Preparation method and application of modified polypropylene non-woven fabric

A polypropylene non-woven fabric and modified technology, applied in textiles and papermaking, fiber treatment, adsorbed water/sewage treatment, etc., can solve the problems of affecting the adsorption separation effect, low saturation equilibrium adsorption capacity, and large apparent pore size, etc. The effect of low price, large saturated adsorption capacity and large water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Measure a certain amount of monomer methacryloylpropyltrimethylammonium chloride (MAPTAC) with a monomer content of 50wt%, add ethanol, and prepare 40ml of a MAPTAC solution with a concentration of 20wt%; weigh the photosensitizer diphenylmethane Ketone (BP) 0.4g, crosslinking agent methylenebisacrylamide (MDAC) 1.08g, nonionic surfactant Tween 80 is 0.54g; add crosslinking agent and surfactant to the monomer solution and mix at low speed Stir, and at the same time add the photosensitizer BP into the ethanol solution to dissolve, and then mix the above two solutions evenly to obtain the grafting solution. Measure 20ml of the above-mentioned grafting solution in a crystallization dish, wash a 10×15cm dish with acetone and hot water 2 Polypropylene spunbonded non-woven fabric (about 2.0g) is put into a crystallization dish for padding for 10 minutes, taken out and placed in a glass container of an ultraviolet light reaction instrument (100W mercury lamp light source), and...

Embodiment 2

[0029] Using ethanol as a solvent, prepare 20ml of a monomeric diallyldimethylammonium chloride (DADMAC) solution with a concentration of 40wt%; weigh 0.2g of photosensitizer benzophenone (BP), crosslinker methylene di Acrylamide (MDAC) 0.54g, surfactant Tween 80 is 0.27g; add cross-linking agent and surfactant to monomer solution and mix at low speed, meanwhile add photosensitizer BP to ethanol solution to dissolve; The two solutions are mixed evenly to obtain the grafting liquid.

[0030] Put the grafting solution in a crystallization dish, and put a 10×15cm dish that has been washed with acetone and hot water 2Put the polypropylene spunbonded non-woven fabric (about 2.0g) into the crystallization dish for padding for 10 minutes, take out the cloth soaked in the grafting liquid, put it in the glass container of the ultraviolet light reaction instrument (100W mercury lamp light source), and then pump it repeatedly Vacuum, send nitrogen three times, and then feed nitrogen as ...

Embodiment 3

[0032] Take ethanol as solvent, prepare 40ml MAPTAC concentration and be the solution of 30wt%, take by weighing photosensitizer BP0.4g, cross-linking agent MDAC1.08g, Tween 800.54g; Prepare grafting liquid and carry out grafting treatment according to embodiment 1 method, obtain Modified polypropylene spunbonded nonwoven fabric with a graft rate of 90.6%.

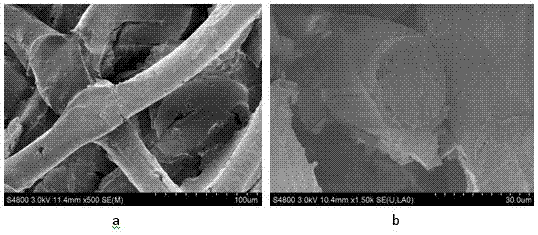

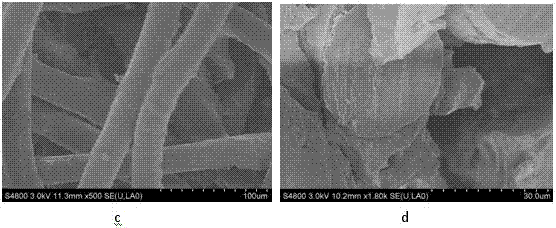

[0033] Referring to accompanying drawing 2, it is the scanning electron micrograph of the modified polypropylene nonwoven fabric surface and section that the present embodiment provides; Among the figure, c and d figure are respectively the scanning electron micrograph of fabric surface and section after grafting, from the figure It can be seen that there is a thick graft layer wrapped around the fabric. From this aspect, it can also be explained that the cationic monomer has been successfully grafted to the polypropylene fabric.

[0034] See attached image 3 , which is the infrared spectrum of the modified polypropylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com