Method for separating and purifying egg white lysozyme

A technology for separation and purification of egg white lysozyme is applied in the field of separation and preparation of lysozyme to achieve the effects of easy large-scale industrial production, short production cycle, and overcoming low purity and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

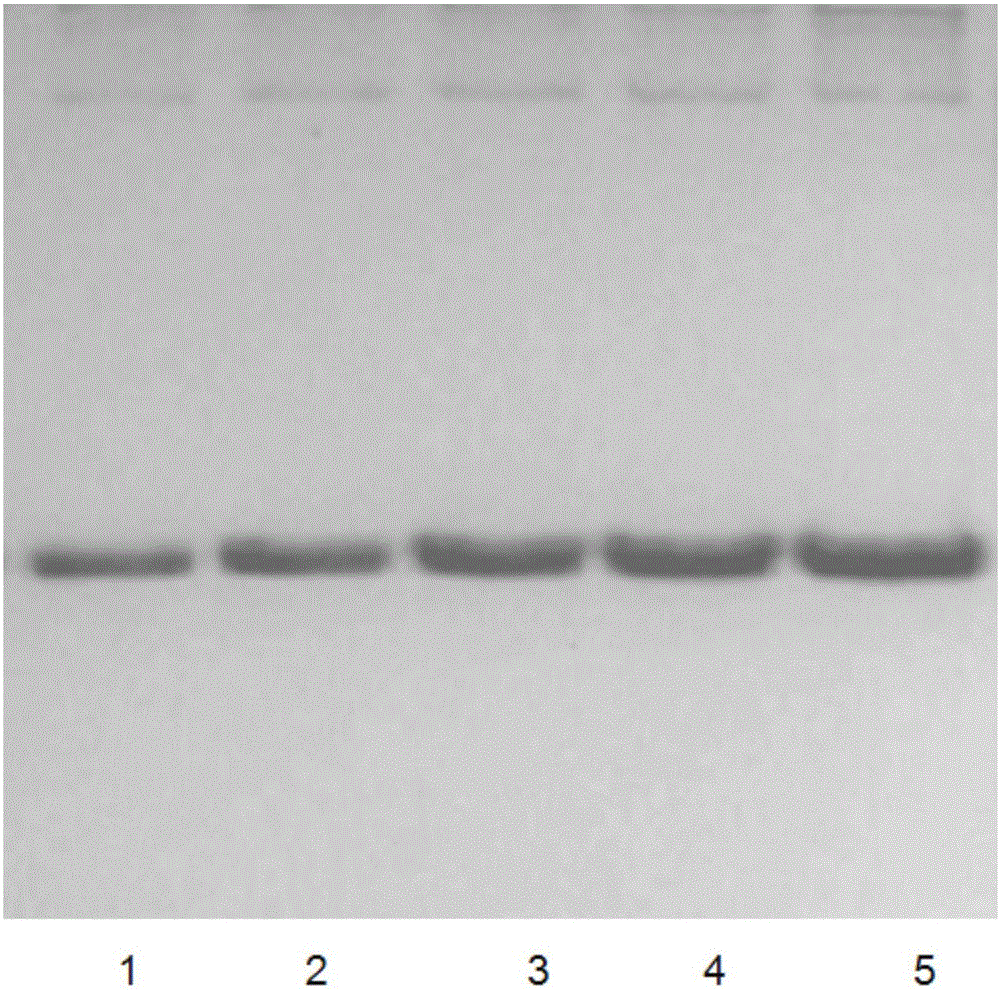

Image

Examples

Embodiment 1

[0024] Collect fresh egg whites, add citric acid-disodium hydrogen phosphate buffer solution with pH 4.6 according to the volume ratio of egg whites and buffer solution at a ratio of 1:2, stir evenly, and let stand overnight in a cold place; centrifuge at 8000rpm to remove the precipitate, and collect the supernatant Solution A, use 0.5M sodium hydroxide solution to adjust the pH to 6; load the CM-agarose ion exchange medium into the column, pretreat it into sodium form, and equilibrate it with citric acid-disodium hydrogen phosphate buffer solution at pH 6; The volume ratio of liquid to medium was 3:1, and the unexchanged protein was washed with deionized water, and finally eluted with 1M sodium chloride solution for 2 column volumes, and the eluate was collected. Use 1M hydrochloric acid to adjust the eluent to pH 5.5, stir evenly for 1 hour, centrifuge at 8000rpm to remove the precipitate, and collect the supernatant B; add polyethylene glycol 2000 to the obtained supernatan...

Embodiment 2

[0026] Collect fresh egg whites, add citric acid-disodium hydrogen phosphate buffer solution with pH 4.6 according to the volume ratio of egg whites and buffer solution at a ratio of 1:2, stir evenly, and let stand overnight in a cold place; centrifuge at 8000rpm to remove the precipitate, and collect the supernatant Solution A, use 0.5M sodium hydroxide solution to adjust the pH to 6; load the CM-agarose ion exchange medium into the column, pretreat it into sodium form, and equilibrate it with citric acid-disodium hydrogen phosphate buffer solution at pH 6; The volume ratio of liquid to medium was 3:1, and the unexchanged protein was washed with deionized water, and finally eluted with 1M sodium chloride solution for 2 column volumes, and the eluate was collected. Use 1M hydrochloric acid to adjust the eluent to pH 5.5, stir evenly for 1 hour, centrifuge at 8000rpm to remove the precipitate, and collect the supernatant B; add polyethylene glycol 2000 to the obtained supernatan...

Embodiment 3

[0028] Collect fresh egg whites, add citric acid-disodium hydrogen phosphate buffer solution with pH 4.6 according to the volume ratio of egg whites and buffer solution at a ratio of 1:2, stir evenly, and let stand overnight in a cold place; centrifuge at 8000rpm to remove the precipitate, and collect the supernatant Solution A, use 0.5M sodium hydroxide solution to adjust the pH to 6; load the CM-agarose ion exchange medium into the column, pretreat it into sodium form, and equilibrate it with citric acid-disodium hydrogen phosphate buffer solution at pH 6; The volume ratio of liquid to medium was 3:1, and the unexchanged protein was washed with deionized water, and finally eluted with 1M sodium chloride solution for 2 column volumes, and the eluate was collected. Use 1M hydrochloric acid to adjust the eluent to pH 5.5, stir evenly for 1 hour, centrifuge at 8000rpm to remove the precipitate, and collect the supernatant B; add polyethylene glycol 2000 to the obtained supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com