Preparation method and application of bamboo fiber micropowder

A technology of ultra-fine powder and bamboo fiber, applied in the chemical industry, can solve the problems of easy destruction of the micropores of the powder, no UV resistance, poor fineness of the ultra-fine powder, etc., to achieve easy crushing and grinding, and reaction efficiency The effect of high and dark colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

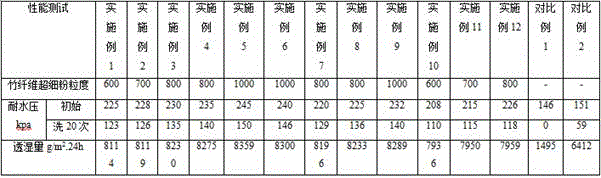

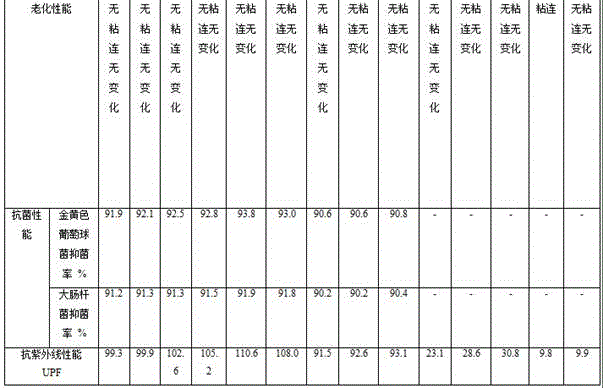

Examples

preparation example Construction

[0033] In order to solve the above problems, the invention provides a kind of preparation method of bamboo fiber superfine powder, specifically comprises the following steps:

[0034] 1) Raw material crushing: the raw material is directly crushed into a 400-500 mesh fine powder with a pulverizer, and the raw material includes bamboo powder containing microporous bamboo fiber; the crushing is carried out by a roller crusher and a ball mill for crushing and grinding.

[0035] 2) Vacuum condensation treatment: Put the fine powder into a closed container, vacuumize it through a vacuum pump, heat it to vaporize the powder, and then perform quenching to obtain a purified fine powder; the main purpose of this step is to remove the fruit in the fine powder It removes impurities such as glue and lignin, and embrittles the fine powder, which is more conducive to the subsequent grinding of fine powder into ultra-fine powder, and does not damage the original antibacterial and anti-ultravio...

Embodiment approach

[0046] As a preferred embodiment of the present invention, the raw materials also include one or more mixtures of bamboo, hemp stalks, jute stalks, flax stalks, sisal stalks, ramie stalks and hemp stalks use.

[0047] As a preferred embodiment of the present invention, step 3) also includes a bleaching process, step 3) specifically: adding sodium hydroxide with a concentration of 8-15g / L to the purified fine powder at 80-100°C Stir the solution for 2-4 hours, then adjust the pH value to 7 with dilute hydrochloric acid, vacuum filter, centrifugal dehydration, add sodium hypochlorite solution to the precipitate, stir for 1-4 hours, after bleaching, vacuum filter, wash with water, and adjust with phosphoric acid The pH value was 7, centrifuged and dehydrated to obtain a bleached precipitate. The number of bleaching times depends on the bleaching effect and bleaching requirements.

[0048] Implementation method:

Embodiment approach 1

[0049] Embodiment 1, a kind of preparation method of bamboo fiber superfine powder specifically comprises the following steps:

[0050] 1) Raw material crushing: the raw material is directly crushed into a fine powder of 400-500 mesh with a pulverizer, and the raw material includes bamboo powder containing microporous bamboo fiber;

[0051] 2) Vacuum condensation treatment: put the fine powder into a closed container, vacuumize through a vacuum pump, heat to vaporize the powder, and then perform quenching to obtain purified fine powder;

[0052] 3) Alkalinization treatment: at 80-100°C, add sodium hydroxide solution with a concentration of 8-15g / L to the purified fine powder and stir for 2-4 hours, then adjust the pH value to 7 with dilute hydrochloric acid, vacuum pump Filter, centrifuge and dehydrate to obtain a precipitate;

[0053] 4) Freeze-drying treatment: freeze-dry the precipitate to obtain activated fine powder;

[0054] 5) Modification treatment: at 60-140°C, mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com