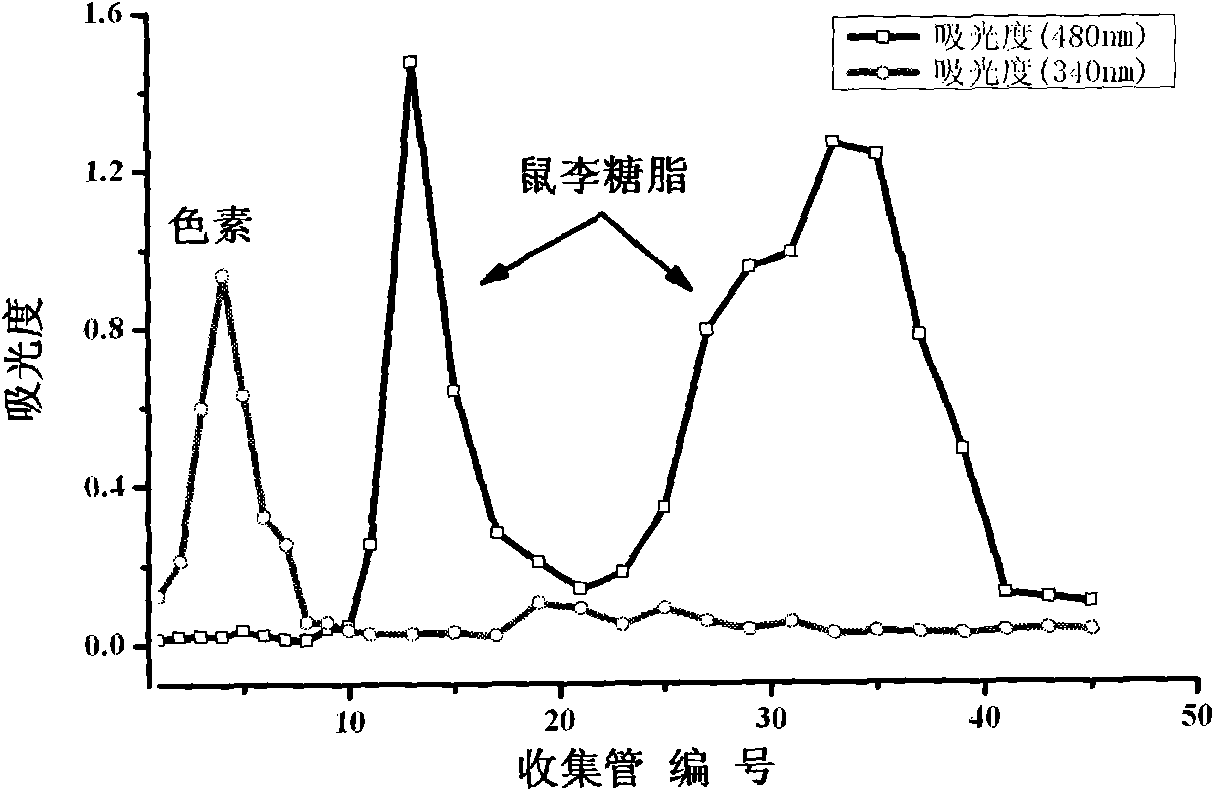

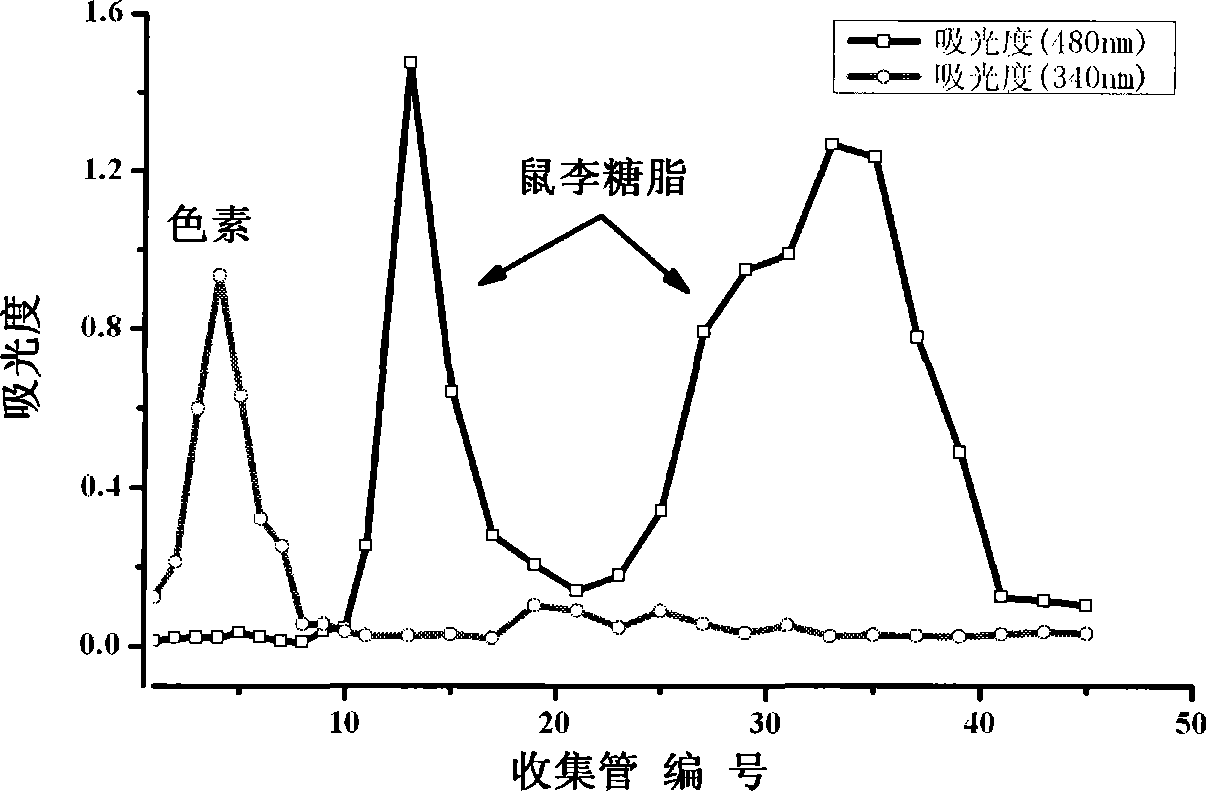

Method for separating and purifying rhamnolipid

ActiveCN101787057AOvercome purityOvercoming small sample loadSugar derivativesSugar derivatives preparationChemistryBatch production

The invention relates to a method for separating and purifying rhamnolipid, which comprises the following steps: dissolving the crude product of rhamnolipid in mixed organic solvent; adding the dissolved sample to a silica gel column; eluting the dissolved sample by using the mixed organic solvent; collecting the eluent and separating pigments from the eluent to obtain rhamnolipid solution; and finally, subjecting the rhamnolipid solution to reduced-pressure distillation and concentration to obtain the purified rhamnolipid. Compared with the prior art, the invention overcomes the defects in the prior art and has the characteristics of simple operation, high sample-loading capacity and high separation efficiency. Therefore, the method of the invention constitutes an extraction method advantageous in simple process and simple, economical and effective application and suitable for industrialized batch production.

Owner:DAQING HUALI ENERGY BIOLOGICAL TECH

One-step preparation method of sodium carboxymethyl cellulose/polyethyleneimine (CMC/PEI) double-network hydrogel with function of efficiently removing Cr (VI)

ActiveCN108339536ACross-linkingEfficient removalOther chemical processesWater contaminantsCarboxymethyl celluloseDouble network

The invention relates to a one-step preparation method of sodium carboxymethyl cellulose / polyethyleneimine (CMC / PEI) double-network hydrogel with a function of efficiently removing Cr (VI). The preparation method comprises the following steps: evenly stirring a CMC colloidal solution and a PEI solution so as to form a mixed colloidal solution, and then adding a crosslinking agent for carrying outa crosslinking reaction so as to obtain the CMC / PEI double-network hydrogel; the one-step preparation method, provided by the invention, of the CMC / PEI double-network hydrogel with the function of efficiently removing the Cr (VI) is simple and easy to control, low in cost, stable and reliable, and can effectively remove the Cr (VI); therefore, the CMC / PEI double-network hydrogel has a broad application prospect in the field of pollution control.

Owner:NANJING UNIV

Method for enriching and purifying procyanidin in pine bark

ActiveCN102093328AHigh adsorption selectivityParsing fastOrganic chemistryAbsorption capacityDistillation

The invention belongs to the field of natural organic chemistry, relating to a method for enriching and purifying procyanidin in pine bark. The method is characterized in that an intermittent distillation and macropore adsorbent resin coupling technology is used to separate and purify the procyanidin, and the technology is good for absorption selectivity of the procyanidin; and by using the intermittent distillation and macropore adsorbent resin coupling technology, absorption is quick and deabsorption is also quick, absorption capacity is large, extraction is convenient and quick, raw material source is rich, production cost is low, separation effect is obvious, extraction purity is high, above 50% of semi-finished product procyanidin and above 95% of final product procyanidin can be achieved, and the defects of low conventional extraction rate and low extraction purity are overcome. In the method, the macropore adsorbent resin which has the advantages of stable physicochemical property, large surface area, fast exchange speed, high mechanical strength, strong pollution resistance capability and good heat stability is selected, the procyanidin is selectively absorbed from solution through physical absorption, absorption is quick and deabsorption is also quick, and absorption capacity is large.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

A method for smelting high-purity nickel-molybdenum alloy by using nickel-molybdenum complex ore

The invention provides a method for smelting high-purity nickel-molybdenum alloy by using complex nickel-molybdenum ore. The alloy comprises the following components in percentage by mass: 8 to 30 percent of Ni, 10 to 30 percent of Mo, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of C, less than or equal to 0.1 percent of Cu, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, and the balance of iron. According to the characteristic that the complex nickel-molybdenum ore is difficult to separate, the high-purity nickel-molybdenum alloy is smelted by adopting the routes of oxidizing and roasting nickel-molybdenum sulfide type mineral to remove sulfur, reducing and smelting high-alkalinity slag to obtain crude alloy, refining high-alkalinity weak oxidative slag to remove silicon and phosphorus and treating and refining Ba-Ca in vacuum to deeply remove phosphorus, sulfur and oxygen; the alloy can be used for nickel-molybdenum alloying and alloying of high nickel-molybdenum alloy steel in high-purity steel production, and has the advantages of high purity, no pollution, good alloying effect and the like; and the method has the characteristics of pure fire method, greenness, no pollution, simplicity in process and the like, realizes efficient utilization of the difficultly separated complex nickel-molybdenum ore, and is worthy of popularization.

Owner:JIANGSU UNIV

Nisin extraction method

InactiveCN102304172AOvercoming craftOvercome purityPeptide preparation methodsDepsipeptidesBiotechnologyOrganic solvent

The invention relates to a nisin extraction method which is characterized by comprising the following steps: (1) adjusting the pH value of a nisin fermentation concentrated solution to 1.7-3.0, and mixing the nisin fermentation concentrated solution with a water-microsoluble organic solvent or water-insoluble organic solvent, wherein the organic solvent is any one of dichloromethane, n-butyl alcohol, ethyl acetate and carbon tetrachloride, or a combination of any two; and (2) stirring, standing, carrying out solid-phase separation to obtain a nisin wet cake, and drying while depressurizing invacuum to obtain the nisin product. The invention has the following main advantage: the nisin is precipitated by means of the organic solvent, thereby overcoming the defects of the existing process such as high salt content and low product purity, and ensuring that the product purity of nisin is higher than 50%. The method is safe, convenient, practical and low in cost.

Owner:LUOYANG QIHONG BIOTECH

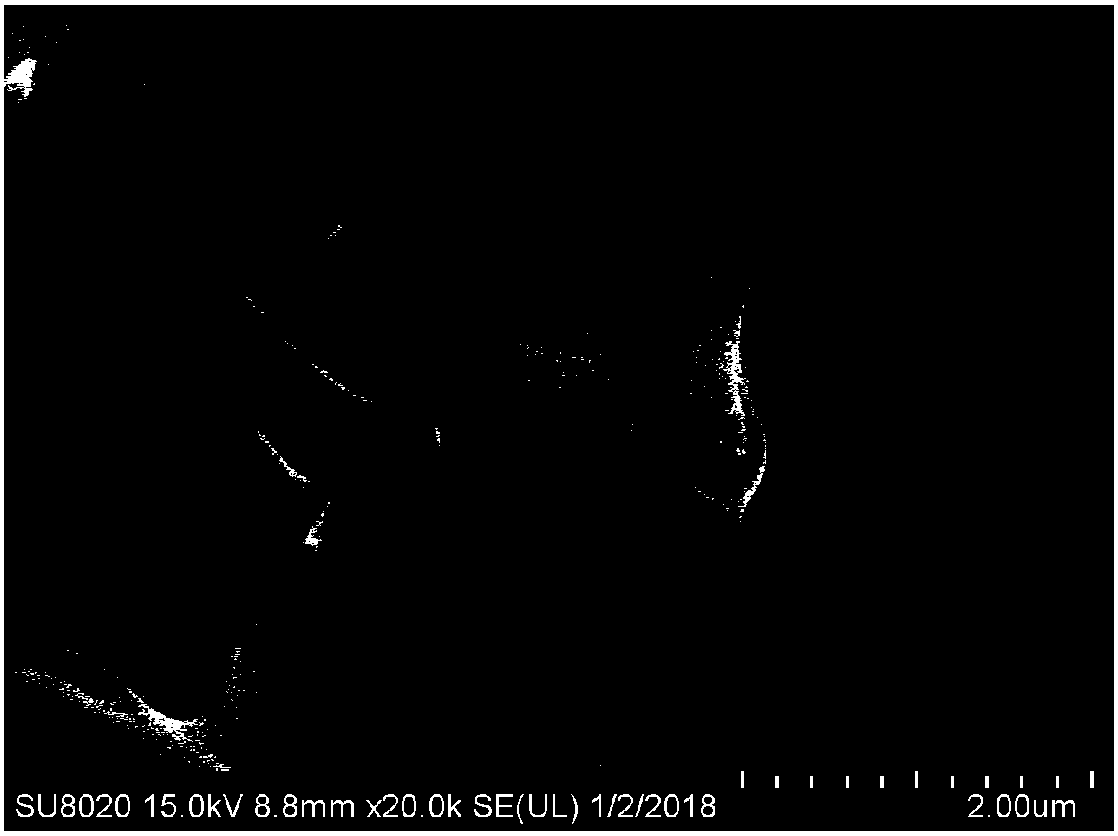

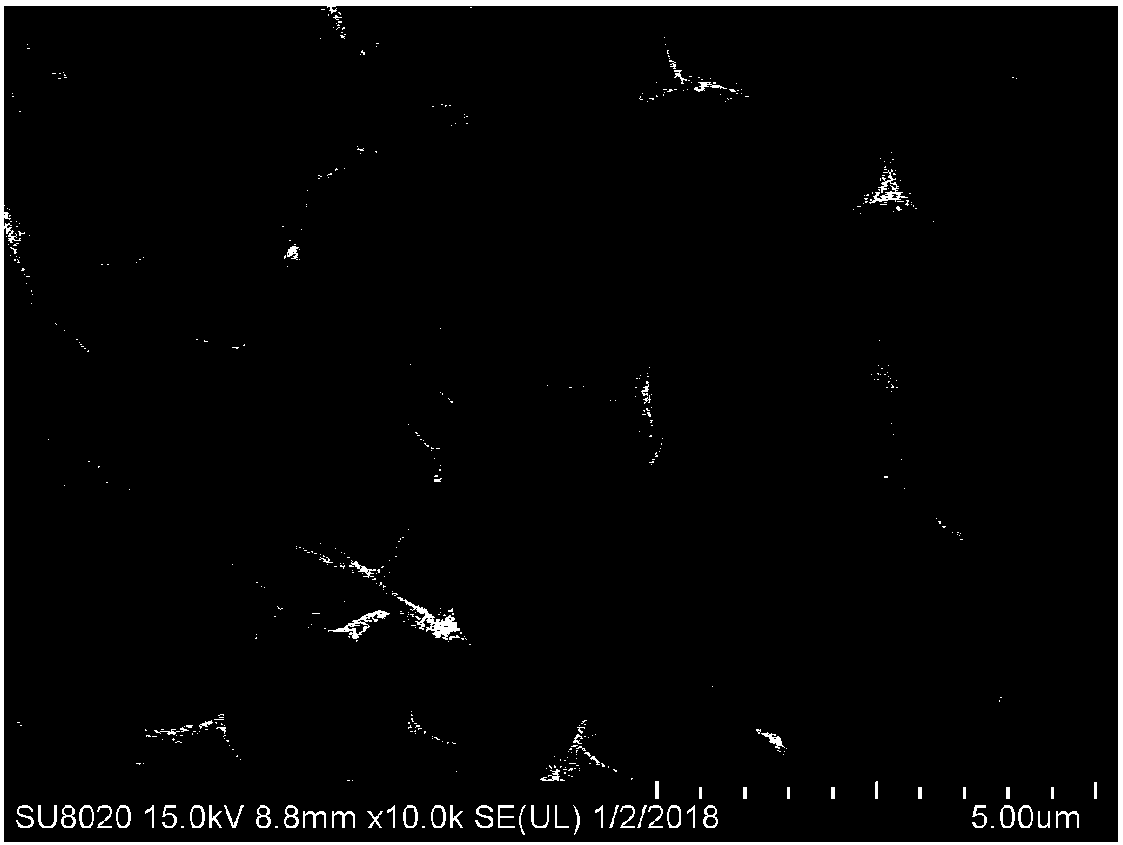

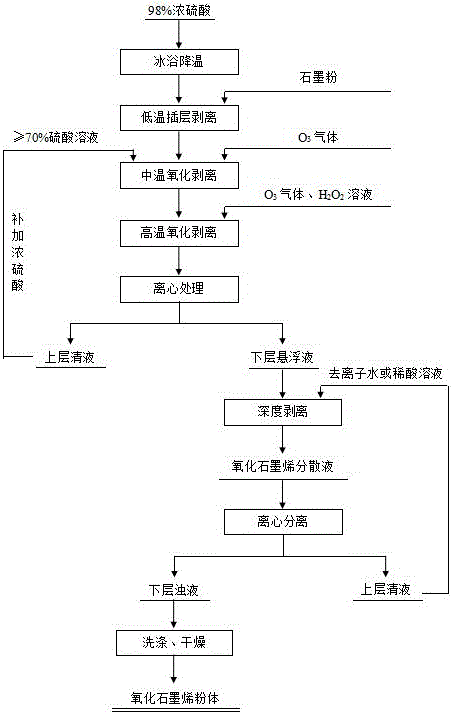

Method for preparing oxidized graphene

ActiveCN106395808AReduce the introductionOvercome Difficult Cleaning ProblemsGraphenePreparation proceduresHot Temperature

The invention discloses a method for preparing oxidized graphene. The method includes steps of adding graphite powder into concentrated sulfuric acid at the low temperature and carrying out ultrasonic treatment under a stirring condition; adding sulfuric acid solution into obtained mixed solution, continuously filling the mixed solution with gas containing ozone, then gradually increasing the temperature until moderate-temperature environments are created and carrying out constant-temperature stirring reaction; continuously filling reaction products with gas containing ozone, starting to add strong oxidizing agent solution into the reaction products, gradually increasing the temperature until high-temperature environments are created and carrying out constant-temperature stirring reaction; carrying out high-temperature oxidation exfoliation to obtain mixed liquid, carrying out centrifugal treatment on the mixed liquid, separating upper-layer clear liquid from lower-layer suspension, deeply exfoliating the lower-layer suspension to obtain dispersion liquid containing the oxidized graphene, or carrying out deep exfoliation, centrifugal separation, washing and drying treatment on the lower-layer suspension to obtain oxidized graphene powder. The method has the advantages that the oxidized graphene prepared by the aid of the method is high in purity, good in safety and large in laminar structure distance, waste acid can be recycled, and preparation procedures are green and environmentally friendly.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for enriching and purifying schizandrol A in schisandra

ActiveCN101786945AHigh adsorption selectivityParsing fastIon-exchange process apparatusEther separation/purificationThermal stabilityAdsorption selectivity

The invention belongs to the field of natural organic chemistry, relating to a method for enriching and purifying schizandrol A in schisandra by utilizing macroporous adsorbent resin. The invention is characterized in that the macroporous adsorption technology, which is used for separating and purfying the schizandrol A, has good adsorption selectivity on the schizandrol A, rapid adsorption, rapid resolution and large adsorption capacity; and the extraction is convenient and fast, the source of raw materials is abundant, the production cost is low, the separating effect is obvious, the extraction purity is high, and the semi-finished product of the schizandrol A of which the content is more than 35% and the final product of the schizandrol A of which the content is more than 98% can be obtained, so that the defects that relatively low extraction rate and low extraction purity of routine extraction are overcomed. The macroporous absorbent resin selected by the invention has stable physicochemical property, larger surface area, fast exchange speed, high mechanical strength, strong anti-pollution ability and good thermostability, thereby being capable of selectively adsorbing the schizandrol A from solution by physical adsorption with the characteristics of fast adsorption, fast resolution and larger adsorption capacity.

Owner:HEILONGJIANG DINGHENGSHENG PHARM CO LTD

Method for preparing cuprous oxide-indium trioxide solid solution superfine powder

InactiveCN102432057AHigh purityEvenly distributedGallium/indium/thallium compoundsCopper oxides/halidesIndiumCopper sulfate

The invention relates to a method for preparing cuprous oxide-indium trioxide solid solution superfine powder. The method comprises the following steps of: performing ultrasonic chemical reduction coprecipitation reaction on 9.99 to 99.99 percent of metal indium (In), copper sulfate (CuSO4.5H2O) and concentrated sulfuric acid (H2SO4) which serve as raw materials by using a sodium hydroxide (NaOH) solution as a precipitating agent, a glucose (C6H12O12) solution as a reducing agent and absolute ethanol (CH3CH2OH) as a stabilizing agent and a dispersing agent; reducing and aging at constant temperature; performing centrifugal separation; washing, and dispersing; and drying, calcining, and thus obtaining the cuprous oxide-indium trioxide solid solution superfine powder. The obtained cuprous oxide-indium trioxide solid solution superfine powder has the particle size of 30 to 50nm, has spherical particles, high purity and a high dispersing property and is distributed uniformly; and the method is simple, has a short production period and is convenient to operate.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of nano-spinel nickel cobalt lithium manganate

ActiveCN106241894AOvercoming uneven particle size distributionOvercoming easy reunionNickel compoundsFiltrationManganate

The invention provides a preparation method of nano-spinel nickel cobalt lithium manganate. The method comprises the following steps: 1. preparation of nano nickel cobalt lithium manganate precursor: uniformly mixing a nickel salt, a cobalt salt and a manganese salt to obtain a mixed solution, adding into a hypergravity field reactor, reacting, and sequentially carrying out filtration, washing and filtration on the reaction solution to obtain the nano precursor; and 2. uniformly mixing the nano precursor obtained in the step 1 with a lithium salt, and sequentially carrying out presintering, roasting and annealing to obtain the nano-spinel nickel cobalt lithium manganate. The method has the advantages of simple technique and low cost, is easy to operate, and can implement quick mass production. The prepared nickel cobalt lithium manganate has the advantages of controllable particle size (the average particle size is 200nm or so), narrow particle size distribution, no aggregation, high crystallinity and complete crystal form.

Owner:XIANGTAN UNIV

Method for preparing lanthanum oxide through microwave calcination

InactiveCN108585015AControl the rate of decompositionOvercome purityRare earth metal oxides/hydroxidesChemistryDecomposition

The invention discloses a method for preparing lanthanum oxide through microwave calcination, and relates to the technical field of rare earth metal smelting. The method for preparing the lanthanum oxide through the microwave calcination, provided by the invention, comprises the steps of heating lanthanum salt to 1050-1250 DEG C in stages under a microwave condition, calcinating and cooling to obtain the lanthanum oxide after completion of the calcination, wherein the heating rate is kept at a constant rate, and heat preservation is needed after the temperature is raised to each temperature stage. By the method, characteristics of absorbing microwave by lanthanum carbonate or lanthanum oxalate are utilized, the lanthanum oxide is prepared in a staged-heating microwave calcination way, thedefects of long production cycle, low heat efficiency, and difficult guarantee of the product purity and the product granularity due to under-burning or over-burning during production of the lanthanumoxide in the conventional calcination way are overcome, and advantages of environment friendliness, high efficiency and easiness in achievement of industrial production are achieved; meanwhile, in the staged-heating way, the decomposition rate of a raw material is controlled, so that the granularity distribution of the product is optimized, and the product quality is improved.

Owner:四川江铜稀土有限责任公司

Fritillariae cirrhosae bulbus polysaccharide extraction, separation and purification technology

ActiveCN106397622AOvercoming the low extraction rateOvercome purityBulk chemical productionDEAE SephadexPyridinium

The invention discloses a fritillariae cirrhosae bulbus polysaccharide extraction, separation and purification technology. As a novel supercritical CO2 extraction technology is utilized, the defects that a general method is low in extraction rate and not high in purity are overcome; quaternary ammonium salt cetyl pyridinium chloride monohydrate and fritillariae cirrhosae bulbus polysaccharide can precipitate in water solution with low ionic strength; when the ionic strength is high, precipitate can be dissolved, dissociated and released, and the purification effect is good; DEAE-Sephadex ionic exchange column chromatography is utilized to further remove neutral impurities and impurities with positive charges, and the separation and purification effect is better.

Owner:CHONGQING THREE GORGES MEDICAL COLLEGE

Coarse gold refining method

ActiveCN106884093AGold content requirements are reducedOvercome purityProcess efficiency improvementSlagPotassium hydroxide

The invention relates to a coarse gold refining method. The coarse gold refining method includes the following specific steps that (1) coarse gold is digested with a salpeter solution, and a filter residue I is obtained by means of filtering; (2) potassium nitrate is added into the filter residue I, roasting is performed after the potassium nitrate and the filter residue I are evenly mixed, and accordingly roasting slag is obtained; (3) a potassium hydroxide solution is added into the roasting slag for digestion, and a filter residue II is obtained by means of filtering; (4) the filter residue II is digested with nitric acid, and a filter residue III is obtained by means of filtering; and (5) hydrochloric acid and hydrogen peroxide are added into the filter residue III for reacting, filter liquor is obtained by means of filtering, and powdered gold can be obtained through treatment. The purity of the powdered gold refined through the method is 99.99% or above, and the method overcomes the defects that a common wet process-pyrogenic process combination product is low in purity, high in smelting temperature, complex in technological process and long in period.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

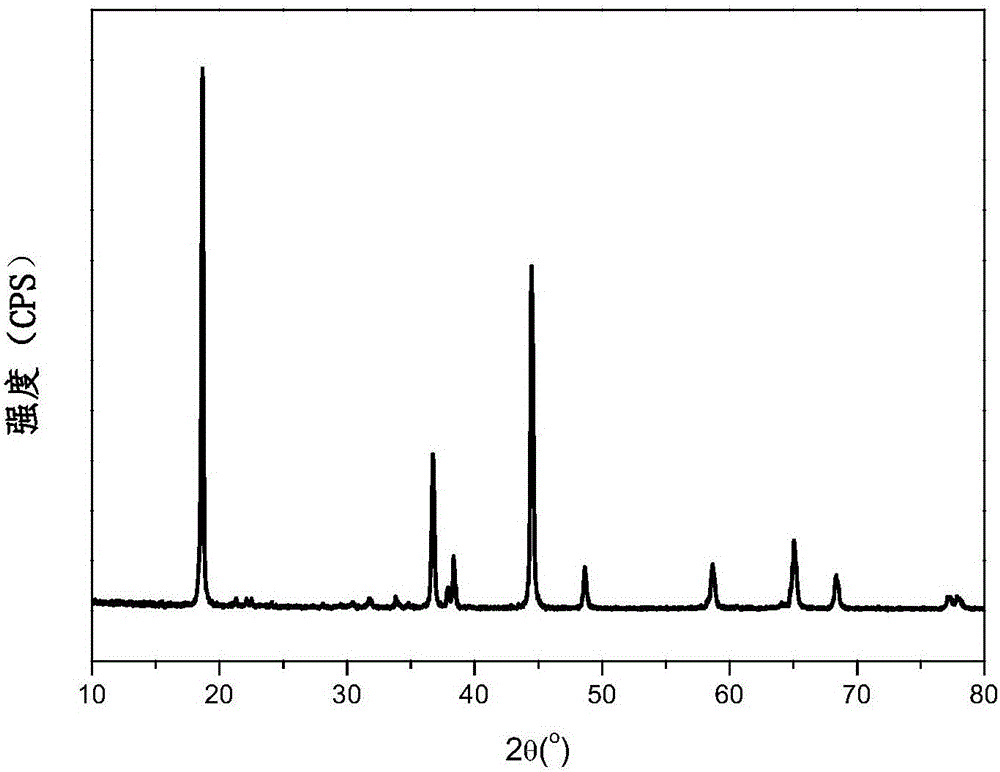

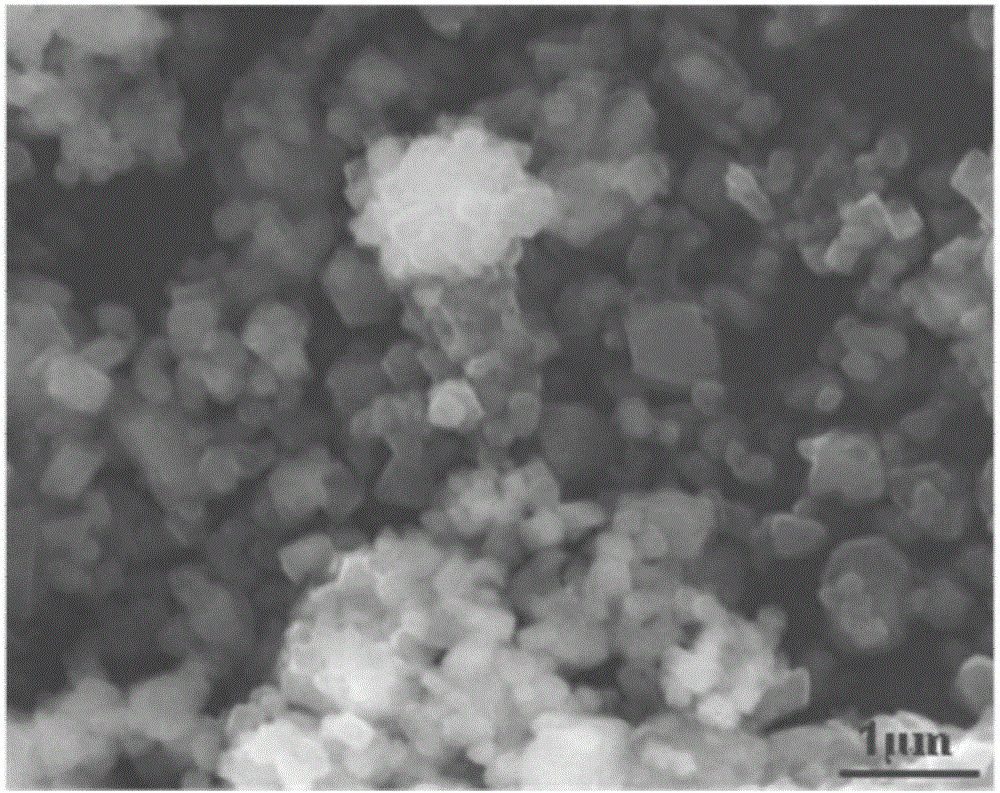

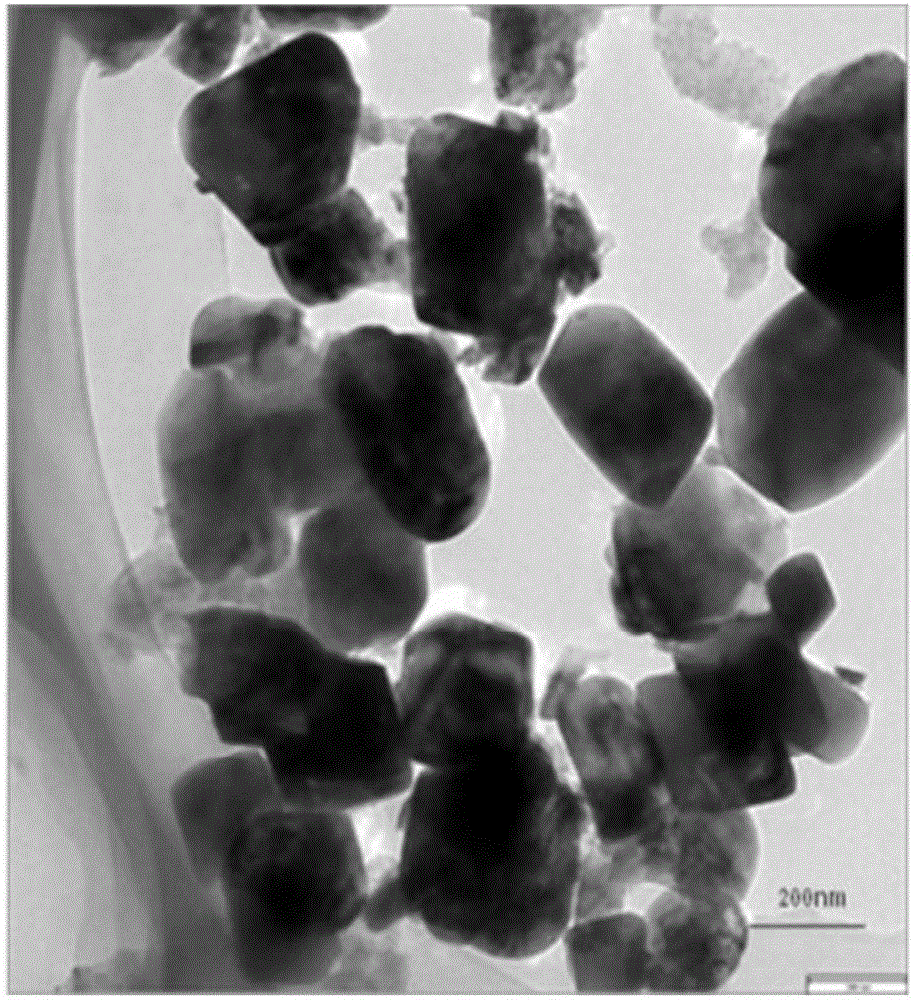

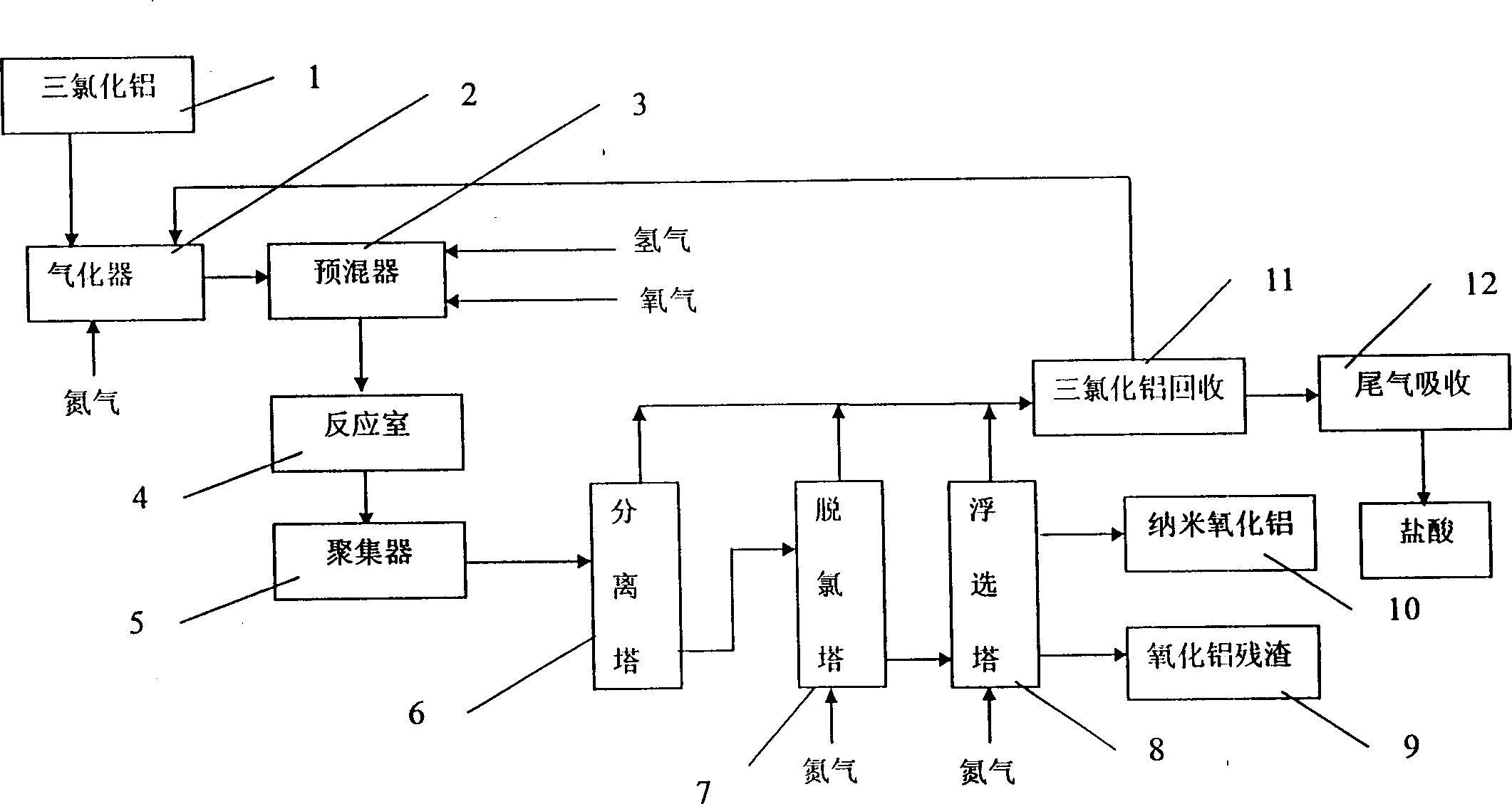

Continuous preparation process of high purity nanometer alumina

The continuous preparation process of high purity nanometer alumina includes the following steps: high temperature gasifying aluminum trichloride, continuous mixing with H2 and O2 in a re-mixer, high temperature hydrolysis and condensation reaction of aluminum trichloride in the high temperature generated through burning H2 inside a reactor, and aggregating the reaction product, gas-solid separation, dechlorinating, floating, etc. to obtain high purity nanometer alumina. By means of controlling the material ratio, the cooling rate in the reactor, and the length and temperature of the aggregator, nanometer alumina powder of different grain sizes may be obtained. By means of tail gas treatment, circular utilization of aluminum trichloride and absorption of HCl to prepare hydrochloric acid, the present invention realizes the best utilization of resource.

Owner:GUANGZHOU HUIFU RES INST CO LTD

Method for enriching and purifying folic acid in houseleek by macroporous absorbent resin

ActiveCN101775016AHigh adsorption selectivityParsing fastOrganic chemistryAbsorption capacityDesorption

The invention relates to a method for enriching and purifying folic acid in houseleek by macroporous absorbent resin, which belongs to the field of natural organic chemistry. The invention is characterized in that the macroporous absorbent technology is used for separating and purifying the folic acid, the adsorption selectivity on the folic acid is good, both the adsorption and the desorption are fast, the adsorption capacity is large, the extraction is convenient and fast, the raw material sources are rich, the production cost is low, the separation effect is obvious, the extraction purity is high, the folic acid semi-finished products with the content higher than 35 percent and the folic acid finished products with the content higher than 98 percent can be obtained, and the defects of relatively low extraction rate and low extraction purity of the conventional method are overcome. The invention adopts the macroporous absorbent resin with the advantages of stable physicochemical property, large superficial area, high exchange speed, high mechanical strength, strong pollution resistance capability and good thermal stability, the folic acid can be selectively absorbed in the solution through physical absorption, and the invention has the advantages of fast absorption, fast desorption and large absorption capacity.

Owner:HEILONGJIANG DINGHENGSHENG PHARM CO LTD

Novel method for extracting astragaloside from radix astragali

InactiveCN103110689AHigh adsorption selectivityNo pollution in the processIon-exchange process apparatusIon-exchanger regenerationReflux extractionAstragaloside

The invention aims at overcoming the defects of relatively low extraction rate, low extraction purity and the like in the prior art, and provides a method for enriching and purifying astragaloside contained in radix astragali by utilizing a water vapor reflux extraction and membrane separation technology and a macroporous adsorption resin coupling method. The method provided by the invention can be used for separating and purifying the astragaloside by adopting the water vapor reflux extraction and membrane separation technology and the macroporous adsorption resin coupling method, has the advantages of complete astragaloside extraction without pollution, good separation effect, high purity and good adsorption selectivity, fast absorption, fast resolution, large adsorption capacity, obvious separation effect and high extraction purity of macroporous resin and can obtain the astragaloside semi-finished products with content more than 30% and astragaloside finished products with content more than 95% and overcome the defects of relatively low conventional extraction rate and low extraction purity.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

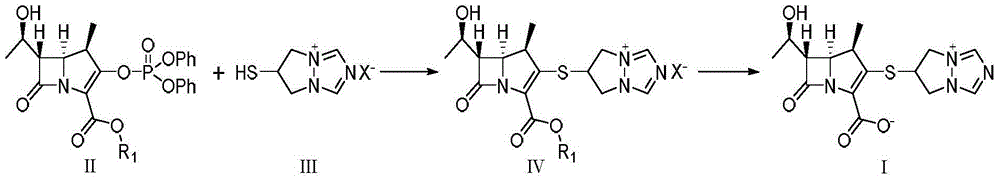

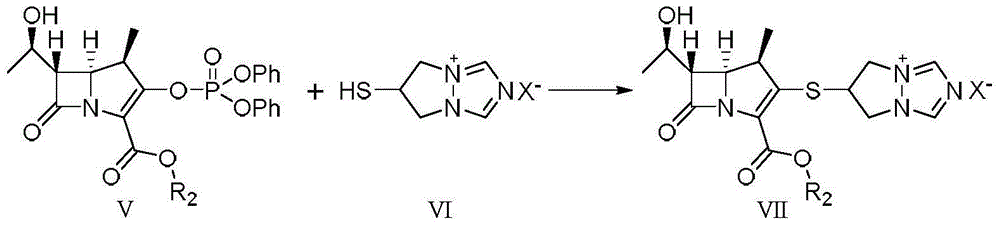

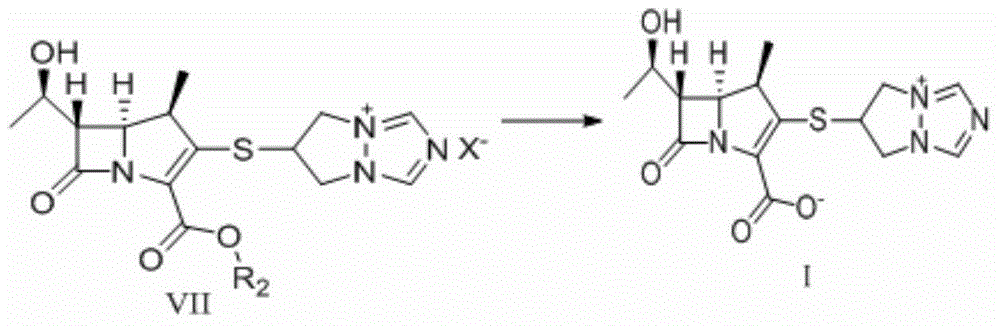

Preparation method of high-purity biapenem

InactiveCN104829633AOvercome stabilityOvercome costsOrganic chemistryBulk chemical productionN dimethylformamideCarboxylic acid

The invention relates to a preparation method of high-purity biapenem, which includes the steps of: (A) carrying out a condensation reaction with a compound represented as the formula V and a compound represented as the formula VI in an acetonitrile solvent in the presence of a less amount of N,N-dimethylformamide and an organic alkali to obtain a compound represented as the formula VII; (B) carrying out a catalytic hydrogenation to the reaction product in the step (A) in a mixed solution composed of an alcohol solvent and a non-proton polarity organic solvent in the presence of a catalyst and an organic alkali to remove a carboxylic acid protective group in the compound represented as the formula VII; and (C) filtering a reaction mixed solution to obtain a filter cake, adding the filter cake in water with stirring to obtain a filtrate, mixing the filtrates, adding an organic solvent under stirring, performing precipitation crystallization, and filtering and drying a product to obtain the biapenem.

Owner:JIANGSU TASLY DIYI PHARMA CO LTD

Method for manufacturing hollow steel with lined pipe by machine drilling and hot rolling

InactiveCN101623718AOvercome inherent flawsDelayed expansion timeBoring/drilling machinesMetallurgySteel tube

The invention discloses a method for manufacturing hollow steel with a lined pipe by machine drilling and hot rolling, belonging to the production method of the hollow steel in steel drilling industry. The invention aims to provide a production method of hollow steel with a lined pipe, which has a matrix with hardly unlimited size and stable quality. The method comprises steps of manufacturing the matrix, machine-drilling a through hole, inserting a mandril, carrying out hot rolling and drawing out the mandril, wherein one steel pipe is inserted into the through hole after the machine drilling, and the mandril is inserted in the steel pipe. The invention has the advantages of compact matrix texture, good product performance, stable quality, and the like, thereby being an ideal method for manufacturing hollow steel with a line pipe, which is used for rock-drilling rods, in particular small-dimension rock-drilling rods.

Owner:SHOUGANG GUIYANG SPECIAL STEEL

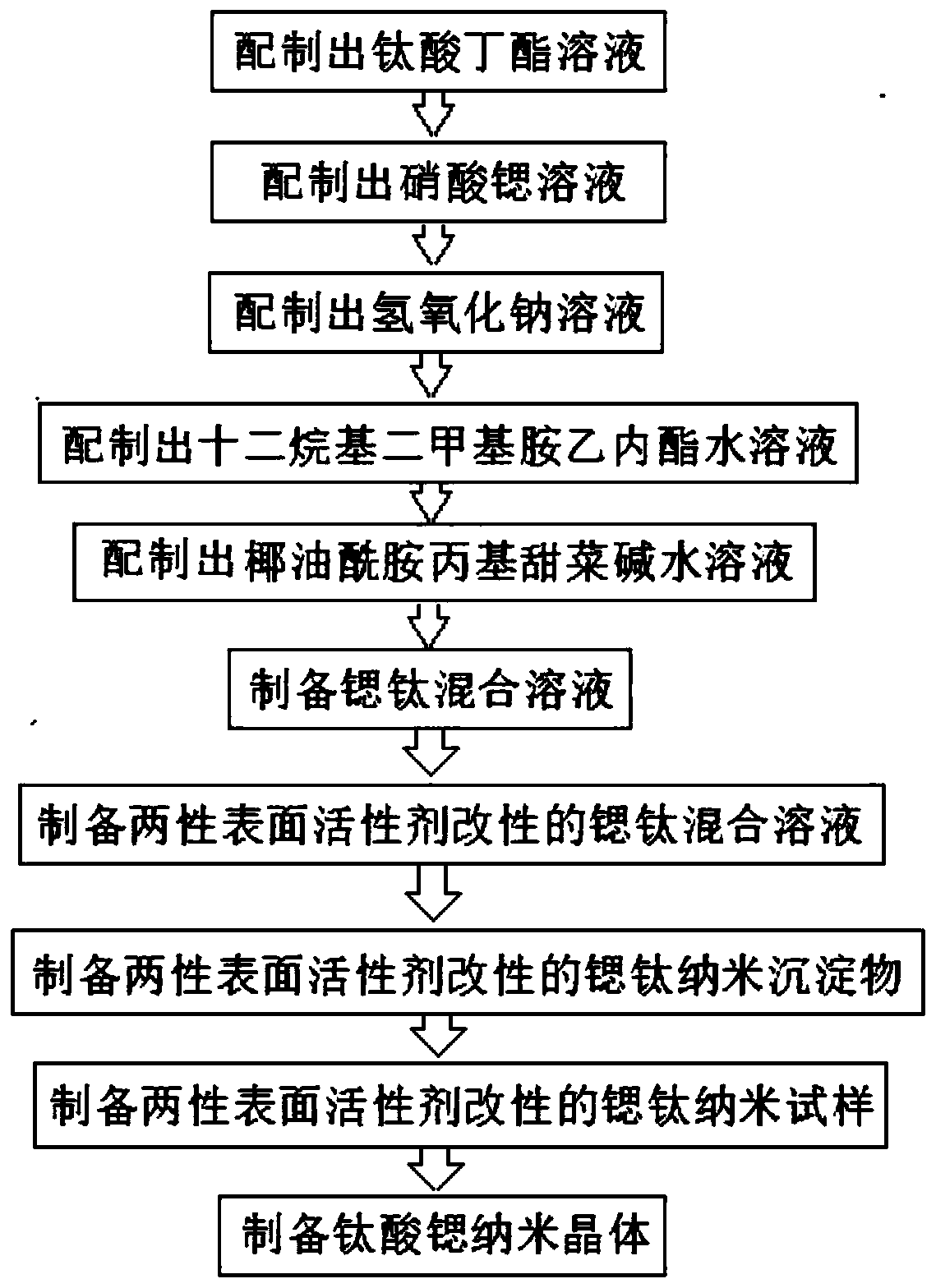

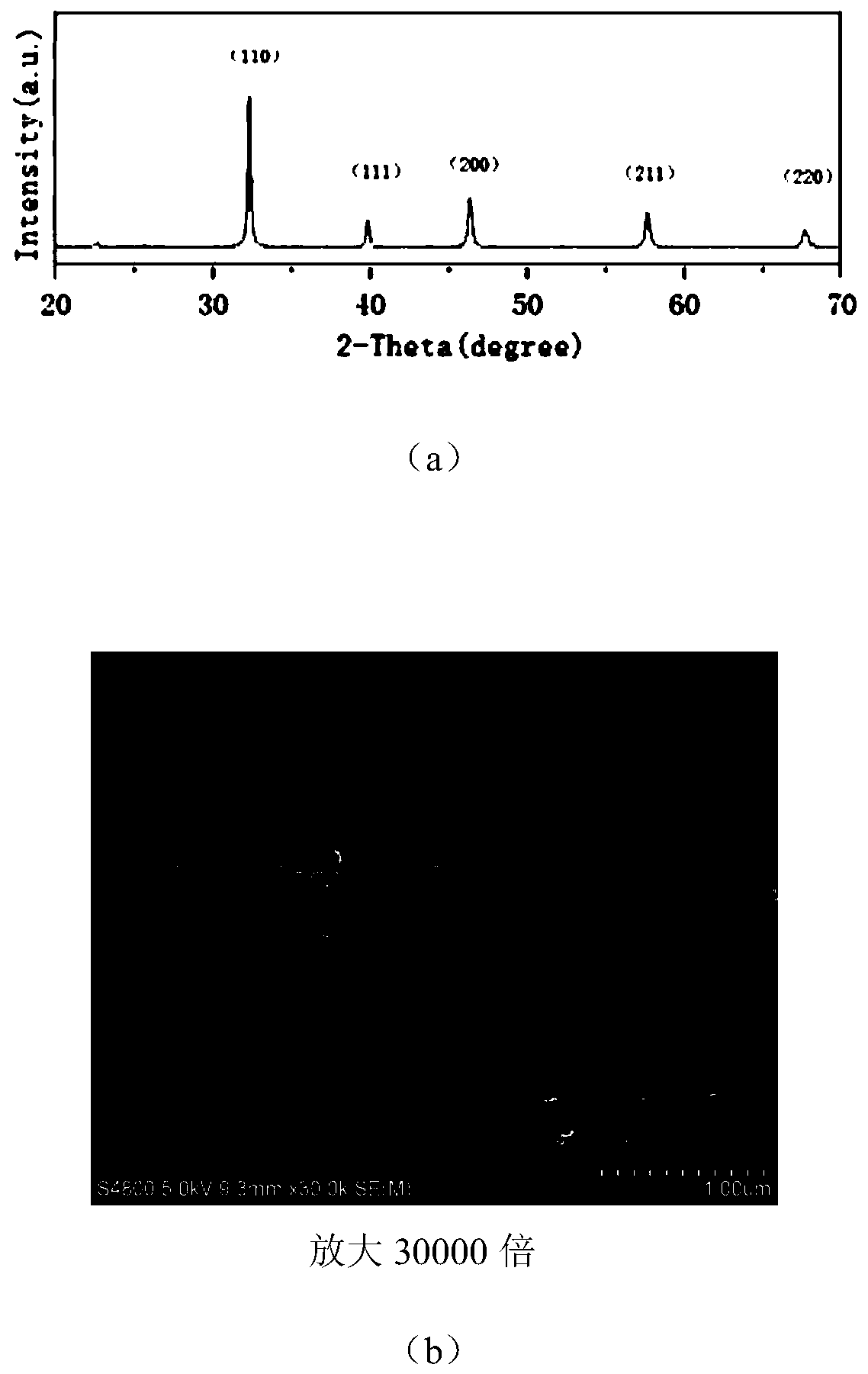

Preparation method of strontium titanate spherical nanocrystals

The invention discloses a preparation method of strontium titanate spherical nanocrystals, and mainly solves the problems that the traditional preparation method of strontium titanate is complex, impurities are easy to generate, and the purity and the particle size of strontium titanate powder are difficult to meet the requirements. The method comprises the following steps: 1) adding an ampholyticsurfactant, dodecyl dimethyl amine ethyl lactone aqueous solution or a cocamidopropyl betaine aqueous solution, into a prepared strontium-titanium mixed solution to obtain an ampholytic surfactant modified strontium-titanium mixed solution; 2) adding a prepared sodium hydroxide solution into the strontium-titanium mixed solution to obtain an ampholytic surfactant modified strontium-titanium nanoprecipitate; 3) sequentially filtering, washing, drying, grinding, drying and sintering the nano precipitate to obtain the strontium titanate spherical nano crystal. The preparation method is simple in operation requirement, short in preparation period and suitable for industrial production. The product is good in dispersity and free of agglomeration, has the characteristics required by preparation of a grain boundary layer capacitor, and can be widely applied to circuits of a radio, a television and a computer.

Owner:XIDIAN UNIV

Method for enriching and purifying cardiac glycoside of wormseed mustard herb

InactiveCN101732391AHigh adsorption selectivityParsing fastDigestive systemBlood disorderDesorptionThermal stability

The invention belongs to the field of natural organic chemistry and relates to a method for enriching and purifying cardiac glycoside of wormseed mustard herb by macroporous absorption resin. The method is characterized in that: the method adopts macroporous absorption technology to separate and purify the cardiac glycoside, has good adsorptive selectivity on the cardiac glycoside, rapid adsorption and desorption, high adsorption capacity, convenient and rapid extraction, rich source of raw materials, low production cost, obvious separation effect and high extraction purity, can obtain a cardiac glycoside semifinished product with content of over 35 percent and a cardiac glycoside final product with content of over 98 percent, and overcomes the disadvantages of low extraction rate and extraction purity in the prior art. The macroporous absorption resin with stable physicochemical property, large surface area, high exchange speed, high mechanical strength, strong antipollution capacityand good thermal stability is selected, can selectively adsorb the cardiac glycoside from solution through physical adsorption, and has rapid adsorption and desorption and large adsorption capacity.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Method for separating and purifying egg white lysozyme

InactiveCN106701717AOvercome purityOvercoming the defect of low yieldEnzymesPurification methodsUltrafiltration

The invention relates to a method for separating and purifying egg white lysozyme. The method comprises the following main steps: collecting egg white of fresh eggs, adding a buffer solution in proportion and carrying out uniform mixing under stirring; then successively carrying out standing and centrifugation to remove precipitates so as to obtain supernatant A; adjusting the pH value of the supernatant A to 6 and then loading a sample of the supernatant A into a chromatographic column packed with a CM-agarose ion exchange medium; carrying out elution by using a 1M sodium chloride solution and adjusting the pH value of eluate to 5.5; carrying out centrifugation to remove precipitates and adding polyethylene glycol 2000 into obtained supernatant B until the concentration of polyethylene glycol 2000 reaches 20 to 25%; successively carrying out stirring and centrifugation; adding a saturated sodium sulfate solution into supernatant C obtained in the previous step until the concentration of sodium sulfate reaches 15 to 20%; successively carrying out uniform mixing and centrifugation; subjecting supernatant D obtained in the previous step to ultrafiltration; and subjecting a solution obtained after ultrafiltration to vacuum freeze drying so as to obtain lysozyme. The method provided by the invention employs a combination of an ion exchange process, a two-aqueous-phase extraction process and a membrane separation process to overcome the defects of low yield and low purity of a single separation and purification method, and is suitable for large-scale production.

Owner:泰州苏鹏蛋业生物科技有限公司

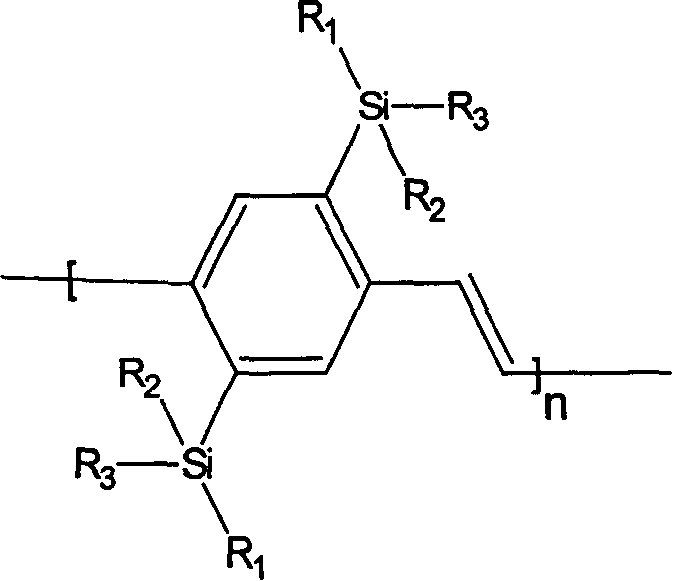

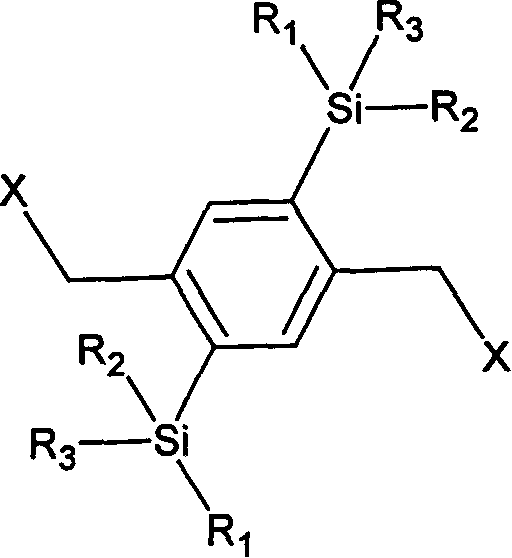

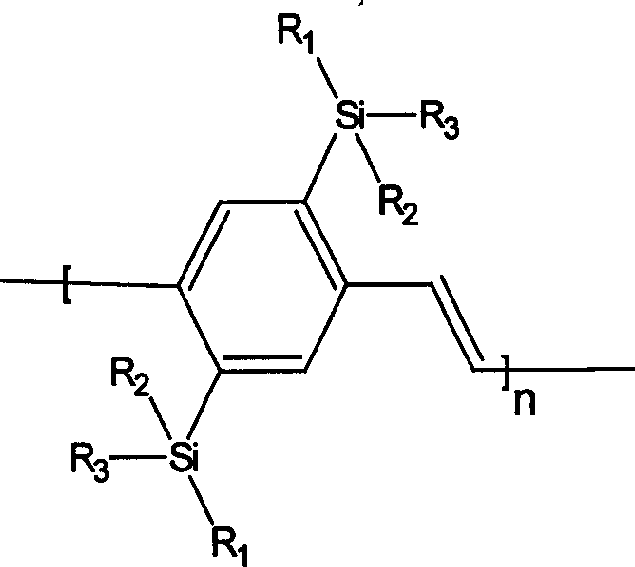

Silicon group containing 1, 4-phenylene vinylidene and its preparation method and use

InactiveCN1631931ASmall dispersionImprove luminosityElectrical apparatusElectroluminescent light sourcesLithiumThermal stability

The invention is the method for preparing 1,4- containing silicon silicon group (Si-PPV) and its application. Compared with the present technology which has complex equipment, low lightening efficiency and unsatisfying heat stability, the invention uses polymer 3 as the raw material, generates 4 which then has coupling reaction with 6, generating 7, and the acquiring the active monomer through mole without water existence, the active monomer is changed into Si-PPV through Gilch reaction. The polymer has outstanding film-making performance, heat stability and lightening efficiency.

Owner:徐良衡

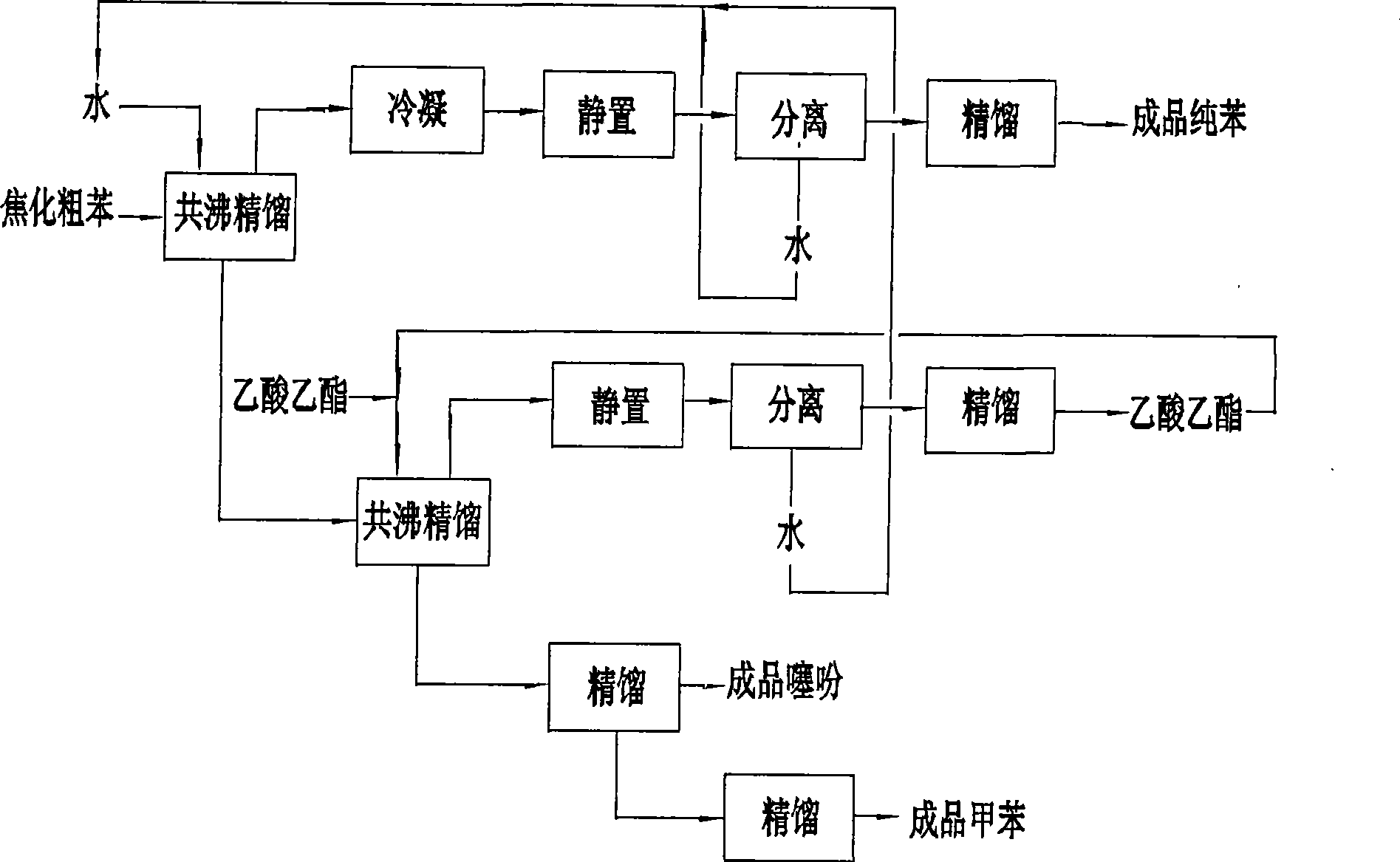

Method for extracting thiophen from coking crude benzol

The invention discloses a method for extracting thiophene from coking crude benzene, which comprises the following steps: (1) the coking crude benzene is taken as a raw material, an entrainer A is added into the coking crude benzene for azeotropic distillation to make the benzene and the entrainer A form an azeotropic mixture, the azeotropic mixture is condensed, kept stand and separated to obtain an organic phase containing the benzene and a saturated solution of the benzene, and the organic phase containing the benzene is rectified under normal pressure to obtain finished pure benzene; and (2) a rectification residual liquid remained after the coking crude benzene and the entrainer A are subjected to azeotropic distillation is added with an entrainer B for azeotropic rectification, formed zeotropic mixtures of the entrainer A and the entrainer B are separated from the thiophene, methylbenzene and homologous compounds, and the remaining rectification residual liquid taking the thiophene and the methylbenzene as main constituents is further rectified to obtain finished thiophene and methylbenzene respectively. The azeotropic mixtures of the entrainer A and the entrainer B are condensed, kept stand and separated to obtain the entrainer A and the entrainer B respectively for recycling. The method extracts a medicine intermediate, namely thiophene with higher value from the coking crude benzene, ensures that the obtained pure benzene achieves the nitration grade quality standard, can be used for basic organic synthesis, enlarge the application field of the coking crude benzene, and has good economic benefit and social benefit.

Owner:HENAN UNIVERSITY

Method for enriching and purifying carmine radish anthocyanin

ActiveCN105440732AExtract completelyEfficient extractionNatural dyesReflux extractionSeparation technology

The invention aims to overcome the shortcomings of relatively low extraction rate, low extraction purity and the like in a conventional technology, and provides a method for enriching and purifying carmine radish anthocyanin with a steam reflux extraction and membrane separation technology and a macroporous adsorption resin coupling process. According to the method, the carmine radish anthocyanin is separated and purified by applying the steam reflux extraction and membrane separation technology and the macroporous adsorption resin coupling process, so that the extraction of the carmine radish anthocyanin is complete, no pollution is caused, the separation effect is good, the purity is high, the macroporous resin adsorption selectivity is high, the adsorption and analysis are quick, the adsorption capacity is relatively large, the separation effect is remarkable, and the extraction purity is high; a final product of the carmine radish anthocyanin with the content of more than 25% is obtained; and the shortcomings of relatively low extraction rate and low extraction purity in the conventional technology are overcome.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Culture method and application of NK cells

InactiveCN112608896AOvercome shortageOvercome purityCell dissociation methodsCulture processNatural Killer Cell Inhibitory ReceptorsErythroid cell

The invention discloses a culture method and application of NK cells, which belong to the technical field of cell culture. The culture method of the NK cells comprises the following steps of (1) antibody coating, (2) separating umbilical cord blood mononuclear cells and preparing serum, (3) activating and culturing the NK cells, and (4) multiplication culture of the NK cells. According to the separation culture method provided by the invention, the problem that lymphocytes are difficult to obtain is solved, erythrocyte pollution is eliminated in the initial stage of culture, the purity of NK cells harvested in the later stage can reach 90% or above, the defect that the culture purity of NK cells of tumor patients is low is overcome, and the culture method has huge advantages in the aspect of application of allogeneic NK cells.

Owner:广州瑞铂茵健康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com