Method for extracting thiophen from coking crude benzol

A technology for coking crude benzene and thiophene, applied in the field of heterocyclic aromatic hydrocarbons and aromatic hydrocarbons, can solve the problems of low product purity, serious pollution, low yield and the like, and achieve the effects of overcoming serious pollution, reducing production costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

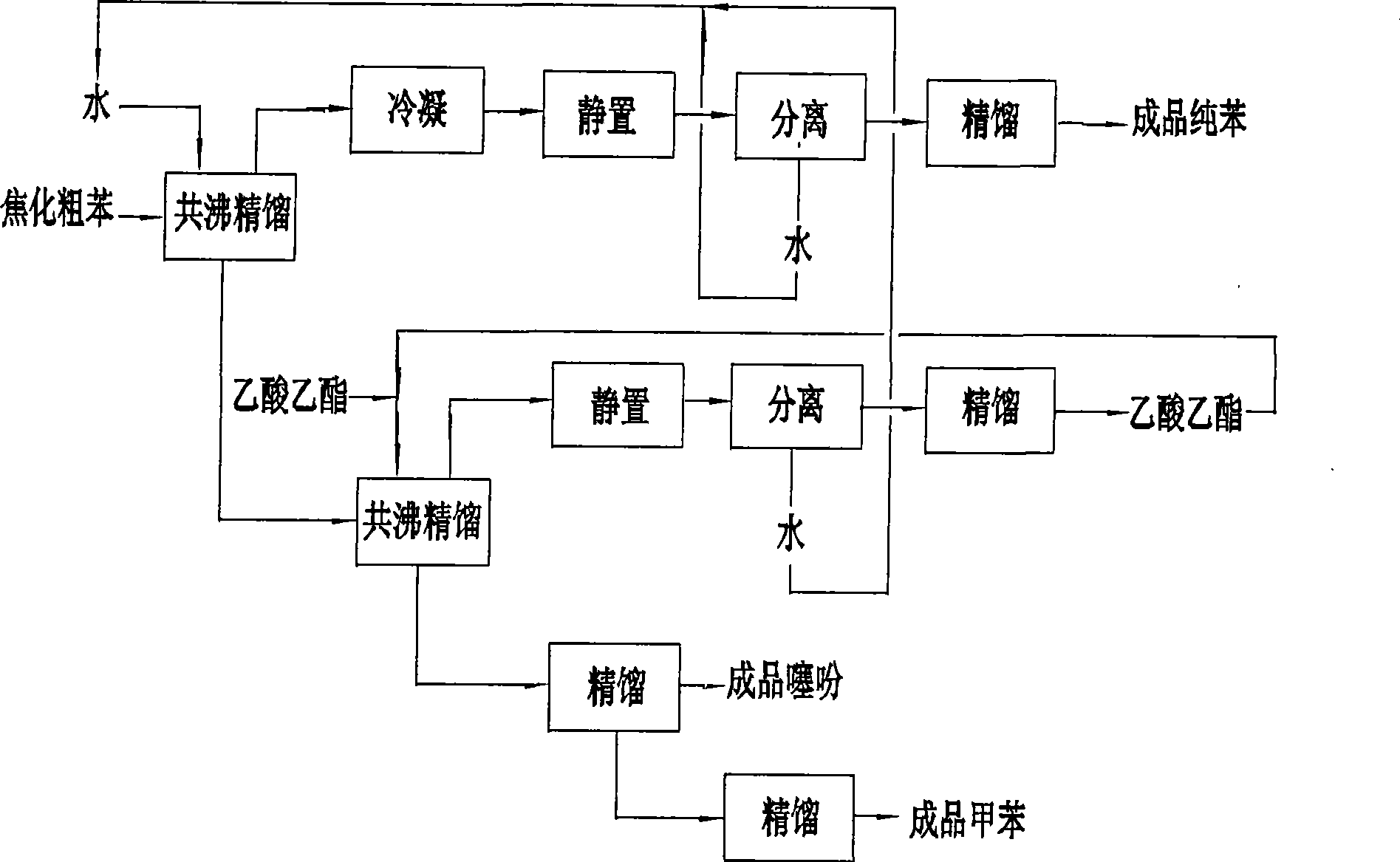

Image

Examples

Embodiment 1

[0022] The method for extracting thiophene from coking crude benzene of the present invention is as follows: (1) first add 319ml (287g) of coking crude benzene and 38g water to a 500ml retort, heat and carry out azeotropic rectification, and collect when the vapor phase temperature is 67.3°C The distillate obtained is colorless and is an azeotrope of benzene and water. By adjusting the flow of cooling water in the condenser, the azeotrope of benzene and water is cooled to 35°C; the azeotrope of benzene and water is transferred In the 500ml separatory funnel, add 3g sodium chloride, after shaking, leave standstill 20min and separate, obtain the organic phase 287ml that the upper layer is mainly benzene, the saturated aqueous solution 28ml of benzene of the lower layer, the saturated aqueous solution of benzene is recycled as water; The organic phase mainly consisting of benzene was transferred to a 500ml retort for rectification, and the fraction at a vapor phase temperature of ...

Embodiment 2

[0026] The method for extracting thiophene from coking crude benzene in this embodiment is as follows: (1) first add 319ml (287g) of coking crude benzene and 76g water to a 500ml retort, heat for azeotropic distillation, and collect The distillate obtained is colorless and is an azeotrope of benzene and water. By adjusting the flow of cooling water in the condenser, the azeotrope of benzene and water is cooled to 34 ° C; the azeotrope of benzene and water is transferred Into the 500ml separatory funnel, add 5g sodium chloride, after shaking, leave standstill 40min and separate, obtain the organic phase 287ml that the upper layer is mainly benzene, the saturated aqueous solution 55ml of benzene in the lower floor, the saturated aqueous solution of benzene is recycled as water; The organic phase mainly consisting of benzene was transferred to a 500ml retort for rectification, and the fraction at a vapor phase temperature of 78.1-81.1°C was collected to obtain pure benzene. The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com