Antibacterial fermentation additive based on covalent organic framework material and preparation and application thereof

A covalent organic framework and additive technology, applied in the fields of microbiology, material chemistry and biology, can solve problems such as bacterial contamination, achieve the effects of improving stability, avoiding economic losses, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

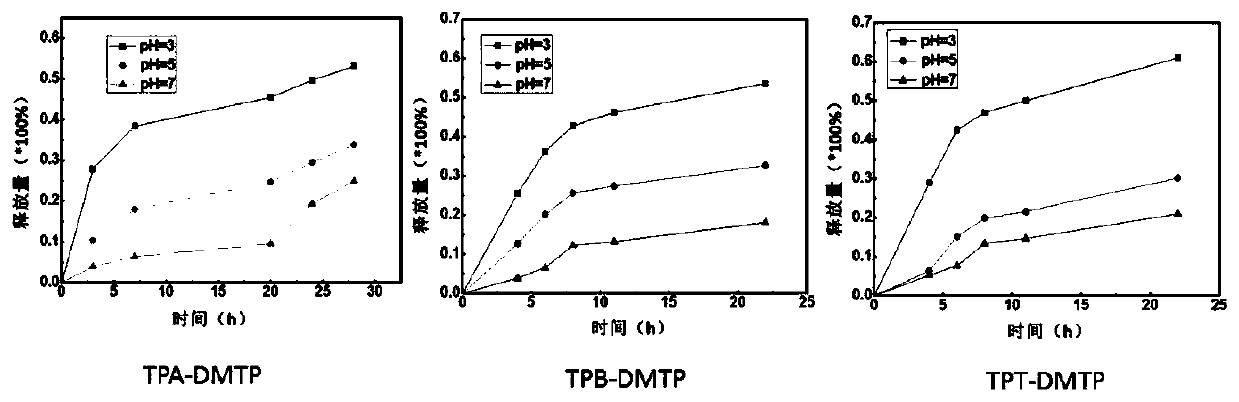

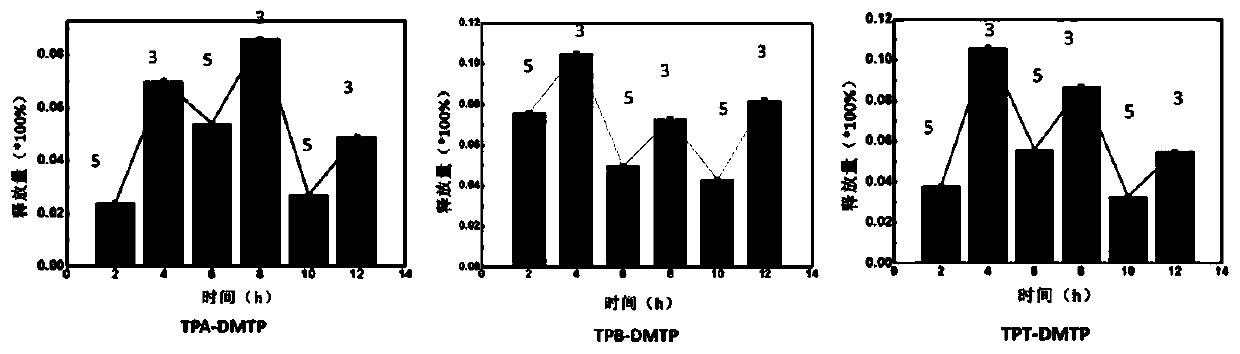

[0029] Embodiment 1: The synthesis of covalent organic framework materials TPA-DMTP, TPB-DMTP, TPT-DMTP used for loading, the specific implementation steps are as follows:

[0030] TPA-DMTP: Weigh the ligands tris(4-aminophenyl)amine (TPA 11.6mg) and 2,5-dimethoxybenzene-1,4-dicarbaldehyde (DMTP 11.7mg) and add them to thick-walled heat-resistant Add 0.2mL o-dichlorobenzene, 0.8mL n-butanol and 0.2mL, 3M acetic acid to the glass tube, then quickly freeze in liquid nitrogen, then vacuumize, and then seal the tube with a flame of an oxygen hydrogen machine. Put the sealed glass tube in an oven at 120°C for 3 days.

[0031] TPB-DMTP: Weigh the ligands 1,3,5-tris(4-nitrophenyl)benzene (TPB 14,1 mg) and 2,5-dimethoxybenzene-1,4-dicarbaldehyde (DMTP 11.7mg) into a thick-walled heat-resistant glass tube, then add 0.6mL o-dichlorobenzene, 0.6mL n-butanol and 0.25mL, 3M acetic acid, then quickly freeze in liquid nitrogen, then vacuumize, and then use a hydrogen oxygen machine flame S...

Embodiment 2

[0035] Example 2: Adsorption of covalent organic framework materials for nisin

[0036] Weigh 10 mg of COFs material and traditional inorganic material SBA-15, add 5 mL of nisin buffer solution containing 0.5 mg / mL directly, shake on a shaker at 37 ° C, take supernatant at regular intervals, and use BCA protein quantification method to quantify The amount of nisin contained in the supernatant was used to calculate the amount of nisin adsorbed by the material, and the final adsorption amount is shown in Table 1.

[0037] Table 1 Adsorption capacity of materials

[0038]

Embodiment 3

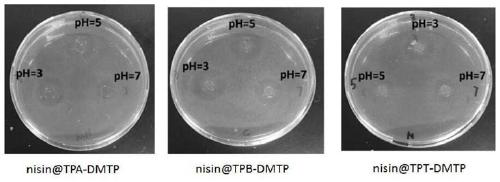

[0039]Embodiment 3: MIC antibacterial test

[0040] Bacterial solution preparation: Pick a single colony of Lactobacillus brevis from the plate and inoculate it into MRS liquid medium, culture at 37°C for 10 hours, and count. Preparation of the porous frame material suspension: weigh a certain amount of the porous frame material compound, put it on a ultra-clean workbench and irradiate it with an ultraviolet lamp for 30 minutes. Prepare several sterile test tubes and mark them. Use the MRS liquid medium to prepare the material into a series of suspensions with different concentrations, place them in centrifuge tubes, and inoculate Lactobacillus brevis so that the concentration of the suspension is 1×10 7 ~2×10 7 CFU / mL (CFU / mL: total number of microbial communities per milliliter of liquid). The control group was sterile liquid medium, liquid medium after inoculation and material suspension without inoculation. Put it on a shaker at 37°C and 150rpm for cultivation, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com