Hydraulic extruding material supplying system and hydraulic extruding material supplying method for 3D bioprinting

A 3D printing and feeding system technology, applied in the field of tissue engineering scaffold 3D printing and biological 3D printing hydraulic extrusion feeding system, to achieve the effect of compact structure, low accuracy of excluding feeding, and real-time control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

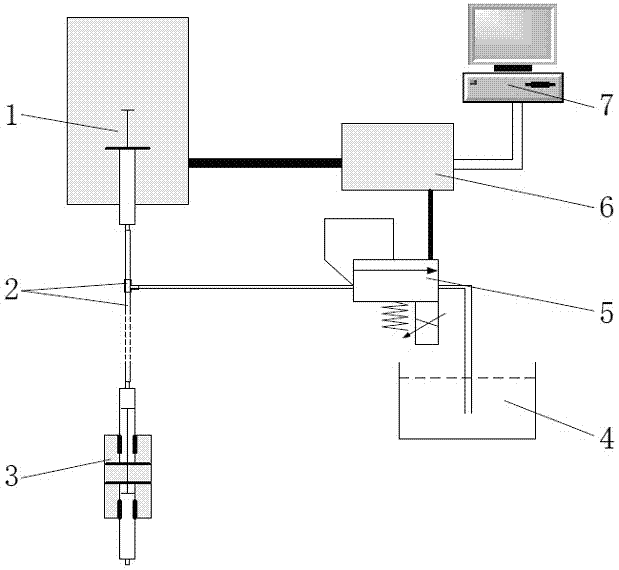

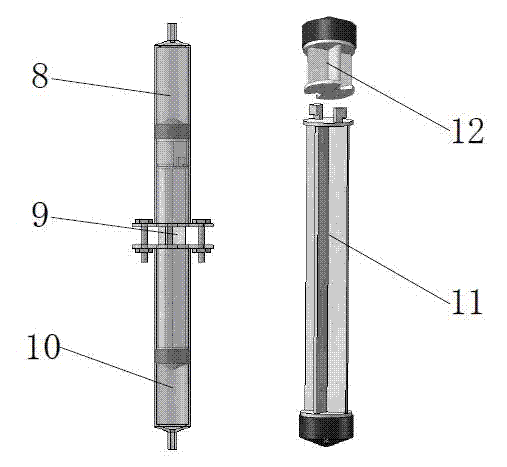

[0030] A hydraulic extrusion feeding method utilizing a hydraulic extrusion feeding system for biological 3D printing, comprising the following steps:

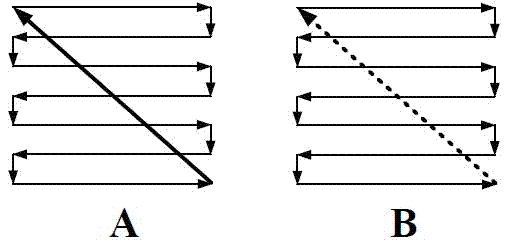

[0031] Prepare 20% gelatin aqueous solution and 5% chitosan solution, mix to obtain gelatin-chitosan mixed solution 10ml, leave standstill to obtain stable and uniform hydrogel solution, pack in the feeding chamber 10, and be installed in the nozzle device 3, Assembling hydraulic feeding systems such as figure 1 Shown; Start the micro-injection pump and the electro-hydraulic proportional overflow valve 5 by the host computer 7, control the feeding rate of the micro-injection pump to be 400ul / min and the regulating pressure of the electro-hydraulic proportional overflow valve 5 to be 200KPa, so that the hydrogel The material is extruded and the bracket is printed according to the processing path; after the printing of a layer of bracket is completed, the regulating pressure of the electro-hydraulic proportional overflow valve 5...

Embodiment 2

[0033] A hydraulic extrusion feeding method utilizing a hydraulic extrusion feeding system for biological 3D printing, comprising the following steps:

[0034] In the hydraulic extrusion feeding system, two nozzle devices are connected through a two-position three-way solenoid valve, such as Figure 4Shown; prepare 20% gelatin aqueous solution and 5% chitosan solution, mix to obtain gelatin-chitosan mixed solution 10ml, stand to obtain stable and uniform hydrogel solution; configure 5% sodium alginate aqueous solution 10ml, stand Obtain a stable and uniform hydrogel solution; put the two materials into two nozzle devices respectively; start the micro-injection pump and the electro-hydraulic proportional overflow valve 5 through the host computer 7, and control the feeding rate of the micro-injection pump to be 400ul / The control pressure of min and electro-hydraulic proportional overflow valve 5 is 200KPa; the two-position three-way solenoid valve is first connected to the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com