Nanoporous silver supported porous silver oxide nanorod composite material and preparation method thereof

A technology of nanoporous silver and composite materials, which is applied in the field of nanoporous silver-loaded porous silver oxide nanorod composite materials and its preparation, can solve the problems of cumbersome preparation process, easy agglomeration, and difficult recycling, and achieve simple and efficient preparation process. Good for infiltration and hard to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

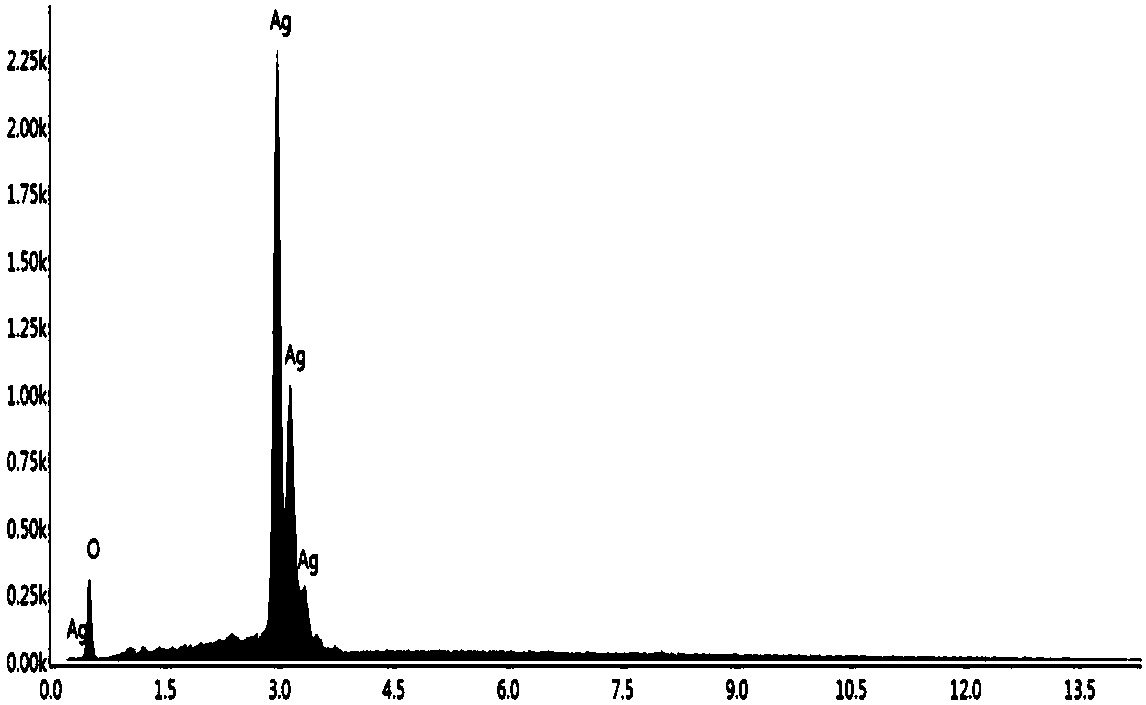

[0031] Cu with a diameter of Ф1mm 35 Zr 35 Ag 30 The amorphous rods were cut into short rods with a length of 10 mm. It is placed in a corrosive solution for free dealloying. The experimental conditions will contain 0.05M HF and 0.5M HNO 3 The mixed solution is used as the etching solution, the volume ratio of HF and HNO3 solution is 1:1, the etching time is 2h, and the etching temperature is 25°C. After taking it out, it is washed with deionized water to obtain nanoporous silver metal. figure 1 It is a scanning electron micrograph of nanoporous silver in this example, which shows that the obtained nanoporous silver has a three-dimensional (3D) nanoporous morphology with a uniform, bicontinuous ligament / hole structure. The nanoporous silver layer has a thickness of 120 μm, a ligament width of 40 nm, and a pore size of 100 nm.

[0032] A platinum electrode was used as an auxiliary electrode, Ag / AgCl was used as a reference electrode, and the nanoporous silver metal obtain...

Embodiment 2

[0036] Cu with a diameter of Ф1.5mm 40 Zr 40 Ag 20 The amorphous rods were cut into short rods with a length of 10 mm. It is placed in a corrosive solution for free dealloying. The experimental conditions will contain 0.1M HF and 0.6M HNO 3 The mixed solution of HF and HNO is used as the corrosion solution 3 The volume ratio of the solution is 1:1, the corrosion time is 3 hours, and the corrosion temperature is 25°C. After taking it out, it is washed with deionized water to obtain nanoporous silver metal. The as-prepared nanoporous silver has a three-dimensional (3D) nanoporous morphology with a uniform, bicontinuous ligament / hole structure. The nanoporous silver layer has a thickness of 130 μm, a ligament width of 50 nm, and a pore diameter of 150 nm.

[0037] A platinum electrode was used as an auxiliary electrode, Ag / AgCl was used as a reference electrode, and the nanoporous silver metal obtained in the previous step was used as a working electrode to form a three-el...

Embodiment 3

[0041] Cu with a diameter of Ф2mm 45 Zr 45 Ag 10 The amorphous rods were cut into short rods with a length of 10 mm. It is placed in a corrosive solution for free dealloying. The experimental conditions will contain 0.25M HF and 4M HNO 3 The mixed solution of HF and HNO is used as the corrosion solution 3 The volume ratio of the solution is 1:1, the corrosion time is 5 hours, and the corrosion temperature is 25°C. After taking it out, it is washed with deionized water to obtain nanoporous silver metal. The prepared nanoporous silver has a three-dimensional (3D) nanoporous morphology with a uniform, bicontinuous ligament / hole structure. The nanoporous silver layer has a thickness of 160 μm, a ligament width of 110 nm, and a pore size of 100 nm.

[0042] A platinum electrode was used as an auxiliary electrode, Ag / AgCl was used as a reference electrode, and the nanoporous silver metal obtained in the previous step was used as a working electrode to form a three-electrode t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com