3D bioprinting forming method

A bioprinting and molding technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of material deformation, long preparation time, inability to meet scientific research and clinical needs, etc., achieve high speed, improve mechanical strength and The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

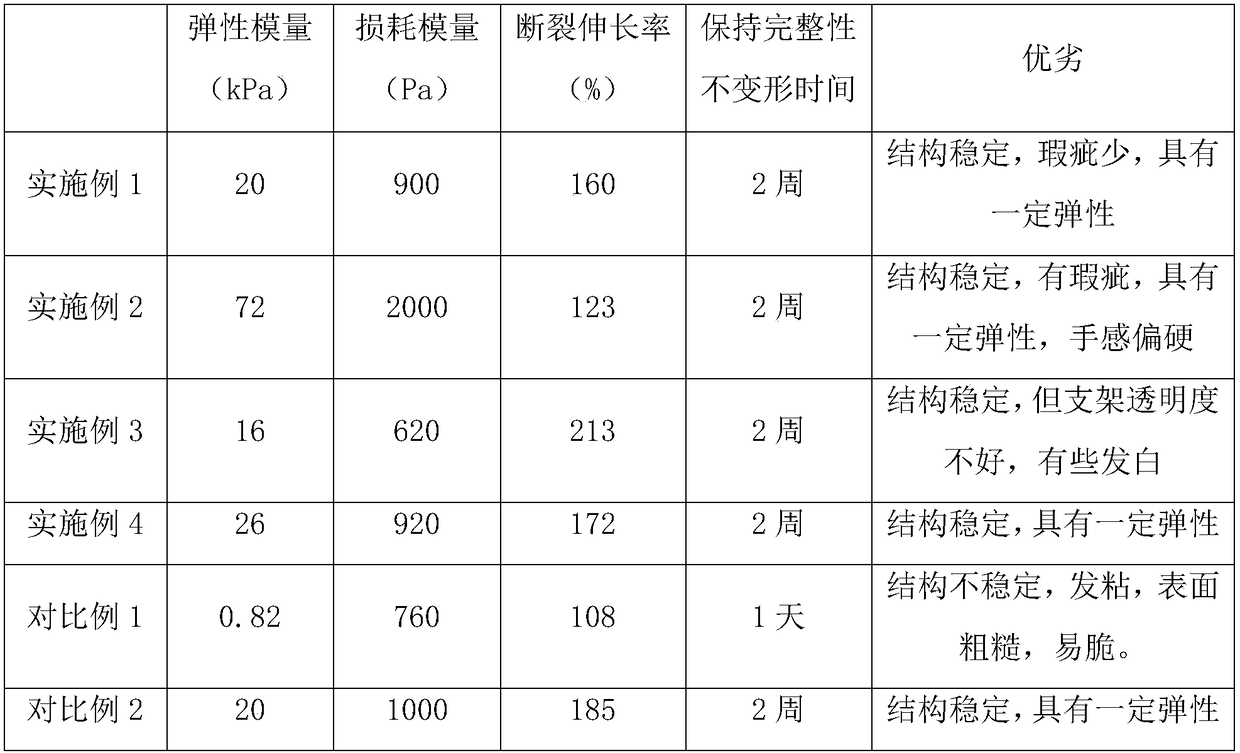

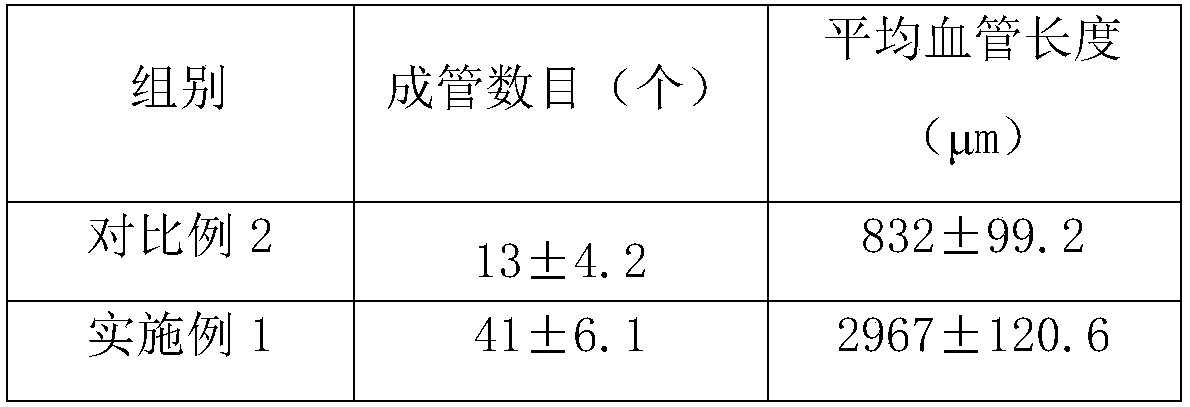

Examples

Embodiment 1

[0033] A kind of 3D printing biological ink, comprises the raw material of following mass percentage and is made of:

[0034] Extracellular Vesicle Suspension 10%

[0035] Pig dermal soft tissue derived extracellular matrix nanofiber powder 5%

[0036] Hydrochloric acid 1%

[0037] Ultrapure water balance.

[0038] The 3D printing bio-ink is prepared according to the following method:

[0039] Mix pig dermal soft tissue-derived extracellular matrix nanofiber micropowder, hydrochloric acid and ultrapure water, stir until completely dissolved, adjust pH to 6.5 with sodium bicarbonate, add extracellular vesicle suspension, mix evenly, and centrifuge to obtain Gel, the bioink material.

[0040] 3D printing forming method, comprising the steps of:

[0041] (1) 3D bioprinting: use the 3D bioprinter to print the composite ink material from the ink injection cylinder at 15°C through the needle to the receiving platform at 8°C according to the established digital model, and store ...

Embodiment 2

[0044] A kind of 3D printing biological ink, comprises the raw material of following mass percentage and is made of:

[0045] Extracellular vesicle suspension 20%;

[0046] Bovine dermis soft tissue-derived extracellular matrix nanofiber powder 15%;

[0047] Phosphoric acid 0.1%;

[0048] Ultrapure water balance.

[0049] The 3D printing bio-ink is prepared according to the following method:

[0050] Mix bovine dermis soft tissue-derived extracellular matrix nanofiber micropowder, phosphoric acid and ultrapure water, stir until completely dissolved, adjust pH to 6 with sodium phosphate, add extracellular vesicle suspension, mix well, and centrifuge to obtain coagulated Glue, the bio-ink material.

[0051] 3D printing forming method, comprising the steps of:

[0052] Carry out 3D printing according to the 3D printing molding method of Example 1, then wash with water, 0.5% (according to the amount of 3D printing bio-ink) glutaraldehyde cross-linking to set the shape.

Embodiment 3

[0054] A kind of 3D printing biological ink, comprises the raw material of following mass percentage and is made of:

[0055] Extracellular vesicle suspension 10%;

[0056] Pig dermis soft tissue-derived extracellular matrix nanofiber powder 8%;

[0057] Hydrochloric acid 1%;

[0058] Distilled water balance.

[0059] The 3D printing bio-ink is prepared according to the following method:

[0060] Mix pig dermal soft tissue-derived extracellular matrix nanofiber micropowder, hydrochloric acid and distilled water, stir until completely dissolved, adjust the pH to 7.45 with sodium hydroxide, add extracellular vesicle suspension, mix well, and centrifuge to obtain a gel , the bioink material.

[0061] 3D printing forming method, comprising the steps of:

[0062] (1) 3D bioprinting: use the 3D bioprinter to print the composite ink material from the ink injection cylinder at 20°C through the needle to the receiving platform at 4°C according to the established digital model, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com