Patents

Literature

103 results about "Biomanufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomanufacturing is a type of manufacturing or biotechnology that utilizes biological systems to produce commercially important biomaterials and biomolecules for use in medicines, food and beverage processing, and industrial applications. Biomanufacturing products are recovered from natural sources, such as blood, or from cultures of microbes, animal cells, or plant cells grown in specialized equipment. The cells used during the production may have been naturally occurring or derived using genetic engineering techniques.

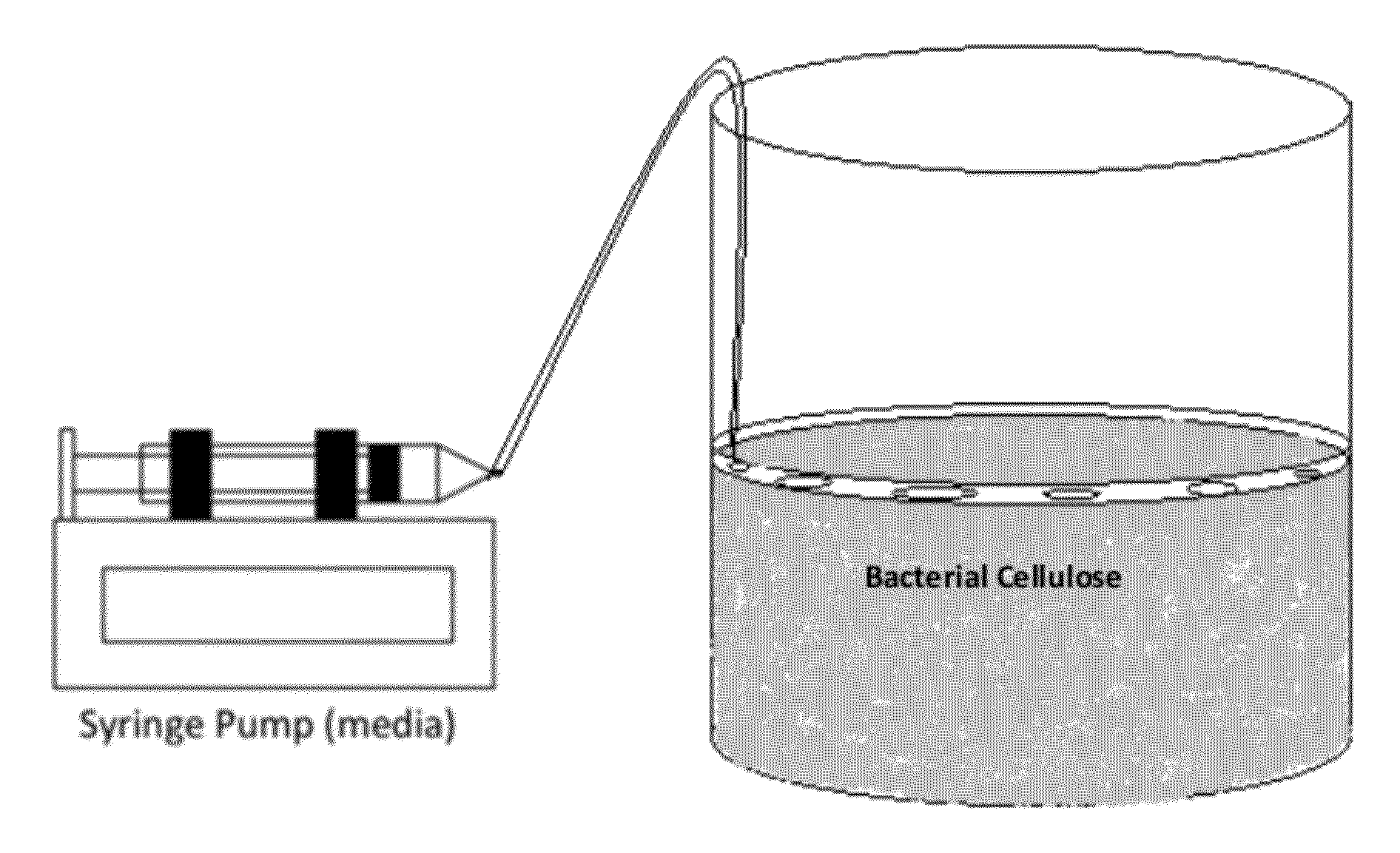

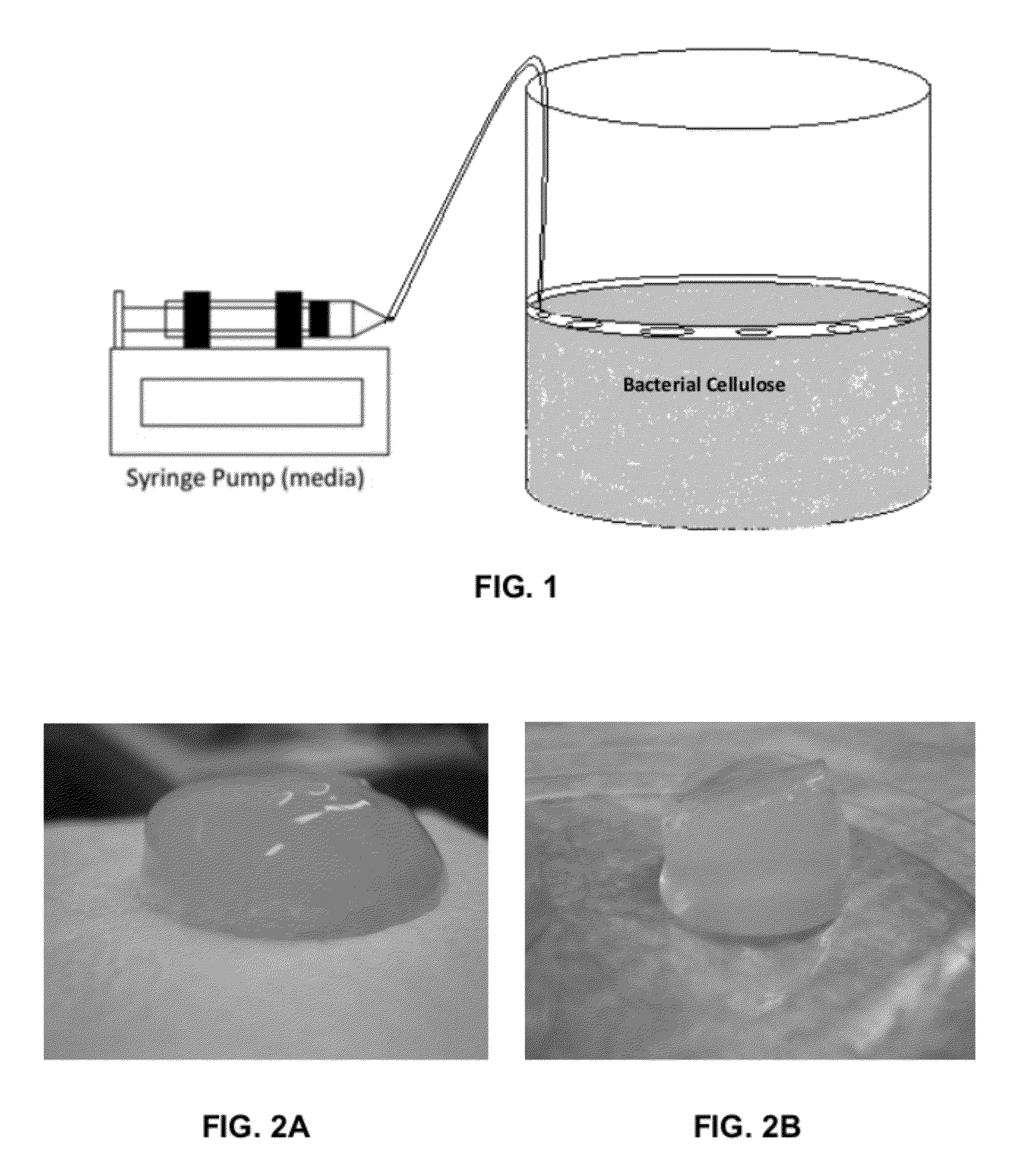

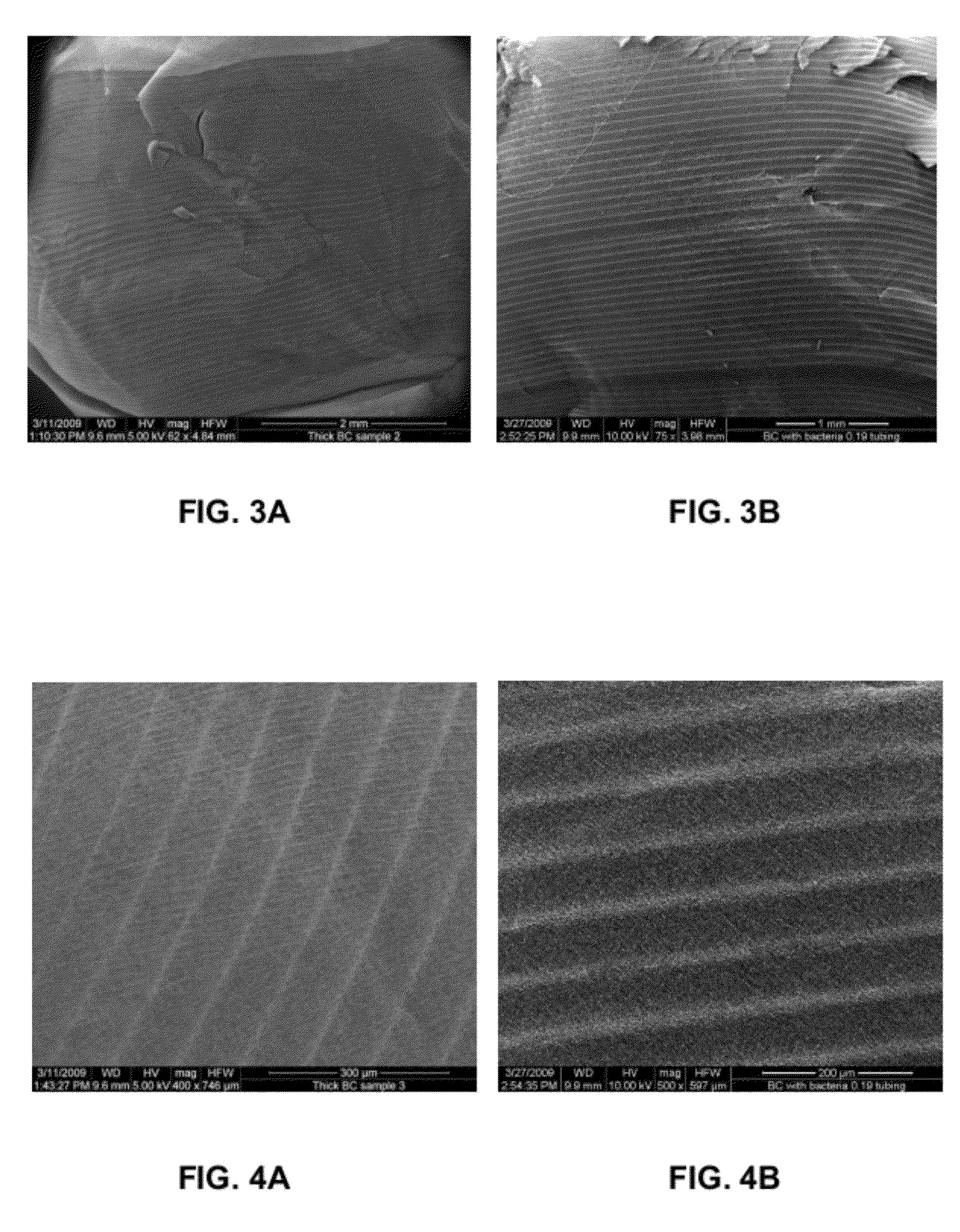

Three-dimensional bioprinting of biosynthetic cellulose (BC) implants and scaffolds for tissue engineering

InactiveUS20120190078A1Improve the level ofOptimize thicknessPharmaceutical delivery mechanismCell culture supports/coatingFiberPorosity

A novel BC fermentation technique for controlling 3D shape, thickness and architecture of the entangled cellulose nano-fibril network is presented. The resultant nano-cellulose based structures are useful as biomedical implants and devices, are useful for tissue engineering and regenerative medicine, and for health care products. More particularly, embodiments of the present invention relate to systems and methods for the production and control of 3-D architecture and morphology of nano-cellulose biomaterials produced by bacteria using any biofabrication process, including the novel 3-D Bioprinting processes disclosed. Representative processes according to the invention involve control of the rate of production of biomaterial by bacteria achieved by meticulous control of the addition of fermentation media using a microfluidic system. In exemplary embodiments, the bacteria gradually grew up along the printed alginate structure that had been placed into the culture, incorporating it. After culture, the printed alginate structure was successfully removed revealing porosity where the alginate had been placed. Porosity and interconnectivity of pores in the resultant 3-D architecture can be achieved by porogen introduction using, e.g., ink-jet printer technology.

Owner:VIRGINIA TECH INTPROP INC

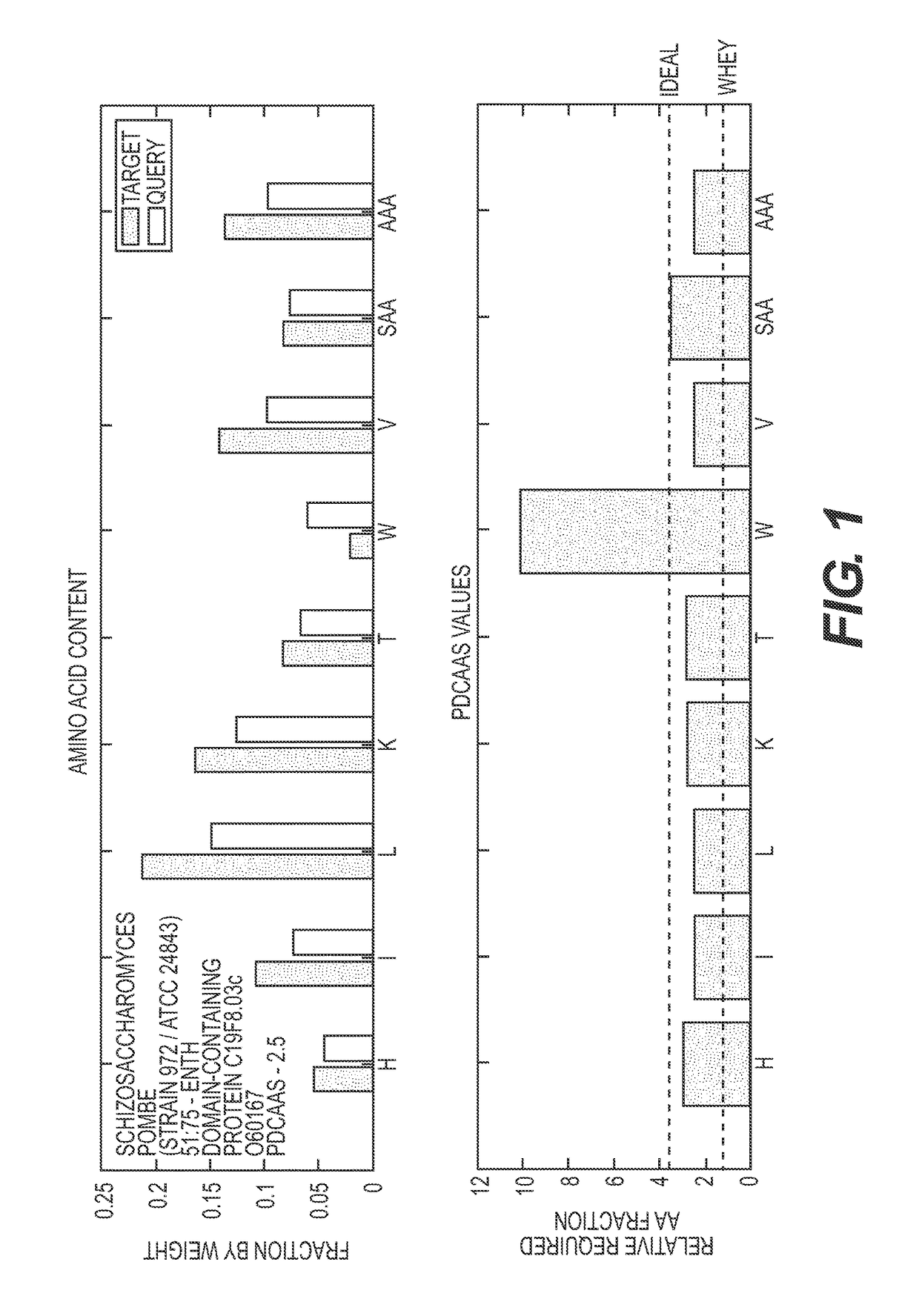

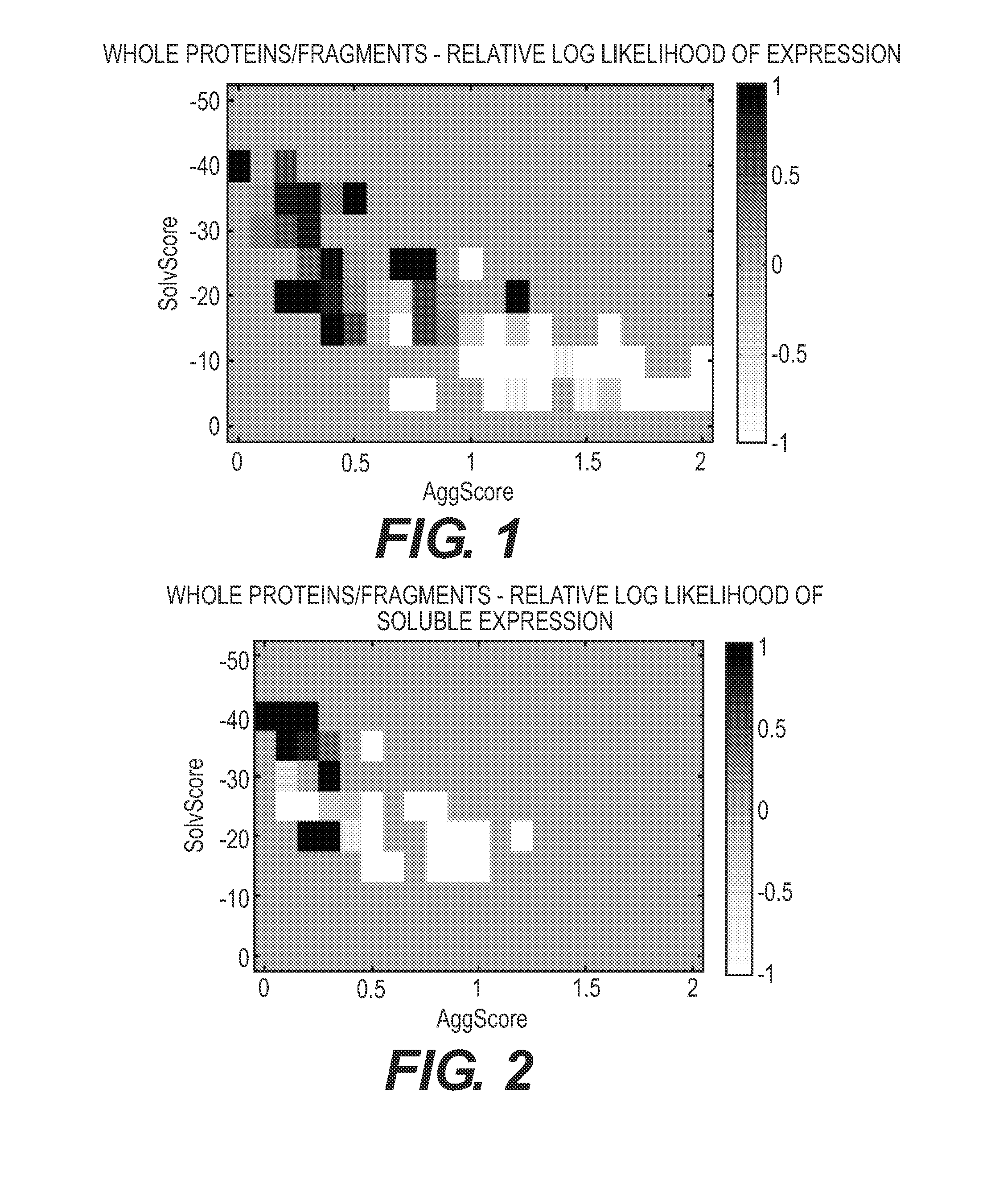

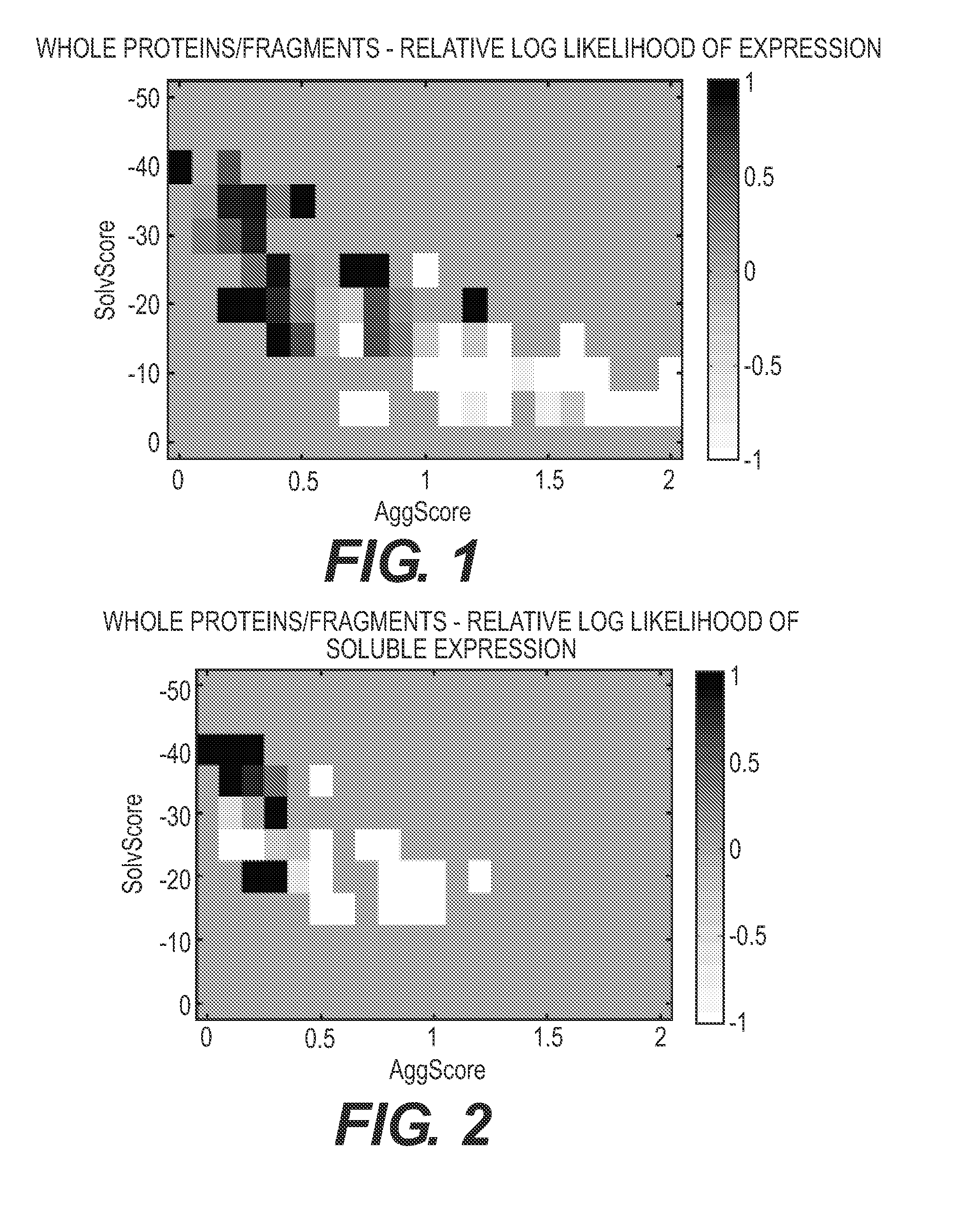

Nutritive fragments, proteins and methods

ActiveUS9700071B2High in proteinInduce postprandial satietyPeptide/protein ingredientsMetabolism disorderBiotechnologyNutrients protein

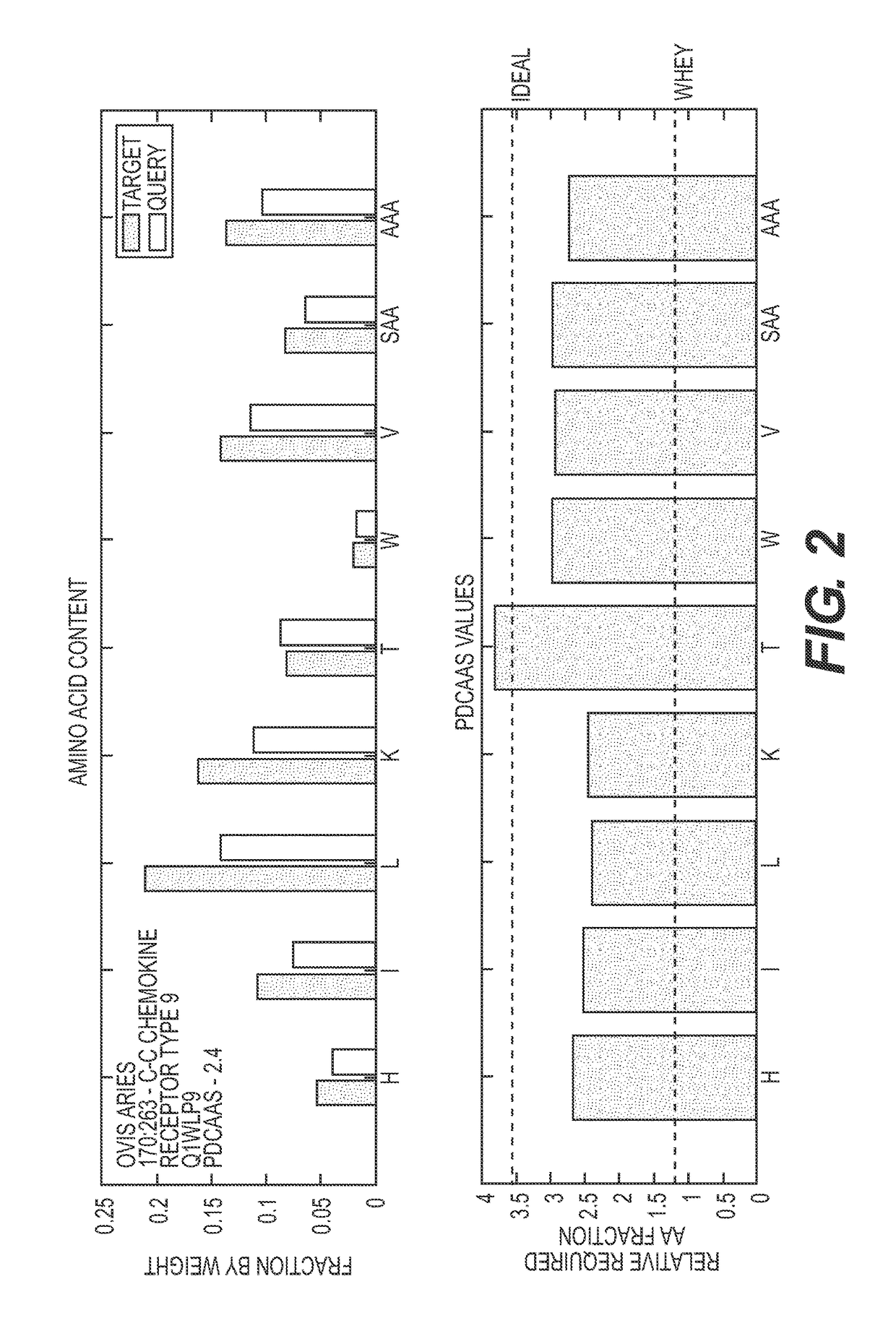

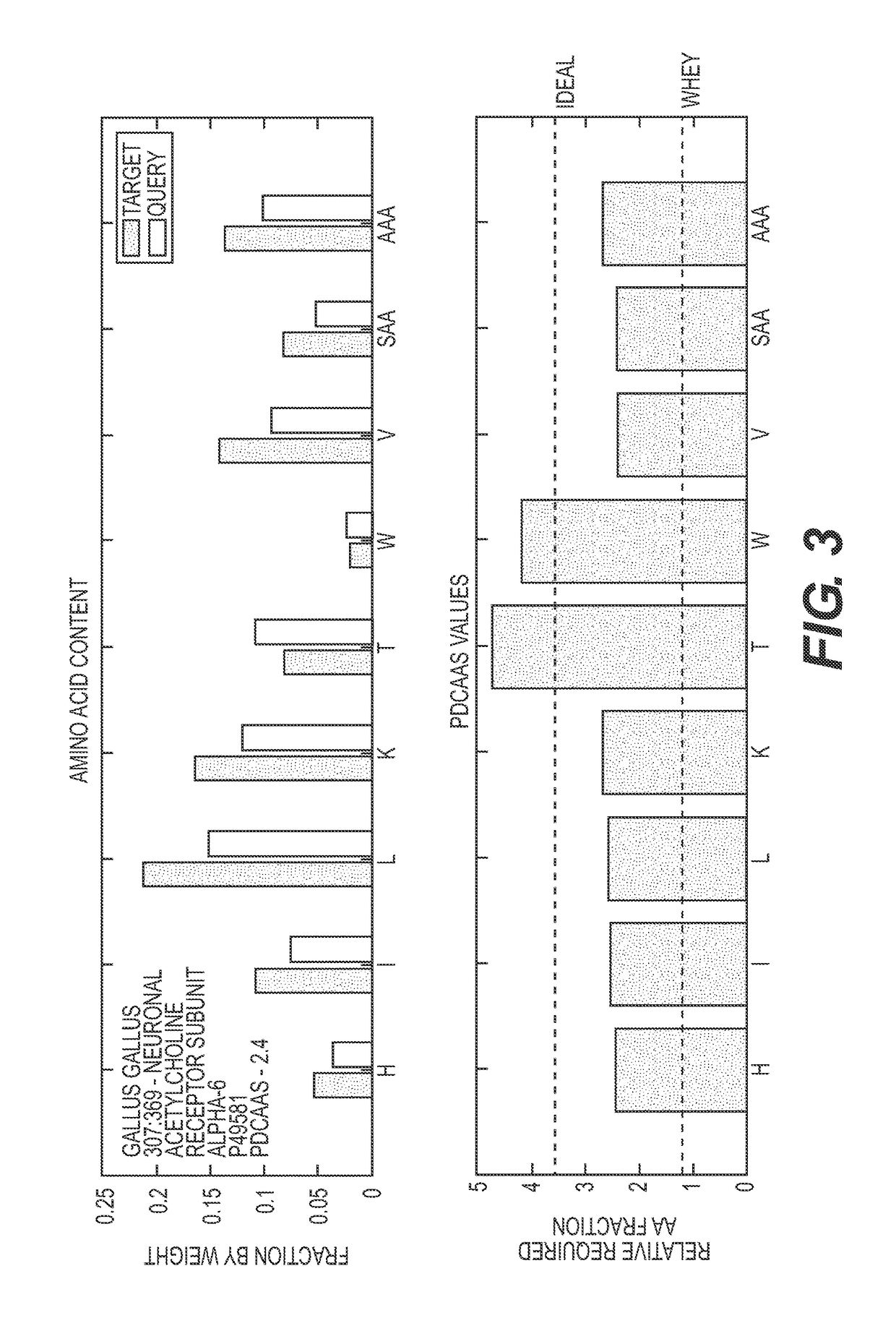

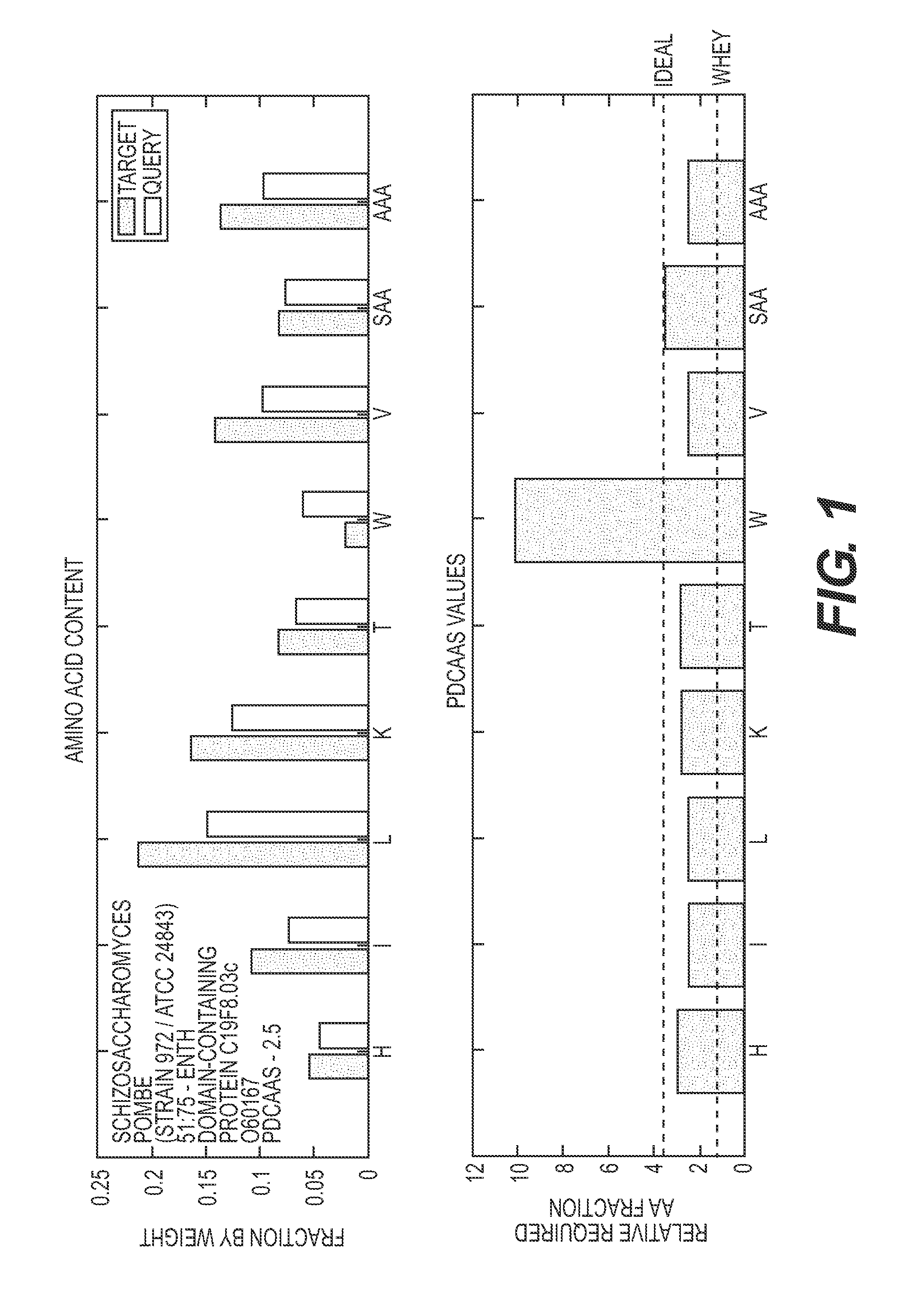

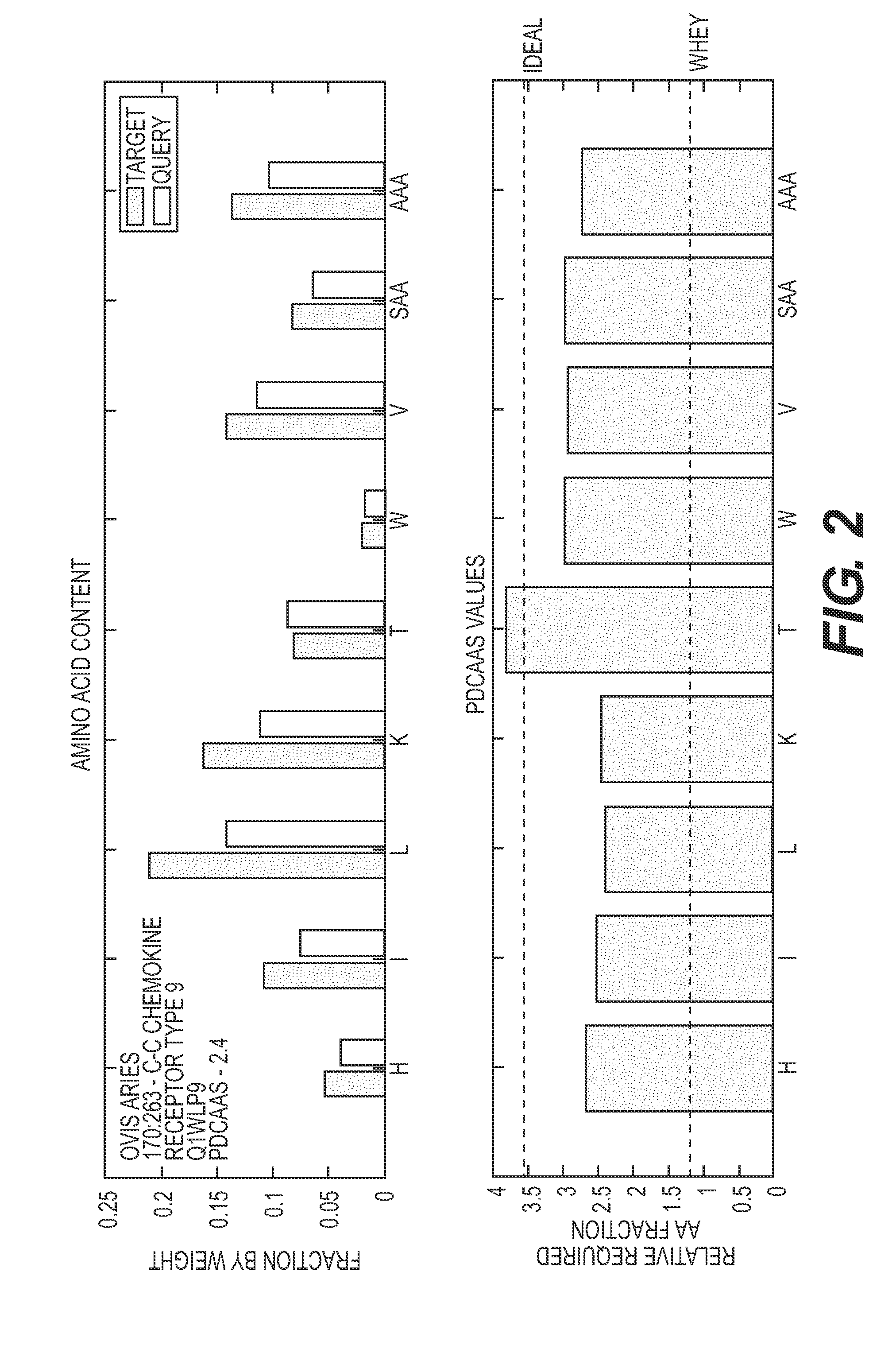

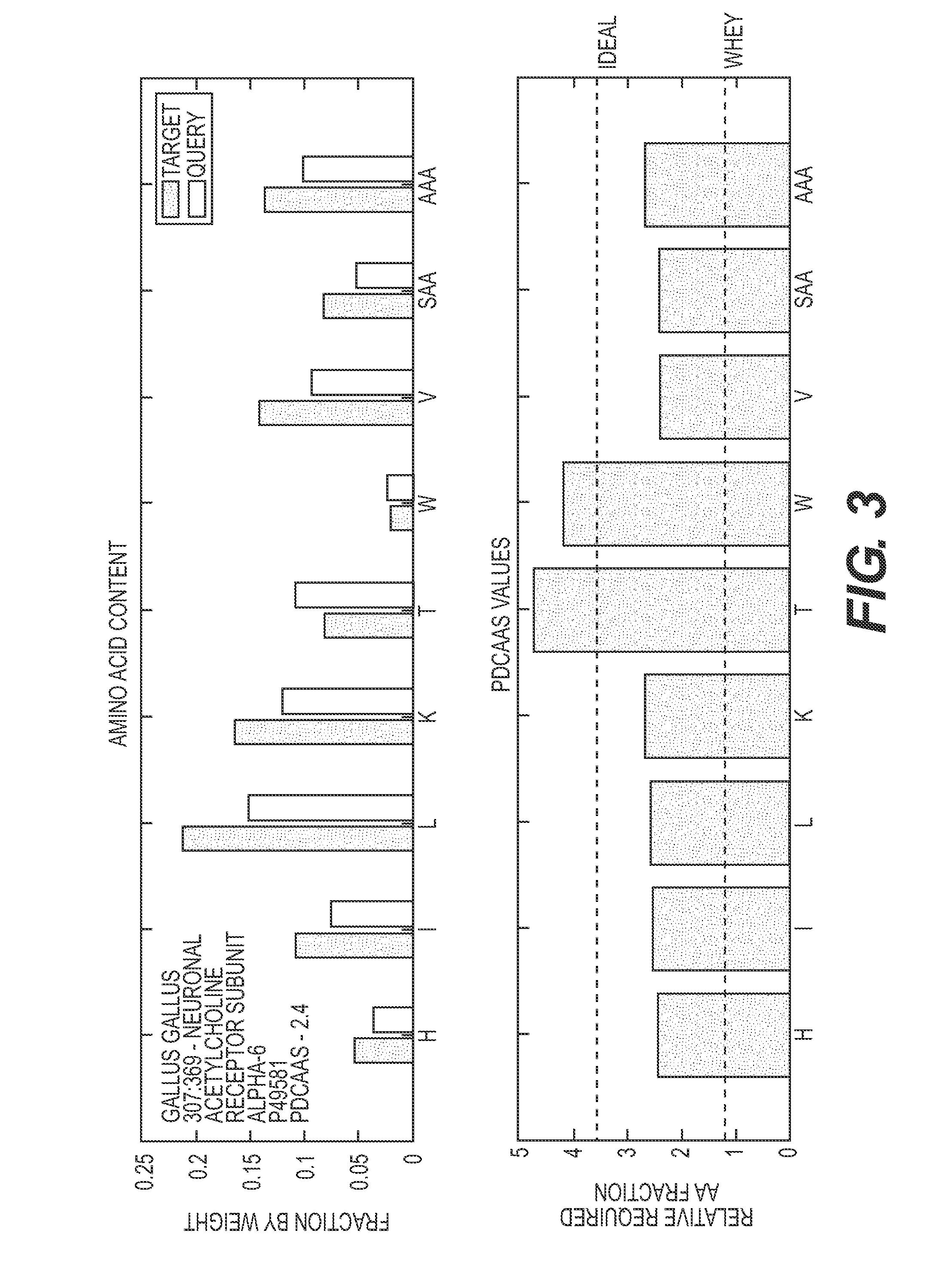

Nutritive proteins are provided. In some embodiments the nutritive proteins comprise a protein digestibility corrected amino acid score (PDCAAS) that exceeds a benchmark protein. Also provided are nucleic acids encoding the proteins, recombinant microorganisms that make the proteins, methods of making the proteins using recombinant microorganisms, compositions that comprise the proteins, and methods of using the proteins, among other things.

Owner:AXCELLA HEALTH INC

Nutritive Fragments, Proteins and Methods

ActiveUS20150080296A1High in proteinInduce postprandial satietyBiocidePeptide/protein ingredientsNutrients proteinMicroorganism

Nutritive proteins are provided. In some embodiments the nutritive proteins comprise a protein digestibility corrected amino acid score (PDCAAS) that exceeds a benchmark protein. Also provided are nucleic acids encoding the proteins, recombinant microorganisms that make the proteins, methods of making the proteins using recombinant microorganisms, compositions that comprise the proteins, and methods of using the proteins, among other things.

Owner:AXCELLA HEALTH INC

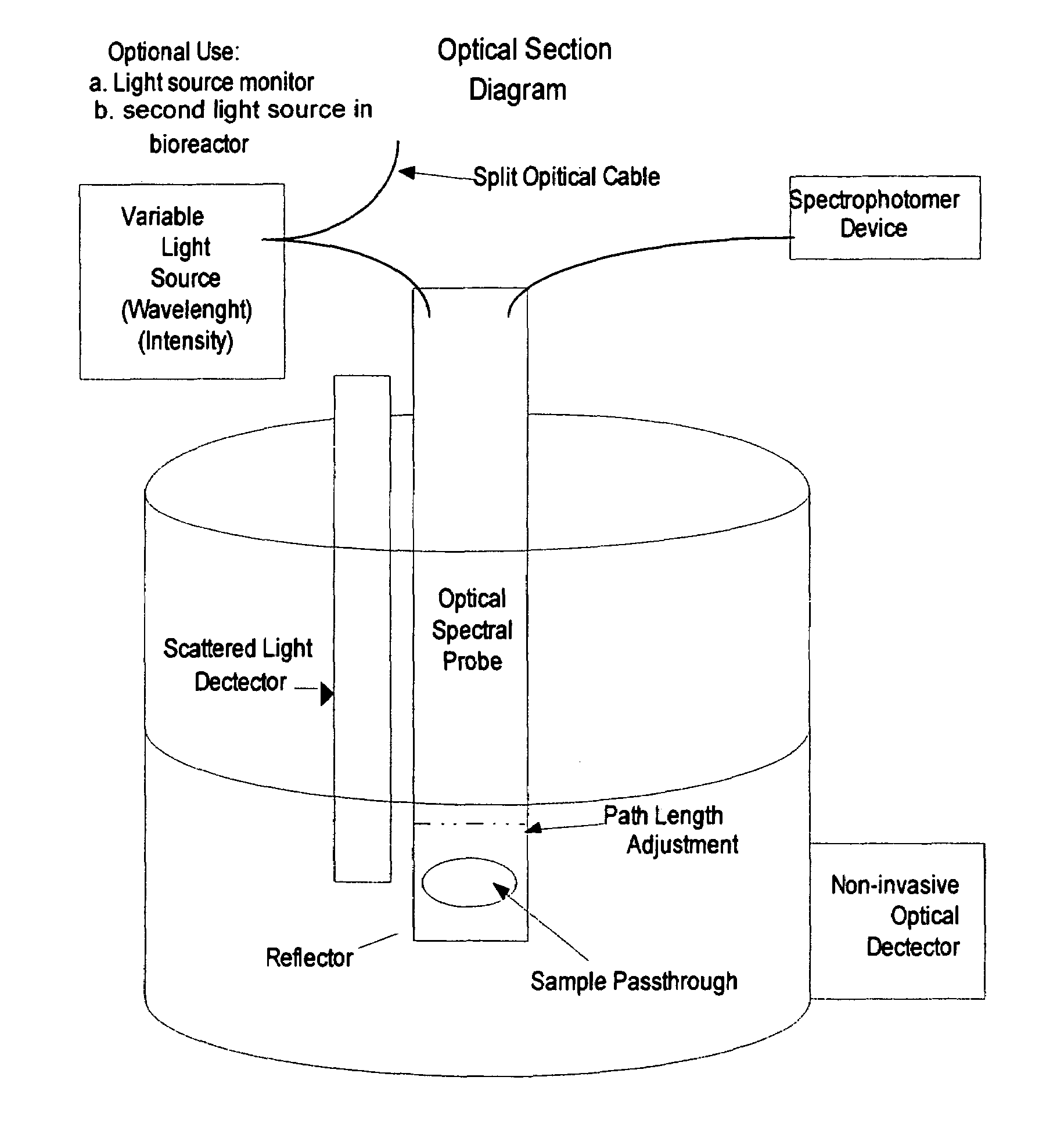

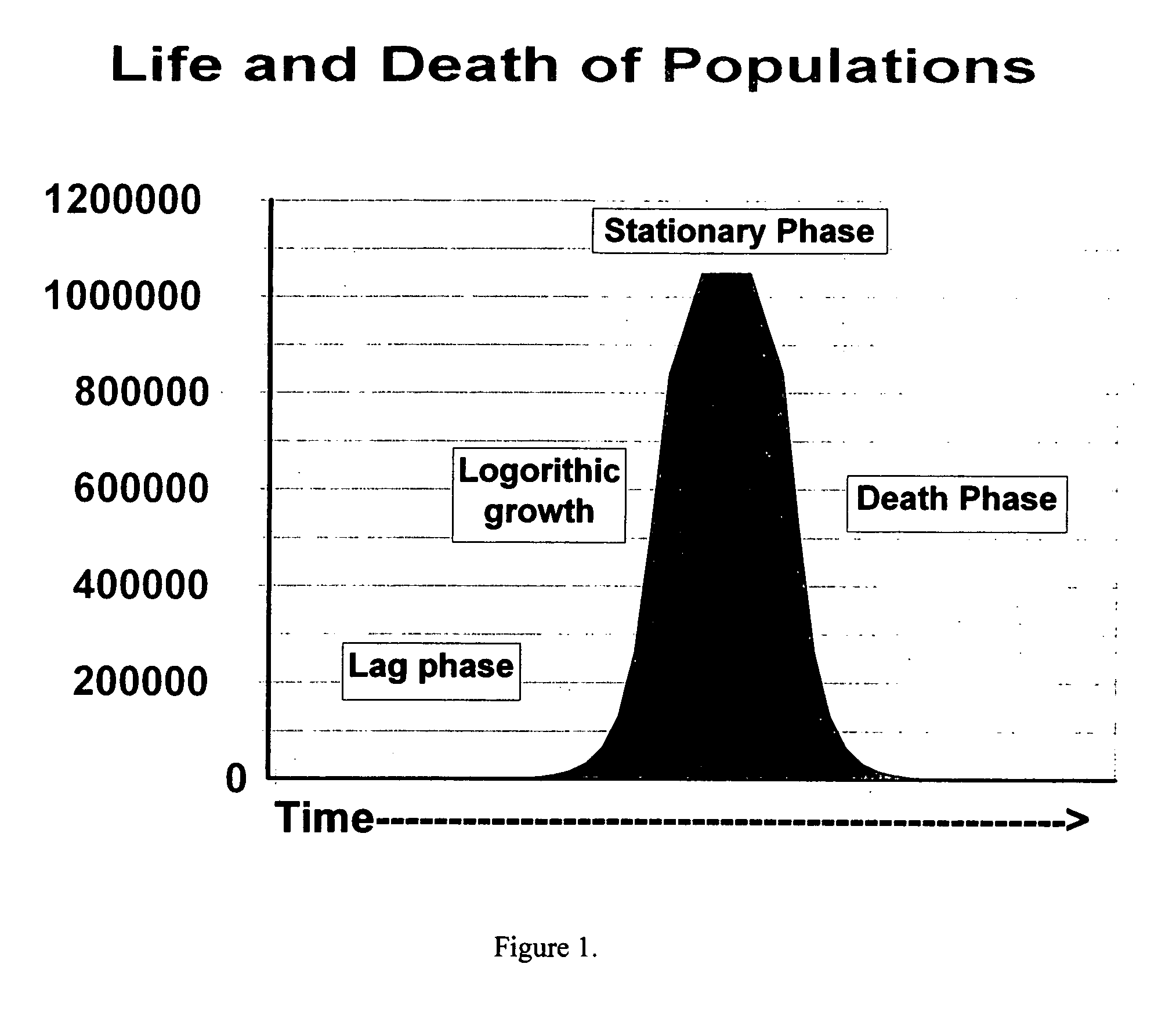

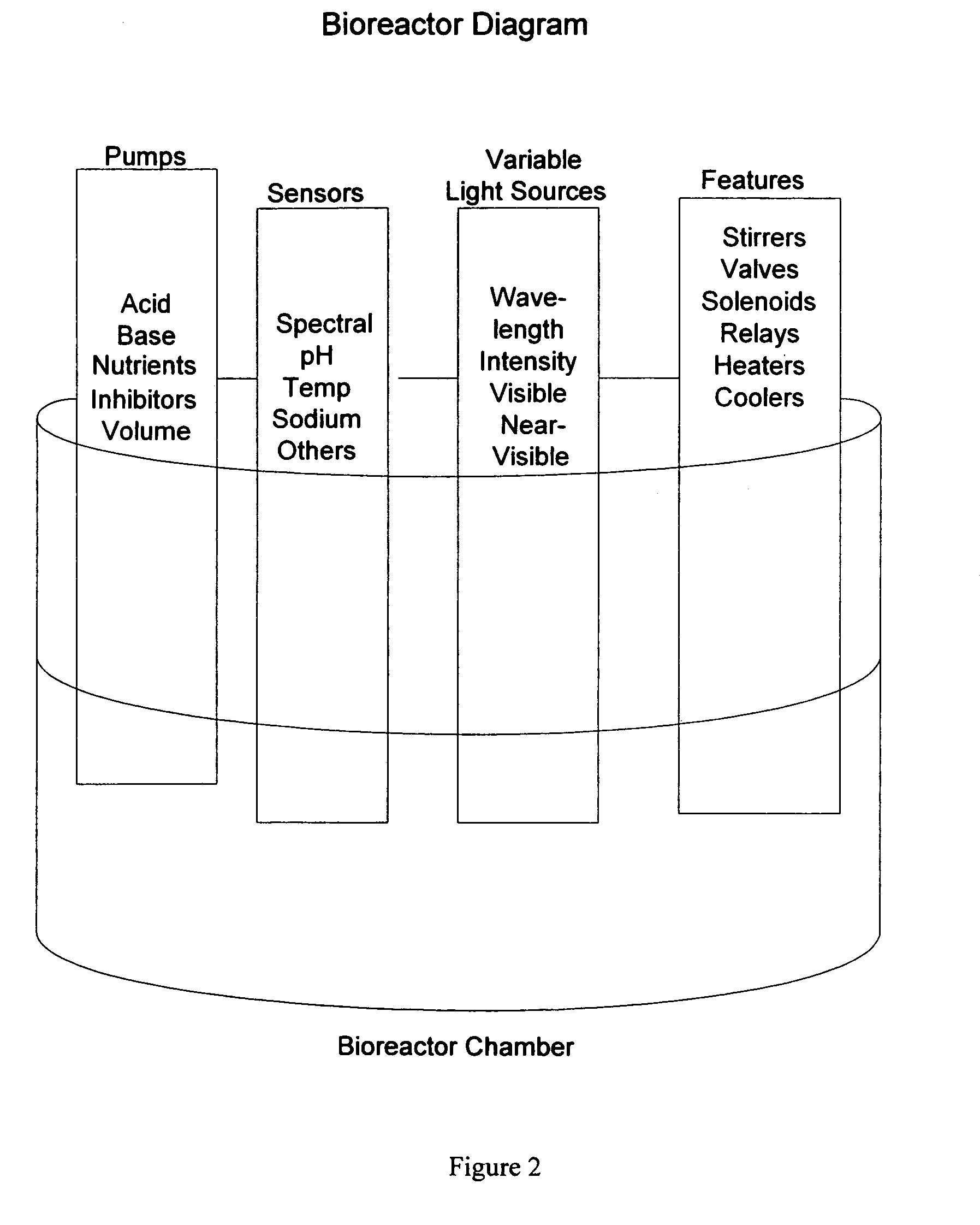

Decision-making spectral bioreactor

InactiveUS7510864B2Bioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteLaboratory scale

This invention fills several voids in bioreactor technology that allows efficient connection of aspects of physical science (optics, electronics, physical chemistry, sensors) to aspects of microbial and cell culture physiology in a uniquely interactive manner. This is accomplished mathematically through decision making software that utilizes detected changes in the course of fermentation. Decisions are aimed at determining the optima for cellular growth, optimizing for production or degradation of metabolites or substrates, or determining the limits of growth under various combinations of conditions. The invention determines optima or limits in a manner more quickly and at less cost than traditional methods. The basis for the computer generated decisions may be first or second derivative changes observed such as inflection points, limits on allowable rates of change, or the like. The most common measured parameter controlling the decision making process is the optically observed growth of the cells (e.g. microbial, animal, or plant cell cultures) under study. Any other measurable parameter (e.g. pH, temperature, pigment production) may be used to control the process (i.e., the independent variable). This process and variations of this process on a laboratory scale are valuable for research and development, education, pilot plant models, and bio-manufacturing optimization, including scale up to production volumes.

Owner:KRICHEVSKY MICAH I +4

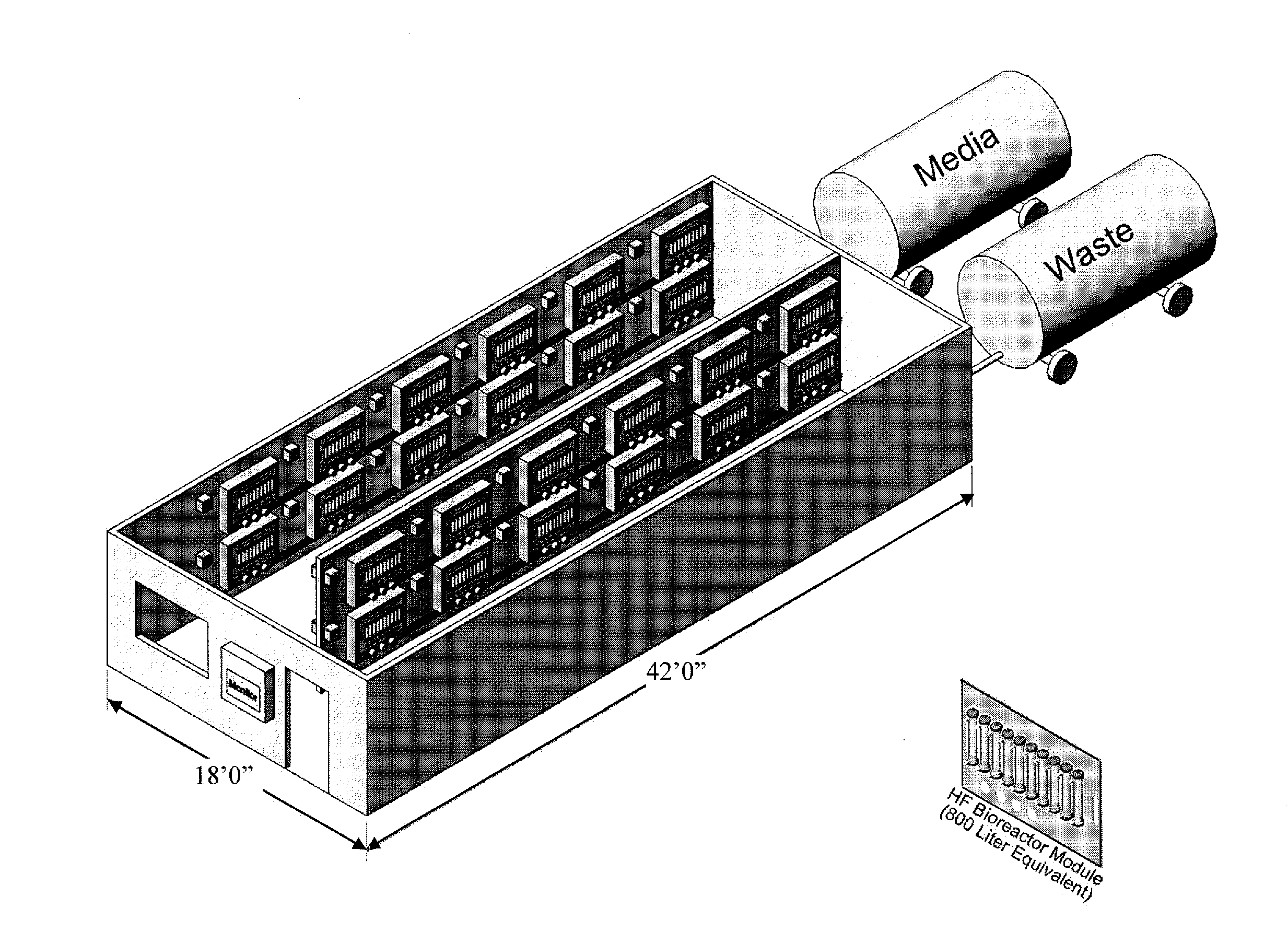

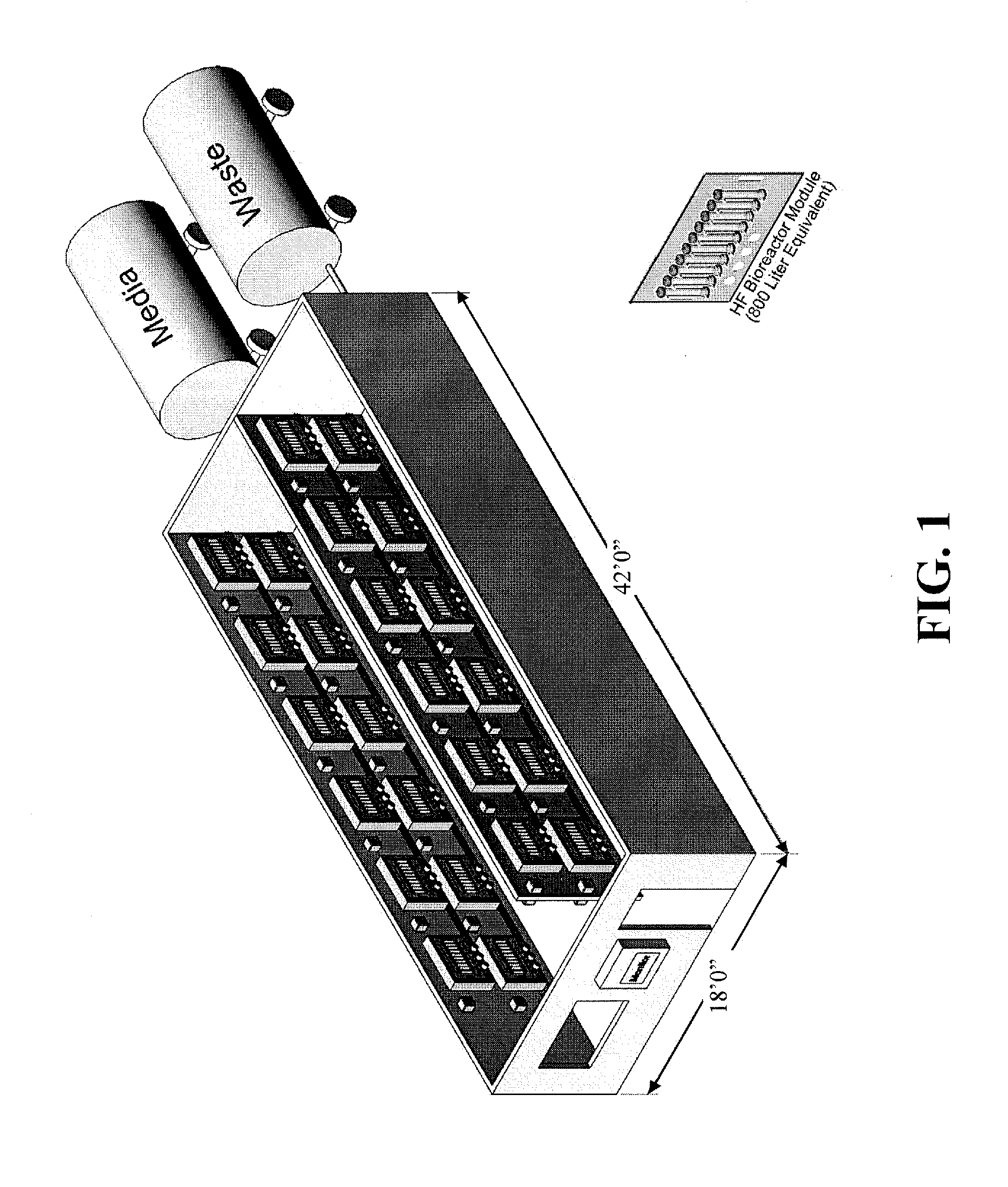

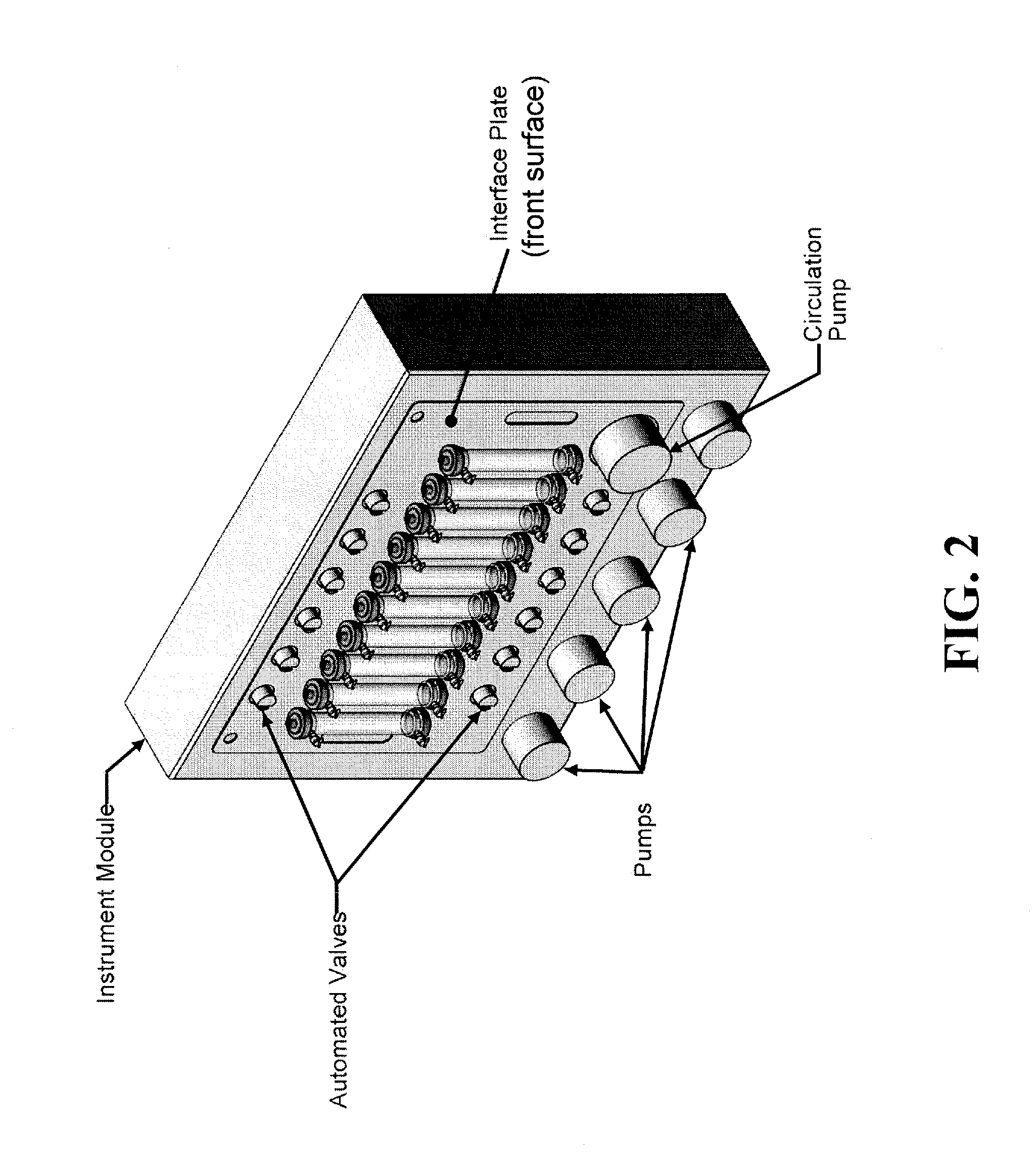

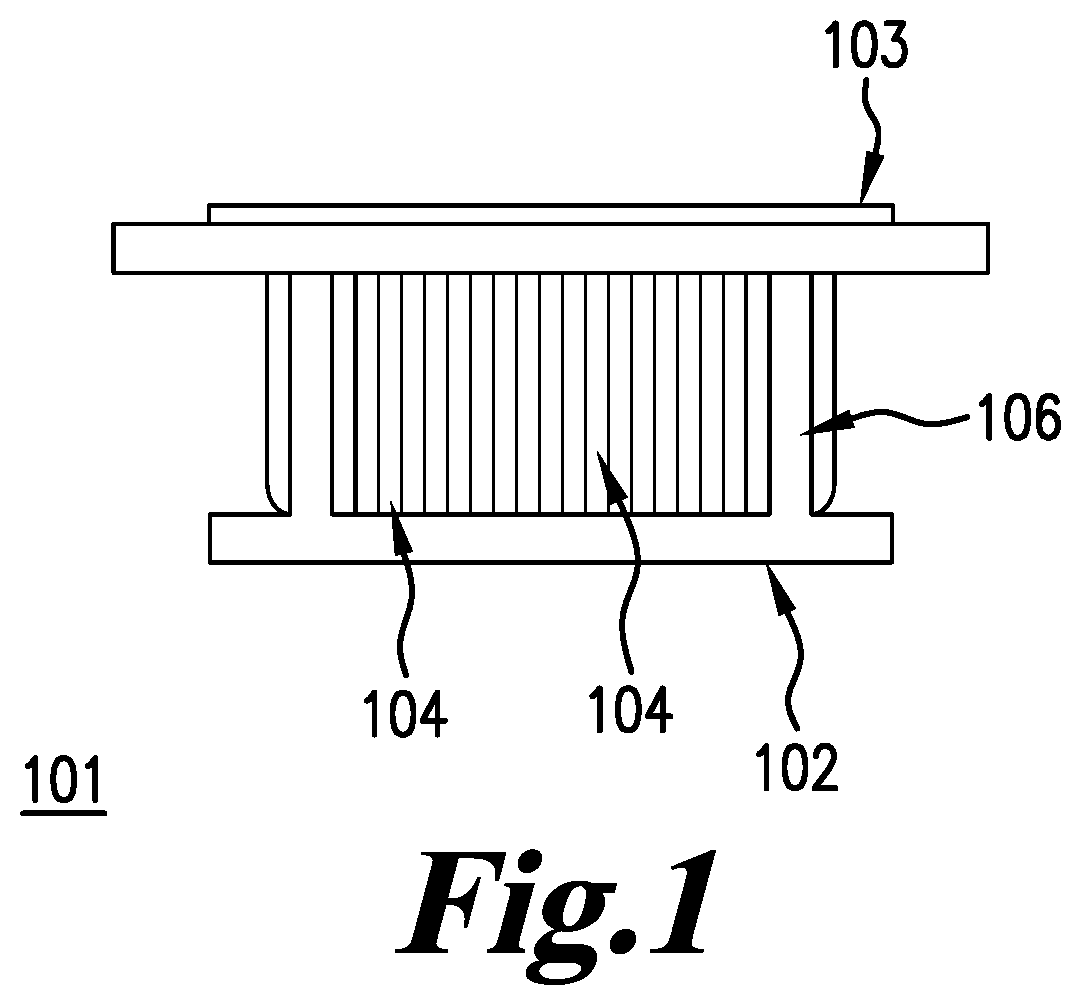

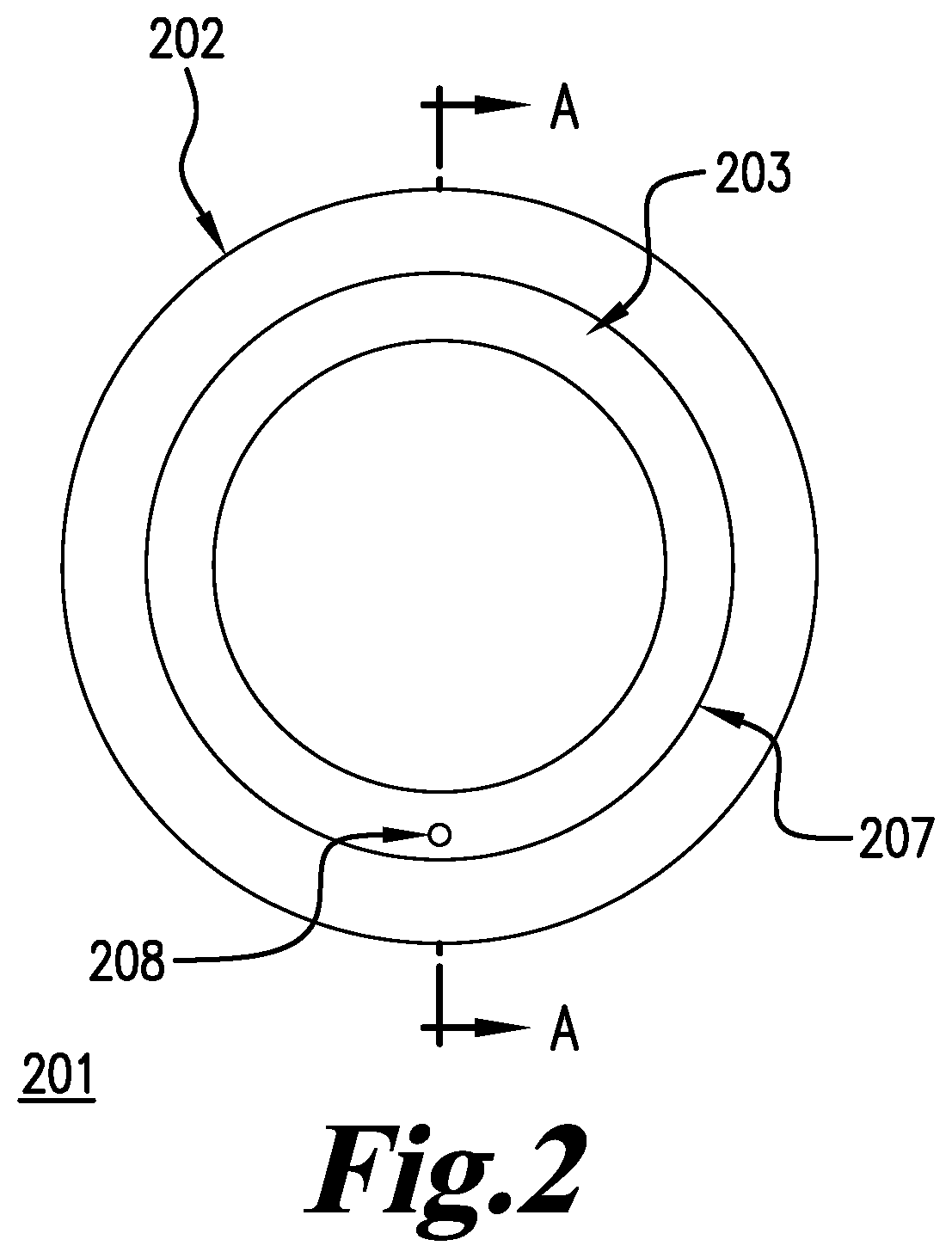

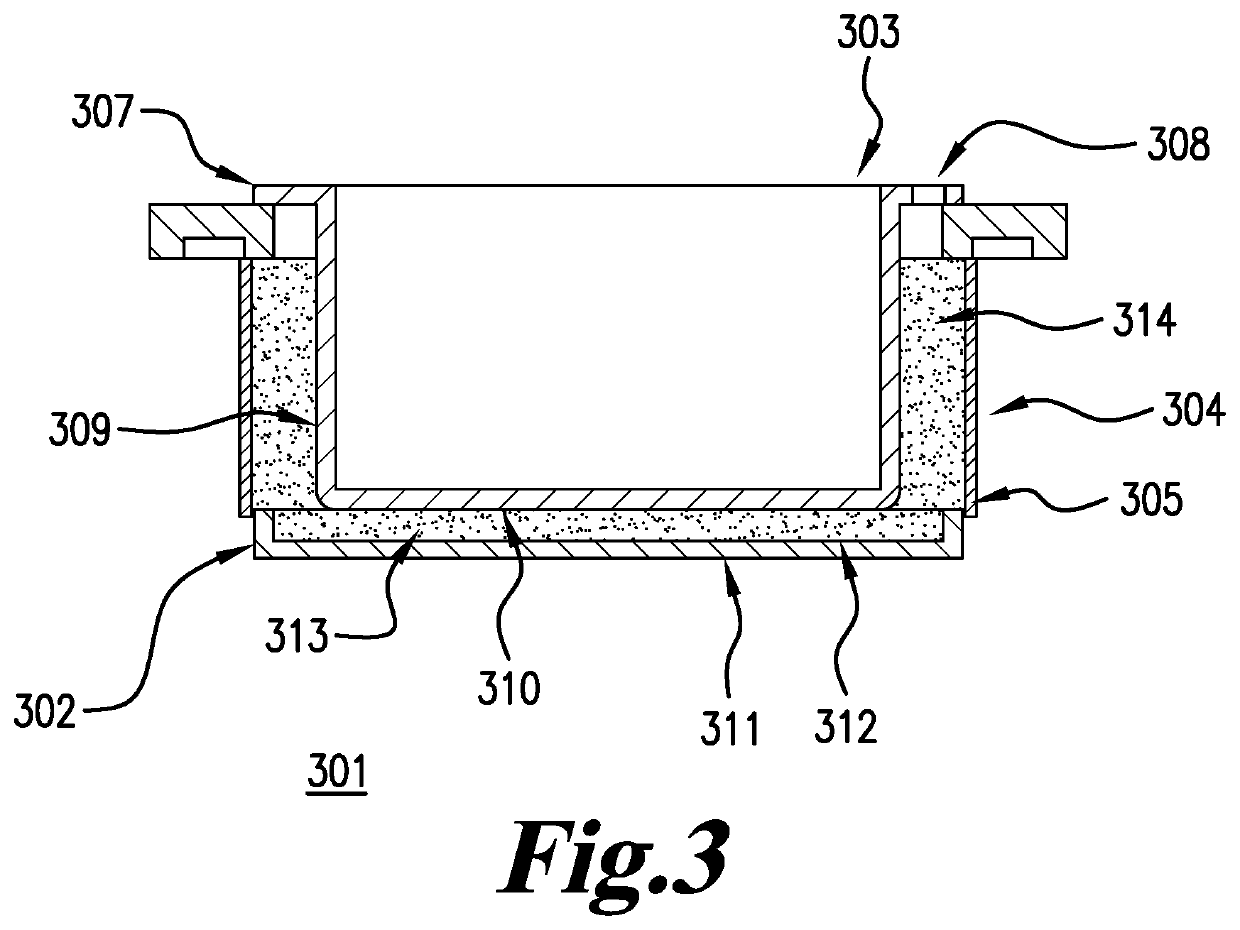

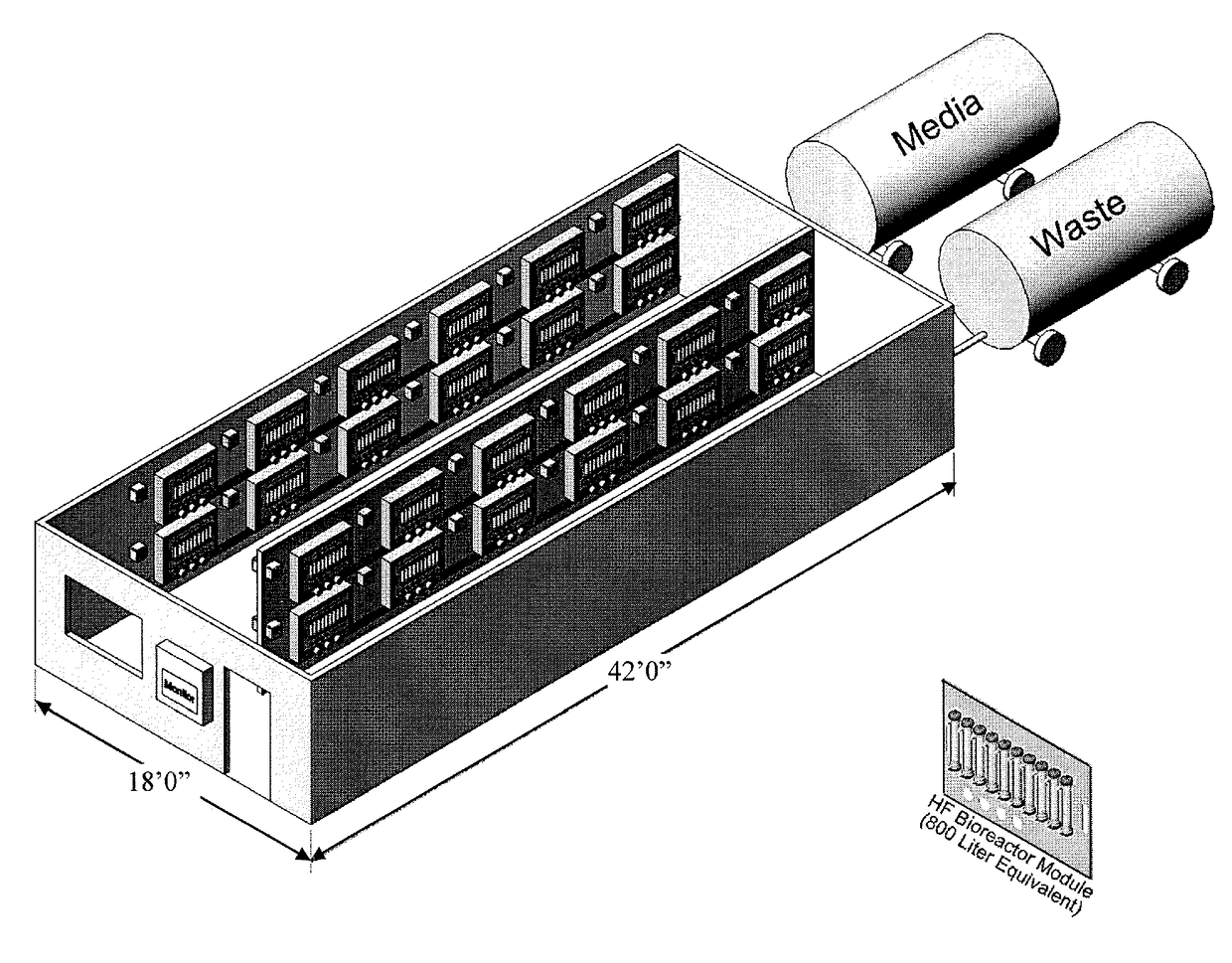

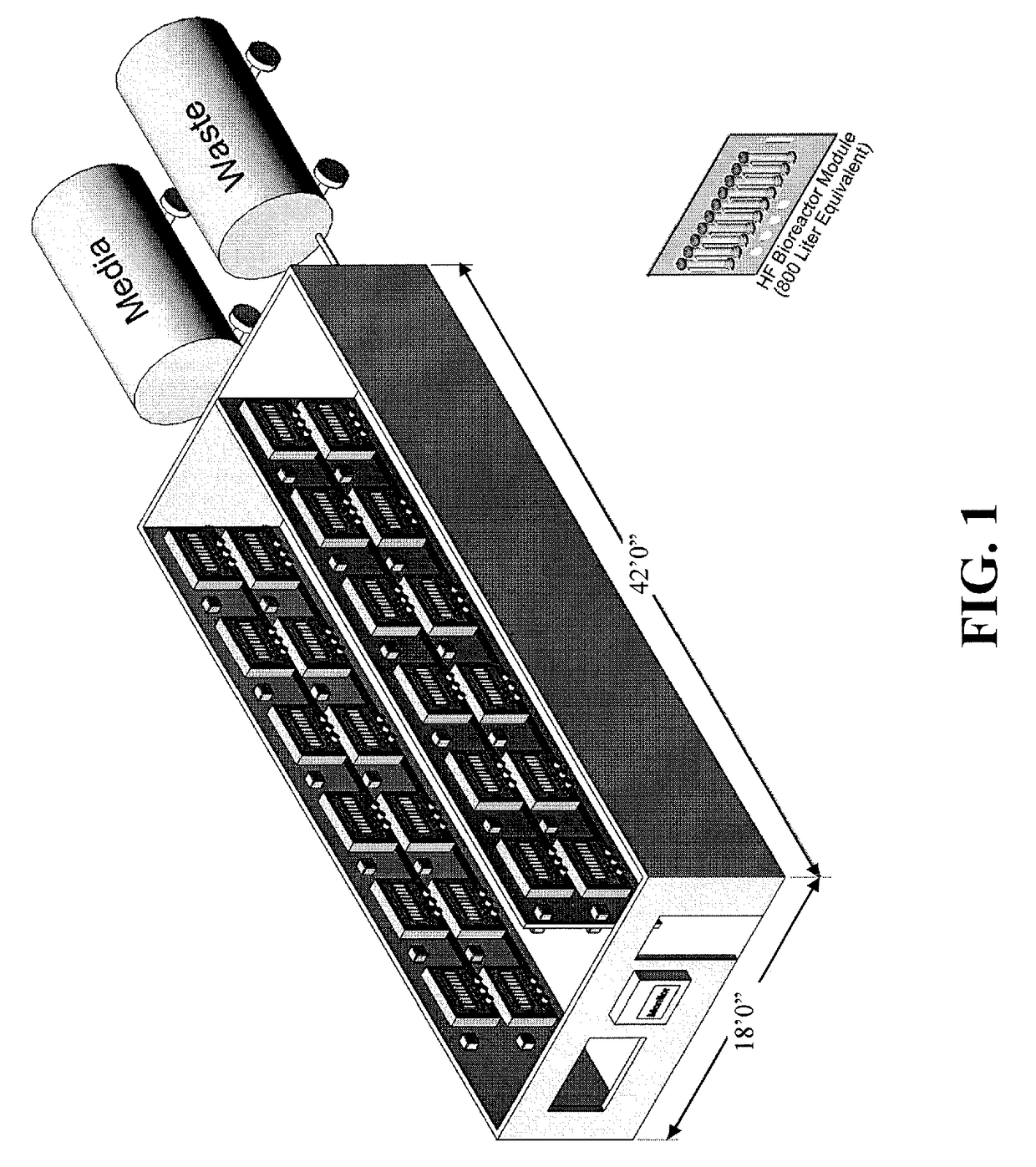

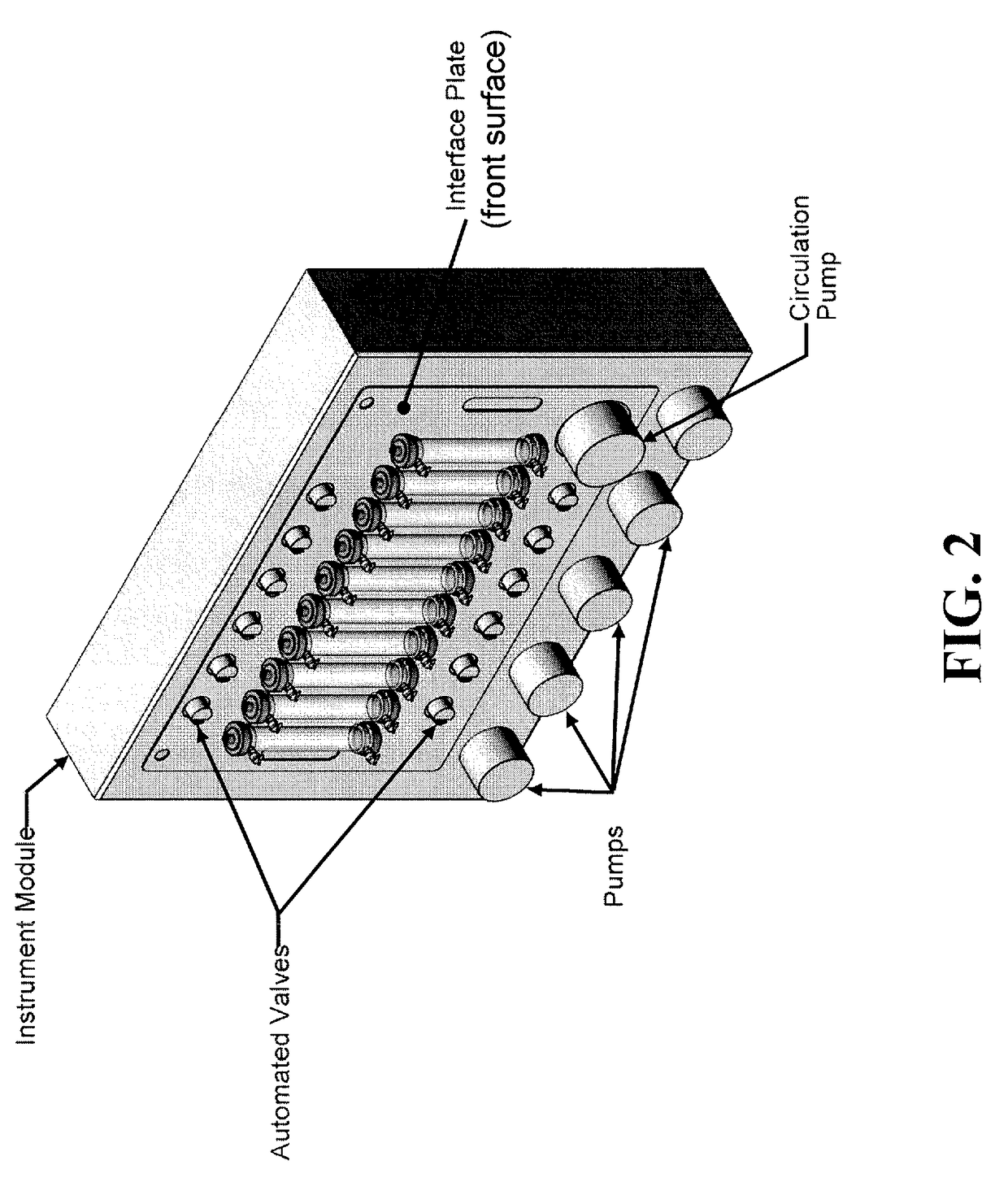

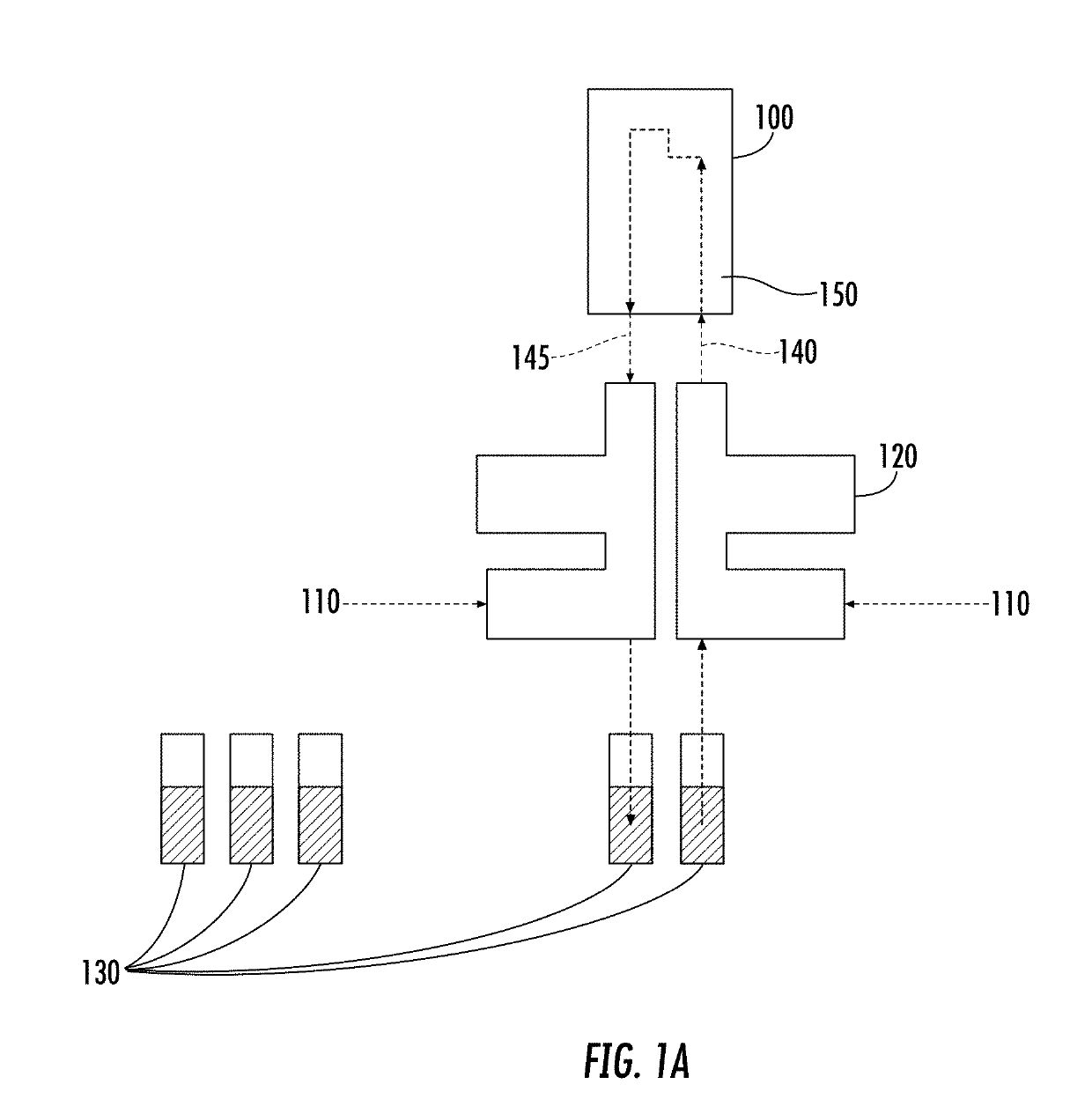

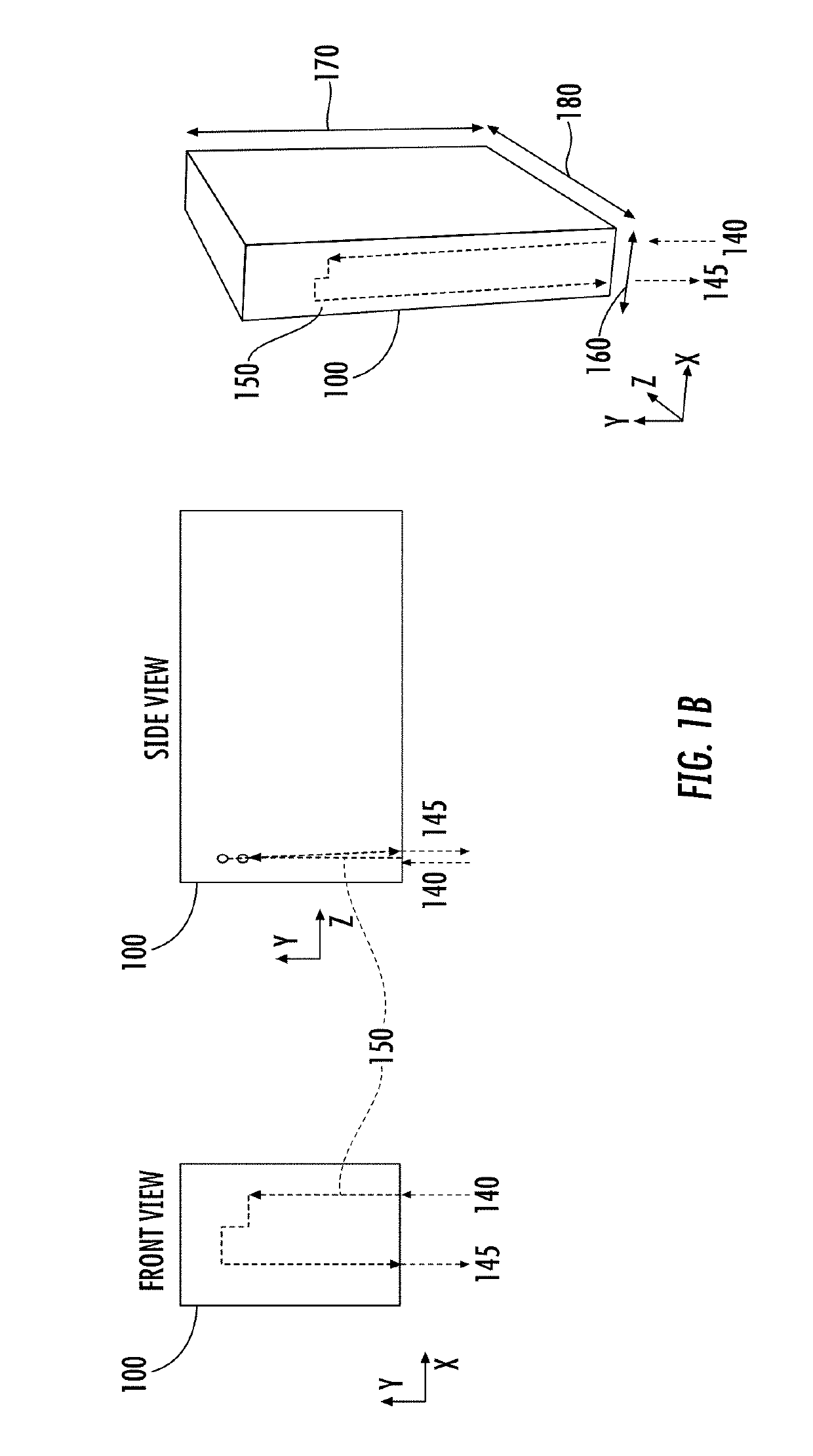

Biomanufacturing suite and methods for large-scale production of cells, viruses, and biomolecules

ActiveUS20150225685A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiomanufacturingVirus

The present invention provides a production module for large-scale production of cells and / or cell-derived products such as antibodies or virus; a production suite comprising a plurality of functionally connected production modules of the invention; and a method for large-scale production of cells and / or cell-derived products using the production modules and / or production suites of the invention.

Owner:BIOVEST INT

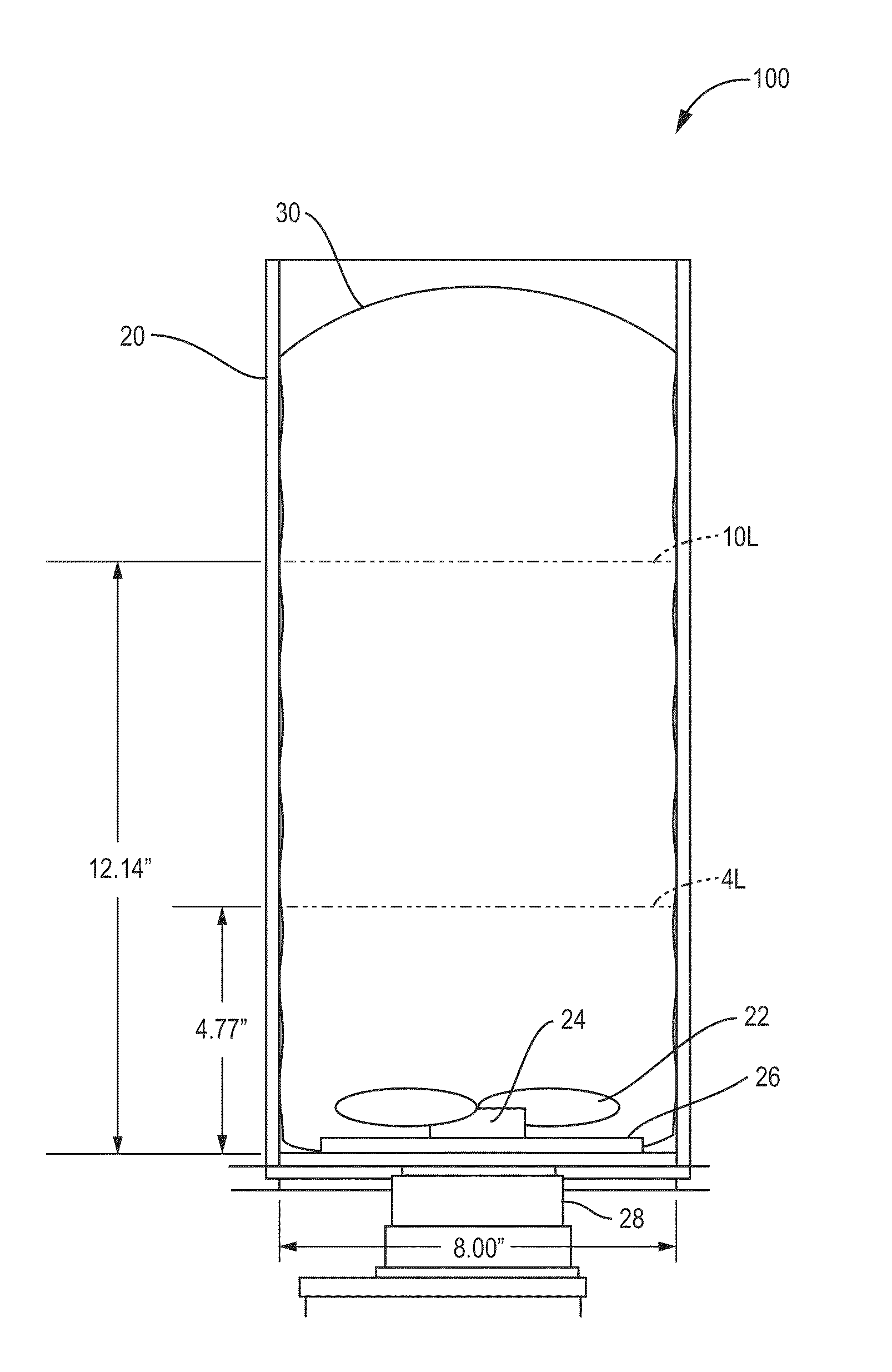

Linearly scalable single use bioreactor system

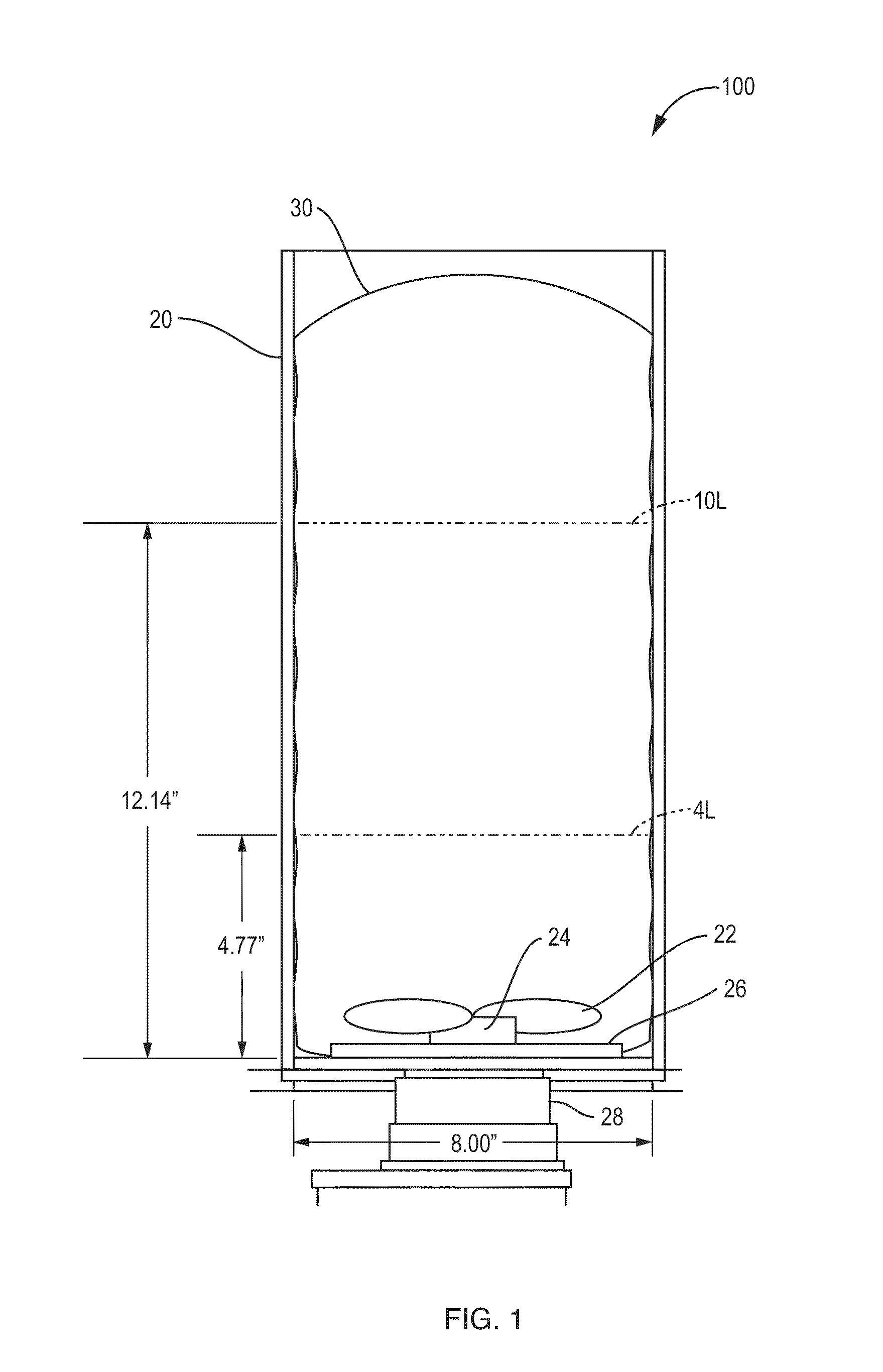

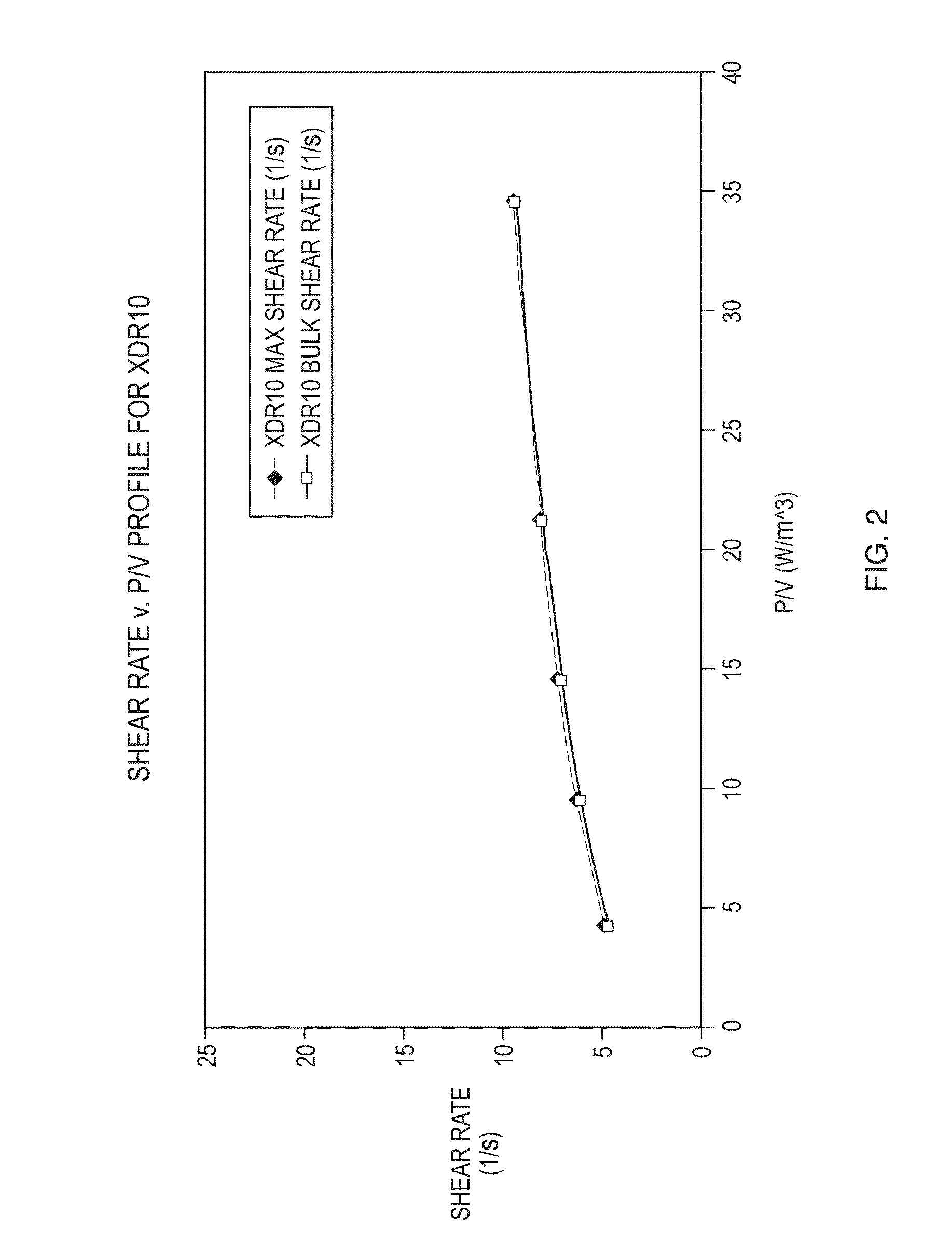

ActiveUS20130288346A1Eliminate needRisk minimizationBioreactor/fermenter combinationsBiological substance pretreatmentsImpellerBiomanufacturing

Disclosed is a single-use bioreactor bag design providing substantially equivalent maximum shear rate at the impeller tip and average or bulk shear rate over a range of power per unit working volume and rpm needed for bioculture processing. The uniformity in shear profile of the bag design providing a unique advantage when used as a scale-down or scale-up platform. Also disclosed is a linearly scalable, single-use, bioreactor system for use in carrying out a scalable biomanufacturing process, the system comprising two single-use bioreactor bags of different volumes, wherein the ratio H / D of the height of the working volume H to the diameter D of the tank, or of the bag is equal to about 1.5, and the bulk shear in each of the bags is substantially constant. The disclosed small scale system models larger scale systems from both a shear / scalability / performance basis and also from a validation and regulatory basis. In summary, the 10 L bioreactor system disclosed provides for “linear scalability” by using the same or substantially simulating the same vessel geometry, gas sparging system, impeller shape and type, polymer composition of the flexible bag / components, process control system, and shear rates as larger 50-5000 L systems.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

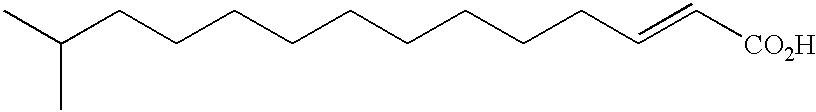

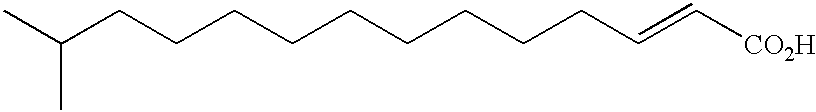

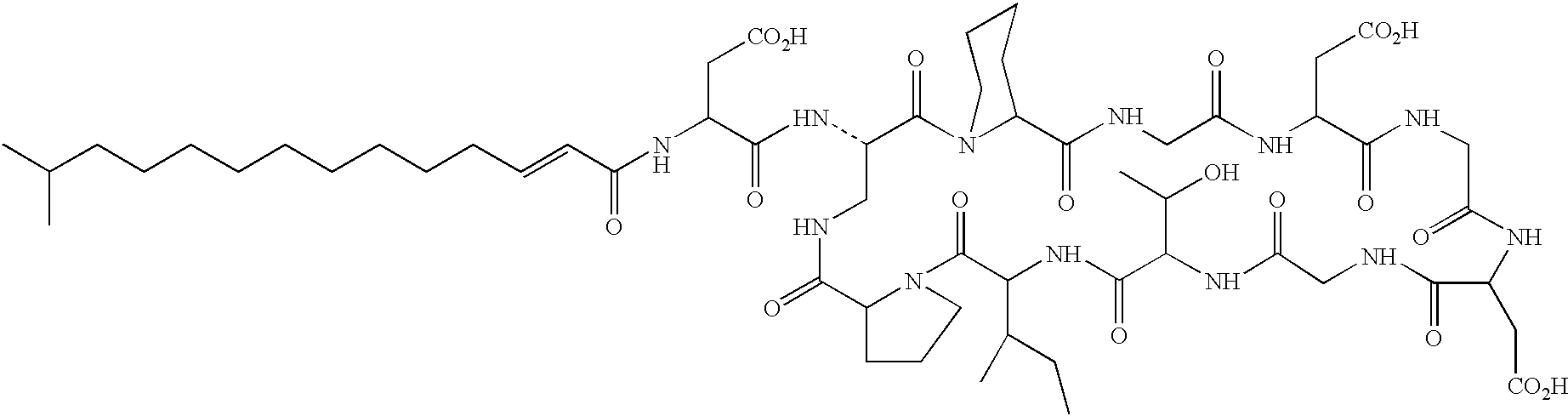

Derivatives of laspartomycin and preparation and use thereof

The present invention provides a laspartomycin core peptide, a laspartomycin core peptide derivative, a antimicrobial laspartomycin derivative, a method for making laspartomycin core peptides, methods for making laspartomycin core peptide derivatives, methods for making antimicrobial laspartomycin derivatives, pharmaceutical compositions of antimicrobial laspartomycin derivatives, methods of inhibiting microbial growth and methods for treating and / or preventing microbial infections in a subject.

Owner:BIOSOURCE PHARM INC

Charged nutritive proteins and methods

ActiveUS20130296231A1Sufficient amountImprove heat generationOrganic active ingredientsBacteriaNutritionTotal amino acids

Charged nutritive proteins are provided. In some embodiments the nutritive proteins an aqueous solubility of at least 12.5 g / L at pH 7. In some embodiments the nutritive proteins an aqueous solubility of at least 50 g / L at pH 7. In some embodiments the nutritive proteins an aqueous solubility of at least 100 g / L at pH 7. In some embodiments the nutritive proteins comprise at least one of a level of a) a ratio of branch chain amino acid residues to total amino acid residues present in the nutritive protein equal to or greater than the ratio of branch chain amino acid residues to total amino acid residues present in a benchmark protein; b) a ratio of leucine residues to total amino acid residues present in the nutritive protein equal to or greater than the ratio of leucine residues to total amino acid residues present in a benchmark protein; and c) a ratio of essential amino acid residues to total amino acid residues present in the nutritive protein equal to or greater than the ratio of essential amino acid residues to total amino acid residues present in a benchmark protein. Also provided are nucleic acids encoding the proteins, recombinant microorganisms that make the proteins, methods of making the proteins using recombinant microorganisms, compositions that comprise the proteins, and methods of using the proteins, among other things.

Owner:AXCELLA HEALTH INC

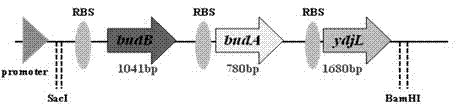

Genetic engineering strain for producing (R, R)-2,3-butanediol, as well as construction method and application thereof

InactiveCN102965324AStable in natureHigh final concentrationBacteriaMicroorganism based processesEscherichia coliEngineering

Owner:NANJING TECH UNIV

Method for developing new-climate economy and realizing global net zero carbon emission

ActiveCN107251724ADevelop carbon circular economyIncrease carbon sinkAgriculture gas emission reductionCultivating equipmentsCarbon storageClean energy

A method for developing new-climate economy and realizing global net zero carbon emission comprises steps of selecting excellent and high-yield biological kinds and repeatedly harvesting in unit time to increase biological carbon catching amount, planting trees, irrigating and planting weeds to form a multi-coverage composite ecological system to expand plant carbon storage amount, improving a ploughing way, utilizing biological fertilizers and improving soil carbon storage amount, producing carbon products and biological products in a bio-manufacturing way and expanding biological carbon sealing amount, breeding high-yield aquatic organisms to increase hydrosphere carbon conversion amount, developing animal husbandry to expand animal carbon transmission amount, collecting organisms to fill and bury to limit atmosphere total carbon amount, replacing fossil fuel by clean energy to control atmosphere carbon increase amount, conserving energy and reducing consumption and reducing man-made carbon emission, comprehensively developing and utilizing atmosphere carbon resource, building a manual carbon stock to create atmosphere carbon dividing amount. Through ways of carbon capture, storage, sealing, conversion, transmission, limit, control, decrease and utilization, global net zero carbon emission can be realized; and ecological, environmental, resource-related, economic and climatic problems can be solved.

Owner:雷学军 +1

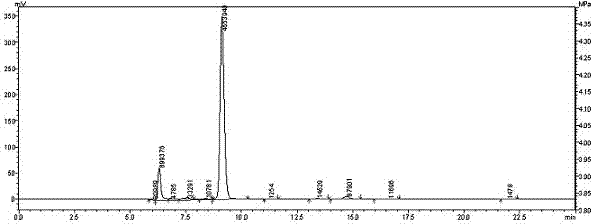

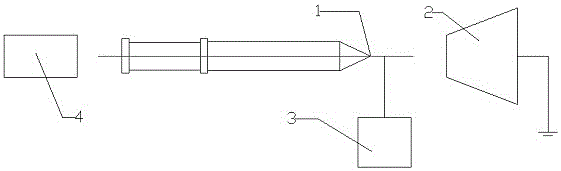

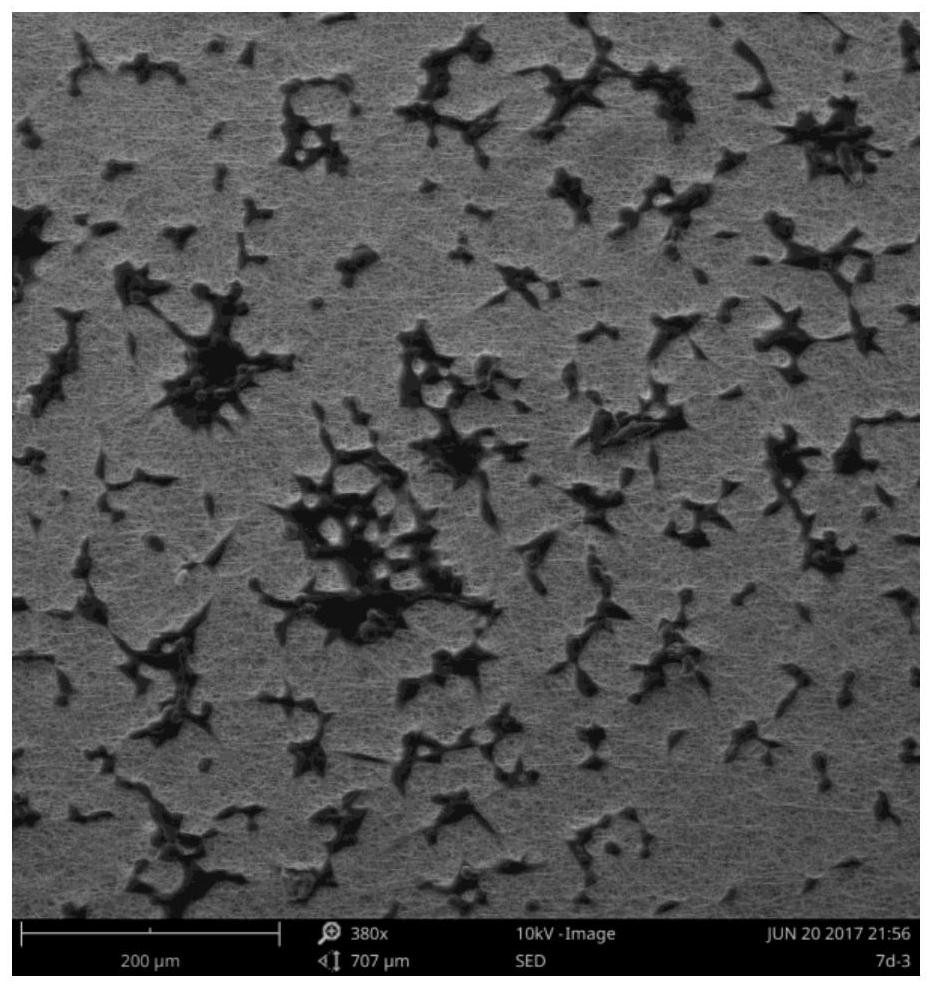

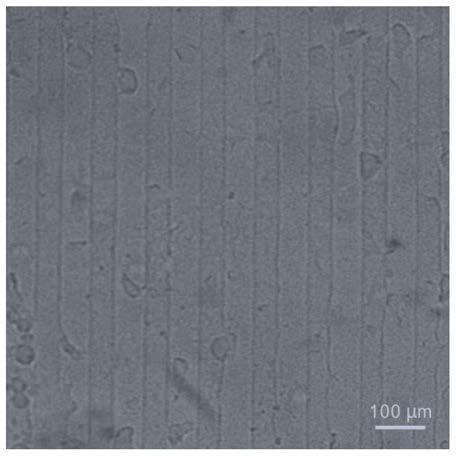

Electrostatic spinning patterning collection method and electrostatic spinning apparatus

InactiveCN105019043AFlexible receptionThe receiving device has designed a set of novel orderly and controllable collection flexibleNew-spun product collectionFilament/thread formingSpinningBiomanufacturing

The invention discloses an electrostatic spinning patterning collection method and an electrostatic spinning apparatus. Based on a conventional electrospinning technical method, through a composite electrospinning material and changing of a receiving apparatus, a novel orderly controllable receiving apparatus and a control method are developed, and an orderly electrospinning fiber structure body with a needed pattern shape is prepared through preparing an organic / inorganic composite material electrostatic spinning liquid with a certain ratio and changing a carrying portion. The method and the apparatus are high in controllability, fibers are directionally consistent and orderly, the electrospinning collection is more flexible, the control method is simpler, and the receiving patterning effect is better. According to the invention, obtained electrospinning fiber films in any shapes can also be applied to such biomedical fields as magnetic medicament transportation, cell marking, biosensors and the like, and the application of electrospinning in industries especially bio-manufacturing is expanded.

Owner:SHANGHAI UNIV

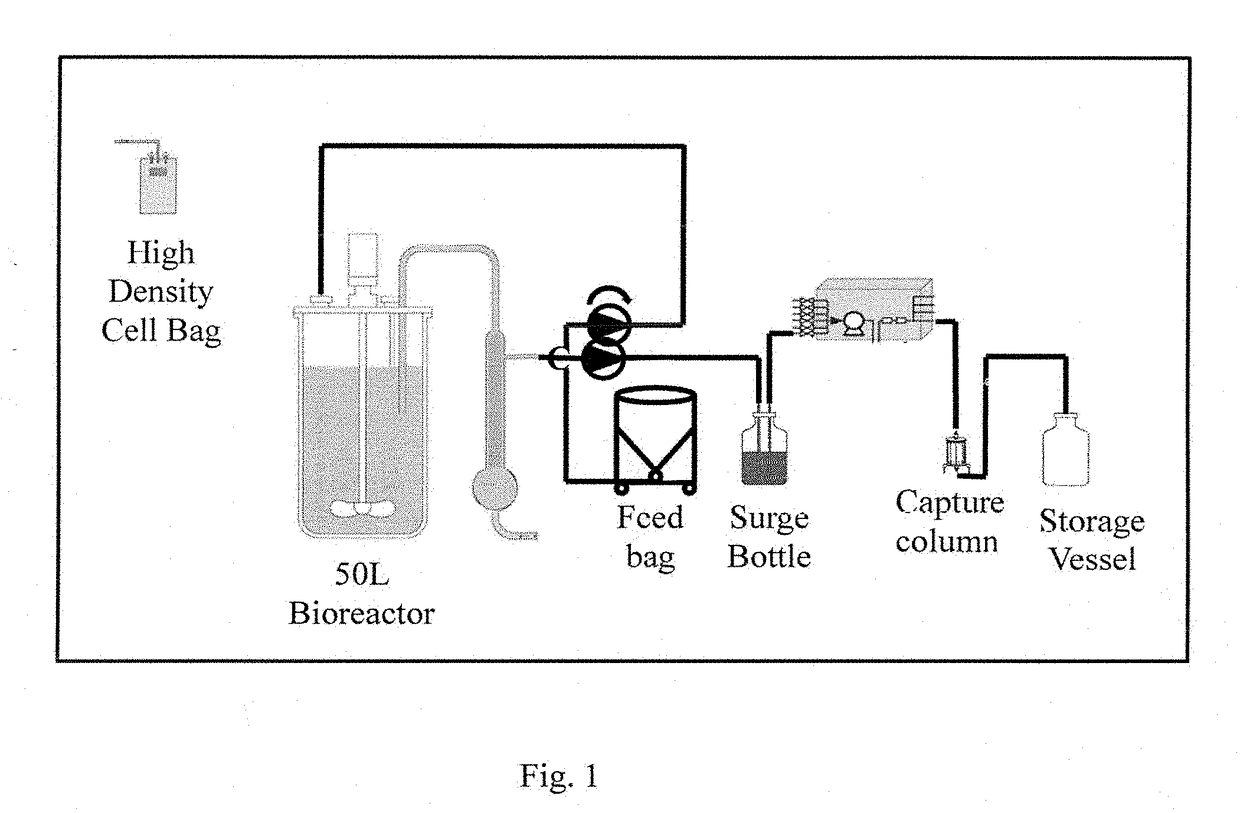

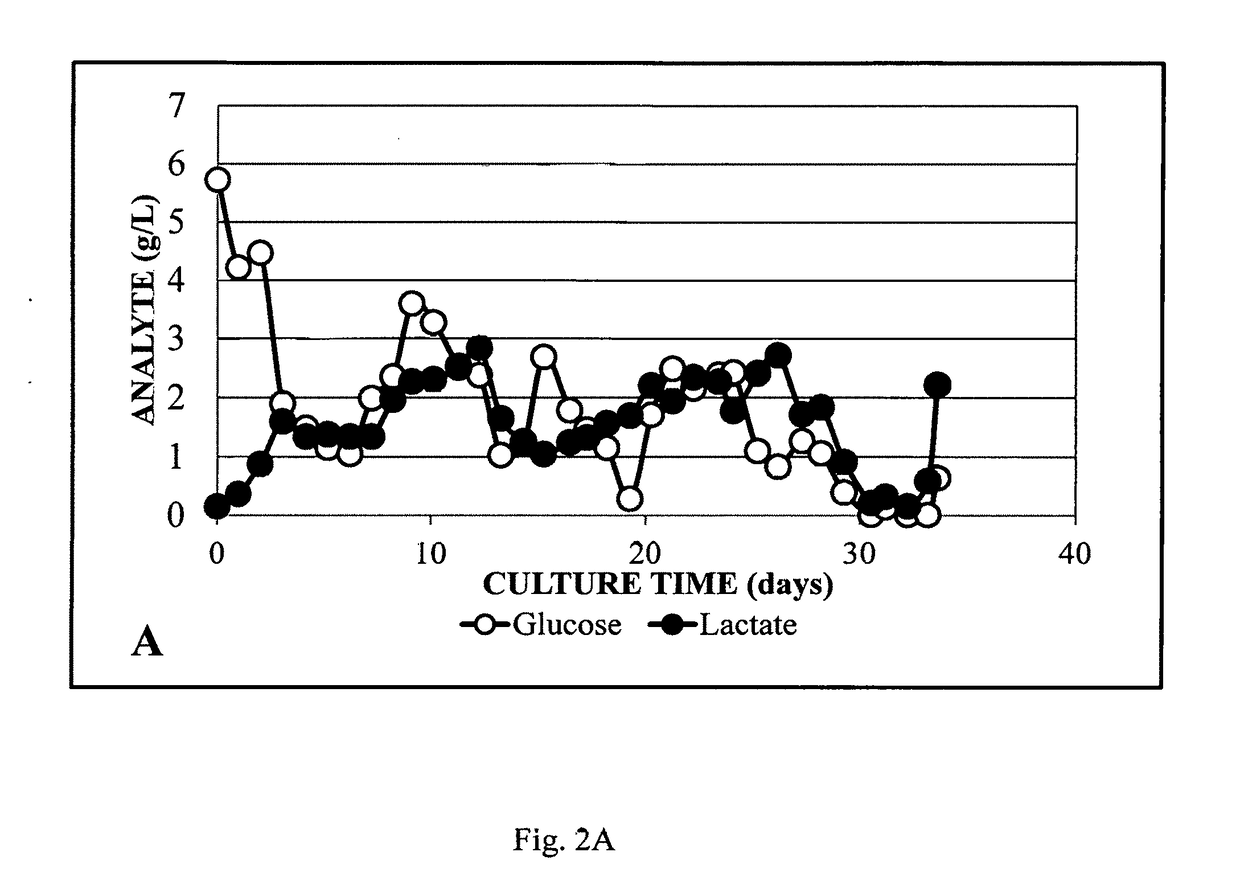

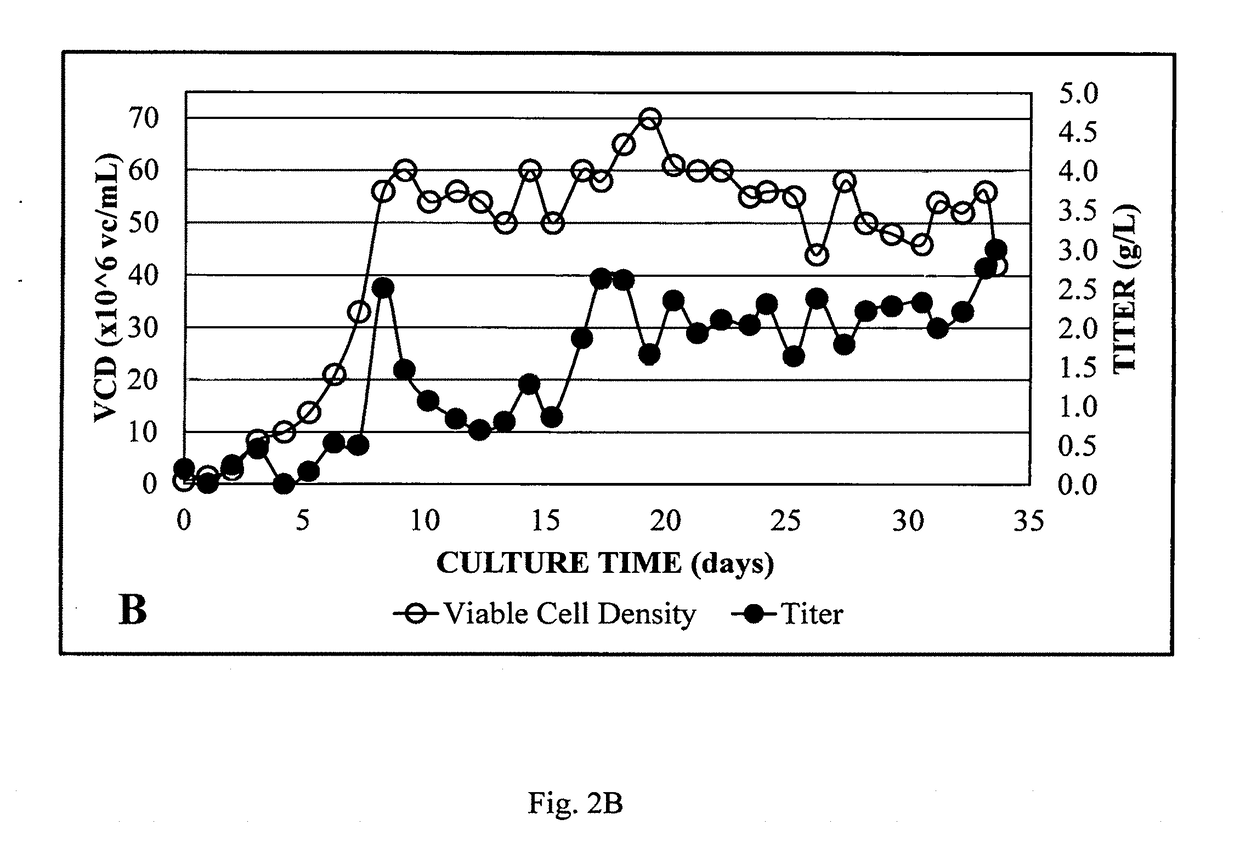

System for rapid continuous manufacturing of monoclonal antibodies

InactiveUS20170204446A1Economically beneficialIncrease cell densitySolid sorbent liquid separationFermentationContinuous flowHolding tank

Described herein is a rapid continuous biomanufacturing platform process that combines a perfusion mammalian cell culture with a synchronized purification of the antibodies produced by the cell culture without the use of intermediate media holding tanks or other large retention devices. This method described herein includes continuous cell culture of mammalian cells expressing the biological of interest and comprising a cell retention device wherein the perfusion of fresh media into the reactor and hence the harvest rate of antibody containing spent media from the reactor has a rate of 1 vessel volume per day (vvd) or less obtained by glucose control with a cell density of between 40 million cell / ml and 60 million cell / nil. Immediate recovery and purification of the antibody is obtained by synchronizing the rate of perfusion with the antibody capture and elution step cycle in a column that contains affinity resin that is between 0.01 and 0.001 times the volume of the bioreactor. The perfusion rate and capture rate were perfectly synchronized by extensive method and media development resulting in equal rates and eliminating the need for holding tanks and cell bleeding. The result is an order of magnitude faster antibody production as compared to conventional fed-batch mode.

Owner:ARTEMIS BIOSYST INC

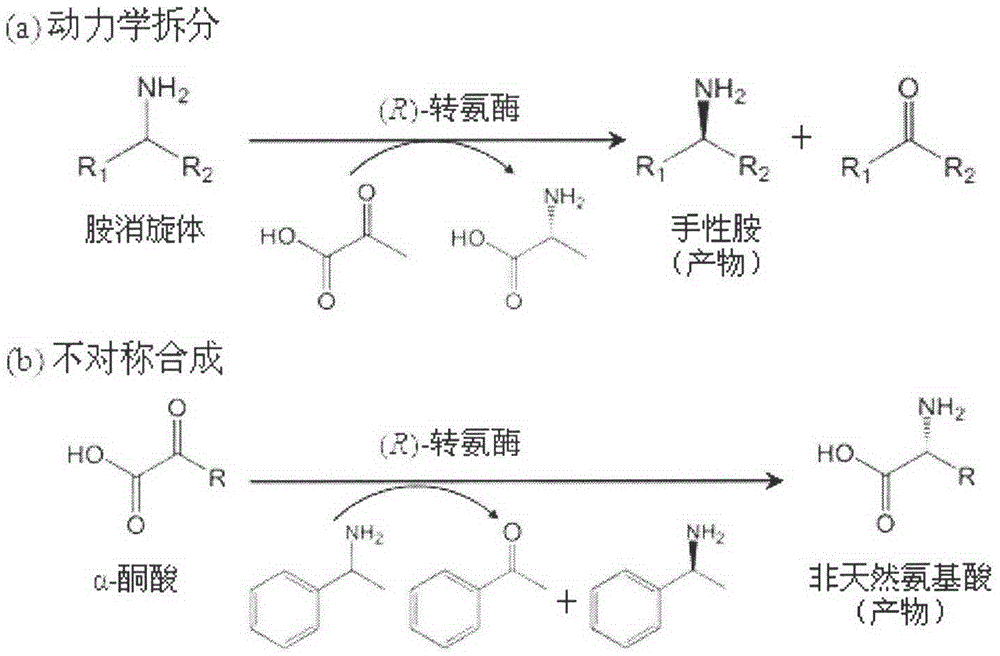

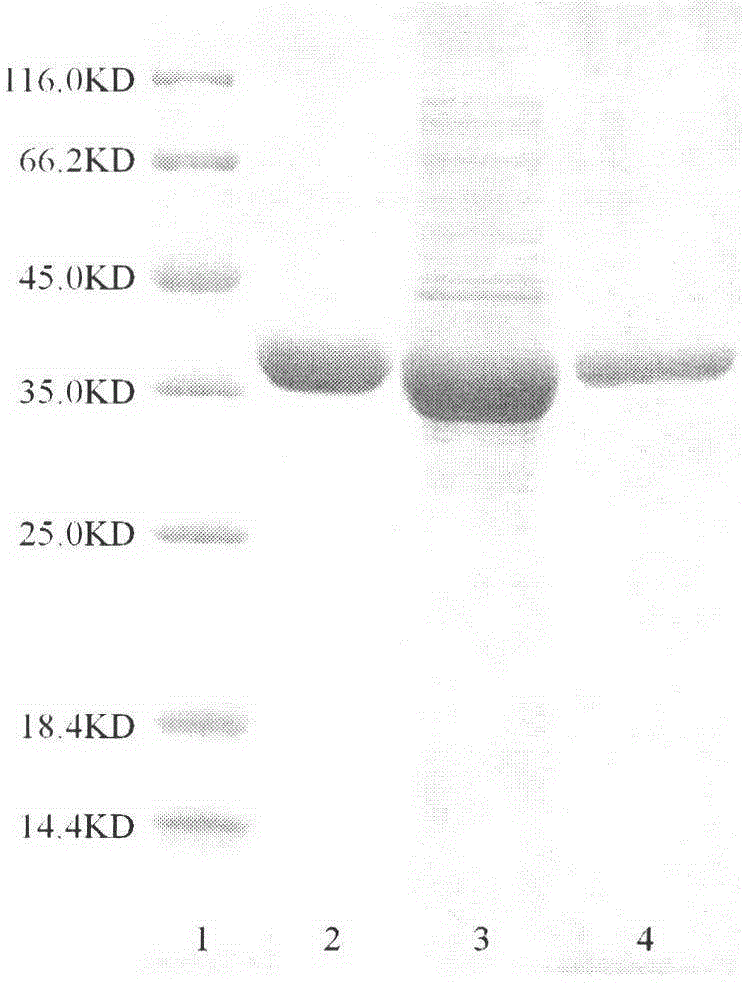

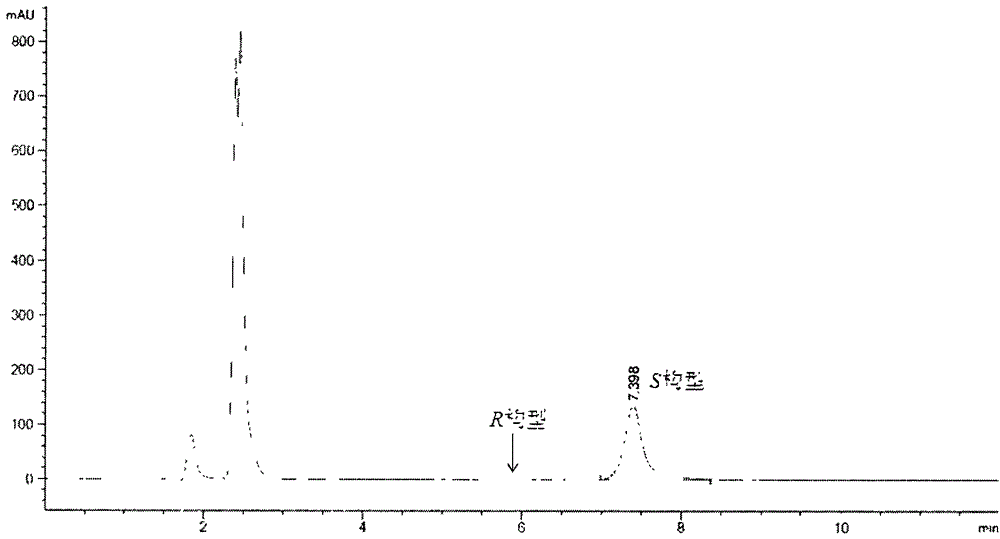

New (R)-transaminase from Trichoderma reesei and application thereof

InactiveCN104630170AIncrease vitalityImprove temperature stabilityTransferasesFermentationNucleotideNucleotide sequencing

The invention discloses a new (R)-transaminase and application thereof. The (R)-transaminase derives from Trichoderma reesei QM6a (named HTR), its gene nucleotide sequence is shown as SEQ ID No.1, and the amino acid sequence is shown as SEQ ID No.2. The new (R)-transaminase HTR is a strict (R) stereoselective Omega-transaminase, has a broad substrate spectrum, and has great application potential in bio-production of chiral amines and unnatural amino acids.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

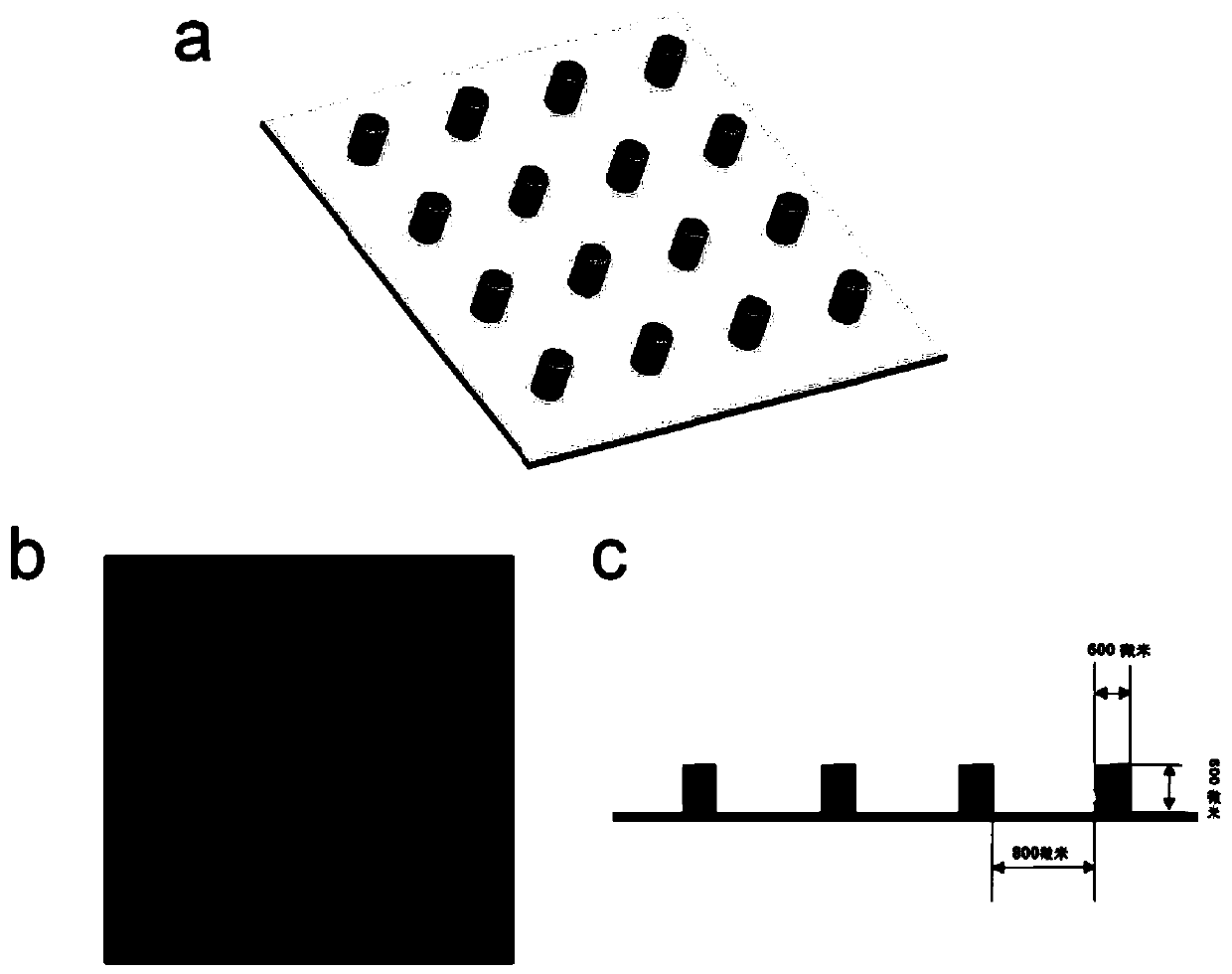

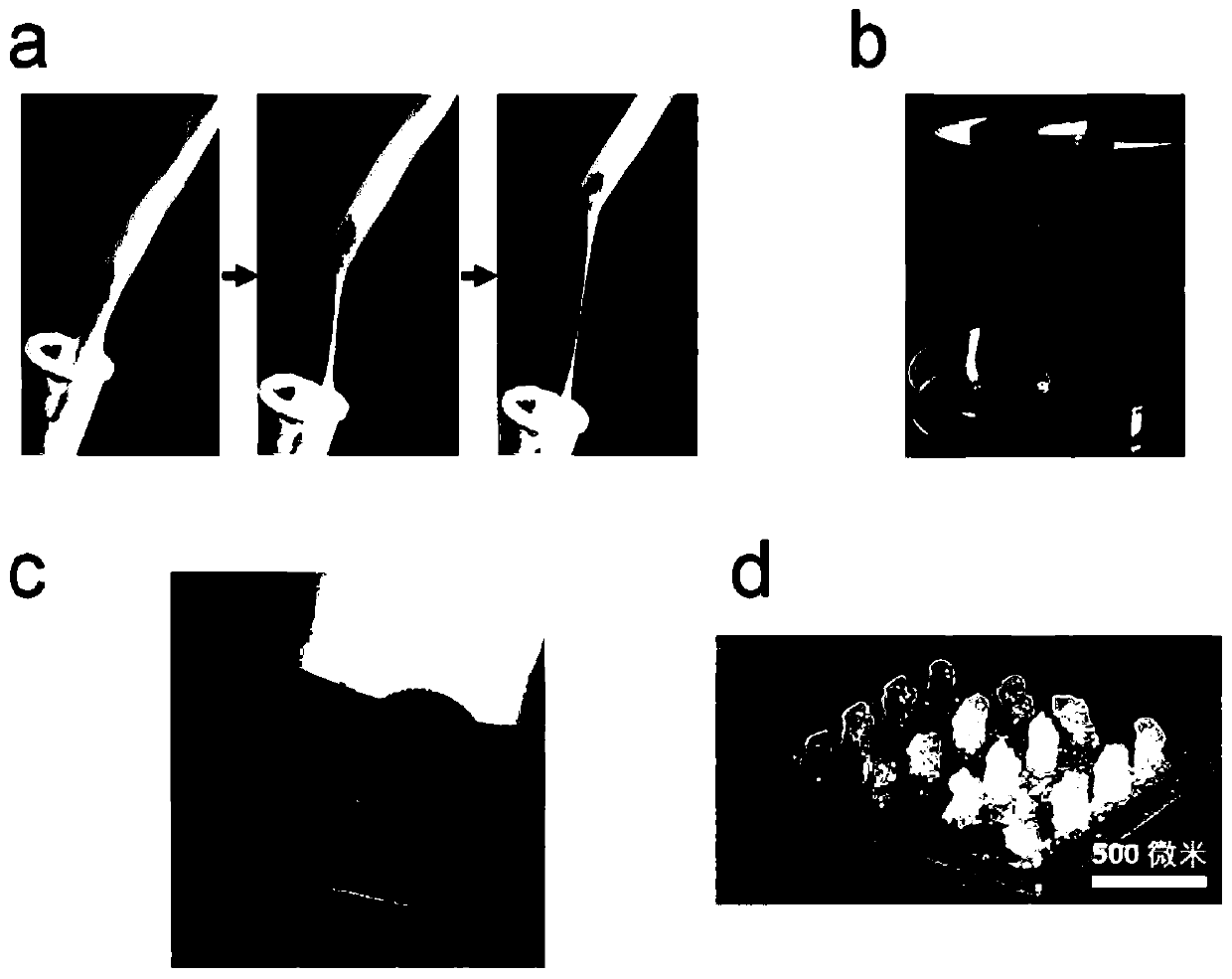

Preparation method and application of 3D print microacupuncture needle paster

ActiveCN110693855AReduce tip sizeEasy to makeAdditive manufacturing apparatusPeptide/protein ingredients3d printComputer printing

The invention discloses a preparation method and application of a 3D print microacupuncture needle paster, and belongs to the field of biomaterials and biological manufacturing. A dual-spray-head melting deposition shaping FDM 3D printer is used, a spray head is used for printing a base of the microacupuncture needle paster, and the other spray head is used for printing a columnar array of the microacupuncture needle paster, wherein the columnar array contains insulin medicines which can intelligently respond to and adjust blood sugar. After the base and the columnar array are obtained, a slide is in contact with the top end of the columnar array, then the top end is stretched to a preset distance to produce a needle point of the microacupuncture needle, cross-linking shaping is performed,and after dewatering and drying are completed under natural state, a microacupuncture needle array paster having certain mechanical properties and containing responsiveness medicines is formed. The microacupuncture needle paster can puncture skin, can intelligently respond according to blood sugar concentration in vivo, can intelligently release loaded medicines, and can intelligently adjust thelevel of the blood sugar. In a 3D print microacupuncture needle manner, painless intelligent response type blood sugar adjustment capable of realizing skin puncture can be realized, and the 3D print microacupuncture needle paster hopefully guides diagnosis and treatment integration of diabetes.

Owner:WUHAN UNIV

Biological nitrogen production method

InactiveCN101990799AIncrease nitrogenReduce dosageFertilising methodsHorticultureScientific theoryPlant growth

As disadvantages of chemical nitrogen production and a large number of used chemical fertilizers become increasingly obvious and the effect of increasing yield becomes increasingly unobvious, the invention provides a biological nitrogen production method. The core of the method is that: according to the characteristics of different nitrogen-fixing microorganisms, the relation between the different nitrogen-fixing microorganisms and plants, different living conditions of the different nitrogen-fixing microorganisms and the plants, and the mechanism principle and related scientific theories of biological nitrogen fixation, and by various measures, systematic coordination, overall cooperation and combined action, the nitrogen-fixing microorganism in soil are cultured and increased, and the nitrogen fixing capacity of the nitrogen-fixing microorganisms is improved; and the nitrogen-fixing microorganisms are used to produce nitrogenous fertilizers so as to meet the requirement of plant growth on nitrogen. The method has the advantages of capacity of continuously reducing the using amount of the chemical fertilizers, gradually recovering and improving soil fertility, improving the stress resistance and quality of crops and saving resources, environmental-friendliness, circular replaceability and sustainable development.

Owner:罗林松

Nutritive Fragments and Proteins with Low or No Phenylalanine and Methods

InactiveUS20150126441A1Increase thermogenesisHigh in proteinBacteriaPeptide/protein ingredientsProtein proteinBiotechnology

Nutritive proteins comprising no phenylalanine (Phe) are provided. In some embodiments the nutritive proteins comprise at least one of a level of a) a ratio of branch chain amino acid residues to total amino acid residues present in the nutritive protein equal to or greater than the ratio of branch chain amino acid residues to total amino acid residues present in a benchmark protein; b) a ratio of leucine residues to total amino acid residues present in the nutritive protein equal to or greater than the ratio of leucine residues to total amino acid residues present in a benchmark protein; and c) a ratio of essential amino acid residues to total amino acid residues present in the nutritive protein equal to or greater than the ratio of essential amino acid residues to total amino acid residues present a benchmark protein. Also provided are nucleic acids encoding the proteins, recombinant microorganisms that make the proteins, methods of making the proteins using recombinant microorganisms, compositions that comprise the proteins, and methods of using the proteins, among other things. The compositions are useful, for example, to provide protein in the diet of subjects with a disorder characterized by accumulation of Phe in the body.

Owner:AXCELLA HEALTH INC

High-yield 3-Methionol saccharomyces cerevisiae engineering bacteria and preparation method and application thereof

InactiveCN103409331AIdentify key metabolic nodesOptimizing Fermentation MediumFungiMicroorganism based processesEnzyme GeneMetabolic network

The invention relates to high-yield 3-Methionol saccharomyces cerevisiae engineering bacteria and a preparation method and application thereof, and belongs to the technical field of biological preparation of food flavors. According to the high-yield 3-Methionol saccharomyces cerevisiae engineering bacteria and the preparation method and application thereof, the engineering bacteria is designed and constructed through the coupling excessive expression of an aminotransferase gene (ARO9) and a decarboxylase gene (ARO10) and the knock-out of a methylthio lyase gene (CY3) in the anabolic pathway of Methionol by taking Saccharomyces cerevisiae S288c as an original strain; the expression of two key enzyme genes in a main synthetic pathway is enhanced, and the expression of the CY3 gene in a side reaction pathway is reduced or eliminated; the bred engineering bacteria (converter) is subjected to multiple-time passage and stable in inheritance, so that the metabolic network and metabolic pathway of the biological synthesis of the Methionol are optimized, and the metabolic flux and yield of the Methionol are obviously increased; a Methionol flavor prepared by fermenting and converting the engineering bacteria is single in structure and chirality and high in fragrance quality.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

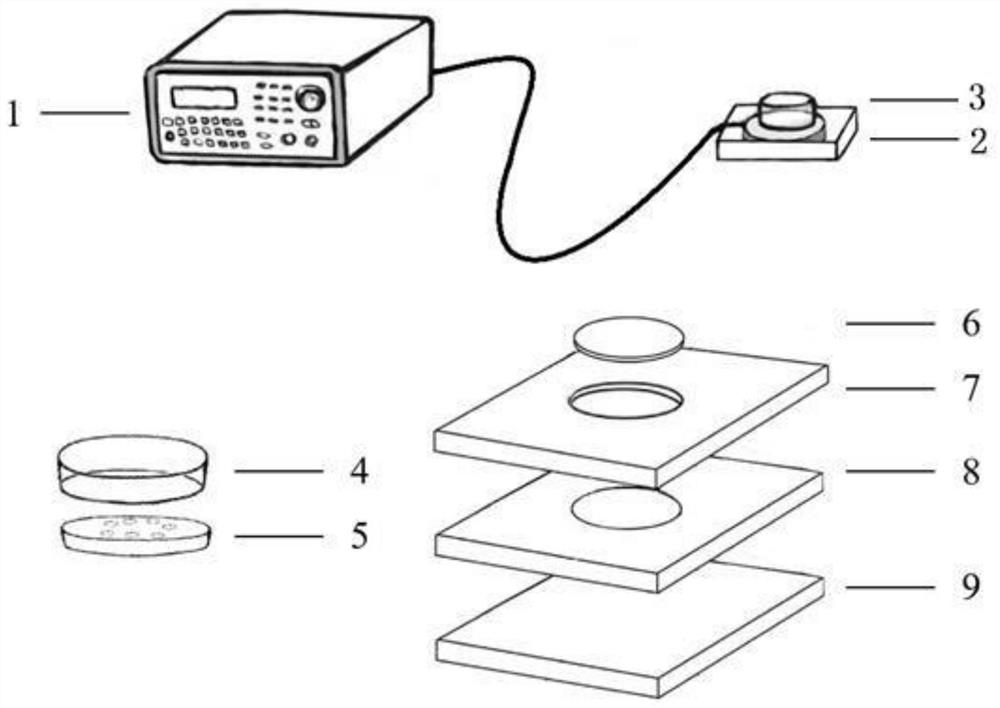

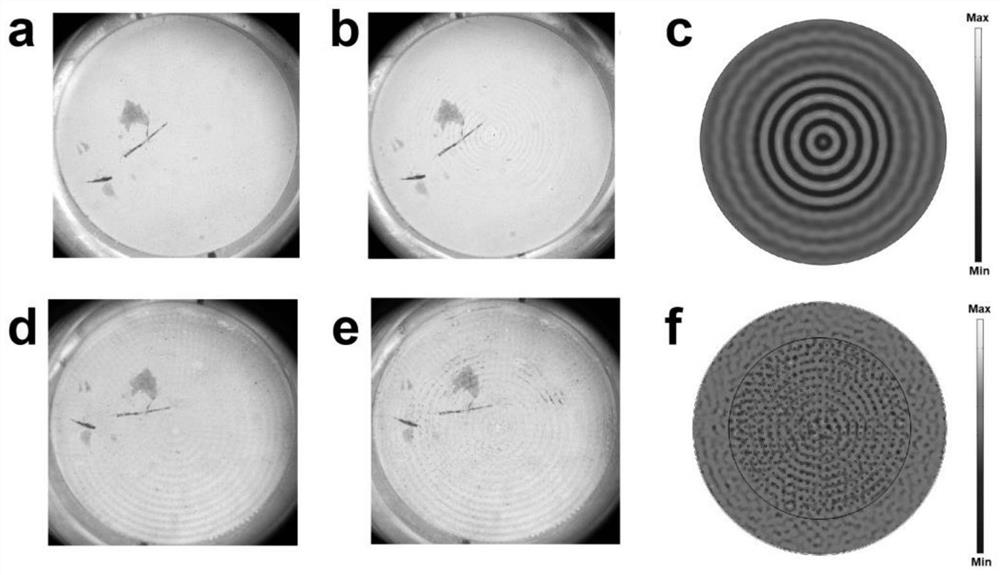

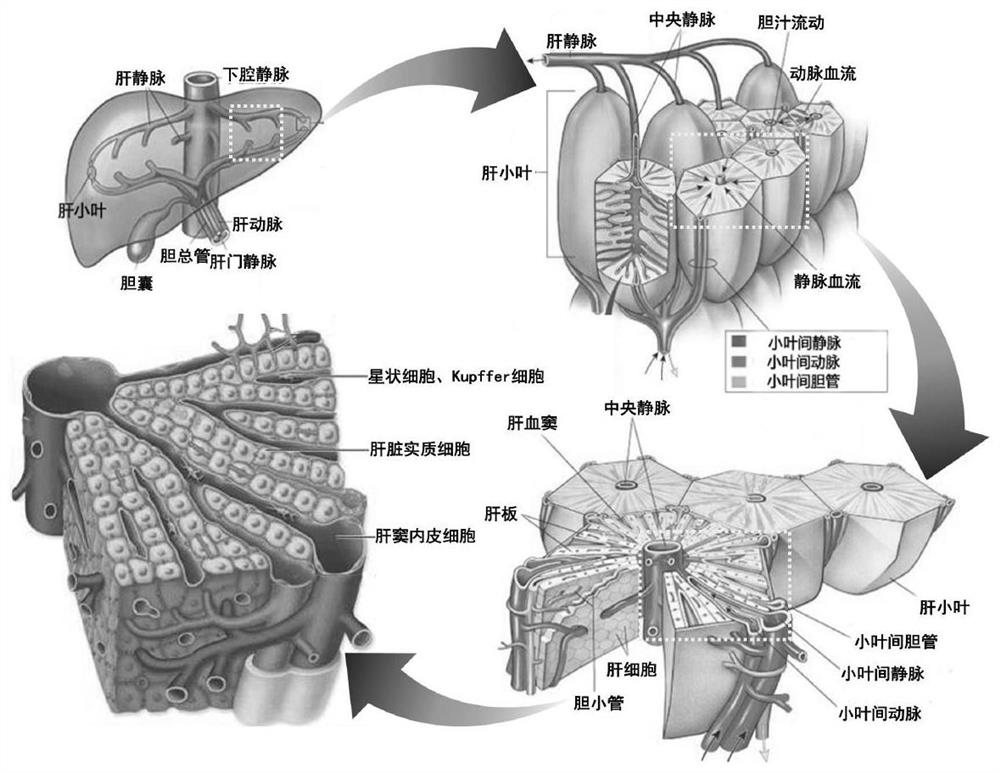

Micro-processing gas matching layer modulation body ultrasonic cell assembling and arranging device, preparation method and application

ActiveCN112899158ASuitable for control needsFlexible Body Ultrasonic Sound Field StyleBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

The invention belongs to the technical field of tissue engineering and biological manufacturing under biomedical engineering, and particularly relates to a micro-processing gas matching layer modulation body ultrasonic cell assembling and arranging device, a preparation method and application. According to the micro-processing gas matching layer modulation body ultrasonic cell assembling and arranging method and device, a sound field generated by an ultrasonic transducer is modulated by processing an acoustic matching layer micro-pattern structure, and cells are assembled and randomly arranged in a cell assembling chamber. According to the device, the acoustic matching layer is processed by utilizing a soft lithography technology for the first time to modulate the sound field for cell assembling, so that a more flexible body ultrasonic sound field style is realized, the device can be more suitable for various cell control requirements of biological research and tissue engineering, and the device has huge application prospects and commercial values.

Owner:SHENZHEN CONVERGENCE BIO-MFG CO LTD

Three dimensionally shaped biofabricated materials and methods of manufacture

PendingUS20210023764A1Minimize timeMinimize wasteAdditive manufacturing apparatusTextiles and paperBiomanufacturingEngineering

Owner:MODERN MEADOW INC

Biomanufacturing suite and methods for large-scale production of cells, viruses, and biomolecules

ActiveUS9902928B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBiomanufacturingVirus

The present invention provides a production module for large-scale production of cells and / or cell-derived products such as antibodies or virus; a production suite comprising a plurality of functionally connected production modules of the invention; and a method for large-scale production of cells and / or cell-derived products using the production modules and / or production suites of the invention.

Owner:BIOVEST INT

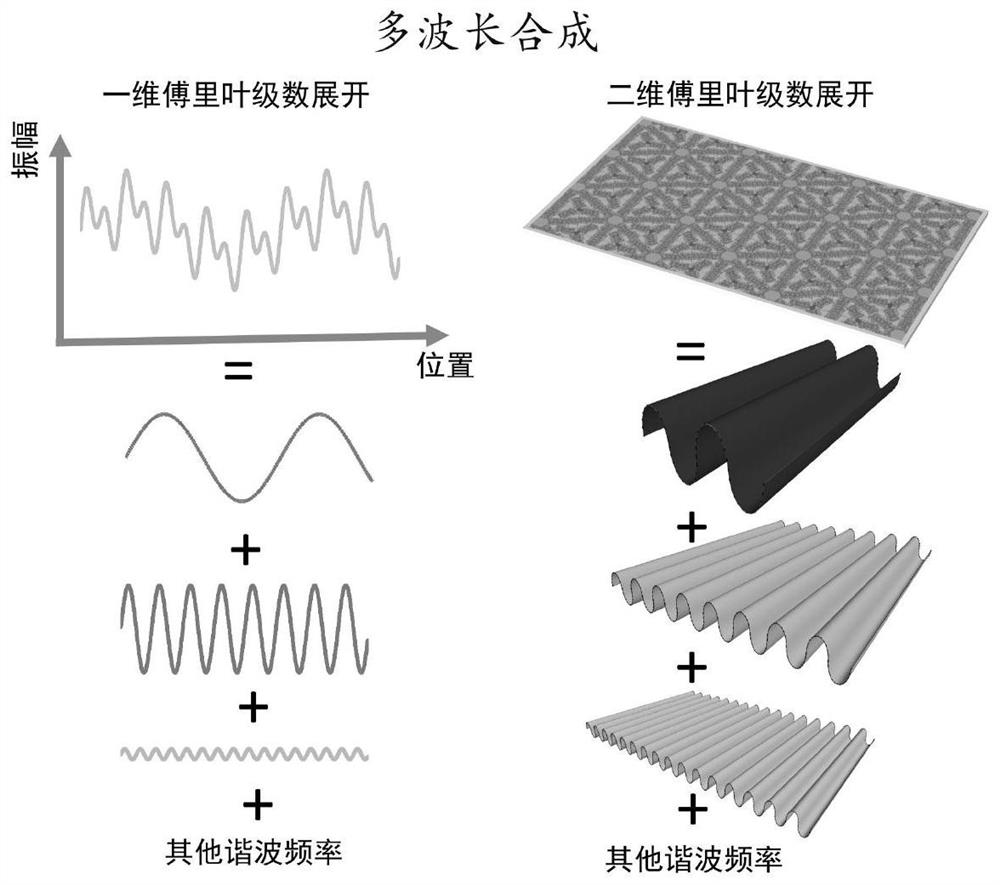

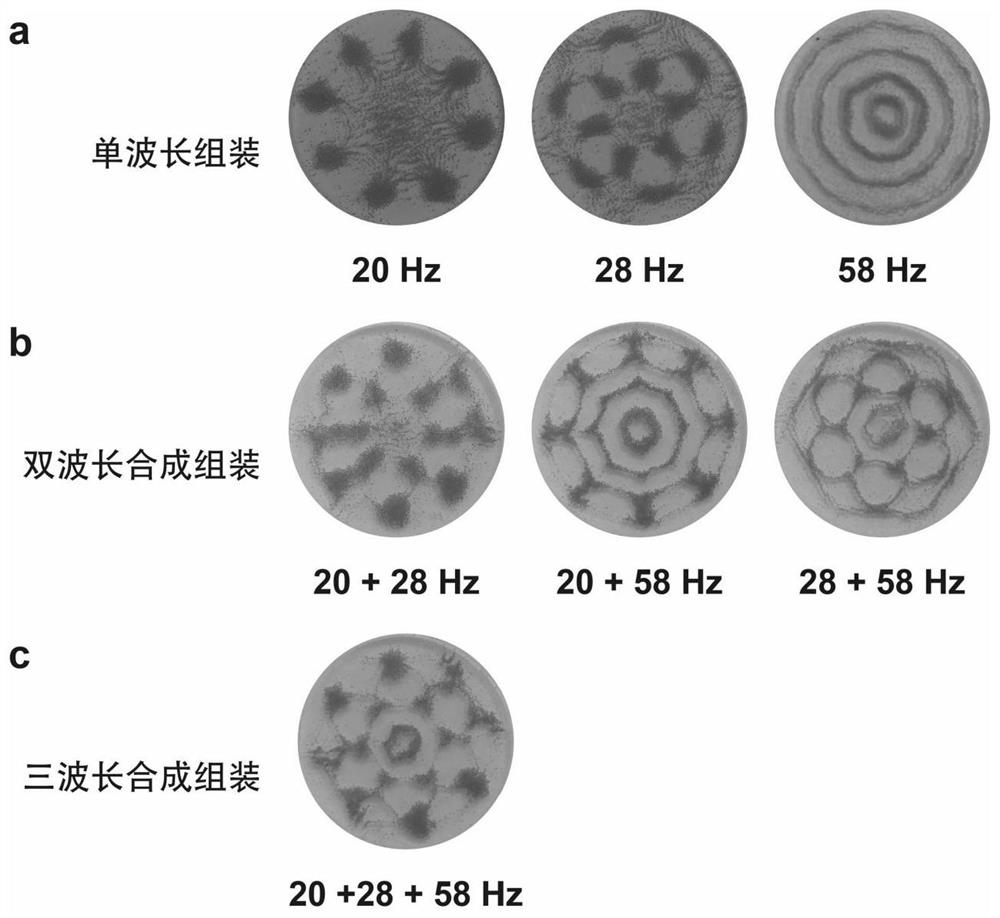

Cell assembly method for Faraday wave multi-wavelength synthesis and application

ActiveCN113604463AEasy to buildEasy to operateCulture processElectrical/wave energy microorganism treatmentBiomanufacturingBiocompatibility

The invention discloses a biological assembly method for Faraday wave multi-wavelength synthesis and application. The method has the advantages that a system is easy to build, operation and control are simple, patterns are dynamically adjustable, biocompatibility is good and the like. The method is different from a cell manipulation principle under a single wavelength condition in an existing acoustic biological assembly method, sine or cosine signals with different wavelengths are synthesized, a single-wavelength assembly mode in a traditional Faraday wave frequency domain is improved into a multi-wavelength assembly mode, and complex and arbitrary pattern arrangement of liquid-bottom multi-scale cells is realized. The method is more suitable for the requirement for complex arrangement of cells in tissue engineering and biological manufacturing, and has huge application prospects and commercial value.

Owner:SHENZHEN CONVERGENCE BIO-MFG CO LTD

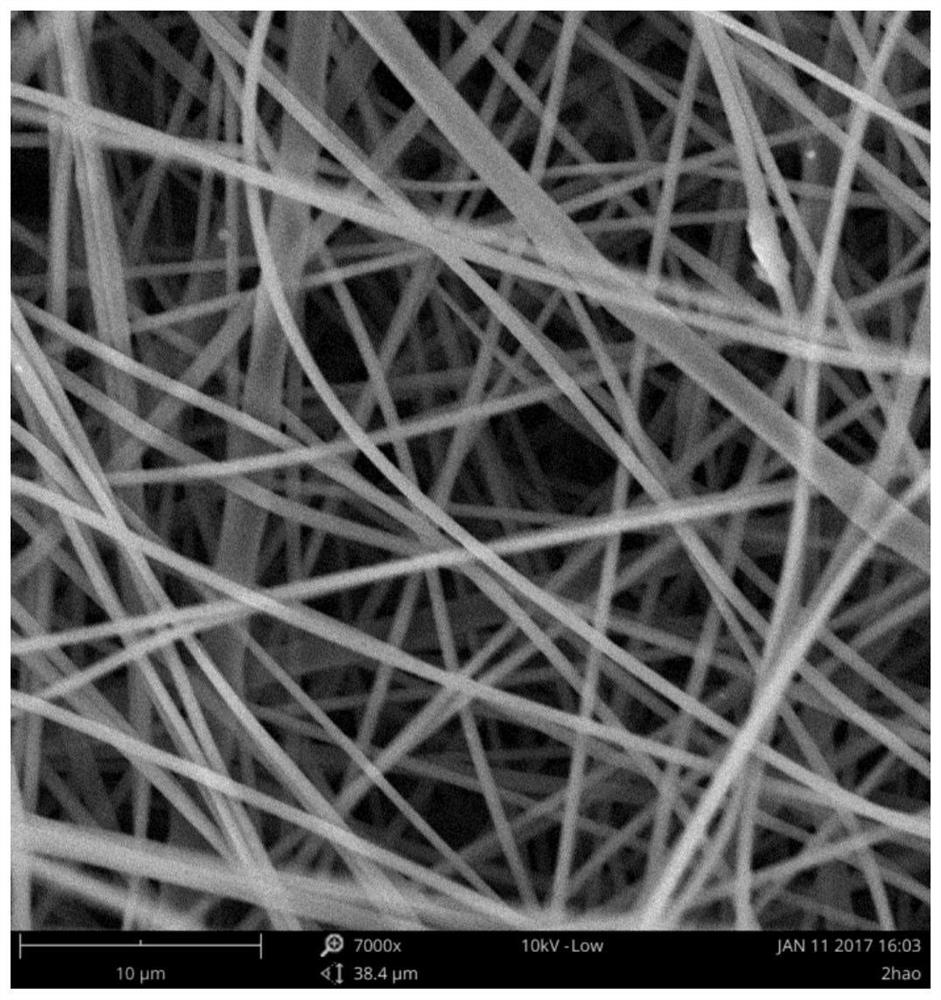

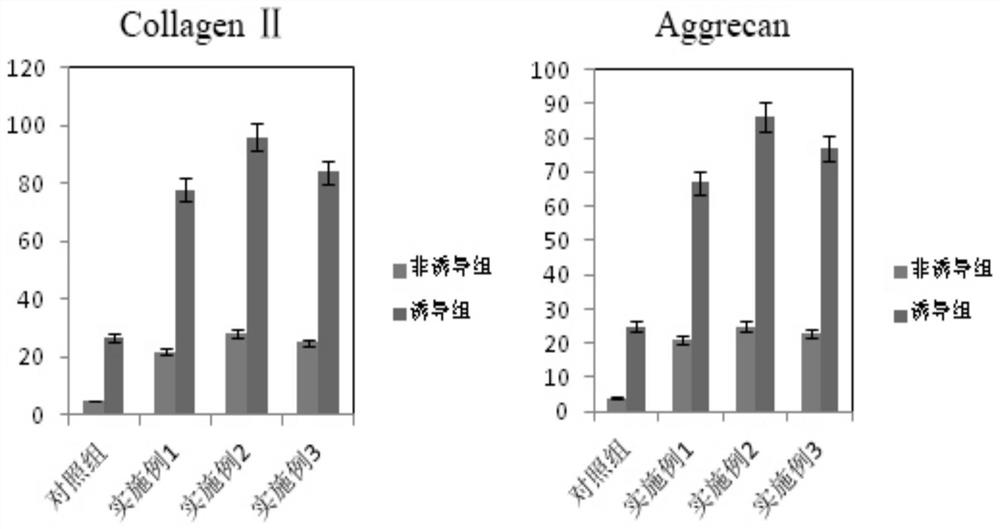

Chitosan-human recombinant collagen electrostatic spinning nanofiber scaffold and preparation method

InactiveCN111821515AGood fiber shapeGood biocompatibilityFibre typesPharmaceutical delivery mechanismFiberSpinning

The invention relates to the technical field of tissue engineering and biological manufacturing, in particular to a chitosan-human recombinant collagen electrostatic spinning nanofiber scaffold and apreparation method. The specific preparation method comprises the following steps: preparing a hexafluoroisopropanol spinning solution with a certain concentration from three components, namely humanrecombinant collagen, chitosan and polycaprolactone according to a certain ratio; and preparing chitosan, humanized recombinant collagen and polycaprolactone electrostatic spinning nanofiber scaffoldsfrom the prepared solution through an electrostatic spinning technology, then cross-linking the nanofiber scaffolds through a cross-linking agent, and applying the cross-linked scaffolds to cartilagetissue regeneration. The chitosan-human recombinant collagen electrostatic spinning nanofiber scaffold prepared by the invention has high fiber morphology, high biocompatibility and biodegradability,has the capability of guiding cartilage regeneration, is remarkable in effect, and can be used for repairing cartilage tissue defects.

Owner:青海创铭医疗器械有限公司

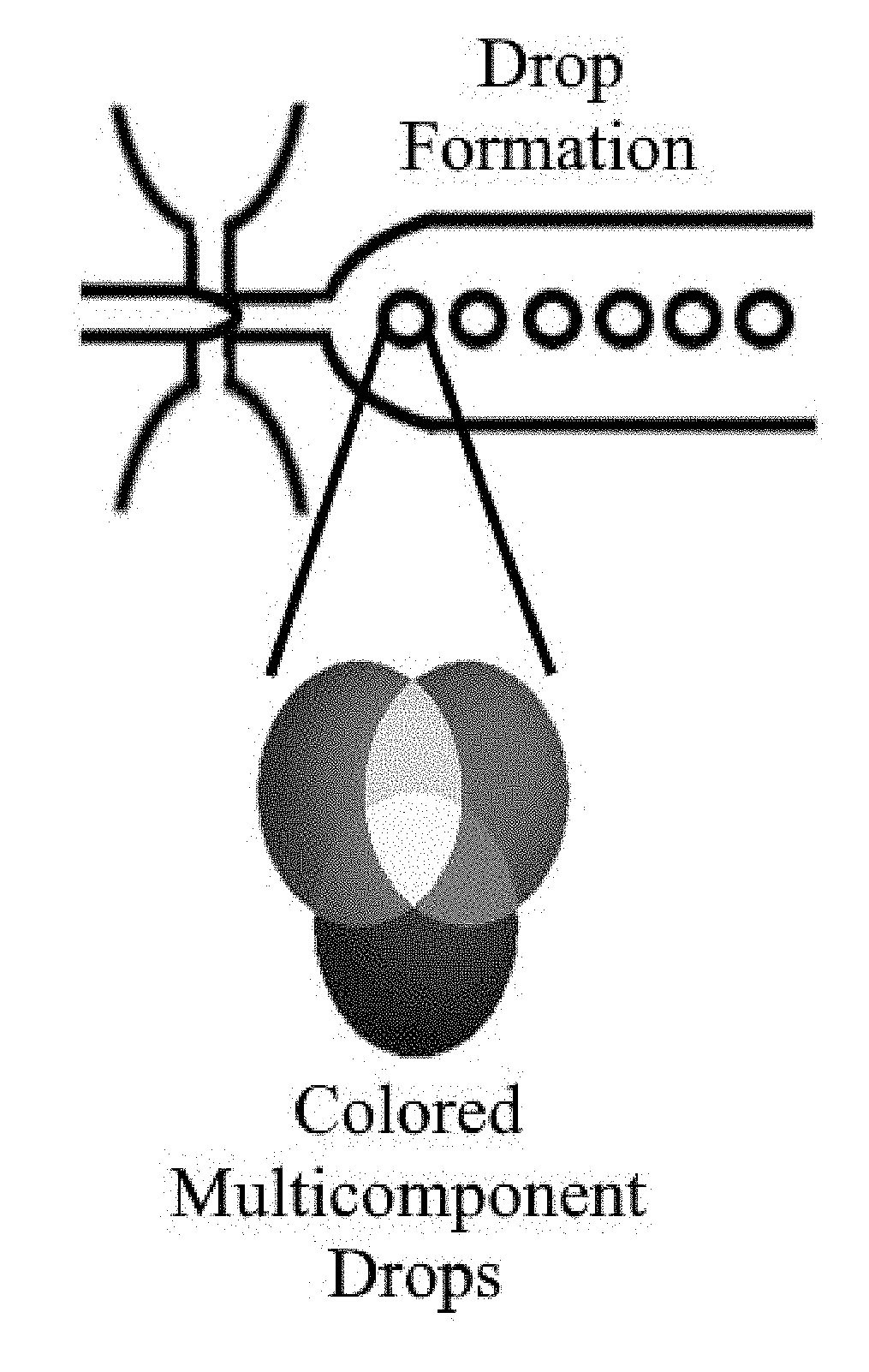

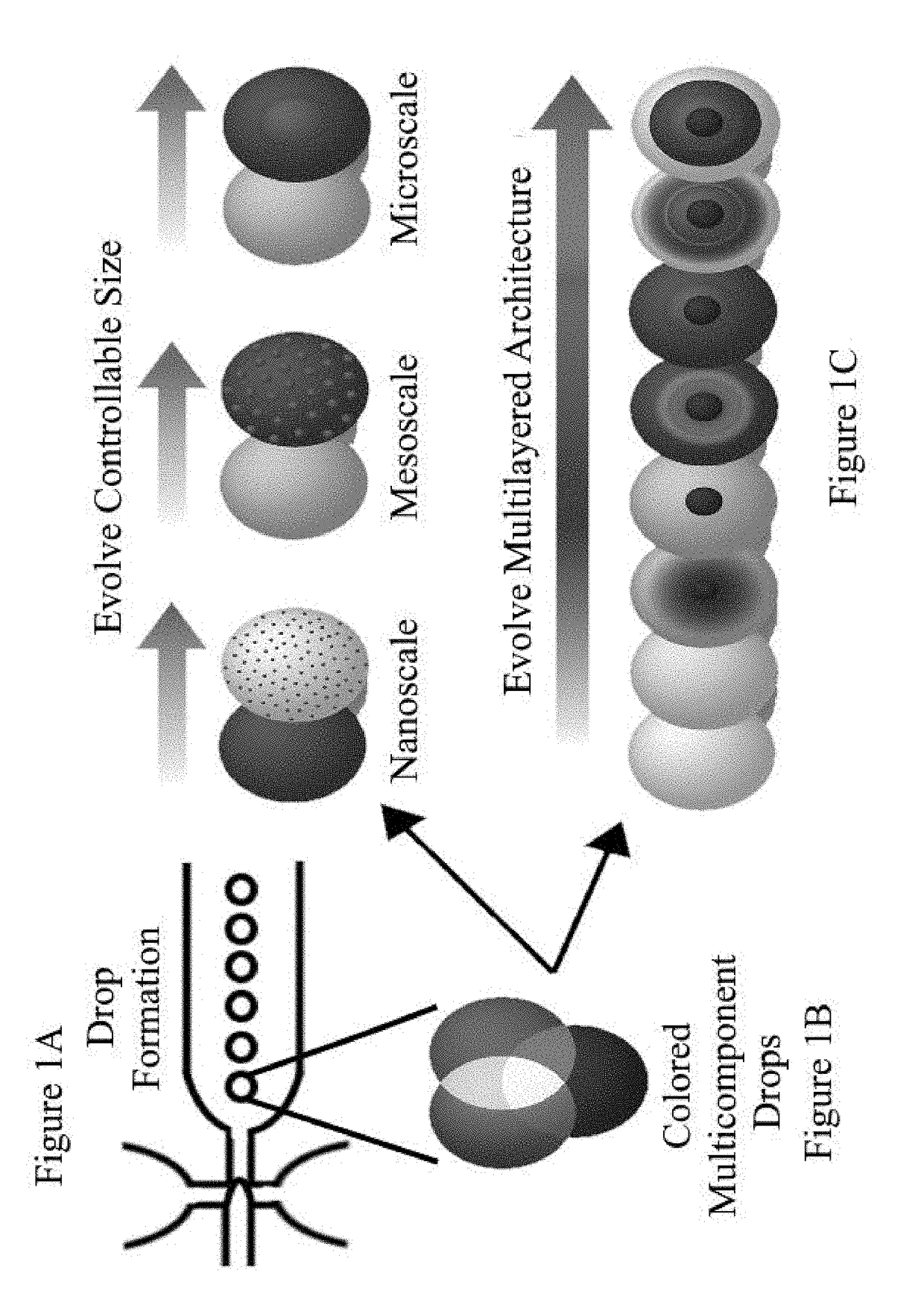

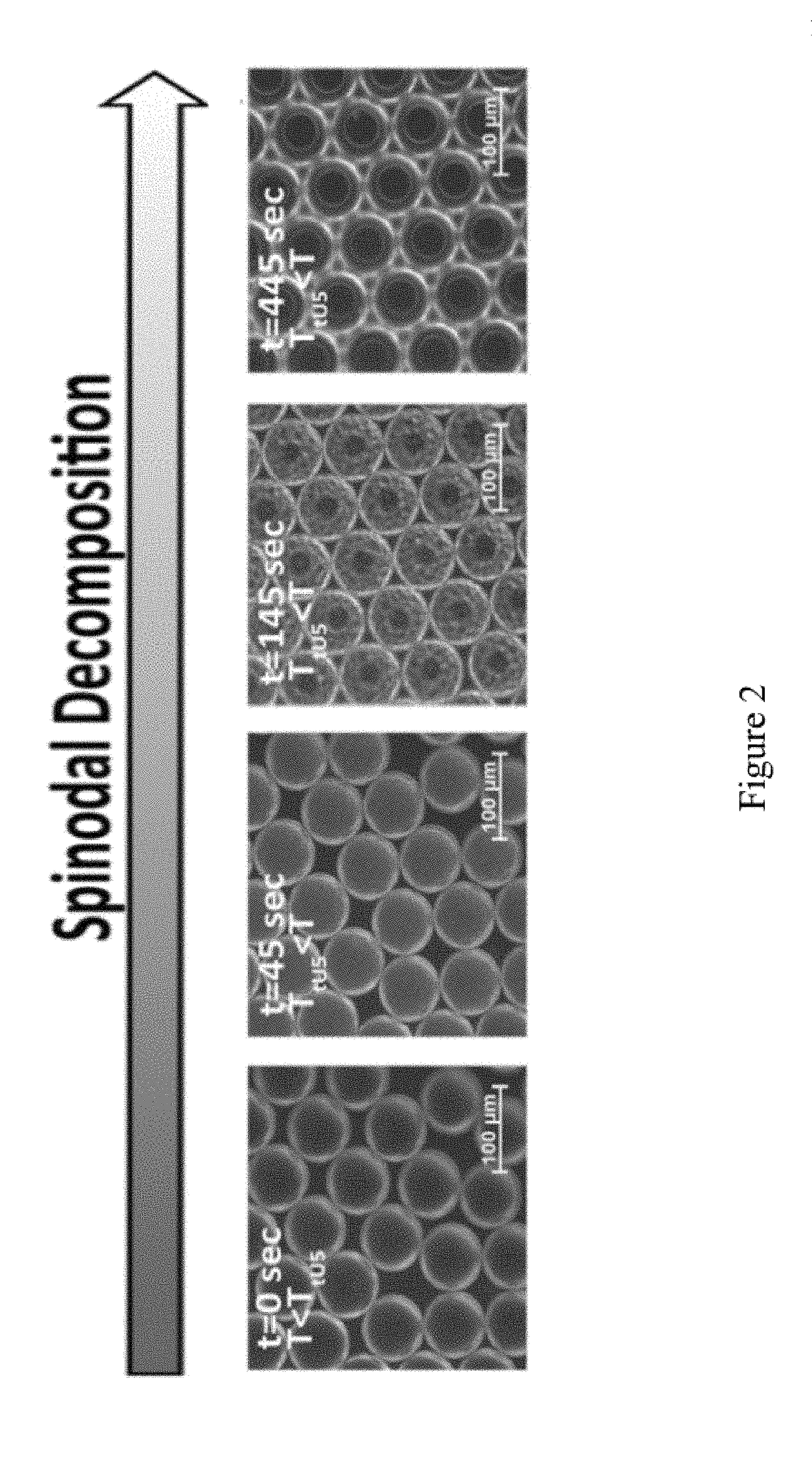

Programmable liquid, gel and biohybrid compartments and methods of use

InactiveUS20170216808A1Bioreactor/fermenter combinationsPowder deliveryCrystallographyBiomanufacturing

Nano- to microscale liquid coacervate particles are provided. The liquid coacervate particles are produced by a process including stimulating a population of liquid droplets containing one or a mixture of components to induce a phase separation point of a first component, and maintaining stimulation at the phase separation point to form a coacervate domain of the first component within each of the droplets to form the liquid coacervate particles. The self-assembled nano, meso, micro and macro liquid coacervate particles and related coated substrates can have utility in drug delivery, bioanalytical systems, controlled cell culture, tissue engineering, biomanufacturing and drug discovery.

Owner:DUKE UNIV

Method for manufacturing D-phenylalanine by bio-enzyme asymmetric transformation

InactiveCN101671716AHigh optical purityEasy to produceMicroorganism based processesFermentationChemical purityChemistry

The invention provides a biological manufacturing method of D-phenylalanine, and belongs to the enzyme engineering technology in the bioengineering field, aiming at solving the technical problem of providing a manufacturing method of D-phenylalanine by bio-enzyme asymmetric transformation which has a simple manufacturing process and can lower the manufacturing cost. The technical key points are asfollows: taking DL-phenylalanine as a raw material to take part in enzyme catalysis reaction by being used as a substrate; taking L-phenylalanine ammonialyase as a catalyst to perform catalytic conversion on L-phenylalanine in the zymolyte DL-phenylalanine to generate trans-cinnamic acid and ammonia; extracting D-phenylalanine as a target which does not take part in reaction; adding zymolyte continuously to improve concentration of the target product D-phenylalanine, forming crystal in enzymatic reaction solution and separating directly; and dissolving D-phenylalanine in the enzymatic reaction solution, regulating pH value to be 1-5, separating and removing cinnamic acid by using the water-insoluble characteristic of cinnamic acid in acid environment, concentrating and crystallizing to obtain the product. The refining purpose can be realized by membrane filtration decoloration and recrystallization of the D-phenylalanine coarse product. The product in the invention has high chemical purity and optical purity and low manufacturing cost.

Owner:淮北新旗氨基酸有限公司

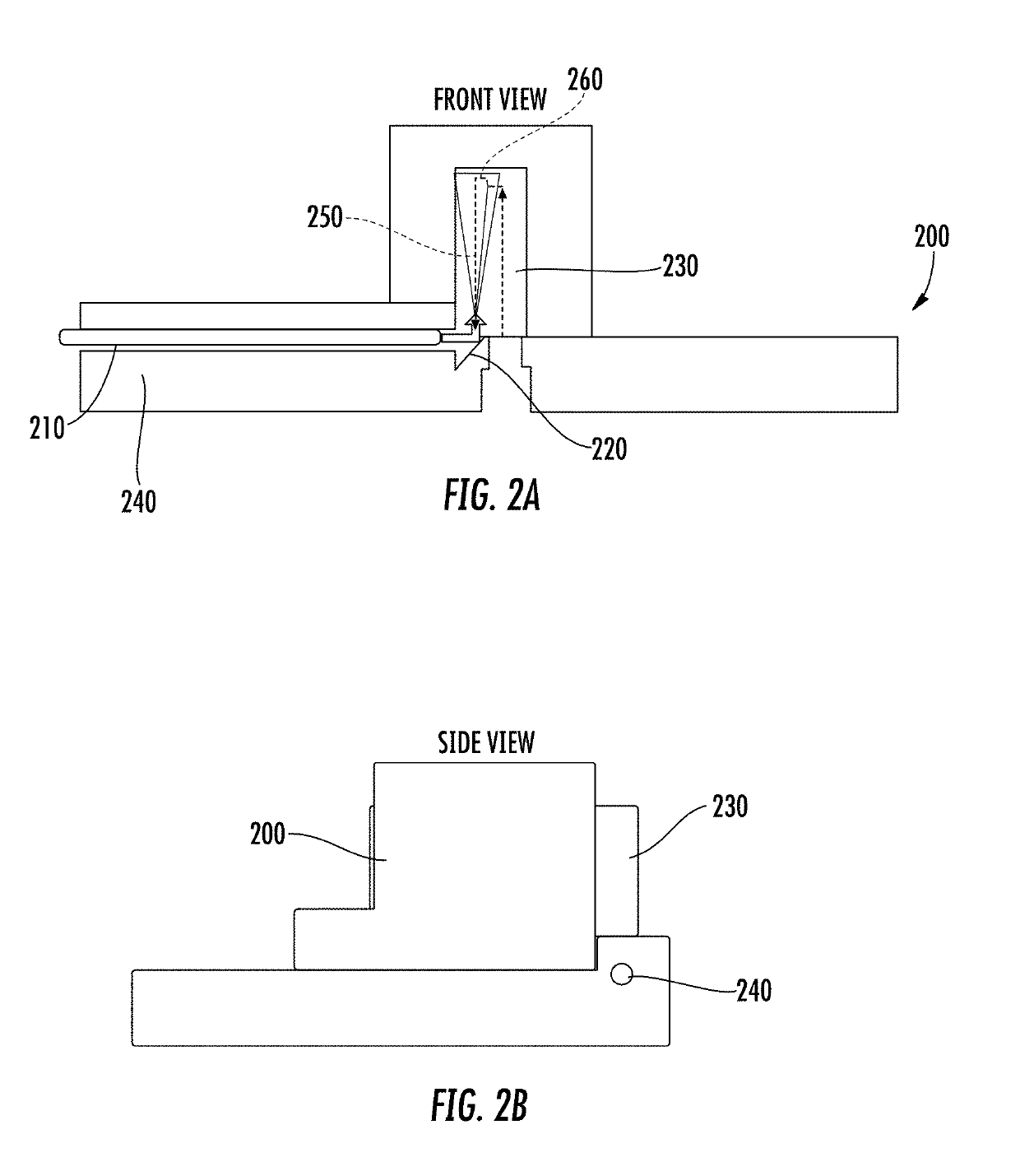

Microfluidic chip device for optical force measurements and cell imaging using microfluidic chip configuration and dynamics

ActiveUS20190250093A1High trafficEnhance the imageMaterial analysis by optical meansLaboratory glasswaresBiomanufacturingMotility

Provided are methods and devices for assessing biological particles for use in cell immunotherapy. By utilizing a microfluidic chip device together with optical force measurement and cell imaging, the methods enable comprehensive assessment and characterization of biological particles with regard to morphology, motility, binding affinities, and susceptibility to external forces, including but not limited to, chemical, biochemical, biological, physical and temperature influences. The methods enable the selection and production of biological particles, such as engineered T-cells, for use in immunotherapy and biomanufacturing.

Owner:LUMACYTE INC

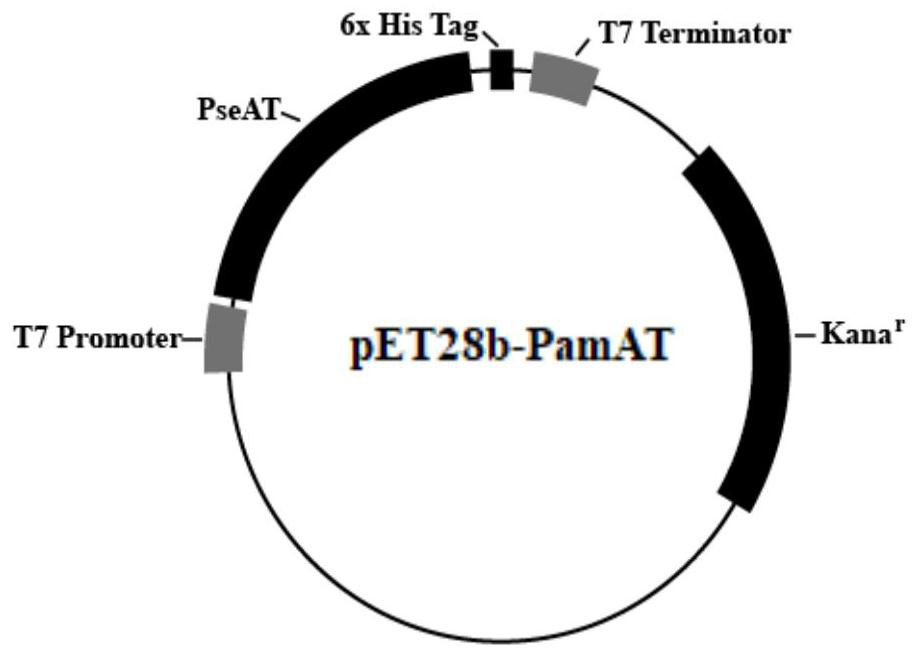

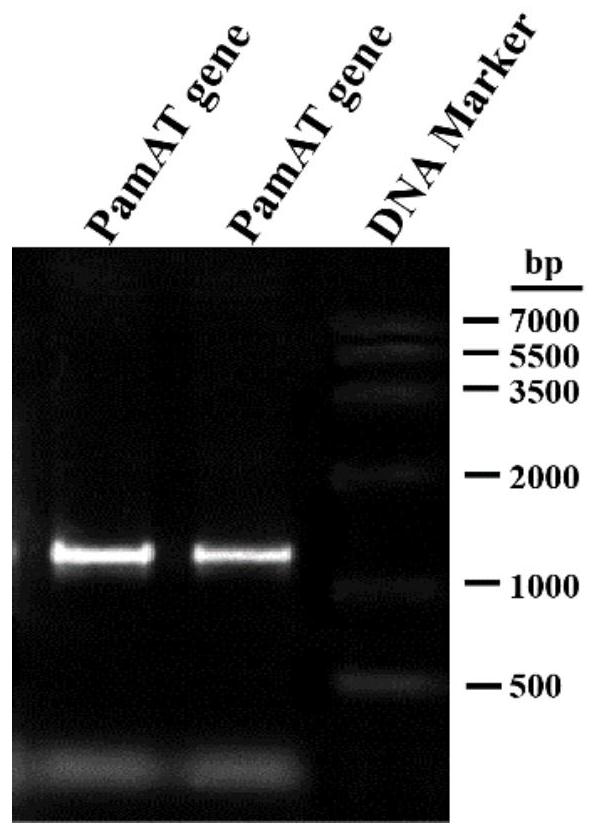

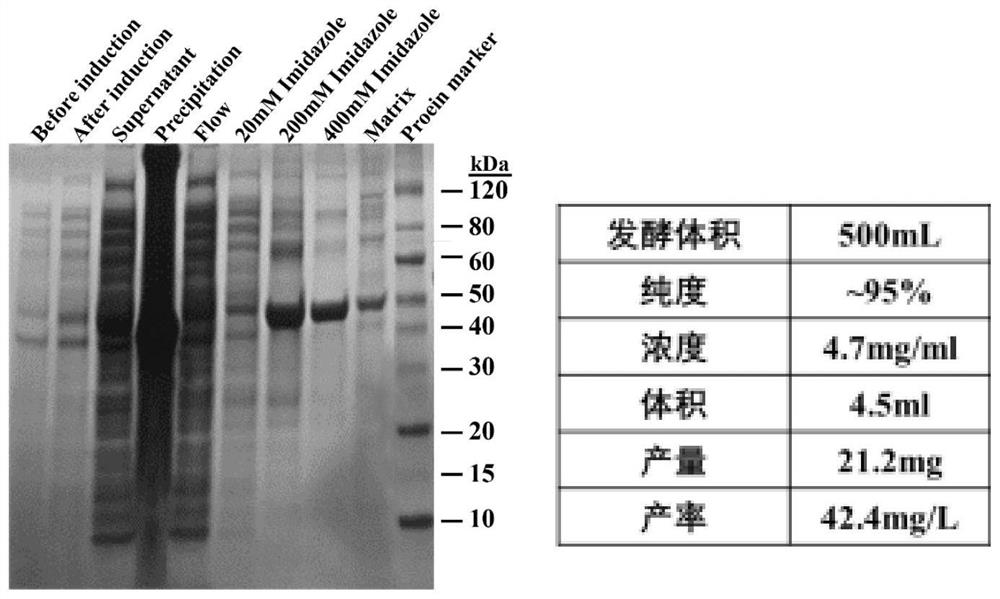

R-transaminase derived from pseudonocardia ammoxidation and synthesis method of R-transaminase

PendingCN112522228AEfficient synthesisBroad substrate spectrumTransferasesFermentationNucleotideAmino acid

The invention discloses R-transaminase derived from pseudonocardia ammoxidation and a synthesis method thereof. The R-transaminase is named as PamAT, the nucleotide sequence of a gene is shown as SEQNO.1, the amino acid sequence is shown as SEQ NO.2, and the R-transaminase contains the amino acid sequence shown in SEQ NO.2 or is provided with at least 90% of identity with the SEQ NO.2 or is subjected to substitution, deletion or addition of one or more amino acids; and the high stereoselectivity means that the content of one stereoisomer is at least about 1.1 times that of the other stereoisomer. The R-transaminase has high stereoselectivity, has a wide substrate spectrum and has great application potential in the aspect of biological manufacturing of chiral amine and non-natural amino acid.

Owner:JIANGSU OCEAN UNIV

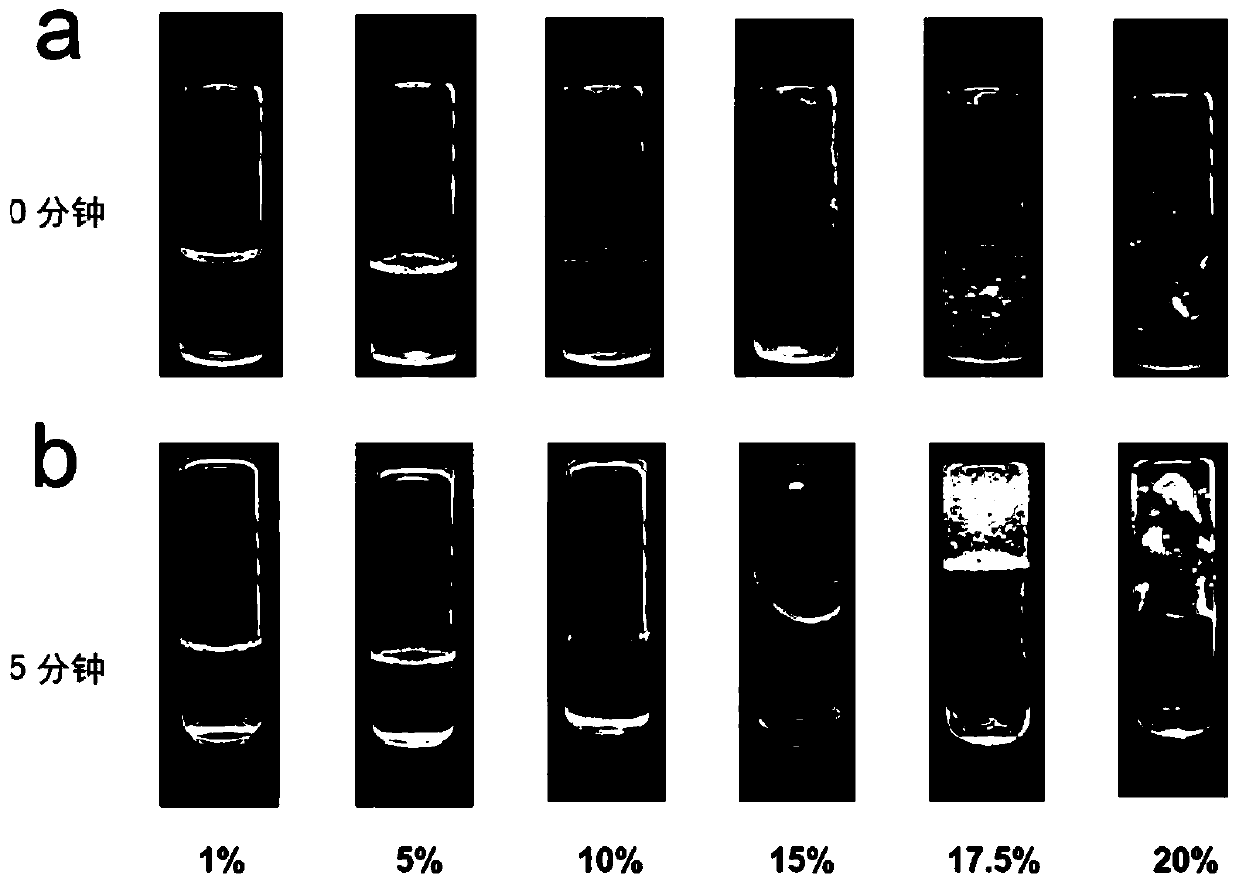

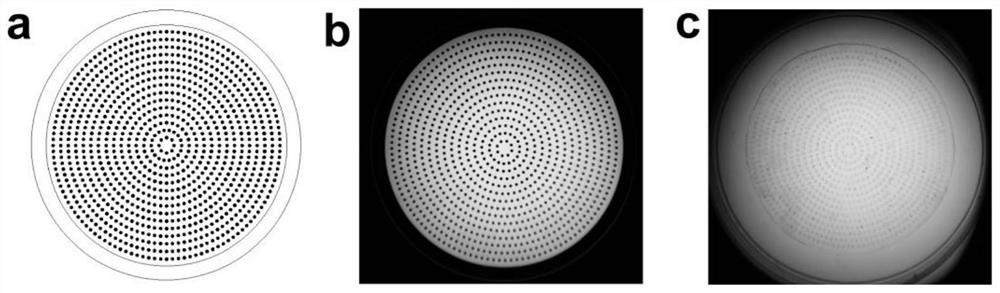

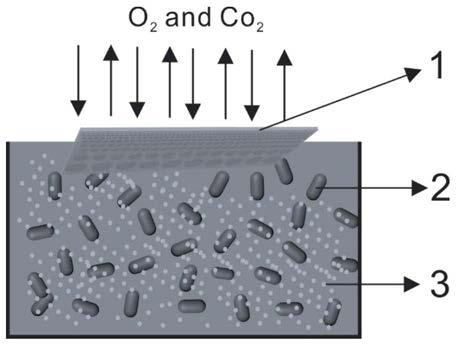

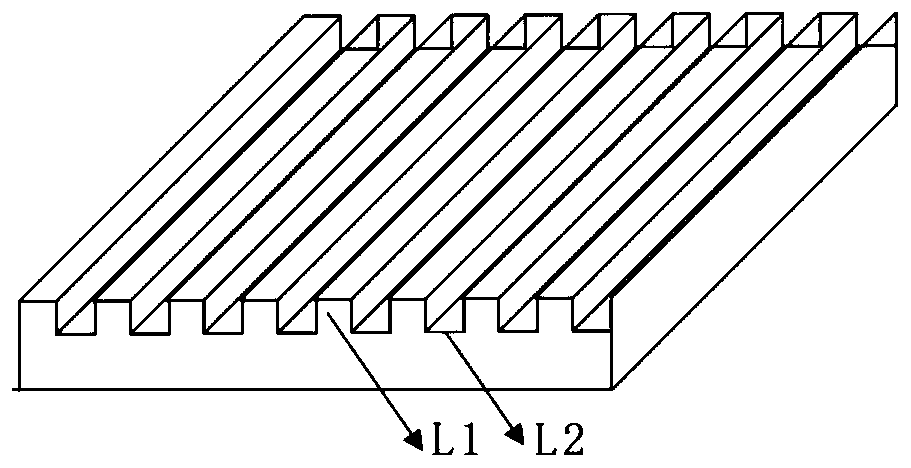

A patterned bacterial cellulose film and its preparation method and application

The invention discloses a patterned bacterial cellulose membrane, and a preparation method and application thereof, and belongs to the technical field of polymer materials and biological manufacturing. The preparation method comprises the steps of: fully mixing a prepolymer A of polydimethylsiloxane with a curing agent B, then adding an organic solvent, then adding water dropwise, stirring the mixture, allowing the mixture to stand to allow the mixture to be initially solidified, heating and solidifying the mixture, removing the organic solvent and water to obtain water-emulsified polydimethylsiloxane functional sponge, floating the patterned PDMS sponge model on the surface of a culture liquid capable of producing bacterial cellulose, and performing fermentation culture for 12-48 h to obtain the patterned bacterial cellulose membrane. The method for preparing the patterned bacterial cellulose membrane by utilizing the PDMS sponge has characteristics of a simple process, short fermentation time, high pattern fidelity, and capability of allowing the pattern height to be 10 [mu]m to 2 mm, and the membrane has good biocompatibility and is an ideal environmentally friendly biomedical material.

Owner:HUAZHONG UNIV OF SCI & TECH

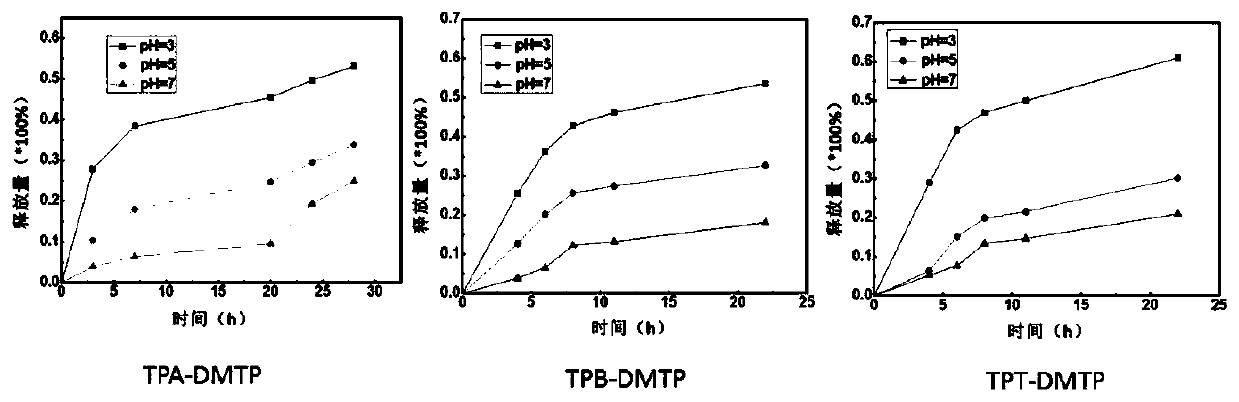

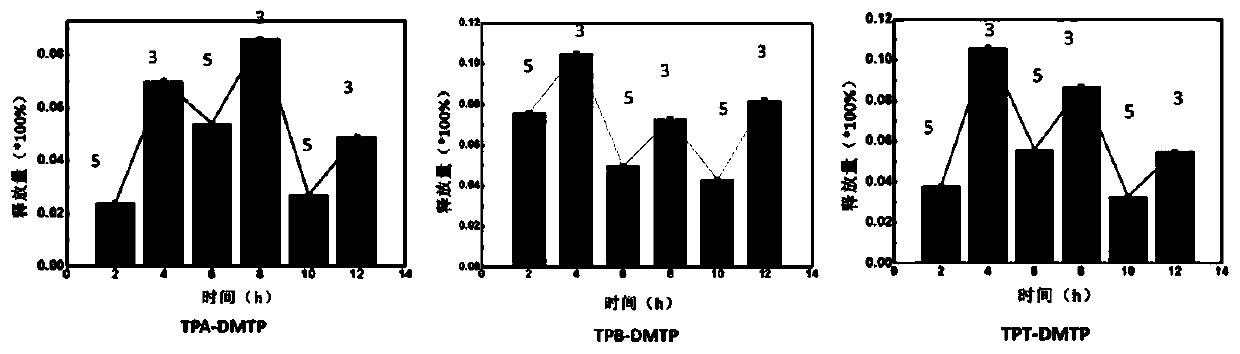

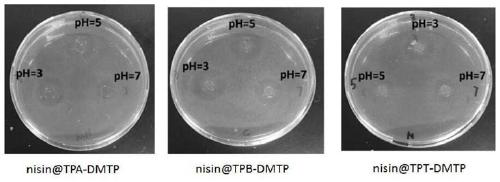

Antibacterial fermentation additive based on covalent organic framework material and preparation and application thereof

Aiming at the regulation and control problem in the fermentation process, a covalent organic framework material is creatively designed as a novel carrier material with wide applicability, and antibacterial molecules (such as protein, enzyme, polypeptide and antibiotics) are efficiently loaded through an adsorption means, so that the intelligent pH response industrial additive is prepared and is used for regulating and controlling infectious microbe pollution in the fermentation process. The novel fermentation additive prepared by the technology has high stability and durability, and successfully solves the problem of infectious microbe pollution in the fermentation process in the field of biological manufacturing.

Owner:NANKAI UNIV

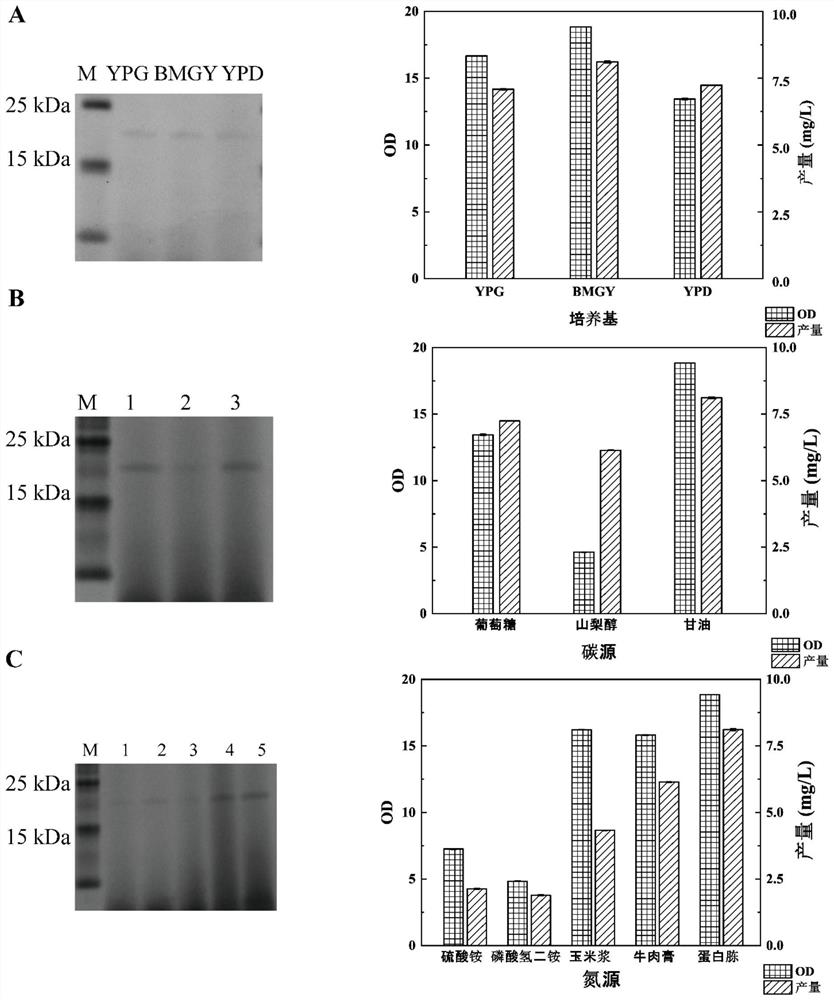

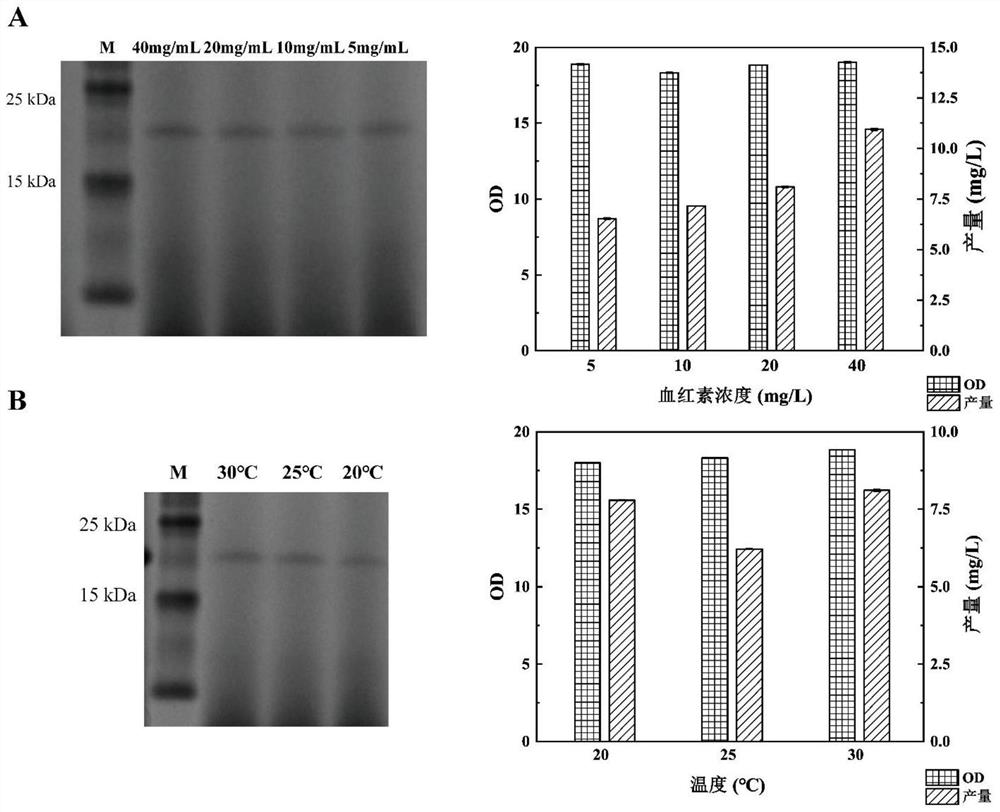

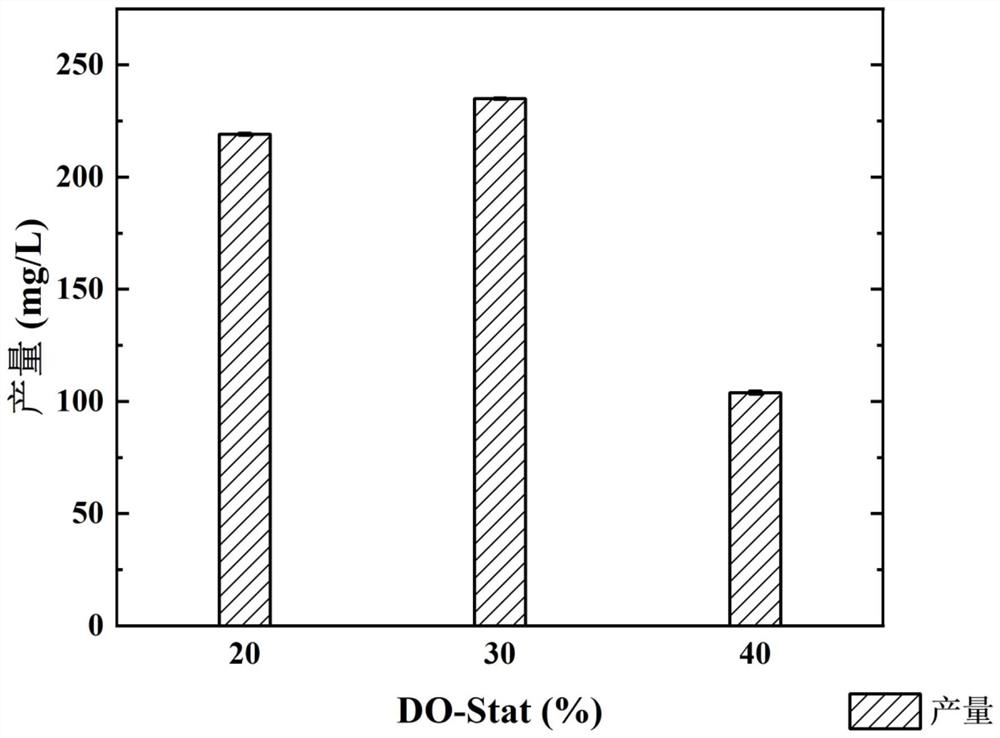

Fermentation method for improving porcine myoglobin produced by pichia pastoris engineering bacteria

ActiveCN113186147APromote growthEfficient expressionFungiHaemoglobins/myoglobinsPichia pastorisBiomanufacturing

The invention discloses a fermentation method for improving porcine myoglobin produced by pichia pastoris engineering bacteria, and belongs to the technical field of bioengineering. According to the method disclosed by the invention, porcine myoglobin-producing pichia pastoris engineering Pichia pastoris X33-GAP-Mb is taken as an original strain, and a culture medium and culture conditions are preliminarily optimized at a shake flask level. The Pichia pastoris X33-GAP-Mb and Pichia pastoris X33-G1-Mb are adopted as starting strains, fermentation condition optimization is performed at the fermentation tank level; it is found that when the DO is 30% and the heme fed-batch concentration is 150 mg / L, the pig myoglobin yield can be significantly increased, and can achieve 285.42 mg / L. The biological manufacturing of the porcine myoglobin has the advantages of low pollution, high product quality and the like, has a development prospect, and has important application significance on the industrial production of the porcine myoglobin.

Owner:JIANGNAN UNIV +1

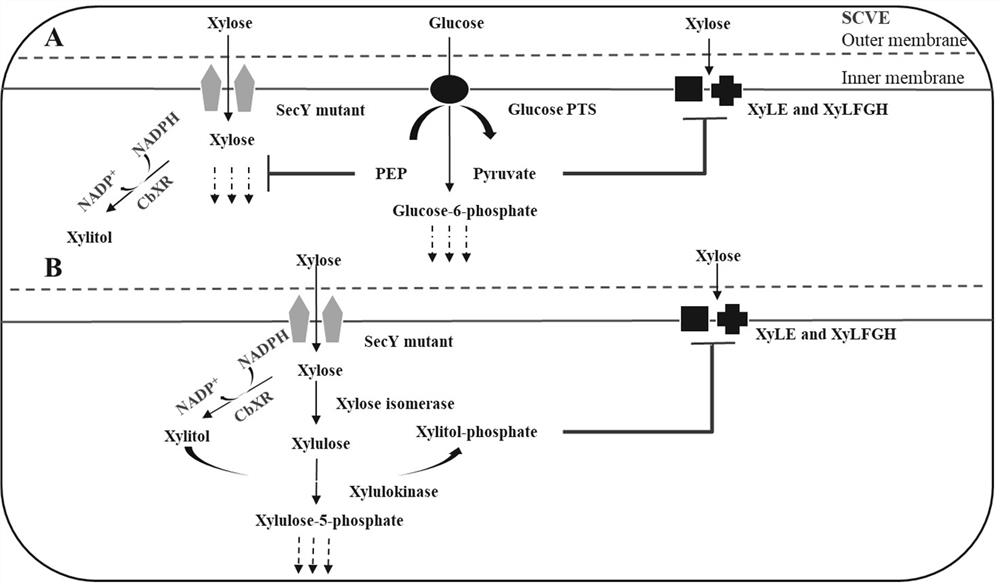

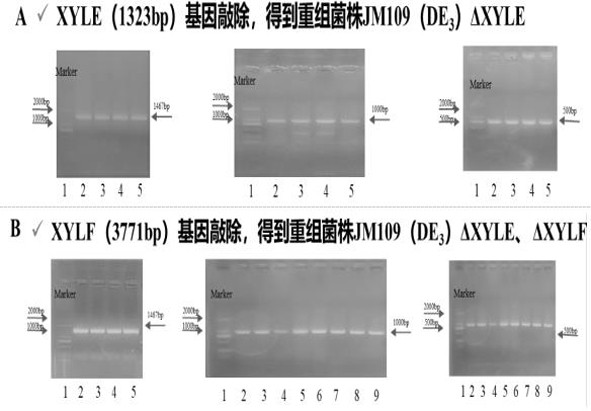

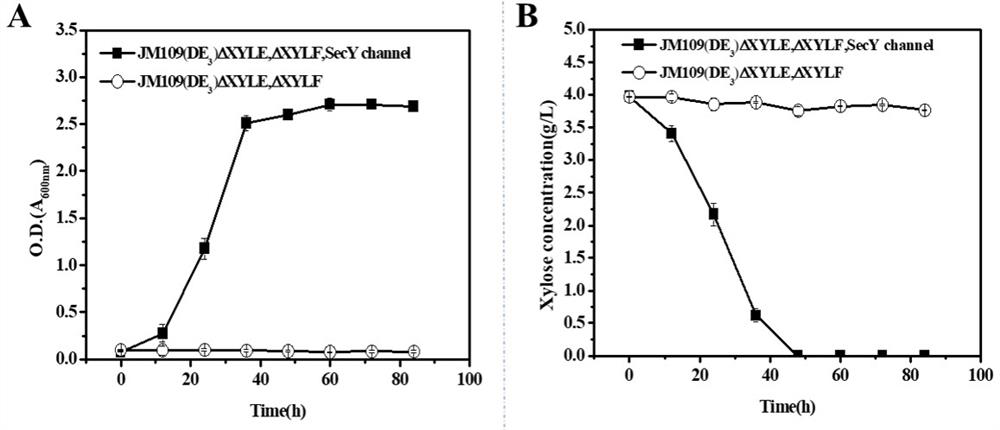

Intelligent regulation and control method for carbon metabolism flow of xylitol produced by escherichia coli

ActiveCN113293121ADisinhibition effectProduction constraintsBacteriaMicroorganism based processesEscherichia coliHeterologous

The invention provides an intelligent regulation and control method for carbon metabolism flow of xylitol produced by escherichia coli, and aims to realize efficient synthesis of xylitol in a process of preparing xylitol by utilizing a cell factory. According to the invention, a strain of SecY engineered Escherichia coli is successfully constructed by introducing a SecY non-specific sugar transport channel and simultaneously overexpressing heterologous xylose reductase (CbXR). The strain can overcome the CCR effect through self-regulation and relieve the inhibition effect of the 5-phosphate xylitol on xylose transported by the strain. By taking the change of an external carbon source as a response signal, the CCR effect and the inhibition effect of the xylitol 5-phosphate are converted into two important regulating switches in a carbon metabolism network, and the metabolic capability of cells on glucose and xylose is regulated. The method can completely metabolize glucose and xylose in any proportion in a substrate, ensures the maximum conversion efficiency of energy to a target product, and better meets the requirements of green biological manufacturing.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com