Patents

Literature

80 results about "3D bioprinting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three dimensional (3D) bioprinting is the utilization of 3D printing–like techniques to combine cells, growth factors, and biomaterials to fabricate biomedical parts that maximally imitate natural tissue characteristics. Generally, 3D bioprinting utilizes the layer-by-layer method to deposit materials known as bioinks to create tissue-like structures that are later used in medical and tissue engineering fields. Bioprinting covers a broad range of biomaterials.

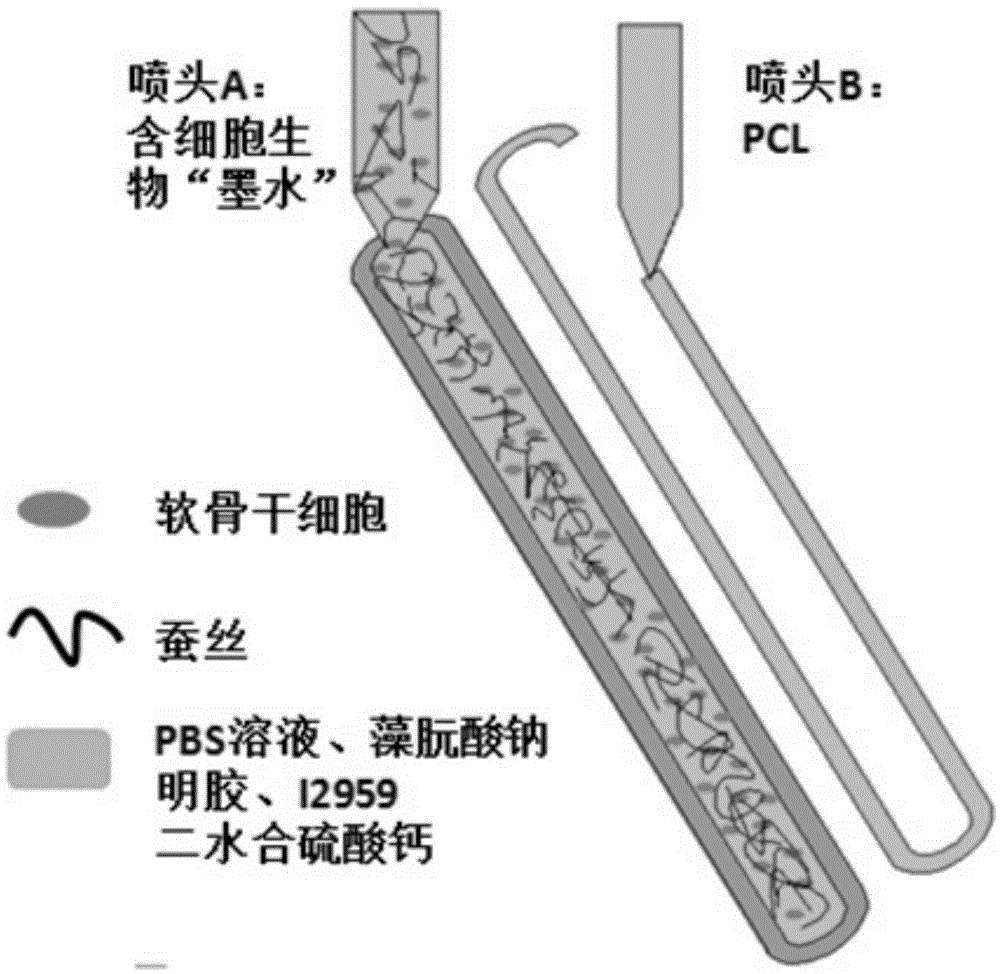

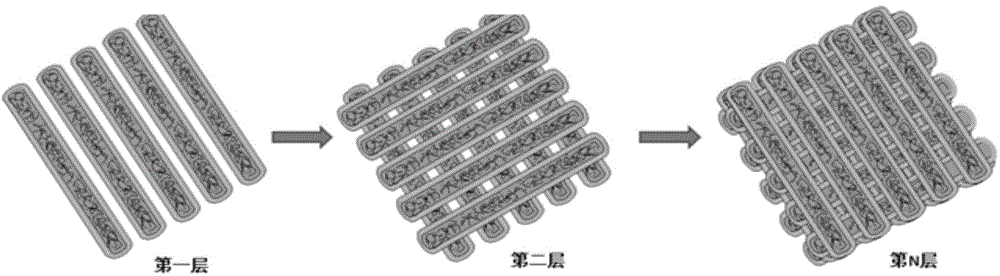

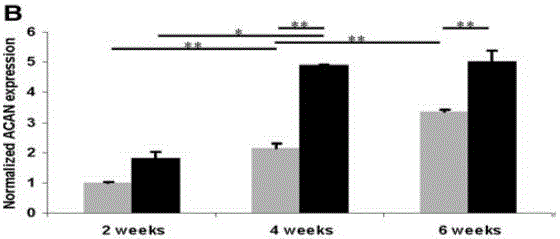

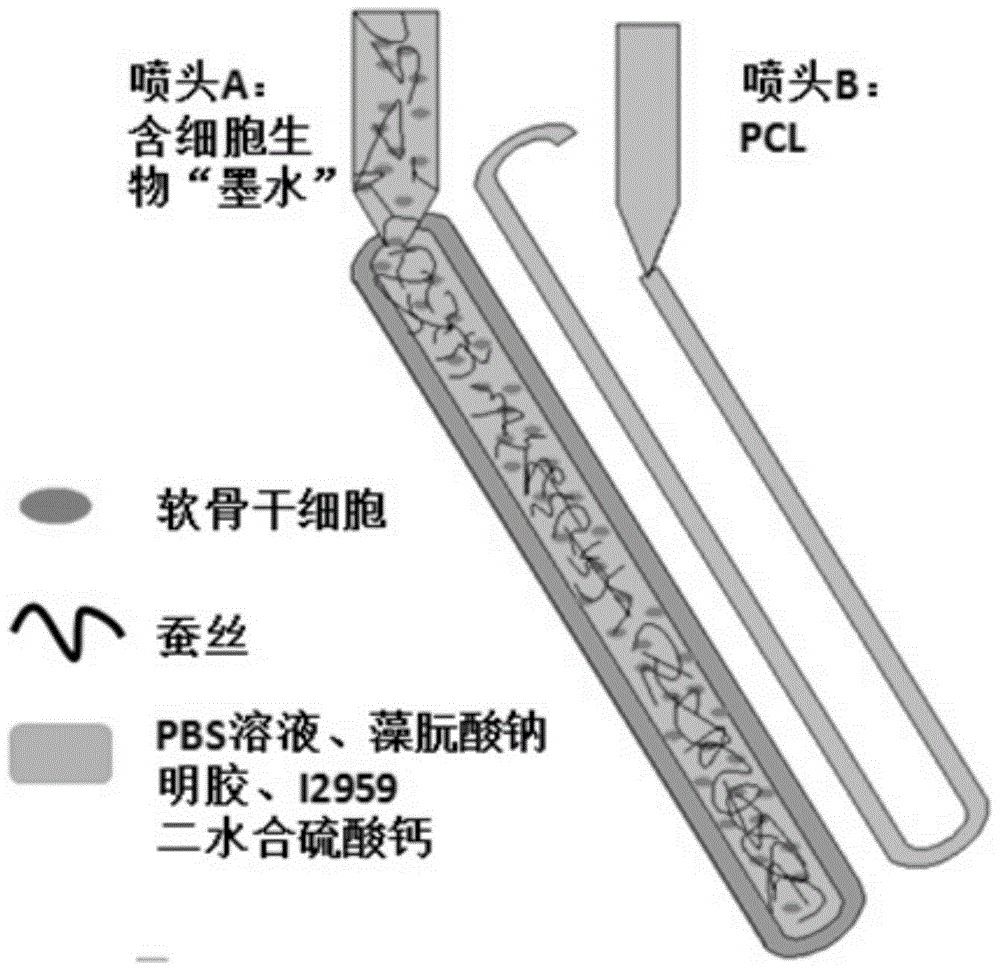

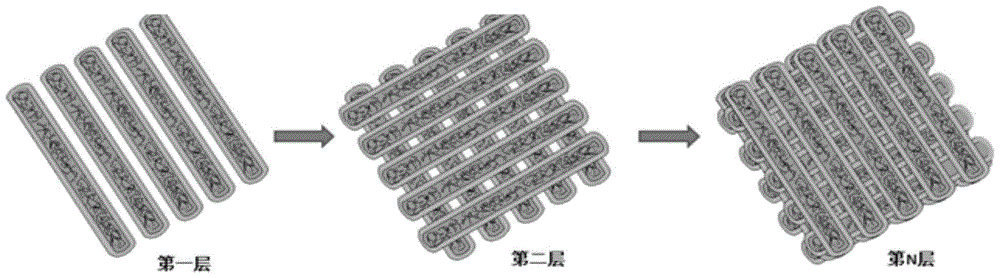

Method for preparing cartilage with high mechanical property based on 3D bioprinting

ActiveCN104399119AImprove mechanical propertiesGood mechanical propertiesProsthesisBiocompatibility TestingBiological materials

The invention provides a method for preparing cartilage with a high mechanical property based on 3D bioprinting. The method comprises the following steps: preparing silk fibers, preparing a gelatin solution, preparing ciological ink containing cells, carrying out 3D cartilage printing, performing cell culture and differentiation on a printed tissue to form the cartilage. The method solves the problems of polarization of 2-dimension culture for cells and high body and surface ratio of cells through the 3D bioprinting technology; sodium alginate and calcium ions form ionic bonds, and gelatin and methacrylic anhydride form covalent bonds, so that the 3D bioprinted cartilage is good in mechanical property and is not easily broken; the gelatin has biocompatibility and degradability of normal biological material hydrogel, has bioactivity, and is good for cell growth and differentiation and realization of cell functions.

Owner:西安博恩生物科技有限公司

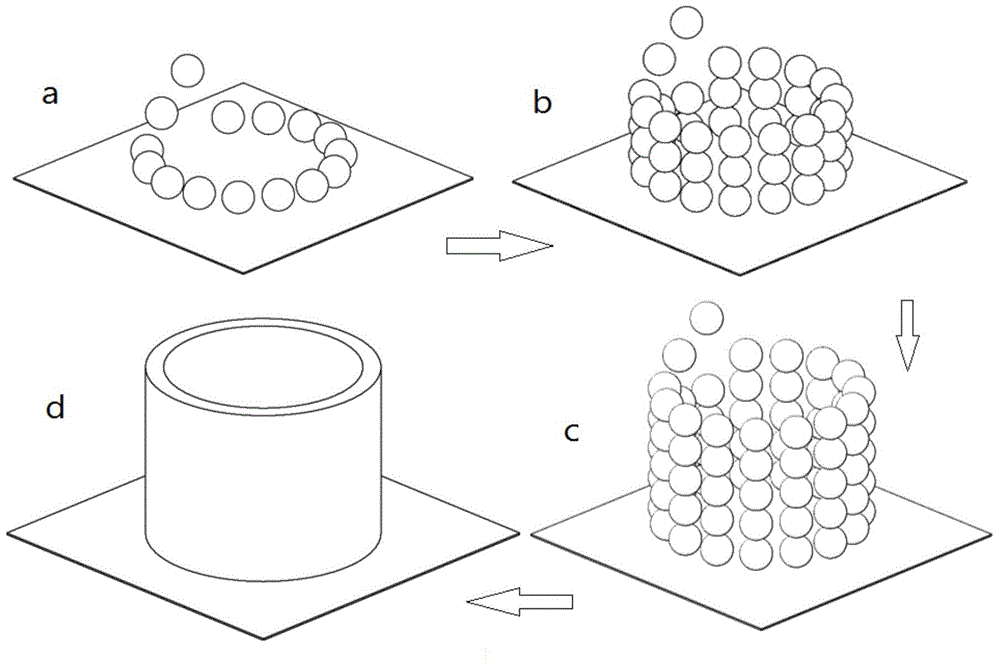

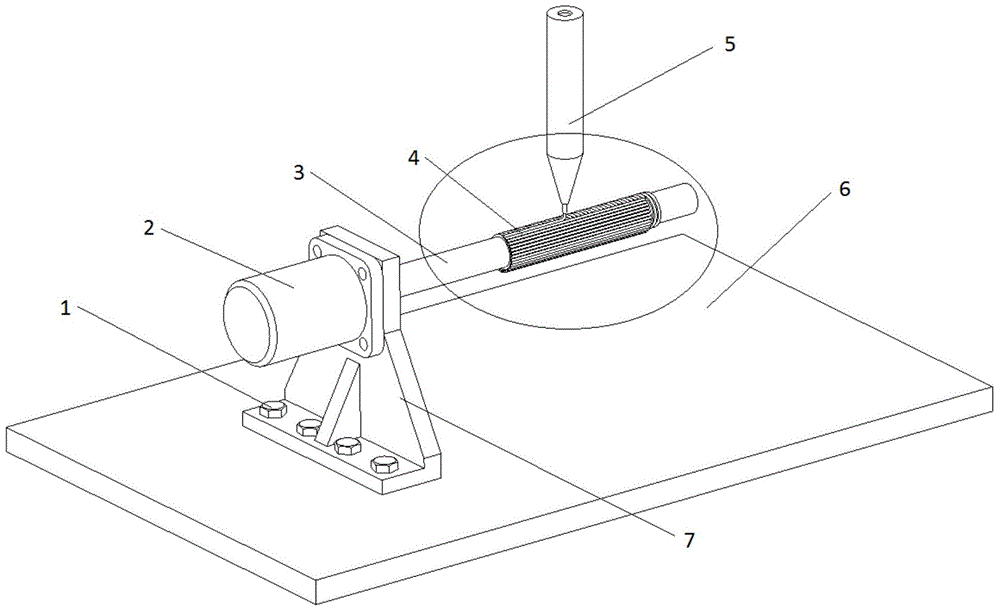

Blood vessel forming device and method for 3D bioprinting

InactiveCN104146794ALess affected by gravityThe overall impact is smallBlood vesselsBiological material testing proceduresBlood Vessel TissueBiomedical engineering

This invention discloses a blood vessel forming device and method for 3D bioprinting. The device and method are used for the bioengineering technology and aim to solve the problems that currently, when blood vessels are printed through the 3D bioprinting technologies, the blood vessels are poor in forming quality and small in forming length. According to the method, biological ink is printed on rotary rods with the surfaces coated with thermo-sensitive hydrogel through the 3D bioprinting technologies, and the needed biological blood vessels can be formed through further biological culture. According to the method, the rotary rods with different diameters and lengths can be prepared for printing the biological blood vessels with different sizes, blood vessel tissue which is uniform in thickness and accurate in printing size can be fast printed, the available 3D printing technologies are diverse, and the device and method are wide in practicability. We call the method a 3D rotational forming printing method (3Denvelop Bioprinting Method).

Owner:周惠兴

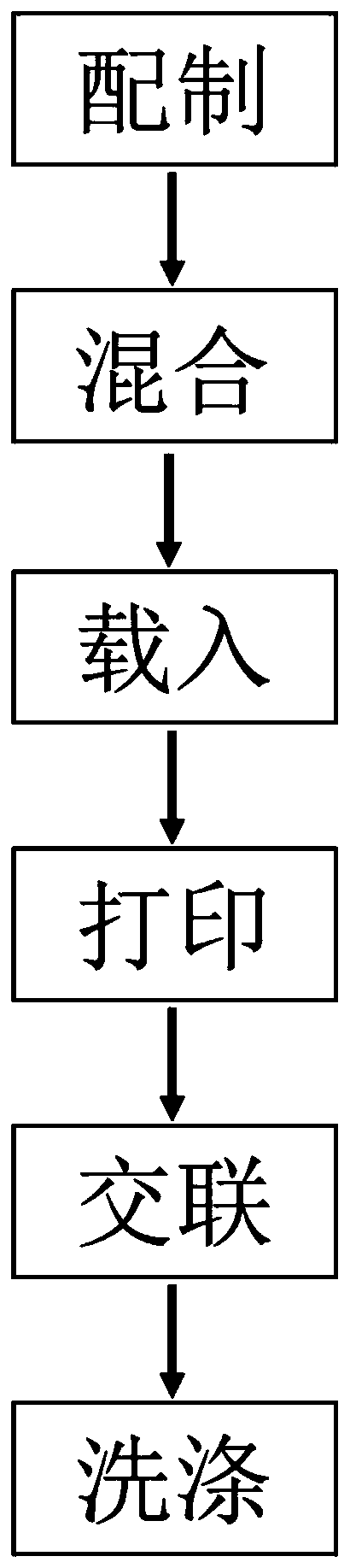

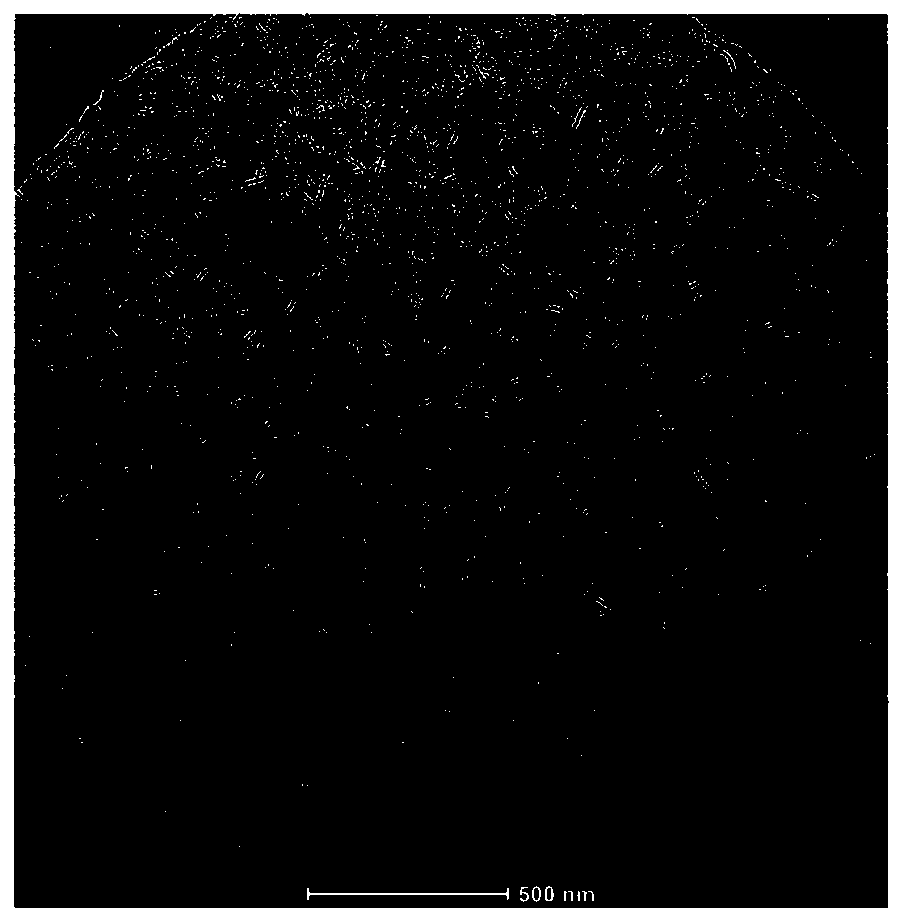

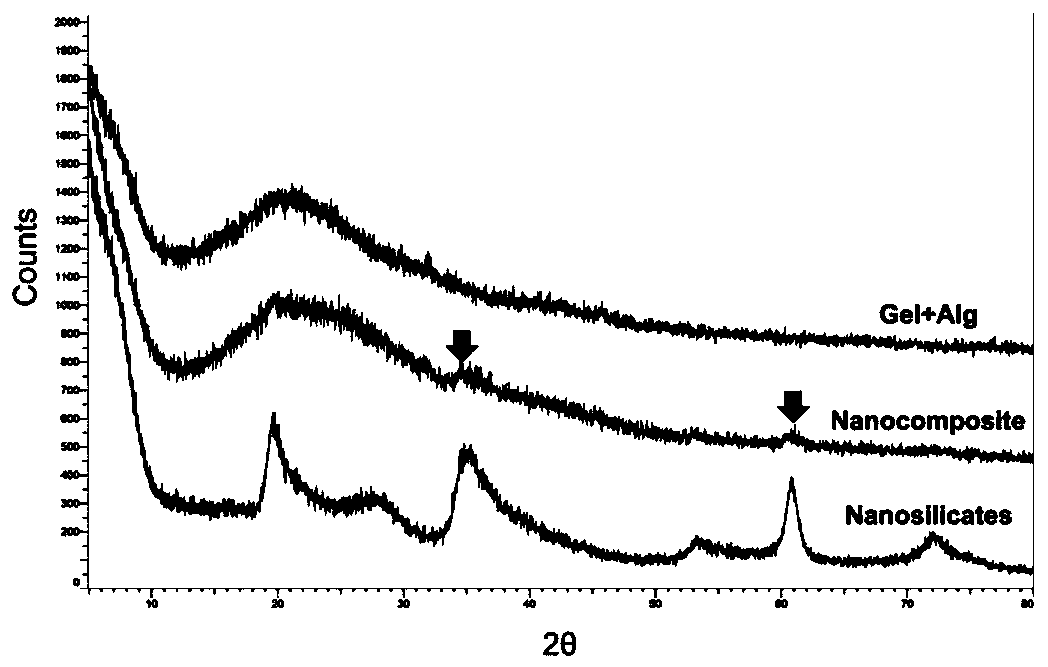

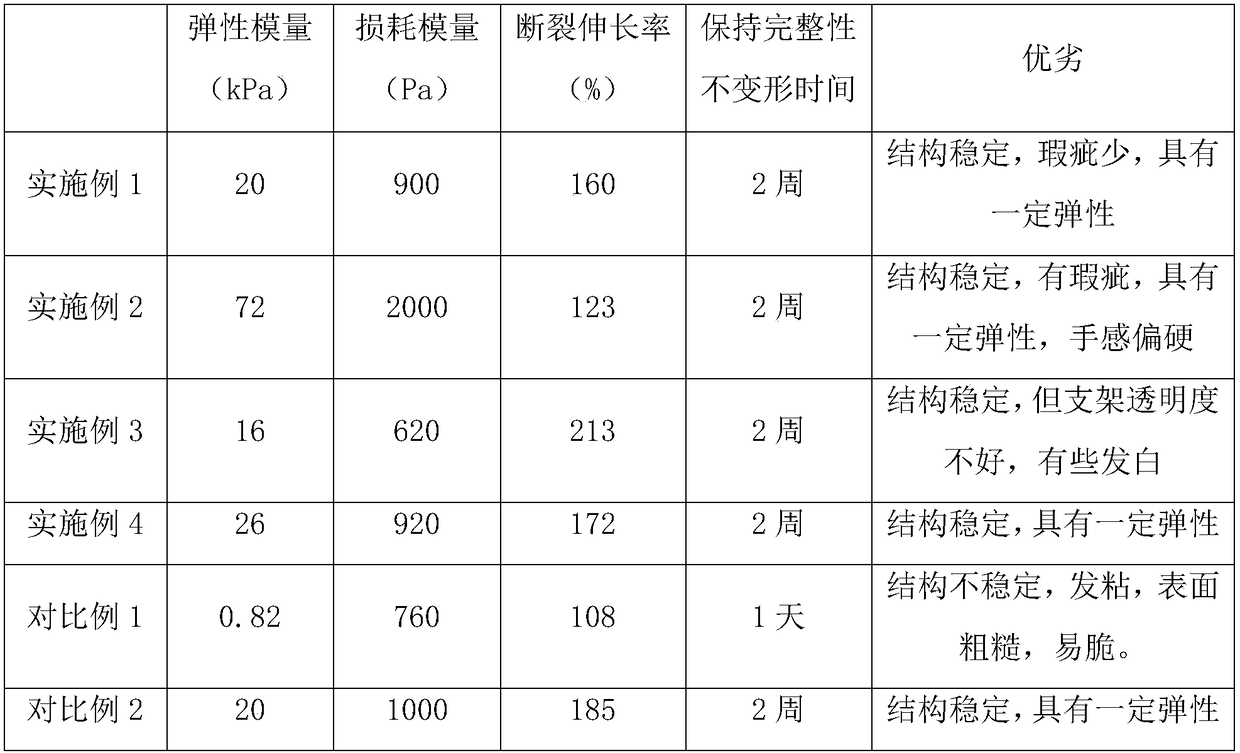

3D bioprinting ink, preparation method of ink, tissue engineering scaffold and preparation method of scaffold

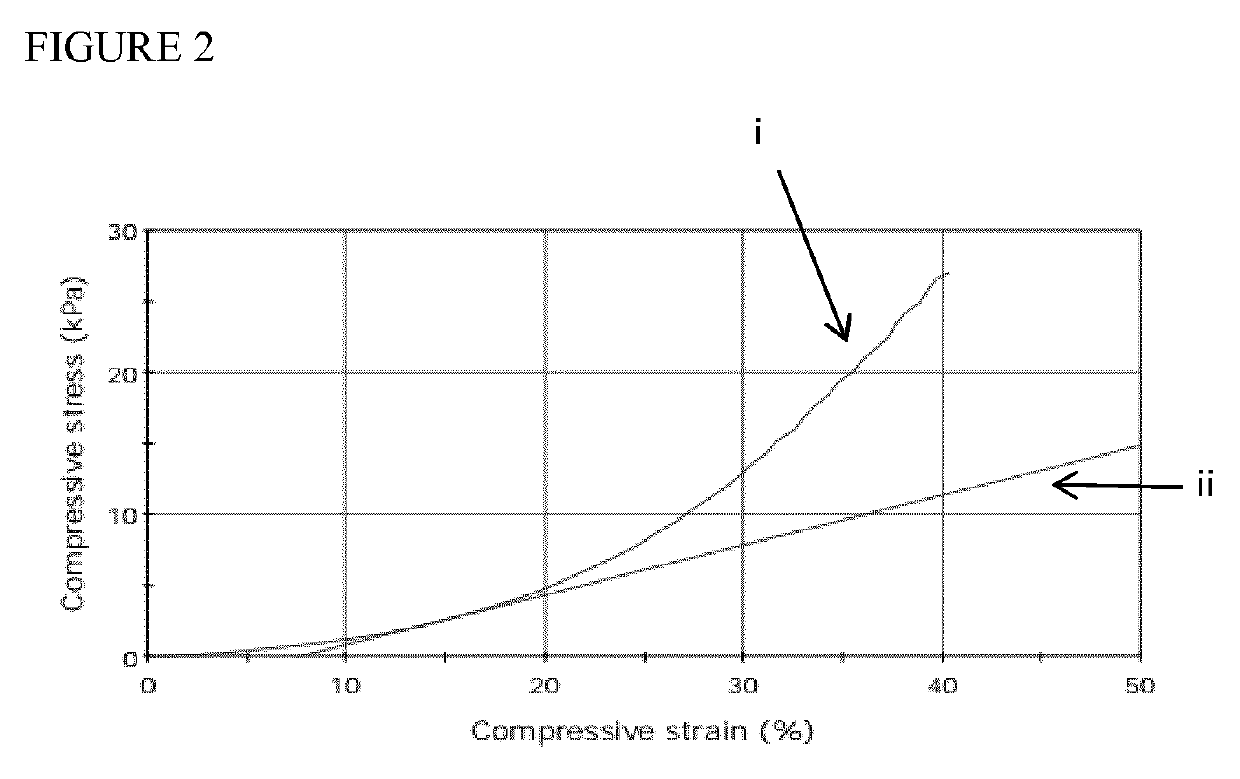

InactiveCN110665063AHigh strengthRelieve painAdditive manufacturing apparatusTissue regenerationComputer printingBiology

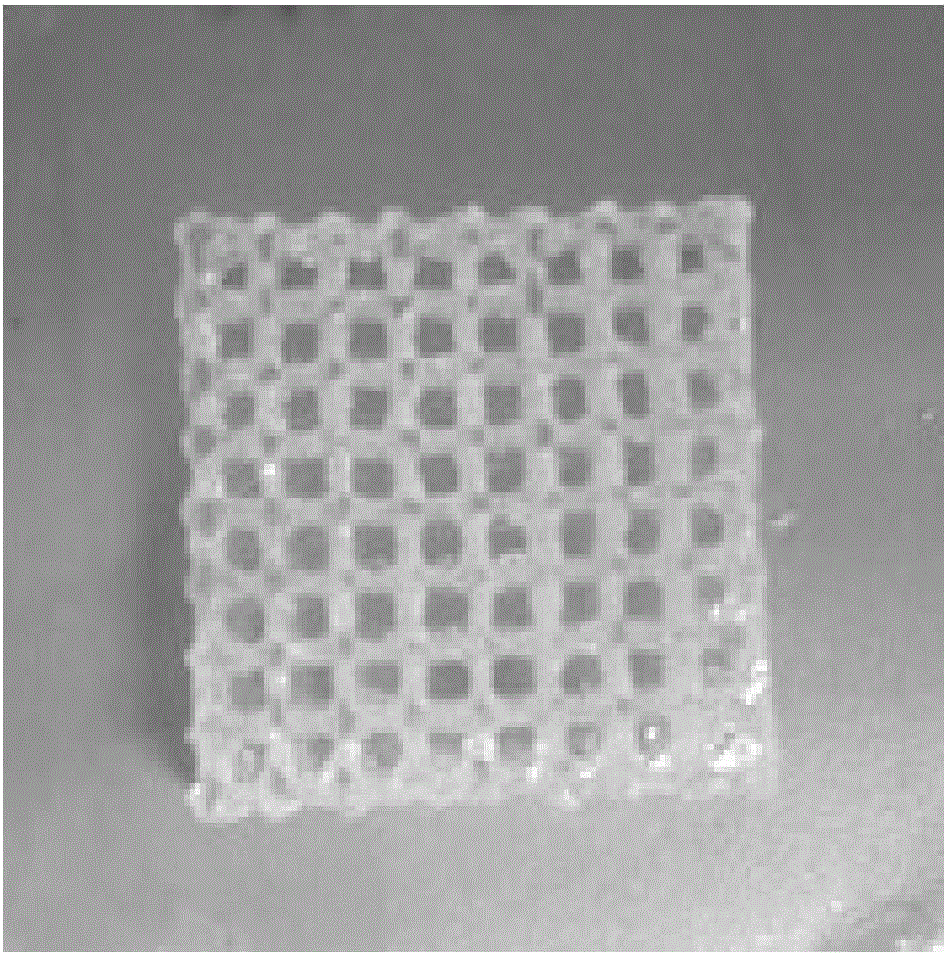

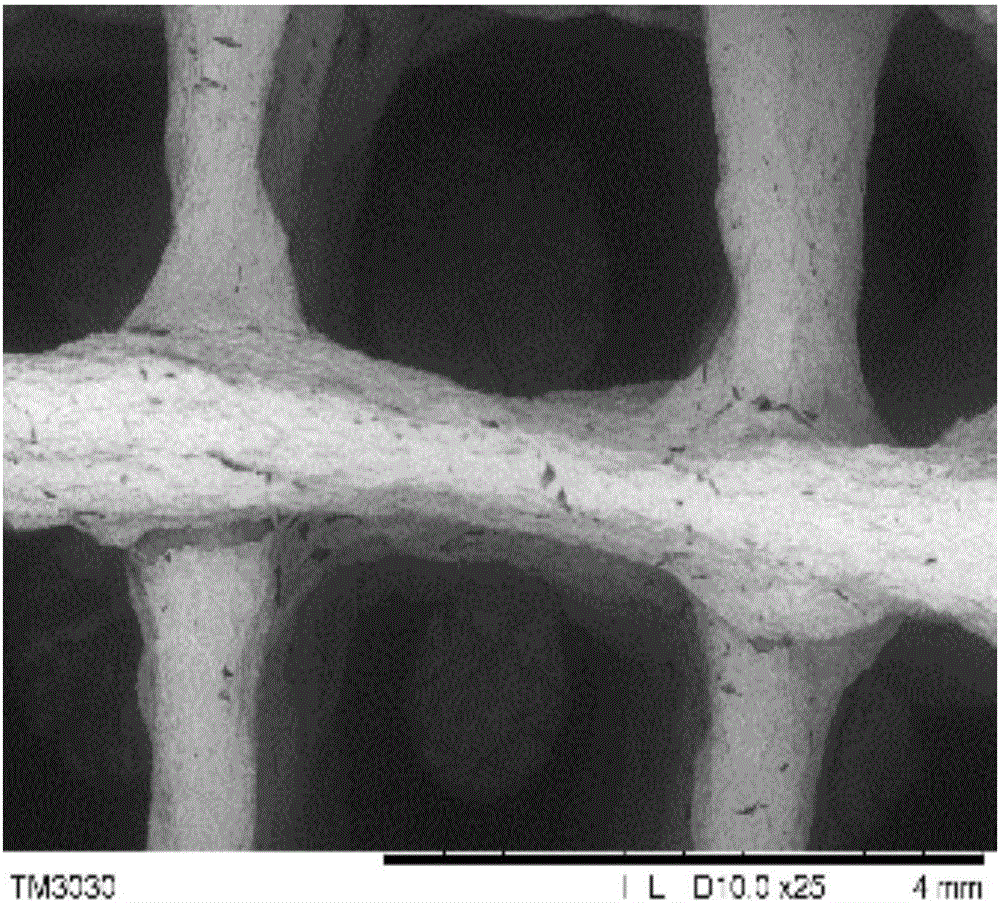

The invention discloses 3D bioprinting ink, a preparation method of the ink, a tissue engineering scaffold and a preparation method of the scaffold. The ink contains the following five components: gelatin, sodium alginate, nano-scale magnesium lithium silicate, deionized water and human mesenchymal stem cells. The preparation method of the ink comprises the following steps: firstly dissolving thesterile gelatin and the sodium alginate into the sterile deionized water in order to prepare a mixed prepolymer solution of 140-200 mg / ml gelatin and 20-60 mg / ml sodium alginate; dissolving the sterile magnesium lithium silicate into the sterile deionized water to prepare 20-60 mg / mL magnesium lithium silicate colloid; mixing the two gel in equal volume to prepare a nanocomposite hydrogel which can be used for 3D bioprinting; and finally, uniformly mixing the pre-cultured human mesenchymal stem cells and the nano-composite hydrogel to obtain the nano composite bio-ink with a final cell concentration of 3 x 10<6> / mL. The functionalized, biomimetic tissue engineering bone scaffold with osteogenesis inducing ability is prepared by using the bio-ink as a raw material and adopting a squeeze type 3D bioprinter through printing, and has potential clinical application value

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

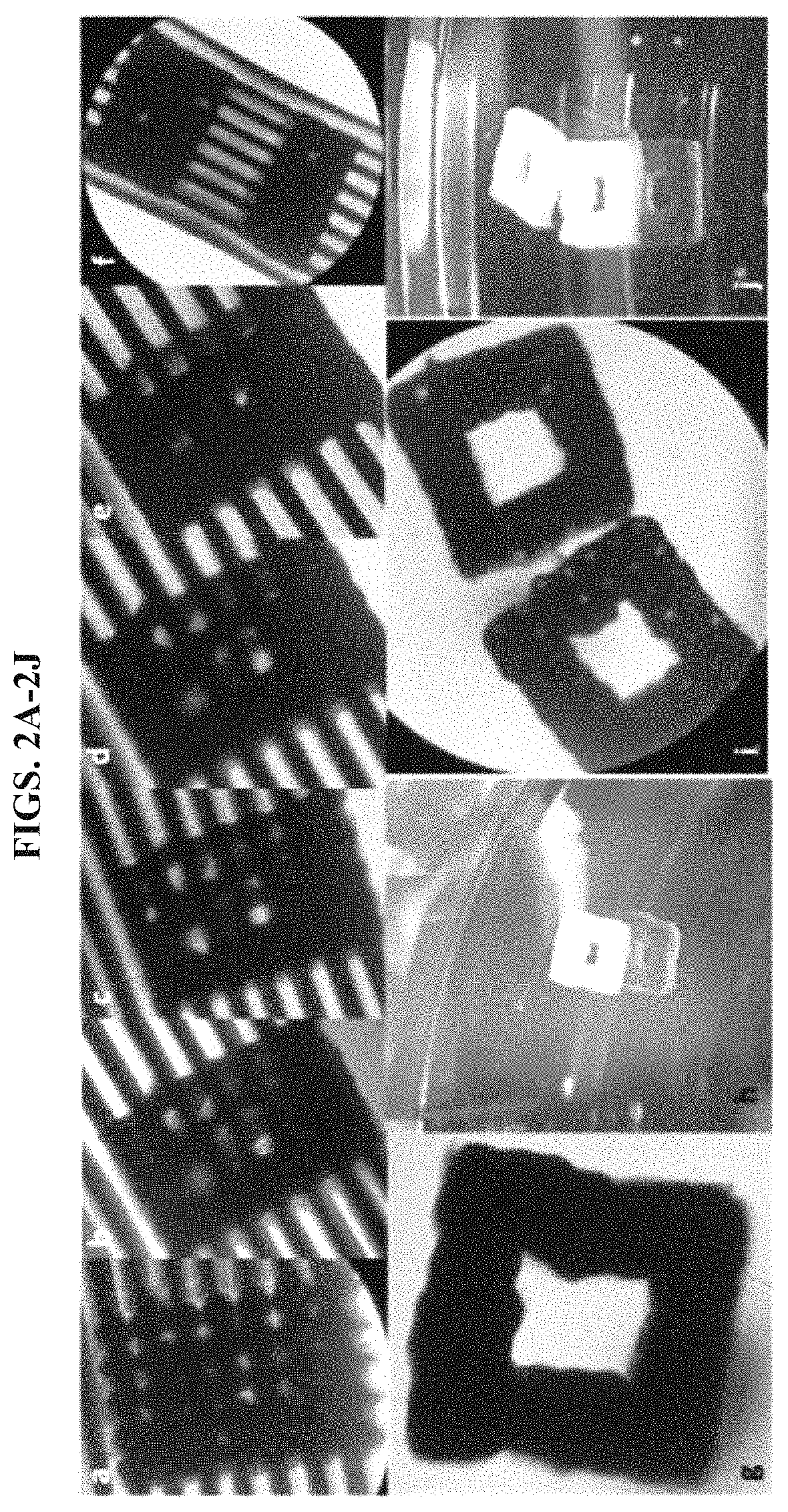

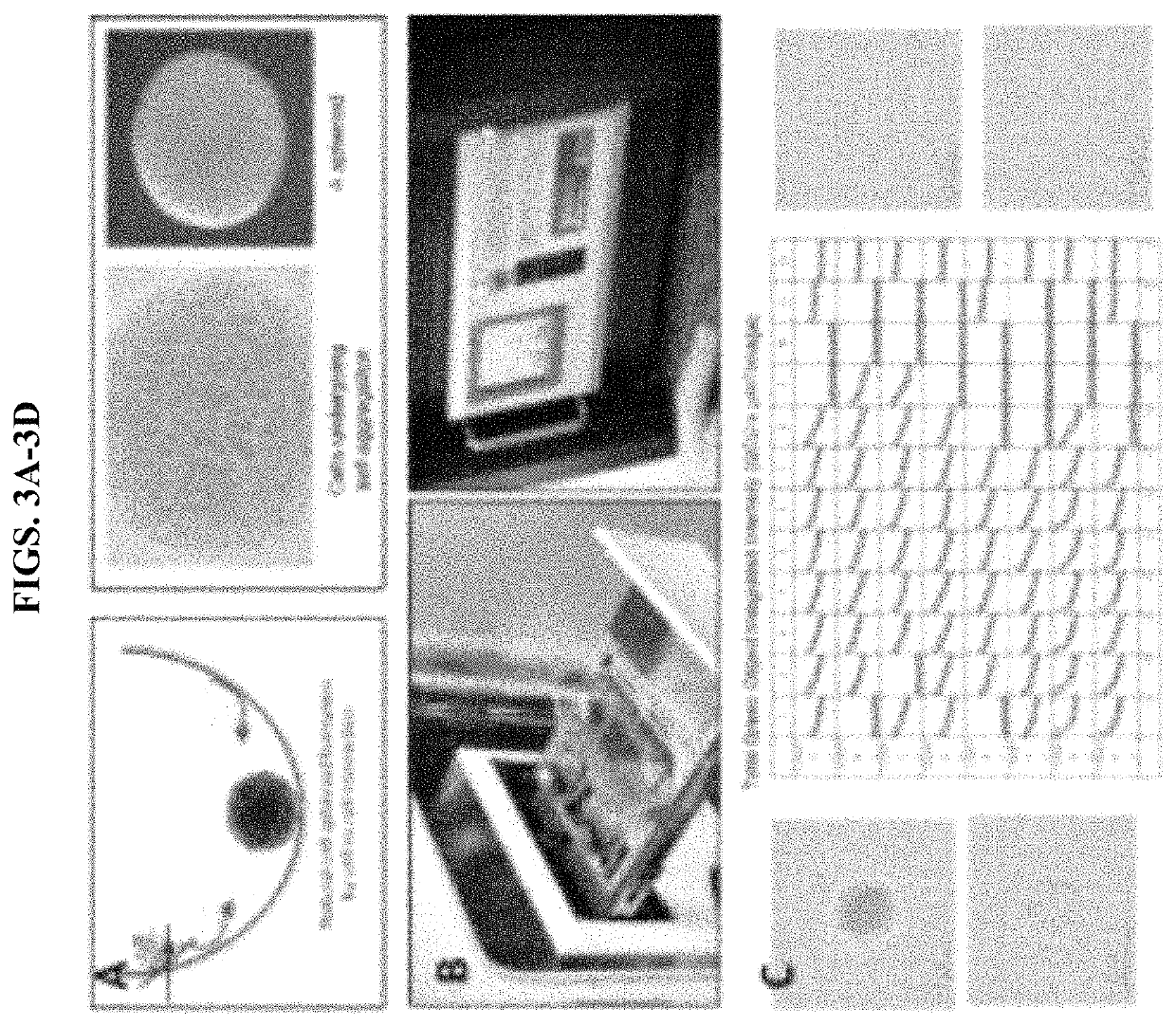

Cellulose nanofibrillar bioink for 3D bioprinting for cell culturing, tissue engineering and regenerative medicine applications

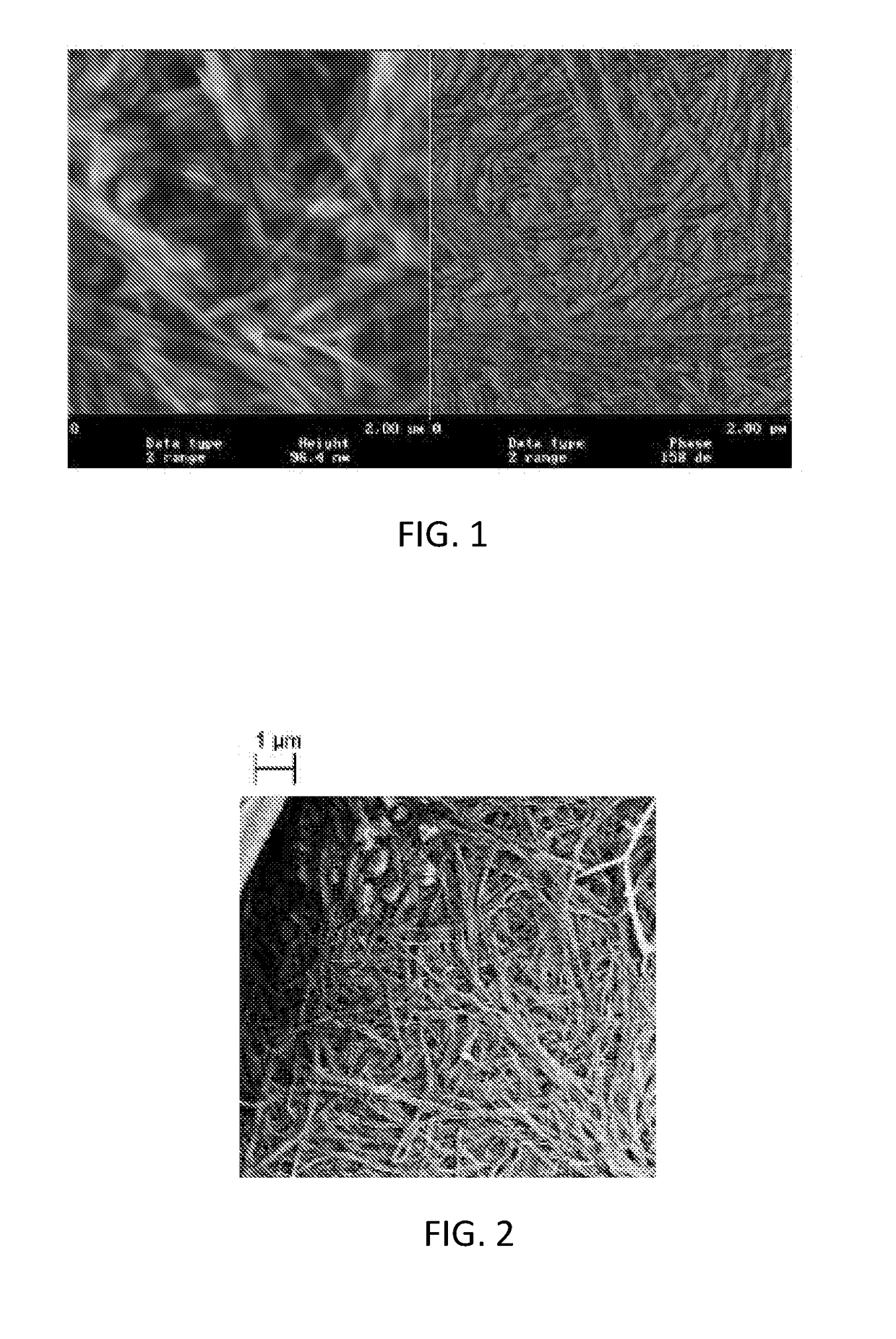

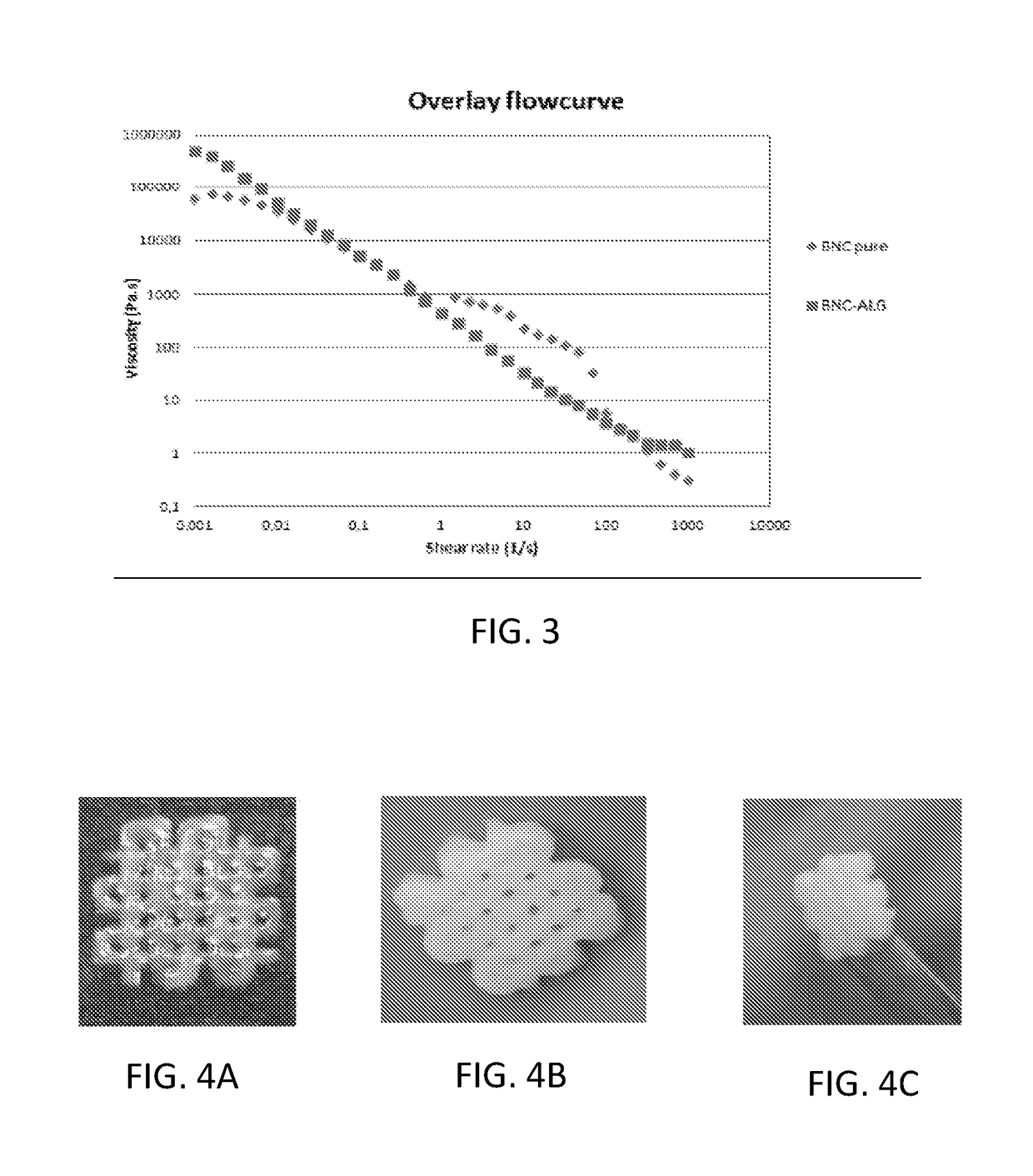

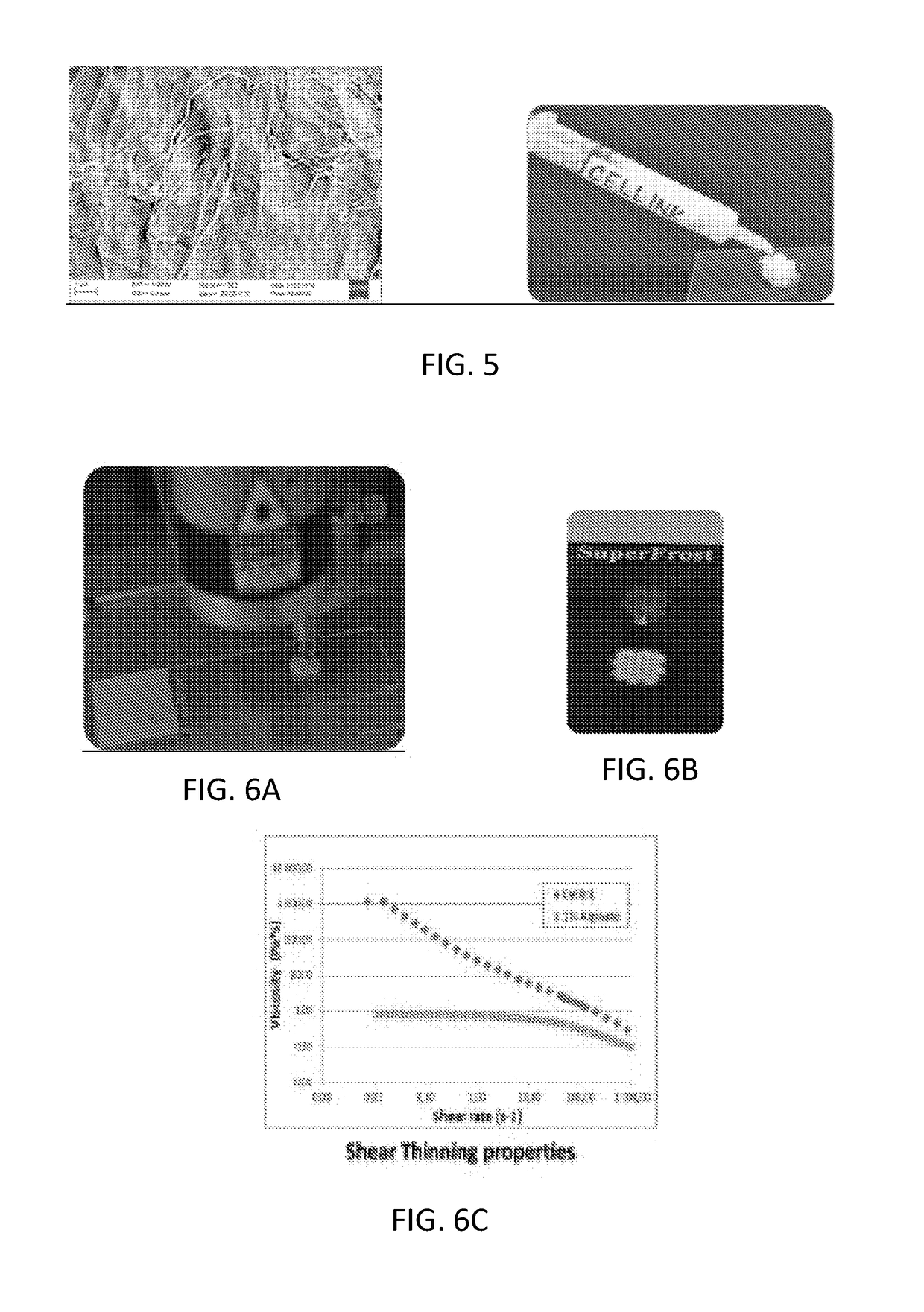

ActiveUS20170368225A1Improve survivabilityAdditive manufacturing apparatusCellulose coatingsCelluloseFiber

The present invention relates to biomaterial in the form of dispersion of cellulose nanofibrils with extraordinary shear thinning properties which can be converted into desire 3D shape using 3D Bioprinting technology. In this invention cellulose nanofibril dispersion, is processed through different mechanical, enzymatic and chemical steps to yield dispersion with desired morphological and rheological properties to be used as bioink in 3D Bioprinter. The processes are followed by purification, adjusting of osmolarity of the material and sterilization to yield biomaterial which has cytocompatibility and can be combined with living cells. Cellulose nanofibrils can be produced by microbial process but can also be isolated from plant secondary or primary cell wall, animals such as tunicates, algae and fungi. The present invention describes applications of this novel cellulose nanofibrillar bioink for 3D Bioprinting of tissue and organs with desired architecture.

Owner:CELLINK AB

Method for preparing tissue engineering blood vessel based on 3D bioprinting technology

ActiveCN104490489AGood biocompatibilityStrong mechanical propertiesSkeletal/connective tissue cellsCell culture supports/coatingDiseaseThrombus

The invention provides a method for preparing a tissue engineering blood vessel based on a 3D (3-Dimensional) bioprinting technology. The method comprises the following steps:alternately printing a blood vessel shape by virtue of a high-polymer material and a human renascent skin fiber cell column, and removing the high-polymer material after fusion to structure a tissue engineering blood vessel; filling late-outgrowth endothelial progenitor cells into the blood vessel, and performing in-vitro dynamic culturing for 7 days in a bioreactor to obtain a differentiated tissue engineering blood vessel, wherein the high-polymer material is one of pluronic F127, poly(N-isopropylacrylamide), methyl cellulose and sodium alginate. The blood vessel obtained by the method is high in biocompatibility and higher in mechanical property, thrombus formation resistant and platelet adhesion resistance, and can be used for repairing and replacing a damaged or disease blood vessel.

Owner:江苏知聚知识产权服务有限公司

Hydrogel material for 3D bioprinting and preparation method and application of hydrogel material

ActiveCN106474560AGood compatibilityImprove structural stabilityAdditive manufacturing apparatusProsthesisHigh cellSolvent

The invention belongs to the technical field of biological materials, and discloses a hydrogel material for 3D bioprinting and a preparation method and application of the hydrogel material. The hydrogel material comprises the following components in percentages by mass: 0.5-10% of gellan gum and / or derivatives, 0.1-20% of PEG and / or derivatives thereof, 0-1% of a crosslinking initiator, 0-15% of biologically active components and the balance of a solvent. The hydrogel material is double-network hydrogel based on the gellan gum and PEG; interpenetrating double-network structures are formed in a physiological environment; and the hydrogel material has good structure and dimensional stability, and has the advantages of quick gum formation under physiological conditions, excellent cell compatibility, small immunological rejection, high cell encapsulation efficiency, controllable mechanical strength, biodegradability and the like. The hydrogel material is applied to 3D bioprinting; the shortcomings of low curing speed, harsh curing conditions, limited mechanical properties, poor cell compatibility and the like are overcome; and the hydrogel material has obvious advantages and good industrialized prospect.

Owner:JINAN UNIVERSITY

Preparation and Applications of 3D Bioprinting Bioinks for Repair of Bone Defects, Based on Cellulose Nanofibrils Hydrogels with Natural or Synthetic Calcium Phosphate Particles

ActiveUS20190307923A1Induce bone formationRepair large defectPharmaceutical delivery mechanismSkeletal/connective tissue cellsPorosityBiopolymer

The present invention relates to preparation of bioink composed of cellulose nanofibril hydrogel with native or synthetic Calcium containing particles. The concentration of the calcium containing particles can be between 1% and 40% w / v. Such bioink can be 3D Bioprinted with or without human or animal cells. Coaxial needle can be used where cellulose nanofibril hydrogel filled with Calcium particles can be used as shell and another hydrogel based bioink mixed with cells can be used as core or opposite. Such 3D Bioprinted constructs exhibit high porosity due to shear thinning properties of cellulose nanofibrils which provides excellent printing fidelity. They also have excellent mechanical properties and are easily handled as large constructs for patient-specific bone cavities which need to be repaired. The porosity promotes vascularization which is crucial for oxygen and nutrient supply. The porosity also makes it possible for further recruitment of cells which accelerate bone healing process. Calcium containing particles can be isolated from autologous bone, allogenic bone or xenogeneic bone but can be also isolated from minerals or be prepared by synthesis. Preferable Calcium containing particles consist of β-tricalcium phosphate which is resorbable or natural bone powder, preferably of human or porcine origin. The particles described in the present invention have particle size smaller than 400 microns, or more preferably smaller than 200 microns, to make it possible to handle in printing nozzle without clogging and to obtain a good resolution. Cellulose nanofibrils can be produced by bacteria orbe isolated from plants. They can be neutral, charged or oxidized to be biodegradable. The bioink can be additionally supplemented by other biopolymers which provide crosslinking. Such biopolymers can be alginates, chitosans, modified hyaluronic acid or modified collagen derived biopolymers.

Owner:CELLINK AB

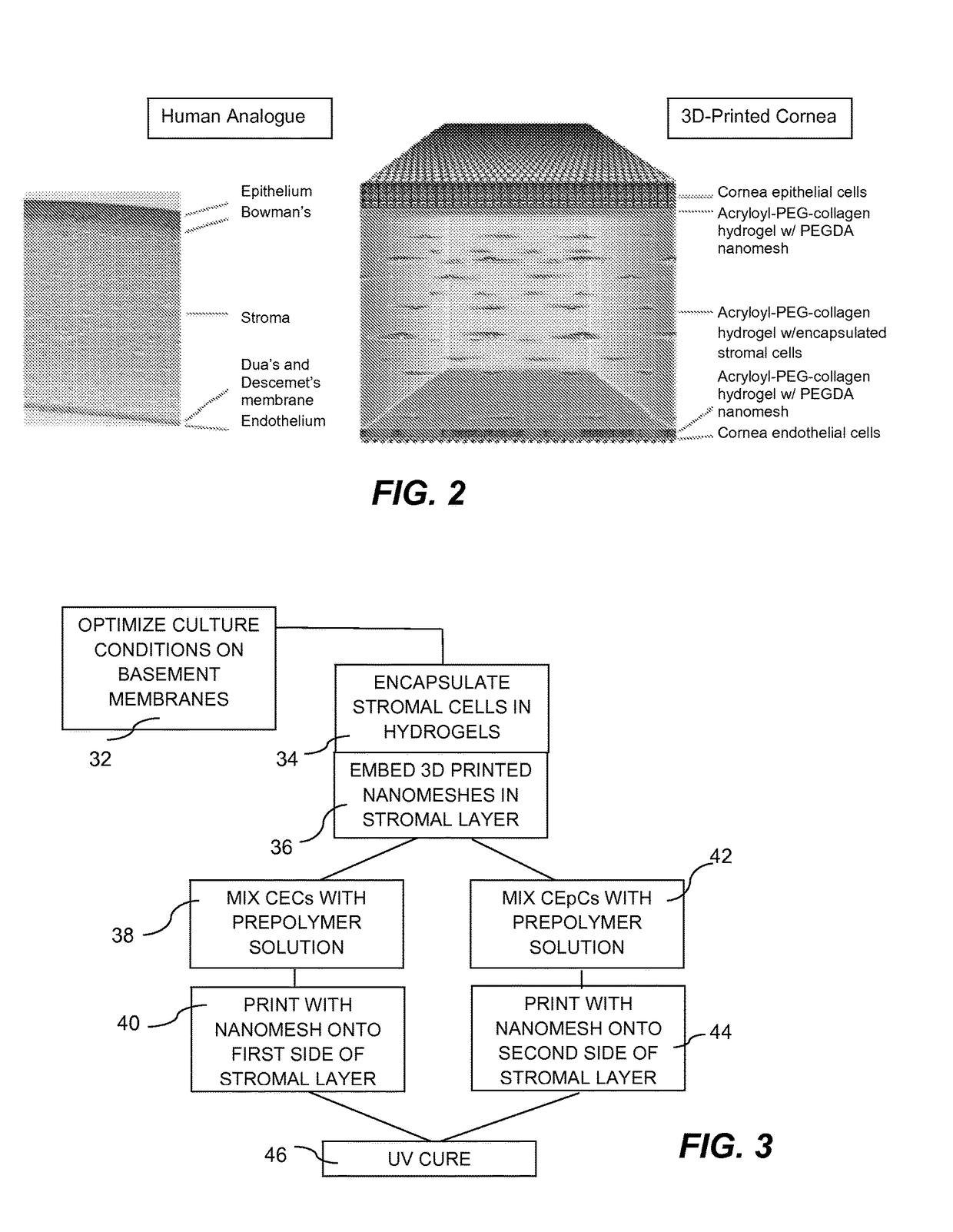

Three-dimensional bioprinted artificial cornea

InactiveUS20170281828A1Restore visionEliminate dependenciesAdditive manufacturing apparatusPharmaceutical delivery mechanismCorneal endothelial cellStromal cell

An artificial cornea is fabricated by separately culturing live stromal cells, live corneal endothelial cells (CECs) and live corneal epithelial cells (CEpCs), and 3D bioprinting separate stromal, CEC and CEpC layers to encapsulate the cells into separate hydrogel nanomeshes. The CEC layer is attached to a first side of the stromal layer and the CEpC layer to a second side of the stromal layer to define the artificial cornea.

Owner:RGT UNIV OF CALIFORNIA

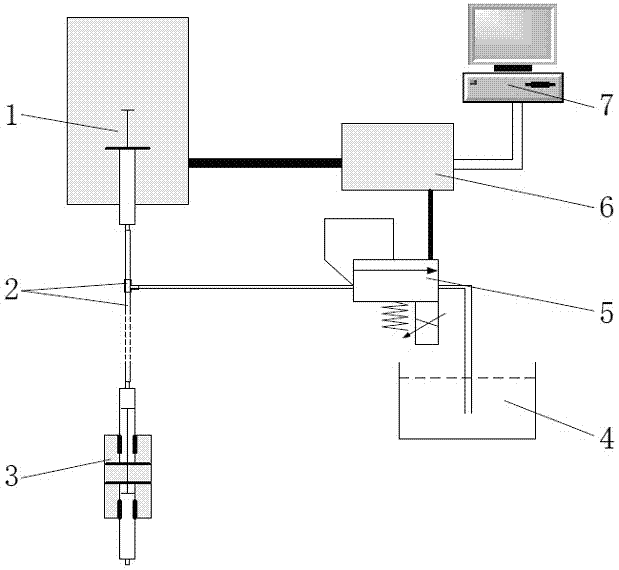

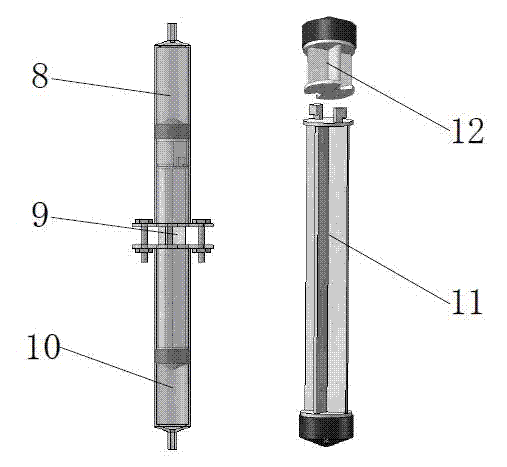

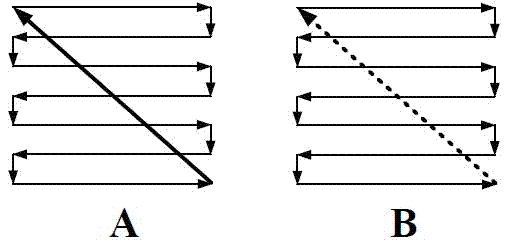

Hydraulic extruding material supplying system and hydraulic extruding material supplying method for 3D bioprinting

The invention relates to hydraulic extruding material supplying system and a hydraulic extruding material supplying method for 3D bioprinting. The hydraulic extruding material supplying system comprises a pressure source, a liquid pipe, a spray head device, a liquid storage box, a electrohydraulic proportional overflow valve, a controller and an upper computer, wherein the pressure source comprises a micro-injection pump and a medical injector; the liquid pipe is connected with the spray head device, the liquid storing box and the electrohydraulic proportional overflow valve to form an extruding circuit and a pressure regulating circuit; the controller is connected with the micro-injection pump and the electrohydraulic proportional overflow valve through data wires and is used for controlling the work of the whole hydraulic material supplying system through the upper computer. With the adoption of the hydraulic extruding material supplying system and the hydraulic extruding material supplying method for 3D bioprinting, the material extrusion can be controlled in real time and can quickly respond; the system and the method are applicable to various extrusion molding 3D bioprinting devices and are not limited by materials and processes.

Owner:SHANGHAI UNIV

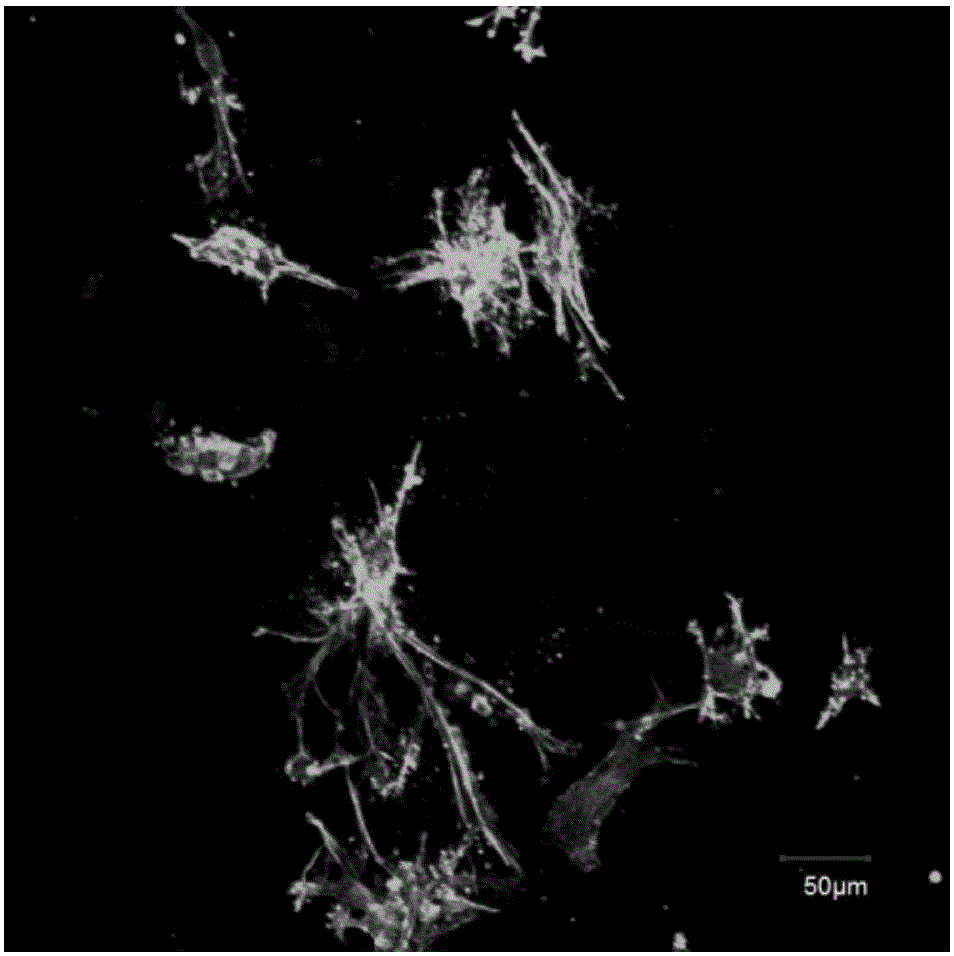

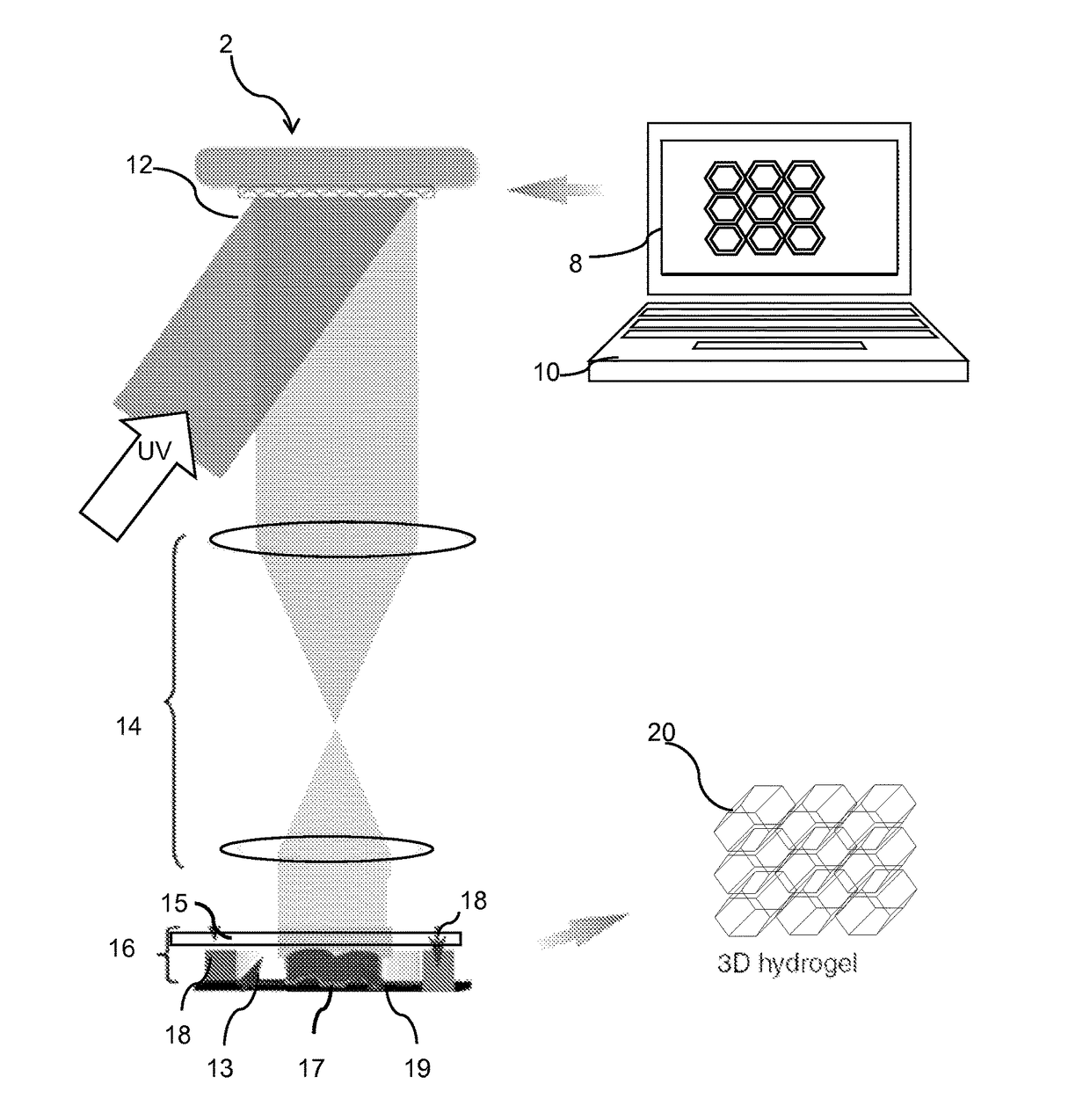

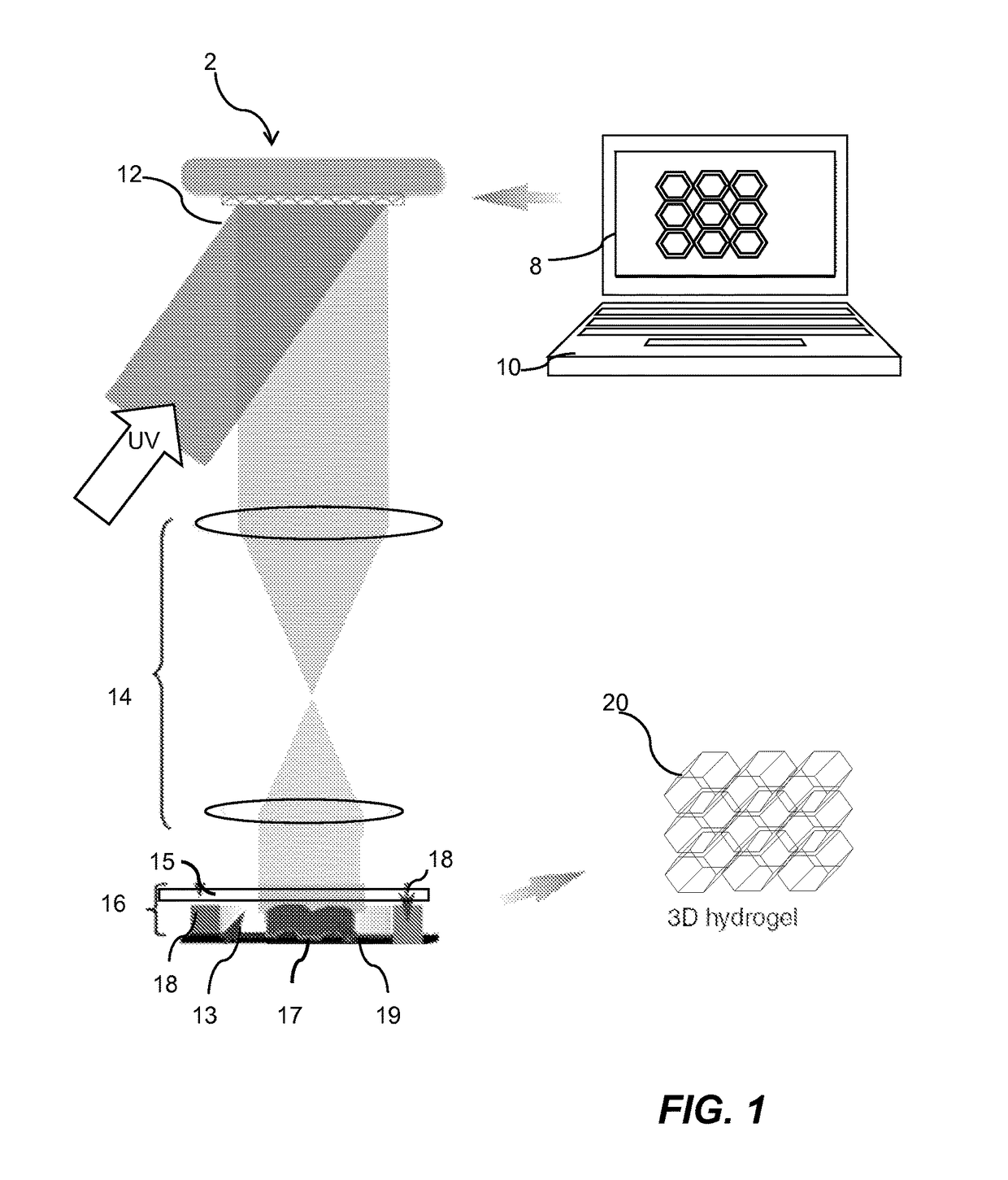

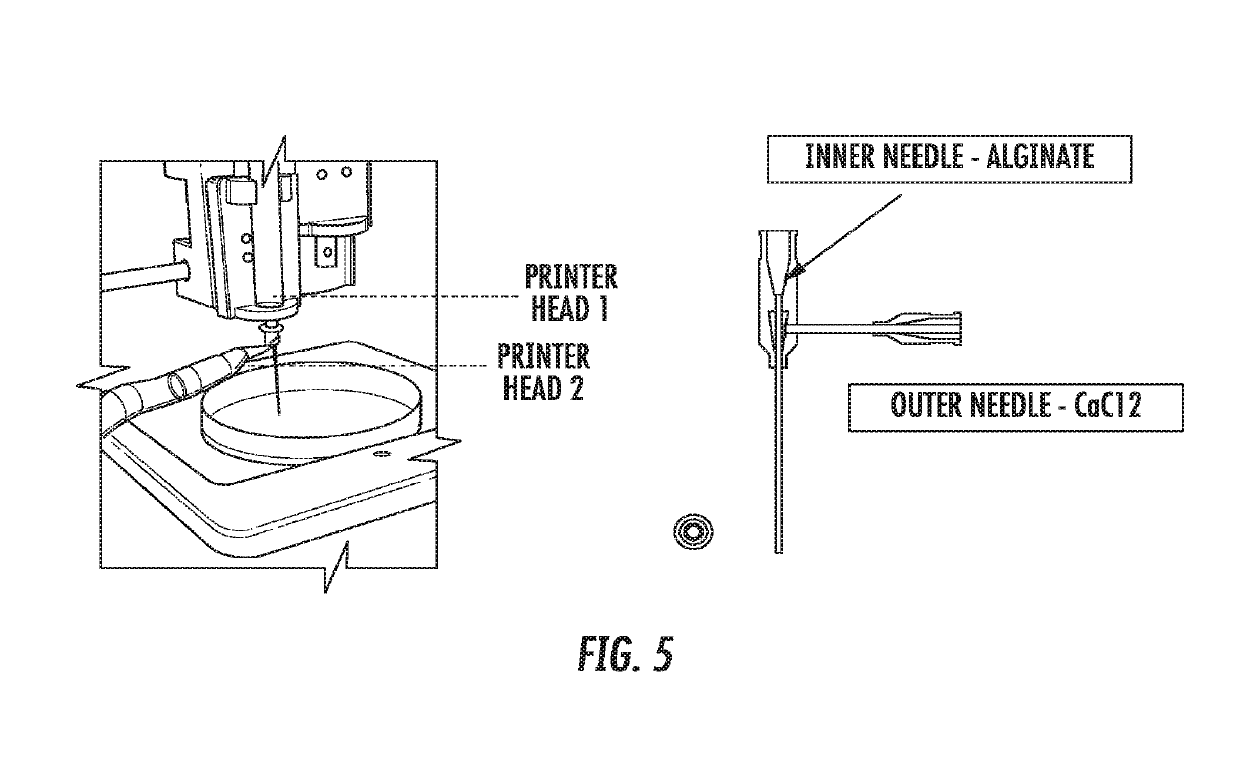

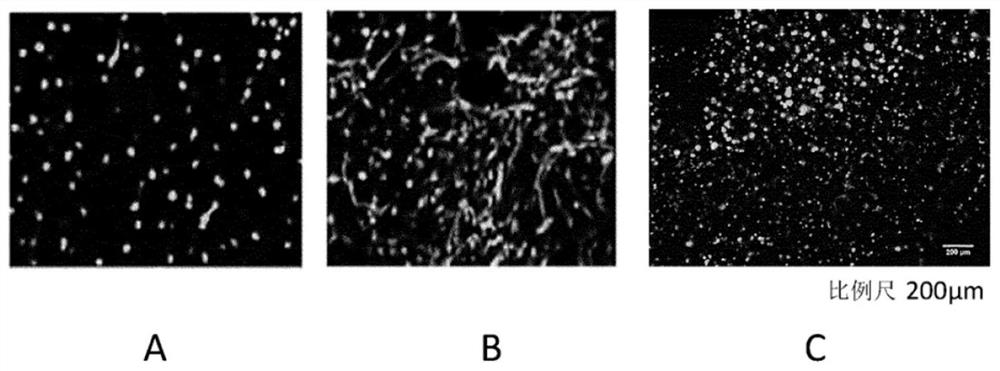

Preparation and applications of rgd conjugated polysaccharide bioinks with or without fibrin for 3D bioprinting of human skin with novel printing head for use as model for testing cosmetics and for transplantation

InactiveUS20190160203A1Artificial cell constructsSkeletal/connective tissue cellsSkin repairHigh productivity

The present invention relates to use of hydrogel based on RGD-conjugated alginate with and without addition of nanocellulose and / or fibrin as a novel bioink for 3D Bioprinting of human skin, particularly dermis. RGD-conjugated alginate provides adhesion sites for the human fibroblasts which result in cell adhesion and stretching which contribute to upregulation of genes producing Collagen I. In this invention, RGD-conjugated alginate is used as one of the components of the bioink for 3D bioprinting. Another innovation described herewith is use of coaxial needle when 3D bioprinting with alginate and RGD-modified alginate bioinks. A coaxial needle makes it possible to crosslink the bioink upon 3D bioprinting operation and thus achieve high printing fidelity which is required for high cell viability, proliferation and production of extracellular matrix. In this invention, the novel RGD-modified alginate bioink together with human fibroblasts is 3D bioprinted and the resulting construct shows high cell viability, high cell proliferation, high degree of stretching of fibroblasts and high productivity of Collagen I. The cell bioink construct biofabricated with this invention is ideal for testing cosmetics and active ingredients of skin care products particularly those used for skin regeneration. It is also ideal to be used as skin grafts for skin repair for patients with damaged or burned skin.

Owner:CELLINK AB

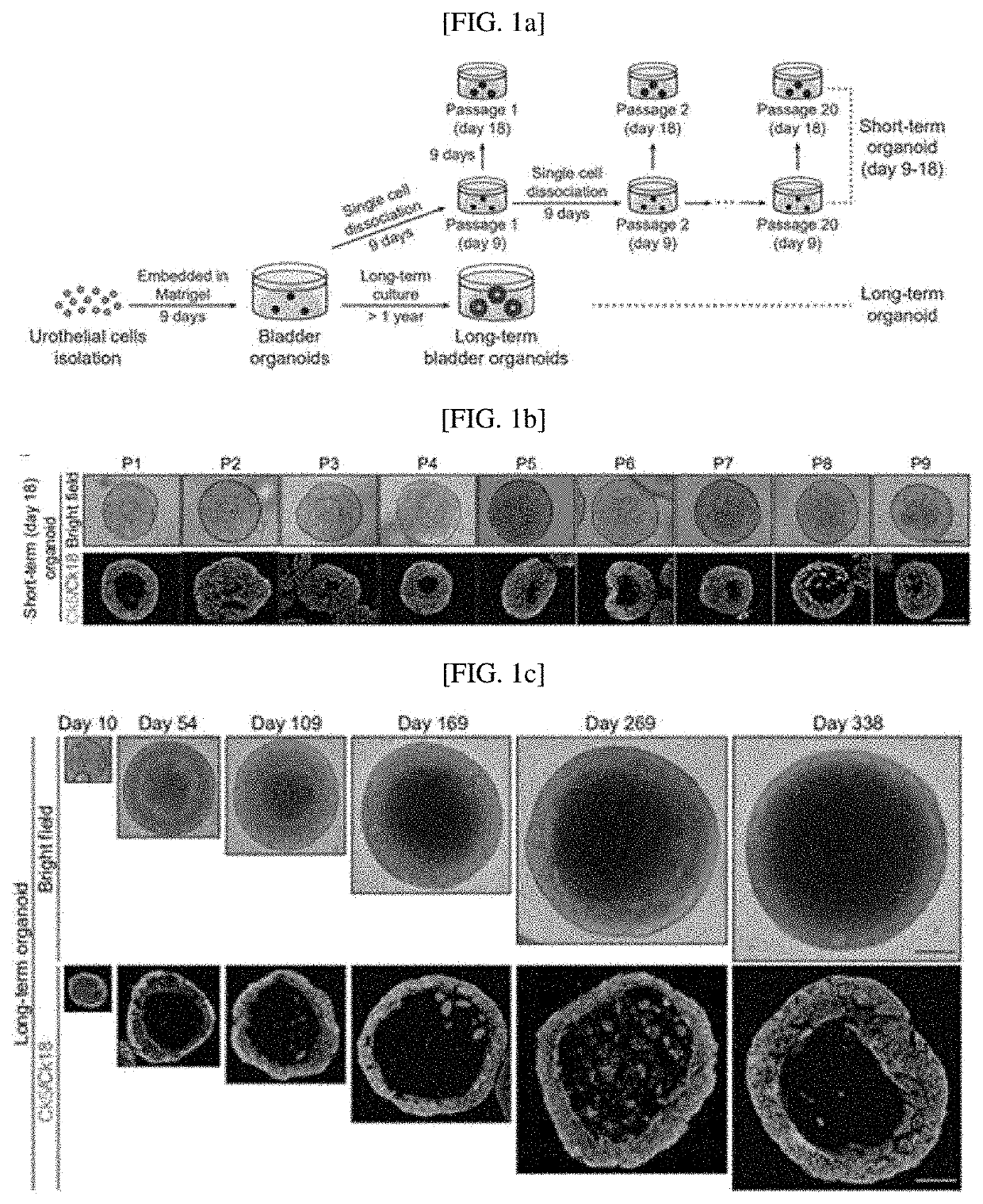

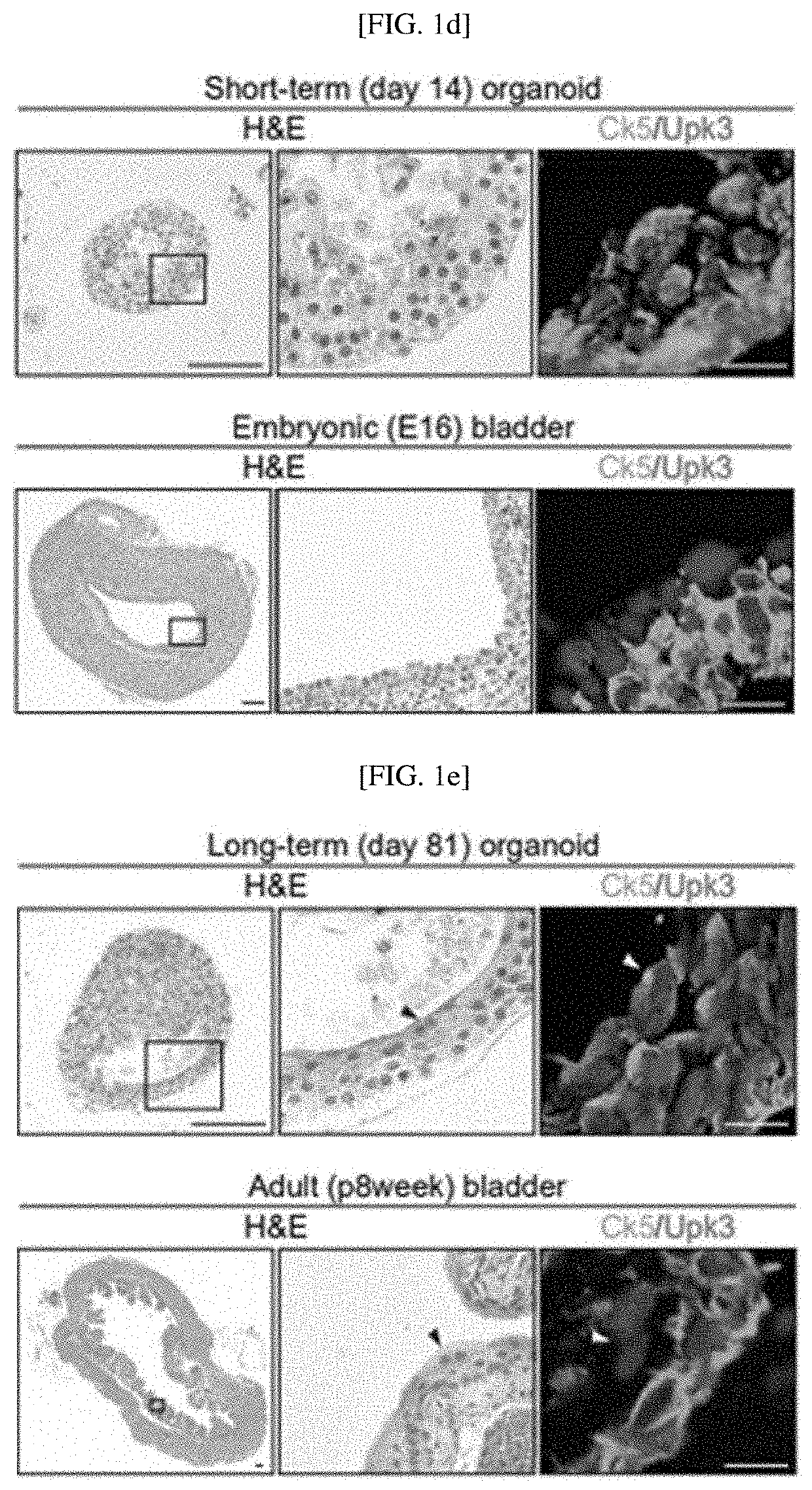

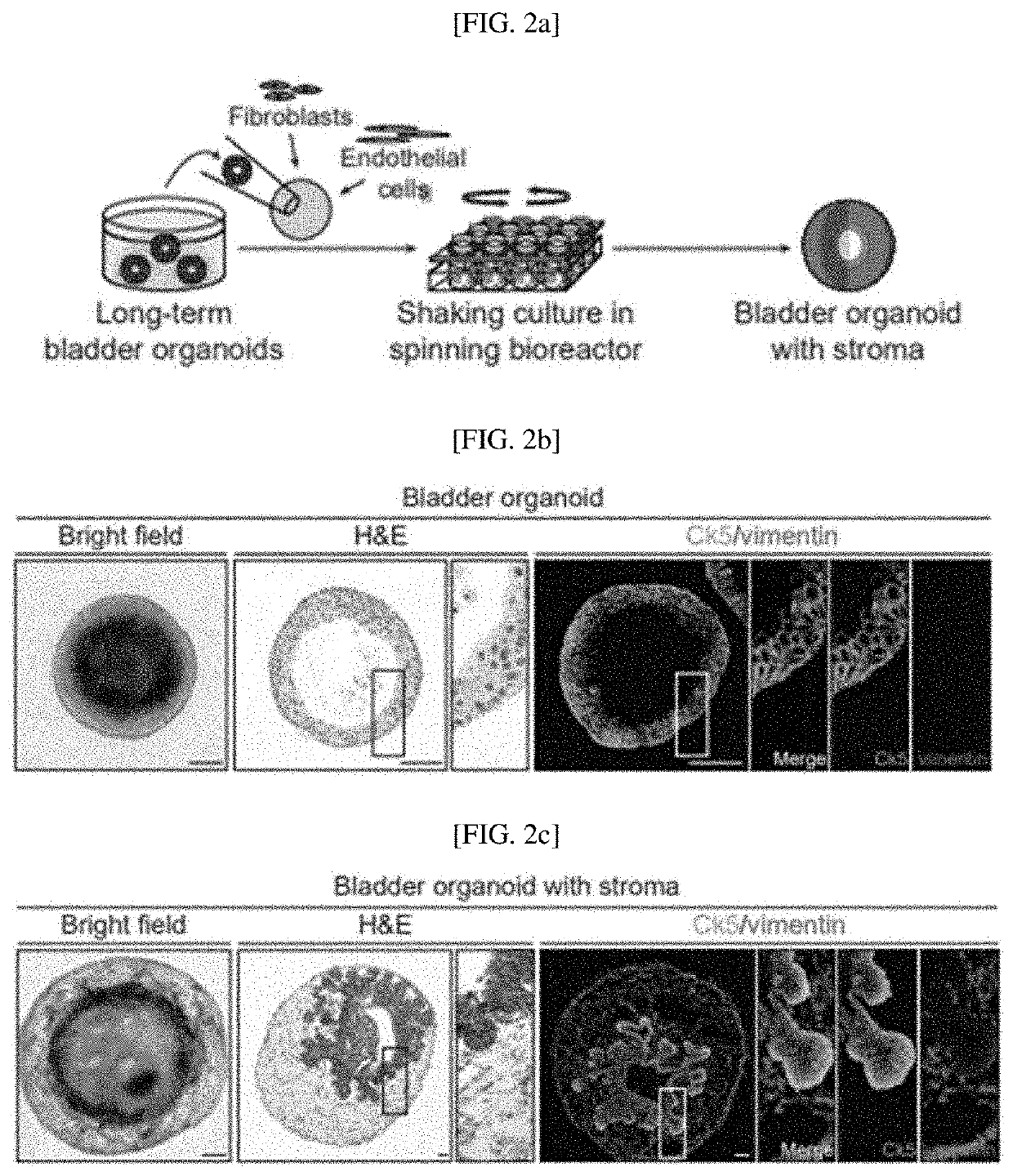

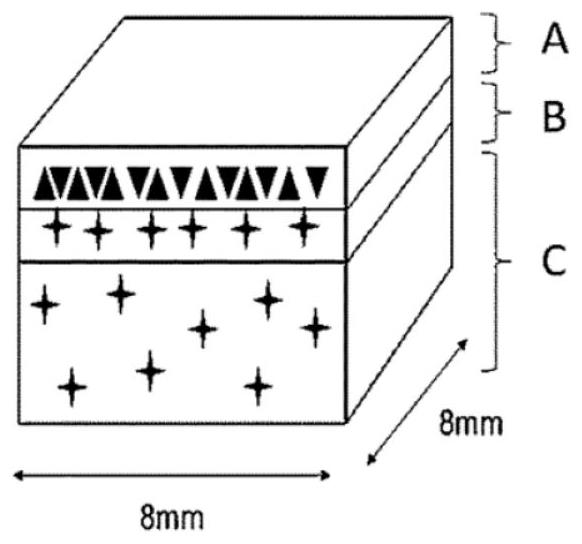

Assembloid - 3D mimetic tissue structure based on patient- derived multiple cell types and method of manufacturing the same

The present invention relates to a 3 dimensional mimetic tissue structure—“Assembloid” based on patient-derived multiple cell types to develop next generation organoid technology serving as a novel platform for new drug development and a disease model and a method of manufacturing the same, and more particularly, to a stem cell- or tumor cell-based 3D multicellular mimetic tissue structure manufactured by reconstituting epithelial or tumor cells with various cellular components of a microenvironment such as stromal cells, vascular cells, immune cells or muscle cells based on three-dimensional (3D) bioprinting, and a method of manufacturing the same. As the stem cell- or tumor cell-based 3D multicellular mimetic tissue structure containing the major factors of a tissue microenvironment, such as stromal cells, vascular cells, immune cells and muscle cells, designed according to the present invention is confirmed to mimic physiological and pathological characteristics of tissue in the body better than conventional organoids, normal and tumor assembloids may be used as a new platform for new drug development and a disease model. More specifically, together with 3D bioprinting technology, it is expected that in vitro bladder tissue and bladder tumor tissue are effectively used as a platform to develop precise and personalized therapeutic options for bladder related diseases including bladder cancer.

Owner:POSTECH ACAD IND FOUND

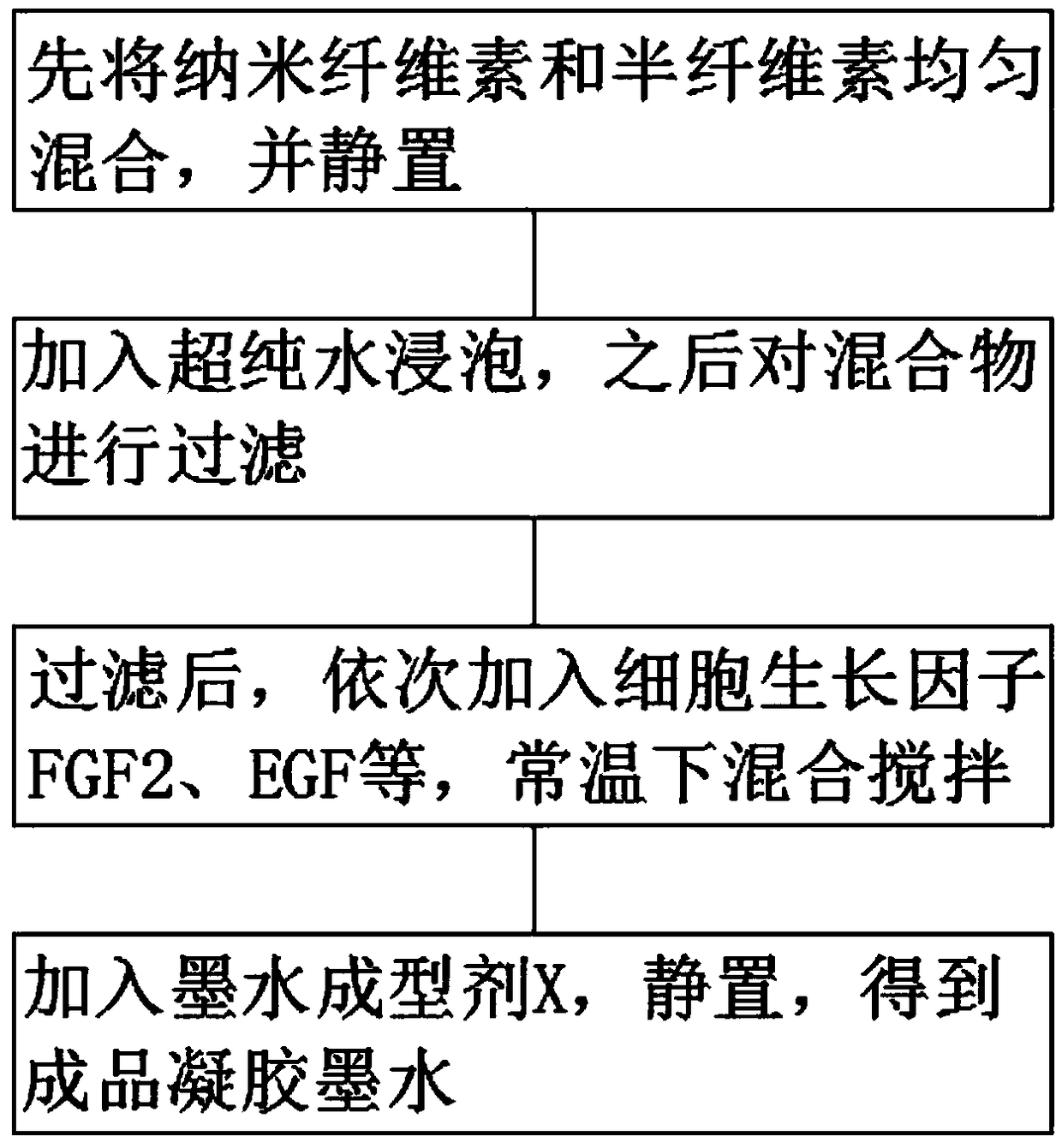

3D bioprinting nano cellulose hydrogel ink

InactiveCN109385140ASmall immune rejectionVersatileAdditive manufacturing apparatusPharmaceutical delivery mechanismNanofiberFibrinogen

The invention discloses 3D bioprinting nano cellulose hydrogel ink comprising the following components, by weight, 1100 parts of nano cellulose, 900 parts of hemicellulose, 1250 parts of ultrapure water, 380 parts of cell growth factor FGF2, 175 parts of EGF, 225 parts of VEGF, 315 parts of collagen, 165 parts of fibrinogen, 60 parts of hyaluronic acid and 700 parts of ink forming agent X, a preparation method of the 3D bioprinting nano cellulose hydrogel ink includes the following steps: uniformly mixing the nanocellulose and hemicellulose and performing standing. The 3D bioprinting nano cellulose hydrogel ink has small human immunological rejection and good biodegradability, has suitable mechanical properties, and has complete functions and low price. In practical application, the stability, reliability, convenience, degradability and environmental friendliness can also meet the needs of users and bring better use prospects.

Owner:深圳市康杰尔生物科技有限公司

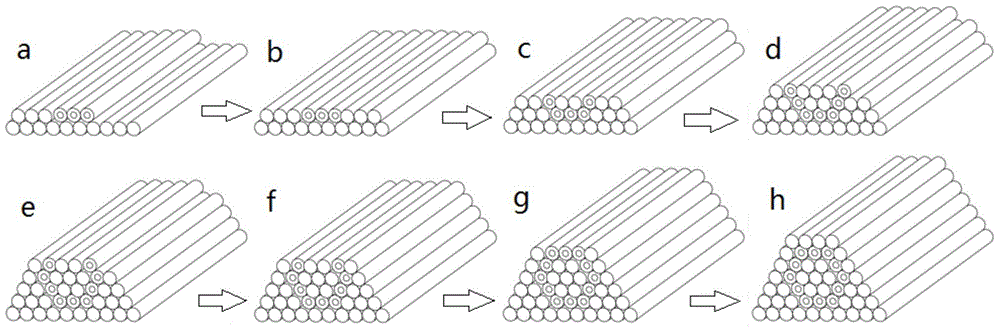

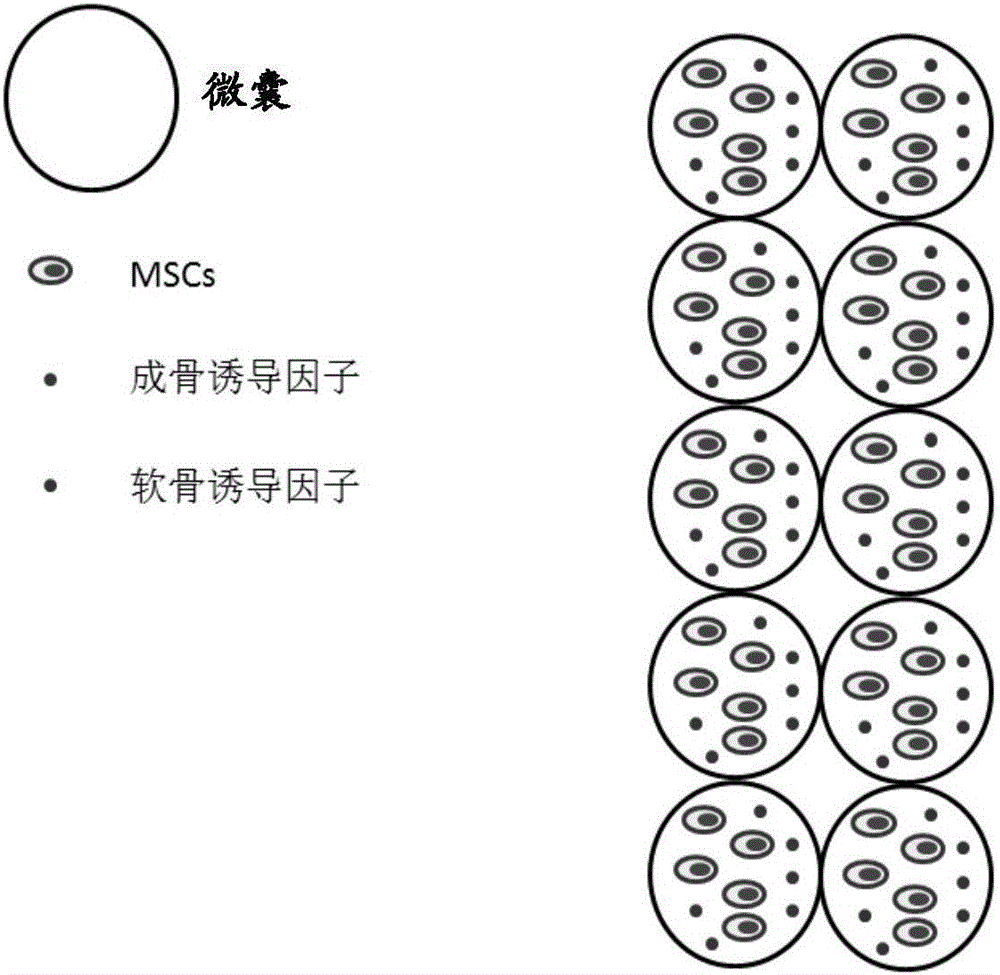

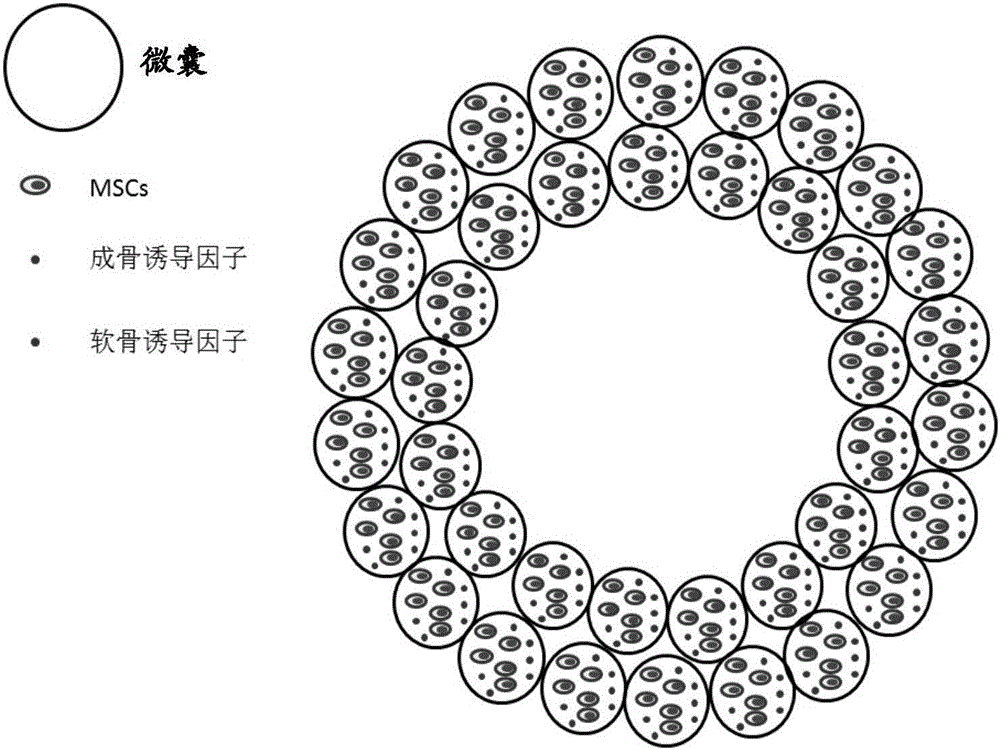

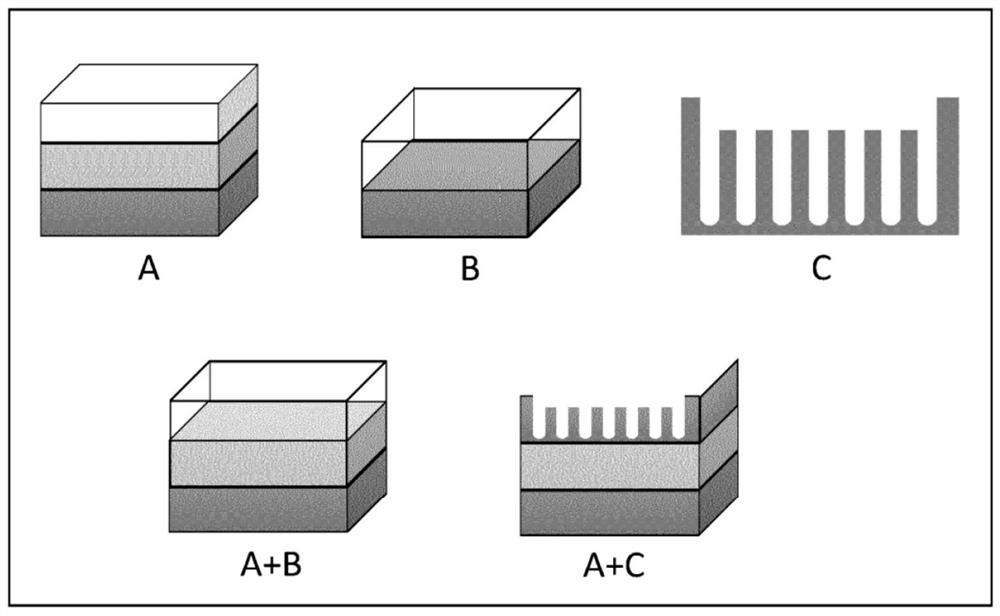

Preparation method of composite structure

ActiveCN106606804APrecise arrangementStructurally and functionally completeMicrobiological testing/measurementBiological testingOsteocyteBiology

Relating to the biology, regenerative medicine, bioprinting (like 3D bioprinting), tissue engineering and other technical fields, the invention particularly provides a method for preparation of a composite structure containing at least two cells, and the composite structure obtained by the method. In particular, preferably the composite structure provided by the invention is a composite structure comprising bones and cartilages, or a composite structure comprising endothelial cells and smooth muscle cells. Therefore, the invention provides a method for preparation of the composite structure containing osteocytes and chondrocytes, a method for preparation of the composite structure containing endothelial cells and smooth muscle cells, and a composite structure obtained by the method. In addition, the invention also relates to various applications of the composite structure.

Owner:SICHUAN REVOTEK CO LTD

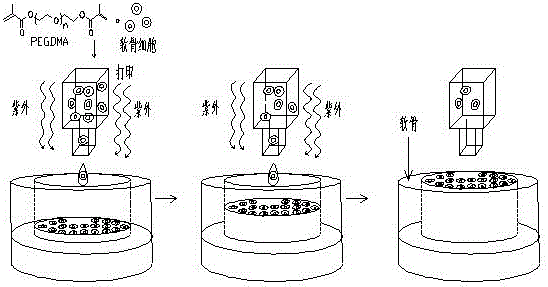

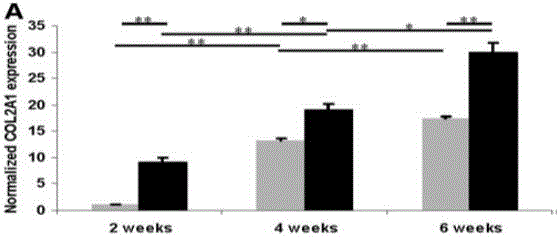

Method of repairing human articular cartilage based on 3D bioprinting

InactiveCN106421915AEasy maintenanceShorten the timeAdditive manufacturing apparatusTissue regenerationPolyethylene glycolCytotoxicity

The invention relates to a method for repairing human articular cartilage based on 3D bioprinting. The method comprises the following steps: a) PEGDMA is prepared from PEG (polyethylene glycol)and methacryloyl chloride and purified; b) human mesenchymal stem cells are separated; c) the human mesenchymal stem cells are subjected to passage and adjusted in density, an induction medium is replaced for culture after cell attachment; d) a bovine femur is washed, a full-thickness cartilage defect is formed at the center of an osteochondral embolism by a sterile living body perforator, and the osteochondral embolism is placed in a DMEM (dulbecco's modified eagle medium) and cultivated into 3D biopaper; e) the purified PEGDMA is dissolved, a photoinitiator 2959 is added, and chondrocytes obtained through induction in the step c) are re-suspended in a filtered and sterilized PEGDMA solution for preparation of bio-ink; f) the bio-ink is added to a disinfected and sterilized bioprinter, and the 3D cartilage is printed on the 3D biopaper according to the designed shape and size and is cultured in the induction medium. The method has the advantages of being simple and quick to operate, accurate, low in cytotoxicity and is expected to become a clinical cartilage repair method.

Owner:武汉枫霖科技有限公司

Method for preparing cartilage with high mechanical properties based on 3D bioprinting

ActiveCN104399119BImprove mechanical propertiesAvoid breakingProsthesisBiocompatibility Testing3d printed

The invention provides a method for preparing cartilage with a high mechanical property based on 3D bioprinting. The method comprises the following steps: preparing silk fibers, preparing a gelatin solution, preparing ciological ink containing cells, carrying out 3D cartilage printing, performing cell culture and differentiation on a printed tissue to form the cartilage. The method solves the problems of polarization of 2-dimension culture for cells and high body and surface ratio of cells through the 3D bioprinting technology; sodium alginate and calcium ions form ionic bonds, and gelatin and methacrylic anhydride form covalent bonds, so that the 3D bioprinted cartilage is good in mechanical property and is not easily broken; the gelatin has biocompatibility and degradability of normal biological material hydrogel, has bioactivity, and is good for cell growth and differentiation and realization of cell functions.

Owner:西安博恩生物科技有限公司

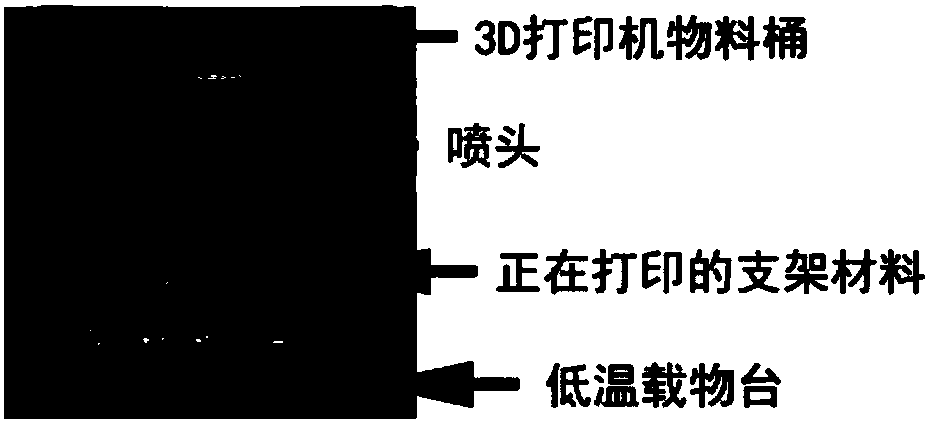

3D bioprinting forming method

ActiveCN108452378AHigh speedHigh mechanical strengthAdditive manufacturing apparatusTissue regenerationUltimate tensile strengthChemical stability

The invention discloses a 3D bioprinting forming method. The 3D bioprinting forming method comprises the following steps: (1), performing 3D bioprinting: printing 3D printing bio-ink according to an established model by using a 3D bioprinter, and storing a printing bracket at low temperature to obtain a shaped gel material; (2), crosslinking: washing the shaped gel material by using water; then adding a crosslinking agent, and performing a crosslinking reaction under a low-temperature condition; finally, washing away the residual crosslinking agent by using water. By the 3D bioprinting formingmethod, low-temperature treatment and a crosslinking method are adopted for printing a target structure, so that rapid progress of 3D printing can be guaranteed, covalent bonds are further introducedinside collagen molecules and between the molecules, most of a collagen structure is retained, and the mechanical strength and the chemical stability of the printing material are improved, the absorption speed thereof in a body are controlled, and thus a collagen biomaterial plays a role conveniently.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV +1

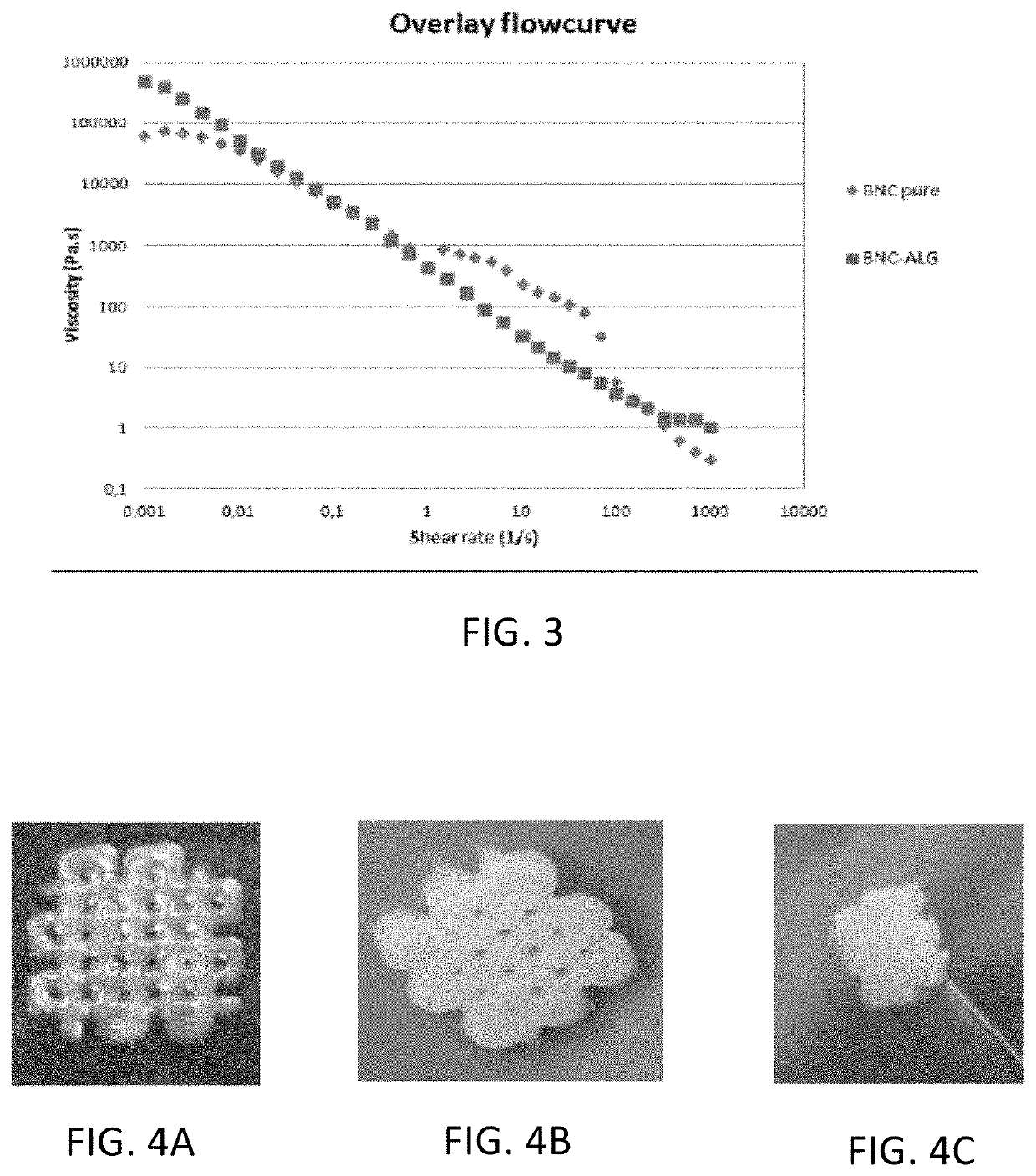

Nanocellulose-containing bioinks for 3D bioprinting, methods of making and using the same, and 3D biostructures obtained therefrom

PendingCN112533652AAdditive manufacturing apparatusPharmaceutical delivery mechanismFibrilCell survival

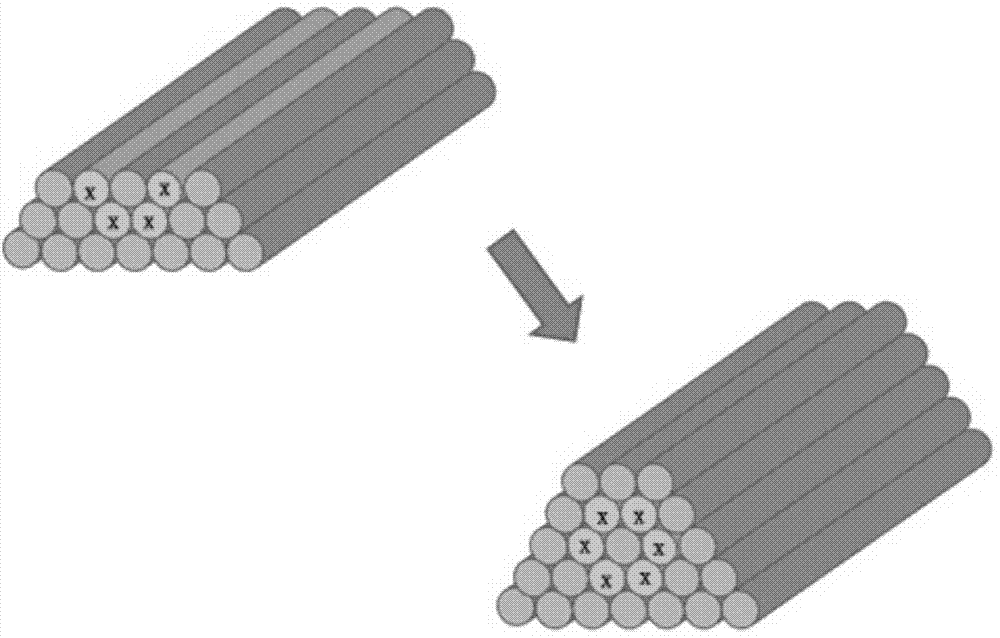

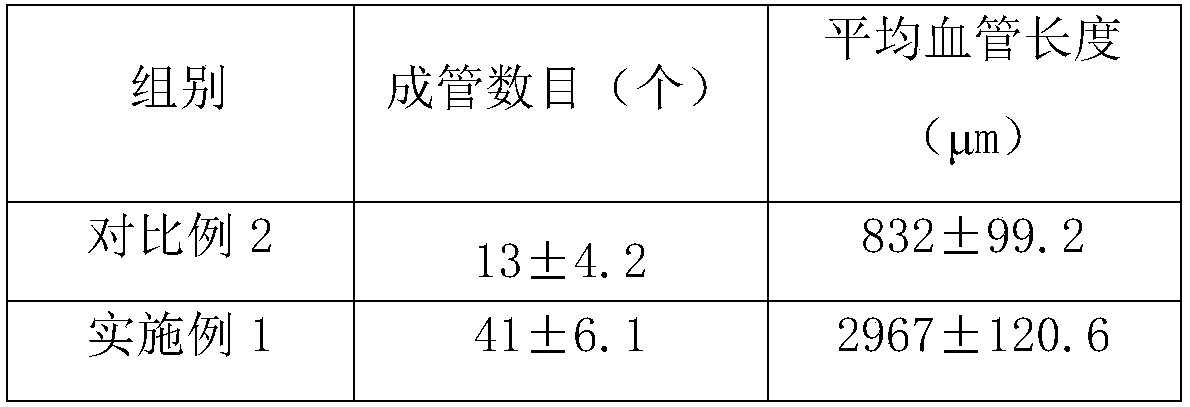

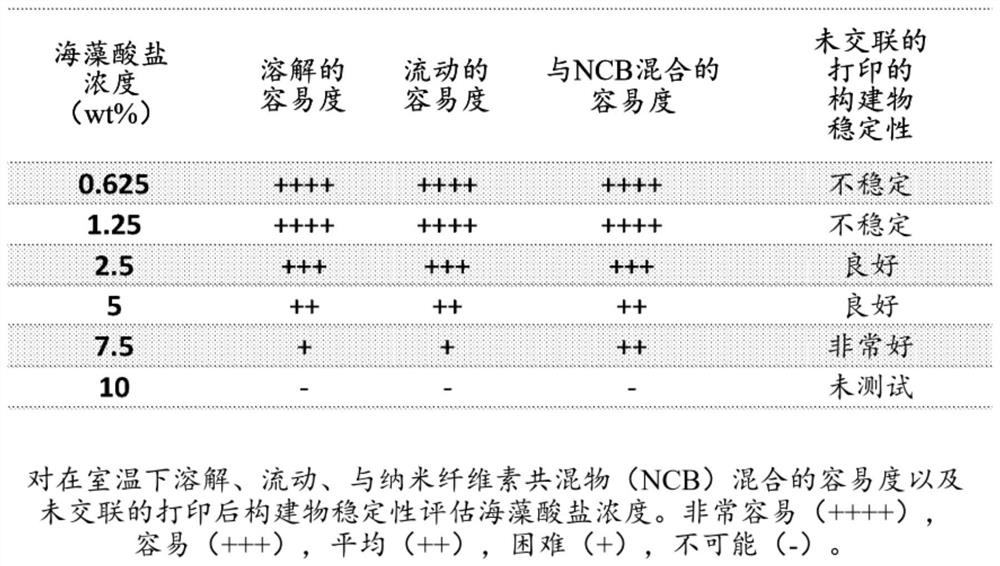

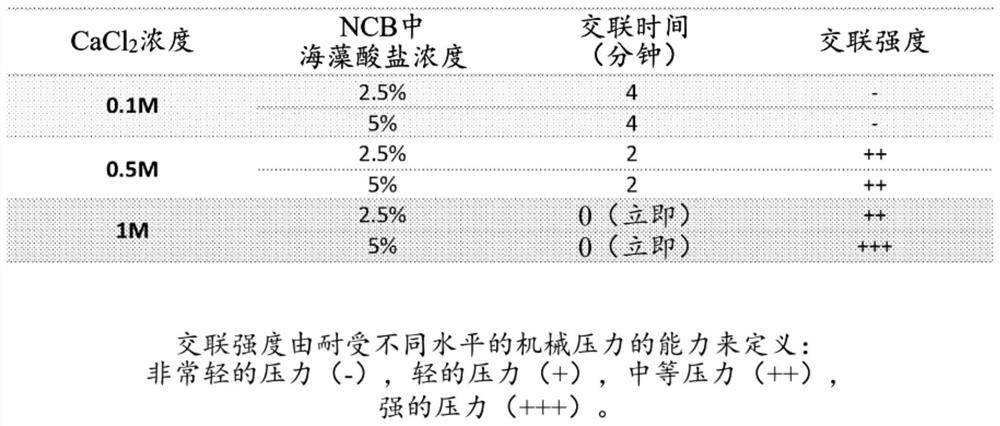

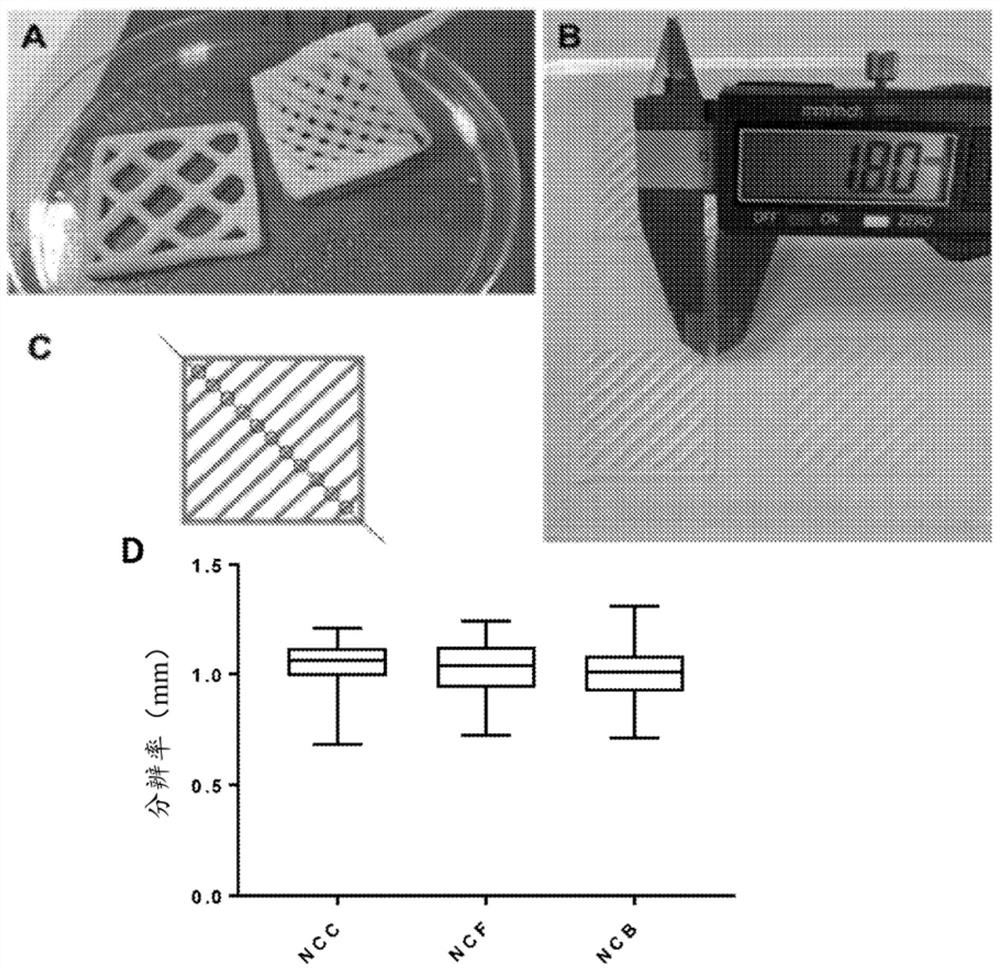

Some variations of the invention provide a bioink composition for 3D bioprinting, comprising: nanocellulose in the form of nanocellulose crystals, nanocellulose fibrils, or preferably a combination thereof; alginate that is ionically crosslinkable in the presence of an ionic crosslinking agent; and water. The nanocellulose-alginate bioinks have favorable rheological, swelling, and biocompatibilityproperties for extrusion-based bioprinting. It is experimentally demonstrated that nanocellulose-alginate bioinks with human nasoseptal chondrocytes enable cartilage bioprinting at high resolution. The disclosed nanocellulose has been proven to be compatible with cell survival and proliferation; to possess nanoscale and microscale architectures mimicking the native extracellular environment, encouraging differentiation and tissue formation; and to have ideal rheological properties to allow extrusion 3D bioprinting. Bioink with a unique blend of crystal and fibril nanocellulose produces a verystable construct volume in culture.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC +1

3D bio-printer head control device and material changing control method of head

InactiveCN110142974AAvoid pollutionSimple structureAdditive manufacturing apparatusManufacturing data aquisition/processingHardware structureMotor control

The invention relates to a 3D bio-printer head control device and a material changing control method of a head, and belongs to the technical field of 3D bio-printer head control. The technical problemto be solved is to provide a 3D bio-printer head structure, a hardware structure of a control device and improvement of the material changing control method of the head. According to the technical scheme used for solving the technical problem, the device comprises a motor control frame, a printing head and a material changing device, wherein the motor control frame is arranged at the top of the 3D bio-printer, a stepping motor is arranged on one side of the motor control frame, two ends of the motor control frame extend outwards and are provided with fixed beams, a threaded shaft is arrangedon the fixed beams, the threaded shaft drives a printing device to move on the Y-axis printing plane through the stepping motor; and the printing device comprises a connecting end and a fixing end, wherein the connecting end is fixedly connected with the fixing end through a bolt, the connecting end is in transmission connection with the threaded shaft, a fixing clamp is arranged at the extendingend of the fixing end, and the fixing clamp is used for clamping a printing head. The control device is applied to the 3D bio-printer.

Owner:TAIYUAN UNIV OF TECH

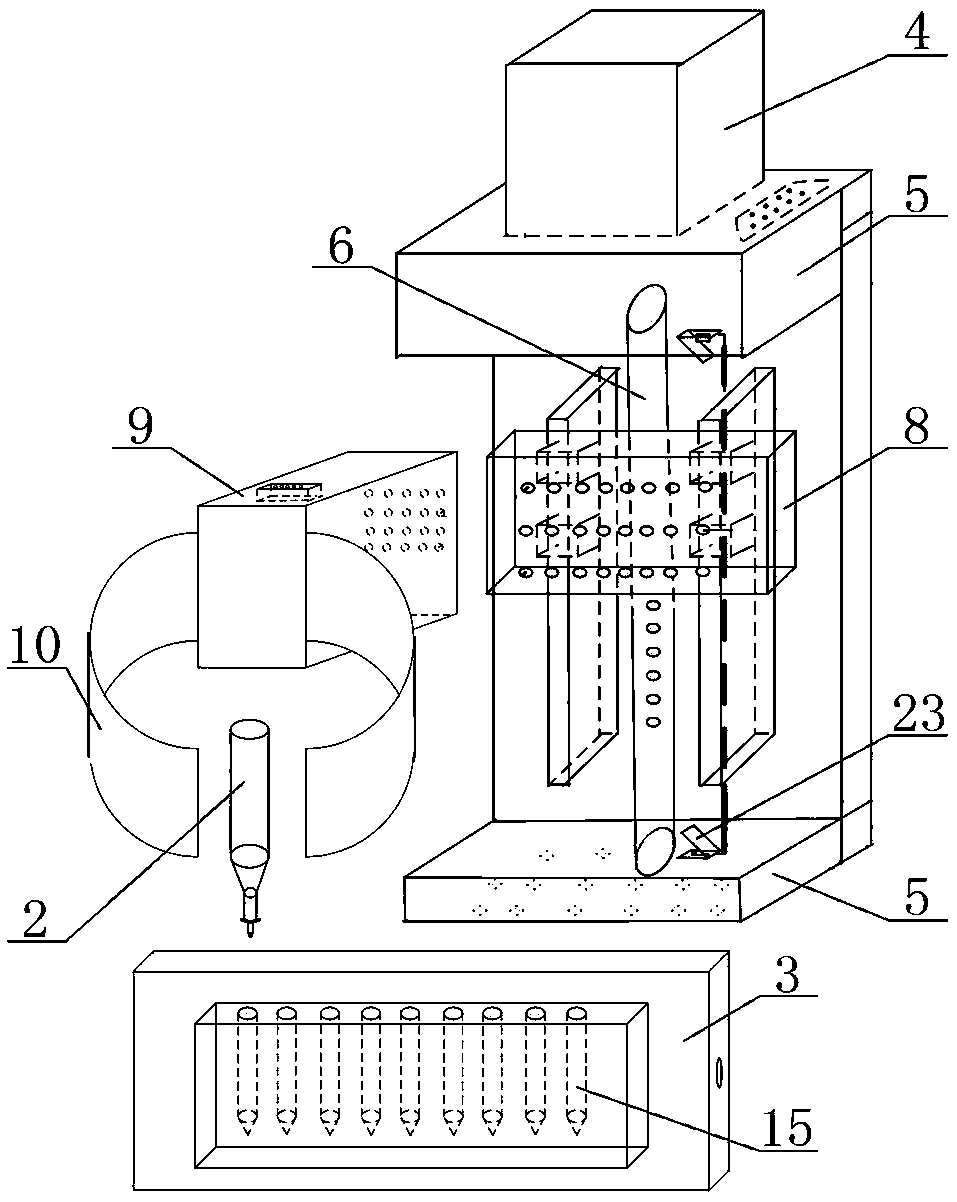

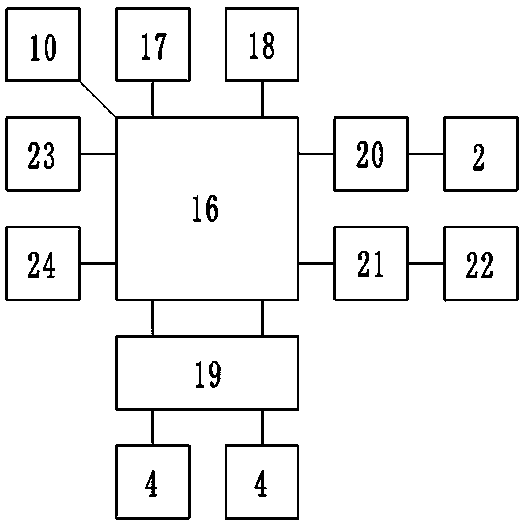

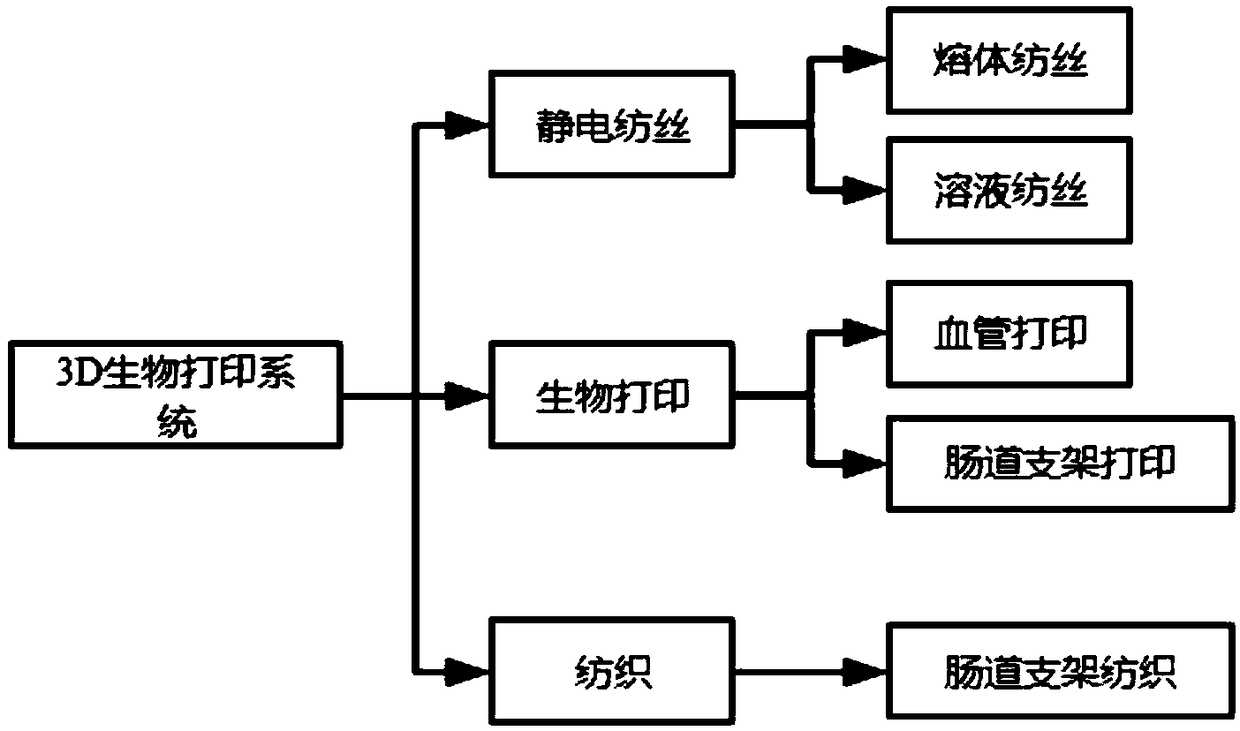

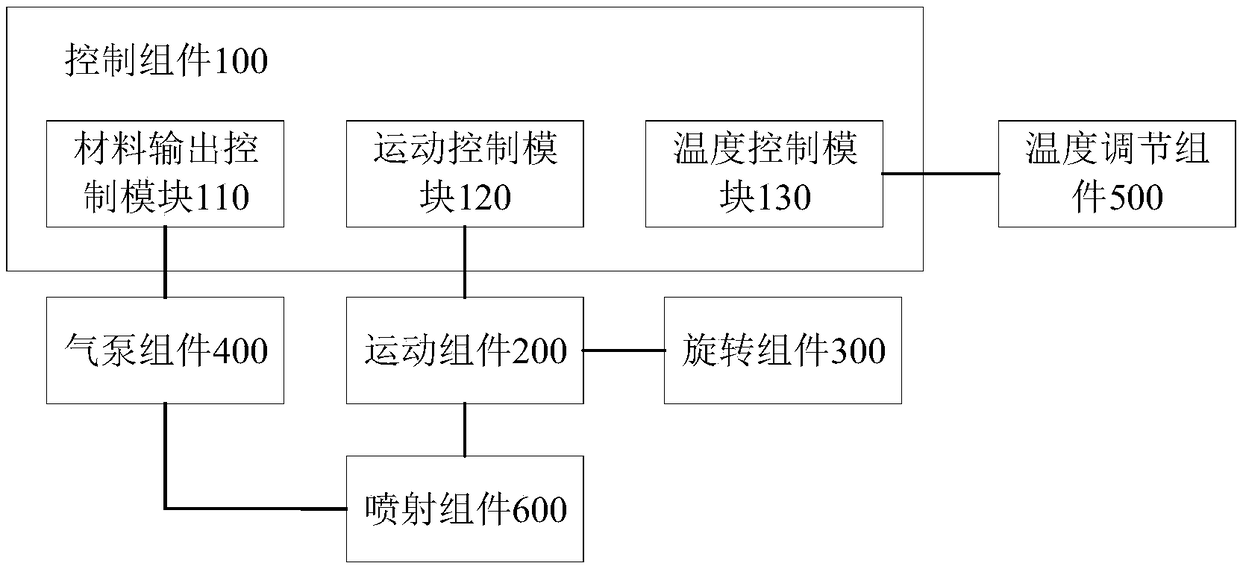

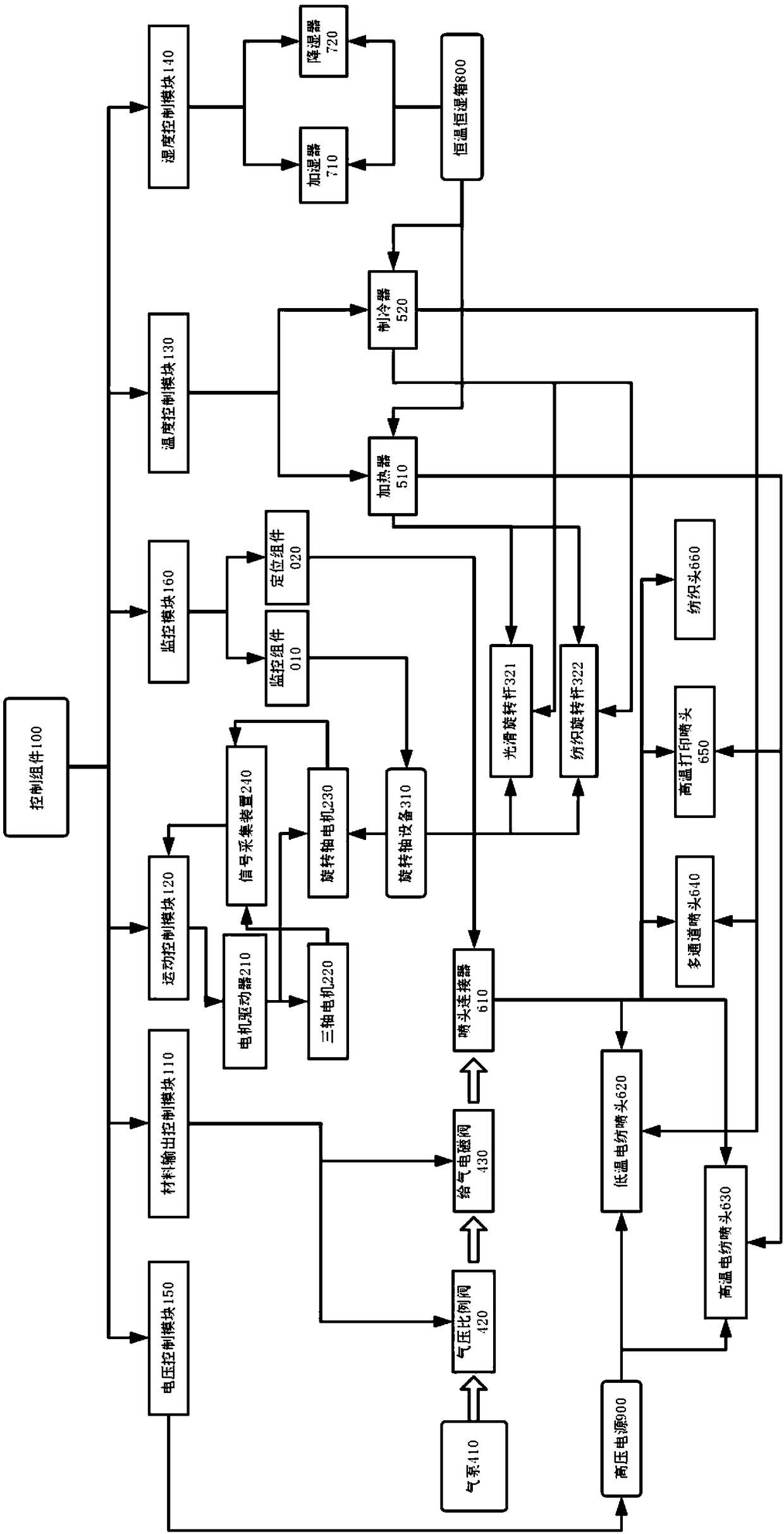

3D bioprinting system

PendingCN109366972ALow costReduce economic costsManufacturing driving meansAdditive manufacturing with liquidsTemperature controlEngineering

The invention provides a 3D bioprinting system. The 3D bioprinting system comprises a control assembly, a motion assembly, a rotating assembly, an air pump assembly, a temperature adjusting assembly and a jetting assembly; the control assembly comprises a material output control module, a motion control module, and a temperature control module, the motion control module controls the rotating assembly and the jetting assembly to move through the motion assembly, the material output control module controls the jetting assembly to jet the material to a rotating rod of the rotating assembly through the air pump assembly, the temperature control module adjusts the jetting temperature of the jetting assembly and the temperature of the rotating rod through the temperature adjusting assembly, in the rotating process of the rotating rod of the rotating assembly, the jetting assembly is controlled to jet or extrude the material to the rotating rod, and rotary printing of the biological product can be achieved; through supporting of the biological product with the rotating rod as the hollow structure, an extra supporting material is not needed, and the material cost and the economic cost areeffectively reduced.

Owner:REGENOVO BIOTECH

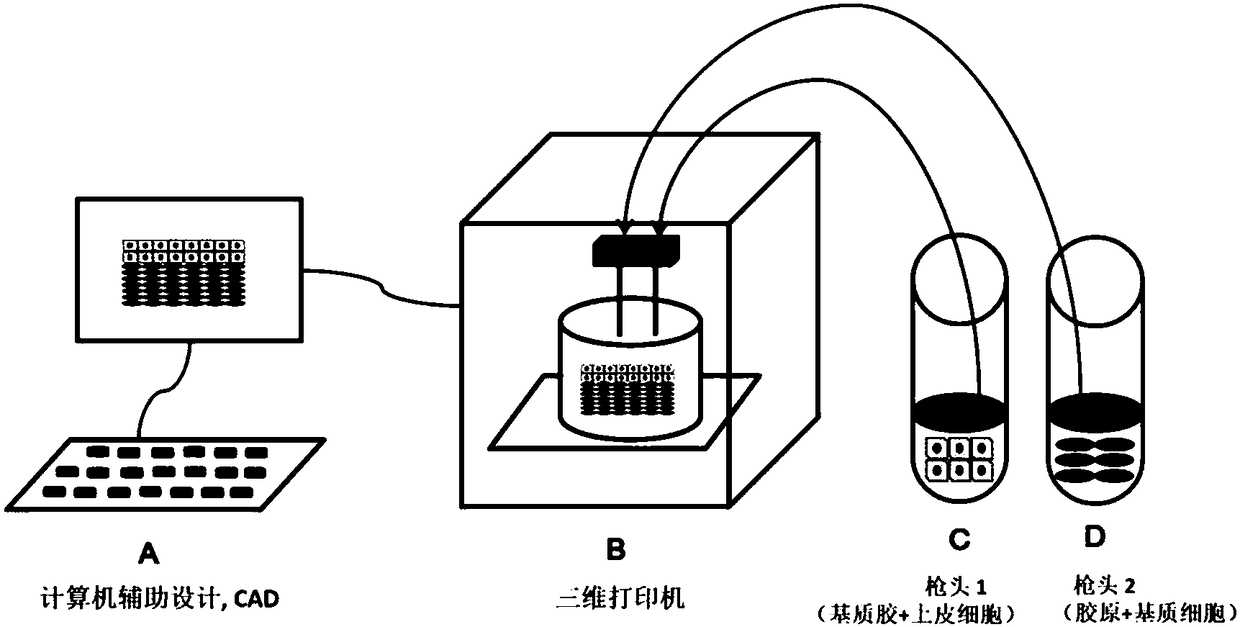

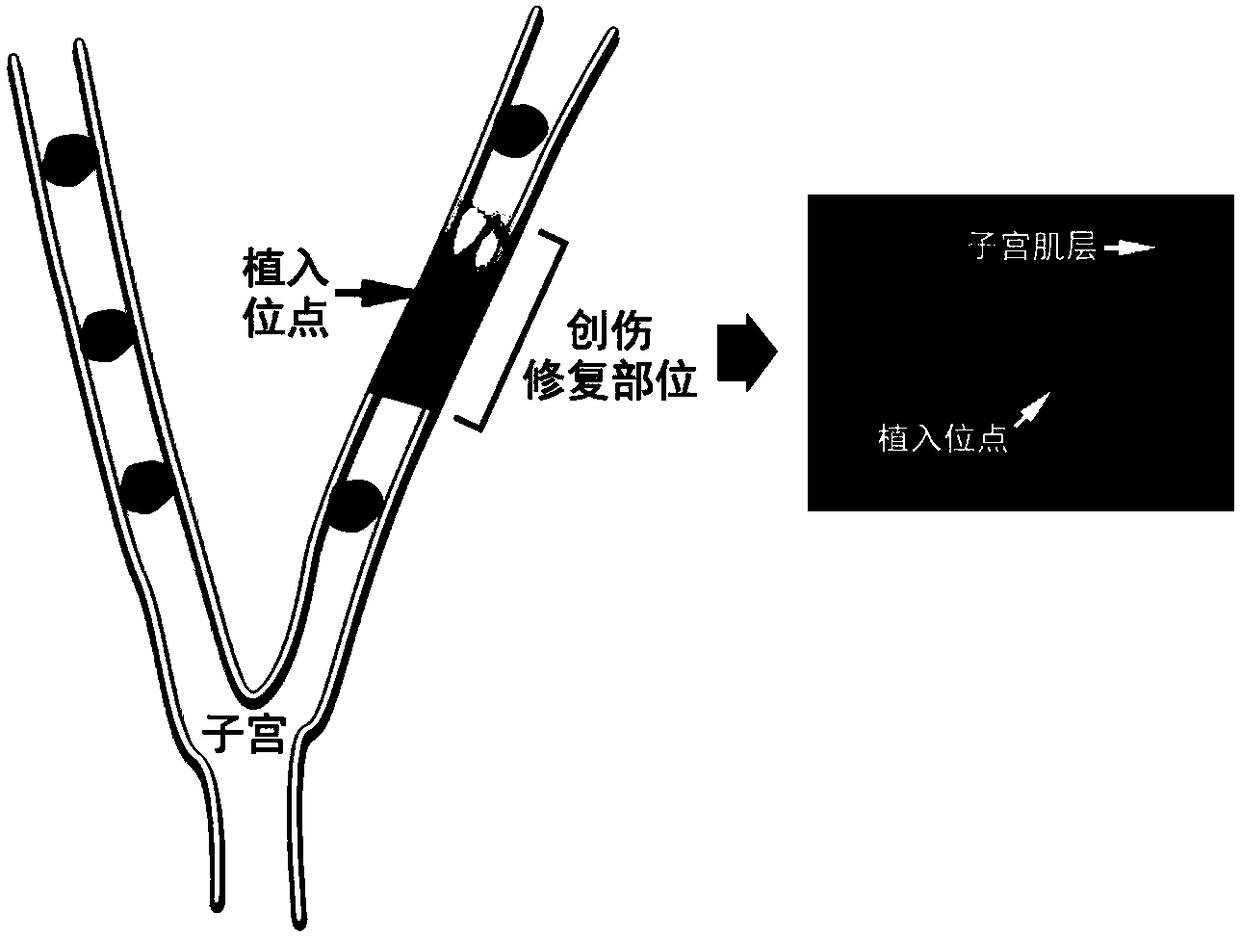

3D printed artificial endometrium and its preparation and application

The invention relates to an artificial endometrium and its preparation and application and particularly relates to an artificial endometrium. The artificial endometrium comprises a biocompatible stent, endometrial stromal cells / epithelial cells and a mixed culture solution. Through a 3D bioprinting technology, the biocompatible stent and the endometrial stromal cells / epithelial cells are processedinto an artificial endometrium with bioactivity. The mixed culture solution comprises a medium and a biohormone. The biocompatible stent is prepared through a 3D printing method. The artificial endometrium can be used as a research tool for pathophysiological mechanisms aiming at artificial endometrial diseases, can be used as a screening model for regulating and affecting factors related to embryo implantation, and can be used as a research tool for preventing or treating directly or indirectly related endometrial lesions caused by any factor.

Owner:SHENZHEN INST OF ADVANCED TECH

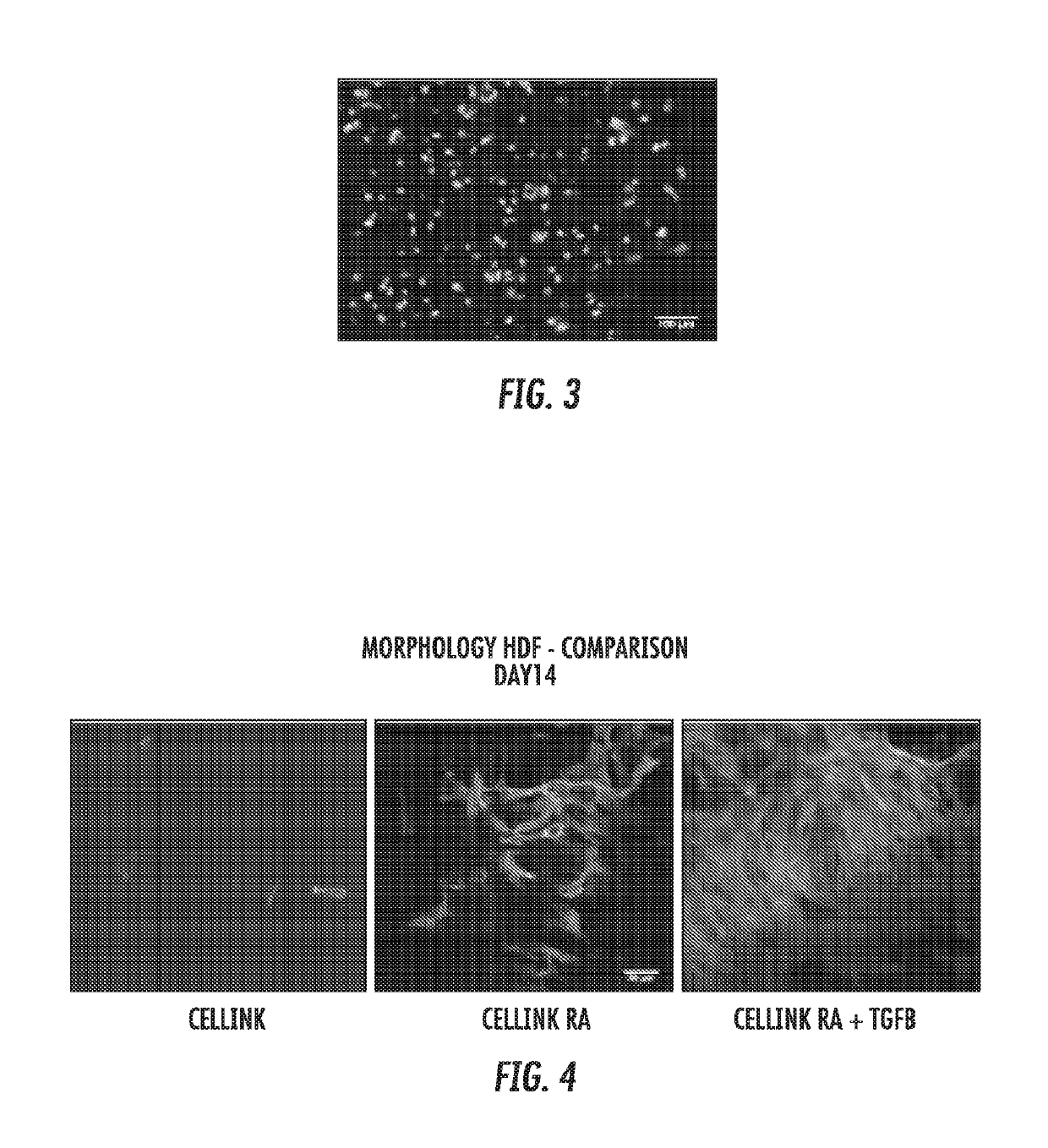

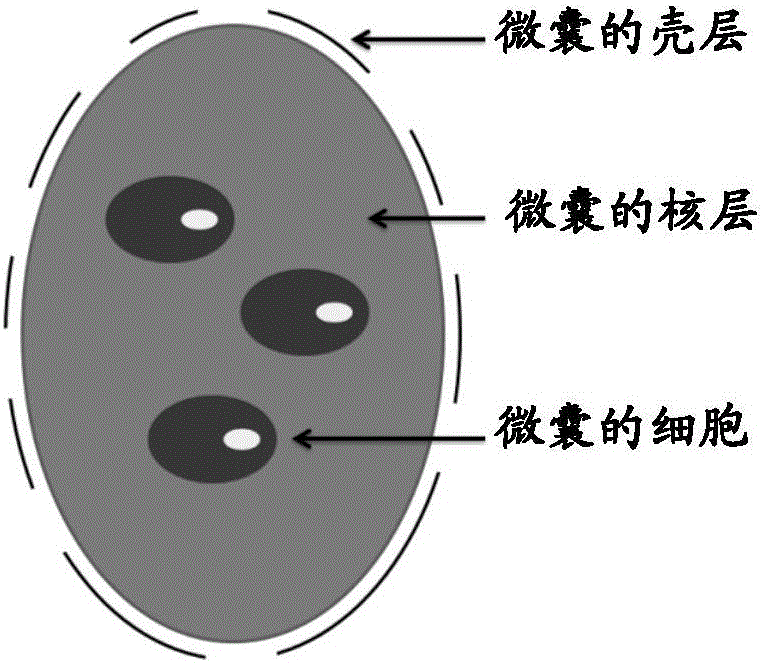

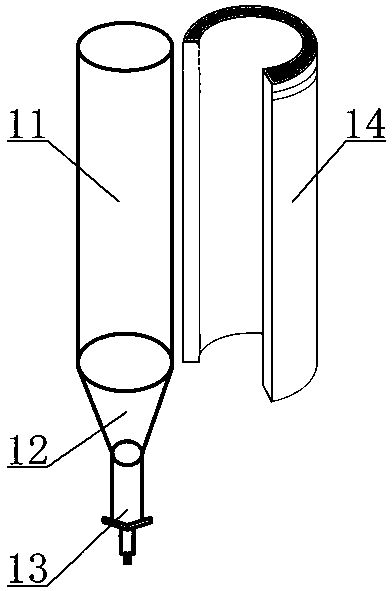

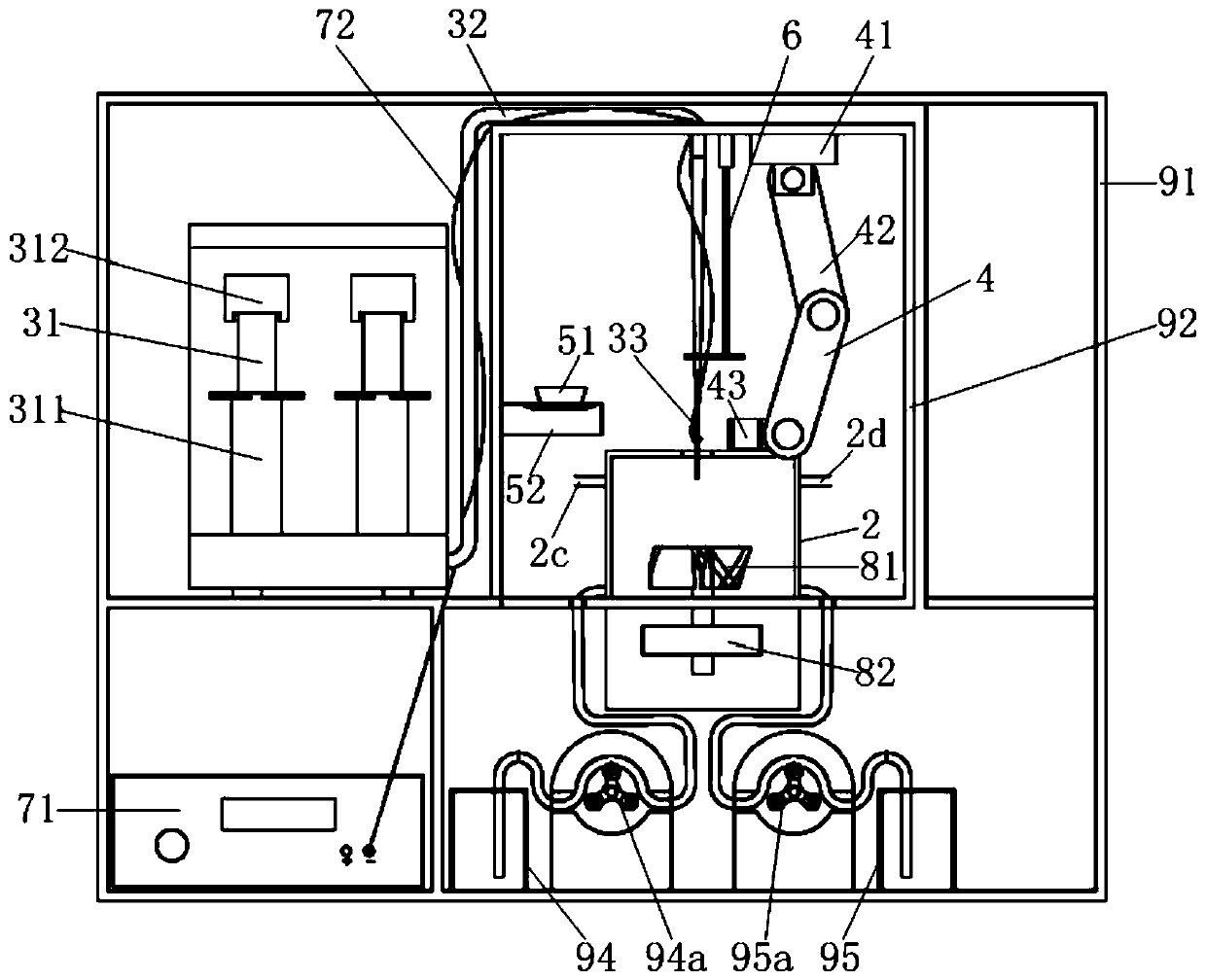

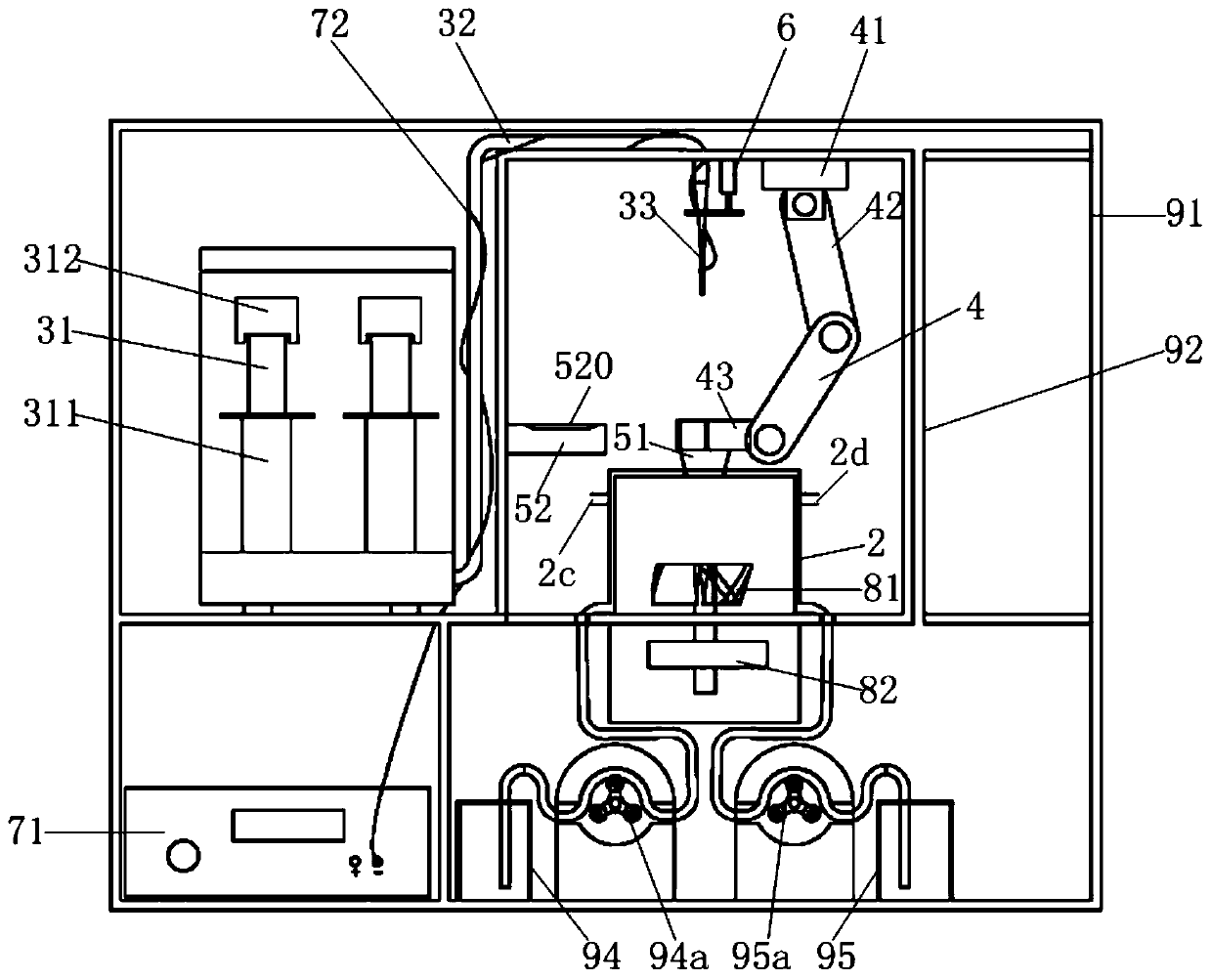

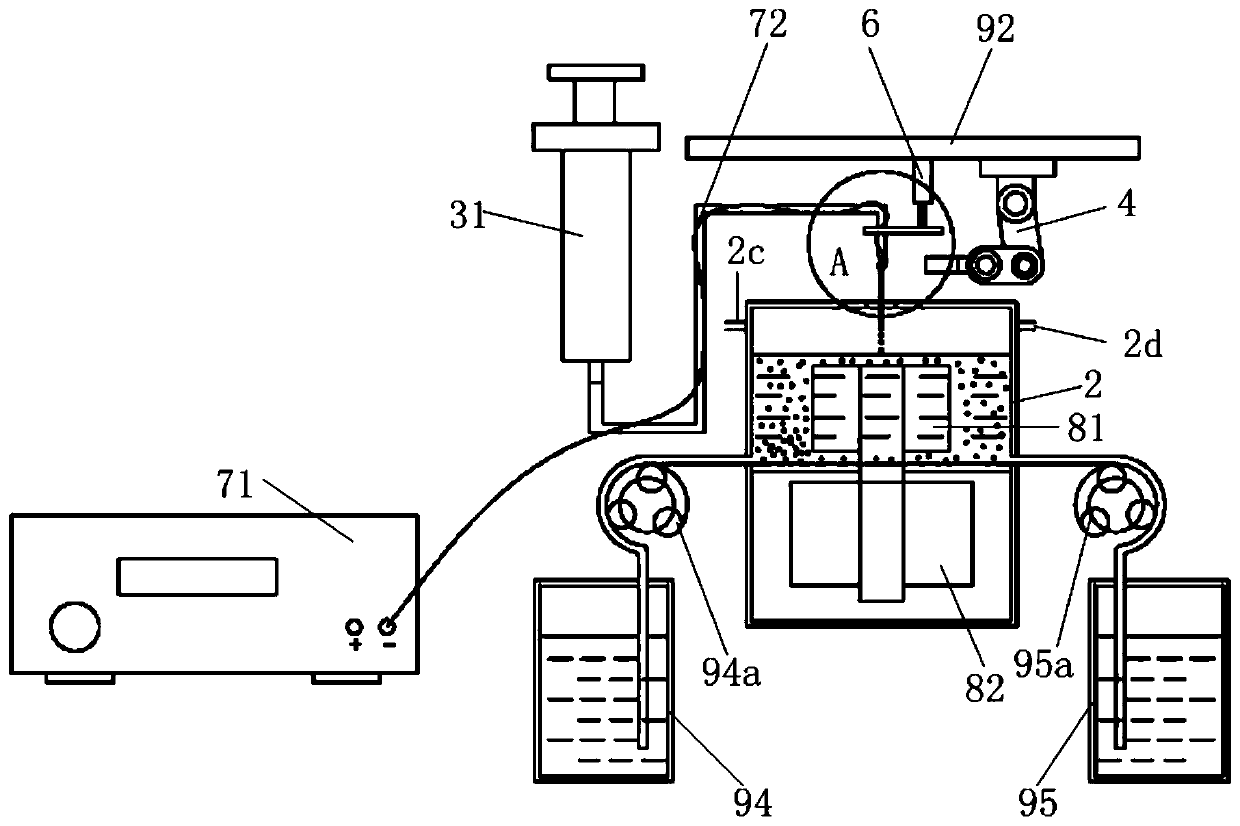

Dynamic perfusion culture system for cell microsphere

InactiveCN110295112AMaintain propertiesQuality improvementBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureCulture cell

The invention provides a dynamic perfusion culture system for a cell microsphere. The system comprises a culture bin, a cell microsphere printing device and a perfusion culture device, the cell microsphere printing device comprises a printing head, the cell microsphere can be printed by the printing head, and the culture bin is used for accommodating and culturing the cell microsphere; the perfusion culture device comprises a liquid storage pot and a first power source, the liquid storage pot is used for storing culture liquid and being communicated with the culture bin, the first power sourceis arranged at a pipe communicating the liquid storage pot with the culture bin, and the culture liquid circularly flows between the liquid storage pot and the culture bin under driving of the firstpower source. The dynamic perfusion culture system for the cell microsphere is high in automation degree, in combination with the cell microsphere printing device and the perfusion culture device, a 3D bioprinting technology and a perfusion culture technology are utilized for culturing cells, and a feasible scheme is provided for characteristic keeping and efficient large-scale multiplication of the cells. The full-automatic multiplication culture system which is urgently needed by modern medical treatment, keeps characteristics of the cells and can efficiently obtain the high-quality cells isprovided.

Owner:华东数字医学工程研究院

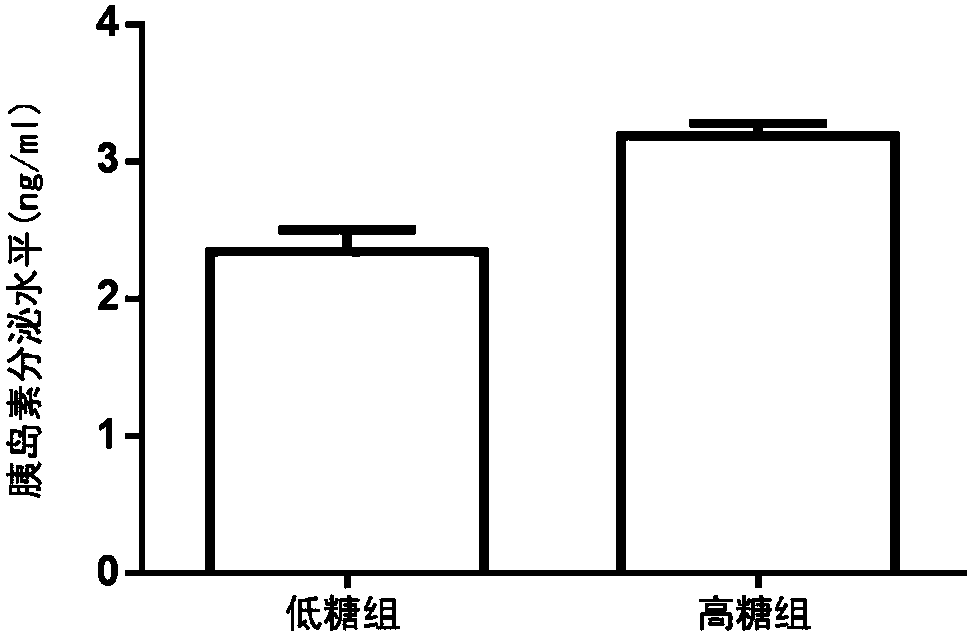

Artificial pancreas islet tissue and preparation and application thereof

The present invention relates to an artificial pancreas islet tissue and particularly comprises a biocompatible stent, islet cells and a mixed culture solution. Through a 3D bioprinting technique, thebiocompatible stent and the pancreas islet tissue are prepared into the biologically active artificial pancreas islet tissue. The mixed culture solution is used for culture and preservation of the pancreas islet cells and tissue. The biocompatible stent is prepared using the 3D printing technique. The artificial pancreas islet tissue can be used as a pathophysiological mechanism research and a therapeutic tool for diabetes.

Owner:SHENZHEN INST OF ADVANCED TECH

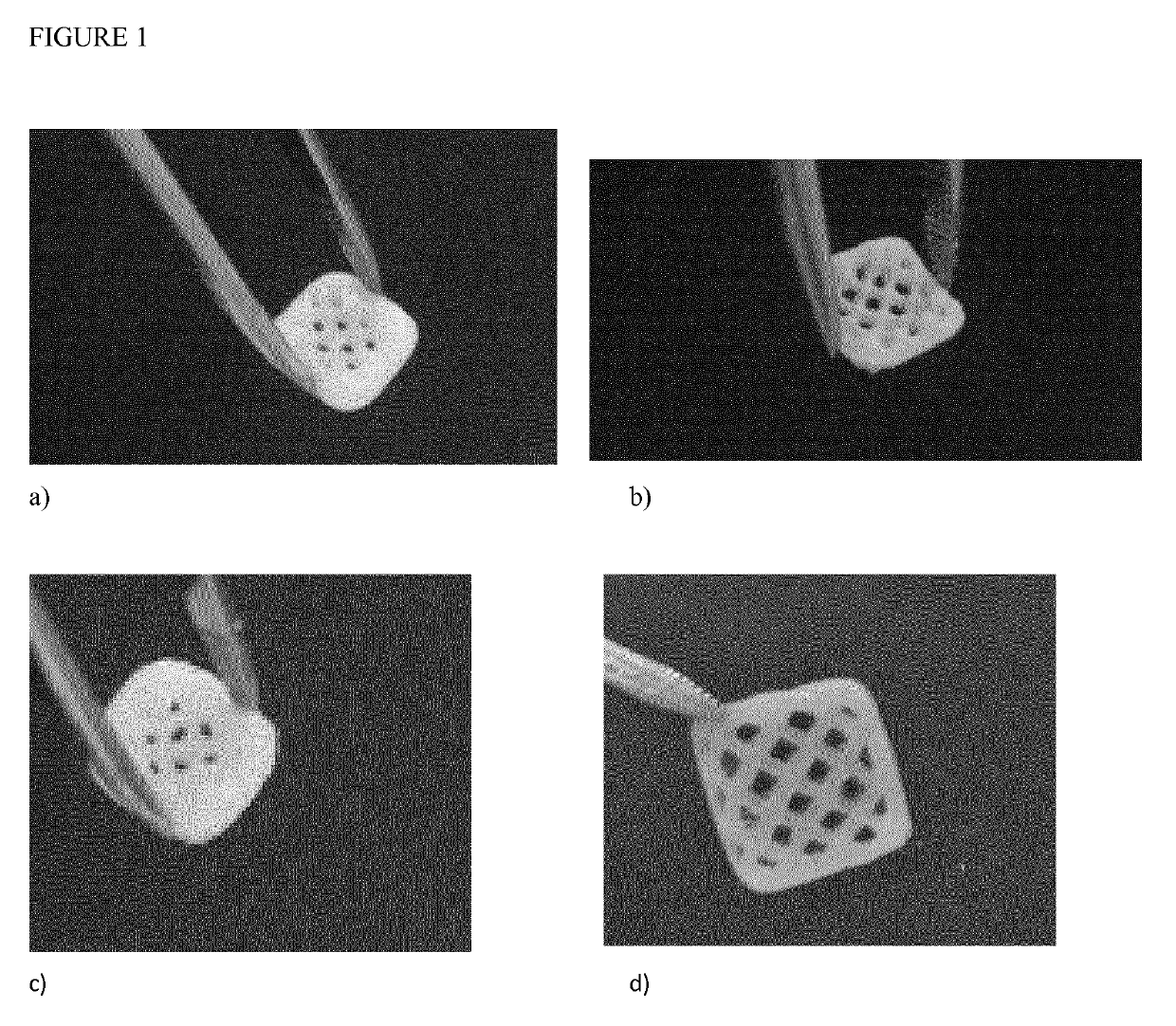

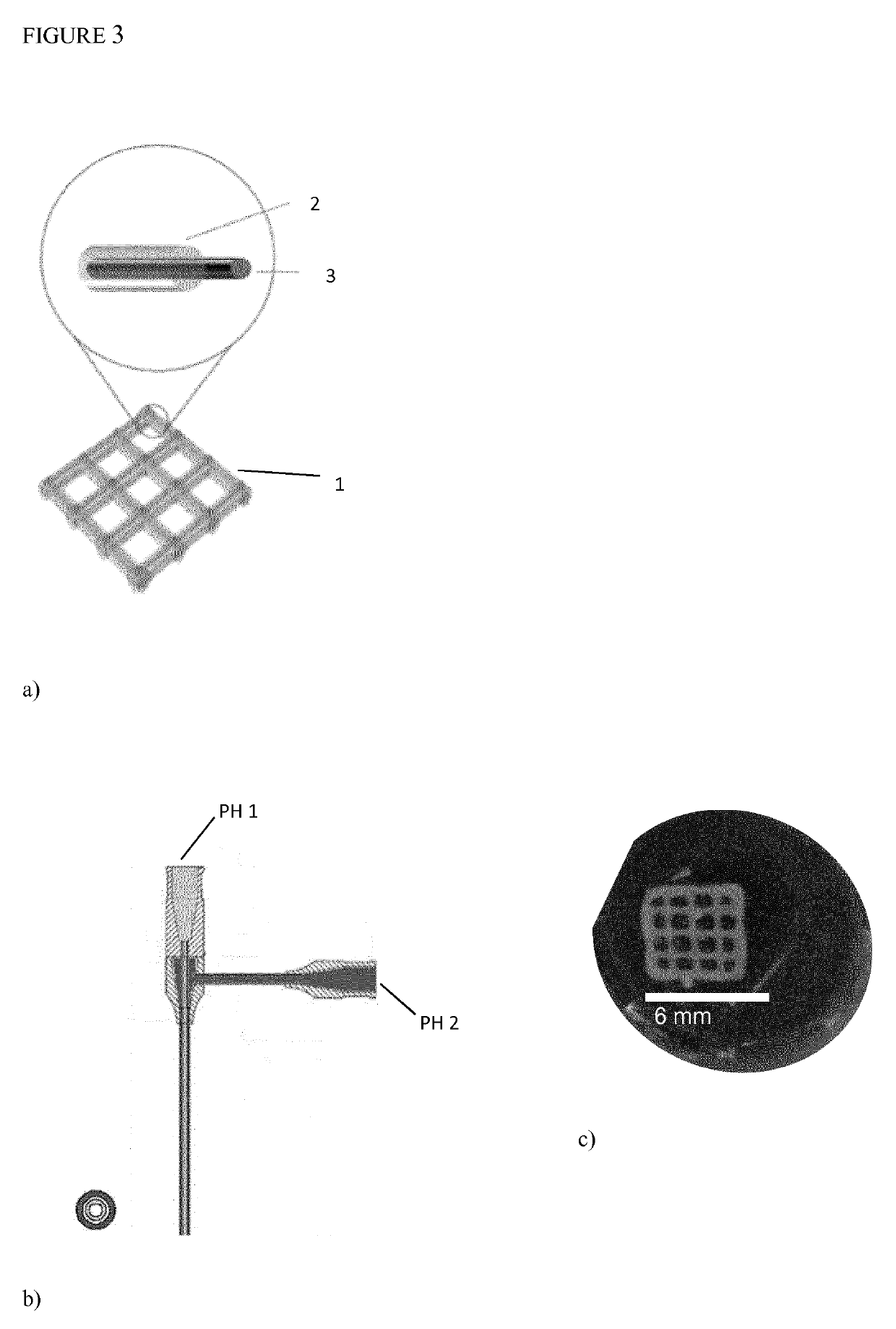

Scaffold-free 3D bioprinting of porcine cells

Provided herein are synthetic, three-dimensional (3D) bioprinted tissue constructs comprising porcine cells and methods of producing and using the same. The synthetic 3D bioprinted tissue constructs are fabricated by bioprinting spheroids comprising porcine cells, including genetically engineered cells, on a microneedle mold and fusing the spheroids to form an engineered tissue construct. Also provided are methods of using scaffold-free 3D bioprinted tissue constructs for applications related to drug screening and toxicity screening.

Owner:INDIANA UNIV RES & TECH CORP

Cellulose nanofibrillar bioink for 3D bioprinting for cell culturing, tissue engineering and regenerative medicine applications

PendingUS20200164103A1Improve survivabilityAdditive manufacturing apparatusCellulose coatingsCellulose3d shapes

The present invention relates to biomaterial in the form of dispersion of cellulose nanofibrils with extraordinary shear thinning properties which can be converted into desire 3D shape using 3D Bioprinting technology. In this invention cellulose nanofibril dispersion, is processed through different mechanical, enzymatic and chemical steps to yield dispersion with desired morphological and rheological properties to be used as bioink in 3D Bioprinter. The processes are followed by purification, adjusting of osmolarity of the material and sterilization to yield biomaterial which has cytocompatibility and can be combined with living cells. Cellulose nanofibrils can be produced by microbial process but can also be isolated from plant secondary or primary cell wall, animals such as tunicates, algae and fungi. The present invention describes applications of this novel cellulose nanofibrillar bioink for 3D Bioprinting of tissue and organs with desired architecture.

Owner:CELLINK AB

3D bioprinted skin tissue model

The present invention relates to a 3D bioprinted skin tissue model, a method for providing said model and the use of said model. The 3D bioprinted skin tissue model comprises at least one bioink A, at least one cell type A, at least one factor A, wherein the bioink A comprises at least one biopolymer, a thickener, at least one extra-cellular matrix or a decellularized matrix, and optionally a photo initiator and / or cellular additions, the at least one cell type A is an epidermal, dermal and / or hypodermal cell or cell line, and the at least one factor A is a growth factor, protein and / or molecule thatstimulates altered or abnormal metabolism of cell type A.

Owner:セルインクバイオプリンティングアーベー

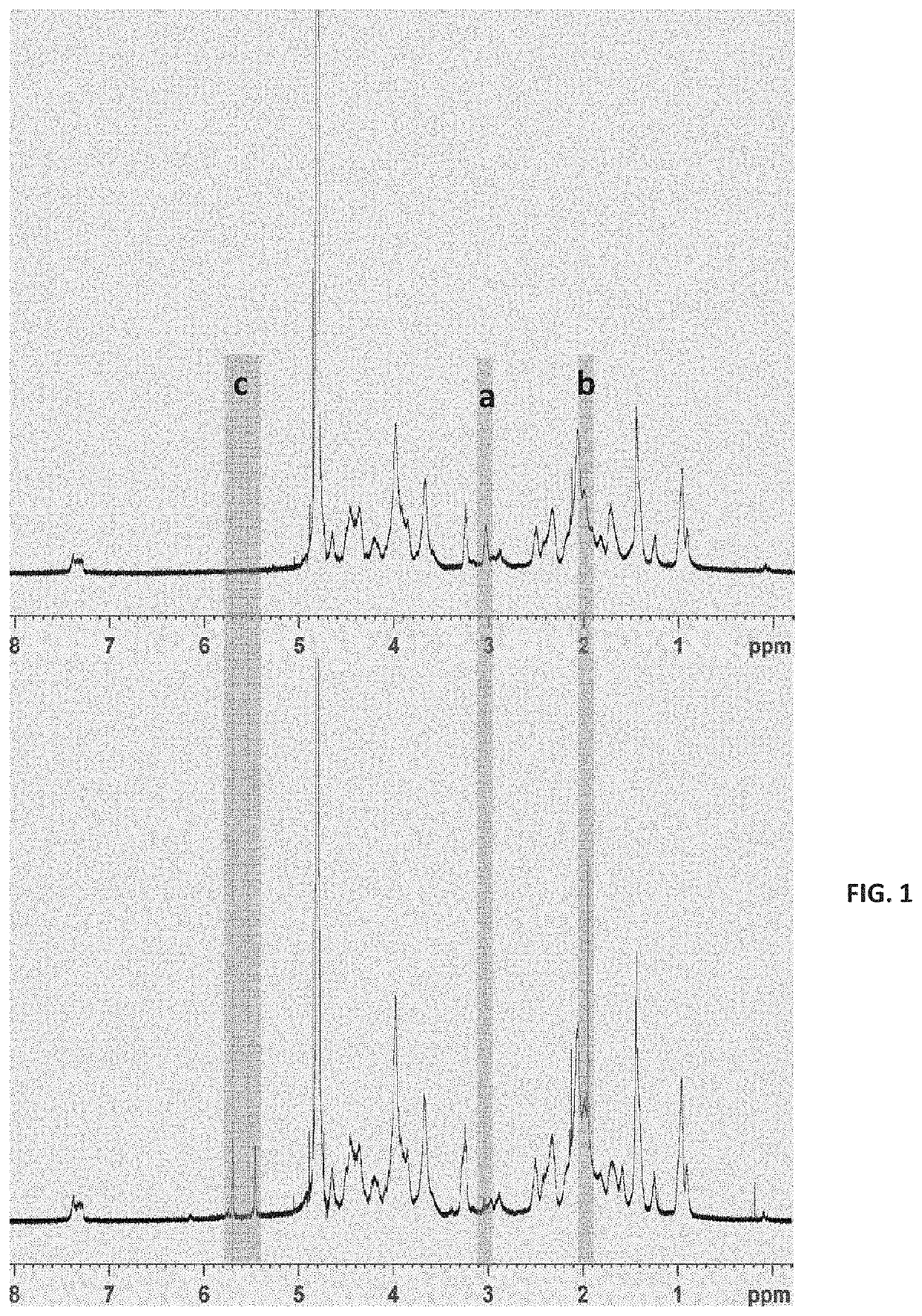

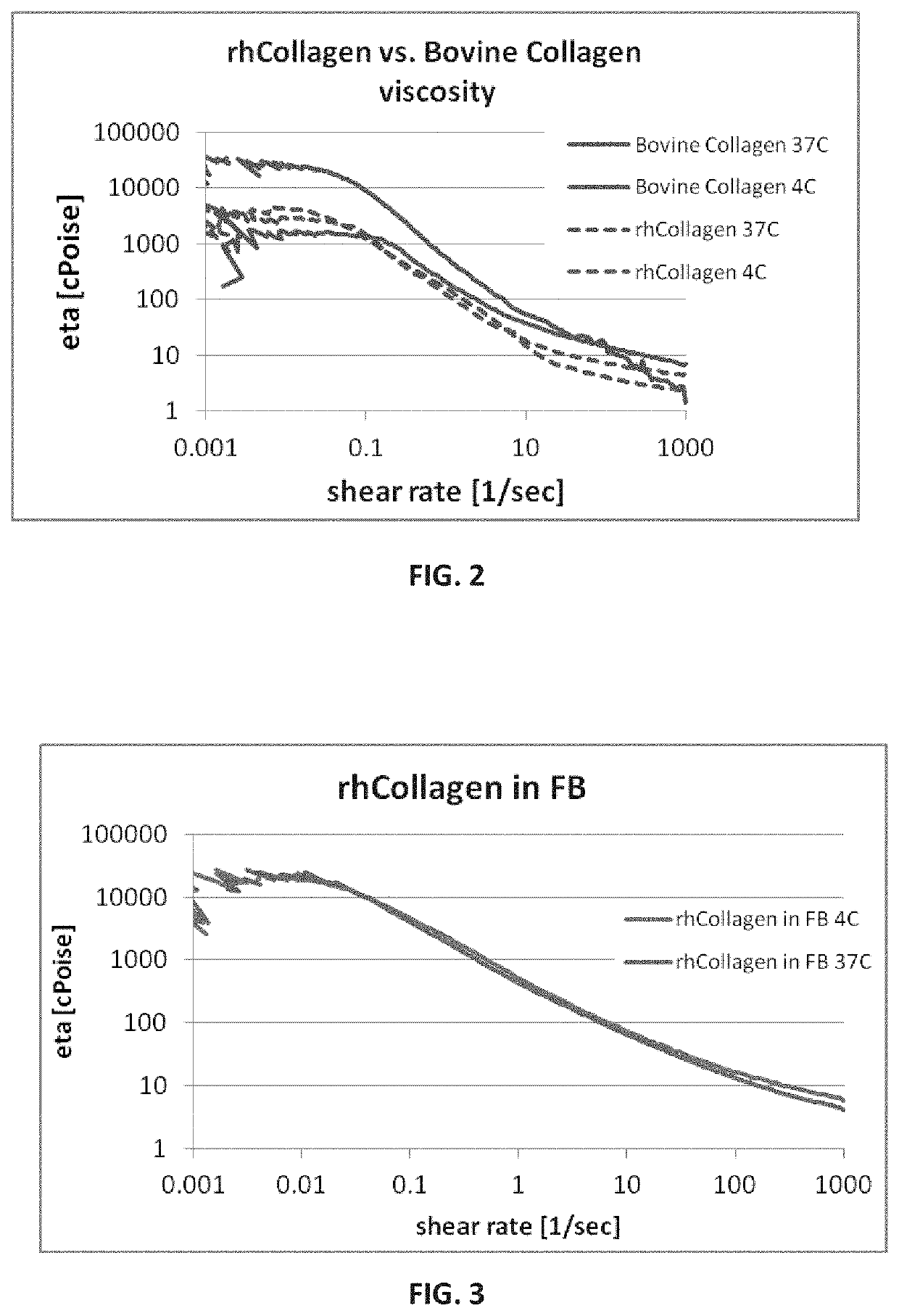

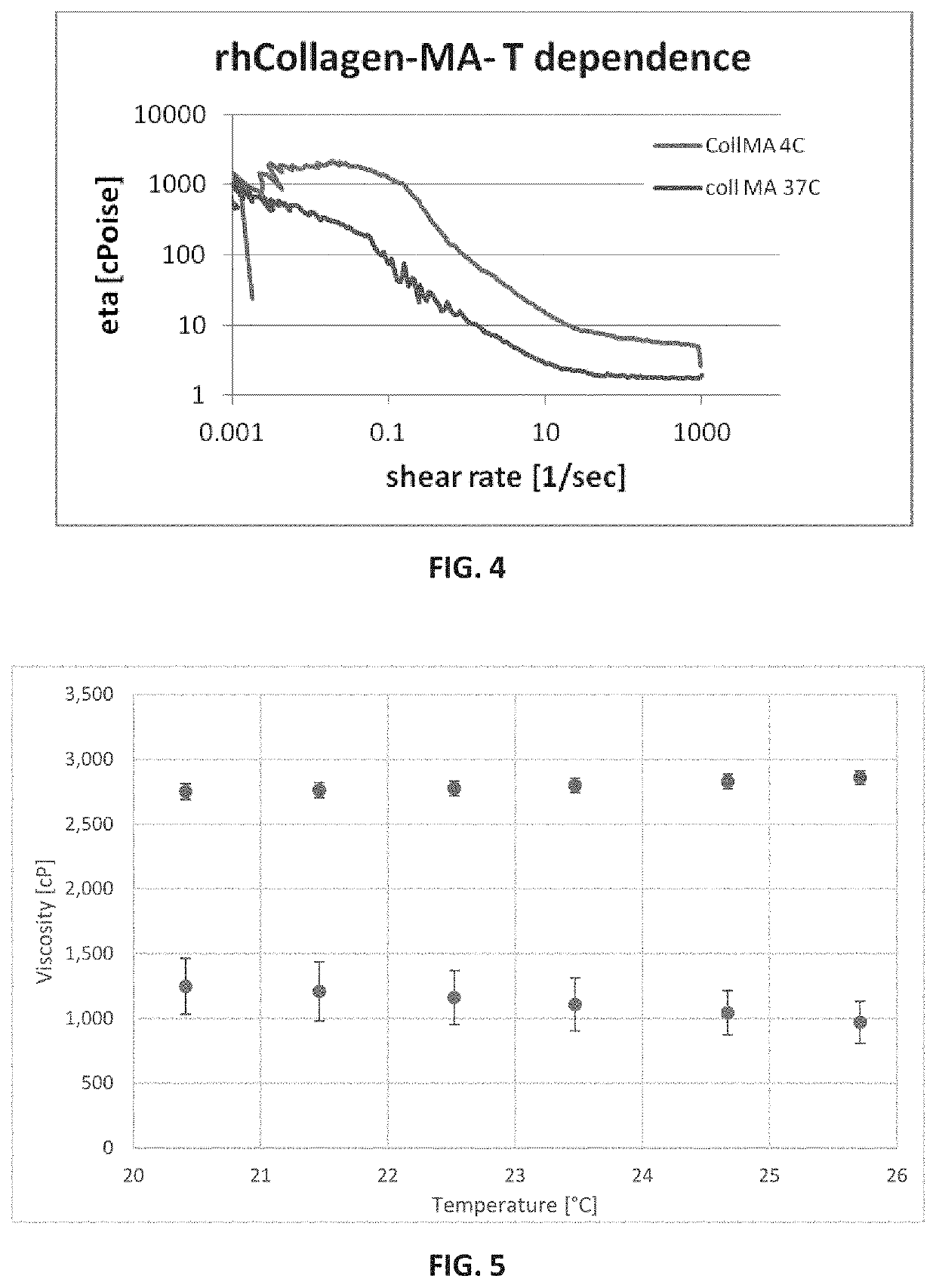

Additive manufacturing using recombinant collagen-containing formulation

PendingUS20200179562A1Additive manufacturing apparatusAdditive manufacturing with liquidsCollagenanOrganic chemistry

Compositions containing curable recombinant human collagen, and kits comprising same, which are usable in preparing modeling material formulations for additive manufacturing (e.g., 3D bioprinting) of 3D objects are provided. Methods utilizing such modeling material formulations in additive manufacturing of 3D objects having a collagen-based material in at least a portion thereof, are also provided. The formulations feature a desired viscosity at a temperature higher than 10° C. (e.g., room temperature or 37° C.) and allow performing the additive manufacturing without cooling the system or a part thereof.

Owner:COLLPLANT LTD

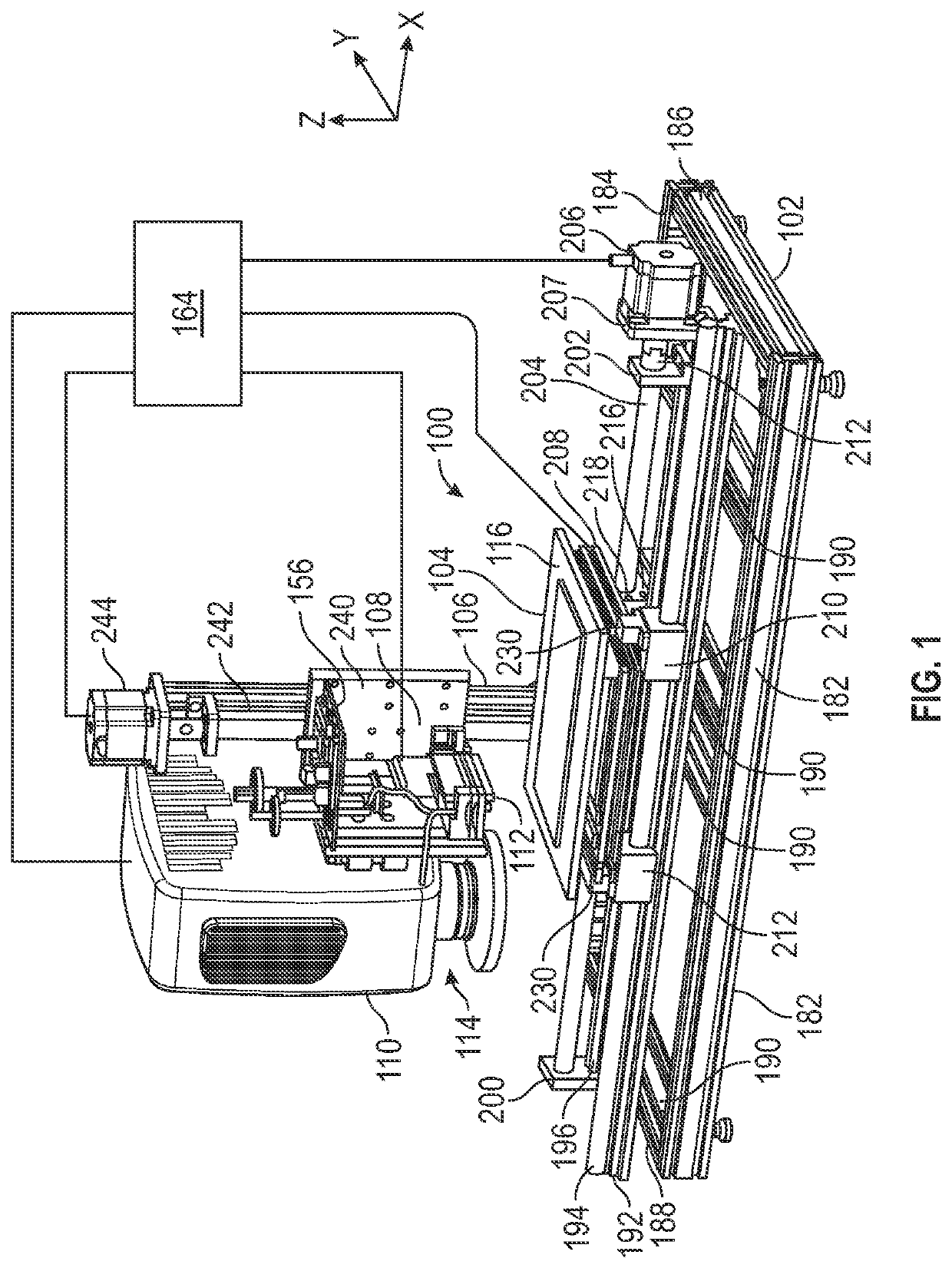

Hybrid printing platform for 3D bioprinting of live organs

PendingUS20220111579A1Manufacturing platforms/substrates3D object support structuresLiving bodyMechanical engineering

A method of forming a three dimensional object includes dispensing droplets of an electromagnetic energy curable liquid onto a surface to form a plurality of layers of the three dimensional object in liquid form, wherein each droplet forms a layer of liquid on the surface which is larger than a minimum feature size of a structure to be formed by curing the curable liquid, and directing electromagnetic energy capable of curing the liquid and having a beam width intersecting the layer of liquid which is at least as small as the smallest feature of a structure to be formed in the curable liquid.

Owner:APPLIED MATERIALS INC

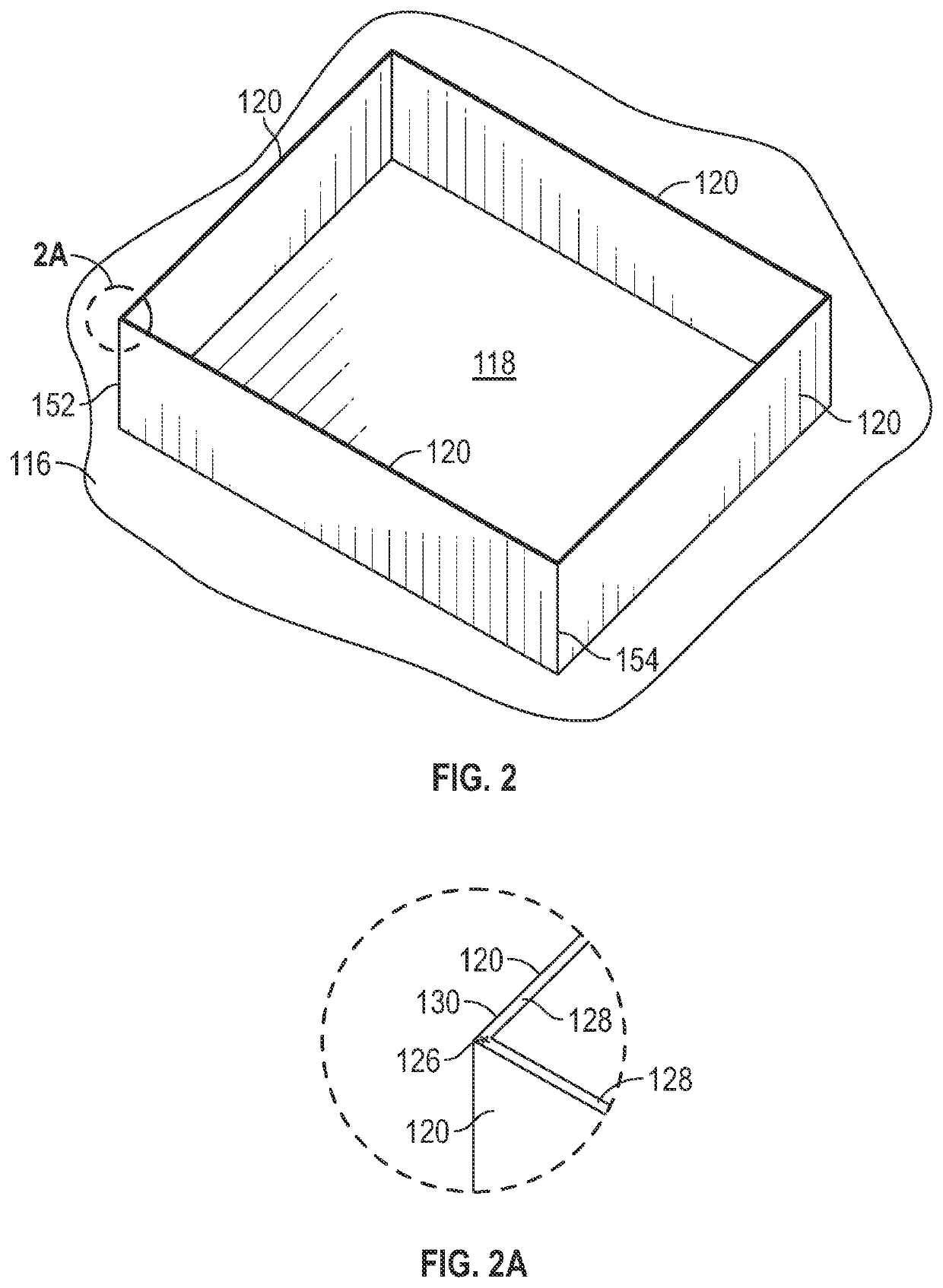

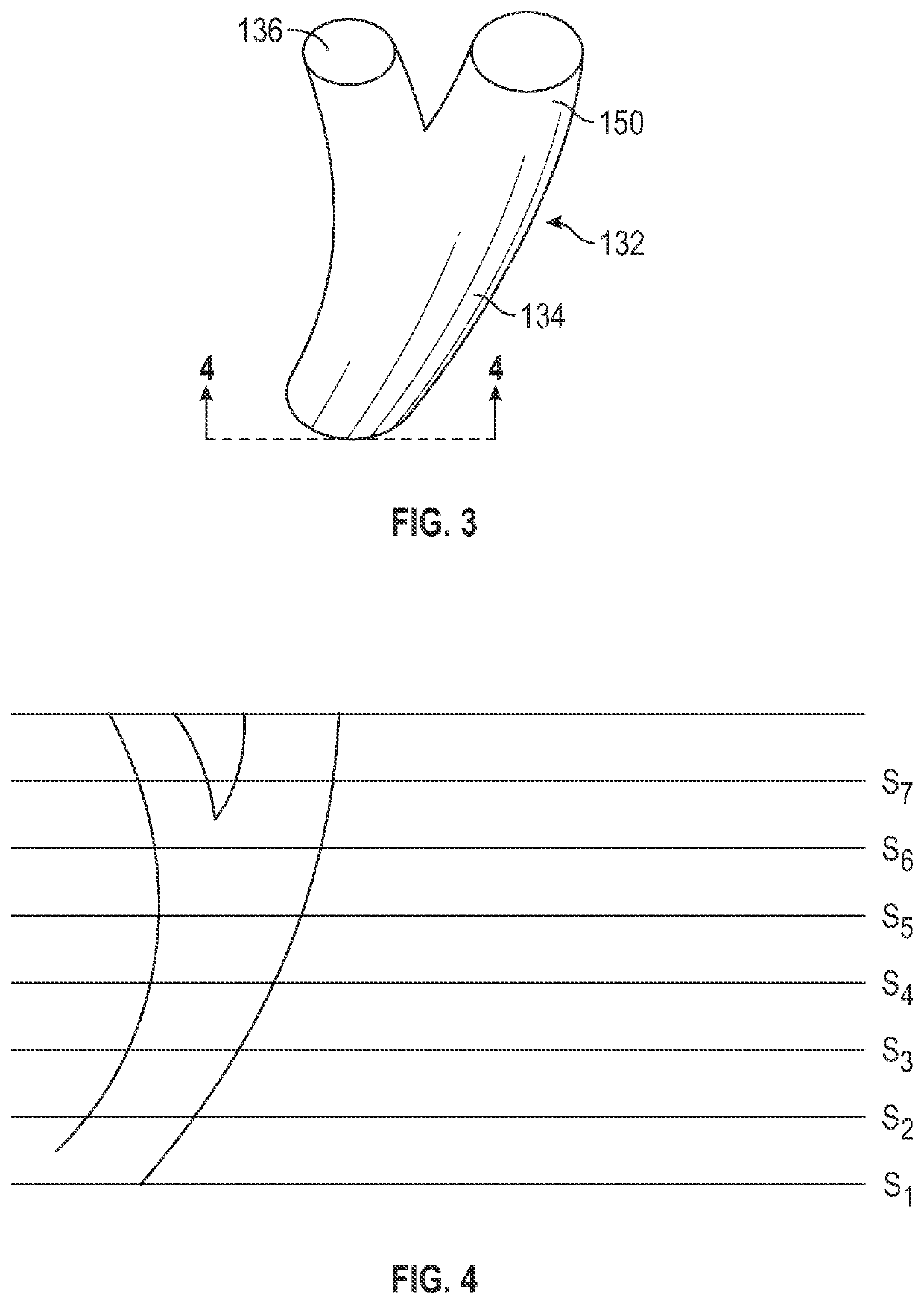

Compact mechanical syringe extruder for 3D bioprinting of cell laden gels

PendingUS20210269776A1Additive manufacturing apparatusArtificial cell constructsMedicineComputer printing

Bioprinting is the layer-by-layer construction of synthetic tissues or scaffolds. Described herein is a motorized extruder which can precisely extrude and retract extrudate such as bioinks in a compact and rapidly-loadable form-factor. This includes a compact bioprinter using a stepper motor coupled with a threaded shaft to directly move the plunger of an extruder. This pneumatic-mechanical system obviates the needs for pneumatic tubing, rods, or other complex elements of existing designs. The direct drive design further allows for a lighter, smaller gantry that is capable of more precise fabrication of bioprinted constructions. This includes delicate vasculature systems that are beyond limits of existing bioprinting technologies.

Owner:CEDARS SINAI MEDICAL CENT

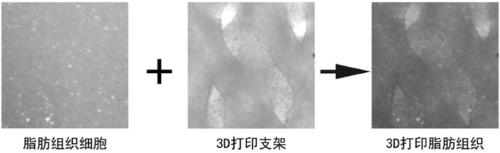

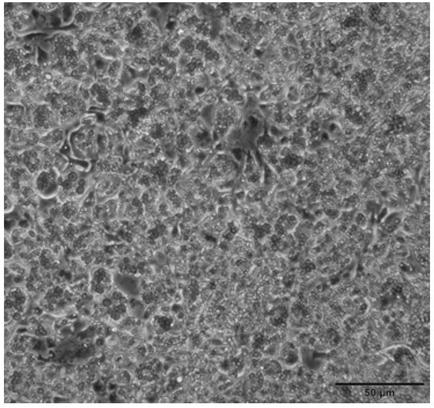

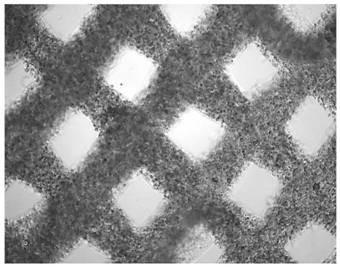

3D printed adipose tissue

InactiveCN109957540AOvercome the problem of loose structure and unsuitable for surgeryTo achieve secretory functionCompounds screening/testingMetabolism disorder3d printMixed culture

The present invention relates to a 3D printed adipose tissue and particularly discloses the artificial adipose tissue. The artificial adipose tissue comprises a biocompatible stent, adipose cells anda mixed culture solution. Through a 3D bioprinting technique, the biocompatible stent and the adipose tissue are prepared into the biologically active artificial adipose tissue. The mixed culture solution is used for culture and preservation of the adipose cells and tissue. The biocompatible stent is prepared using the 3D printing technique. The artificial adipose tissue can be used as a pathophysiological mechanism research and therapeutic tool for adipose-related endocrine and metabolic diseases.

Owner:SHENZHEN INST OF ADVANCED TECH

3D bioprinting in-vivo tumor model and building method thereof

ActiveCN111304168AFast preparationStable manufacturingCell culture supports/coatingTumor/cancer cellsNude mouseHydrogel scaffold

The invention relates to a 3D (three-dimensional) bioprinting in-vivo tumor model and a building method thereof, and belongs to the technical field of biology or the field of biological 3D printing. The tumor model comprises tumor cells and a hydrogel stent, wherein the hydrogel stent is a 3D stent obtained in a 3D bioprinting mode; and the hydrogel stent is transplanted into an animal body to form the in-vivo tumor model. The building method of the in-vivo tumor model comprises the steps of mixing, printing, hydrogel stent culture and transplantation. The invention aims at providing the high-tumorigenic-rate in-vivo tumor model capable of being fast and stably prepared in large scales, and the building method of the in-vivo tumor model. The tumor cell carrying hydrogel stent can be fast and stably prepared in large scales by using a 3D bioprinting technology; after in vitro culture for a short time, the tumor cell carrying hydrogel stent is transplanted into a nude mouse body to obtain a high tumorigenic rate; tumor models of different parts and different types can be built according to research requirements; and the tumor models are built in a personalized manner.

Owner:THE FIRST AFFILIATED HOSPITAL OF WANNAN MEDICAL COLLEGE YIJISHAN HOSPITAL OF WANNAN MEDICAL COLLEGE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com