Patents

Literature

55 results about "Industrial Additive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating lignocellulose raw material through steam explosion and producing biogas, cellulose and lignin simultaneously

InactiveCN102051383ASolve the problem of component separationAchieve separationWaste based fuelFermentationHigh concentrationIndustrial Additive

The invention relates to a method for treating lignocellulose raw material through steam explosion and producing biogas, cellulose and lignin simultaneously. The traditional utilization of the lignocellulose raw material only uses a single component and aims to produce a single product, thus the function of each component can not realized and the economic benefit is low. The method in the invention uses the steam explosion technology as a core, wherein hemicellulose, cellulose and lignin are separated from the lignocellulose raw material for high-value use. The method comprises the following steps: performing steam explosion on the lignocellulose raw material; degrading hemicellulose to soluble sugar; extracting soluble sugar with water for biogas fermentation, wherein lignin and cellulose are easy to separate when hemicellulose is removed; extracting high-concentration lignin with low concentration base; and leaving high concentration cellulose when hemicellulose and lignin are removed. The biogas produced by the method has low sulfur content and can be directly used; the extracted lignin can be used to produce resins, adhesives, rubber industry additives and the like; cellulose can be used for papermaking and preparing products such as polyol, carboxymethyl cellulose, cellulose acetate and textile fibre. By adopting the method in the invention, the biomass of lignocellulose can be completely utilized and no pollutant is discharged; and the method is easy for industrialization operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

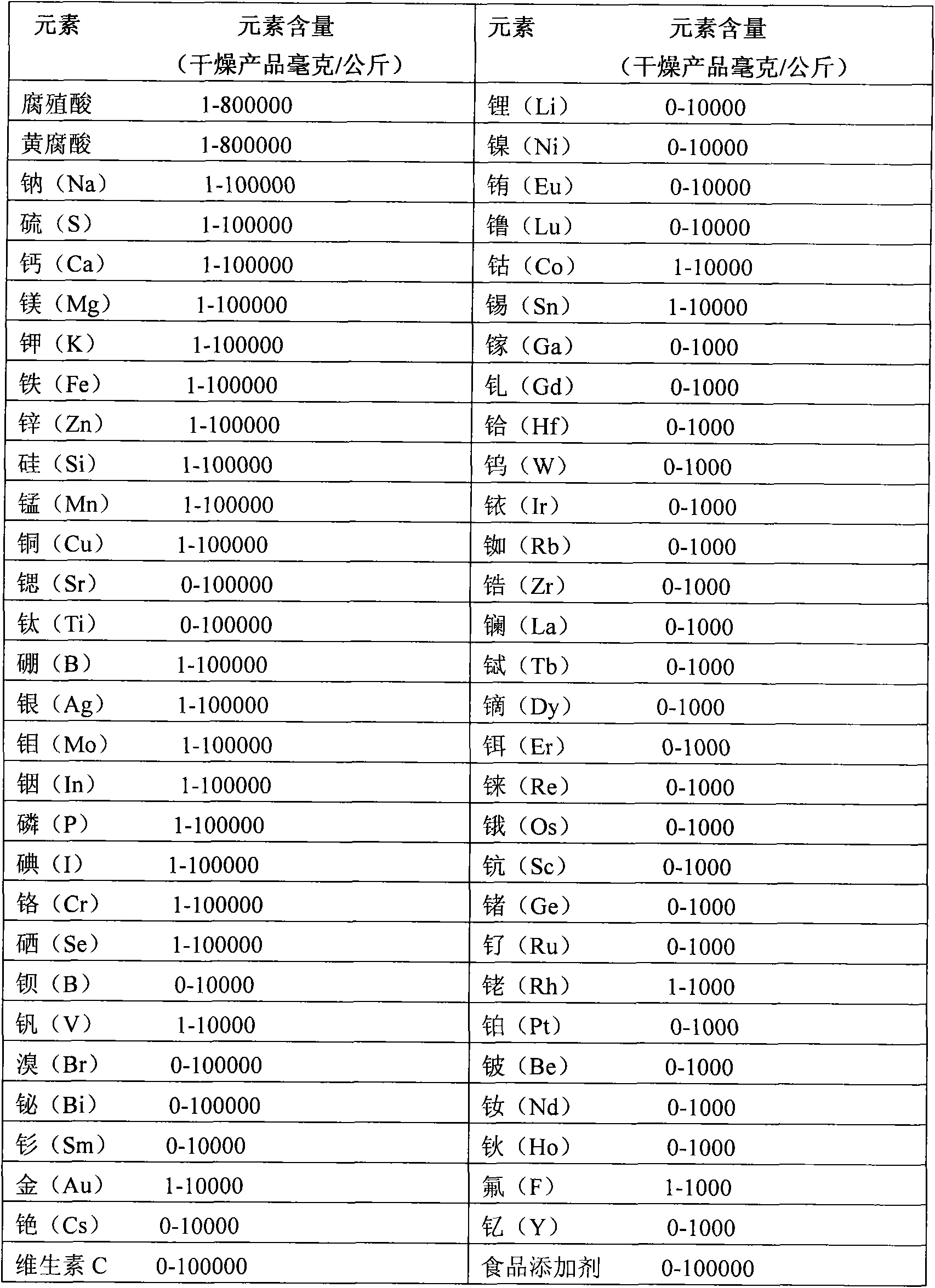

Production method and application of humic acid and fulvic acid extracted from humus and organic salts of mineral compounds thereof

The invention discloses a method for extracting humic acid and fulvic acid from humus, which comprises the following steps: adopting the humus containing mineral substances as a natural source; preparing an alkaline extractant, the pH of which is between 8 and 13; and then, according to the total weight of extracting liquid, computing and adding the humus containing the mineral substances, whereinthe weight percentage of the humus is 10w / w%-30w / w%; stirring the liquid at the temperature of 30 DEG C-80 DEG C; after a determined time and when the liquid is stirred to reach a determined temperature, adding 50w / w% of hydrogen peroxide (H2O2), the weight percentage of which is 2%w / w%-8%w / w%, and stirring continuously; and after adding the hydrogen peroxide, carrying out solid-liquid separationand purification on the extracting liquid to obtain clear extracting liquid. The humic acid and the fulvic acid and the organic salts of the mineral compounds thereof obtained by the method of the invention can be widely applied to the application of the humus in agriculture, veterinary science, environmental protection, industrial additive, medicine and food additive, thereby having positive practical significance to nutrition supplement, nutrition absorption and health of human beings.

Owner:唐毅

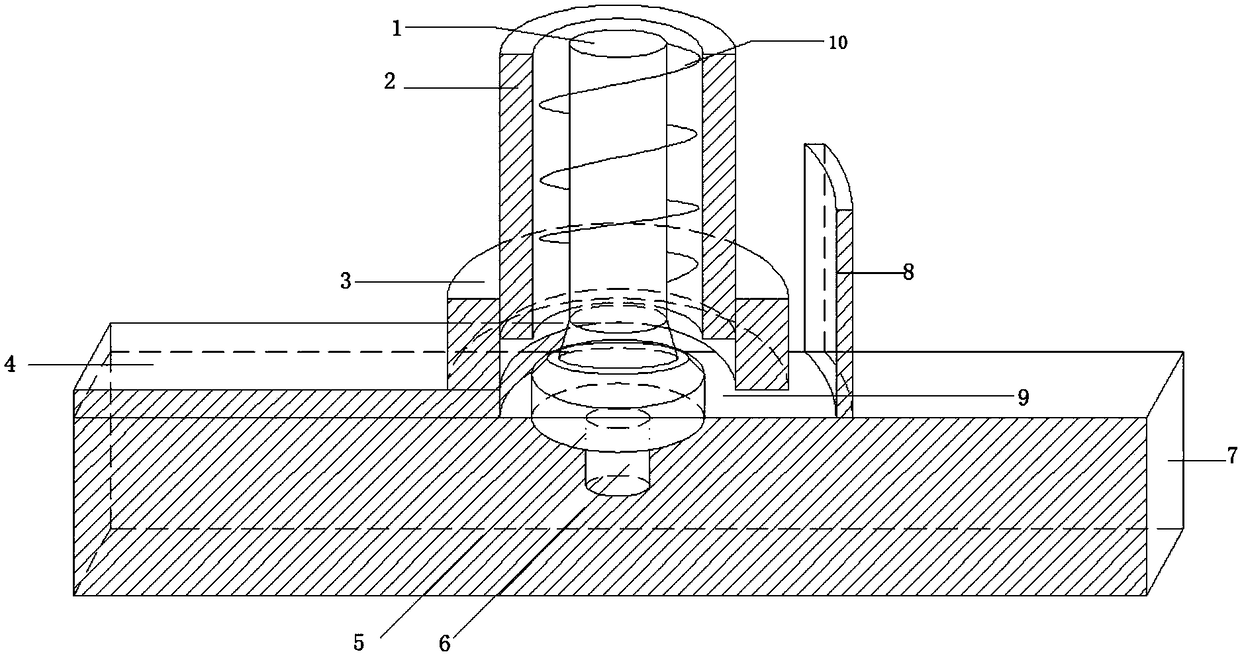

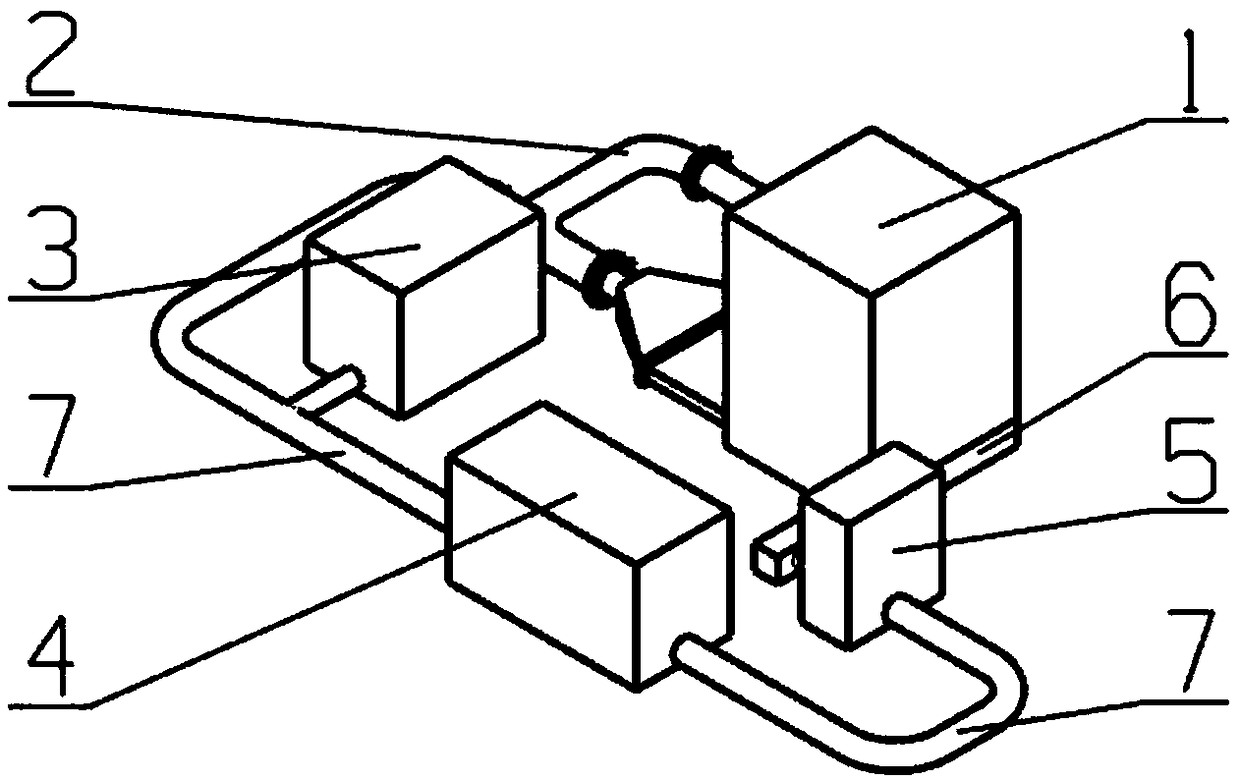

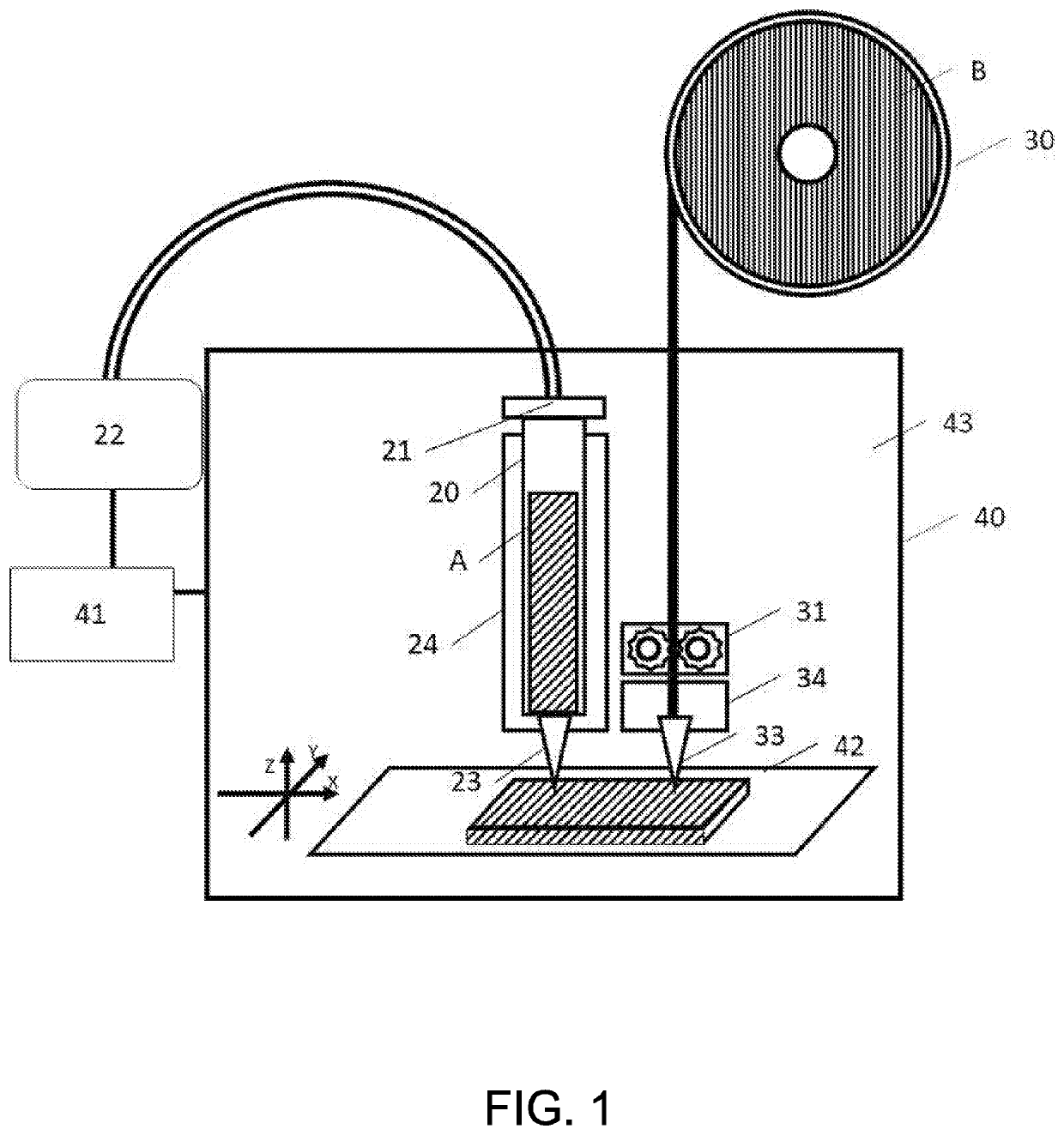

Novel stir friction additive manufacturing machine

InactiveCN108161448AHigh strengthSimplify the manufacturing processOther manufacturing equipments/toolsNon-electric welding apparatusIndustrial AdditiveLaser additive manufacturing

The invention belongs to the field of industrial manufacturing, and provides a novel stir friction additive manufacturing machine. The novel stir friction additive manufacturing machine comprises a powder feeding system, a grinding system, a welding system, a powder outlet and a striker plate. The machine is mainly used for the field of industrial additive manufacturing, the core principle adoptsmechanical friction, and then the cost is low compared with laser additive manufacturing. In the additive manufacturing process, it can be guaranteed that no gap exists in contact of an additive layerand the workpiece surface, the mechanical property of workpieces is greatly improved, and the stability of the workpieces is greatly improved. Therefore, the workpieces obtained after additive manufacturing is uniform in stress in the use process, and the service life is prolonged. Accordingly, the advantages of the mechanics and mechanical design are fully combined, and then the additive manufacturing process is simplified, and the cost is lowered.

Owner:DALIAN UNIV OF TECH

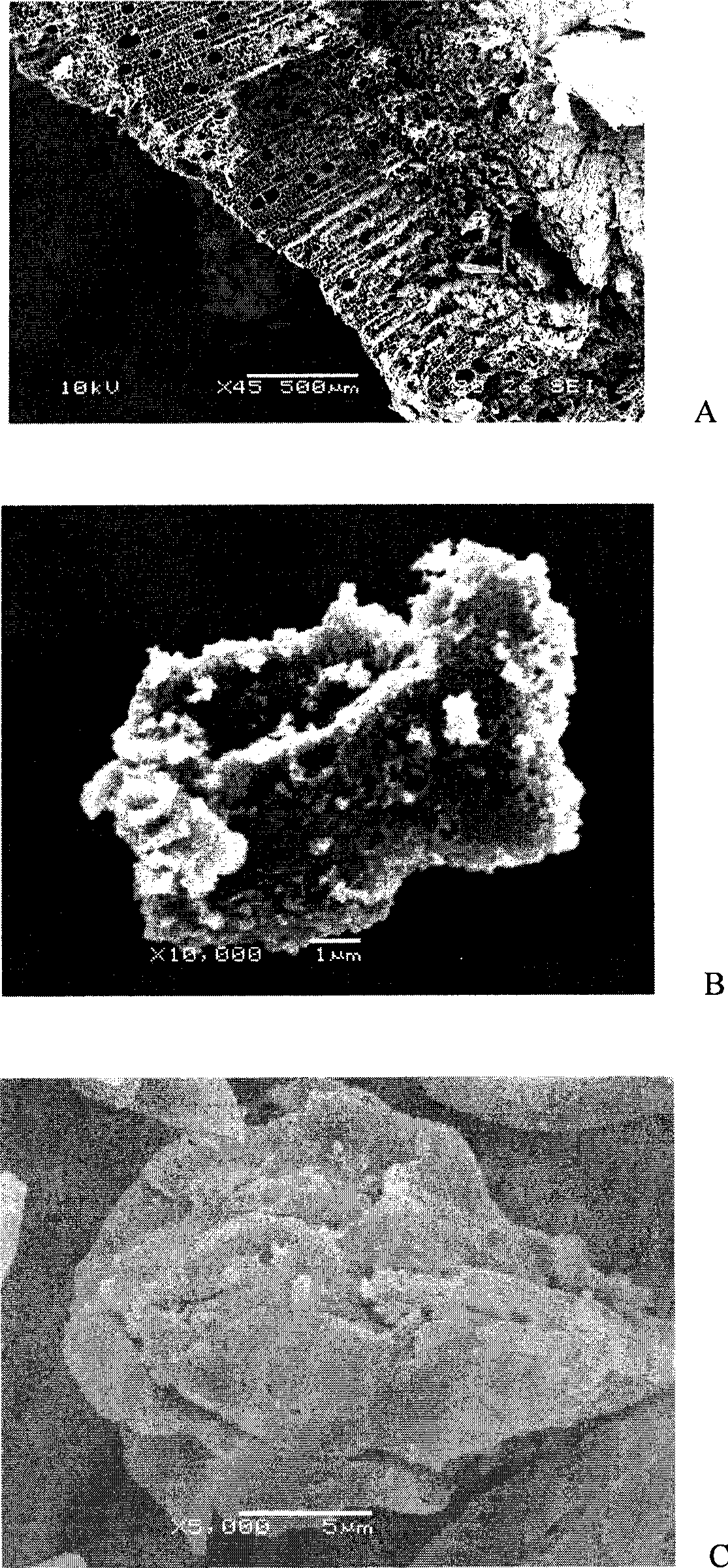

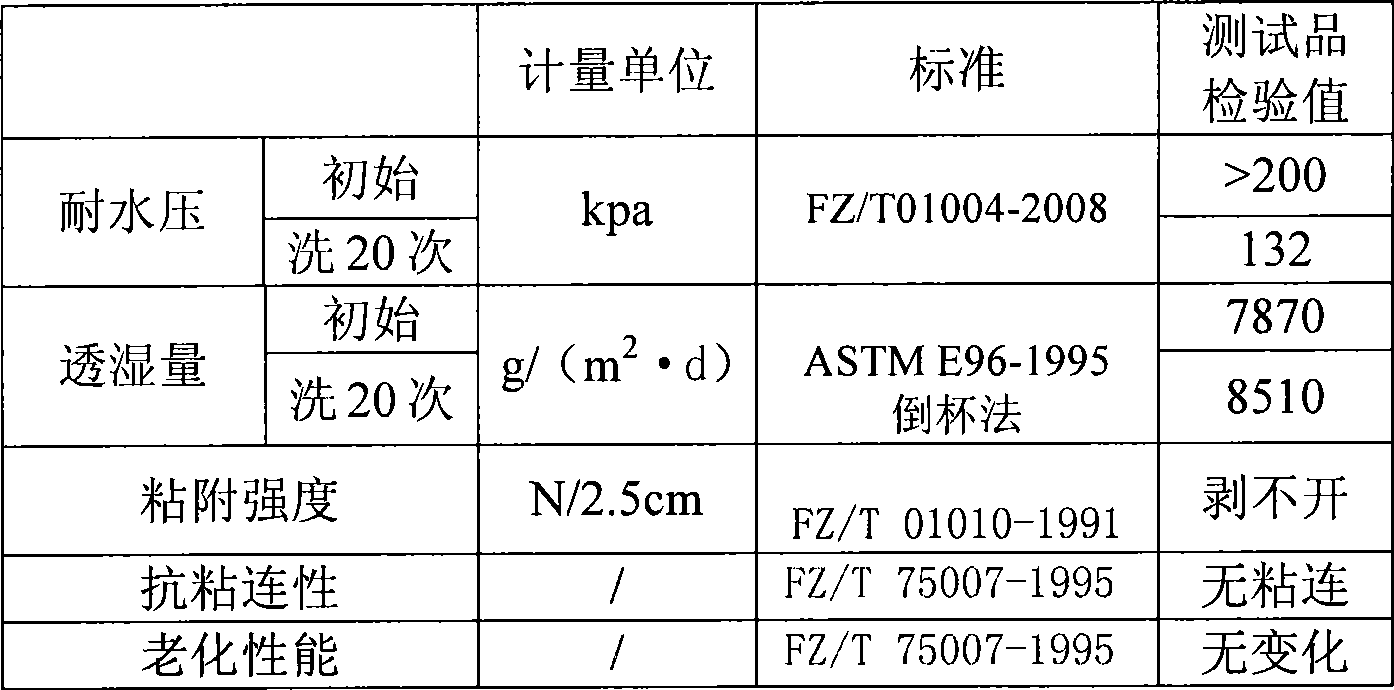

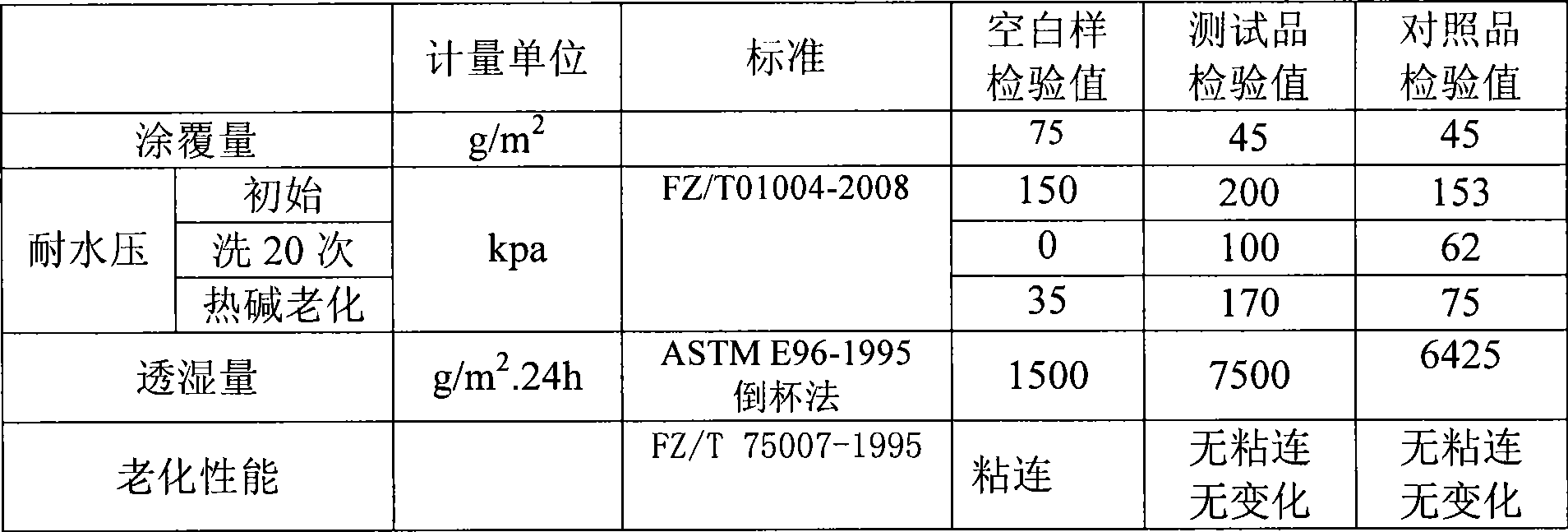

Micropore ligno-cellulose ultramicro powder, as well as preparation method and application thereof

InactiveCN101481459AMaintain microporous structureHigh water pressure resistanceFibre treatmentLignin material coatingsChemical industryCellulose

The invention relates to microporous lignocelluloses submicron powder, the application method and the application thereof, belonging to the chemical industry field. The method takes materials containing microporous lignocelluloses as raw materials which are physically smashed and ground many times. The modification treatment is carried out on intermediate products by a chemical treatment method among each physical smashing and grinding process so as to obtain the submicron powder with the fineness of larger than 500 mesh and about one micrometer of micropores distributed on the powder. The submicron can serve as an industrial additive to be applied to textile functional coating, synthetic leather, paint, leather products coating, can increase the waterproof, moisture absorption, combining fastness and aging resistant performance of the products, has vapor permeability and extensive use.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +2

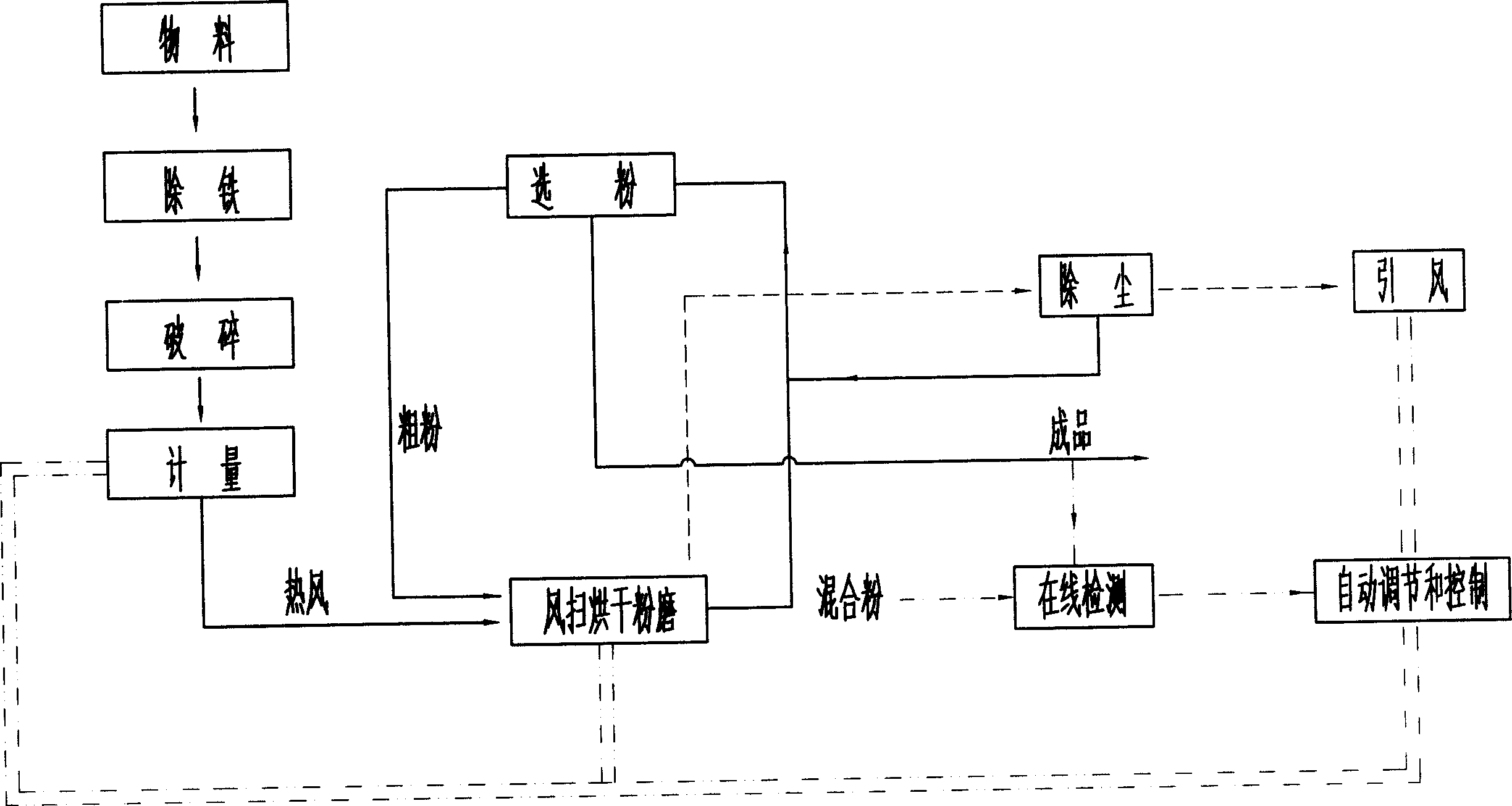

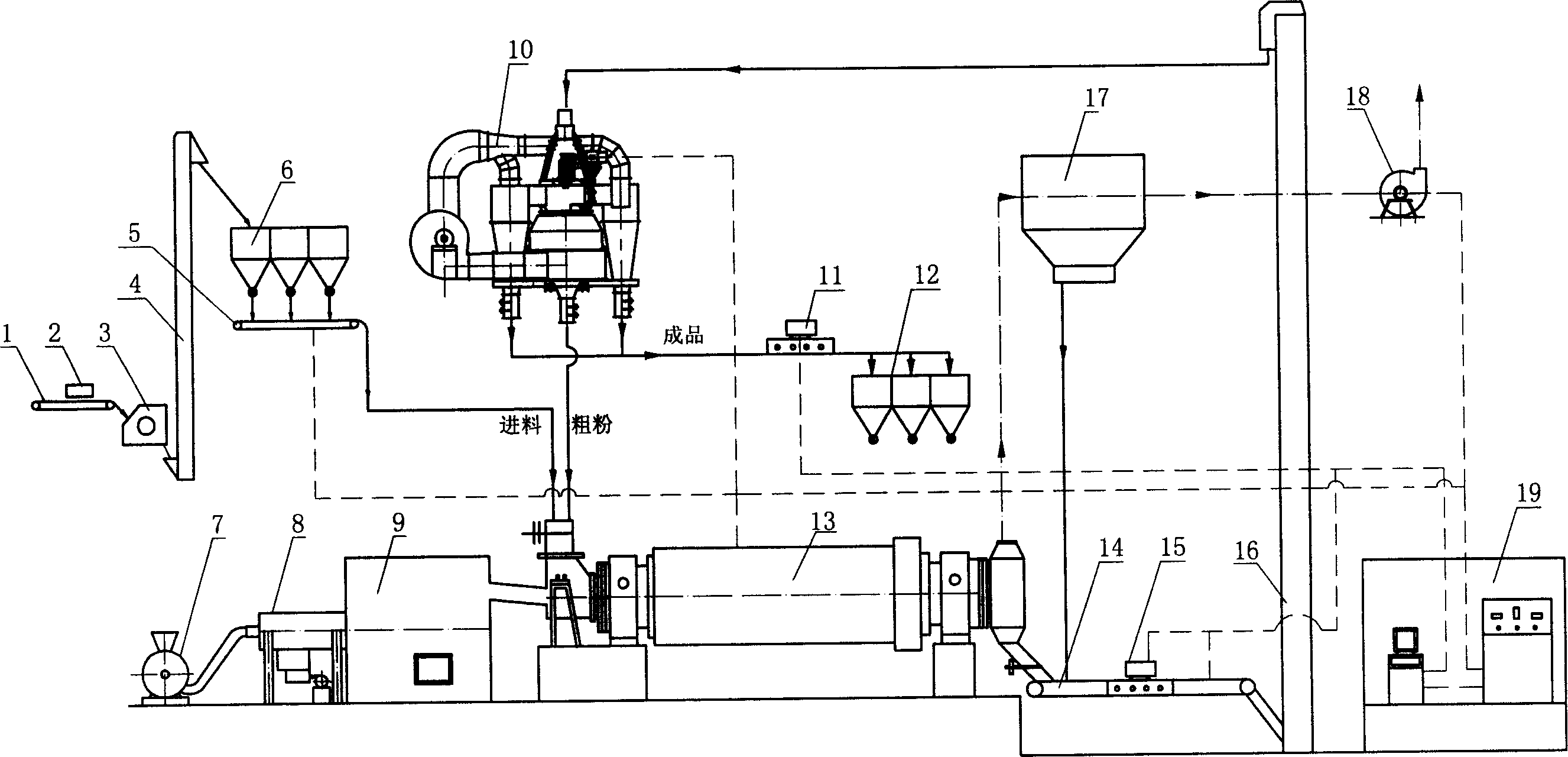

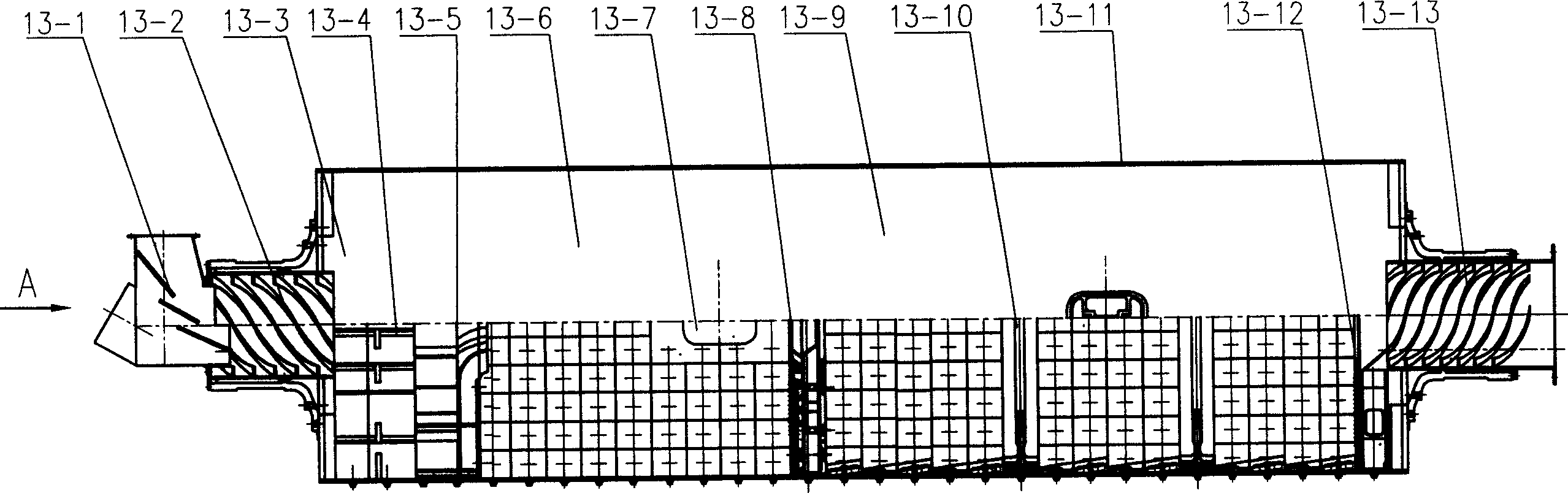

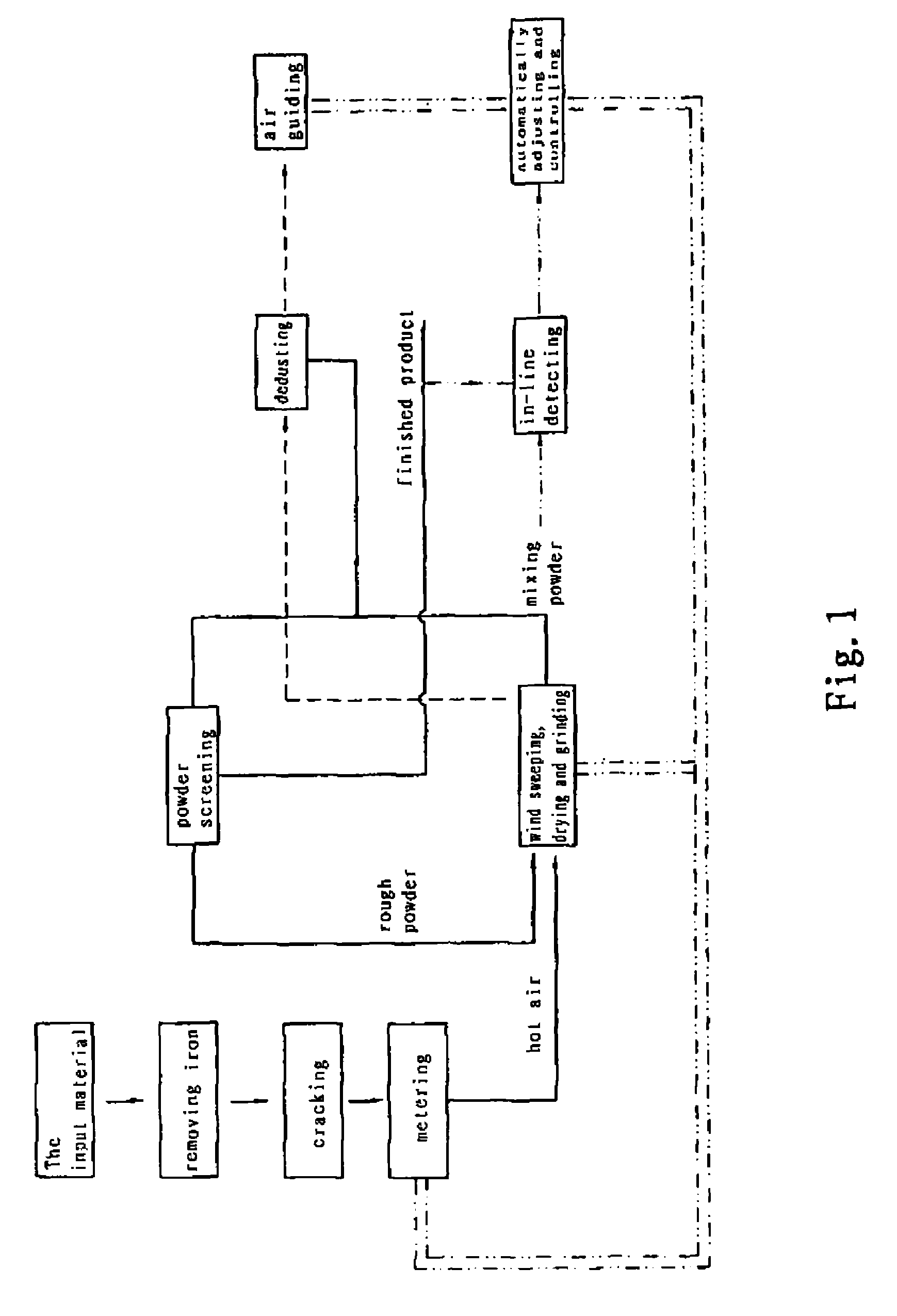

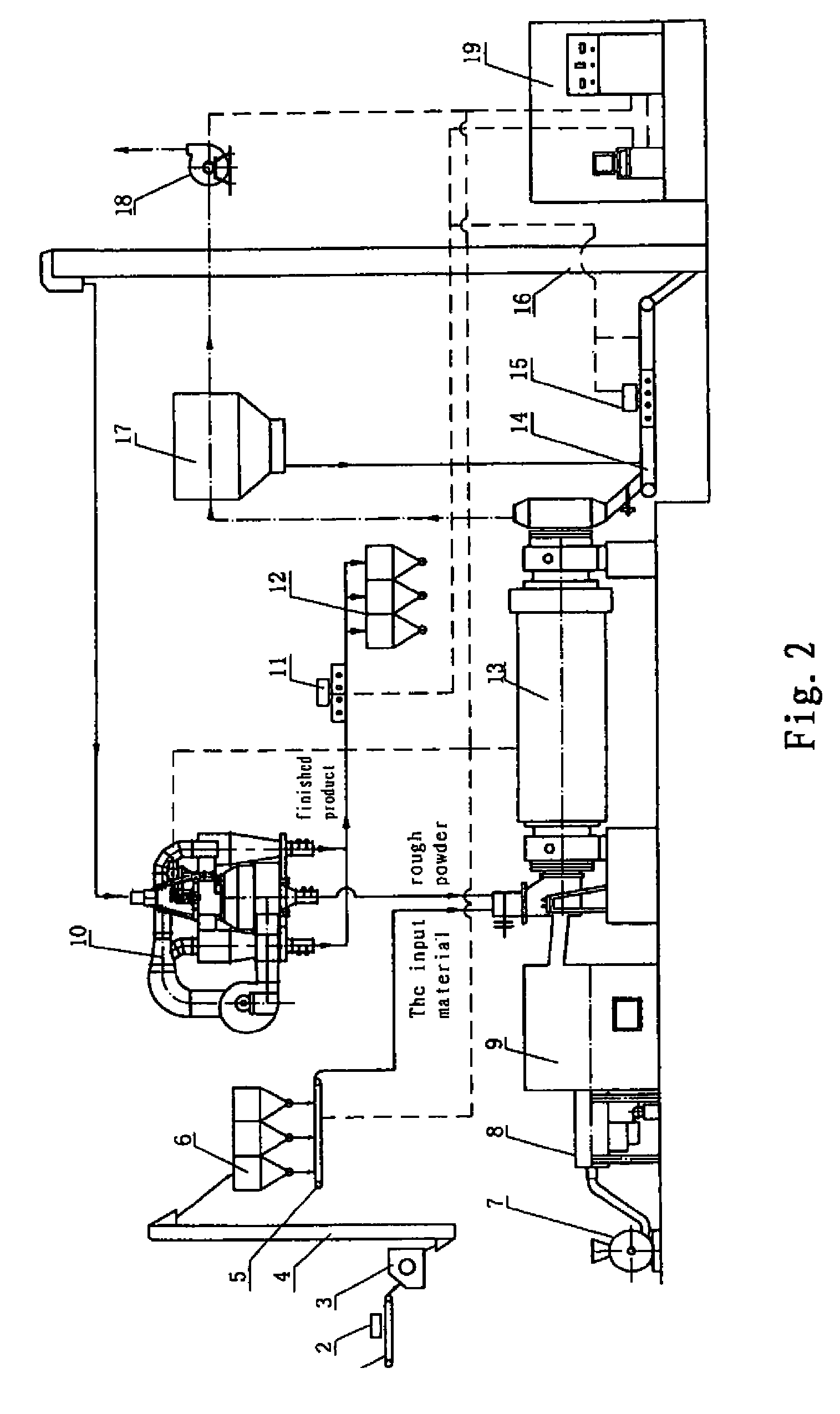

Energy-saving environment-friendly type industrial residue closed-circuit high-yield super-fine mill controlling technique and equipment thereof

InactiveCN1733365ARealize automatic controlRealize regulationSolid separationGrain treatmentsSocial benefitsAutomatic control

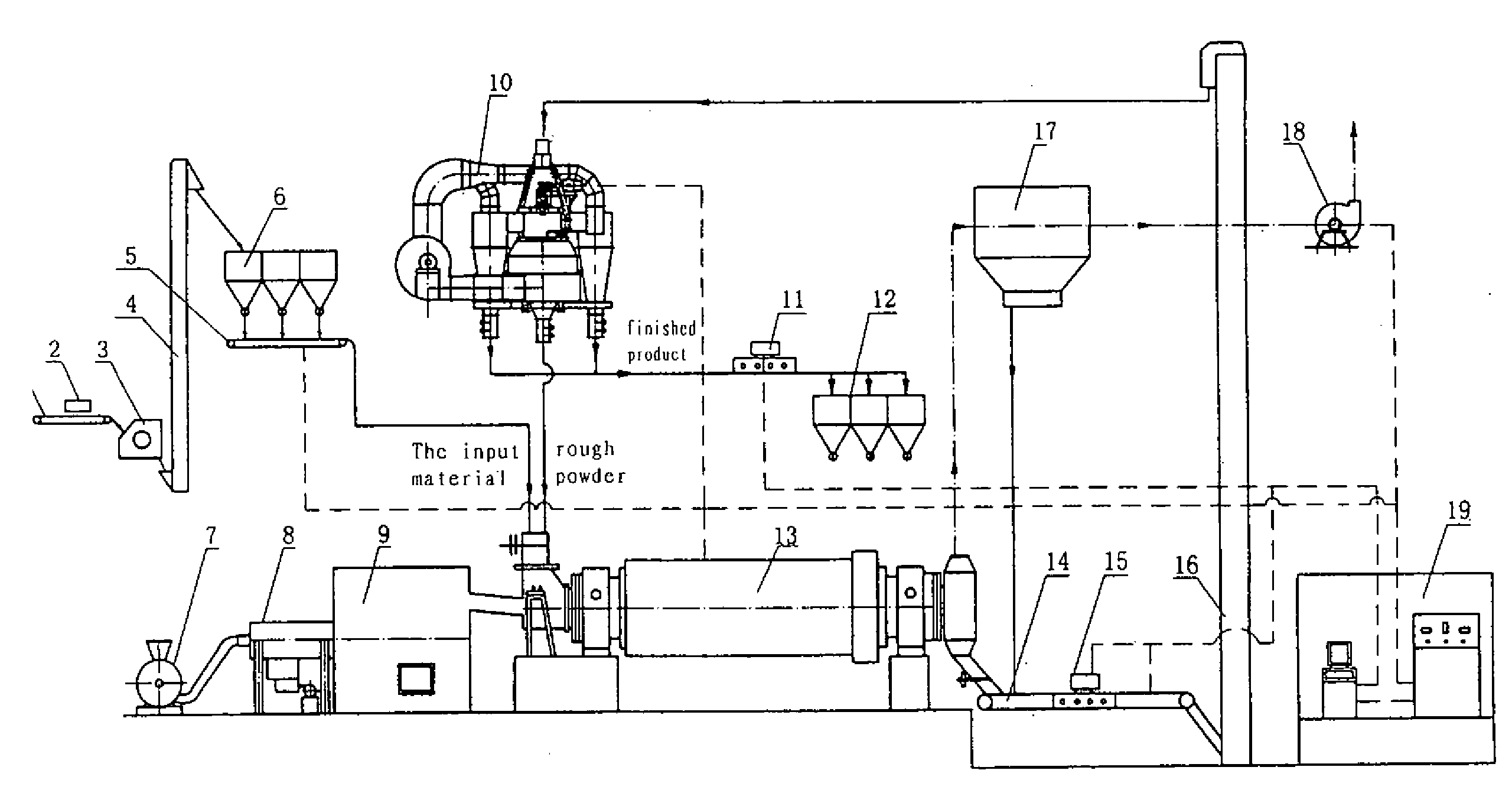

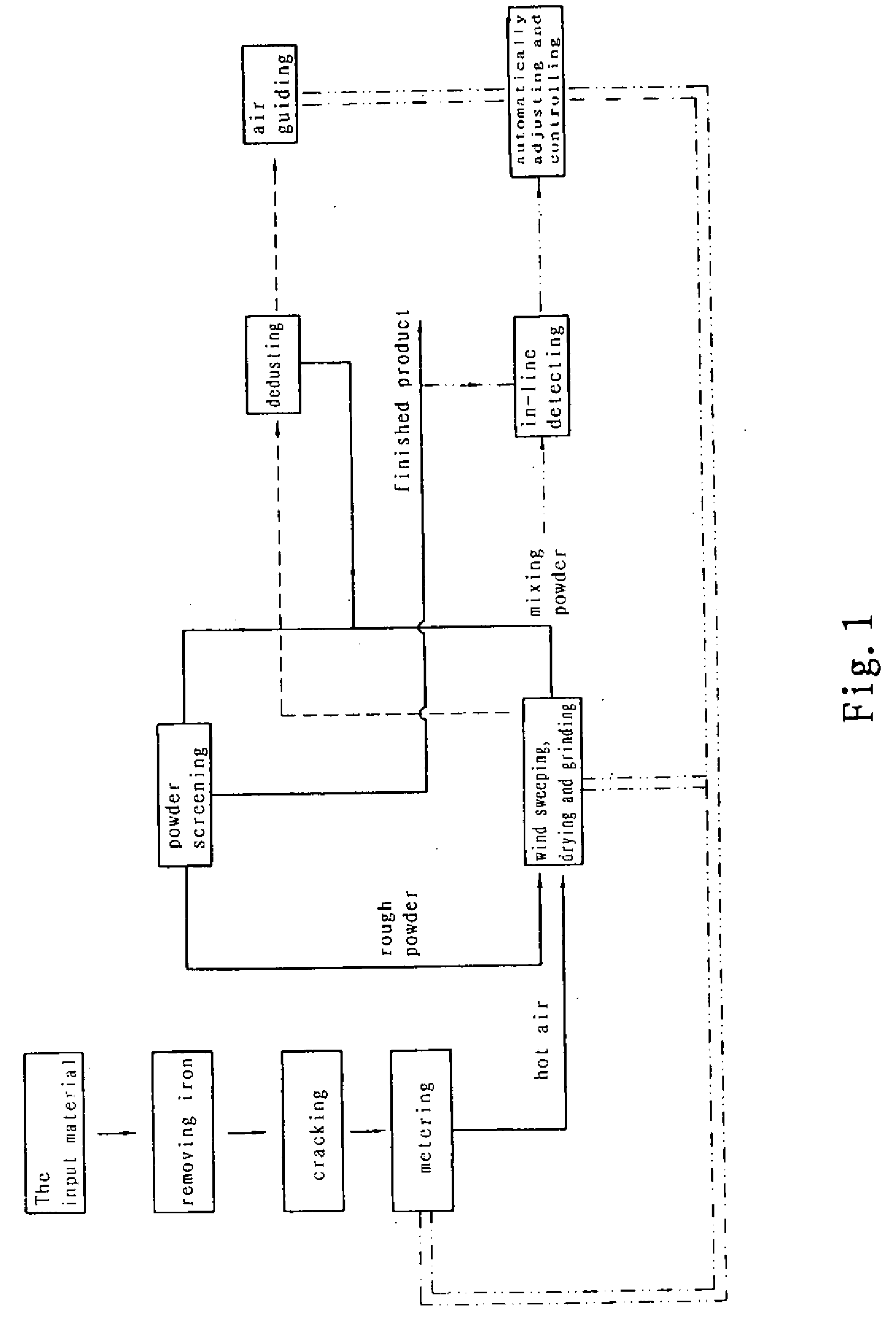

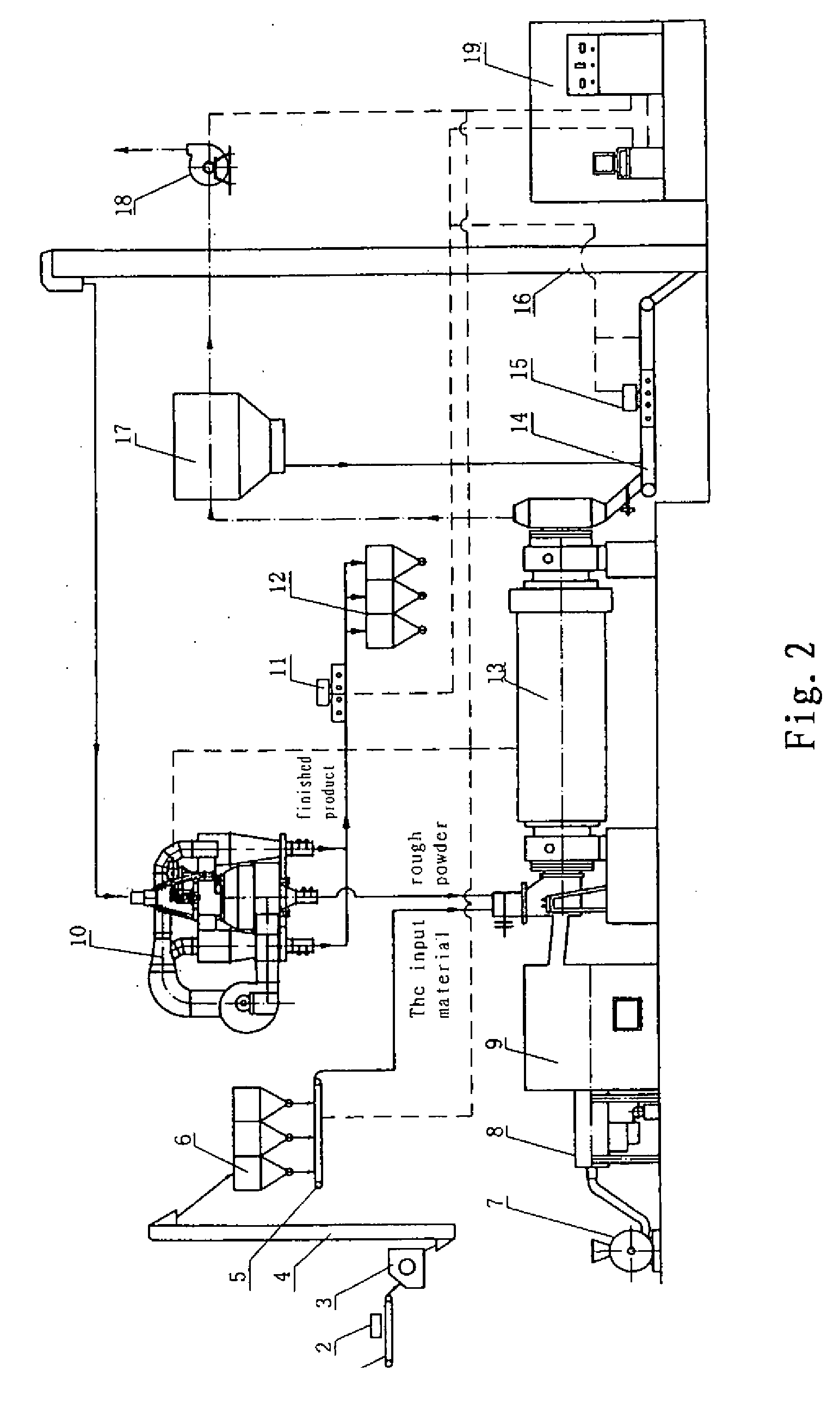

This invention provides energy-saving environmental friend closed-loop high yield high fineness grinding control technique and its device for industrial solid waste. The technique integrates baking and grinding, uses detection on line, adjust and control the parameters automatically. Thereby, the invention cuts process, realizes automatic control and adjustment, increases application value of the said waste and its added value. The equipments comprise added air-swept baking grinder, online laser particle detector, automatic controller, and high-effect powder selector and dust catcher, which decreases occupation of land, investment and energy consumption, increases efficiency and quality, and has well economic and social benefit.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

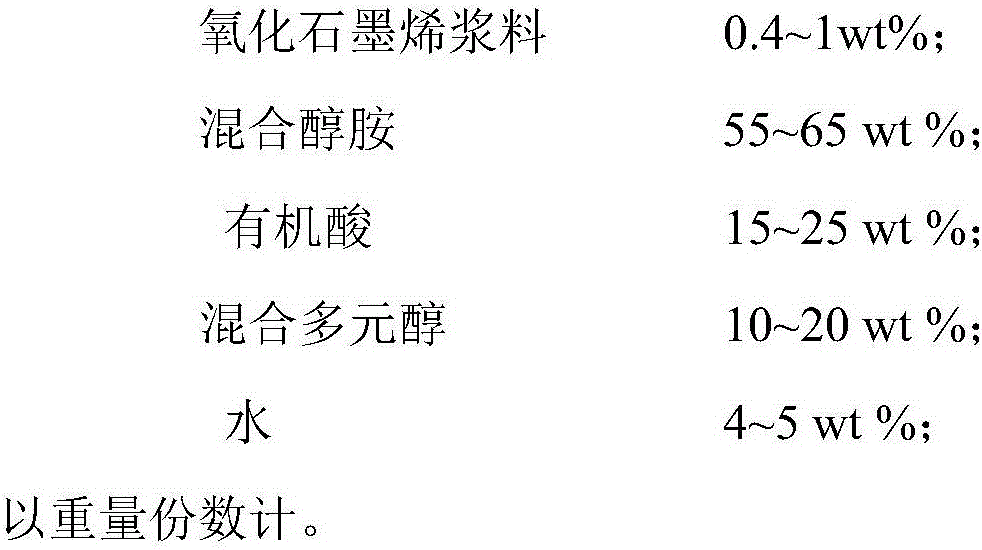

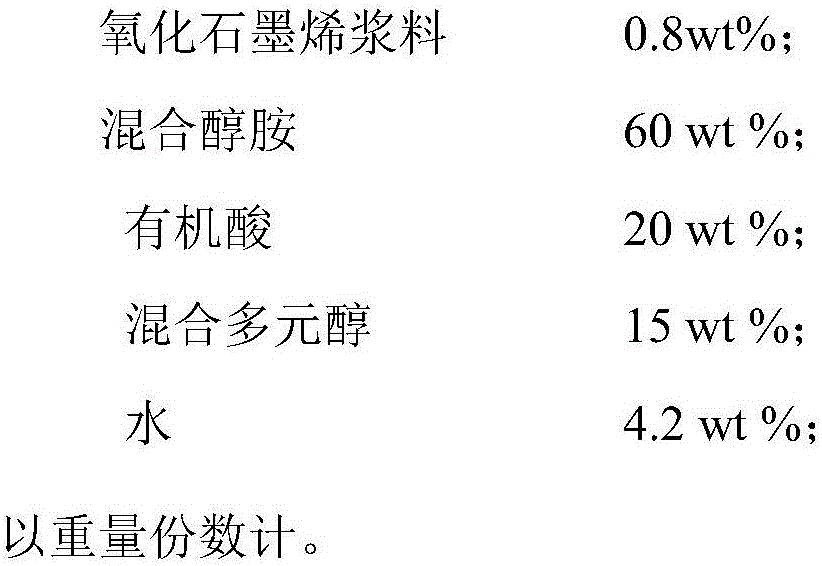

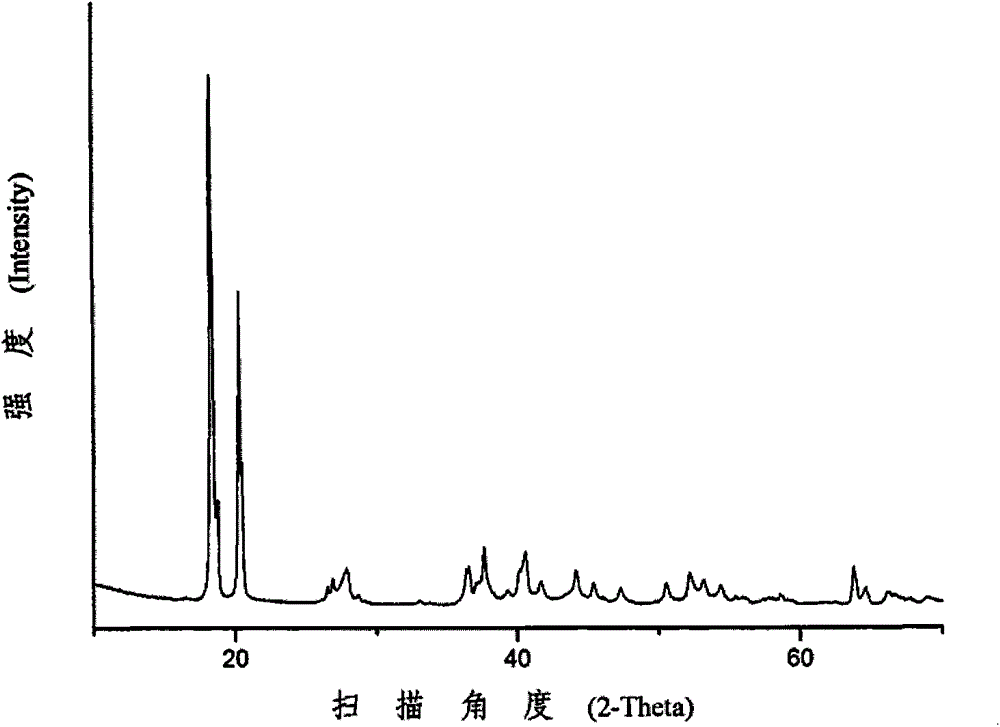

Steel slag activating agent and preparation method and application thereof

ActiveCN106746778ATroubleshoot activation issuesSolve pollutionCement productionSlagIndustrial Additive

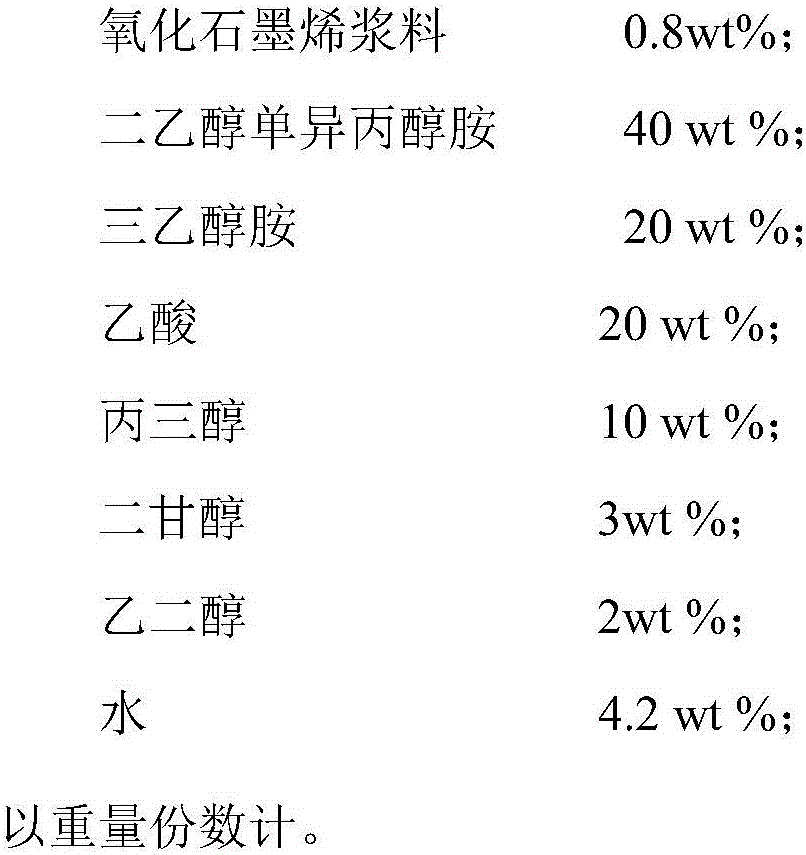

The invention discloses a steel slag activating agent, and belongs to the technical field of industrial additives. The steel slag activating agent is prepared from graphene oxide paste, mixed alcohol amine, organic acid, mixed polyhydric alcohols and water. The steel slag activating agent is applied to steel slag powder grinding, the activating effect is better, the crystals of a steel slag hydration product are induced to orderly grow, the activating property of the steel slag micropowder is improved, and the problem of activating of steel slag micropowder is solved. The steel slag micropowder can be widely applied to cement and concrete industries, the problem of pollution to environments by steel slag is solved, the demand of cement and concrete enterprises on high-quality raw material is relieved, and the market prospect is better. The activating agent has the advantages that the energy consumption in the production phase is little, and the waste gas, waste liquid and waste slag are not produced; the control of production technology is simple, and the rate of finished products is high; compared with the existing production technology, the energy consumption and environment burden are not increased in the powder grinding phase, and the electric consumption of powder grinding is decreased.

Owner:江苏润天建材(集团)有限公司

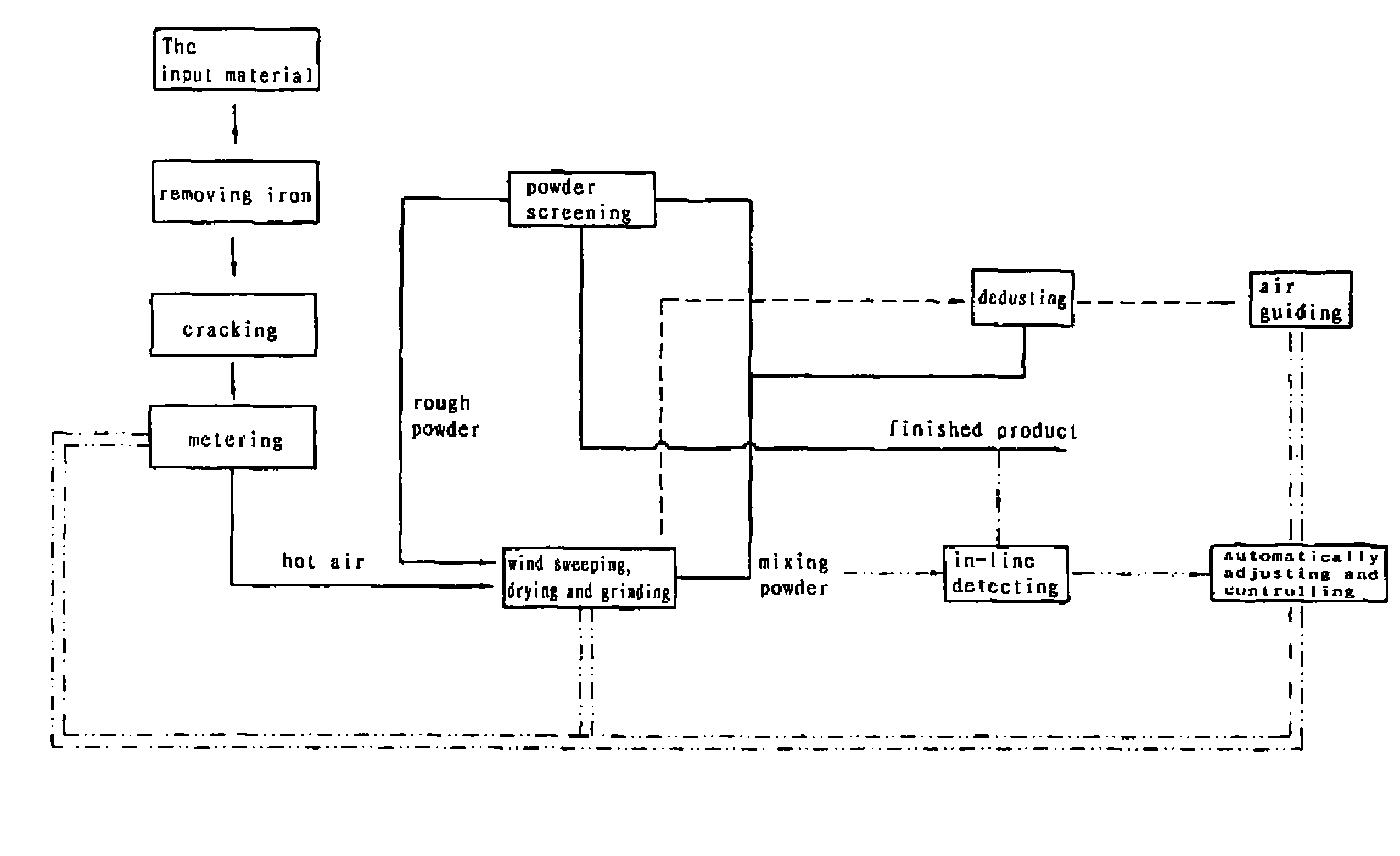

Control method for superfine powder grinding industrial waste slag in an energy-saving and environmental-friendly type of closed cycle with high yield and the apparatus for the same

The present invention provides a control method for superfine powder grinding industrial waste slag in an energy-saving and environmental-friendly type of closed cycle with high yield and the apparatus for the same. The method combines a drying process and a powder grinding process, adopts an in-line monitoring process, automatically adjusts and controls the operating parameters. Therefore, the invention changes the conventional open cycle into a closed cycle, shortens the cycle, achieves the automatic control and adjustment of the operating parameters, and obtains the superfine product with high yield. So the invention enhances the application value of industrial waste slag, extends the applicable field of industrial waste slag, and increases the extra value of final product. The apparatus primarily adds a wind sweeping drying grinder, an in-line laser particle detector, and an automatic control device, furthermore selects a screener and a deduster with high efficiency and product quality and therefore needs less space, investment and energy consumption, improves the work efficiency, the quality of the product and overall efficiency. The apparatus can automatically adjust and control the operating parameters, improve the physical and chemical characteristics of industrial waste slag, and change the industrial waste slag to industrial additive or admixture with good performance; therefore it has good economic and social benefit.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

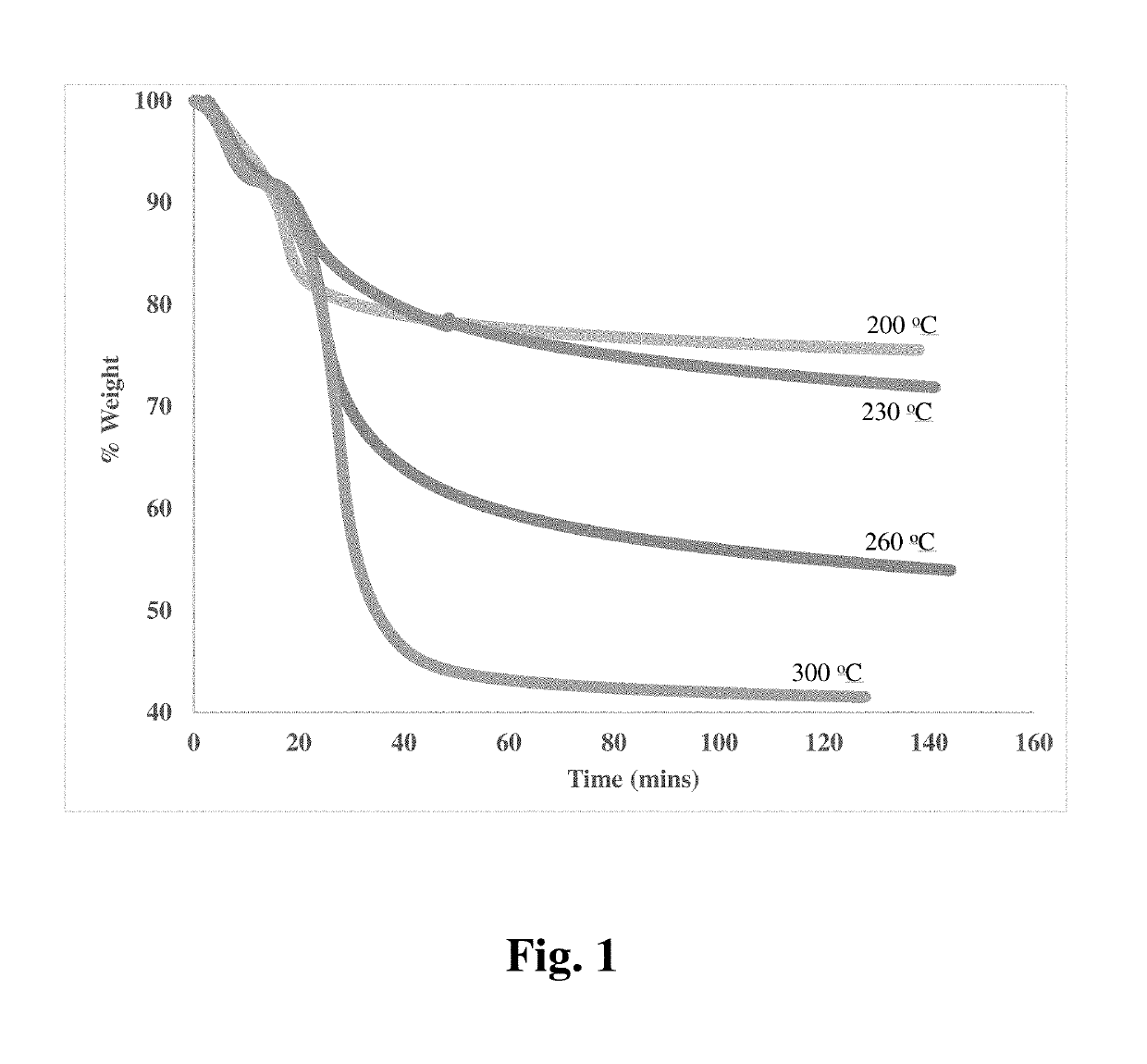

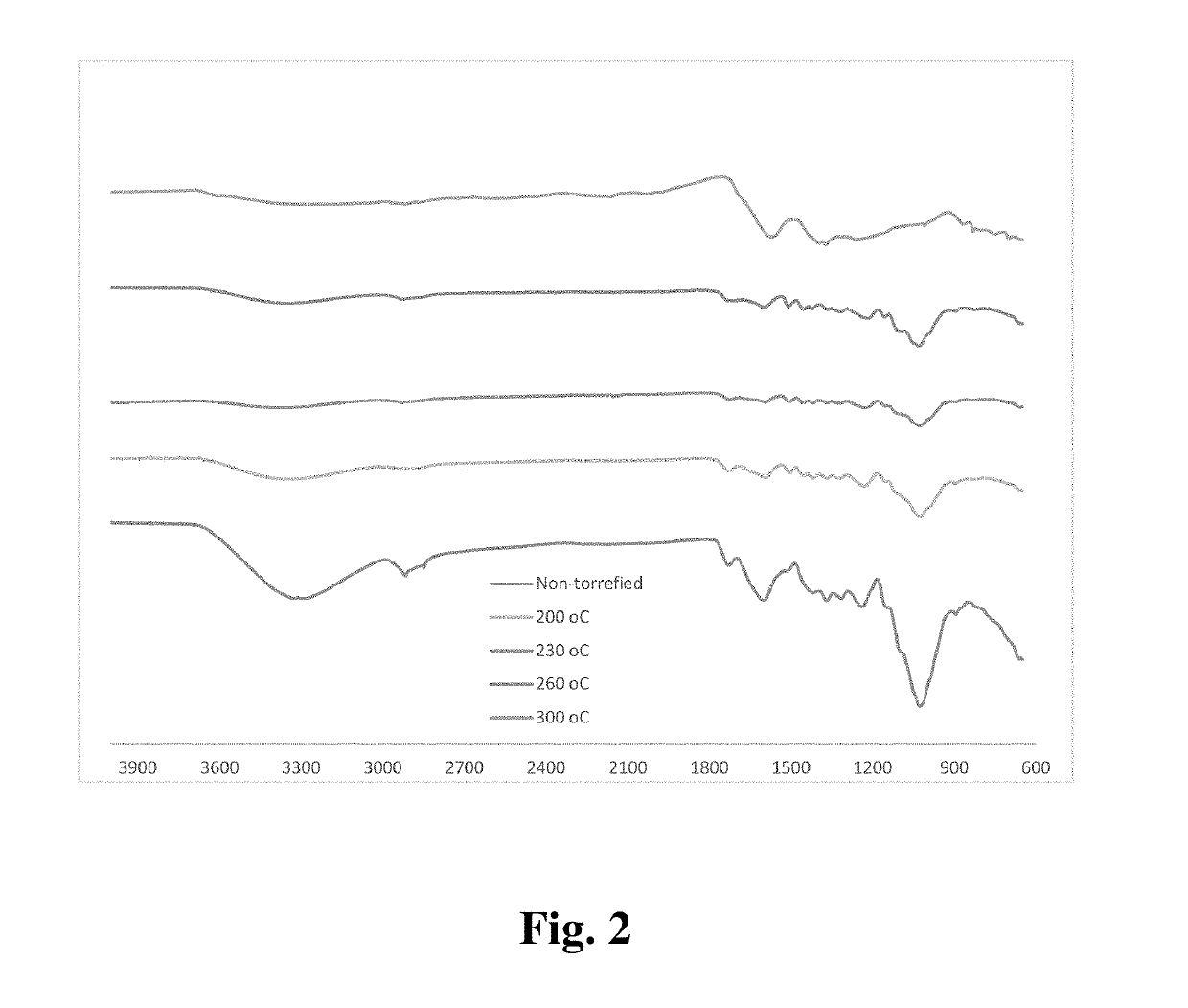

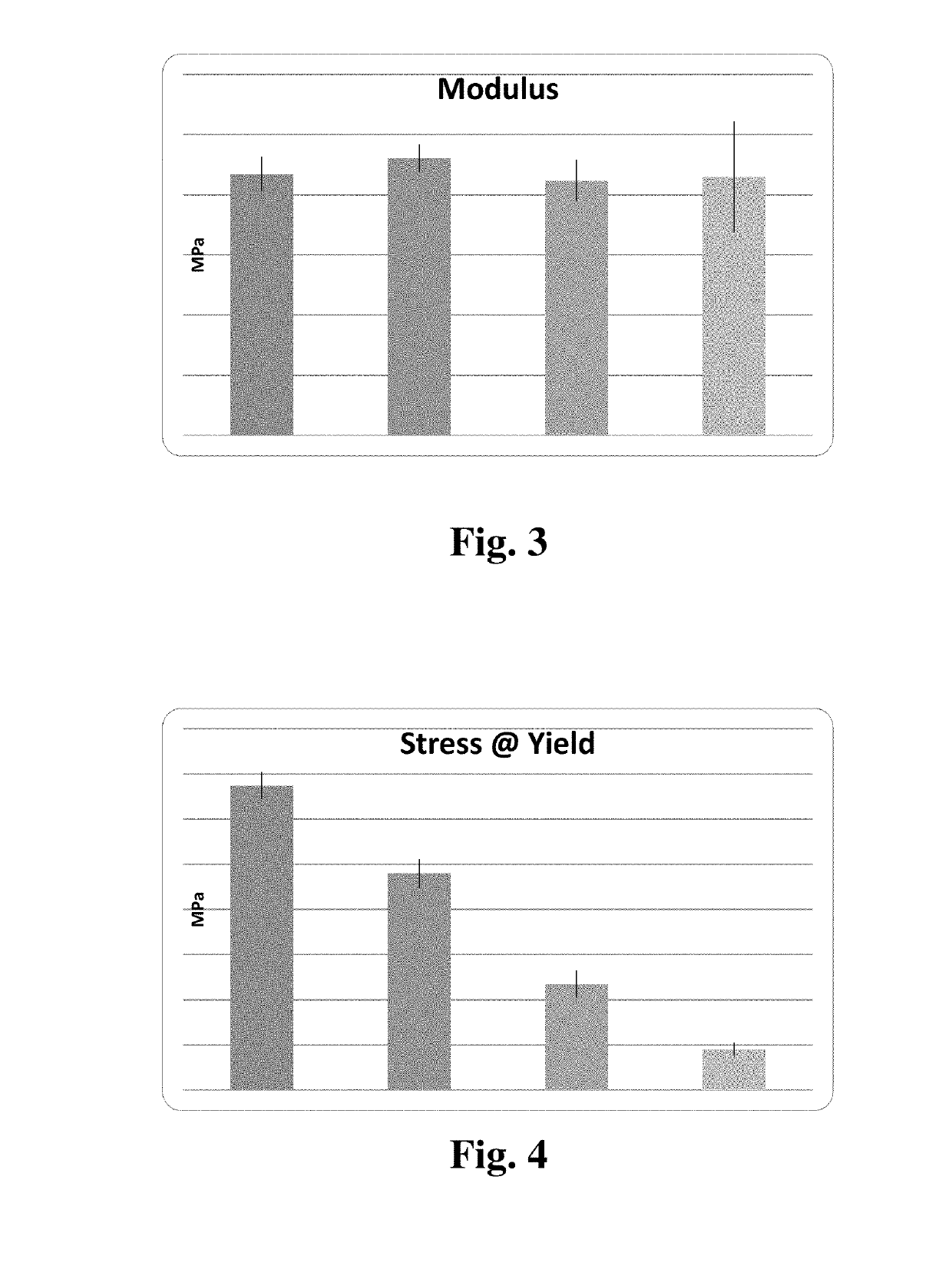

Plastics containing torrefied biomass additives

Plastics (e.g., virgin or recycled or reclaimed) are combined with torrefied biomass to create a composite with surprisingly high heat deflection, good mechanical and barrier properties. The composite provides an alternative to conventional composites which contain industrial additives, fillers, and colorants. The torrefied biomass replaces conventional industrial additives and also provides improvement to diminished properties of recycled or reclaimed plastics. The composites described herein can be incorporated into a variety of end products such as cutlery, containers for packaging, hot server items, hard plastic casings, 3-D printed items, and other items.

Owner:UNITED STATES OF AMERICA

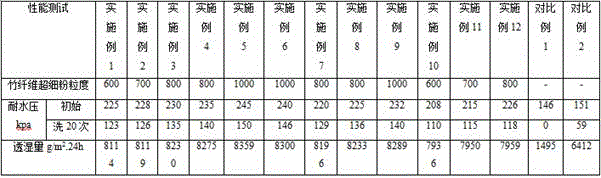

Preparation method and application of bamboo fiber micropowder

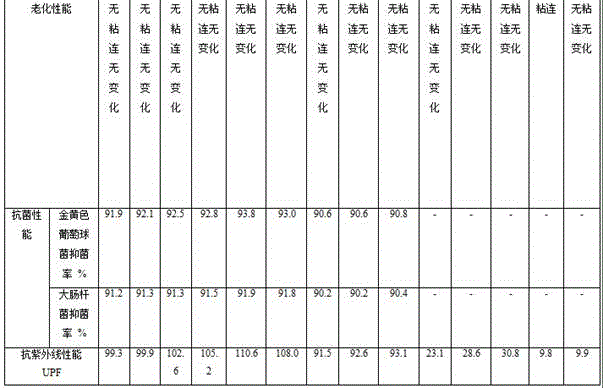

ActiveCN105646823ASolve the antibacterial effect is not goodReduced UV resistanceAntifouling/underwater paintsPaints with biocidesChemical treatmentAging resistance

The invention discloses a preparation method and application of bamboo fiber micropowder. The method comprises the following steps: by using microporous bamboo fiber powder as a raw material, carrying out physical pulverization, and carrying out chemical treatment for modification, thereby obtaining the bamboo fiber micropowder with the fineness of 600 meshes or above. The bamboo fiber micropowder can be used as an industrial additive in paints and various coatings, can enhance the water resistance, moisture penetrability, aging resistance, ultraviolet resistance and mold resistance of the product, and can be added into a paint or varnish to deepen the color of the paint. The bamboo fiber micropowder can also be used in a sol addition material.

Owner:宜兴市华夏化工材料有限公司

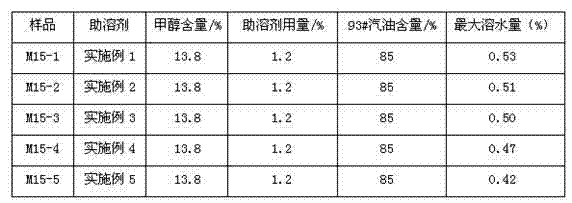

Vehicle methanol gasoline cosolvent

ActiveCN103695052AImprove stabilityStrong solubility aidLiquid carbonaceous fuelsDiacetone alcoholHeptyl alcohol

The invention belongs to the technical field of vehicle fuel oil additives, and relates to efficient vehicle methanol gasoline cosolvent which is a mixture comprising the following seven different alcohols: 3-20 parts of ethylene glycol monobutyl ether oleate, 2-5 parts of diacetone alcohol, 4-10 parts of glycol monoethyl ether, 10-80 parts of butanol, 5-50 parts of pentanol, 5-20 parts of hexanol, 0.5-10 parts of heptanol and 0.5-10 parts of octanol. According to the invention, the cosolvent has high hydrotropy; prepared methanol gasoline can be stored for long time under a low-temperature condition of -30 DEG C, and the water resistance capability is up to 0.5%; and the efficient cosolvent is free of metal and other elements, is reasonable in element variety and has no adverse influence on an engine, and the combustion performance of the cosolvent is approximate to that of gasoline. The efficient vehicle methanol gasoline cosolvent is a brand new technology and product in the field of methanol gasoline, and is of far reaching importance in improving the quality of methanol gasoline and standardizing industrial additive technologies.

Owner:YANKUANG GRP CO LTD +1

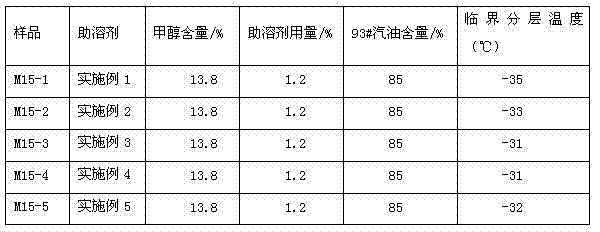

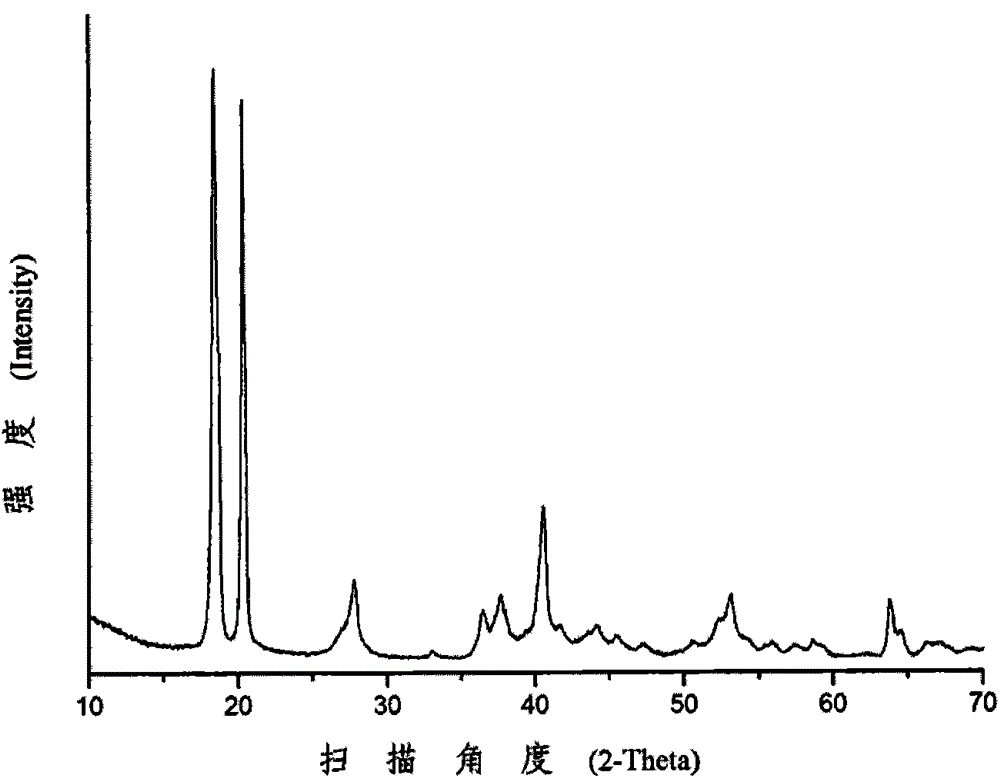

Process for preparing ultrafine aluminum hydroxide by seed crystal precipitation method

ActiveCN104671266ALow costNo pollution in the processAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateAluminium hydroxide

The invention provides a process for preparing ultrafine aluminum hydroxide. Alumina crude ore or crude aluminum hydroxide is dissolved in alkali lye so that a meta-aluminate solution is prepared, and the meta-aluminate solution and seed slurry are mixed and crystallize in a stator-rotor reactor so that the ultrafine aluminum hydroxide is prepared. The process has a low production cost and no pollution. The ultrafine aluminum hydroxide has good performances and can be used as an industrial additive and a fire retardant.

Owner:BEIJING SUN SILVER SCI & TECH

Process for manufacturing organic attapulgite clay anti-blocking agent

InactiveCN103739378AWide variety of sourcesSimple preparation processFertilizer mixturesSide effectIndustrial Additive

The invention belongs to the field of industrial additives and in particular relates to a process for manufacturing an organic attapulgite clay anti-blocking agent. The process comprises the steps of (1), weathering and drying light attapulgite clay; (2), breaking the dried attapulgite clay by using a breaker and sieving to obtain fine soil with a particle size of 8-10mm; (3), adding the broken clay into a kiln and drying at 280-350 DEG C till the content of water is less than 5%; (4), mixing the dried clay with a surfactant evenly according to a certain ratio; (5), grinding the processed clay in the step (4) into attapulgite powder with 300-500 meshes by using a grinding device, filling the attapulgite powder in bags and packaging. According to the process, the inorganic clay is used as the raw material, so that the process is extensive in source of raw materials, simple and free of toxic or side effect; the anti-blocking agent is good in anti-blocking effect; no pollutant is produced in the process of manufacturing.

Owner:MINGGUANG CITY HAIGANGAONI MINING CO LTD

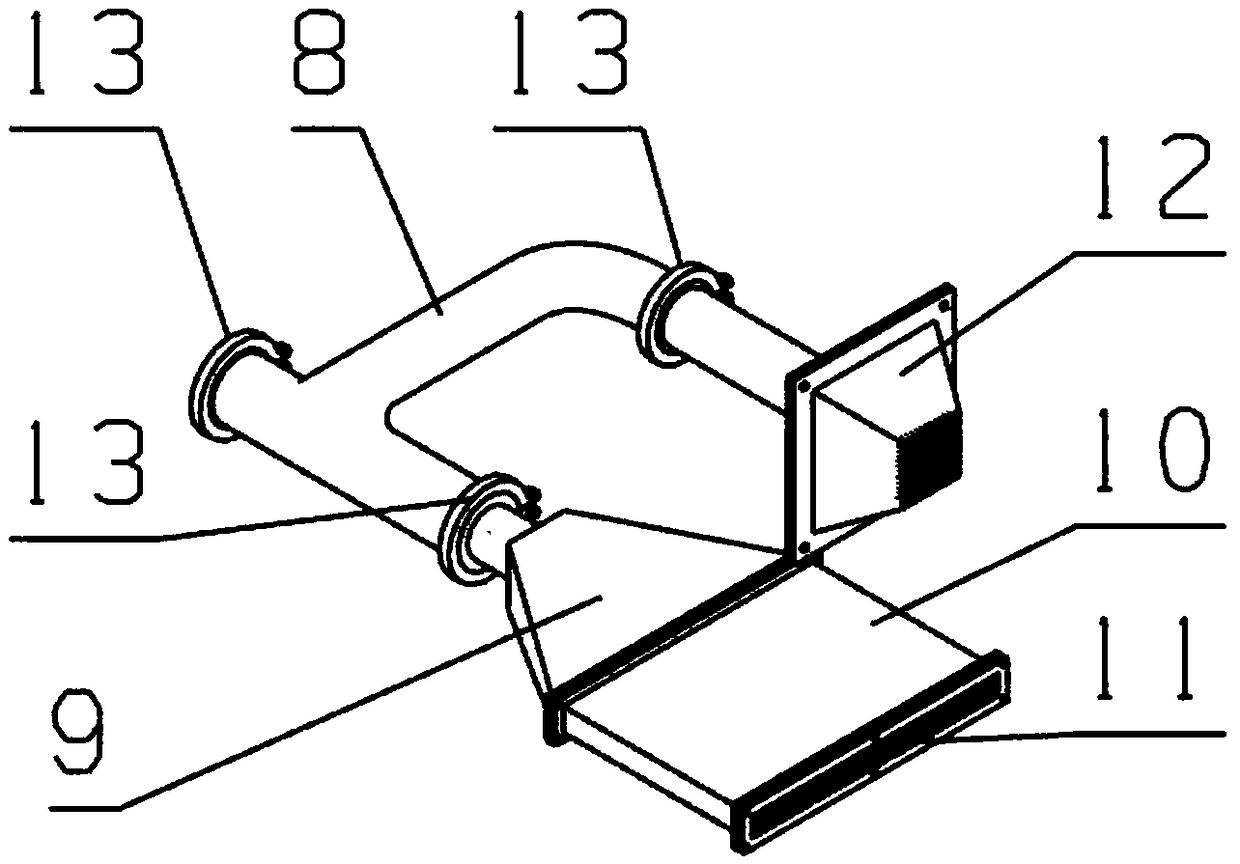

Visualized 3D printing equipment circulation filtering system simulation device and method

ActiveCN109285437ARapid Design-Manufacture-ValidationRealize wind field visualizationGas treatmentDispersed particle filtrationSelective laser meltingIndustrial Additive

The invention belongs to the technical field of 3D printing equipment, and relates to a visualized 3D printing equipment circulation filtering system simulation device and a method. According to the device and method of the invention, a simulation test design idea is adopted; an additive manufacturing equipment circulation system is simplified; a transparent glass material is adopted to simulate aforming cabin, so that the visualization of a circulation system wind field can be realized; an air inlet structure is of a segmented structure, and is connected by snap rings, and therefore, disassembly and installation can be facilitated; the air inlet structure is formed by means of a non-metal 3D printing technology, and therefore, the rapid design, manufacturing and verification of the air inlet structure can be realized; and the research and development cycle of the air inlet structure is shortened, the research and development costs of the air inlet structure are reduced, and the problem of the iteration cycle of the structural design and manufacture of a current circulation system can be solved. The device and method of the invention are suitable for the design of a circulation system in the research and development process of industrial additive manufacturing equipment, especially powder bed laser selective laser melting (SLM) and has a high value in the research and development of the equipment.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

High-temperature-resistant packaging material and preparation method thereof

The invention discloses a high-temperature-resistant packaging material and a preparation method thereof. The high-temperature-resistant packaging material is prepared from the following components by weight: 10-25 parts of polyethylene terephthalate, 15-30 parts of epoxy resin, 5-10 parts of talcum powder, 3-8 parts of silicon dioxide, 3-8 parts of glycidyl butyl ether, 5-10 parts of glass fiber powder, 5-10 parts of aluminum silicate fibers, 5-15 parts of polyetherimide, 5-10 parts of aminosilane, 5-10 parts of phenylsilane, 2-5 parts of a coupling agent and 2-5 parts of an antioxidant. Compared with the prior art, the high-temperature-resistant packaging material provided by the invention has the advantages that the high temperature resistance of the packaging material is greatly improved and the application scope of the packaging material is greatly broadened since a variety of environment-friendly high-temperature-resistant raw materials are adopted, a variety of environment-friendly pollution-free industrial additives are used, a coupling agent is employed for improving the interfacial effect of organic substances and inorganic substances and all the components are cooperated with each other.

Owner:TAISHAN SHIHENG PACKAGING MATERIAL CO LTD

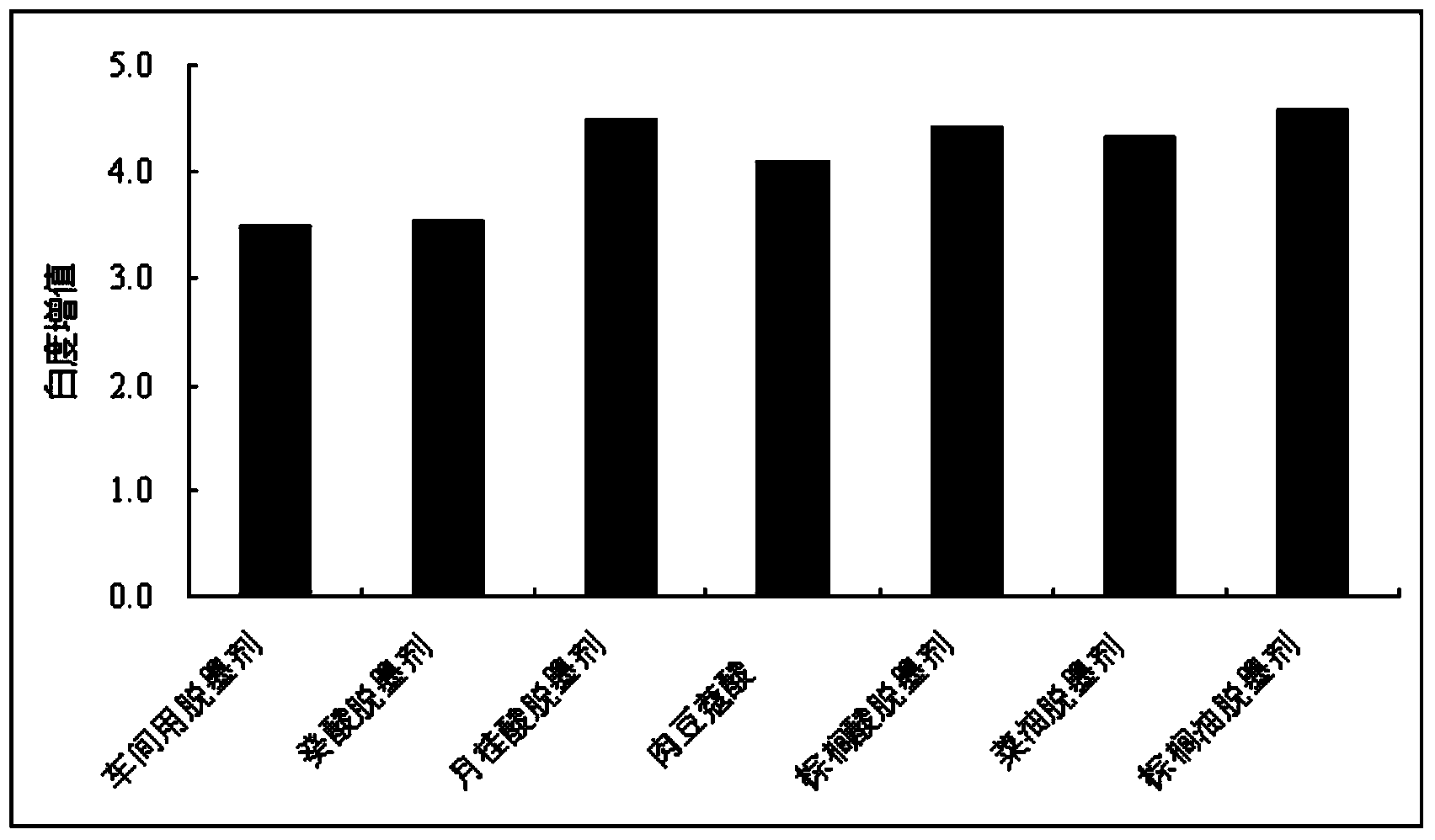

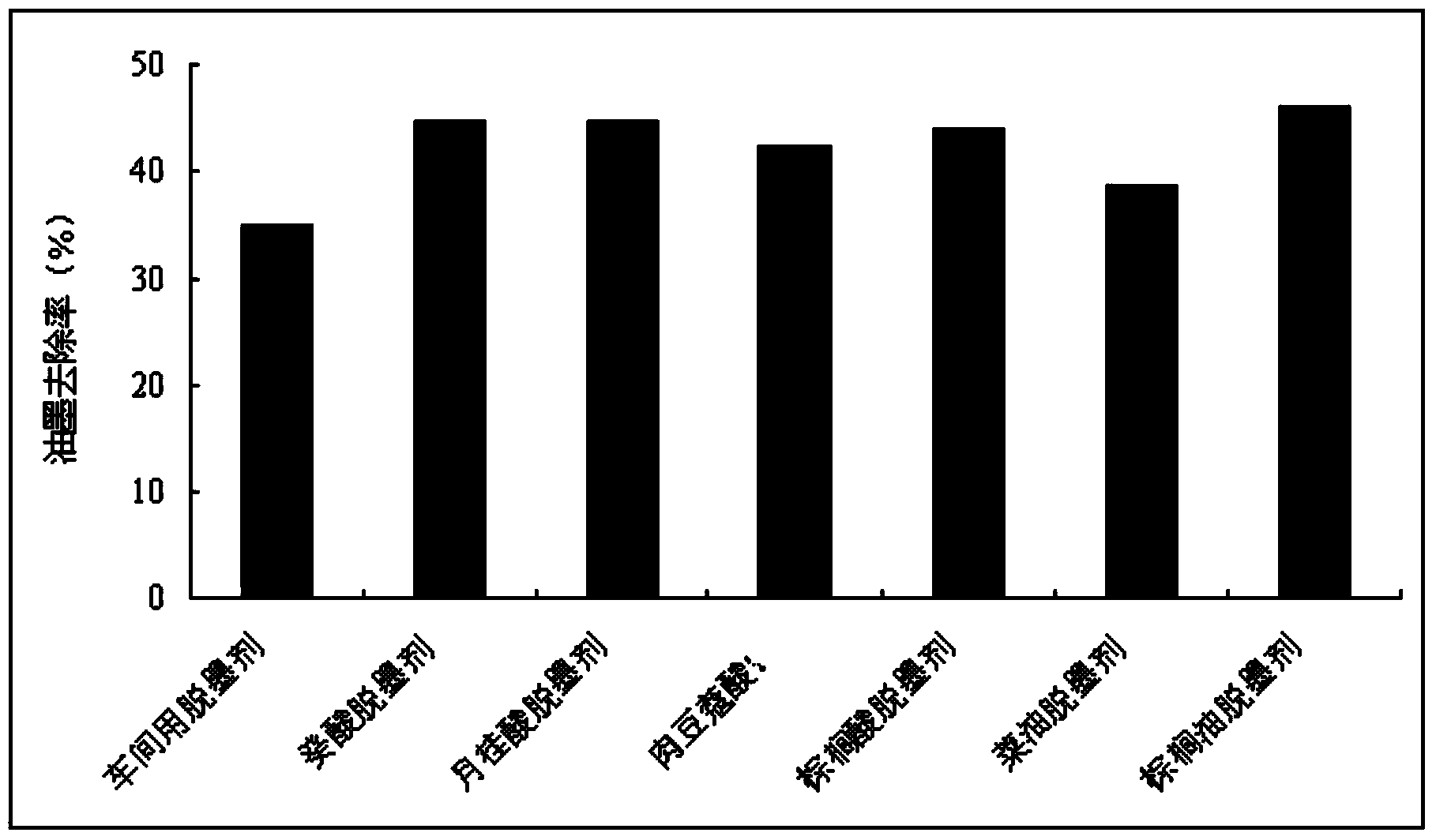

Preparation method of biomass-based deinking agent

InactiveCN103756402AAchieve the goal of energy saving and emission reductionEfficient methodChemical paints/ink removersEnvironmental resistanceIndustrial Additive

The invention relates to a preparation method of a biomass-based deinking agent. The preparation method comprises the following steps: sodium laurate is dissolved in a sodium hydroxide solution to prepare an evenly mixed solution; then ZnO particles are added in the prepared mixed solution; the adding quantity of the ZnO is 1 / 2-1 / 3 of the mass of lauric acid; finally, biomass raw materials are added, the mixture is heated to 85-95 DEG C and reacts for 10-18 h to obtain the biomass-based deinking agent. The preparation method uses natural and reproduceable biological resources as the raw materials to develop environment-friendly function materials and an auxiliary agent with high efficiency, energy conservation and low pollution, realizes the chemical replacement of key industrial additives, and achieves biological degradation and environmental protection. The biomass-based deinking agent is used as a high-efficiency deinking agent so as to achieve the purposes of energy conservation and emission reduction.

Owner:SHANDONG UNIV

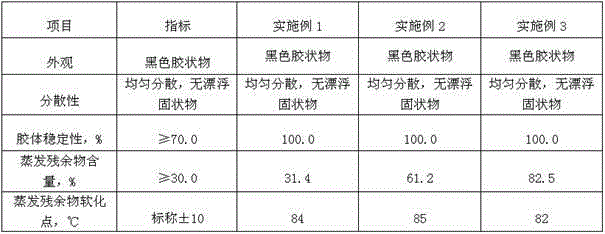

Anti-collapse agent of zwitterionic emulsified asphalt for drilling fluid

ActiveCN103980868AWith anti-collapse performanceImprove stabilityDrilling compositionBetaineIndustrial Additive

The invention provides an anti-collapse agent of zwitterionic emulsified asphalt for drilling fluid. The anti-collapse agent comprises the following raw material components in percentage by weight: 20.0-35.0% of industrial additive oil, 15.0-30.0% of asphalt, 7.0-18.0% of sulfonated asphalt, 0.4-0.8% of dodecyldimethylsulfopropyl betaine, 1.0-2.0% of organic stabilizer, 8.0-15.0% of aviation kerosene and 5.0-42.0% of water. According to the invention, an emulsifying agent is reselected, the organic stabilizer is also added, so that the anti-collapse agent has anti-collapse performance and relatively high storage stability and is capable of avoiding the layering phenomenon; the anti-collapse agent can be used for obtaining high-quality products by adding relatively few raw materials and has relatively strong anti-frost property; the quality of the products can be regulated within a certain range, and the anti-collapse agent has a wide market popularization value.

Owner:YUMEN OIL FIELD KEDA CHEM

Method for processing wild fish balls

Owner:杭州先吃饭吧科技有限公司

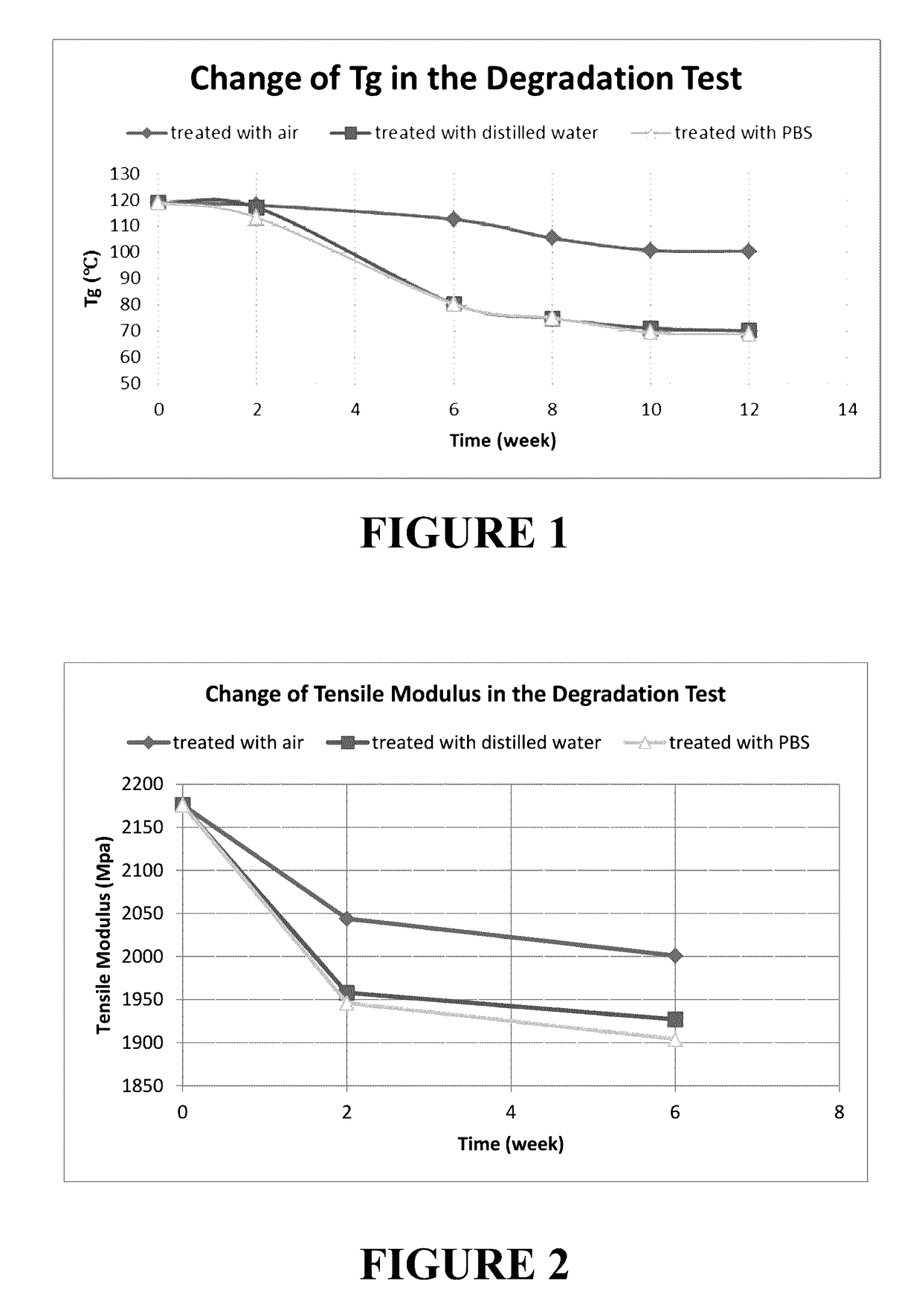

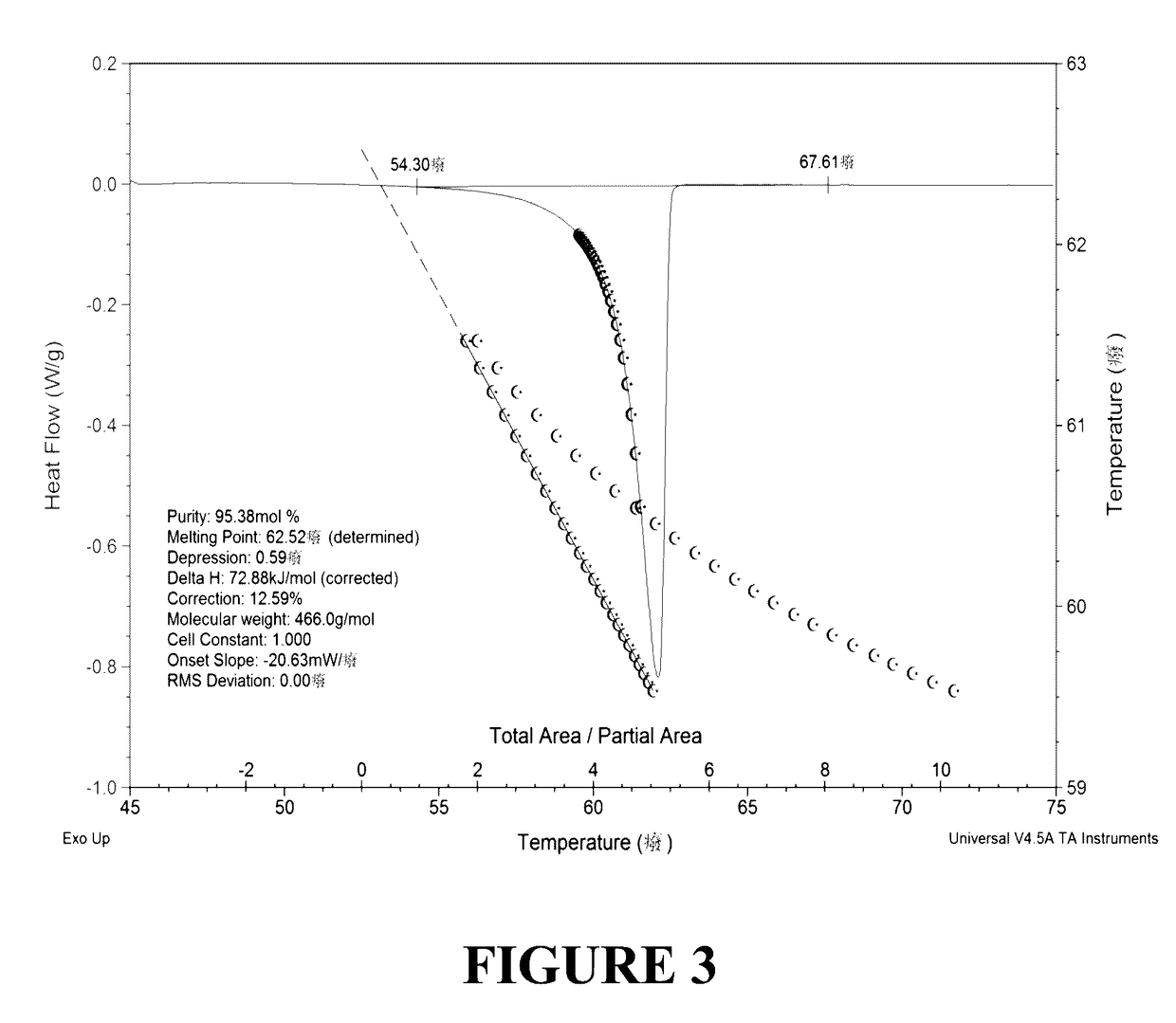

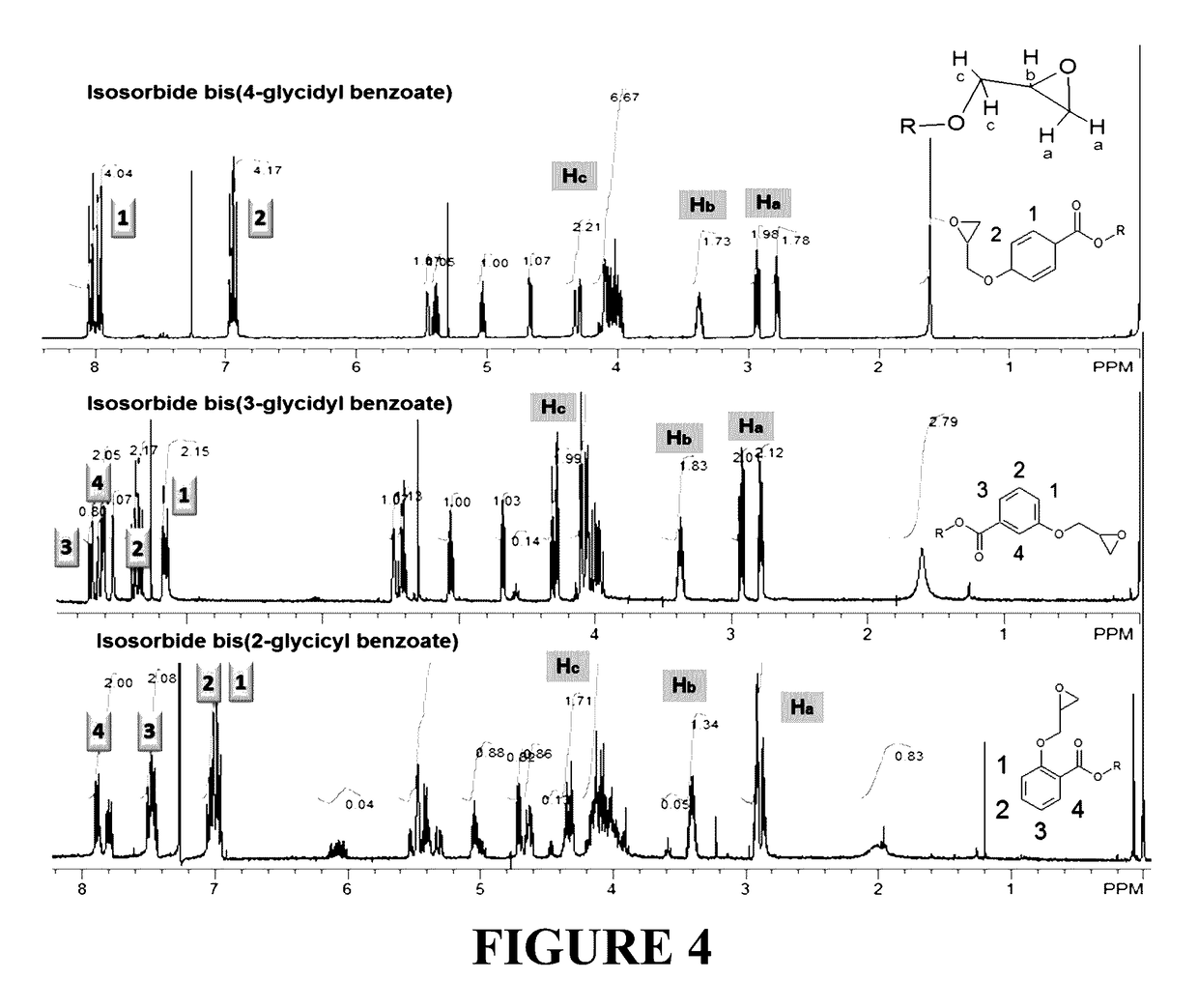

Isosorbide-derived epoxy resins and methods of making same

Isosorbide-derived epoxies and methods of making same are disclosed. Isosorbide and its isomers are attached to glycidyl ether to make crosslinkable epoxy resin monomers. Adding the hydrophobic functional group into the backbone of isosorbide epoxy or adjusting the amount and type of crosslinker is operable to modify the mechanical properties and water uptake ratio (from <1 wt % to >50 wt %) of the isosorbide-derived epoxies for different uses. High water uptake epoxies with controllable biodegradation rate are suitable for drug delivery systems or extracellular matrices for biomedical applications, while low water uptake epoxies with strong mechanical properties may be used for can coatings, bone cements and other industrial additives and adhesives.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Control method for superfine powder grinding industrial waste slag in an energy-saving and environmental-friendly type of closed cycle with high yield and the apparatus for the same

InactiveUS8006925B2High yieldEasy to combineGas current separationCocoaSocial benefitsAutomatic control

The present invention provides a control method for superfine powder grinding industrial waste slag in an energy-saving and environmental-friendly type of closed cycle with high yield and the apparatus for the same. The method combines a drying process and a powder grinding process, adopts an in-line monitoring process, automatically adjusts and controls the operating parameters. Therefore, the invention changes the conventional open cycle into a closed cycle, shortens the cycle, achieves the automatic control and adjustment of the operating parameters, and obtains the superfine product with high yield. So the invention enhances the application value of industrial waste slag, extends the applicable field of industrial waste slag, and increases the extra value of final product. The apparatus primarily adds a wind sweeping drying grinder, an in-line laser particle detector, and an automatic control device, furthermore selects a screener and a deduster with high efficiency and product quality and therefore needs less space, investment and energy consumption, improves the work efficiency, the quality of the product and overall efficiency. The apparatus can automatically adjust and control the operating parameters, improve the physical and chemical characteristics of industrial waste slag, and change the industrial waste slag to industrial additive or admixture with good performance; therefore it has good economic and social benefit.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

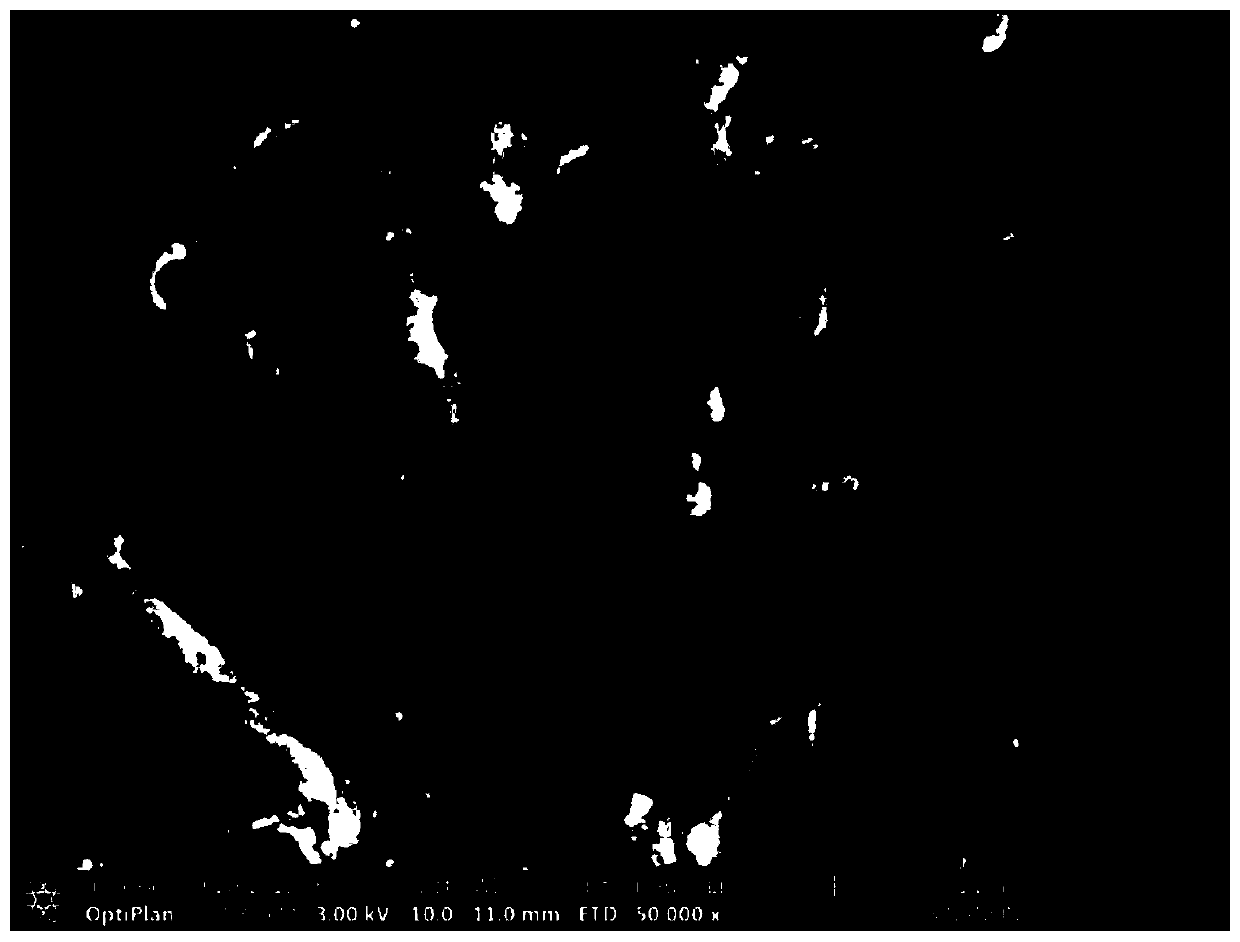

Carbon nanotube pre-dispersion for modification of silicone rubber and preparation method thereof

The invention relates to the field of carbon nanotubes, and relates to a carbon nanotube pre-dispersion for modification of silicone rubber and a preparation method thereof. The carbon nanotube pre-dispersion is a carbon nanotube additive that can be effectively dispersed in silicone rubber resin. The carbon nanotube pre-dispersion can disperse single-walled, double-walled and multi-walled carbonnanotubes, and is suitable for industrial additives improving the antistatic grade of silicone rubber. The preparation process of the carbon nanotube pre-dispersion includes: fully mixing a silicone oil oligomer, a carbon tube wetting agent and a carbon tube dispersing agent to obtain a good carrier; and grinding the good carrier and carbon nanotubes under the grinding action of a three-roller machine to obtain the carbon nanotube pre-dispersion. Preparation of the carbon nanotube pre-dispersion only needs two-step reaction, and is simple and practicable. The carbon nanotube pre-dispersion hasthe advantages of small adding amount, short dispersion period, good carbon tube dispersity, good silicone rubber stability and the like, can be widely applied to various anti-electromagnetic shielding carbon nanotube composite silicone rubber, and has important commercial application value.

Owner:JIANGXI COPPER TECHNOLOGY RESEARCH INSTITUTE CO LTD

Edible beeswax lipsticks and preparation method thereof

PendingCN109602644ALow priceEconomical and practicalCosmetic preparationsMake-upWater bathsVitamin C

The invention relates to the fields of lipsticks and preparation technologies thereof, and discloses edible beeswax lipsticks and a preparation method thereof. The edible beeswax lipsticks are prepared from the following raw materials: honey, beeswax, olive oil, almond oil, EV oil, vitamin C and lipstick powder. The preparation method of the edible beeswax lipsticks comprises the following steps:uniformly mixing the honey, the olive oil, the almond oil, the EV oil, the vitamin C and the lipstick powder, and carrying out stirring so as to obtain a mixture; adding the beeswax into the mixture,and carrying out water bath so as to obtain heated liquid lipstick; and then, carrying out cooling so as to have liquid lipsticks molded, thereby obtaining the edible beeswax lipsticks. The edible beeswax lipsticks disclosed by the invention are prepared from natural honey and beeswax as the main raw materials without addition of any industrial additives during the preparation process; so that, the prepared lipsticks are capable of making people beautiful while nourishing the lip. The lipsticks are edible, and are prepared by adopting a simple preparation method; and thus, the prepared ediblebeeswax lipsticks are low in cost, high in economical efficiency and practicality, harmless to human health and conducive for use by a large number of people.

Owner:拜城县供销合作颂蜜源蜂农专业合作社

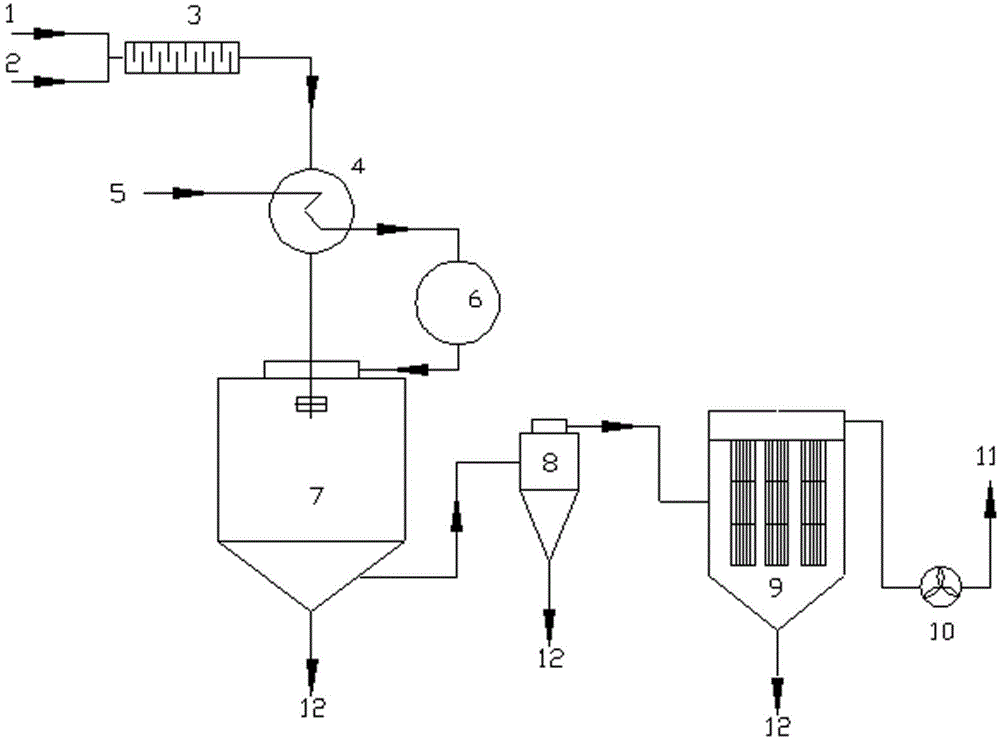

Production process and production device for preparing industrial additives from electrostatic acid and application thereof

ActiveCN104451714ARealize continuous productionStable and controllable neutralization exothermCeramicwareComing outCyclone

The invention relates to a production process and a production device for preparing industrial additives from electrostatic acid and an application thereof. The provided process and device can be used for preparing the electrostatic acid into the industrial additives, so as to effectively utilize the industrial additives. According to the technical scheme, the production process for preparing industrial additives from electrostatic acid comprises the following steps: 1) respectively conveying the electrostatic acid and liquid caustic into a static mixer and a heat exchanger for mixing and cooling, and drying the mixture in a spray dryer; conveying the mixture into the spray dryer; 2) drying the mixture after atomizing; 3) discharging airflow coming out from the spray dryer by using an induced draft fan; 4) finally, collecting granularity, namely granular industrial additives, from the spray dryer, a cyclone separator and a bag type dust collector. The device for preparing industrial additives from electrostatic acid is characterized by comprising the static mixer, the heat exchanger, an air heater, the spray dryer, the cyclone separator, the bag type dust collector and the induced draft fan.

Owner:ZANYU TECH GRP CO LTD +1

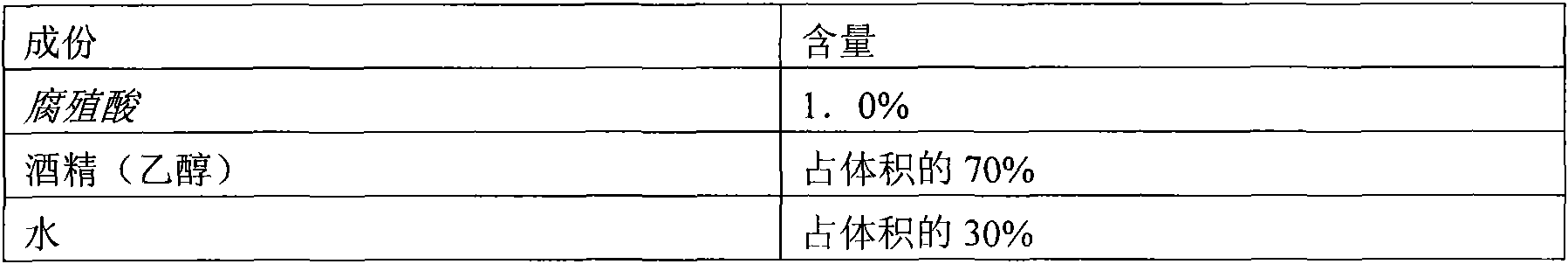

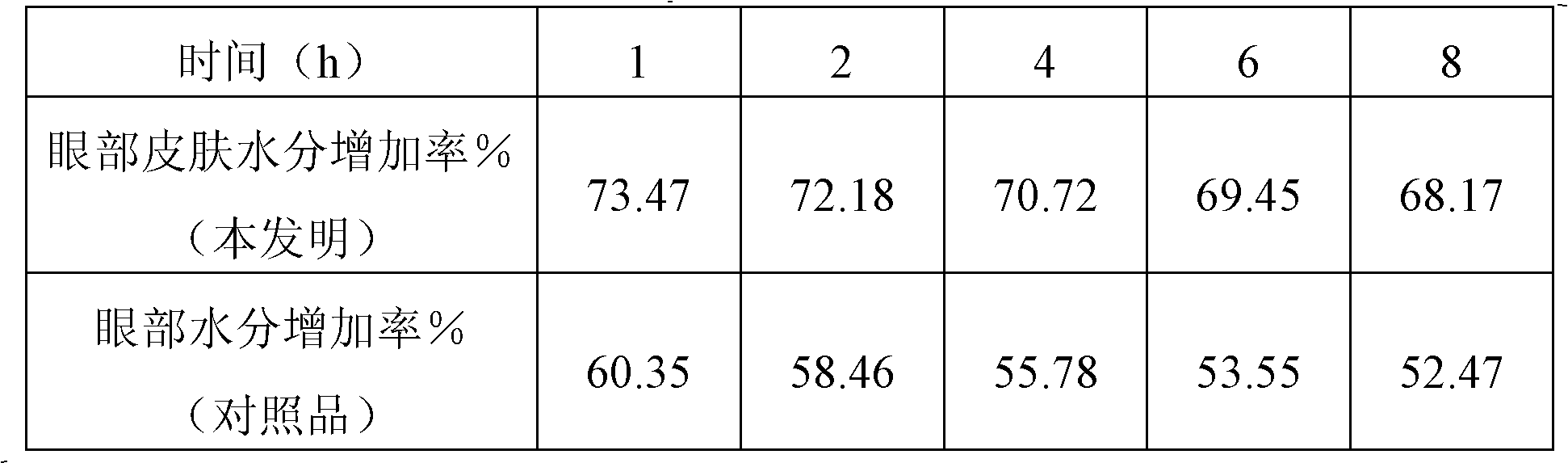

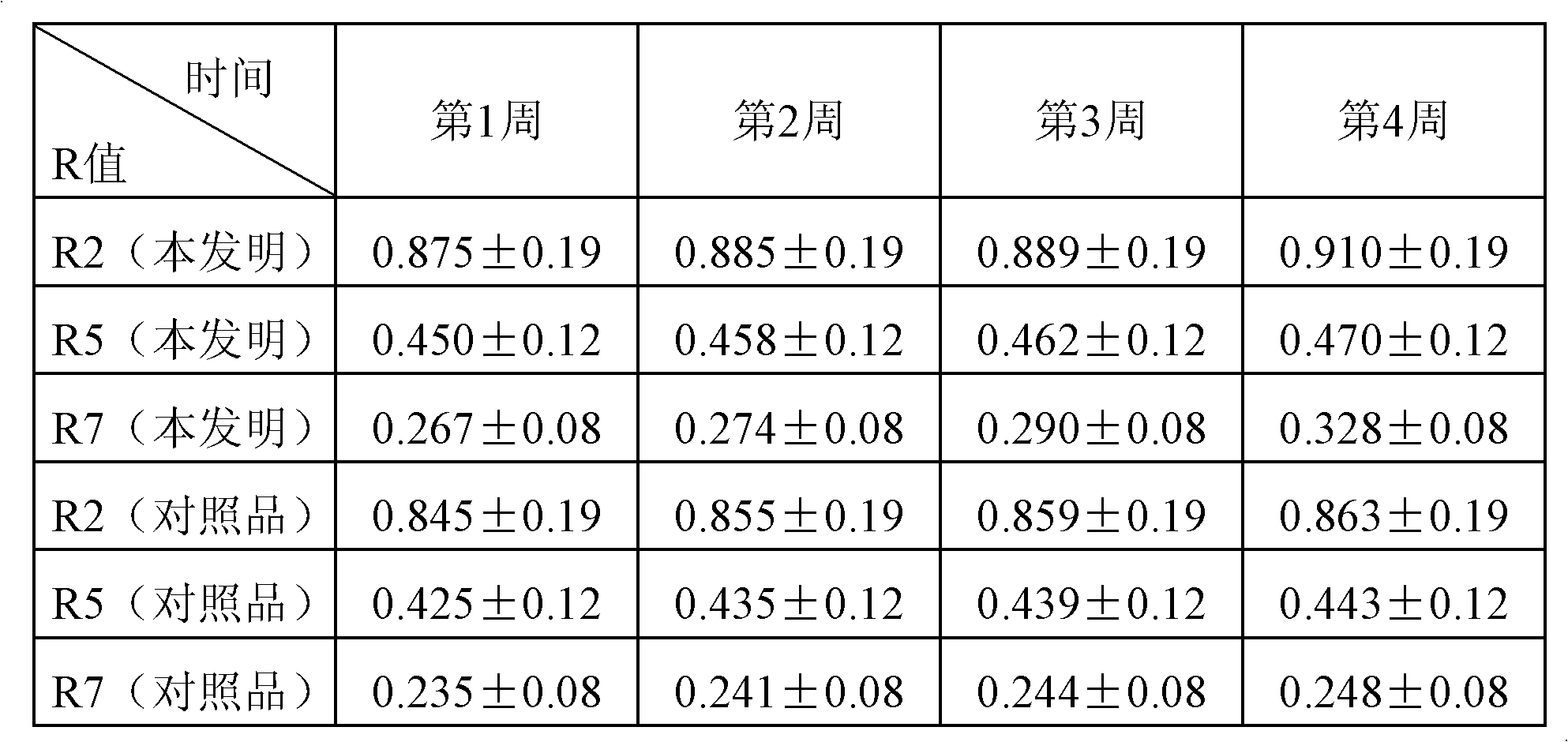

Traditional Chinese medicine composition multifunctional liquid used for removing under-eye dark circles, preparation method thereof, and application thereof

InactiveCN102366358AEfficient removalRestore elasticityCosmetic preparationsToilet preparationsTO-18Industrial Additive

The invention discloses a traditional Chinese medicine composition multifunctional liquid used for removing under-eye dark circles, a preparation method thereof, and an application thereof. The multifunctional liquid used for removing under-eye dark circles is prepared from raw materials of, by weight: 17 to 19 parts of red peony root, 8 to 10 parts of cortex mori, 14 to 16 parts of florists dendranthema, 10 to 12 parts of common motherwort herb, 16 to 18 parts of medlar, 9 to 11 parts of szechwan lovage rhizome, 6 to 8 parts of tree peony root-bark, 7 to 9 parts of nutgrass galingale rhizome, 4 to 6 parts of ginseng, and 15 to 17 parts of ligusticum. A trade name of the multifunctional liquid is Jixianglian plant under-eye-dark-circle-removing multifunctional liquid. The multifunctional liquid is directly applied on peripheral skins of eyes, and under-eye dark circles can be effectively removed. The multifunctional liquid can be effectively absorbed by skins, and provides functions of moisturizing, elasticity recovering, and wrinkle removing. No chemical industrial additive is added in the multifunctional liquid. According to the multifunctional liquid, all adopted materials are pure natural extracts. The effects of the multifunctional liquid are completely achieved by traditional Chinese medicine extracts. The natural extracts are obtained by combined extraction according to a certain traditional Chinese medicine formula, such that a characteristic of genuine traditional Chinese medicine formulation is realized.

Owner:上海莲氏轩生物工程有限公司

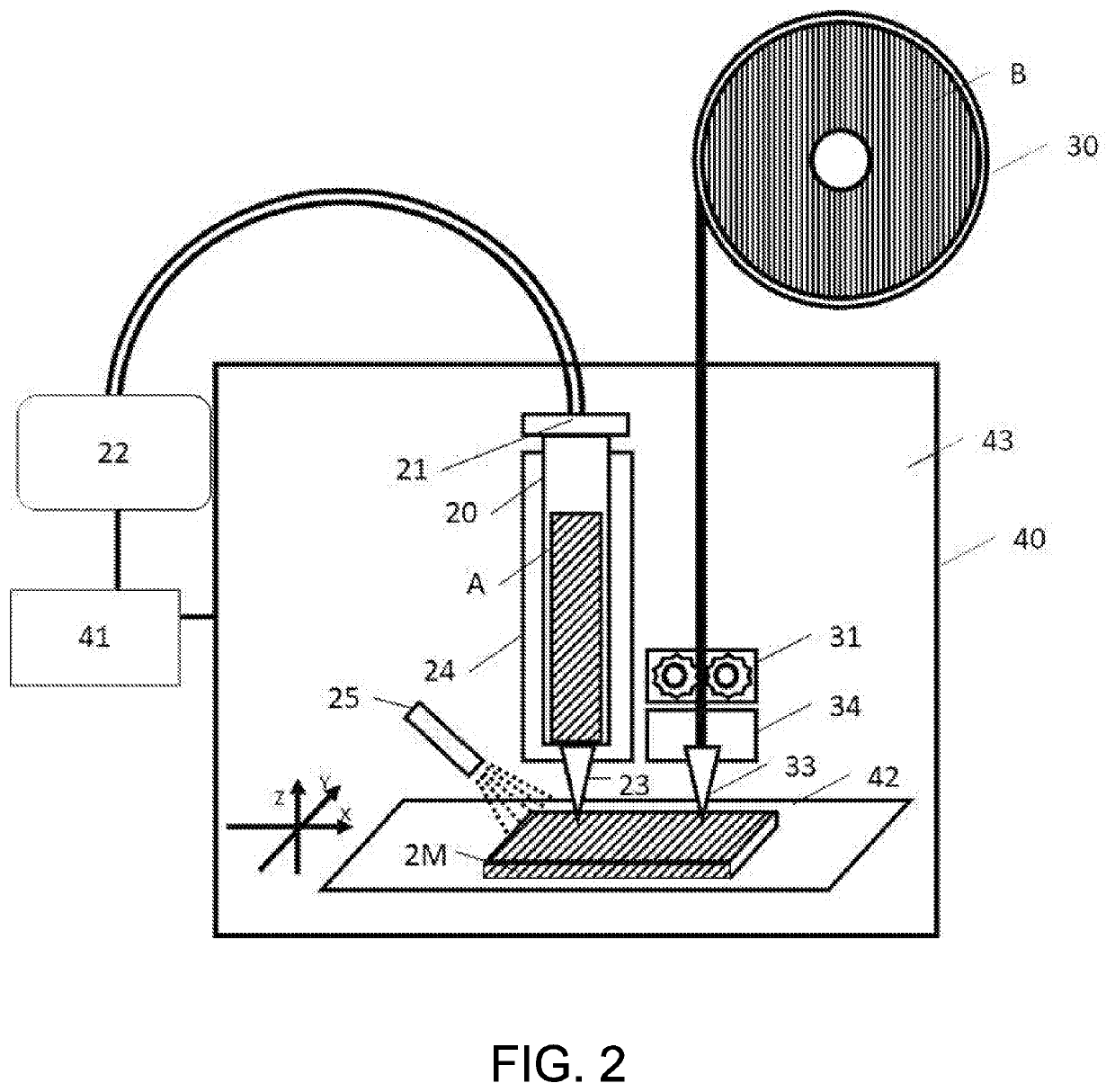

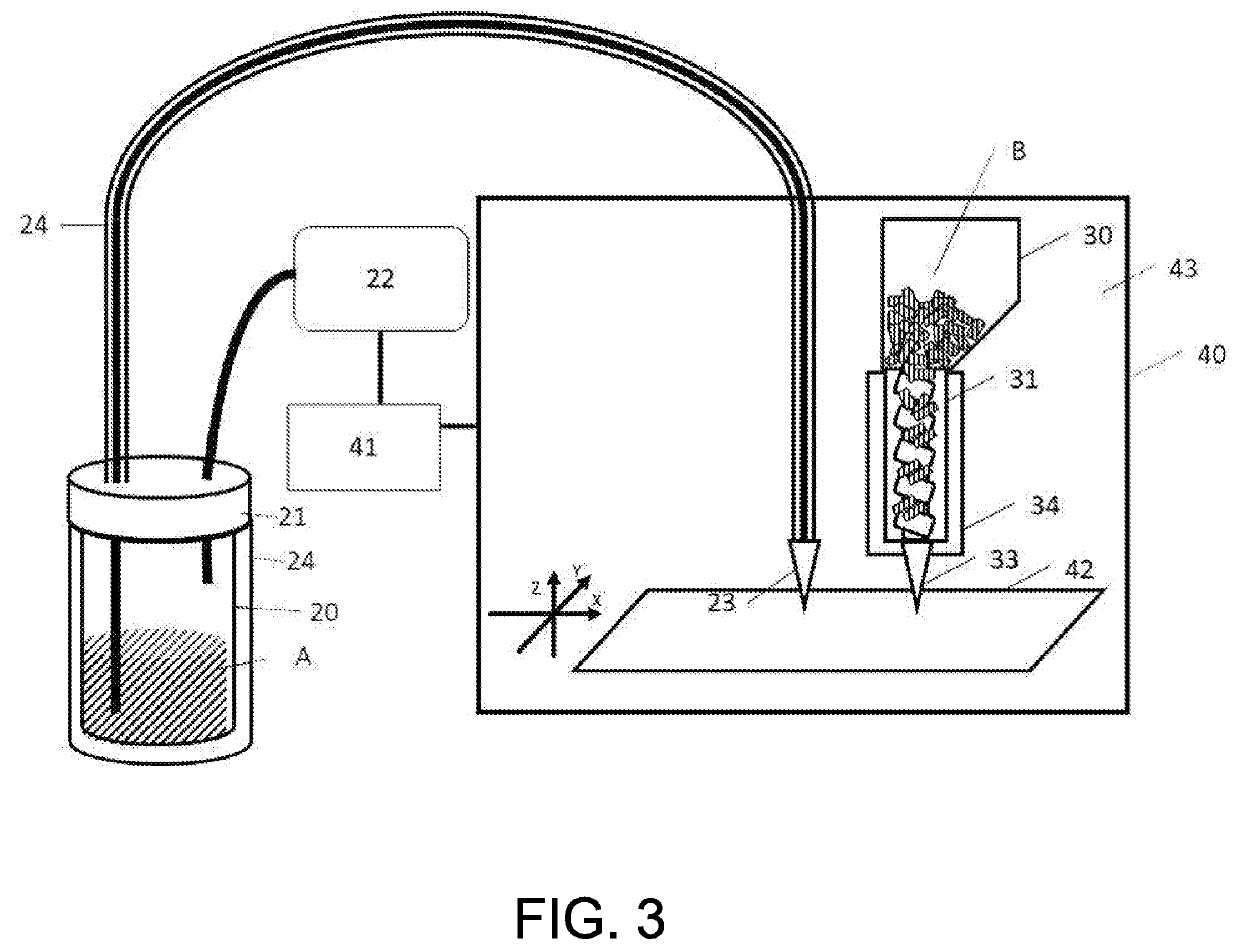

Three-dimensional molding apparatus and three-dimensional molding method using different types of materials

ActiveUS20200384683A1Improve mechanical propertiesImprove thermal stabilityManufacturing platforms/substratesManufacturing driving meansTemperature controlIndustrial Additive

A three-dimensional molding apparatus is provided and includes a reservoir portion, a nozzle portion, a liquid-sending unit, and a temperature control unit that correspond to each of the two or more different types of materials, a molding stage, a relative movement mechanism for moving the stage and the nozzle portions, and a control computer. By using this apparatus, industrial additive manufacturing with two or more different types of materials can be realized with high precision, and high-definition molded products in which different types of materials are arbitrarily combined can be produced.

Owner:KJ CHEM

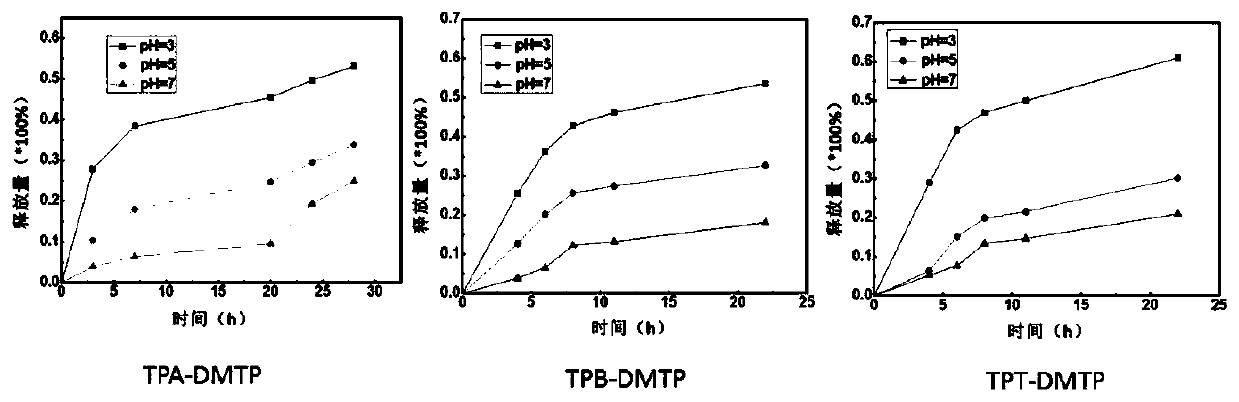

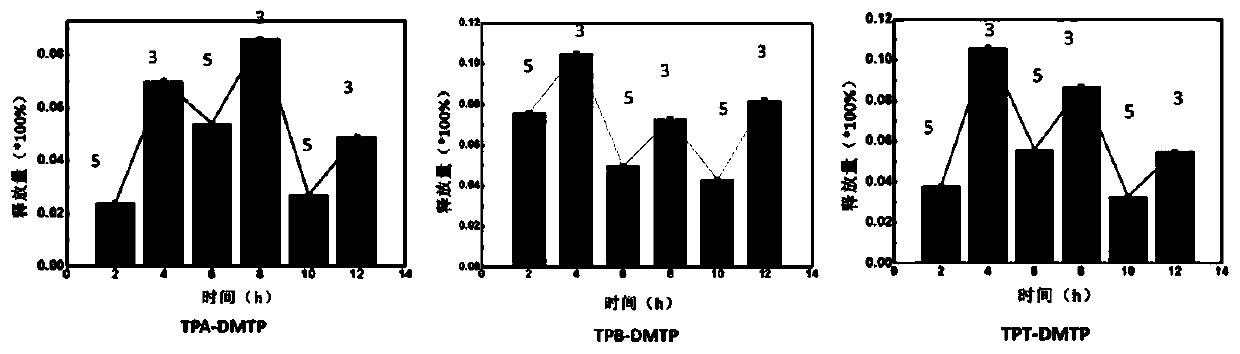

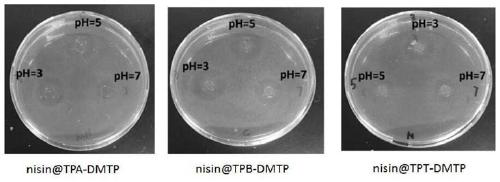

Antibacterial fermentation additive based on covalent organic framework material and preparation and application thereof

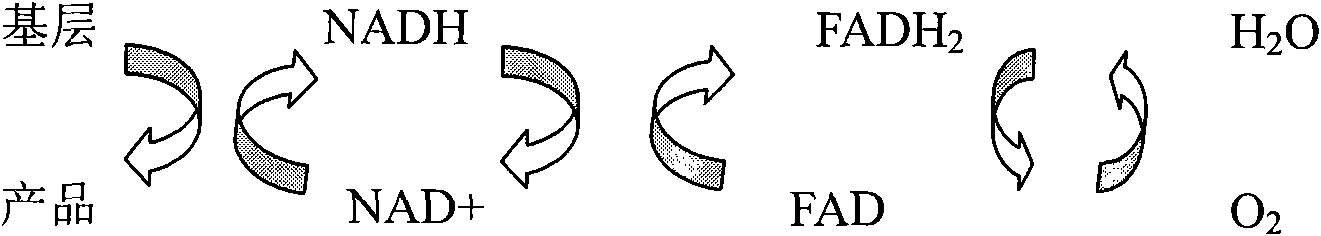

Aiming at the regulation and control problem in the fermentation process, a covalent organic framework material is creatively designed as a novel carrier material with wide applicability, and antibacterial molecules (such as protein, enzyme, polypeptide and antibiotics) are efficiently loaded through an adsorption means, so that the intelligent pH response industrial additive is prepared and is used for regulating and controlling infectious microbe pollution in the fermentation process. The novel fermentation additive prepared by the technology has high stability and durability, and successfully solves the problem of infectious microbe pollution in the fermentation process in the field of biological manufacturing.

Owner:NANKAI UNIV

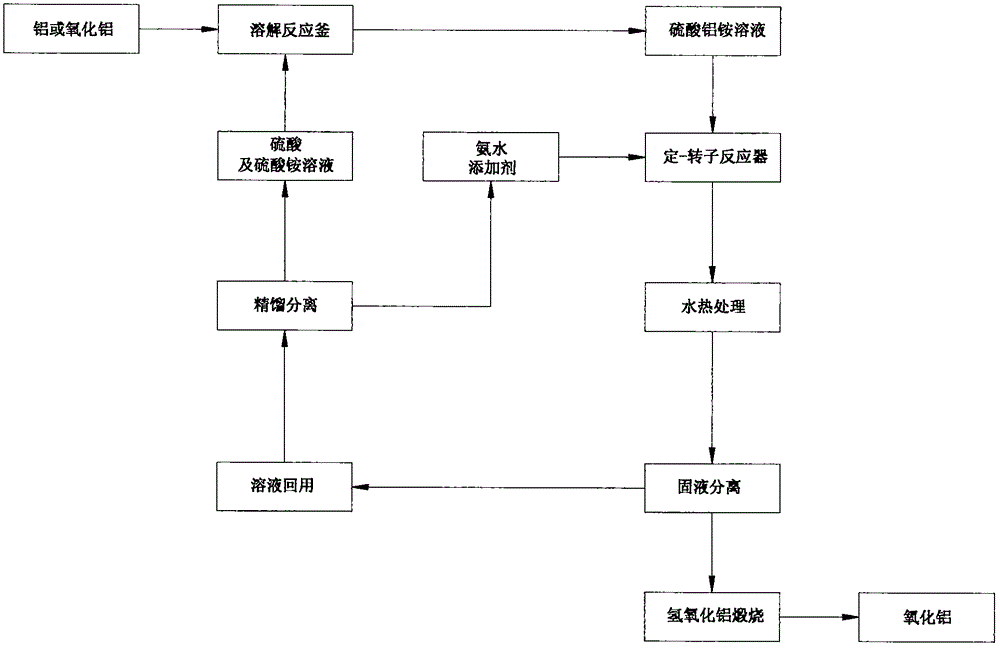

Preparation technique of aluminum hydroxide and aluminum oxide powder

ActiveCN105692667ANo pollution in the processSimple ingredientsAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationDispersityIndustrial Additive

The invention provides a preparation technique of aluminum hydroxide and aluminum oxide powder. The technique comprises the following steps: mixing an reaction intermediate aluminum ammonium sulfate and ammonia water in a stator-rotor reactor to react, carrying out hydrothermal treatment on the aluminum hydroxide slurry obtained by the reaction, carrying out solid-liquid separation, and treating the separated liquid, wherein most of the treated liquid can be recycled; and carrying out washing and drying on the separated solid to obtain a high-dispersity solid aluminum hydroxide material, and carrying out further roasting to obtain the aluminum oxide powder. The preparation technique provided by the invention has the advantages of low cost and no pollution. The produced aluminum hydroxide and aluminum oxide materials have the advantages of high dispersity, uniform particle size and high performance. The aluminum hydroxide can be used as an industrial additive, flame retardant or the like, and the aluminum oxide can be used as a catalyst or a raw material in electronic industry and ceramic industry.

Owner:BEIJING SUN SILVER SCI & TECH

Polyester fiber containing wormwood component and wormwood fragrance and preparation method of polyester fiber

InactiveCN113862819AHas the effect of repelling mosquitoes and insectsEliminate the tasteMonocomponent polyesters artificial filamentArtifical filament manufactureBiotechnologyTextile fiber

The invention provides polyester fiber containing a wormwood component and wormwood fragrance and a preparation method of the polyester fiber, and relates to the technical field of textile fibers. The polyester fiber containing the wormwood component and the wormwood fragrance is prepared from the following materials in parts by weight of 8 to 11 parts of radix stemonae, 6 to 9 parts of flos caryophylli, 6 to 9 parts of herba taraxaci, 8 to 11 parts of radix et rhizoma rhei, 6 to 9 parts of flos gardeniae, 2 to 3 parts of rhizoma coptidis, 30 to 35 parts of wormwood, 5 to 7 parts of cellulase, 50 to 55 parts of polyester, 15 to 18 parts of lignans, 16 to 19 parts of nanoscale titanium dioxide and 25 to 28 parts of fiber-forming polymer. By adding a wormwood powder mixture and a wormwood extract, the taste of an industrial additive is effectively removed, meanwhile, the wormwood has the mosquito-repelling and insect-preventing effects, and secondly, the fragrance generated by the wormwood acts on nasal mucosa, so that the content of immune globulin S (SlGA) secreted by antibodies on the nasal mucosa is increased; and the increase of the content enables virus not to survive easily on the nasal mucosa and the respiratory mucosa.

Owner:郑杰

Bee wax lipstick

InactiveCN110664665ALow priceEconomical and practicalCosmetic preparationsMake-upBiotechnologyVitamin C

The invention discloses a bee wax lipstick. The bee wax lipstick is characterized by comprising, by weight, 0.5-2 parts of bee wax, 0.5-1.5 parts of olive oil, 0.1-0.3 part of a radix astragali extract, 0.05-0.1 part of vitamin E, 0.05-0.1 part of vitamin C, 0.05-0.3 part of a flos lonicerae japonicae extract, 0.05-0.3 part of an impatiens balsamina leaf extract, and 0-1.5 parts of lipstick powder. According to the bee wax lipstick, the bee wax and the olive oil which are edible serve as raw materials, no industrial additives are applied during preparation, and therefore the prepared bee wax lipstick can not only make people beautiful but also moisturize lips, and belongs to an edible lipstick; a preparation method is simple and convenient, and the obtained edible bee wax lipstick is low in cost and high in economic practicability and causes no damage to human bodies; and meanwhile, the flos lonicerae japonicae extract and the impatiens balsamina leaf extract which have antibacterial effects are added, and vitamin C and vitamin E which have anti-oxidation effects are added, and thus the bee wax lipstick can be adopted by a large number of people.

Owner:青川县川申农特产开发有限公司

Environment-friendly plasticizer

The invention relates to the technical field of chemical and industrial additives, in particular to an environment-friendly plasticizer. The plasticizer is prepared from, by weight, 7-8 parts of 3-diphthalate-di-(4-chlorphenyl)ester, 22-30 parts of phthalic anhydride, 15-20 parts of 2-propyl heptanol, 15-18 parts of phytosterol, 17-19 parts of organic solvent, 12-15 parts of oxides, 13-14 parts offlexible PVC, 0.2-0.3 part of roseolic acid, 12-18 parts of acetalized polyvinyl alcohol, 35-45 parts of glycerol, 25-35 parts of plant oil, 0.5-1 part of sodium alcoholate, 10-20 parts of fatty acidmethyl ester, 16-18 parts of butyl acrylate, 12-14 parts of glycidyl methacrylate, 12-15 parts of epoxidized fatty acid methyl esters, 6-8 parts of aero graphite, 6-8 parts of rosin, an appropriate amount of palm oil and 10-12 parts of bonding agent. The plasticizer solves the problems that existing plasticizers contain toxic substances and easily cause damage to the human body.

Owner:广州富飞化工科技有限公司

Blackberry essence as well as preparation method and application thereof

InactiveCN112410121AQuality improvementHigh degree of reductionEssential-oils/perfumesFood scienceBiotechnologyFood additive

The invention relates to the technical field of spice additives, in particular to blackberry essence as well as a preparation method and application thereof. The blackberry essence comprises 0.38%-3.2% of a delicate aroma component, 2.75%-27.2% of a fruit aroma component and 3.3%-13% of an ester aroma component. The preparation method of the blackberry essence comprises the following steps: heating a solvent to 70-100 DEG C, adding an aroma improver into the solvent, conducting complete dissolving, adding other aroma raw materials, and conducting uniform stirring. The method has the advantagesof simple and easy raw materials, simple operation, low technical requirements on operators and simplified process, and reduces the loss of blackberry aroma caused by repeated processing in the preparation process. The blackberry essence disclosed by the invention is stable and vivid in aroma quality and strong in characteristics, can be used as a food additive to be applied to preparation of foods with blackberry aroma, can also be used as an industrial additive to be applied to preparation of daily necessities, cosmetics and the like with blackberry aroma.

Owner:广东馨杰生化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com