3D bioprinting ink, preparation method of ink, tissue engineering scaffold and preparation method of scaffold

A tissue engineering scaffold and bioprinting technology, applied in the field of medicine, can solve the problems of increasing the cost of preparation and increasing the complexity of the production process, and achieve the effects of reducing treatment costs, relieving patients' pain, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

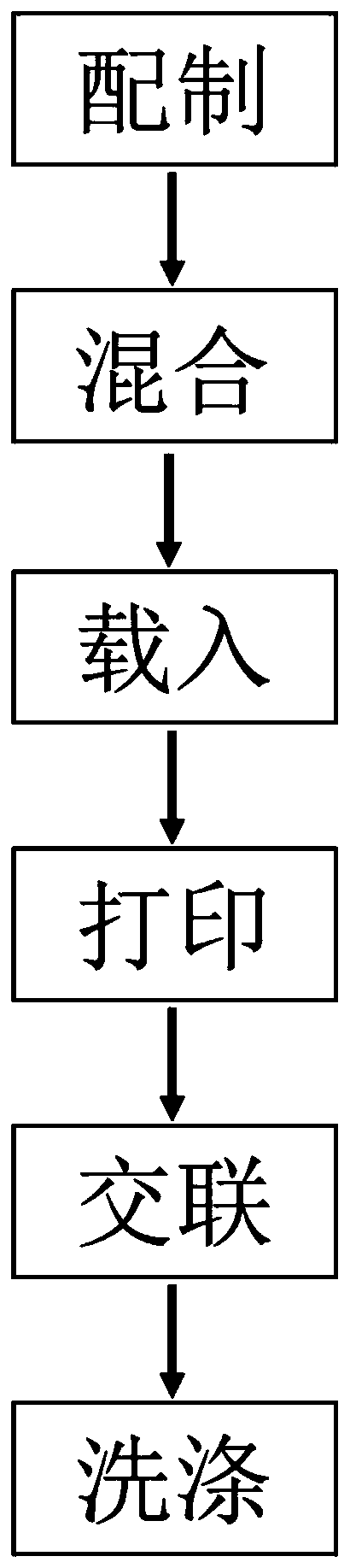

[0042] A preparation method for 3D bioprinting ink, comprising the following steps:

[0043] S1, weighing raw materials

[0044] Weigh the gelatin particles, sodium alginate powder and lithium magnesium silicate powder according to the set amount, and sterilize and disinfect the gelatin particles, sodium alginate powder and lithium magnesium silicate powder;

[0045] S2, preparation of raw materials

[0046] Dissolve the gelatin particles obtained in S1 with sterile deionized water to obtain a gelatin solution, add sodium alginate powder to the gelatin solution, and obtain a mixed prepolymer solution of gelatin-sodium alginate after dissolving, dissolve the lithium magnesium silicate powder in In sterile deionized water, lithium magnesium silicate colloid was obtained;

[0047] S3, mixed

[0048] Mix the gelatin-sodium alginate mixed prepolymer solution obtained in S2 with the lithium magnesium silicate colloid in equal volumes to obtain a nanocomposite hydrogel, and combin...

Embodiment 1

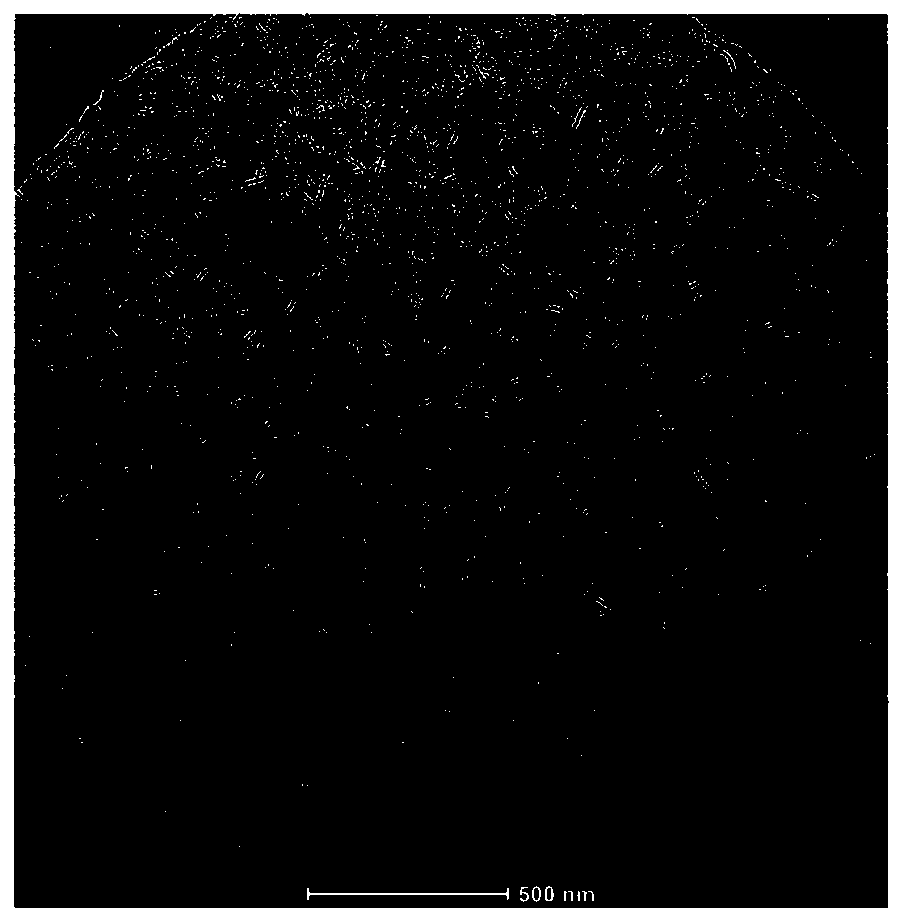

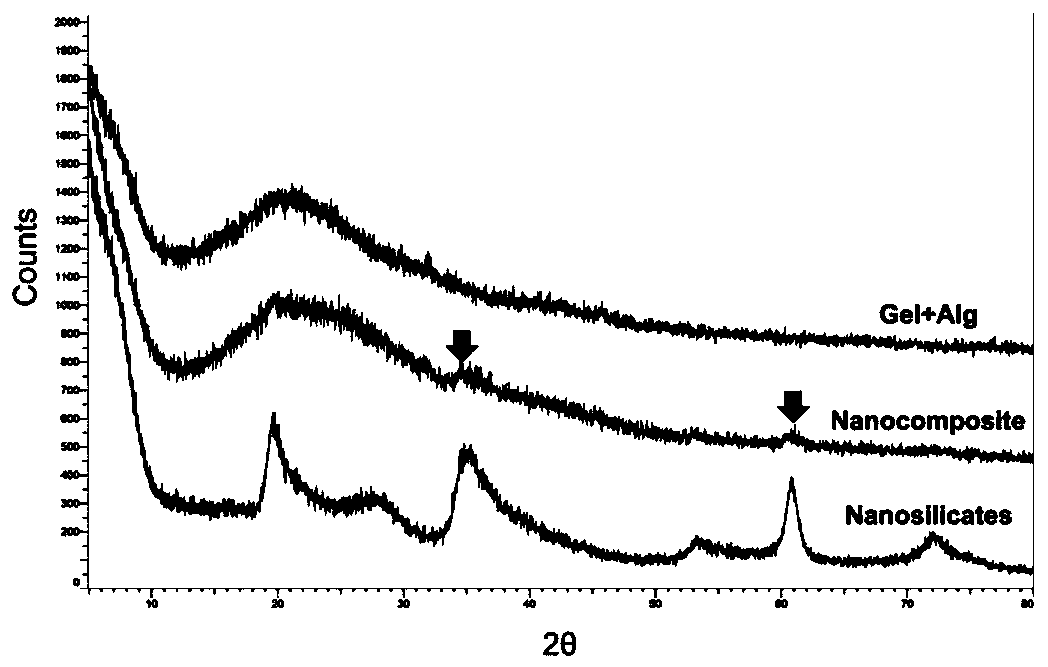

[0060] The formulations of bioactive tissue engineering bone scaffolds listed in this example include nanocomposite hydrogels and human bone marrow mesenchymal stem cells, wherein the nanocomposite hydrogels include gelatin, sodium alginate, nanoscale lithium magnesium silicate and Deionized water; nanocomposite hydrogel including gelatin 70mg / mL~100mg / mL, sodium alginate 10mg / mL~30mg / mL, magnesium silicate lithium 10mg / mL~30mg / mL, among them, human bone marrow mesenchymal stem cells The volume ratio of the suspension to the nanocomposite hydrogel was 1:400.

[0061] Such as figure 1 Shown, as a preferred embodiment of the present invention, specifically carry out according to the following steps:

[0062] Step 1. Preparation of raw materials: First, put the pre-weighed gelatin granules, sodium alginate powder and lithium magnesium silicate powder in a sterile centrifuge tube, sterilize with ethylene oxide, and set aside; add the gelatin granules to the Put a corresponding v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com