Hydrogel material for 3D bioprinting and preparation method and application of hydrogel material

A technology of bioprinting and 3D printing, applied in additive processing, medical science, prosthesis, etc., to achieve good industrialization prospects, controllable mechanical strength, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A hydrogel material for 3D bioprinting, consisting of gellan gum, polyethylene glycol acrylate (PEGDA), solvent, and bioactive components. In this example, the bioactive component uses bone morphogenetic protein BMP-2 , its preparation method is as follows:

[0026] (1) Utilize acryloyl chloride to modify PEG end groups by conventional methods to obtain polyethylene glycol acrylate;

[0027] (2) According to the mass fraction, dissolve 0.75% gellan gum, 10% PEGDA, and 0.1% initiator I-2959 in the PBS solution at 80°C, stir evenly, and then add bone morphogenetic protein BMP at 37°C -2, mixing evenly to obtain a hydrogel material;

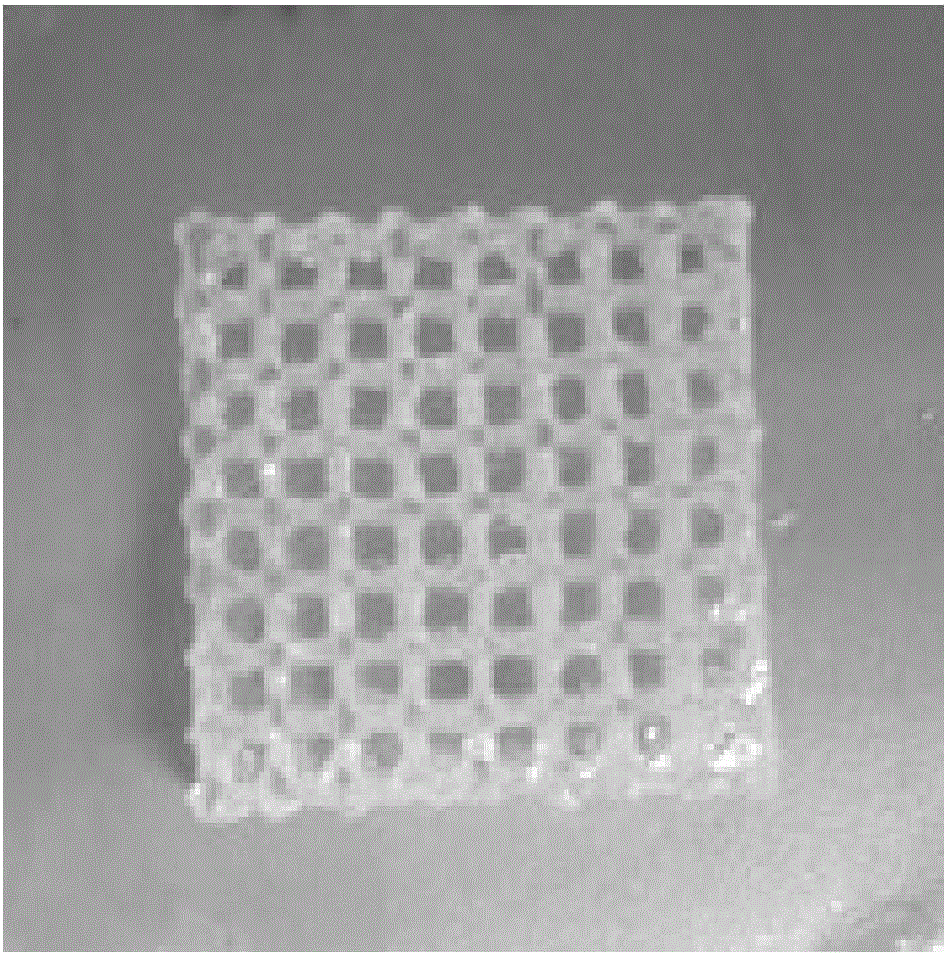

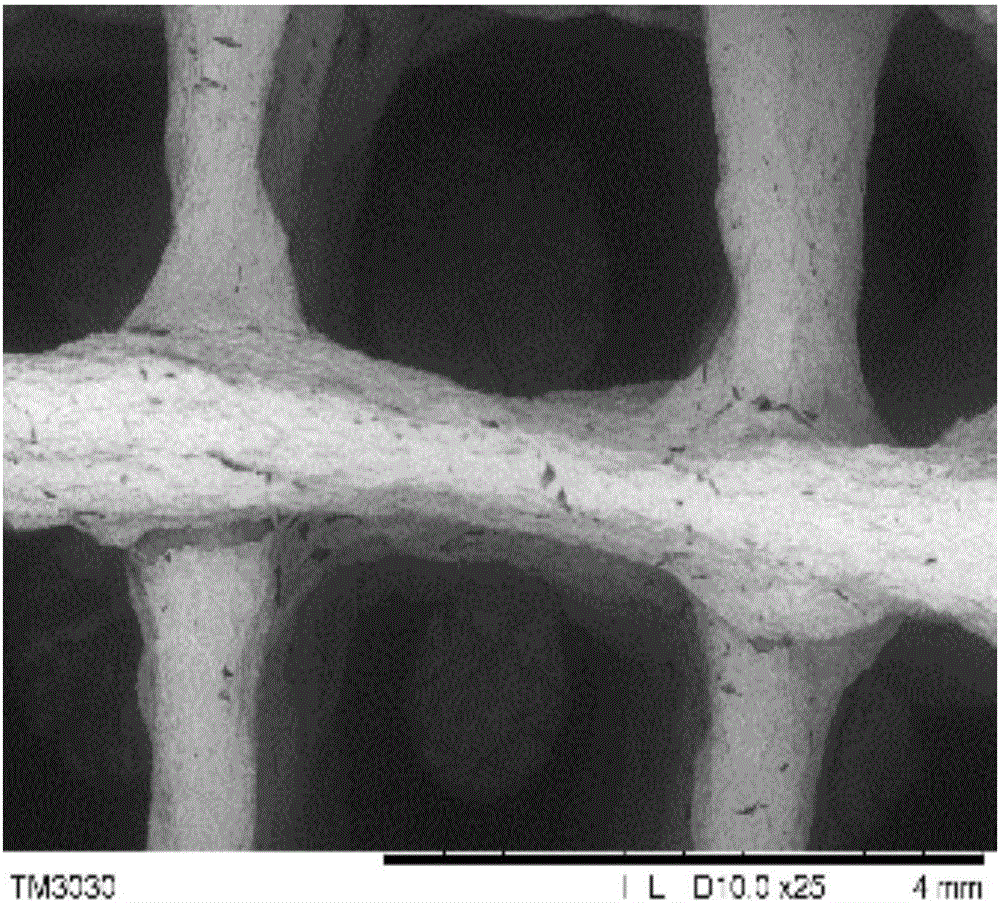

[0028] (3) 3D printing: mix the above hydrogel material with precursor osteoblast suspension evenly, and the cell density is 5×10 5 cells / mL, placed in the ink tube of the 3D bioprinter, printed into a cell-containing scaffold with a certain structure, after printing, put the material in a UV reaction instrument for 10 minutes, the waveleng...

Embodiment 2

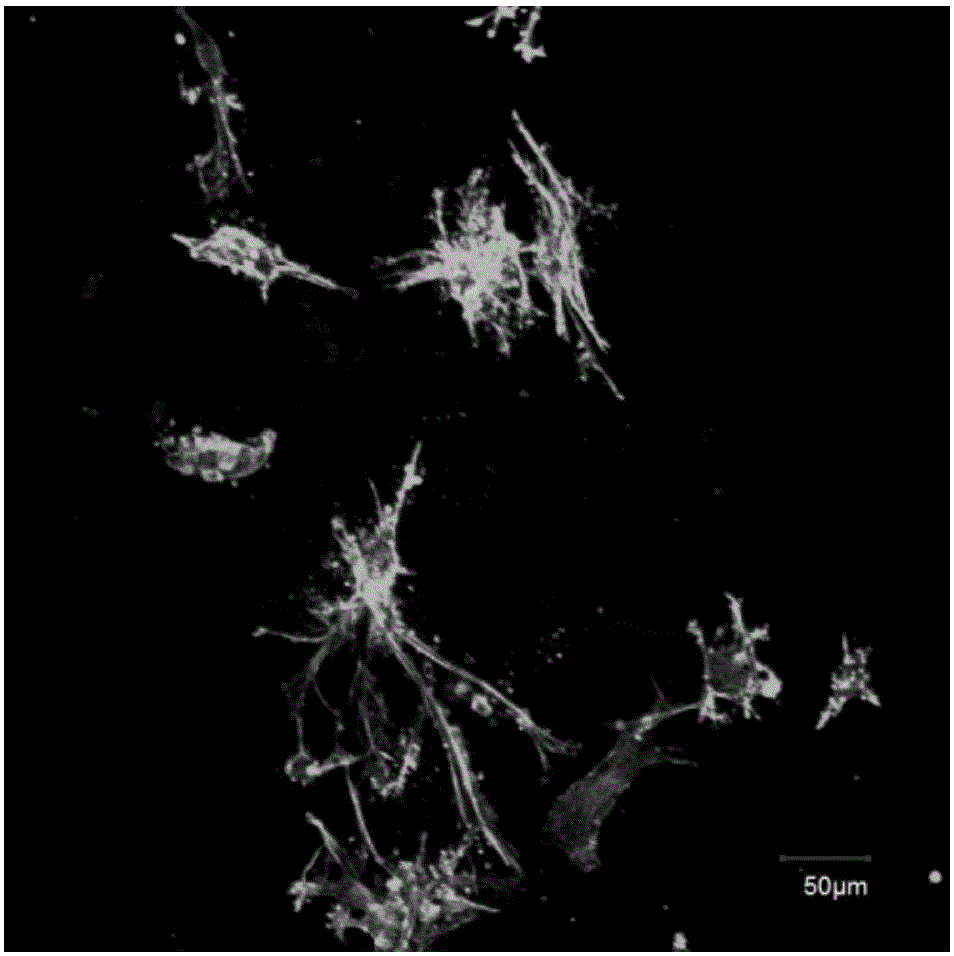

[0031] A hydrogel material for 3D bioprinting, which consists of mercaptolated gellan gum, alkynylated polyethylene glycol, solvent, and bioactive components. In this example, the bioactive component uses the small molecule drug TWS119 (TWS119 is A small-molecule drug that has a significant effect on directionally inducing neural stem cells to differentiate into neurons), the preparation method of which is as follows:

[0032] (1) Utilizing cysteine to modify gellan gum by conventional methods to obtain thiolated gellan gum;

[0033] (2) Utilizing propargyl bromide to modify the PEG end group by conventional methods to obtain alkynylated polyethylene glycol;

[0034] (3) By mass fraction, 0.6% mercaptolated gellan gum, 10% alkynylated polyethylene glycol, and 0.1% initiator I-2959 were dissolved in deionized water at 80° C., stirred evenly, and then Add nanoparticles containing small molecule drug TWS119 (0.5% of TWS119 dosage) at 37°C, mix well to obtain a hydrogel materia...

Embodiment 3

[0038] A hydrogel material for 3D bioprinting, consisting of thiolated gellan gum, polyethylene glycol, solvents, and bioactive components. In this embodiment, the bioactive component uses basic fibroblast growth factor (bFGF) , its preparation method is as follows:

[0039] (1) Utilizing cysteine to modify gellan gum by conventional methods to obtain thiolated gellan gum;

[0040] (2) According to the mass fraction, 1.5% gellan gum and 1% PEG-6000 were dissolved in deionized water at 80°C, stirred evenly, and then 100ng / mL basic fibroblast growth factor was added at 37°C ( bFGF), mixed uniformly to obtain a hydrogel material;

[0041](3) 3D printing: add bone marrow mesenchymal stem cell suspension to the above hydrogel material, and the cell density is 1×10 5 cells / 100μL, placed in the ink tube of the 3D bioprinter, printed a certain structure of the cell-containing scaffold, and immediately placed the material in the bone marrow mesenchymal stem cell culture medium afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com