Patents

Literature

156 results about "Amorphous matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The amorphous matrix of the nucleolus is digested by pepsin and is therefore protein in nature. There is strong evidence based on autoradiographic studies that nucleolar RNA is discharged into the cytoplasm; there is also cytological evidence that this is so.

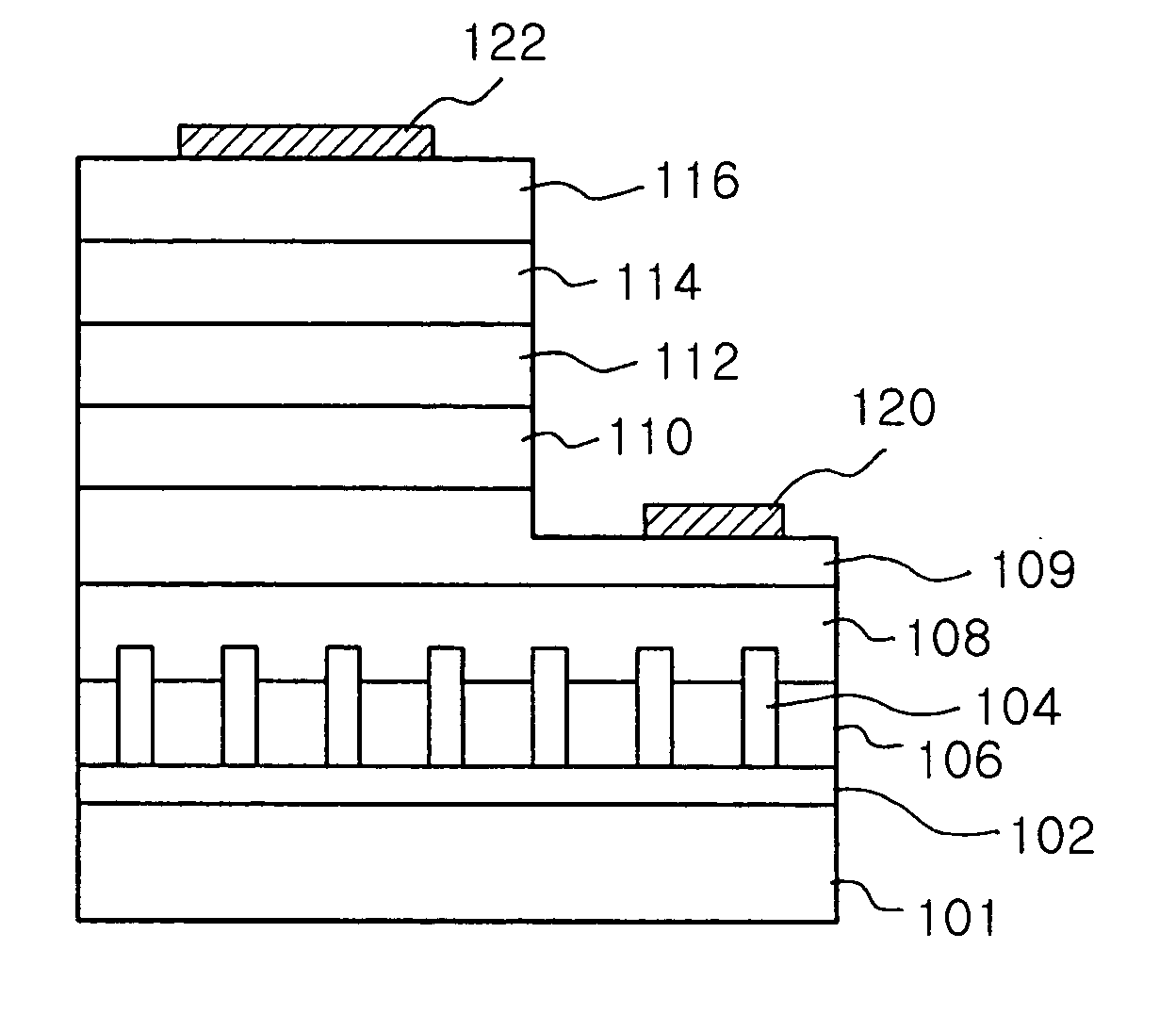

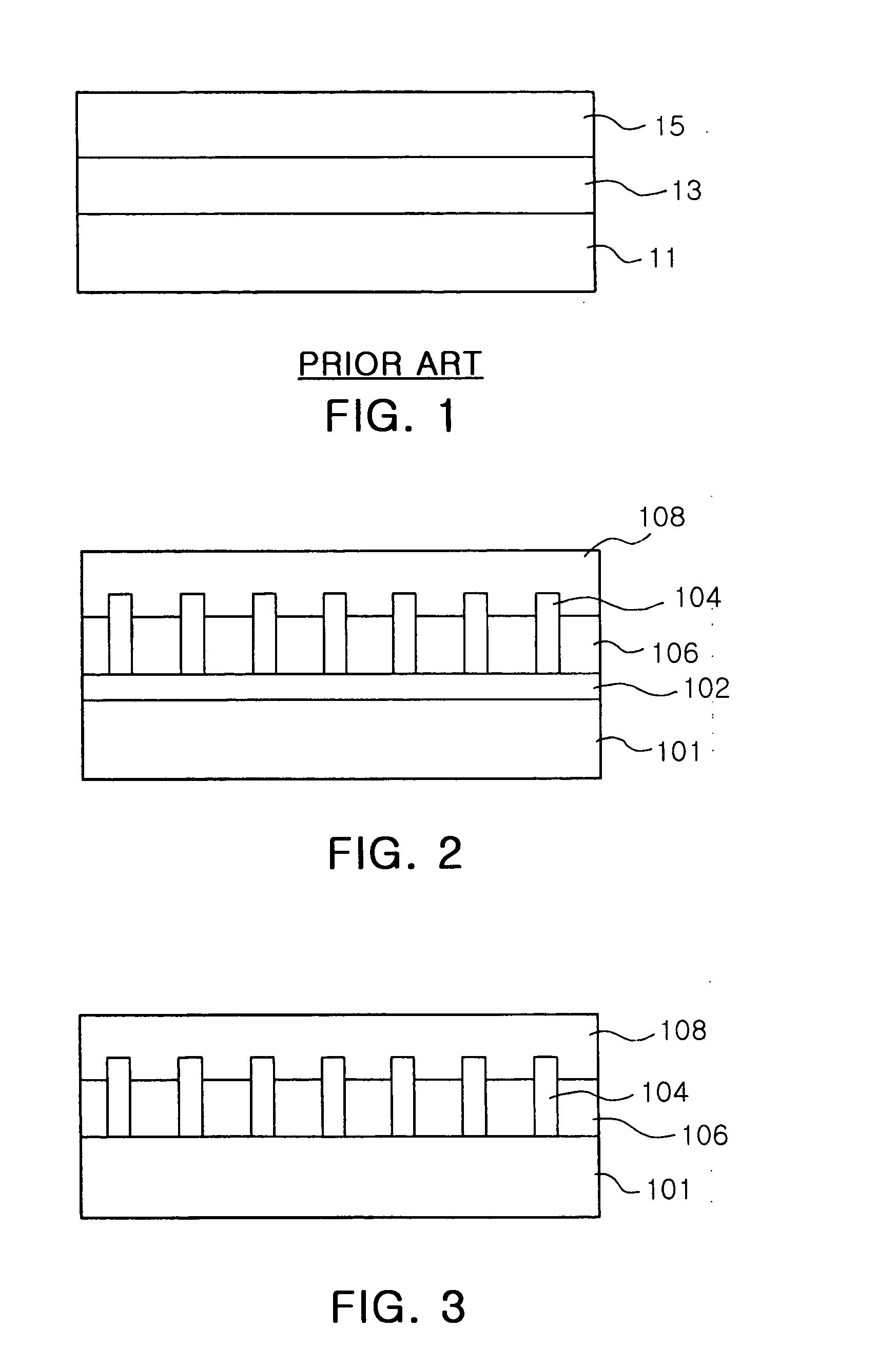

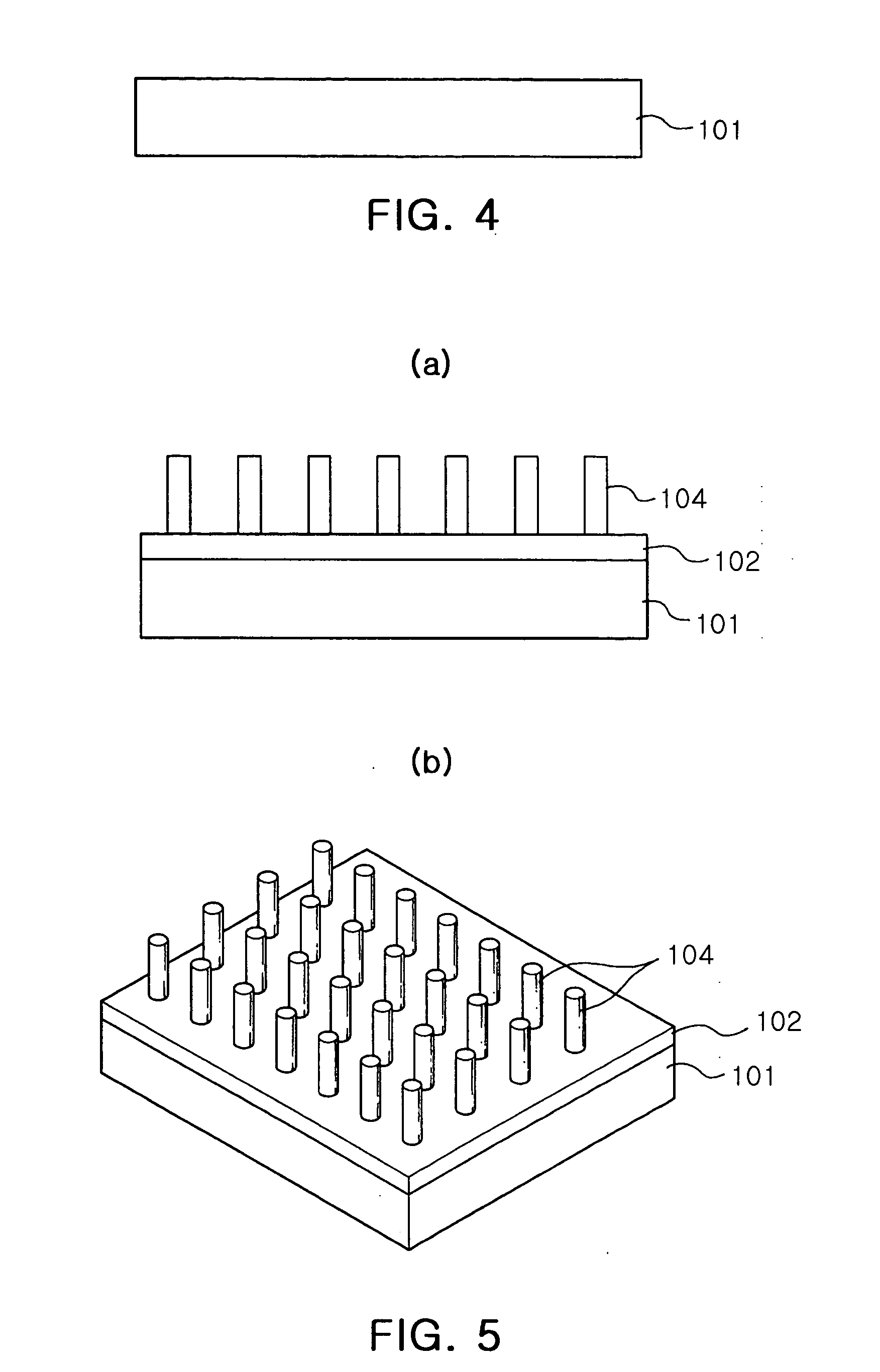

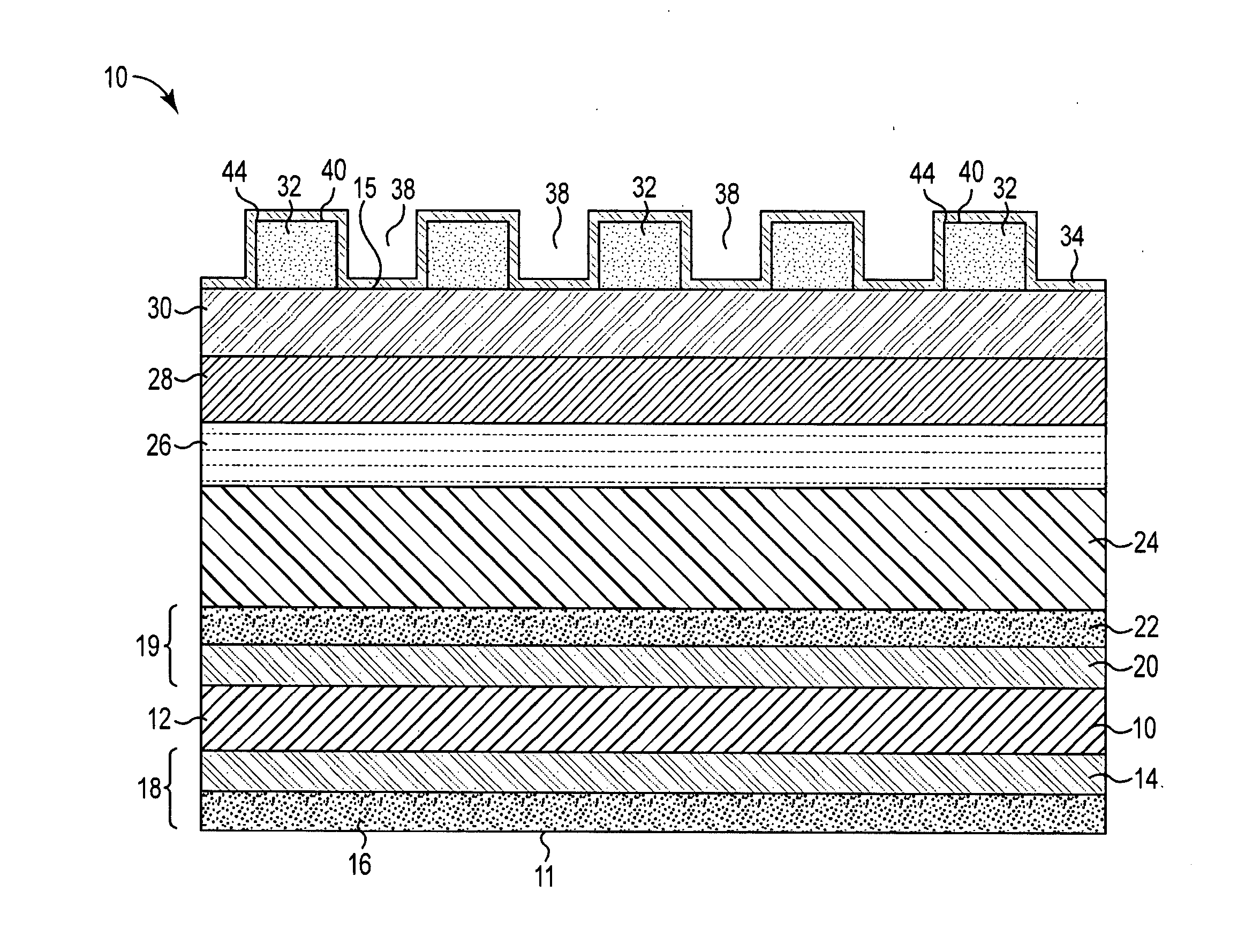

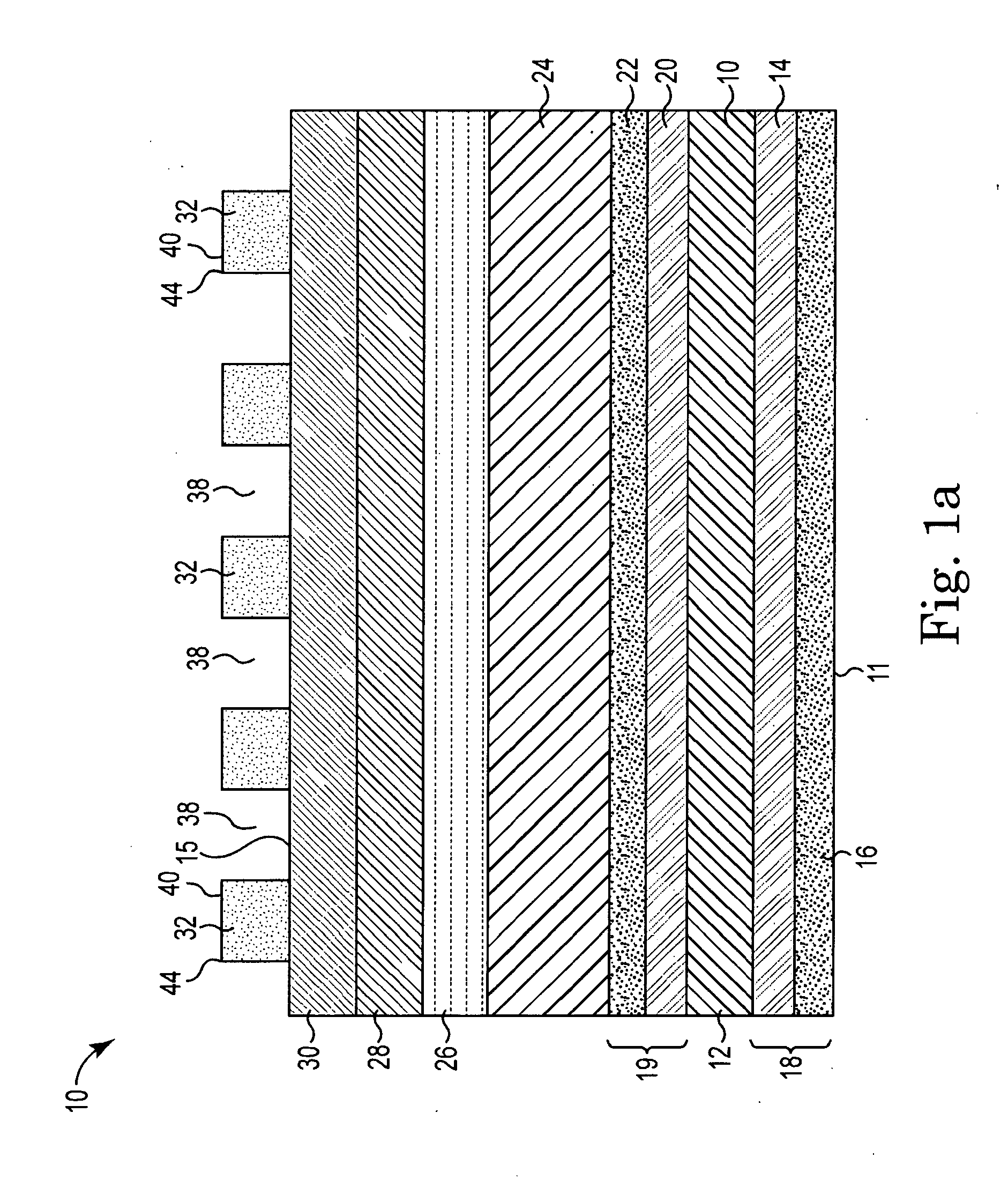

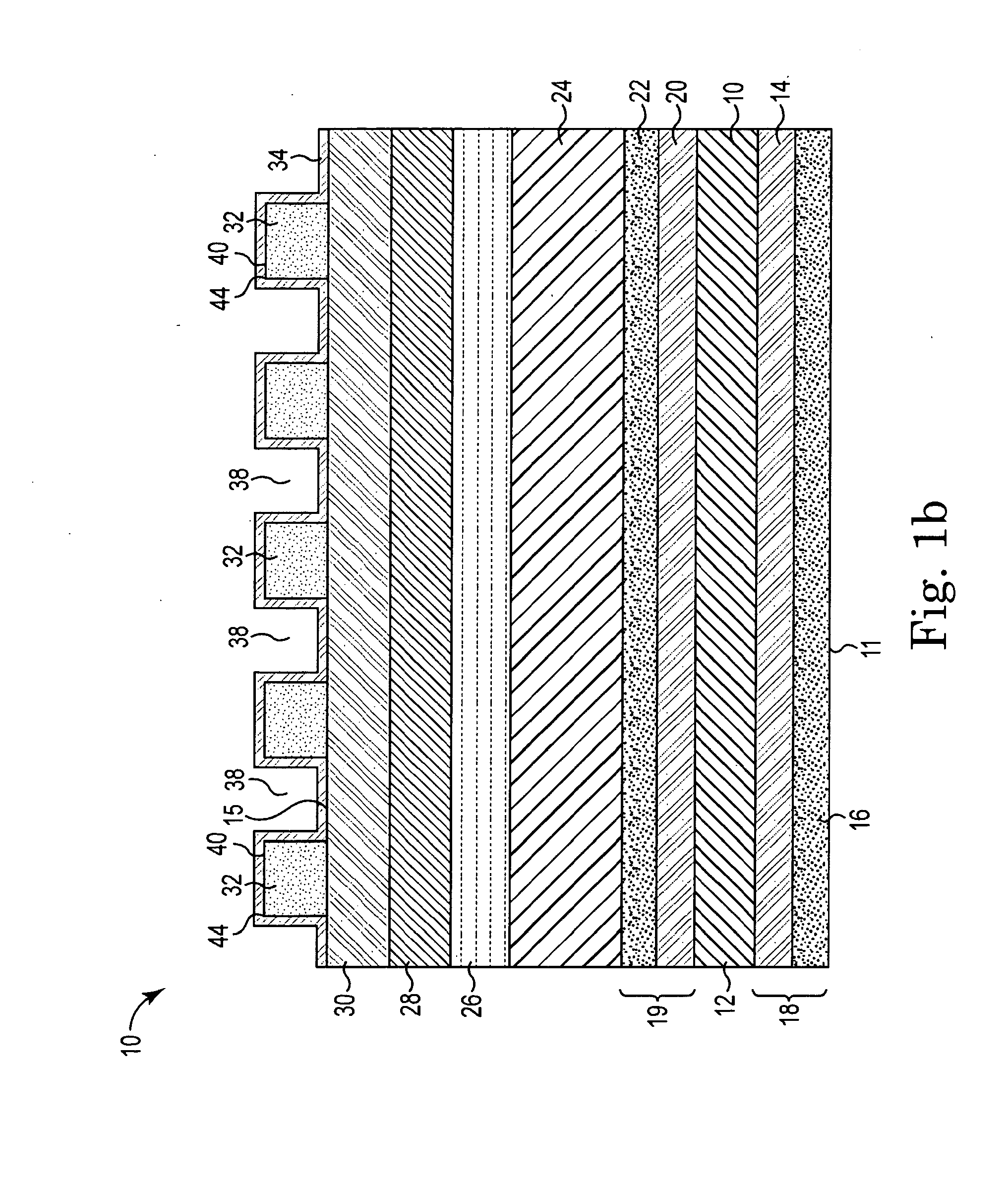

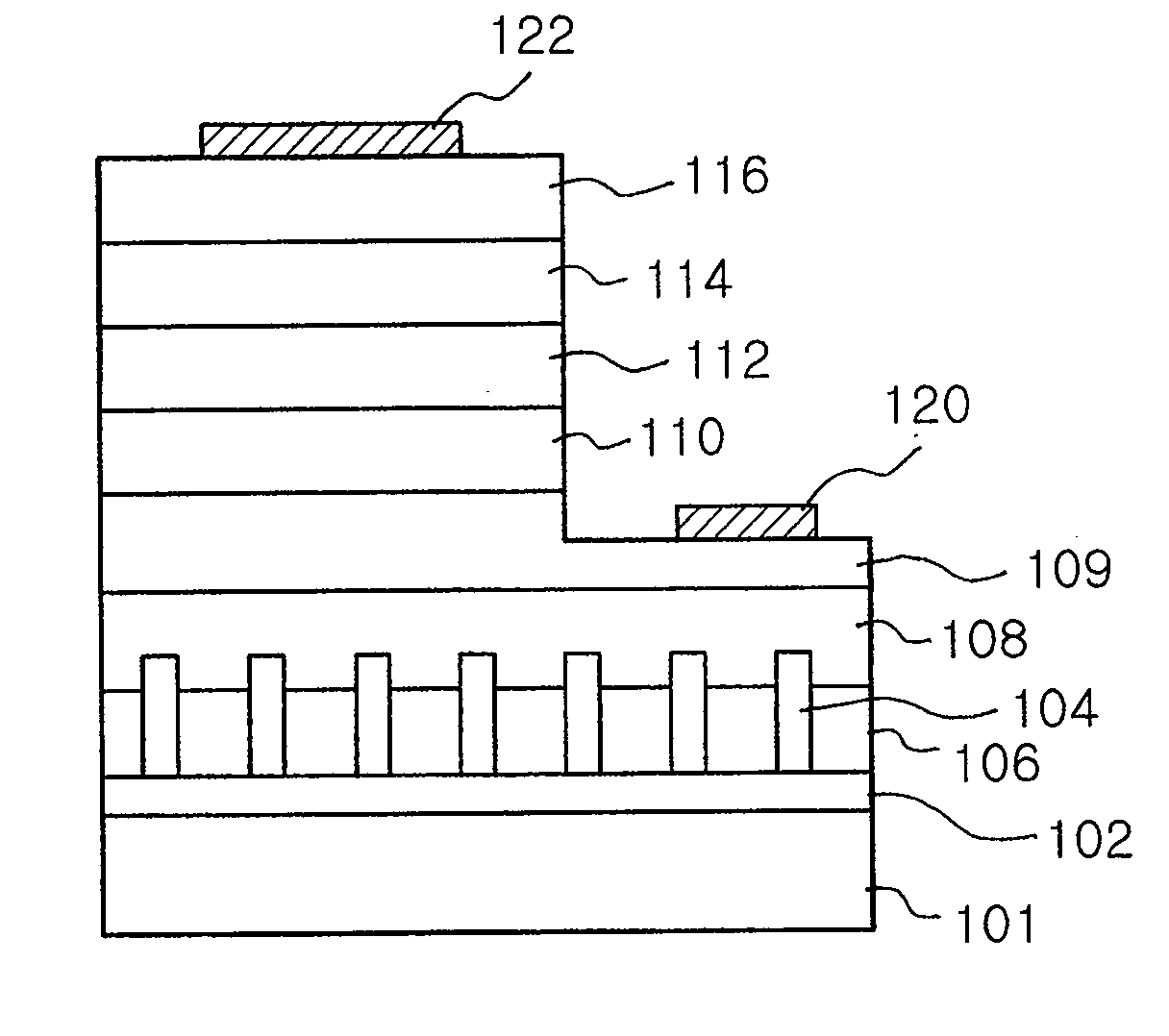

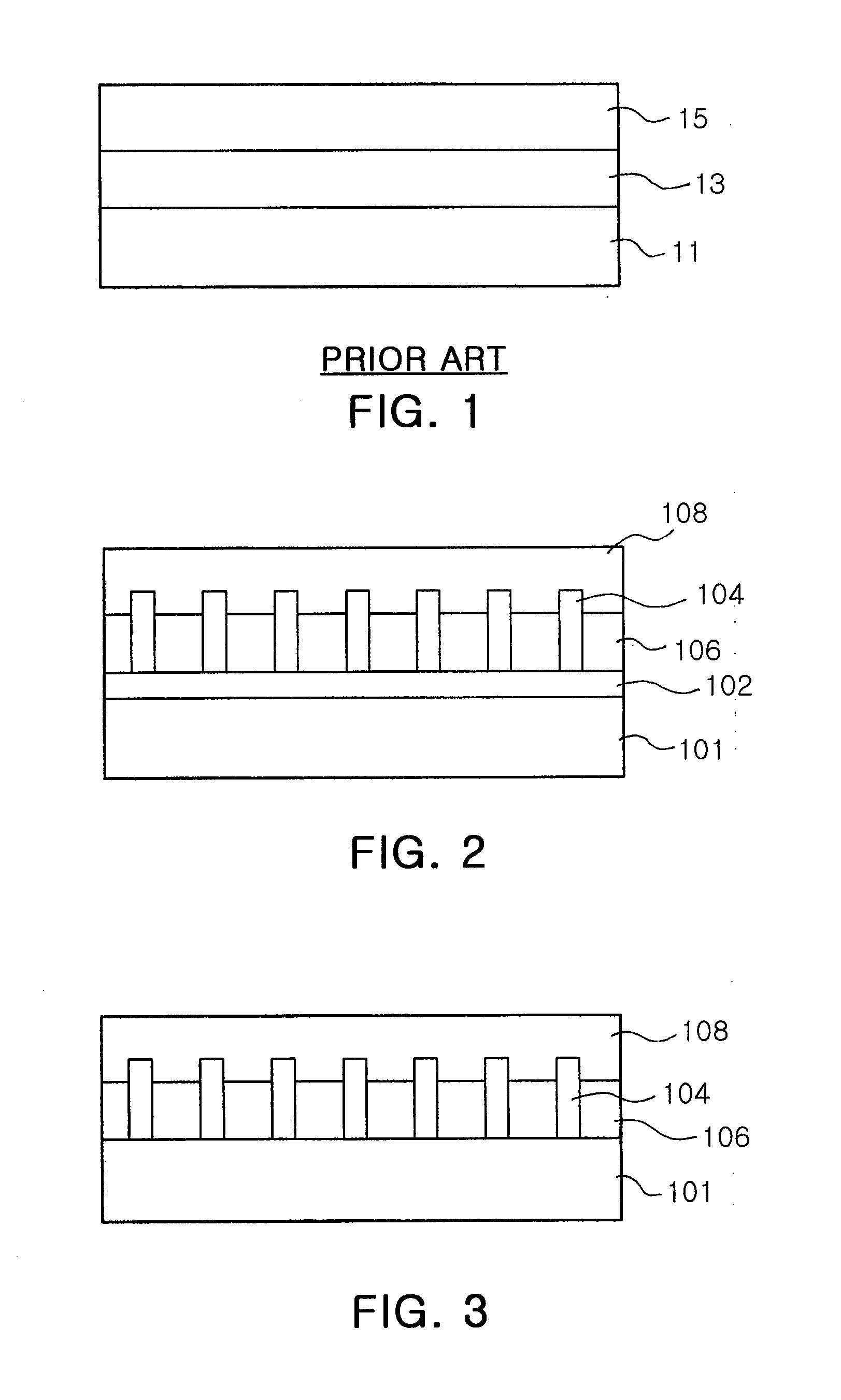

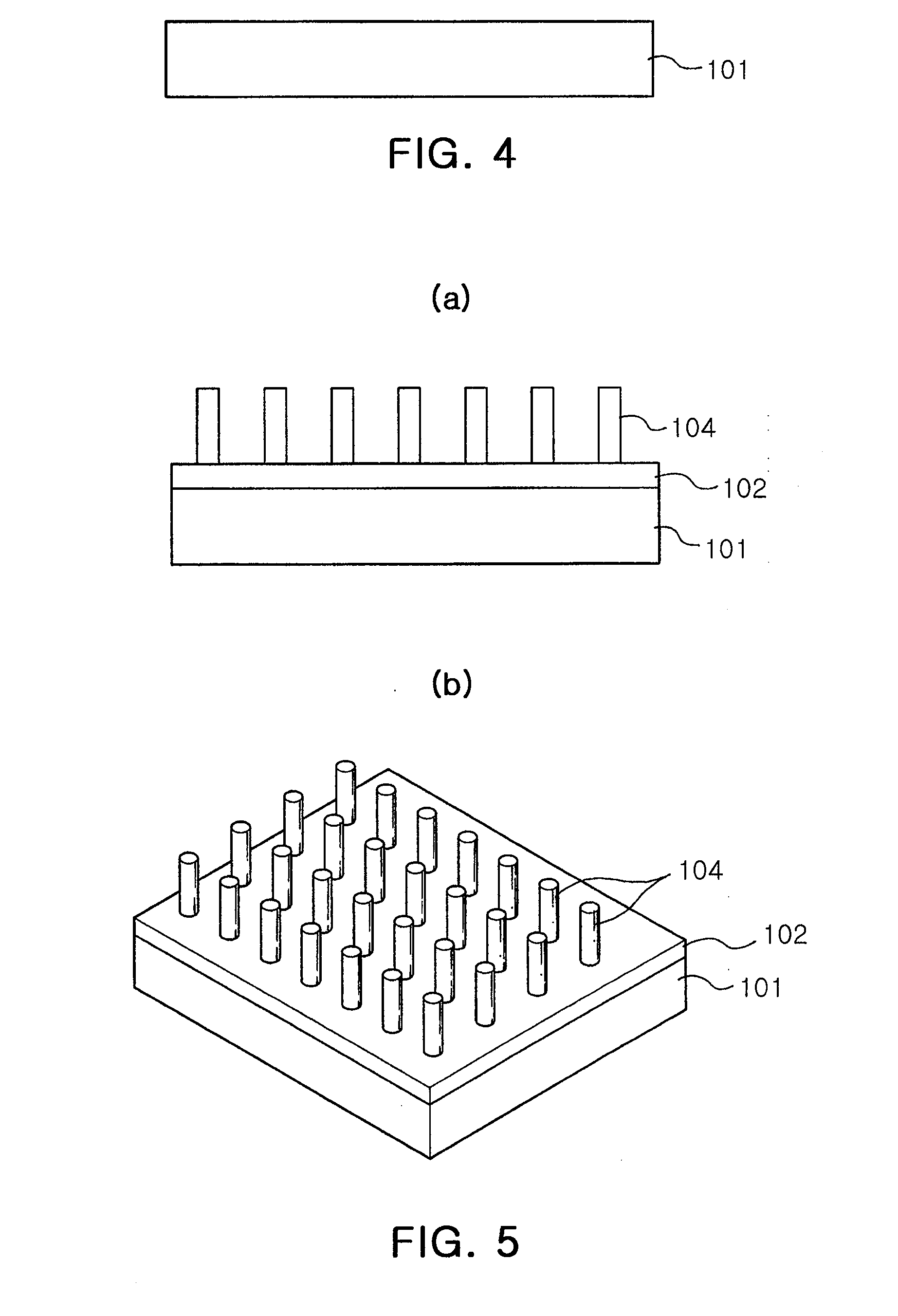

Nitride based semiconductor device using nanorods and process for preparing the same

ActiveUS20060091408A1Reduce thermal stressInhibit the generation of cracksSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialAmorphous matrix

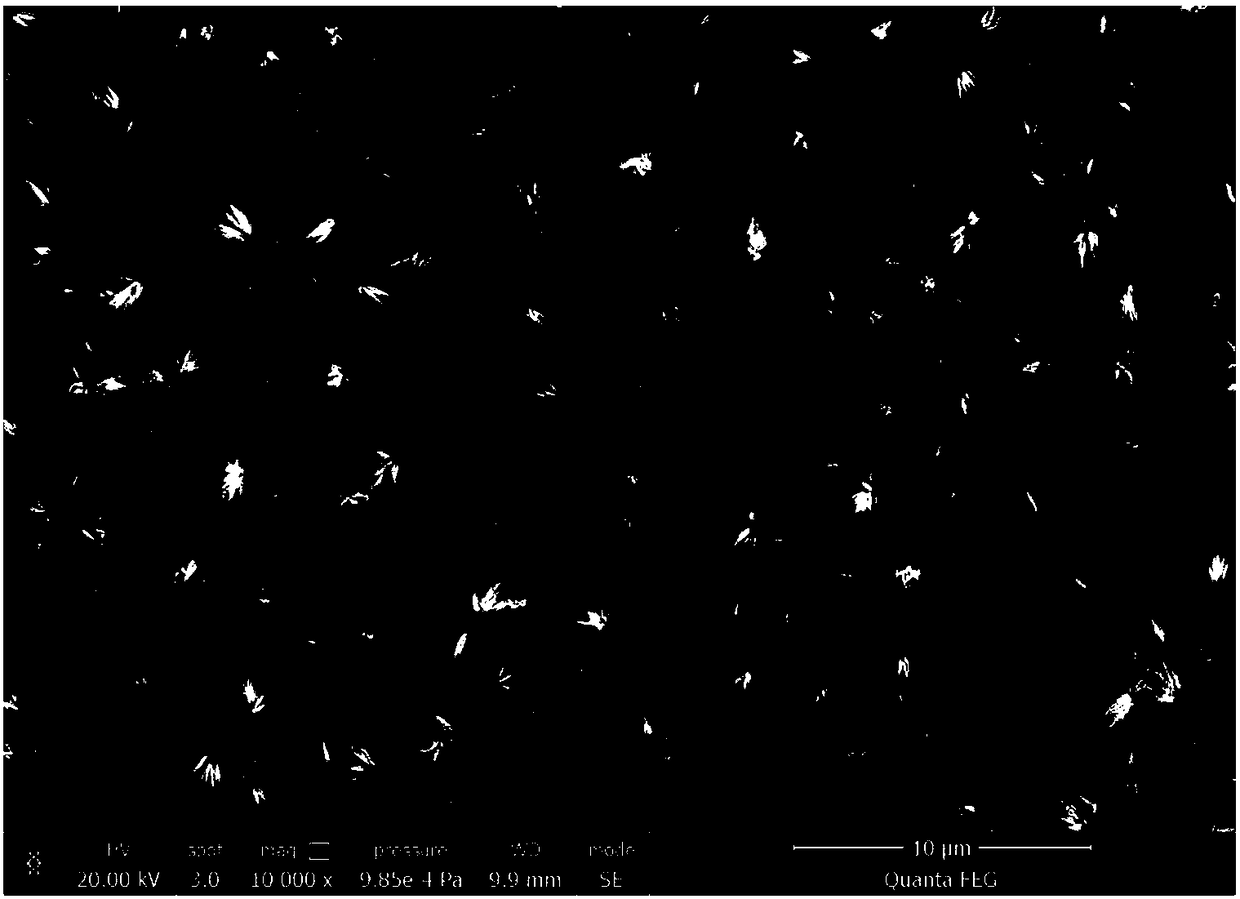

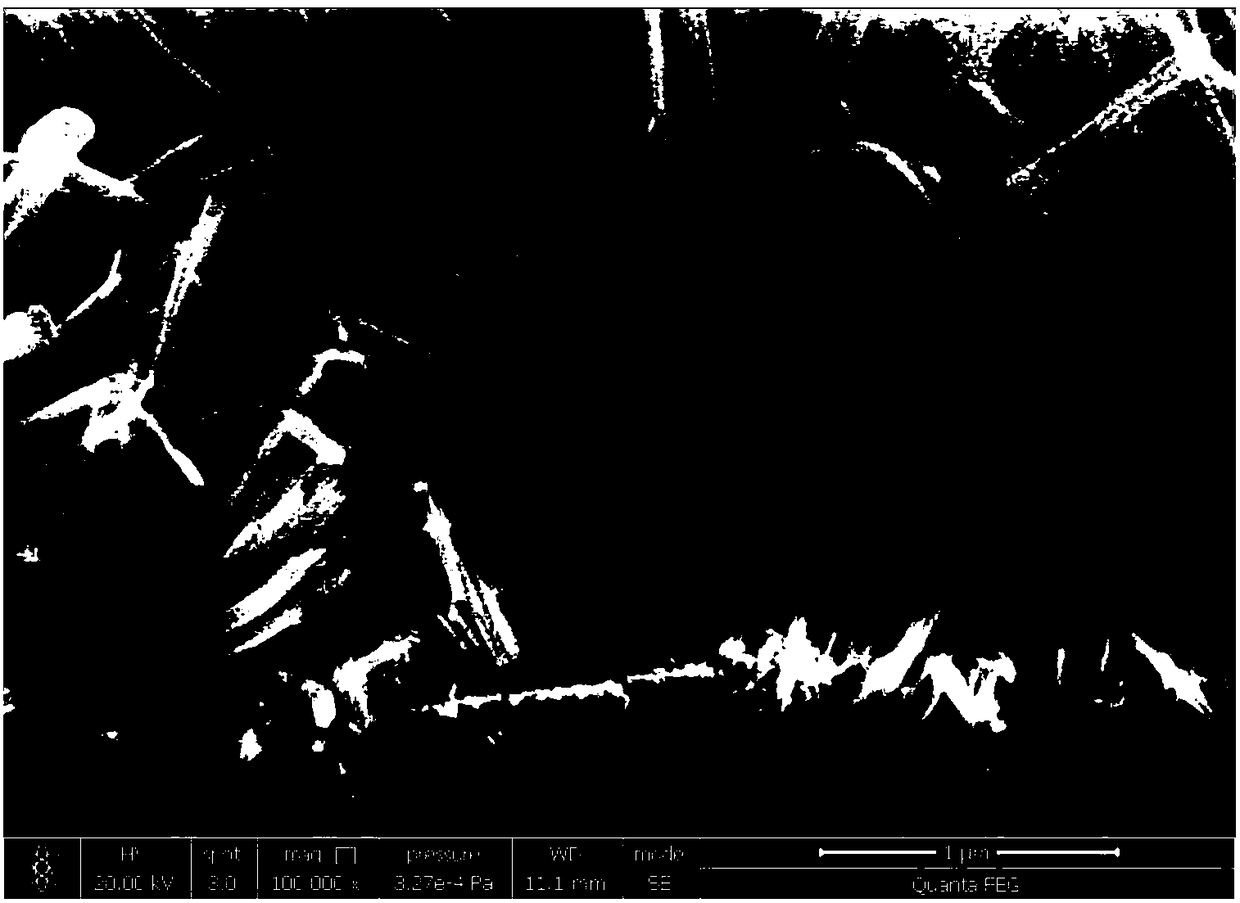

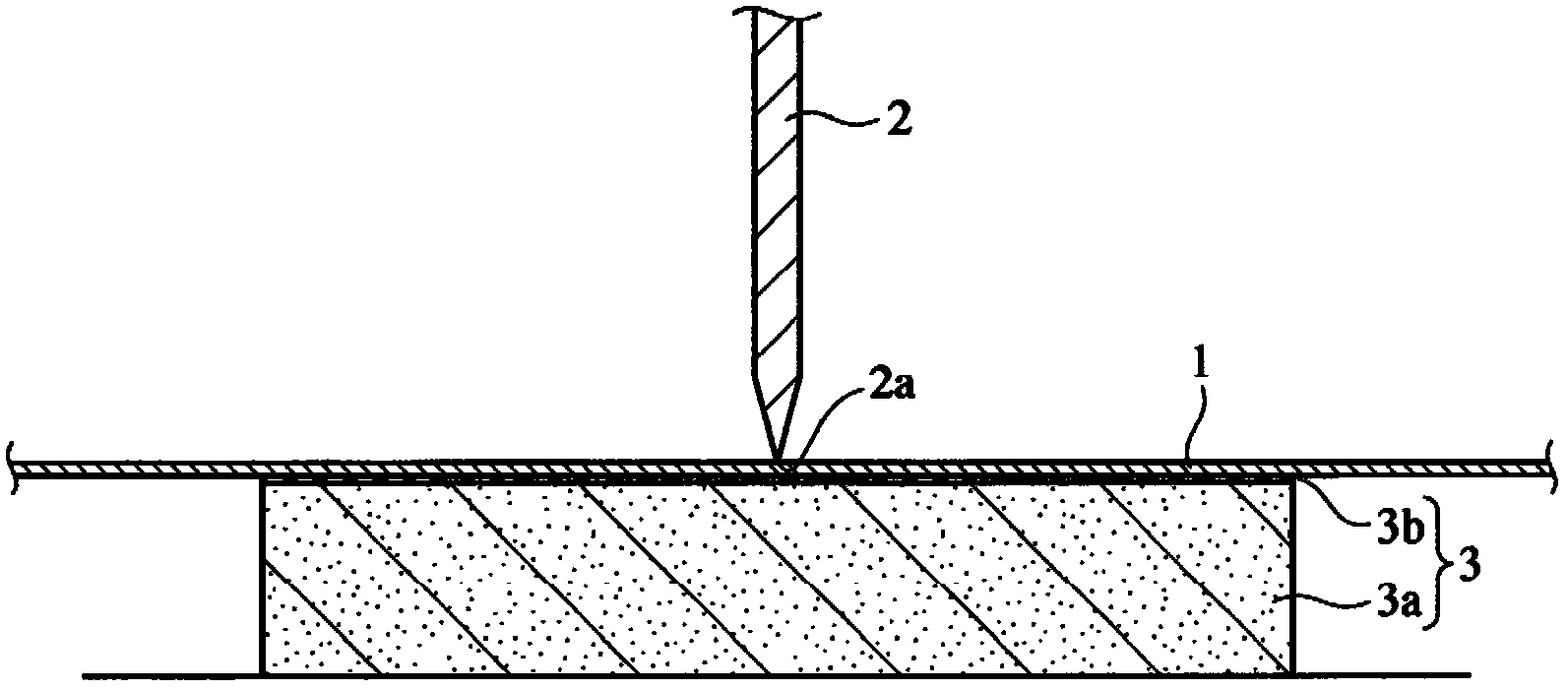

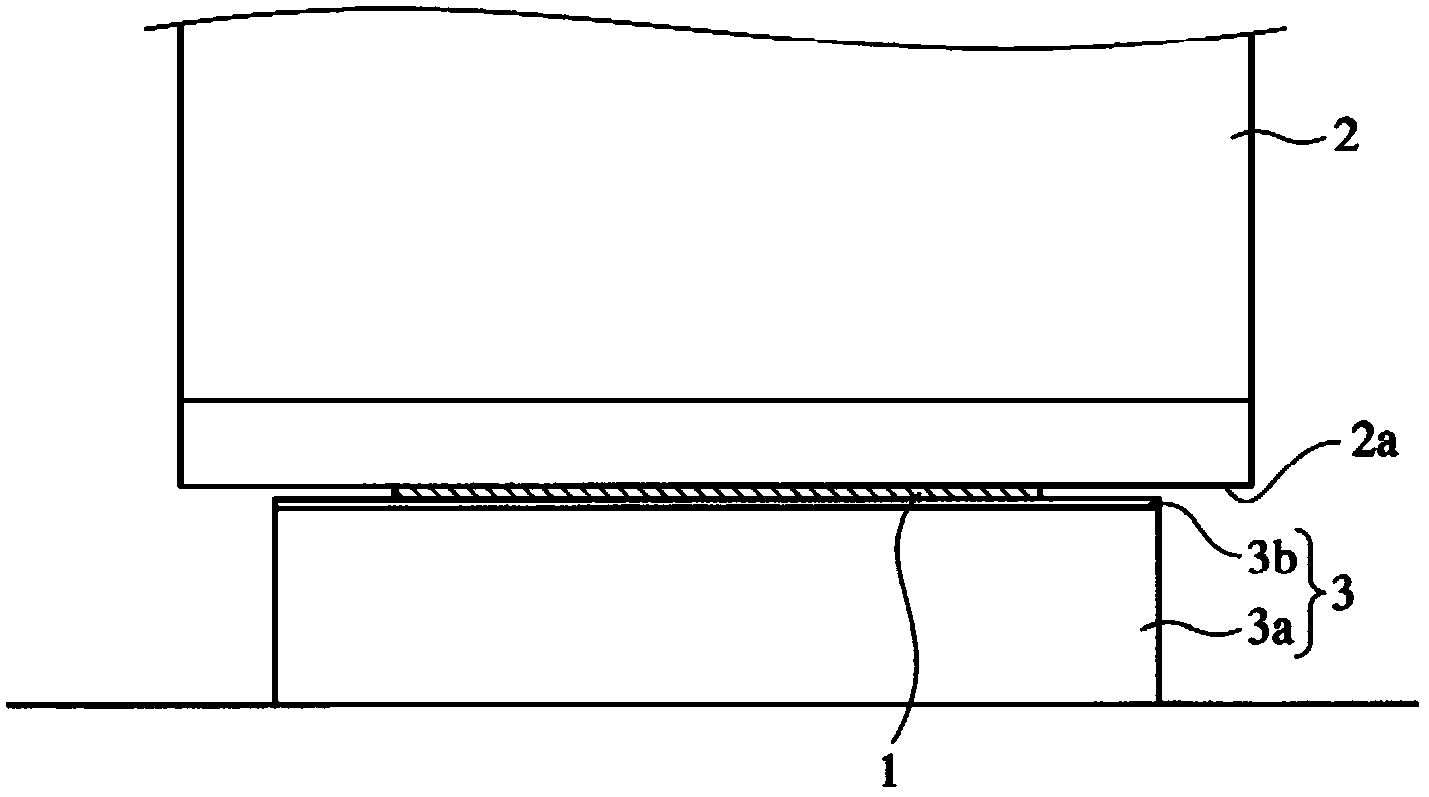

Disclosed are a nitride based semiconductor device, including a high-quality GaN layer formed on a silicone substrate, and a process for preparing the same. A nitride based semiconductor device in accordance with the present invention comprises a plurality of nanorods aligned and formed on the silicone substrate in the vertical direction; an amorphous matrix layer filling spaces between nanorods so as to protrude some upper portion of the nanorods; and a GaN layer formed on the matrix layer.

Owner:SAMSUNG ELECTRONICS CO LTD

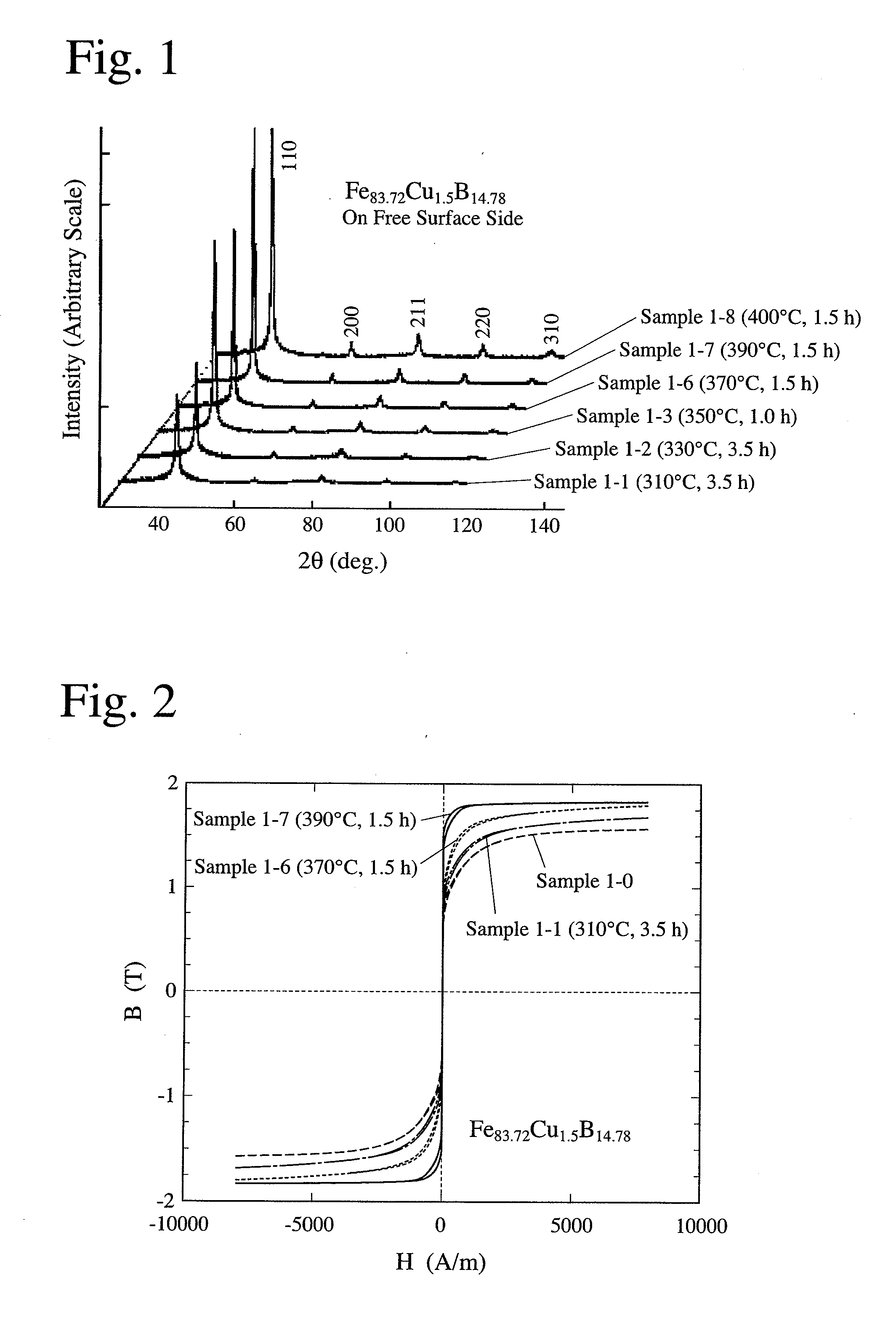

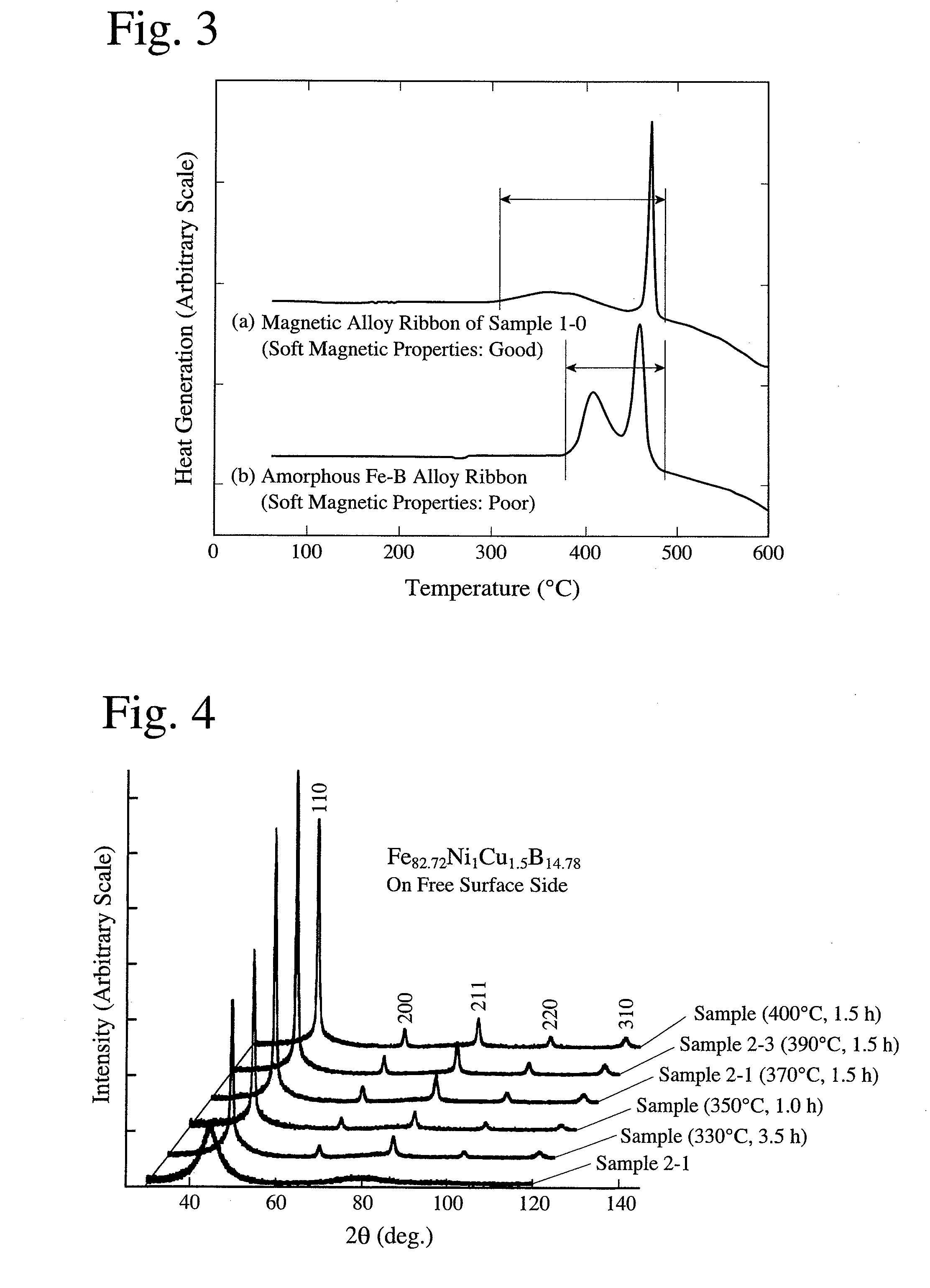

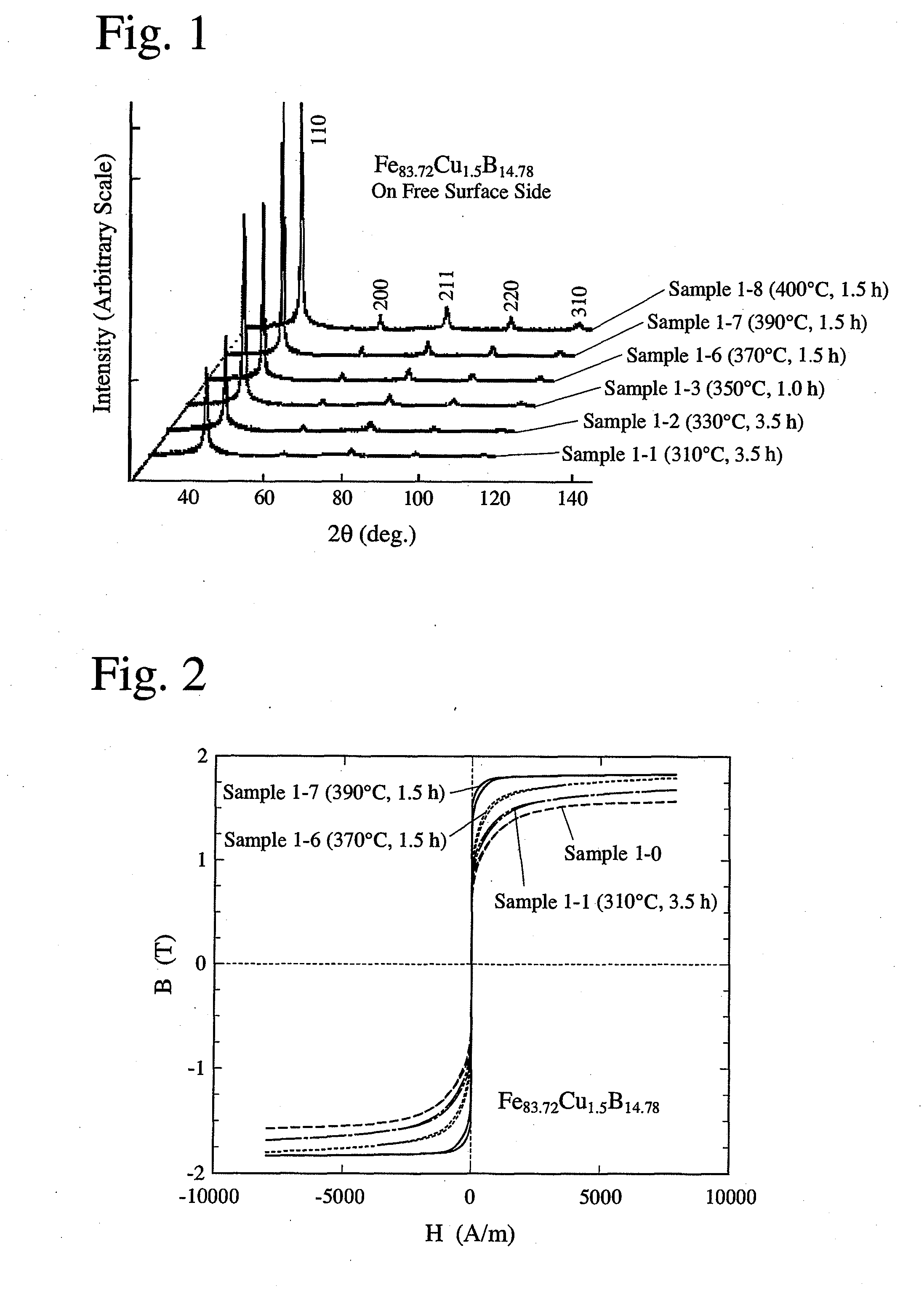

Nano-crystalline, magnetic alloy, its production method, alloy ribbon and magnetic part

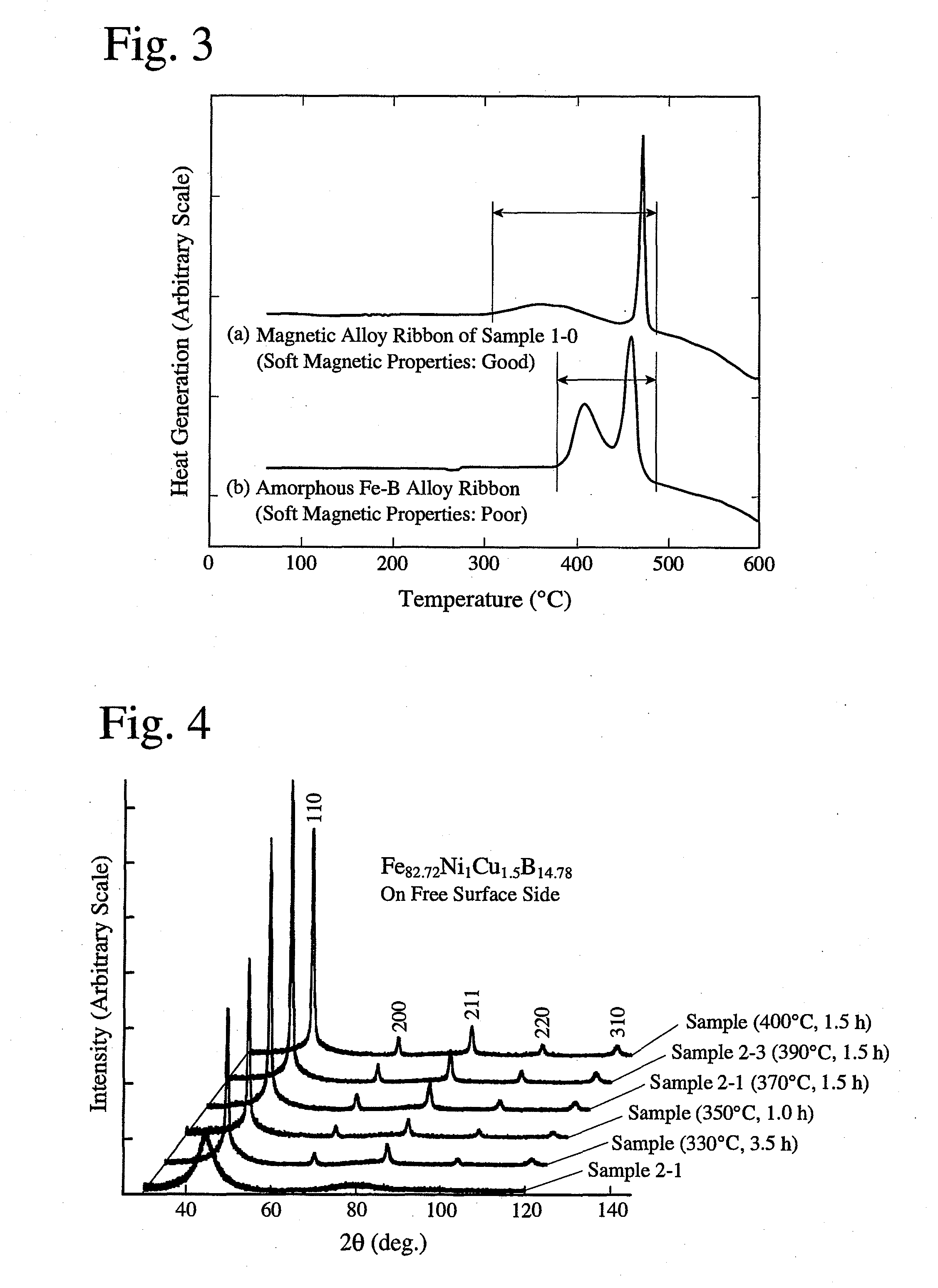

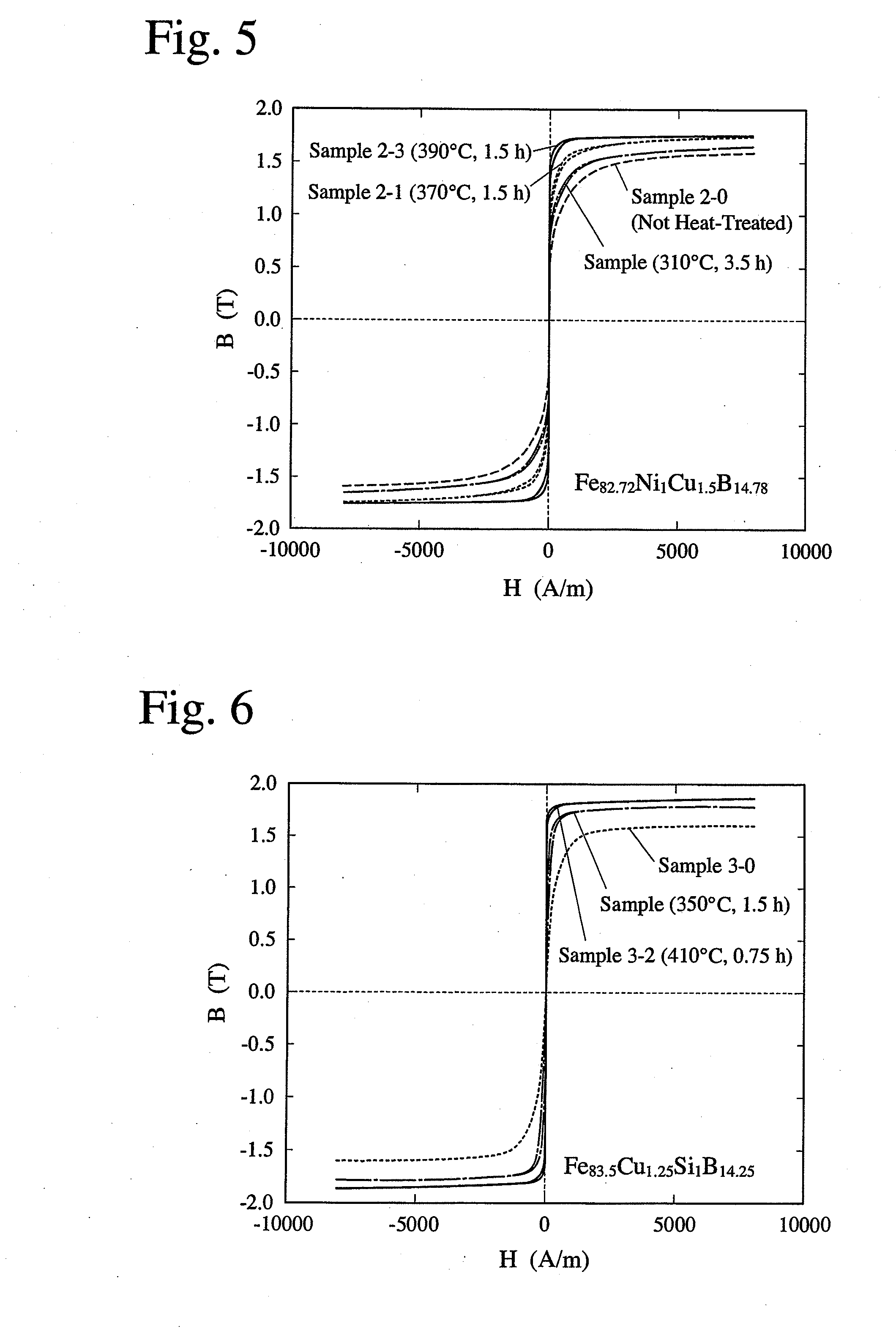

ActiveUS20090266448A1High magnetic flux densityLow coercivityMagnetic materialsVolumetric Mass DensityNano crystalline

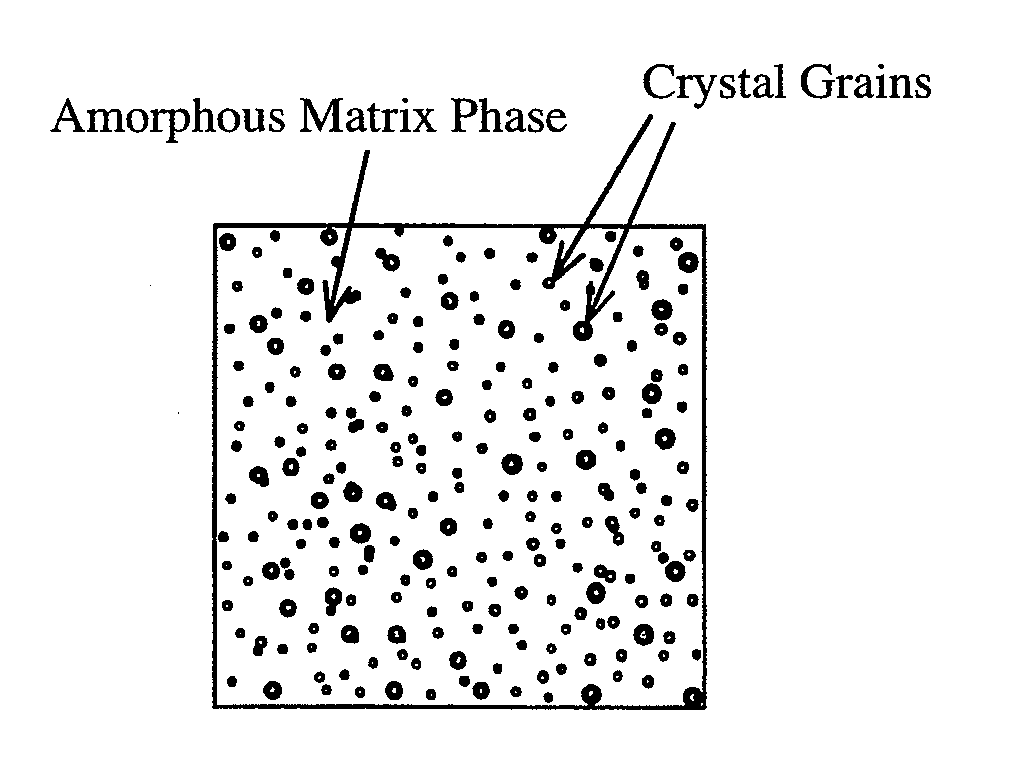

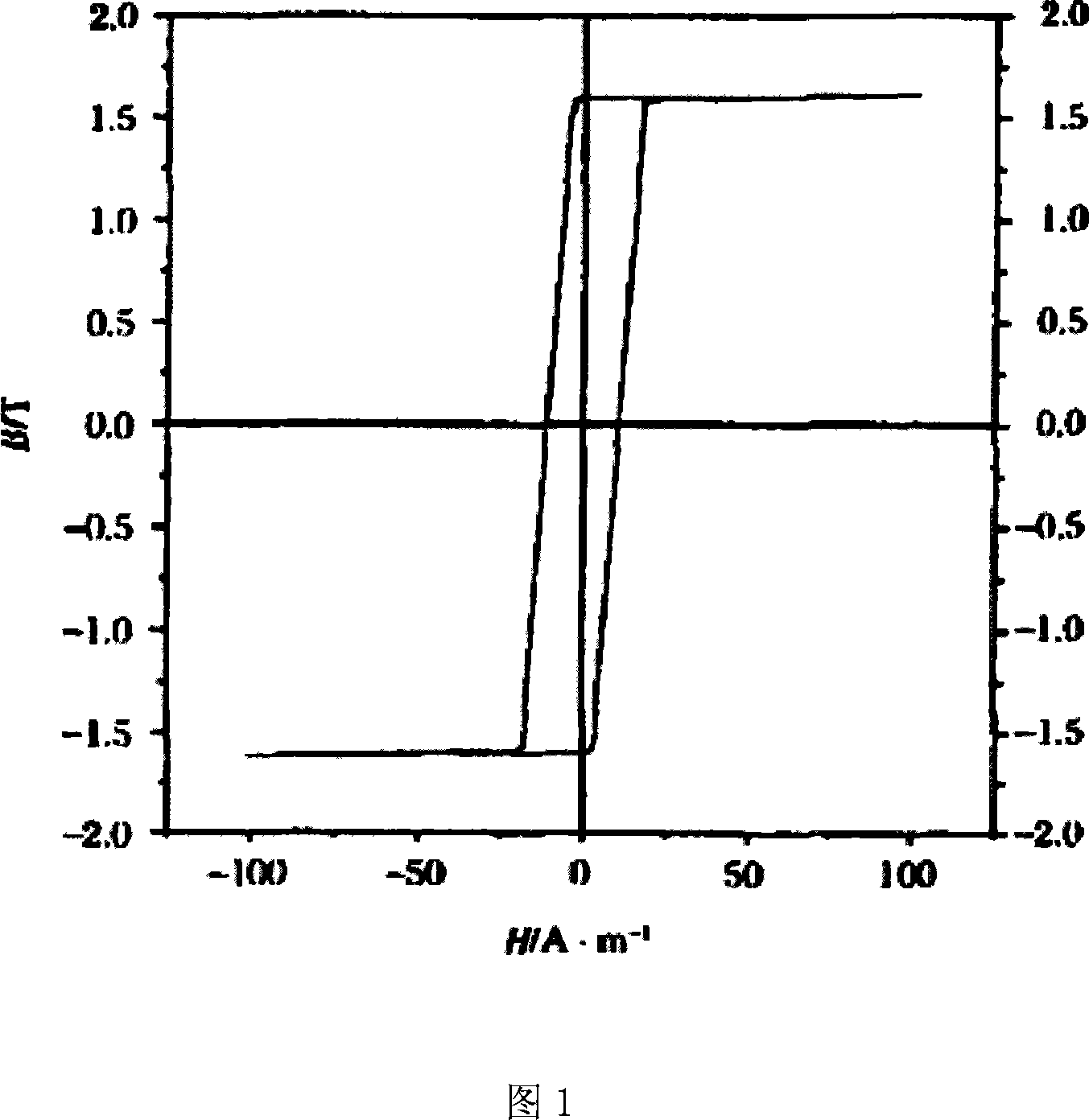

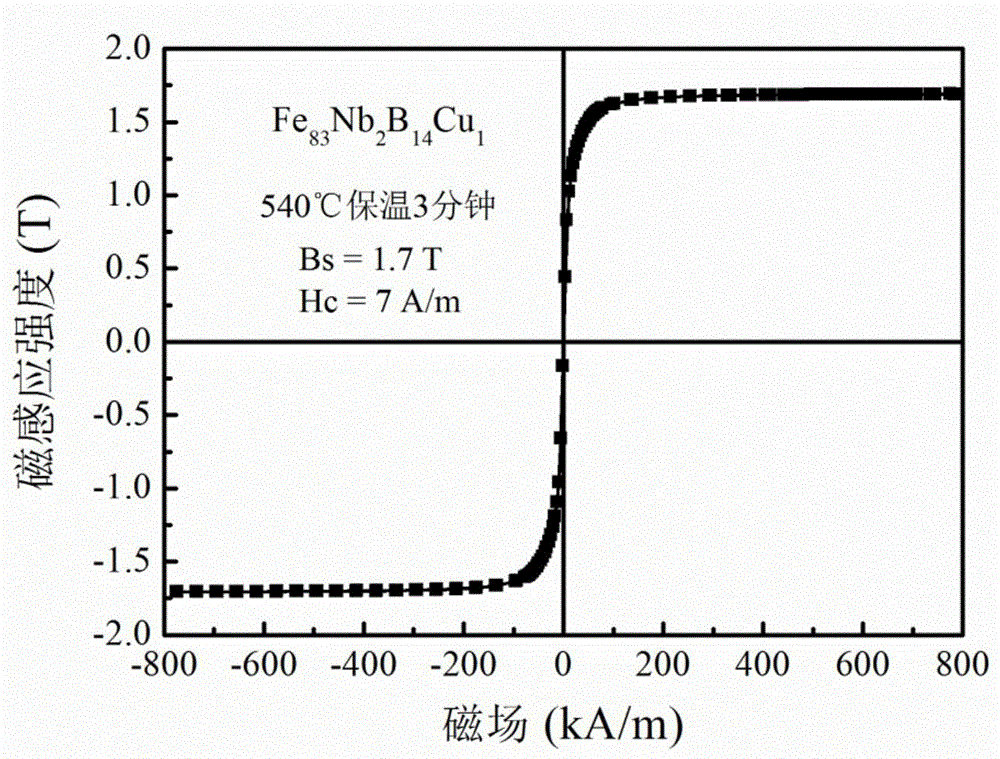

A magnetic alloy having a composition represented by the general formula of Fe100-x-yCuxBy (atomic %), wherein x and y are numbers meeting the conditions of 0.1≦x≦3, and 10≦y≦20, or the general formula of Fe100-x-y-zCuxByXz (atomic %), wherein X is at least one element selected from the group consisting of Si, S, C, P, Al, Ge, Ga and Be, and x, y and z are numbers meeting the conditions of 0.1≦x≦3, 10≦y≦20, 0≦z≦10, and 10<y+z≦24), the magnetic alloy having a structure containing crystal grains having an average diameter of 60 nm or less in an amorphous matrix, and a saturation magnetic flux density of 1.7 T or more.

Owner:HITACHI METALS LTD

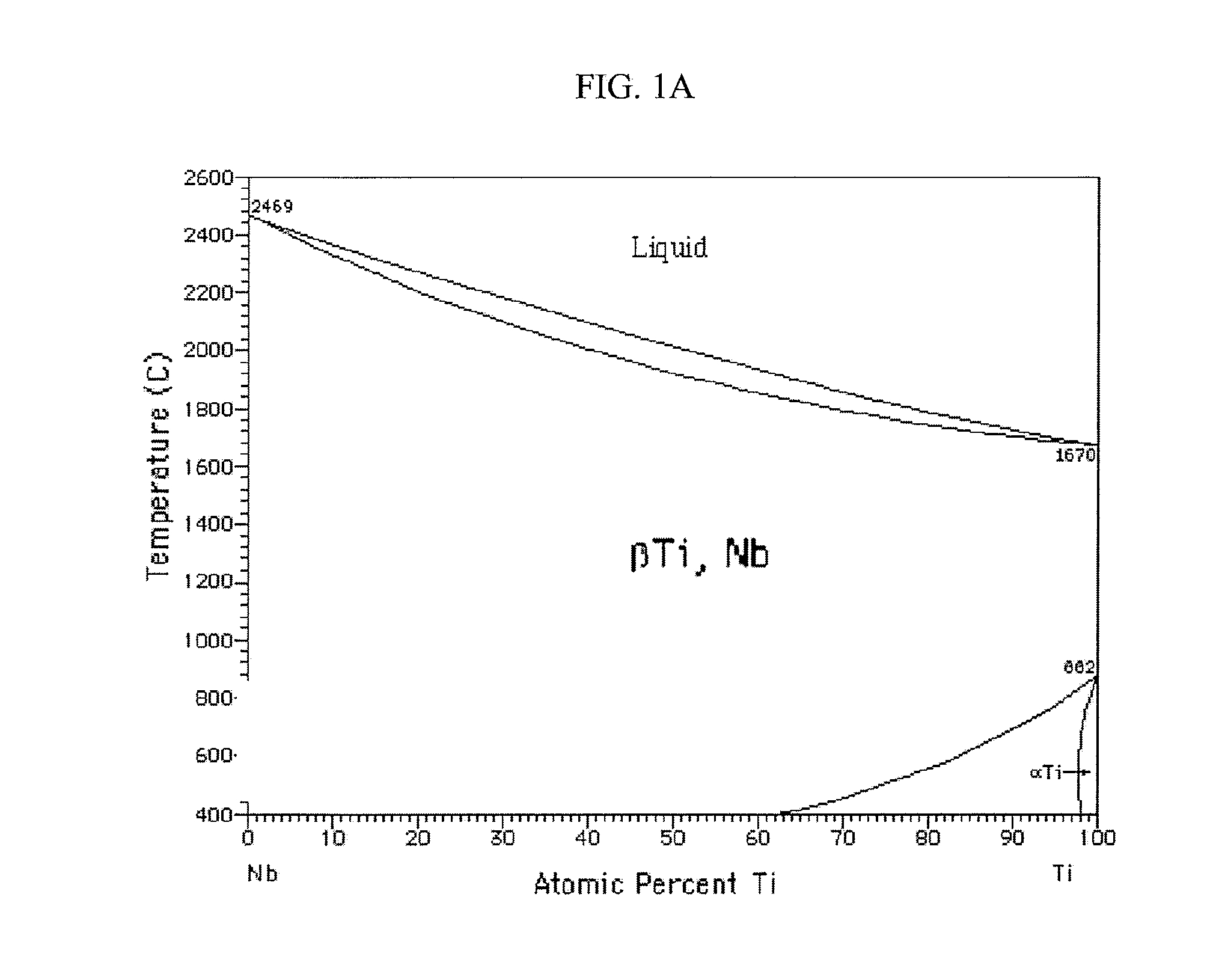

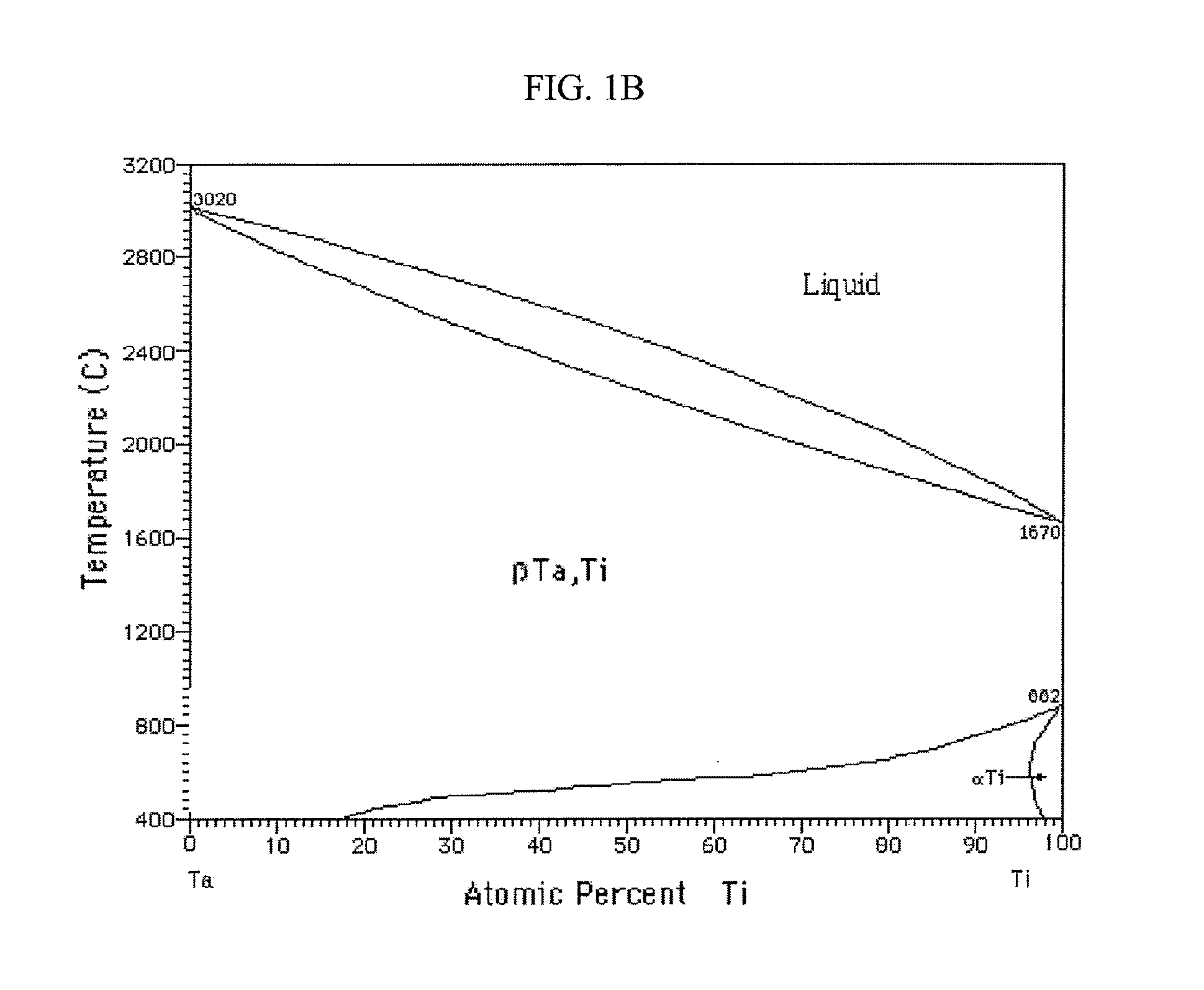

Titanium-based bulk amorphous matrix composite and method of fabricating thereof

InactiveUS20130333814A1Maintain good propertiesImprove hydrogen permeabilityTitaniumAmorphous matrix

A Ti-based bulk amorphous matrix composite including a composition represented by Formula 1, in at %:TiaZrbBecCudNieMfIg Formula 1where M is at least one of Nb and Ta, I is an impurity, and a, b, c, d, e, and f vary within the ranges 38≦a≦50, 11≦b≦18, 12≦c≦20, 6≦d≦10, 6≦e≦9, 1≦f≦20 and 0.01≦g≦0.5, with a+b+c+d+e+f+g=100.

Owner:KOREA INST OF SCI & TECH

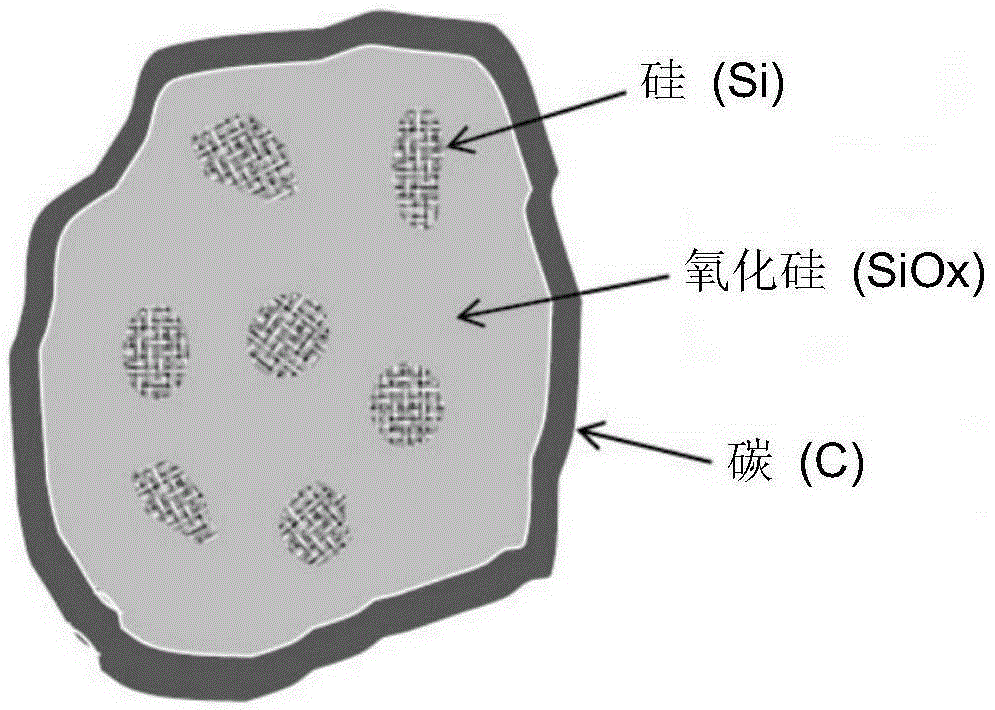

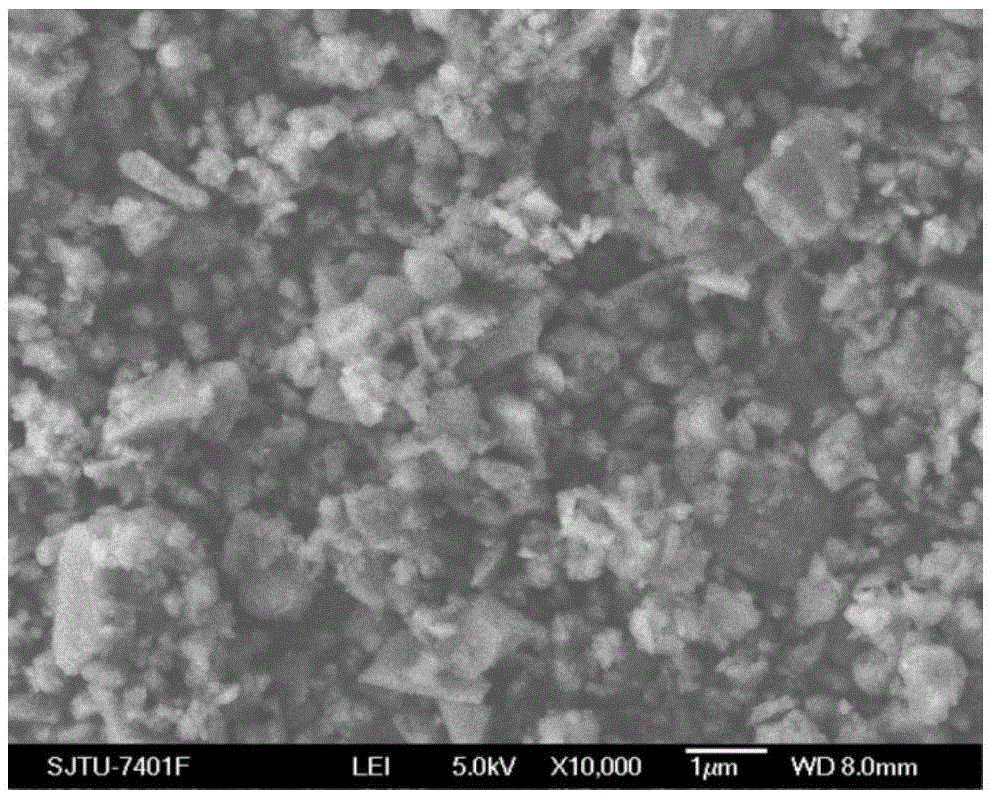

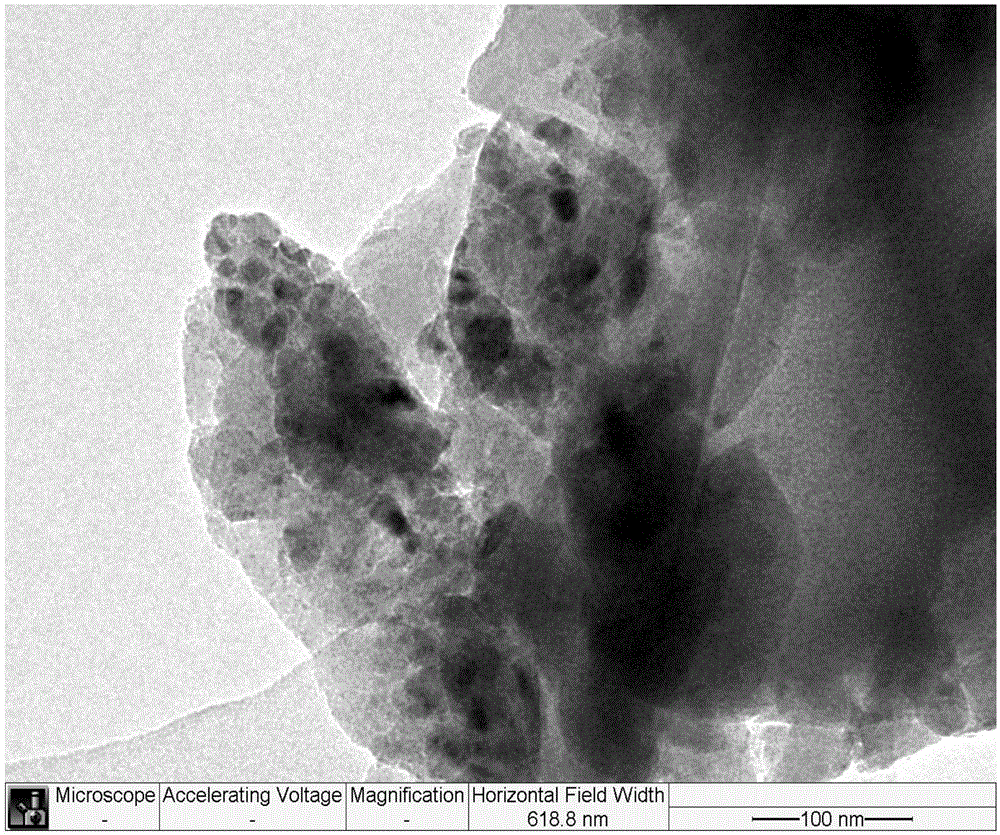

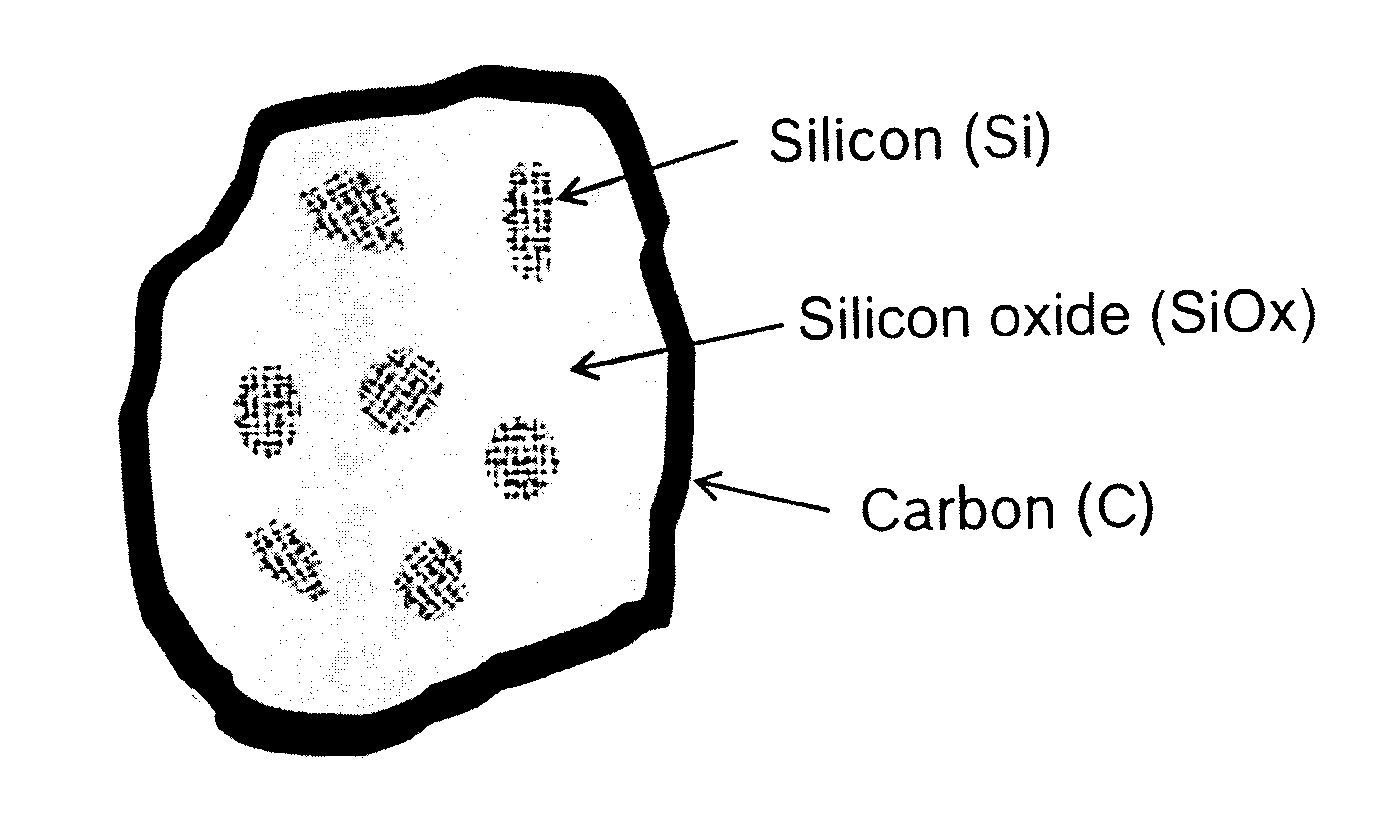

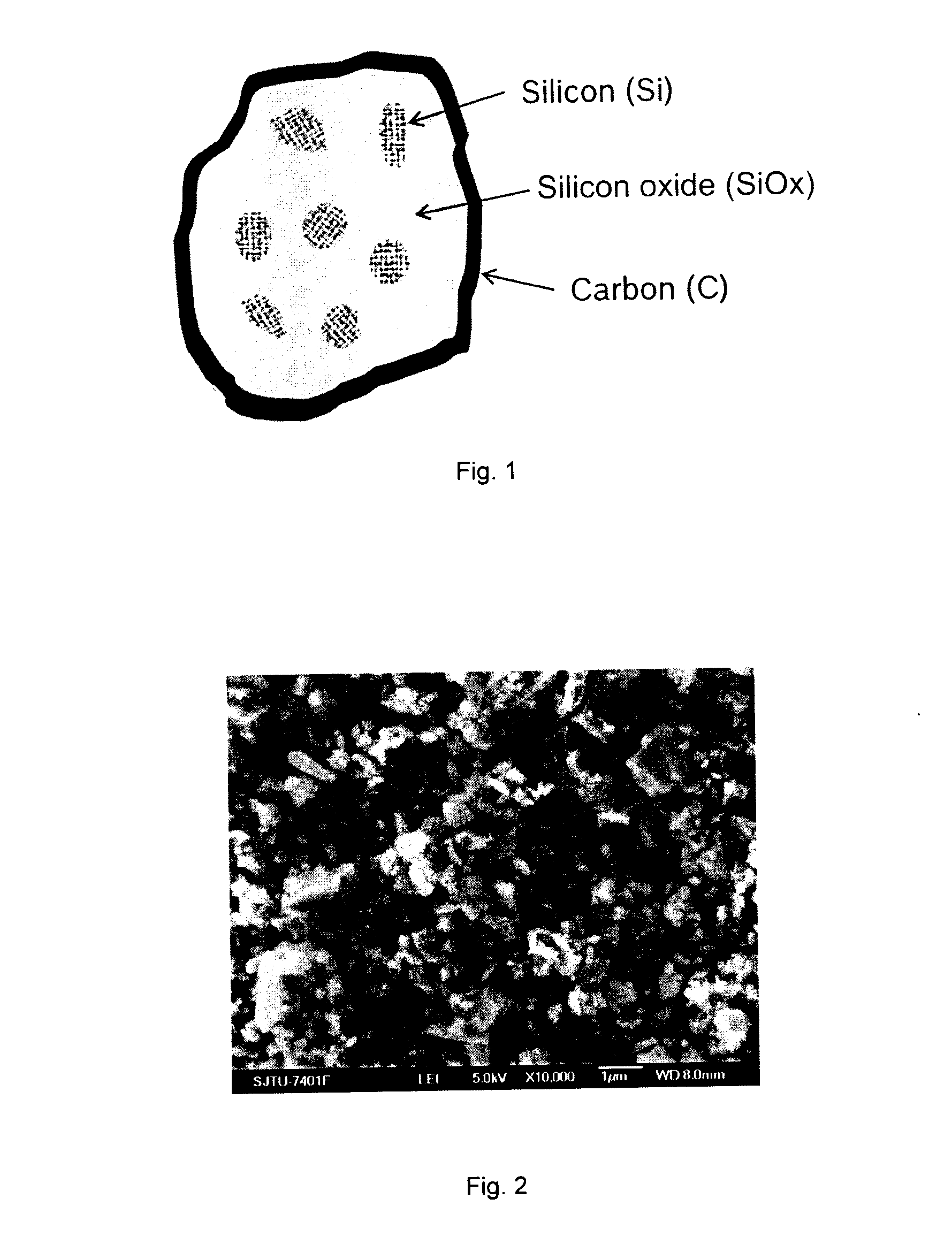

SiOx/Si/c composite material and process of producing thereof, and anode for lithium ion battery comprising said composite material

Owner:ROBERT BOSCH GMBH +1

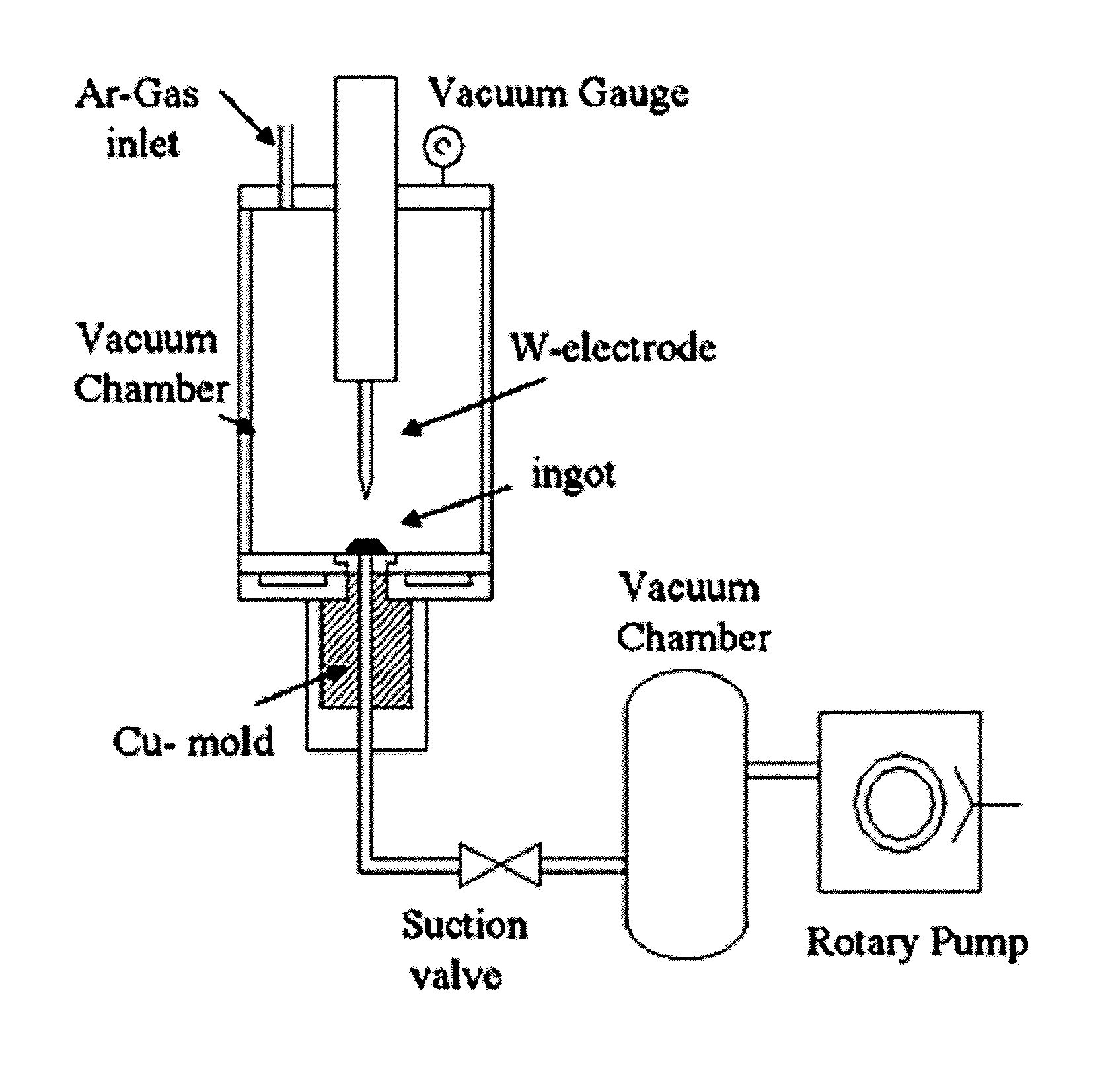

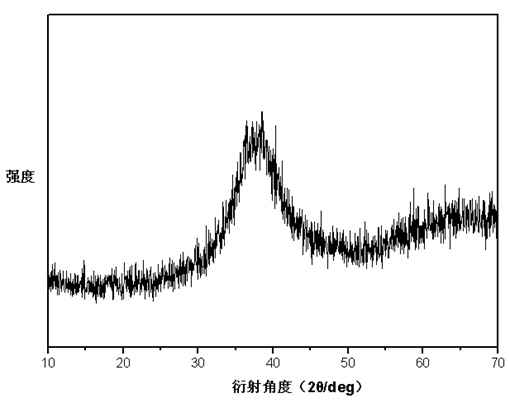

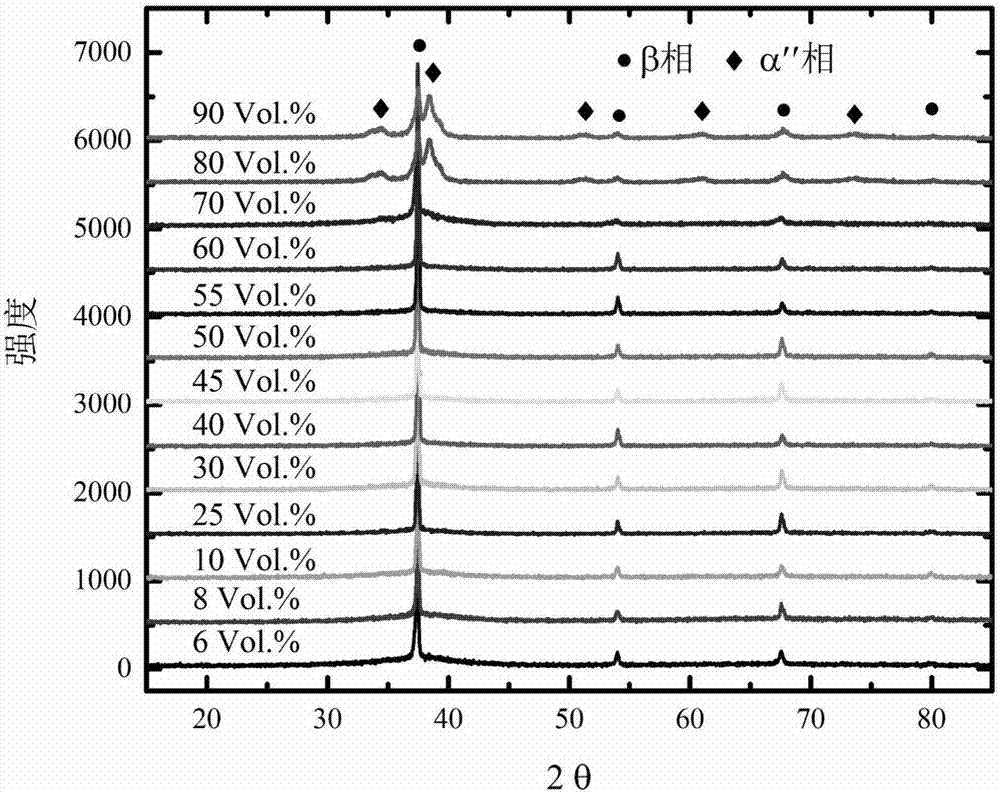

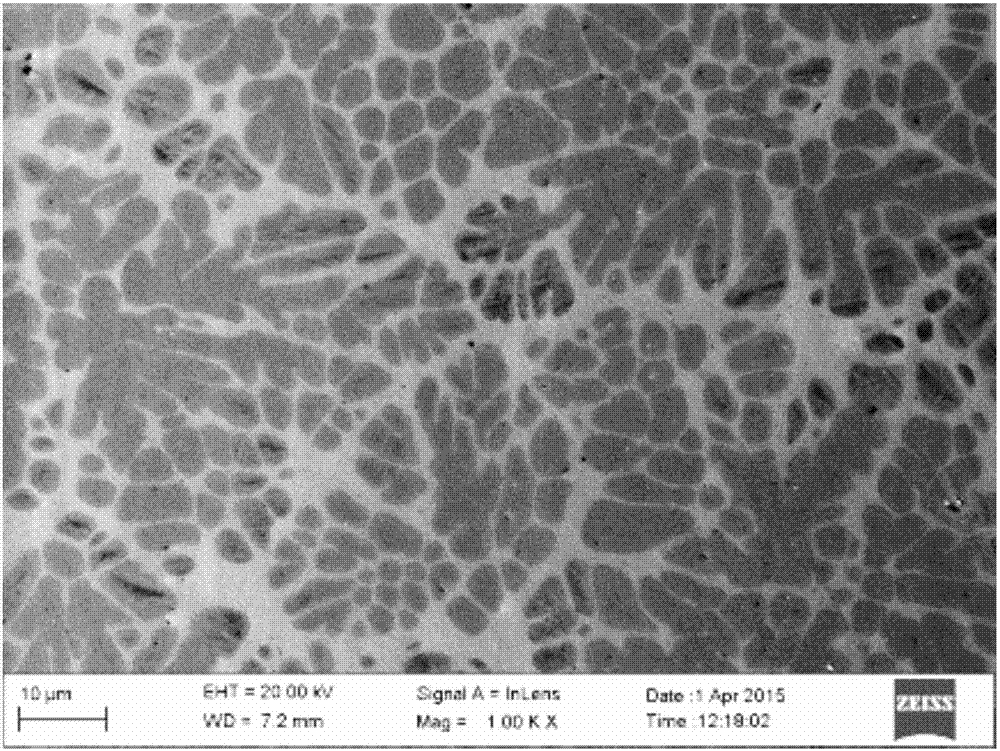

Fe-based amorphous or nanocrystalline soft magnetic alloy and preparation method thereof

InactiveCN101650999AImprovement and optimization of comprehensive soft magnetic propertiesLow costMagnetic materialsElectric arc furnaceAmorphous matrix

The invention discloses a Fe-based amorphous or nanocrystalline soft magnetic alloy, aiming to favorable performance and low cost. Alloy components can be expressed as FeaSibBcCudNbeMf, wherein M is Al, Ni or P; a, b, c, d, e and f are atom percentages, and the change range is as follows: a is more than or equal to 65 and less than or equal to 85, b is more than or equal to 5 and less than or equal to 20, c is more than or equal to 5 and less than or equal to 25, d is more than or equal to 0 and less than or equal to 5, e is more than or equal to 0 and less than or equal to 5, and f is more than or equal to 0.1 and less than or equal to 10; and a+b+c+d+e+f=100. The preparation method comprises the following steps: placing raw materials of pure ferrum, pure copper, and the like into a vacuum electric arc furnace to smelt to obtain an alloy ingot; crushing, placing into a quartz test tube, and preparing an amorphous alloy ribbon by using a single-rolling ribbon throwing method; placing into a tubular annealing furnace, adjusting the temperature to 510-580 DEG C, isothermally annealing under the protection of Ar gas and getting out of the furnace to cool; and obtaining amorphous alloys with different microstructures or nanocrystalline alloys with nanometer crystal particles evenly arranged on an amorphous matrix through controlling alloy cooling speed and heat treatment temperature as well as time.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

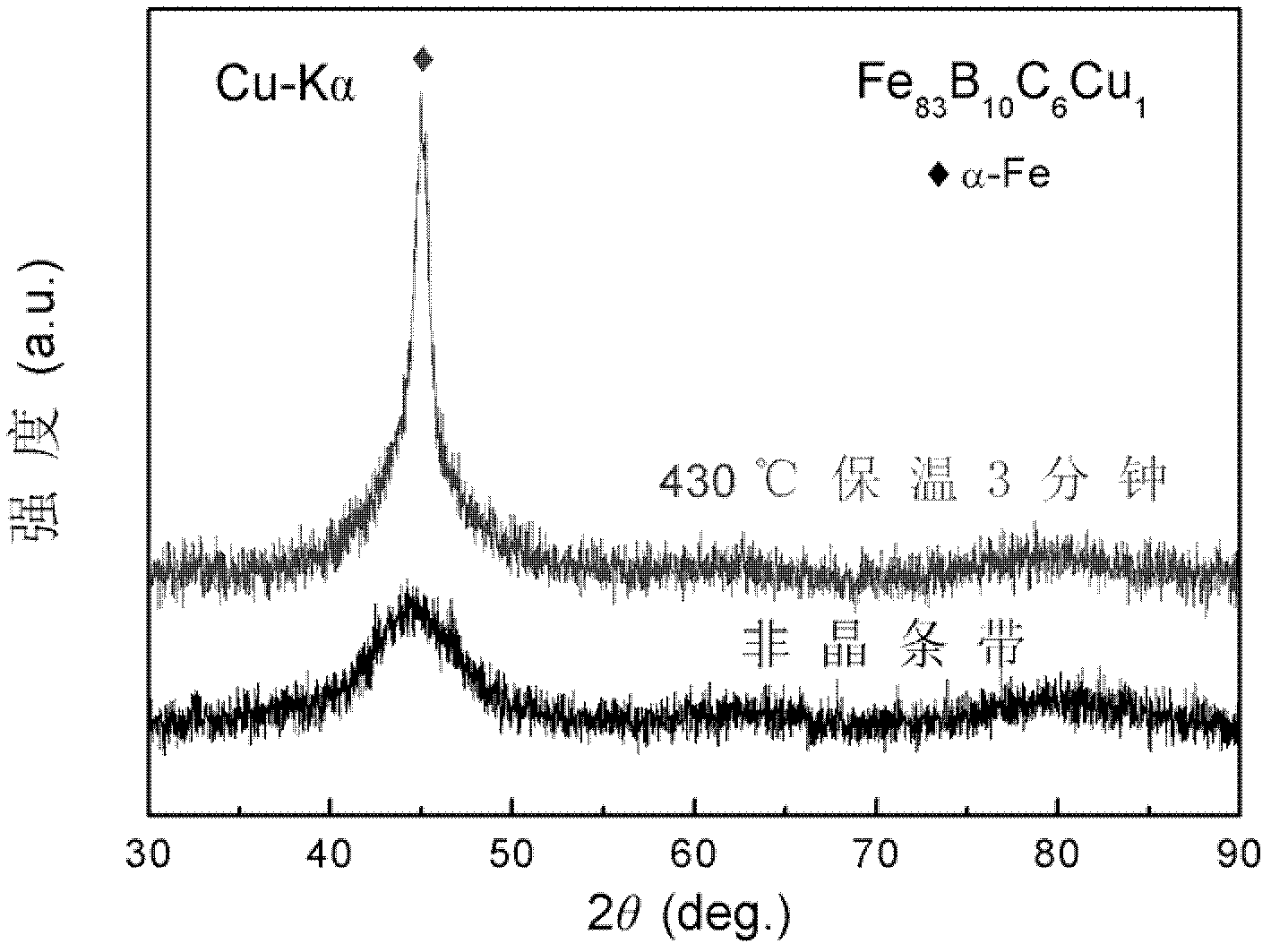

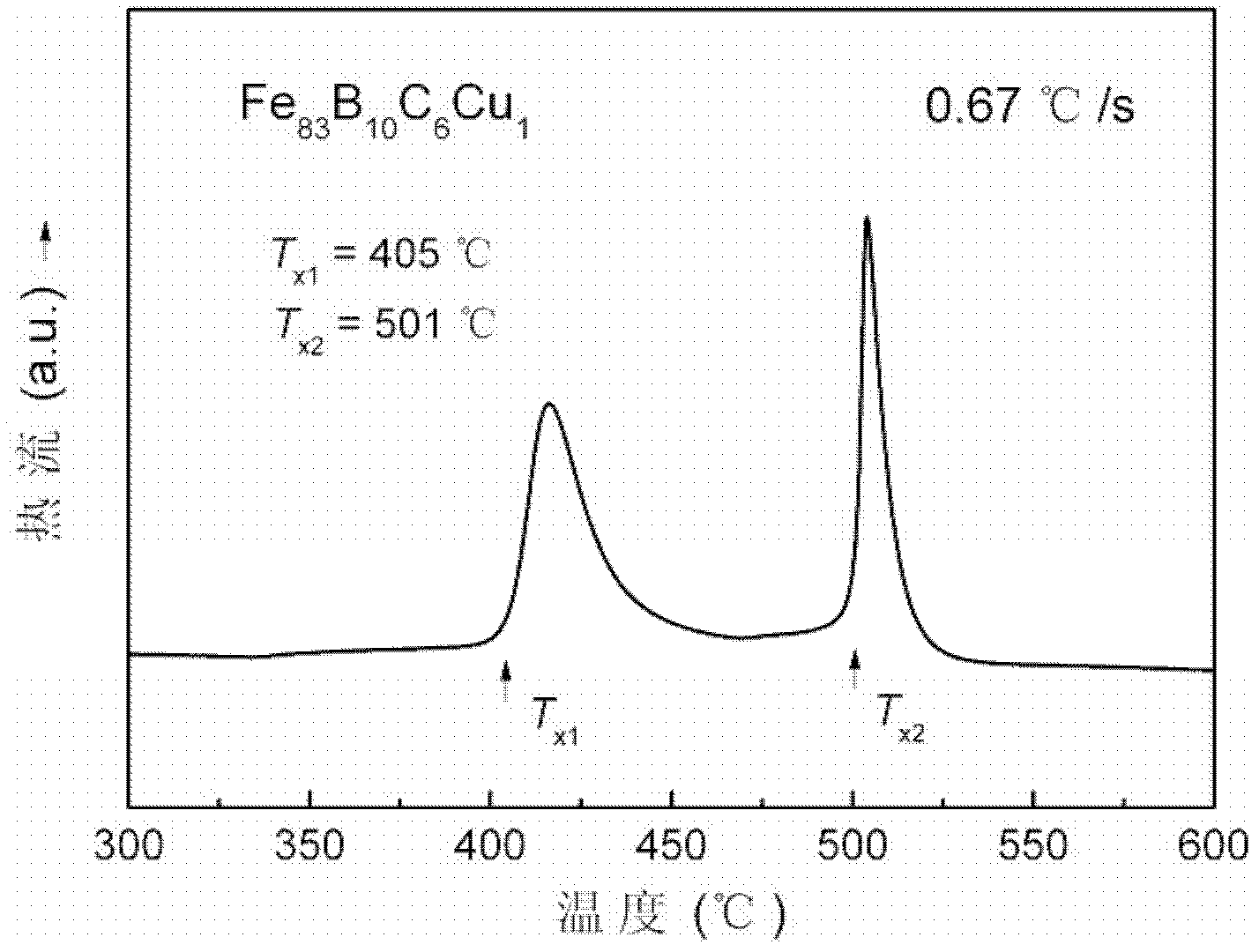

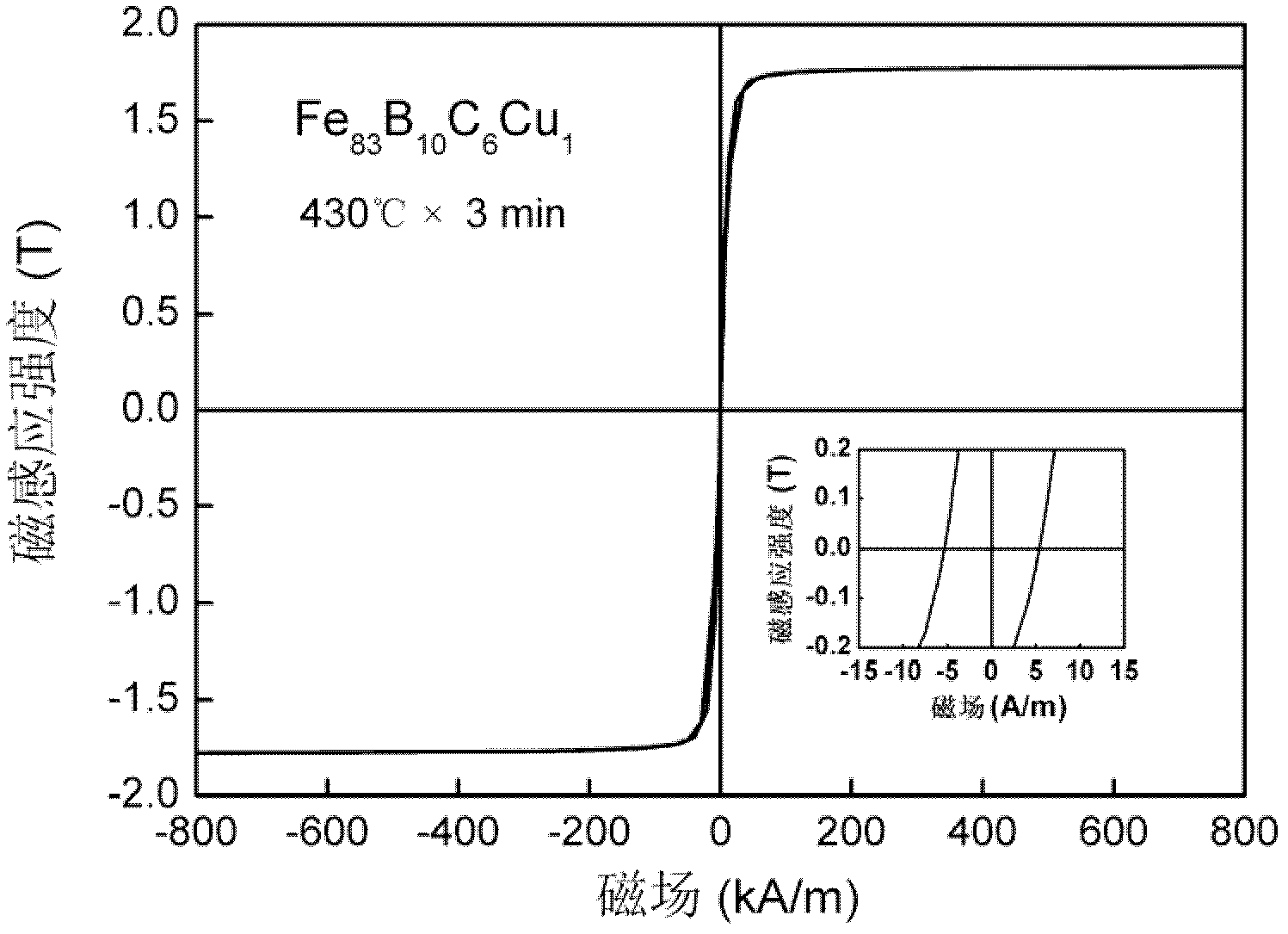

Iron-based nanocrystalline soft magnetic alloy with high saturation magnetic induction and low cost

ActiveCN102304669AHigh saturation magnetic inductionLow coercivityMagnetic materialsProcessing costAmorphous matrix

The invention relates to an iron-based nanocrystalline soft magnetic alloy. The alloy is characterized in that: the alloy meets the following relation in composition: FeaBbCcMdCue, wherein M represents one or more of Si, Al, Cr and Mn, the subscripts a, b, c, d and e represent the atom percents of the corresponding elements of the alloy respectively and meet the following conditions: 78<=a<=88, 4<=b<=16, 3<=c<=10, 0<=d<=8, 0.3<=e<=1.5 and a+b+c+d+e=100. The iron-based nanocrystalline alloy consists of an amorphous matrix phase and a nanocrystalline phase. The alloy is obviously characterized in that: the alloy has excellent soft magnetic performances such as high saturation magnetic induction, low coercivity, low loss and the like; and the alloy does not contain precious metal elements and volatile elements, thereby reducing the processing cost of the raw materials and bringing convenience to popularization and application. The invention also relates to a preparation method of the alloy.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

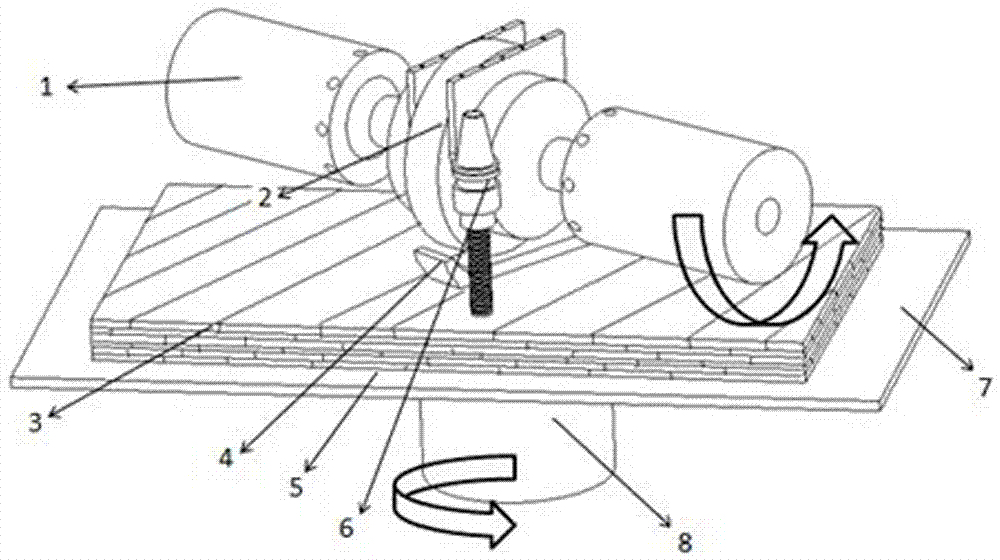

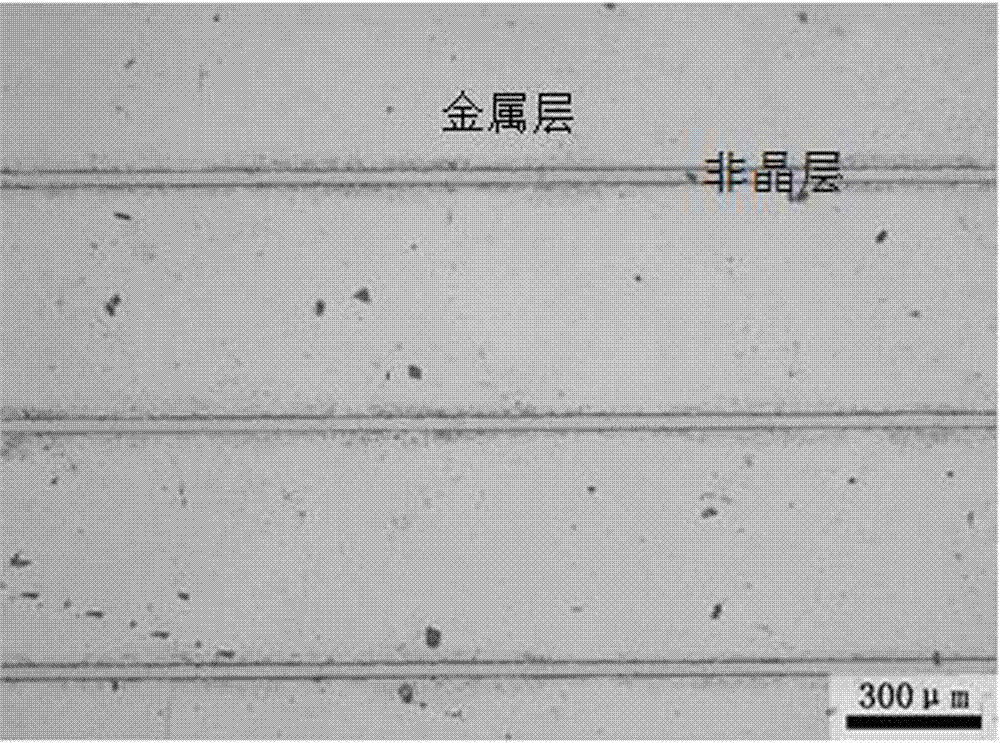

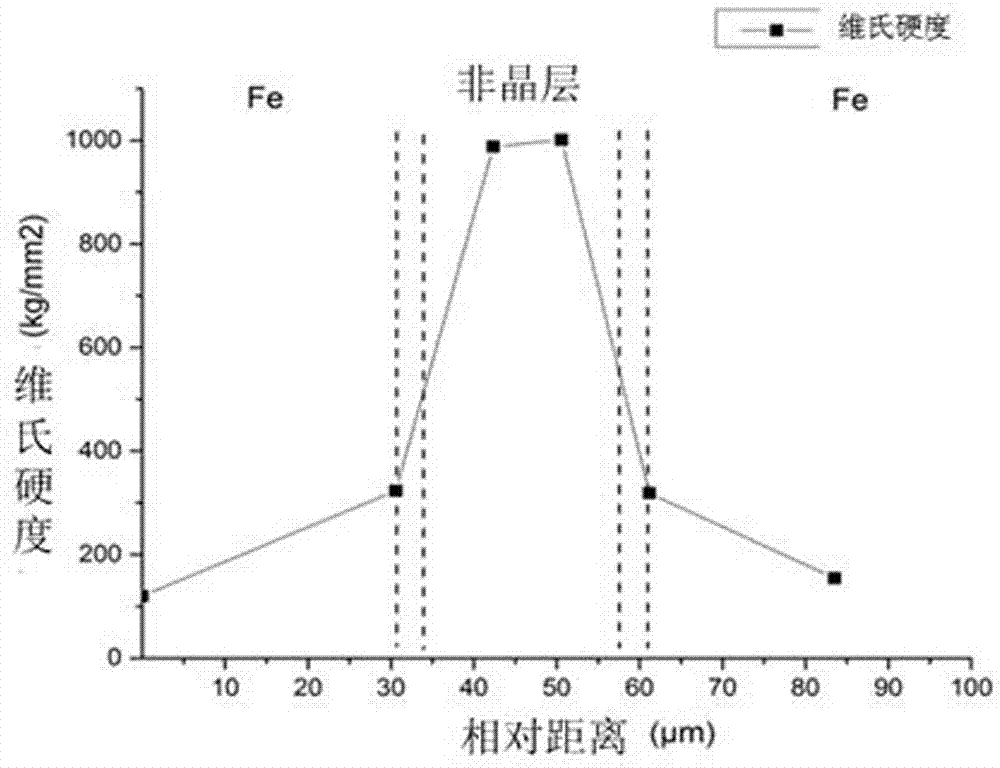

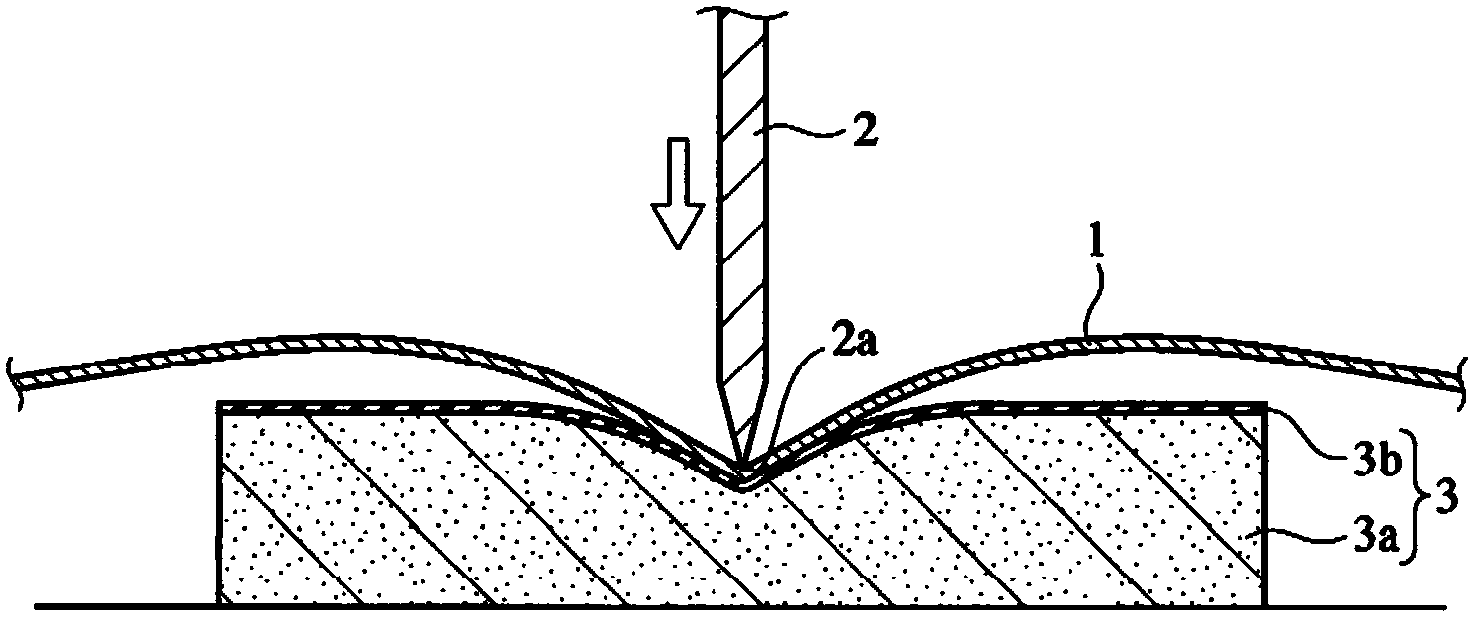

Ultrasonic accumulation preparation method for amorphous/metal micro-laminated composite

InactiveCN106862748AReduce residual internal stressOvercoming poor plasticity at room temperatureWelding/soldering/cutting articlesNon-electric welding apparatusMetal foilAmorphous matrix

The invention relates to an ultrasonic accumulation preparation method for an amorphous / metal micro-laminated composite. The preparation method comprises the steps that laminating data of a part are extracted, amorphous / metal foil is welded onto a metal foil substrate layer by layer through the ultrasonic solidification technique, the welded amorphous / metal micro-laminated composite is cut layer by layer according to a set part contour, and finally the part composed of the amorphous / metal micro-laminated composite is obtained. By adoption of the method, manufacturing of the three-dimensional complex-shaped part composed of the amorphous / metal micro-laminated composite and manufacturing a large-size amorphous-matrix micro-laminated composite can be achieved easily. The micro-level multi-interface effect of the composite can overcome the disadvantages of poor indoor-temperature plasticity and low breaking tenacity of amorphous alloy, and low residual internal stress and good structural stability of the interior of the formed three-dimensional part can be guaranteed through the ultrasonic solidification technique.

Owner:ZHONGBEI UNIV

SiOx/Si/C Composite Material and Process of Producing thereof, and Anode for Lithium Ion Battery Comprising Said Composite Material

ActiveUS20160079591A1High reversible capacityLow oxygenSecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon coatingNano silicon

An SiOx / Si / C composite material, includes SiOx / Si composite particles and a carbon coating layer coated on the SiOx / Si composite particles. The SiOx / Si composite particles include nano-silicon crystallites embedded in an SiOx (0<x≦2) amorphous matrix phase. The SiOx / Si composite particles have an Si:O molar ratio of 5:1-1.1:1, preferably 2:1-1.2:1. A process for producing an SiOx / Si / C composite material, includes a) milling SiO powder together with a metal reductant in a molar ratio of 125:1-10:1, preferably 2:11-5:1, b) totally removing the oxidation product of the metal reductant to obtain SiOx / Si composite particles, and c) coating the SiOx / Si composite particles with carbon to obtain the SiOx / Si / C composite material.

Owner:ROBERT BOSCH GMBH

Fe based large block amorphous nano-crystal magnetic element preparation method

InactiveCN101145420AHigh densityImprove efficiencyInductances/transformers/magnets manufactureMagnetic materialsHigh densityNanocrystal

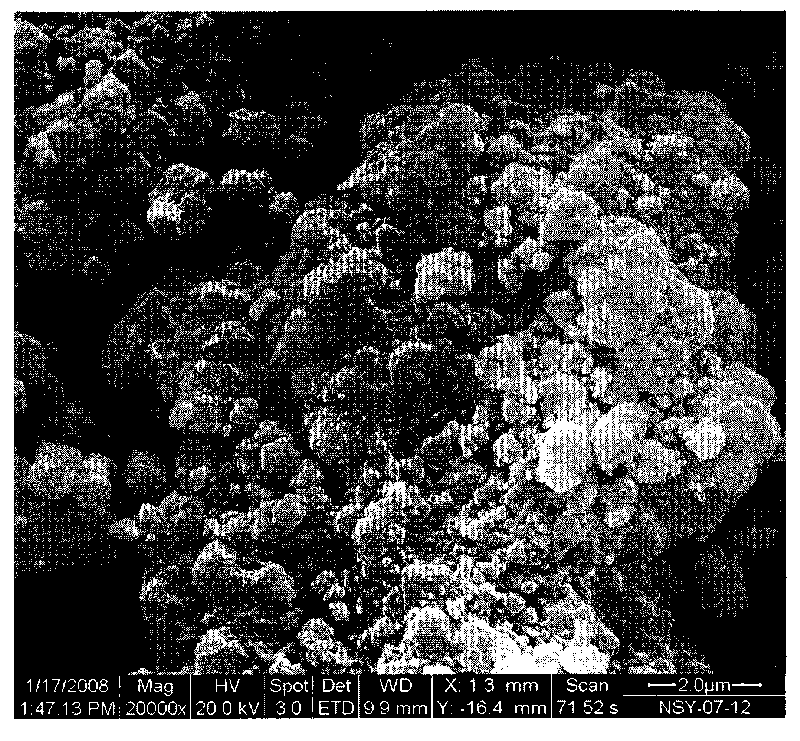

The invention discloses a preparation method of Fe-based bulk amorphous nano-crystal magnetic elements, which comprises the following steps: pre-crashing a Fe-based amorphous belt to flakes of (0.5-1)*(0.5-1)cm<2> size; placing the pre-crashed flakes to a ball mill for an appropriate period of time to obtain amorphous powder of 10nm-200nm size under the protection of inert gases or reducing gases, against sample oxidation; mixing the obtained amorphous powder with a binder; and applying a pressure within a temperature range of glass transition until the pressure is more than or equal to 100MP. For the rapid quenching of amorphous powder, under the reasonable control of temperature, pressure and solidification conditions, the high-density bulk is yielded and simultaneously a large quantity of nano-crystal bulk alloys, with uniform size distribution, are separated out of the amorphous matrix, forming a nano-crystal / amorphous composite phase structure, and the size of the nano-crystals is significantly less than that of those formed by the crystallization of amorphous bulk under normal pressure.

Owner:TONGJI UNIV

Izm-2 zeolite-based catalyst and process for hydroconversion/hydrocracking of hydrocarbonated feedstocks

The present invention relates to a catalyst comprising at least one IZM-2 zeolite, at least one amorphous matrix, at least one hydro-dehydrogenating element selected from the group formed by the elements from group VIB and from group VIII of the periodic table and excluding platinum and palladium. The catalyst also optionally contains a controlled quantity of at least one doping element selected from phosphorus, boron and silicon, optionally at least one element from group VB of the periodic table of the elements, and optionally a group VIIA element. The invention also relates to hydrocracking and hydrotreatment processes implementing this catalyst.

Owner:INST FR DU PETROLE

Composite material containing double-pore structure Y-type zeolite, and preparation method thereof

ActiveCN101746778AAvoid secondary reactionsFaujasite aluminosilicate zeoliteAmorphous matrixMaterials science

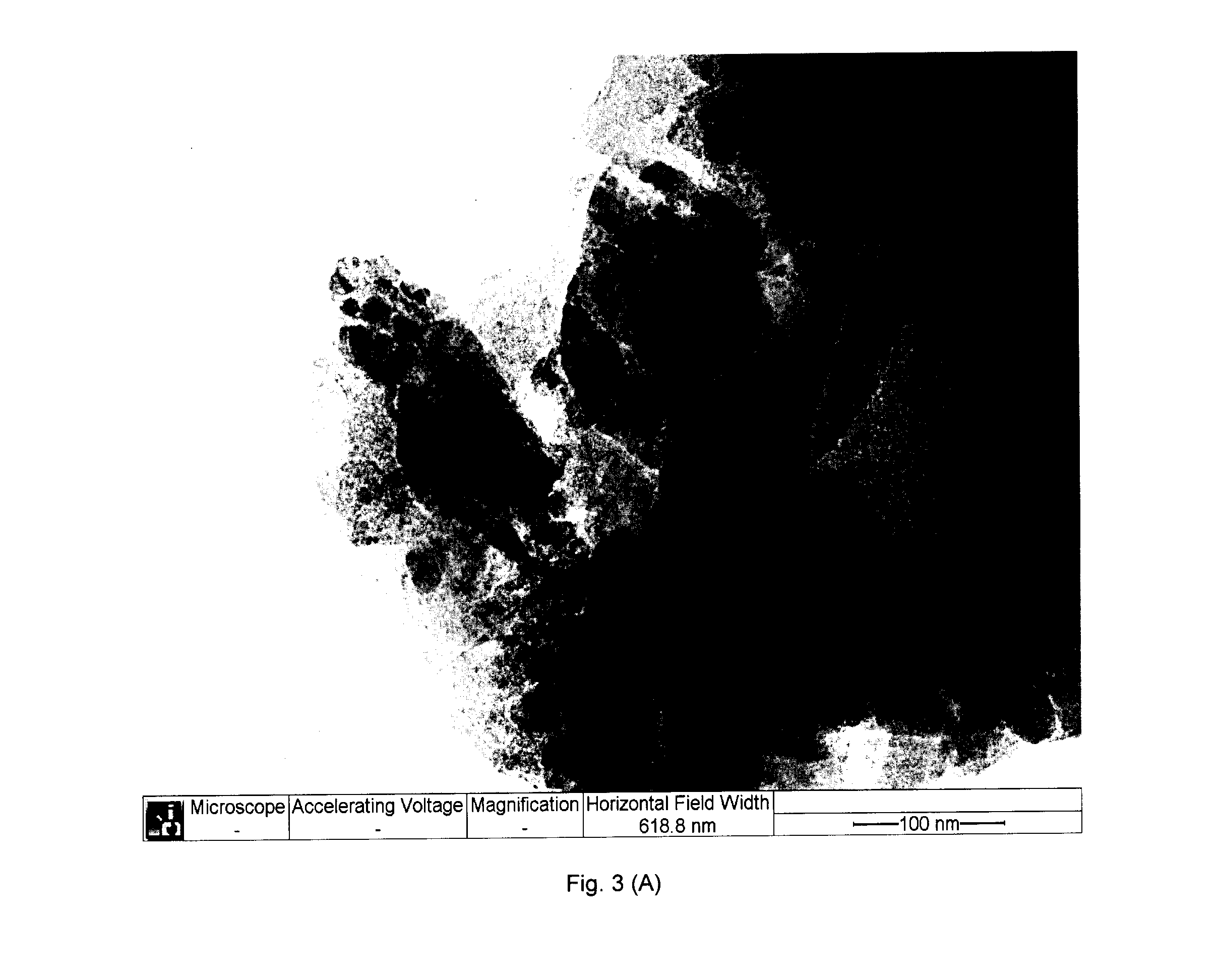

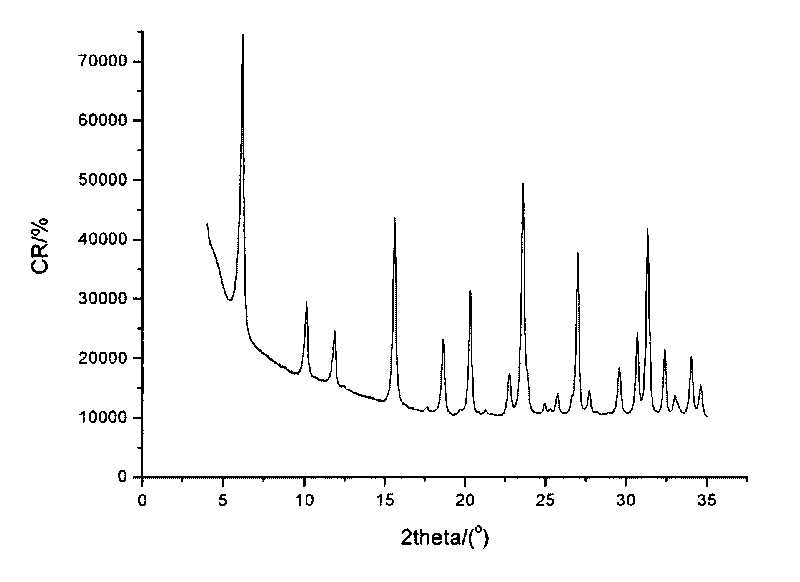

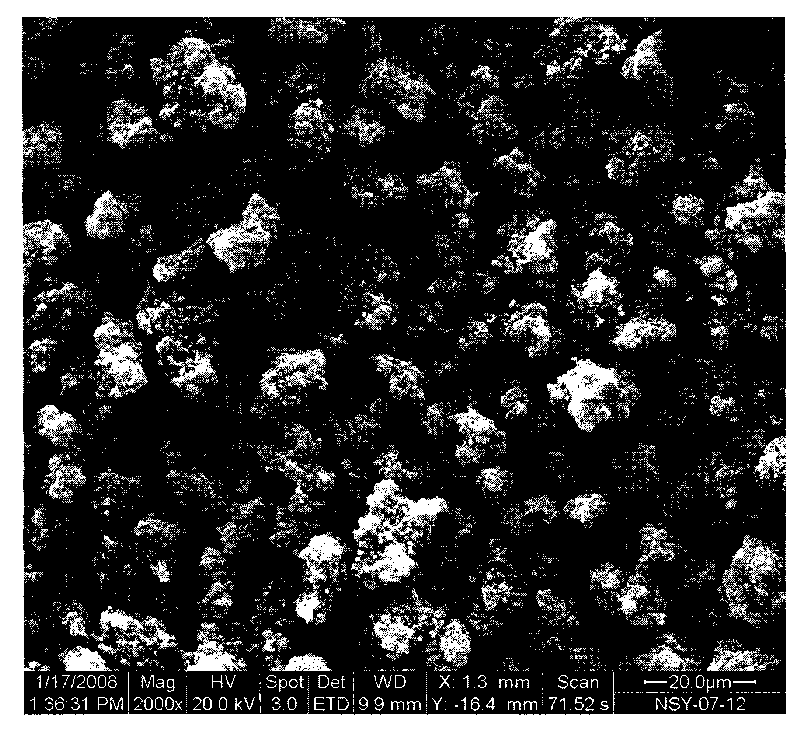

The invention discloses a composite material containing double-pore structure Y-type zeolite, which is characterized in that the composite material contains NaY zeolite and the balance of amorphous matrix; based on the weight of the composite material, the NaY zeolite accounts for 40 to 85 percent; the secondary structure of the composite material is a similar sphere; the similar sphere is formed by staggering and stacking Y-type zeolite generated by crystallization andmetakaolin amorphous intermediates generated during crystal transformation, and has gaps and holes; the sphere also has nest channels inside; the particle size is 3,000 to 25,000 nm; the surface area measured by a BET method is 280 to 800 M<2> / g; the total pore volume is 0.35 to 0.45 ml / g; the pore volume of 1.7 to 300 nm middle / big holes is 0.05 to 0.150 ml / g and accounts for 20 to 35 percent of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

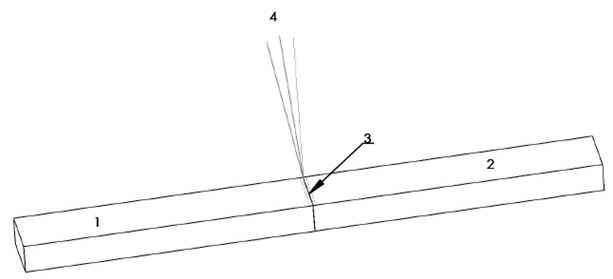

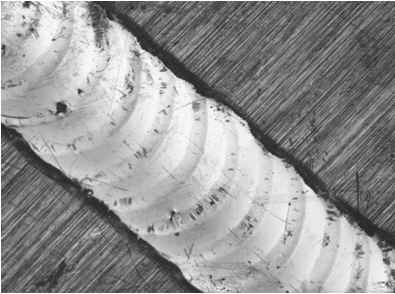

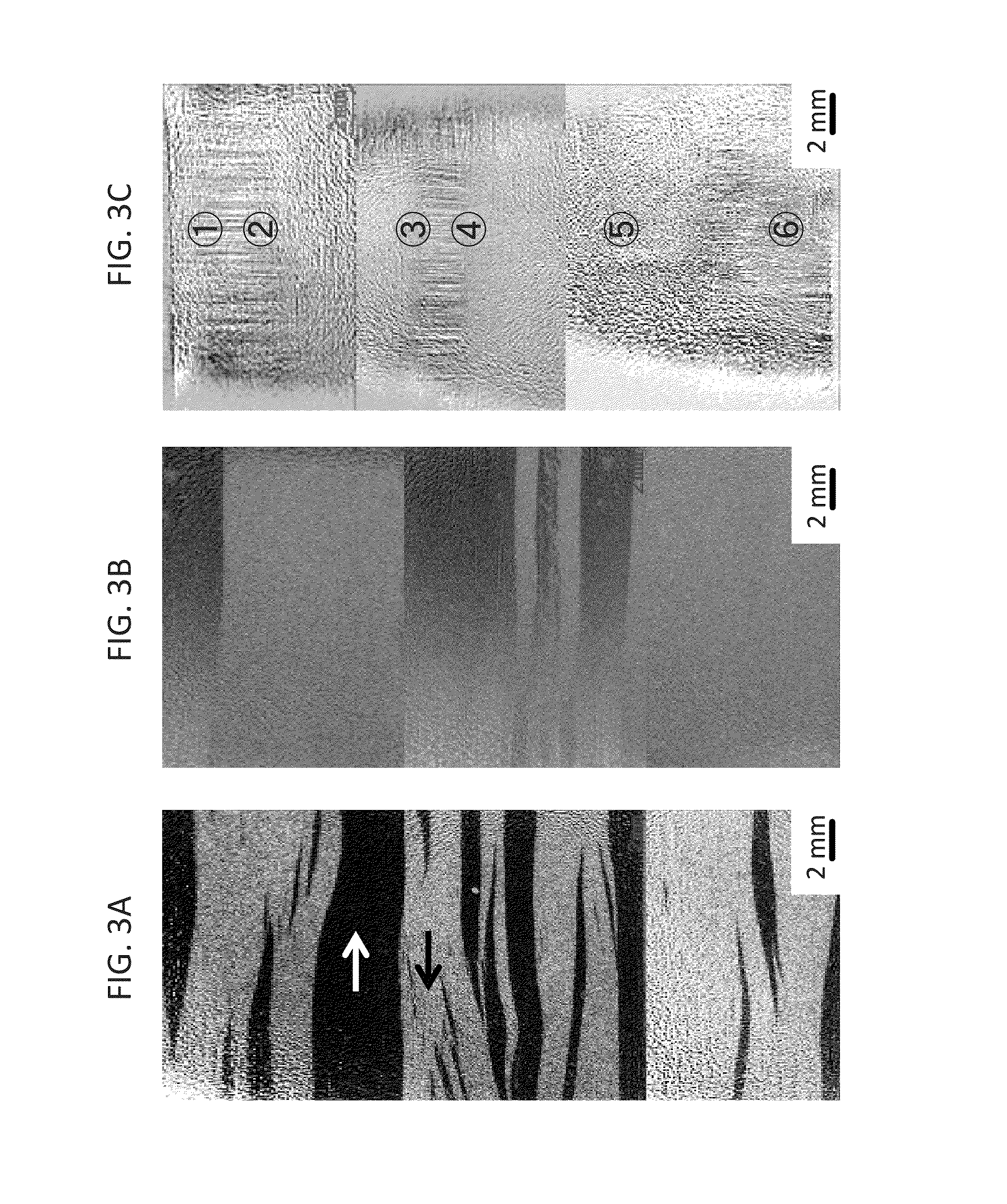

Laser welding method for amorphous matrix material

ActiveCN102430862ANo obvious crystallizationImprove welding strengthLaser beam welding apparatusAlloyWeld strength

The invention provides a laser welding method for an amorphous matrix material. The laser welding method comprises the following step of welding a weldment on a matrix material to be welded by using pulse laser under the protection of inert atmosphere, wherein the matrix material to be welded is amorphous alloy, and the weldment is amorphous alloy or stainless steel; and the welding conditions are as follows: the laser power is 1-6.5 kW, the spot diameter is 0.1-1.0 mm, the laser emitting frequency is 1-20 Hz, the gas pressure of the inert atmosphere is 0.1-1 MPa, and the gas flow of the inert atmosphere is 1-15 mL / min. The laser welding method for the amorphous matrix material, provided by the invention, not only can be used for welding among amorphous alloys, but also can be used for welding between the amorphous alloy and stainless steel. No obvious crystallization phenomenon occurs before and after welding, and the welding strength is higher.

Owner:BYD CO LTD

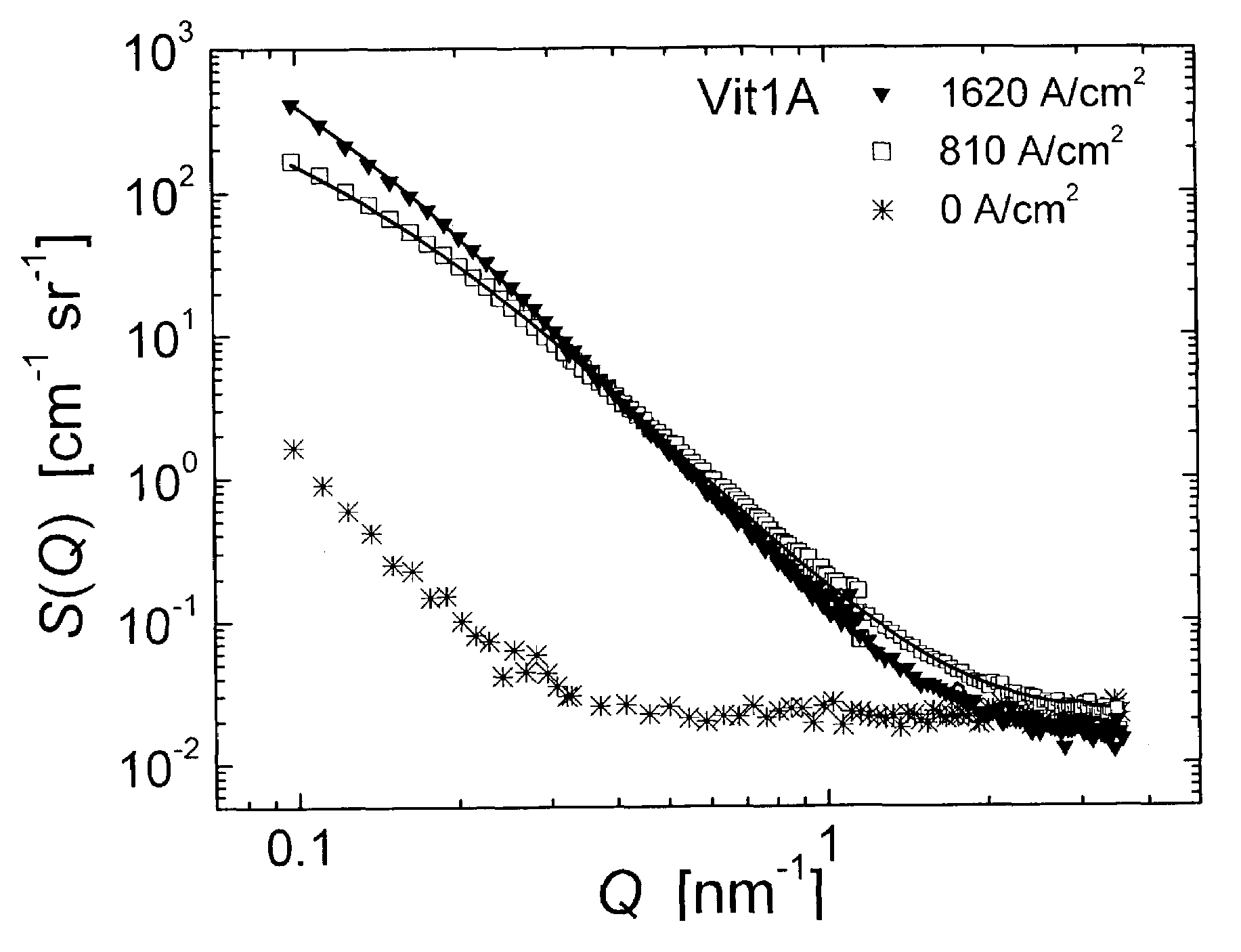

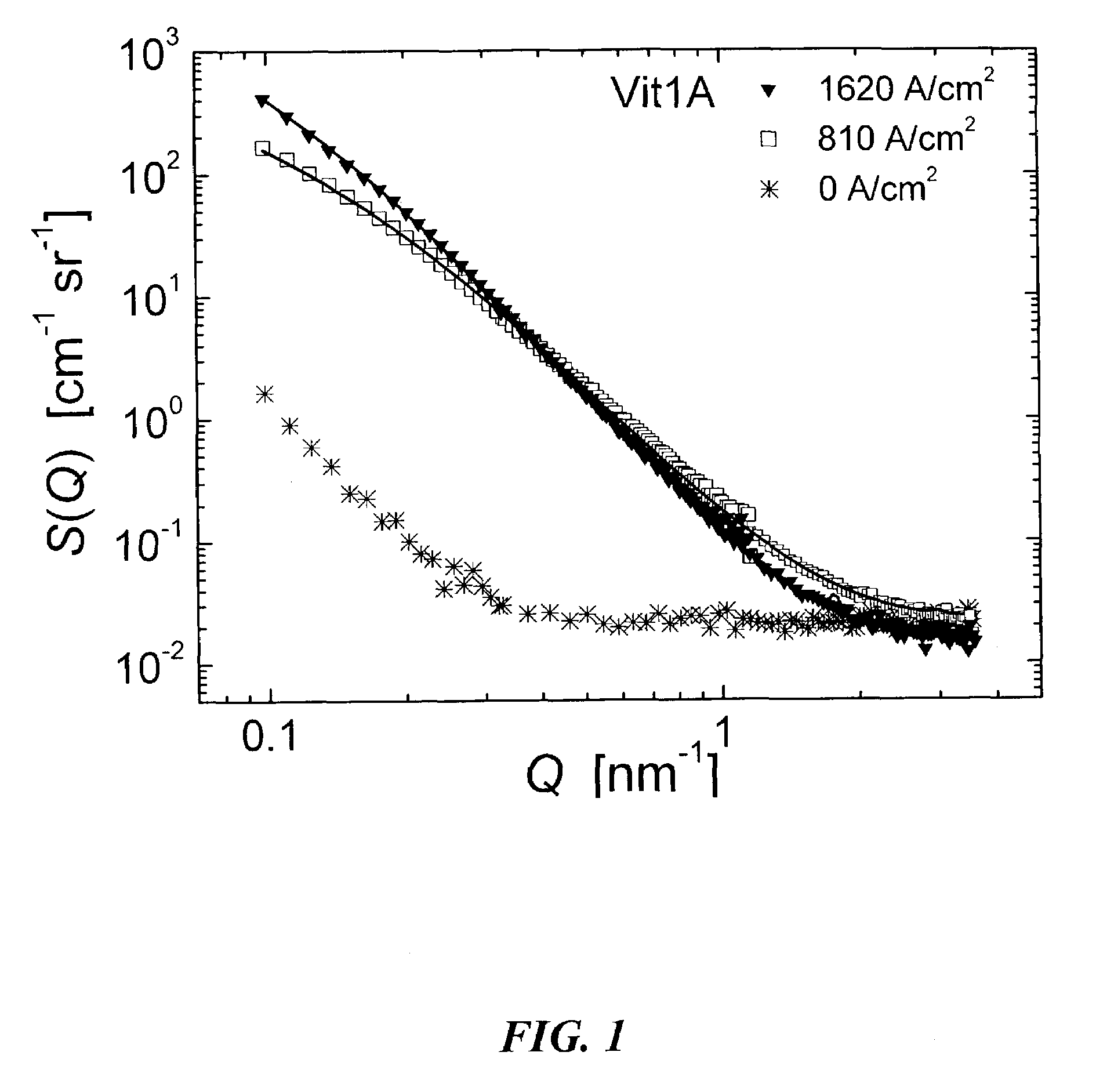

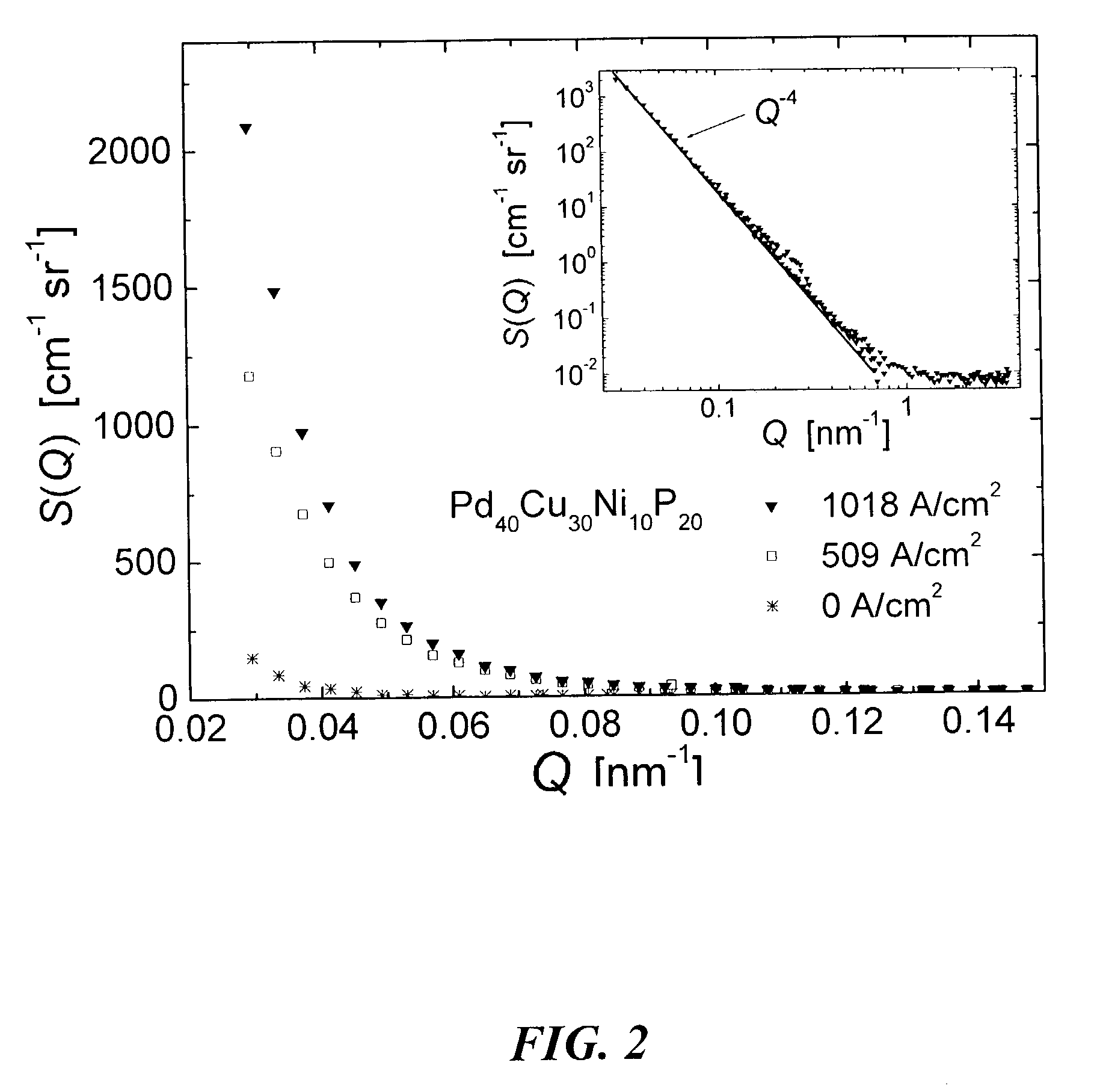

Metallic glasses with crystalline dispersions formed by electric currents

Owner:RGT UNIV OF CALIFORNIA

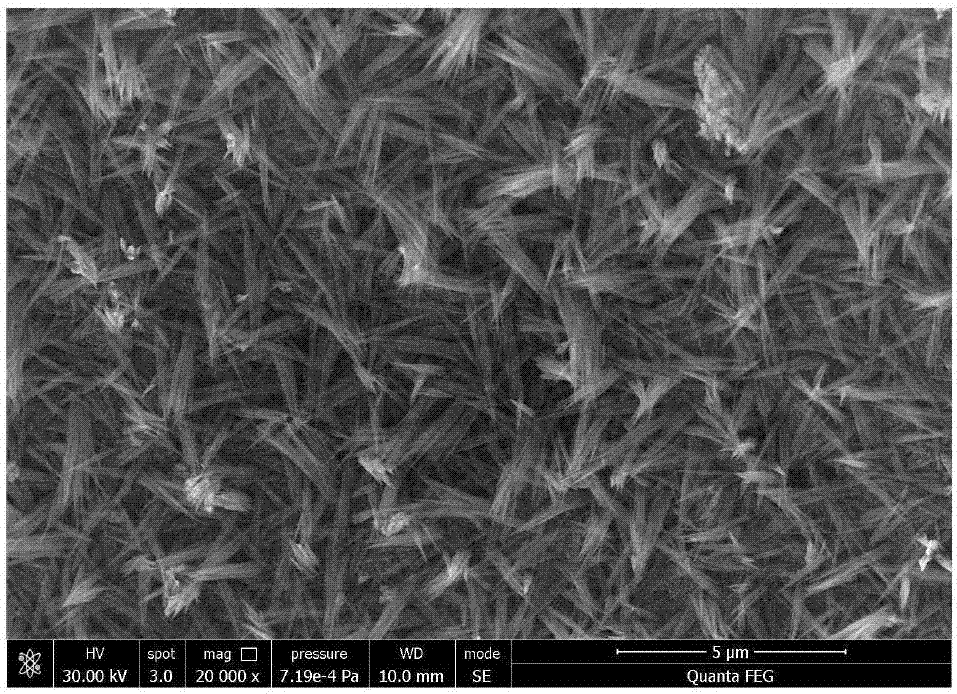

Nano-porous copper-loaded shape-controlled copper-based oxide composite as well as preparation method and application thereof

InactiveCN108597892AAvoid wastingSimple manufacturing processHybrid capacitor electrodesOxide compositeSupercapacitor

The invention relates to a nano-porous copper-loaded shape-controlled copper-based oxide composite as well as a preparation method and application thereof. The composite comprises an amorphous matrixat a core layer, nano-porous copper layers clamped at the two sides of the amorphous matrix and a copper-based oxide layer prepared through in situ oxidation, wherein the amorphous matrix is a TixCuyZrz alloy ingredient, x, y and z are atomic percents, x is more than or equal to 45 and less than or equal to 60, y is more than or equal to 40 and less than or equal to 50, z is more than or equal to1 and less than or equal to 5, and the sum of x, y and z is equal to 100; and the thickness of each nano-porous copper layer is 1.5-4[mu]m, ligament width is 32-55nm, and aperture size is 18-42nm. Theinvention simplifies preparation technology and avoids unnecessary energy waste, and copper-based oxides are generated through in situ oxidation on the surface of nano-porous copper and are firmly combined with a substrate, so that the composite can be taken as electrode slices of a supercapacitor independently.

Owner:HEBEI UNIV OF TECH

Thin strip of alloy containing initial ultrafine crystals and method for cutting same, and thin strip of nanocrystalline soft-magnetic alloy and magnetic part employing same

ActiveCN103748250AStable pressingReduce wearMagnetic materialsMetal working apparatusNanocrystalline siliconAmorphous matrix

The present invention relates to a method for cutting a thin strip of an alloy that contains initial ultrafine crystals and has a structure in which ultrafine crystal grains having an average grain diameter of 30 nm or smaller have been dispersed in an amorphous matrix phase in an amount of 5-30 vol.%. The method comprises placing the thin strip on a flexible bed that can be sharply deformed by local pressing, bringing the blade of a cutter into horizontal contact with the surface of the thin strip, pressing the cutter against the thin strip, so that a pressure is evenly applied to the thin strip, and thereby bending the thin strip along the blade edge of the cutter to brittlely cut the thin strip.

Owner:HITACHI METALS LTD

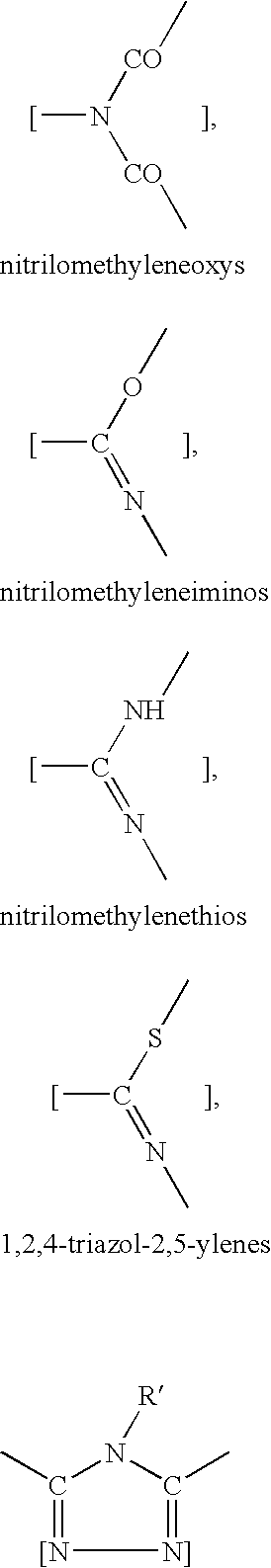

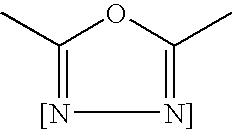

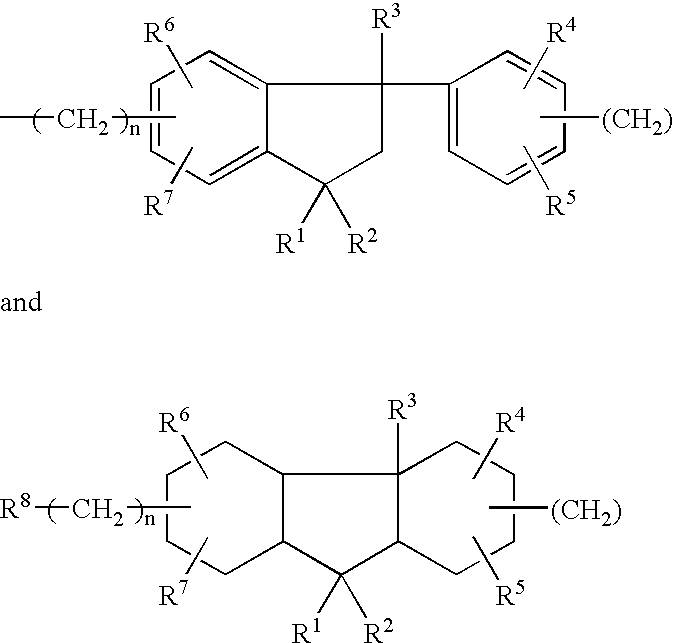

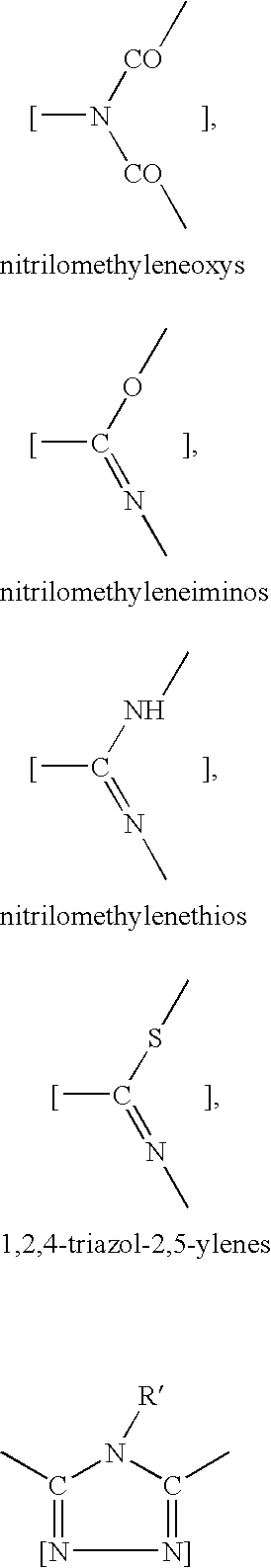

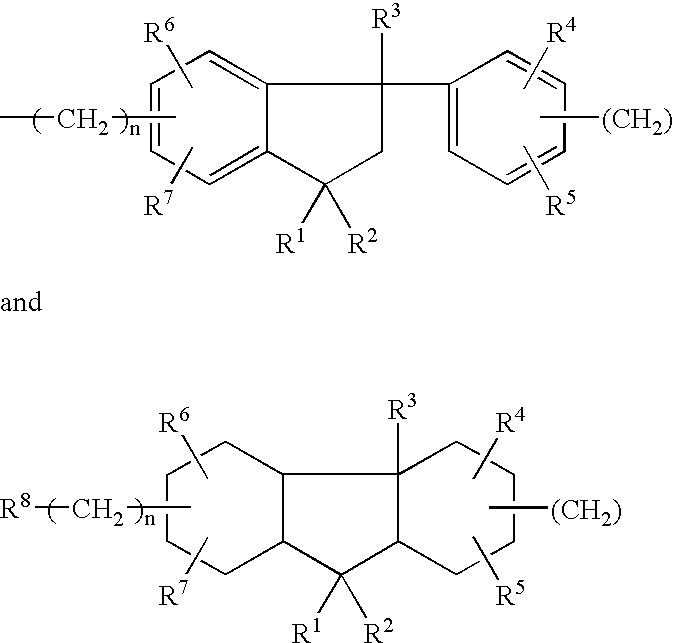

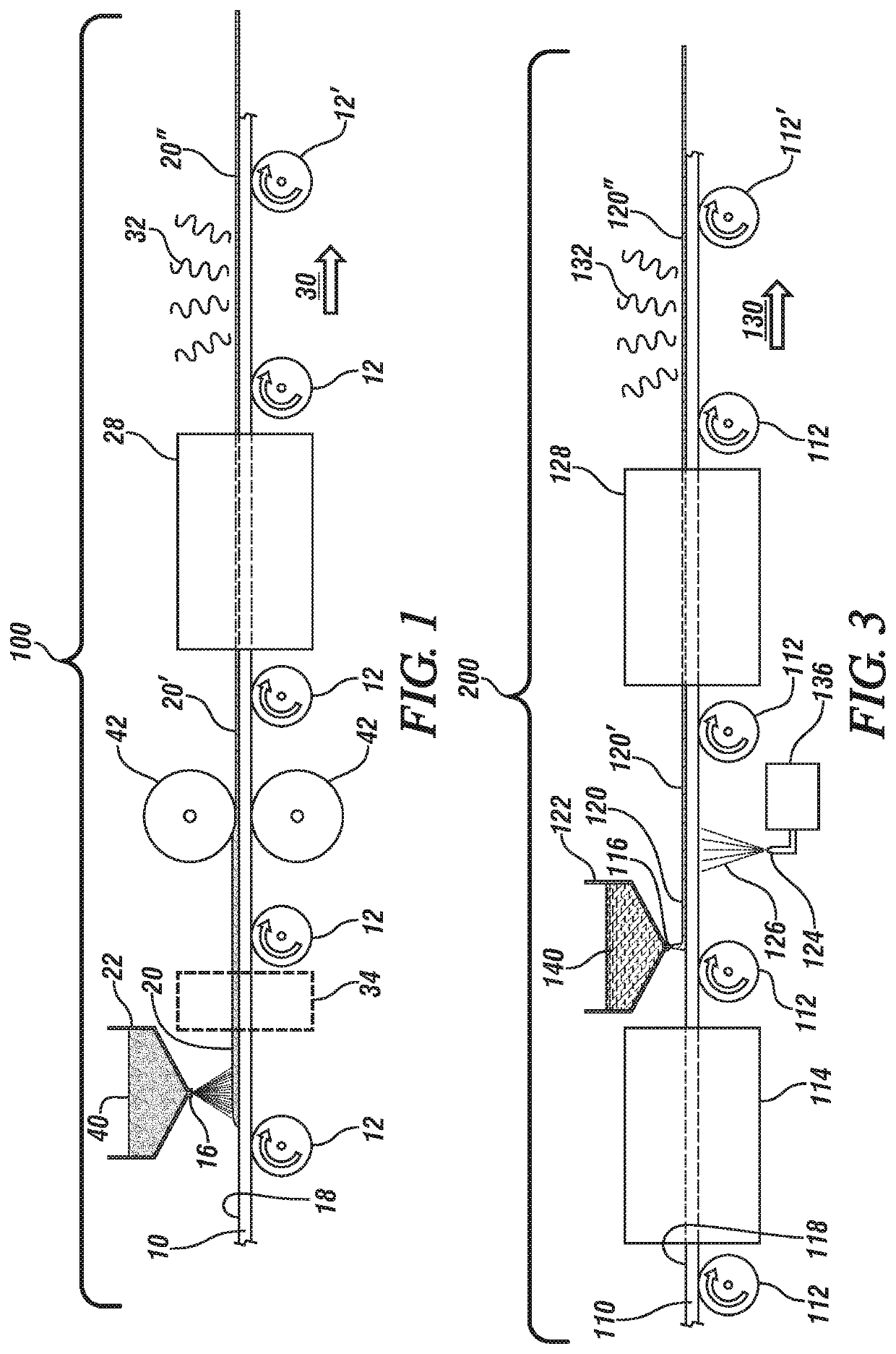

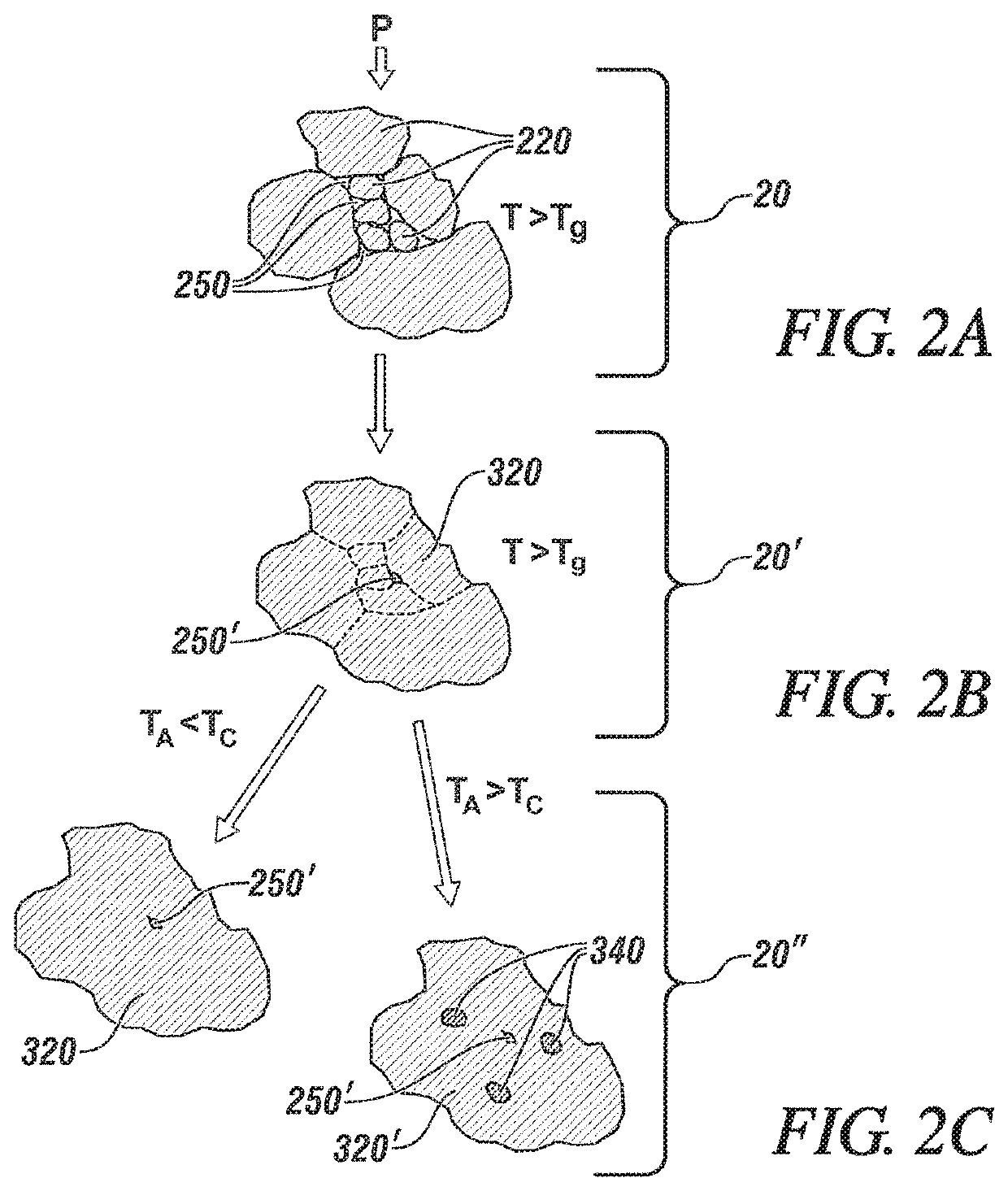

Encapsulated toner compositions incorporating organic monomeric glasses

The present invention is an electrostatographic core shell toner which includes as a core material of at least two nonpolymeric compounds each independently corresponding to the structure (R1Y1)p[(Z1Y2)mR2Y3]nZ2Y4R3. M is zero or one, n is zero up to an integer at which said compound starts to become a polymer and p is an integer of from one to eight. Each of R1 and R3 is independently a monovalent aliphatic or cycloaliphatic hydrocarbon group an aromatic group or a multicyclic aromatic nucleus. Each of R2, Z1 and Z2 independently represent multivalent aliphatic or cycloaliphatic hydrocarbon groups or an aromatic group. Y1, Y2, Y3 and Y4 each independently represent one or more linking groups. The core material is surrounded by a shell that includes an amorphous matrix.

Owner:EASTMAN KODAK CO

Optical glass

InactiveUS20090093356A1Increase chanceExcessive equipmentGlass/slag layered productsSilicon oxideAmorphous matrix

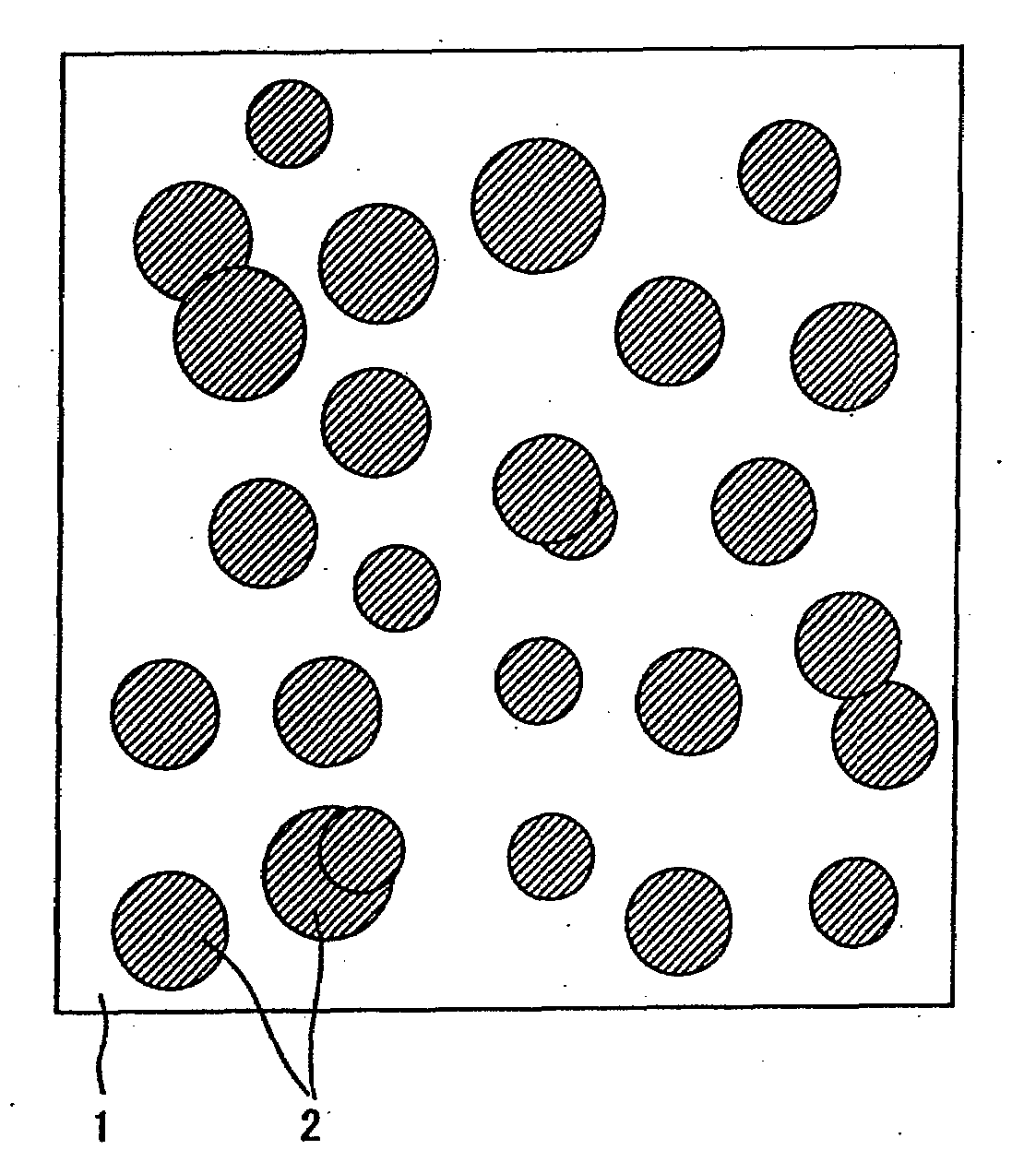

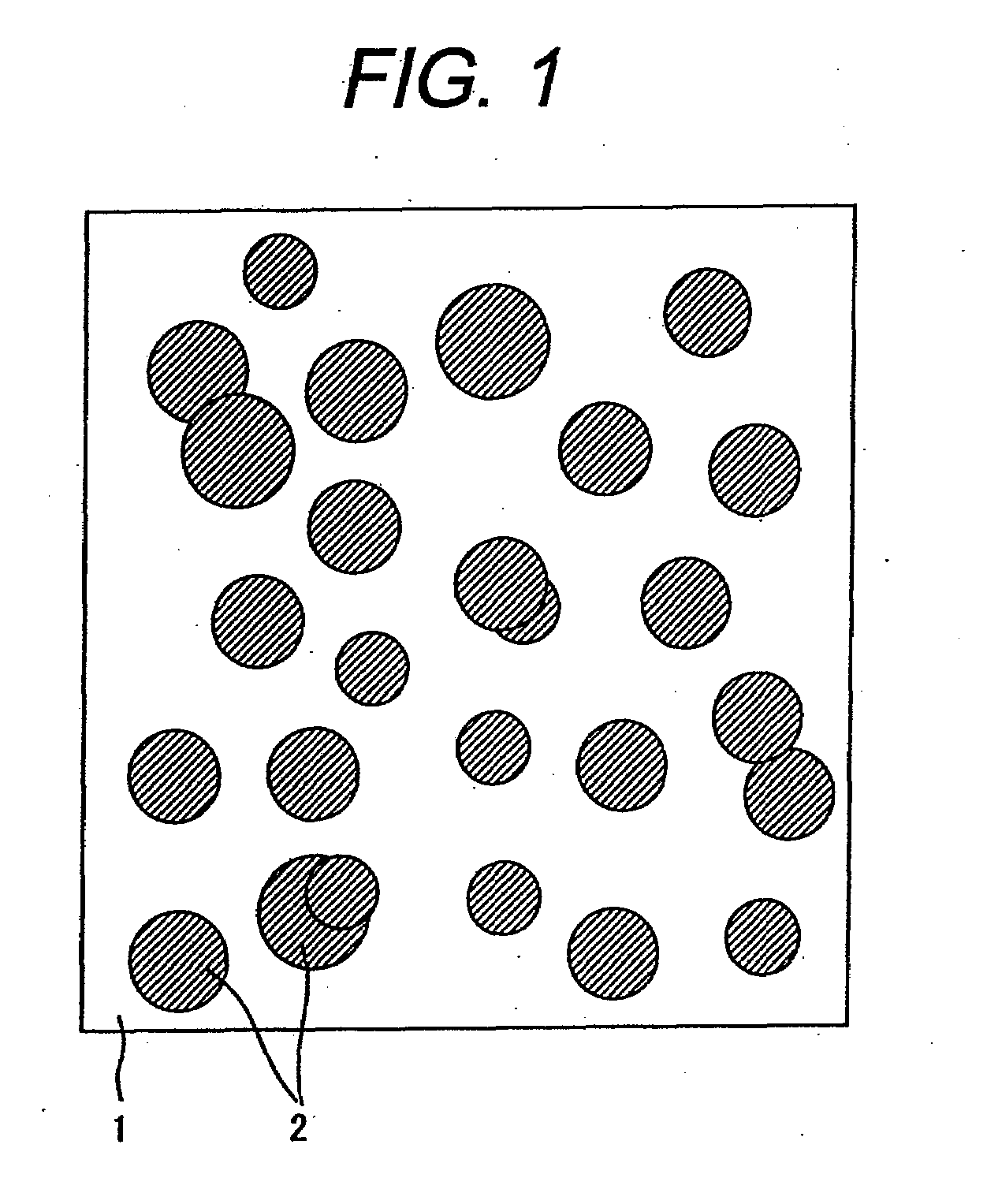

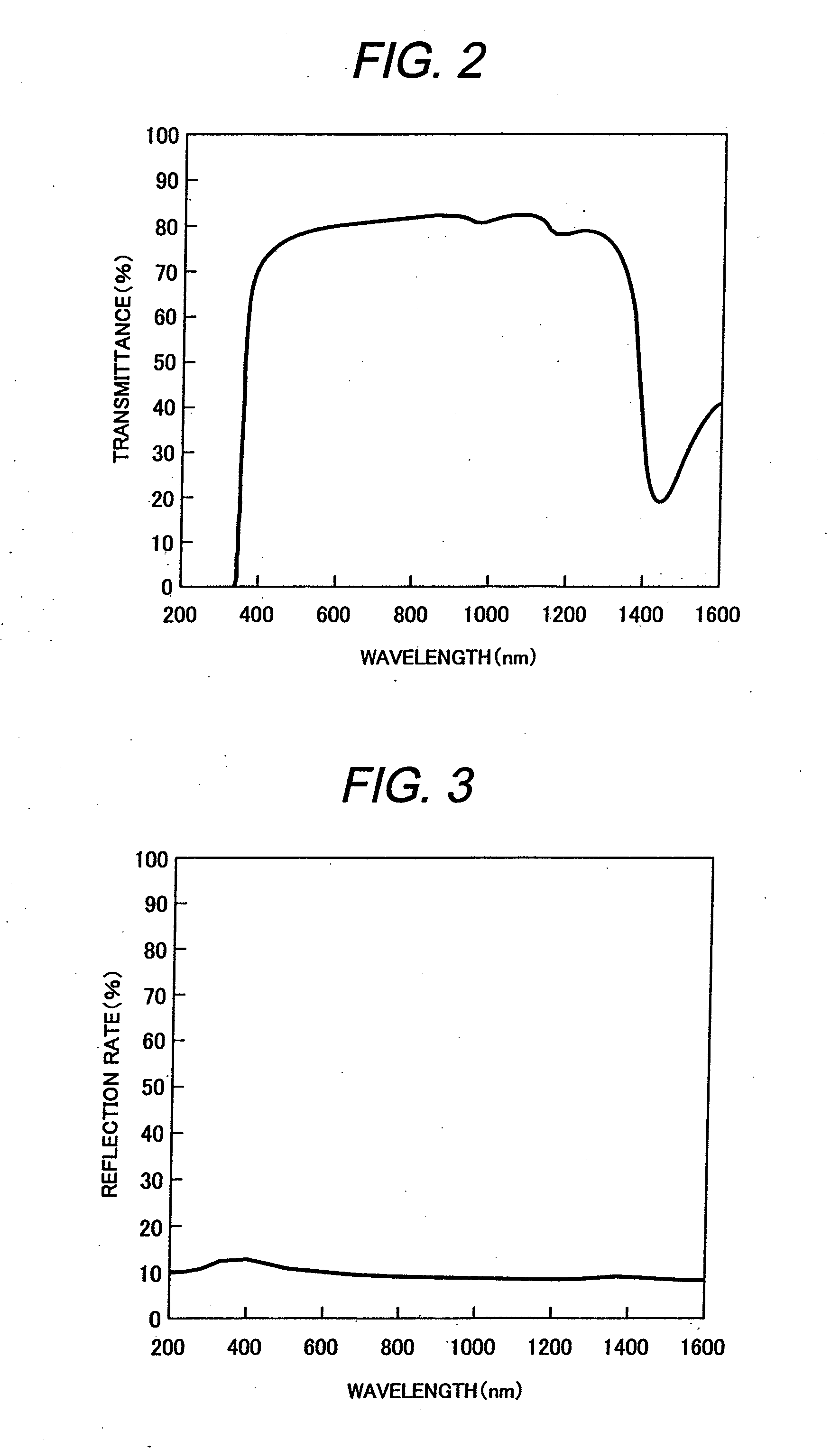

Optical glass constituted by an amorphous matrix and crystal grains dispersed in the amorphous matrix, wherein the amorphous matrix comprises a first oxide of at least one of silicon oxide and phosphor oxide and a second oxide of at least one of titanium oxide and zirconium oxide, and wherein the crystal grains is at least one of titanium oxide, zirconium oxide and silicon, an average grain size of the titanium oxide grain being 3 nm to 20 nm, and the average grain size of the silicon crystal being 3 nm to 8 nm.

Owner:HITACHI LTD

Nano-crystalline, magnetic alloy, its production method, alloy ribbon and magnetic part

ActiveUS20110085931A1High magnetic flux densityLow coercivityMagnetic materialsAmorphous matrixNano crystalline

Owner:HITACHI METALS LTD

Encapsulated toner compositions incorporating organic monomeric glasses

The present invention is an electrostatographic core shell toner which includes as a core material of at least two nonpolymeric compounds each independently corresponding to the structure (R1Y1)p[(Z1Y2)mR2Y3]nZ2Y4R3. M is zero or one, n is zero up to an integer at which said compound starts to become a polymer and p is an integer of from one to eight. Each of R1 and R3 is independently a monovalent aliphatic or cycloaliphatic hydrocarbon group an aromatic group or a multicyclic aromatic nucleus. Each of R2, Z1 and Z2 independently represent multivalent aliphatic or cycloaliphatic hydrocarbon groups or an aromatic group. Y1, Y2, Y3 and Y4 each independently represent one or more linking groups. The core material is surrounded by a shell that includes an amorphous matrix.

Owner:EASTMAN KODAK CO

Optoelectronic devices with thin barrier films with crystalline characteristics that are conformally coated onto complex surfaces to provide protection against moisture

InactiveUS20140224317A1Improve barrier propertiesHigh level of electricalFinal product manufactureSemiconductor/solid-state device detailsConformal coatingAmorphous matrix

The present invention provides optoelectronic devices containing at least one conforming, thin film barrier coating provided on a nonplanar surface comprising a plurality of junctures. The barrier coating has a hybrid morphology including crystalline domains distributed in an amorphous matrix. The conformal coatings protect the optoelectronic device with long-lasting, durable, high quality barrier protection even though the coatings have sufficient crystalline characteristics so that many embodiments are electrically conductive.

Owner:RGT UNIV OF MINNESOTA +1

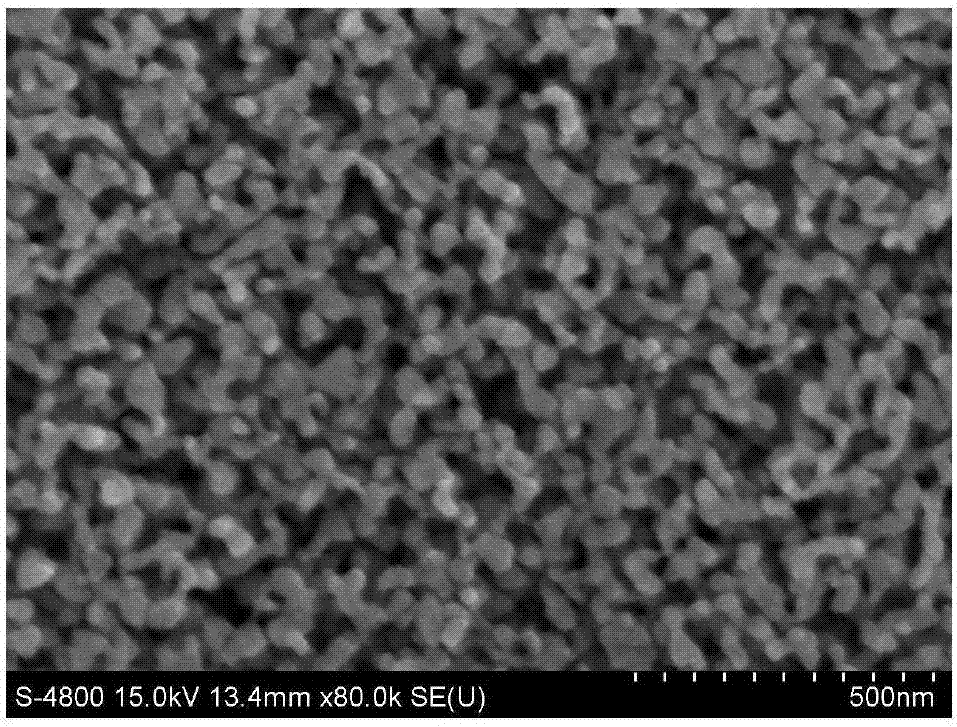

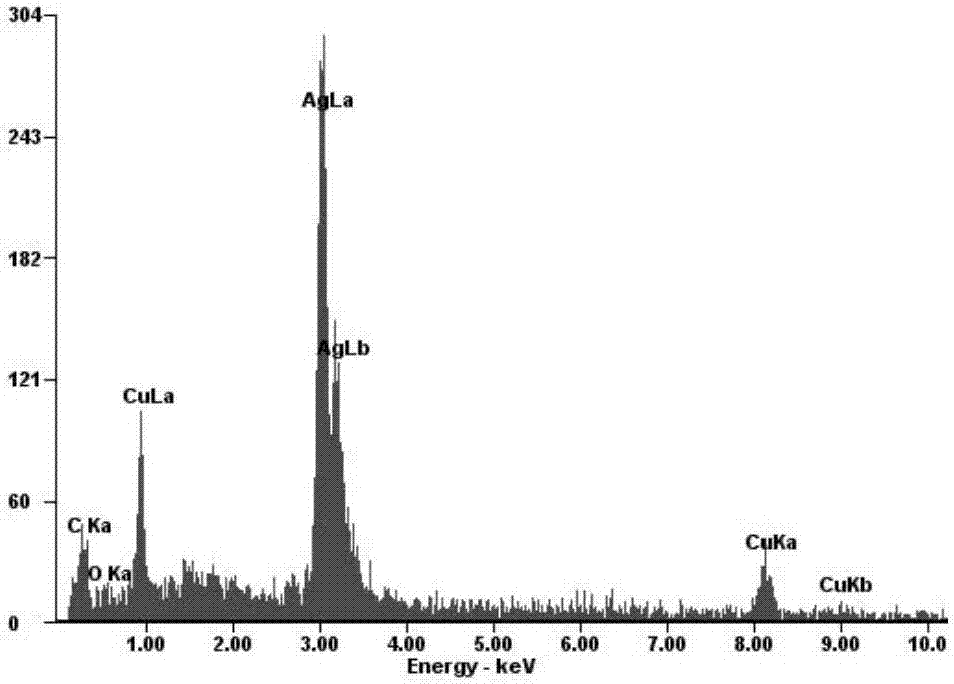

Nano-porous copper-silver bimetal/bimetal oxide and preparation method and application thereof

ActiveCN107338402AOvercoming the disadvantage of being fragileExcellent mechanical propertiesMaterial nanotechnologyBiocideMechanical integrityAlloy

The invention discloses a nano-porous copper-silver bimetal / bimetal oxide and a preparation method and application of the nano-porous copper-silver bimetal / bimetal oxide. Nano-porous copper-silver bimetal obtained after an amorphous matrix is dealloyed is used as an anode for electrochemical oxidation, the finally-obtained bimetal oxide is loaded to the surface of the nano-porous copper-silver bimetal in a nanowire shape, and the amorphous matrix is the CuxZryAgz alloy ingredient, wherein x, y and z are atomic percents, x is larger than or equal to 35 and is smaller than or equal to 45, y is larger than or equal to 35 and is smaller than or equal to 45, z is larger than or equal to 10 and is smaller than or equal to 30, and the sum of x, y and z is 100. The preparation process is simpler, the mechanical integrity is better, cyclic reuse can be achieved, bar products are easy to recycle, and secondary pollution of powder products is avoided.

Owner:HEBEI UNIV OF TECH

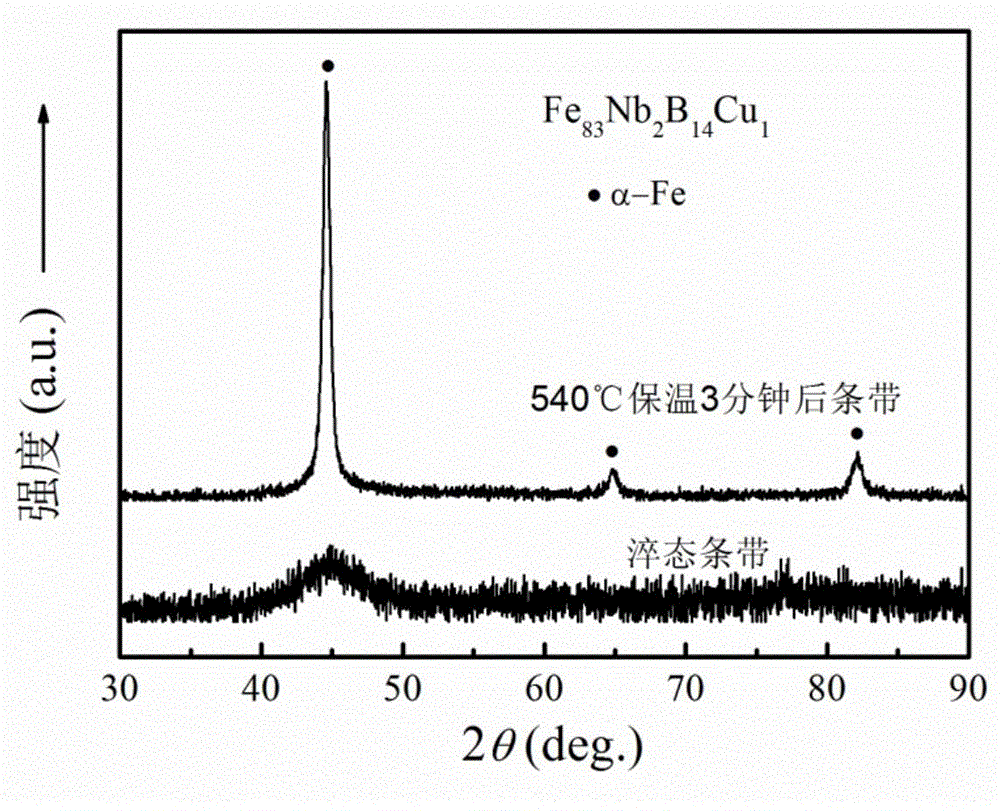

Fe-based nano crystal soft magnetic alloy material and preparation method thereof

InactiveCN104831169AStrong Amorphous Formation AbilityStrong magnetic propertiesMagnetic materialsTO-18Nanocrystal

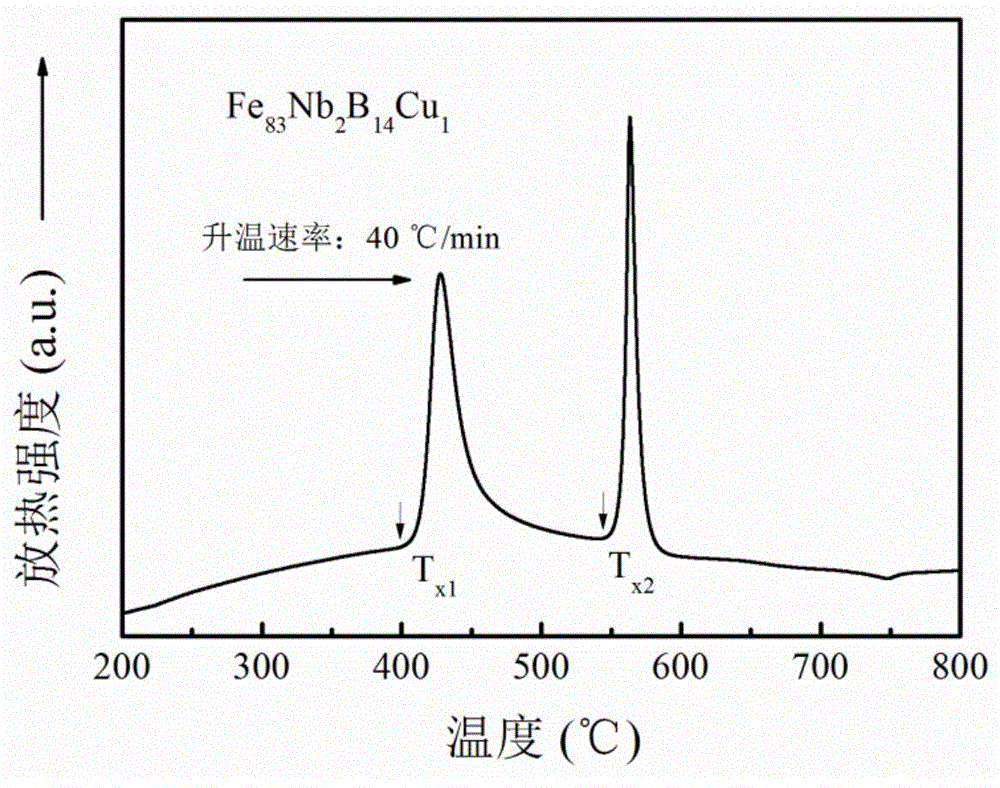

The invention provides a Fe-based nano crystal soft magnetic alloy material and a preparation method thereof. A molecular formula of the material is FeaNbbBcCud, wherein, a, b, c and d respectively present atom percentage content of corresponding elements, a is greater than or equal to 80 and less than or equal to 85, b is greater than or equal to 1 and less than or equal to 3, c is greater than or equal to 12 and less than or equal to 18, d is greater than or equal to 0.8 and less than or equal to 1.2, wherein, sum of a, b, c and d is 100. The alloy material has high Fe element content and low Nb element content, production cost is reduced; a structure comprises an amorphous matrix and an alpha-Fe NANO crystal grain phase with average crystal grain size less than 20nm body-centered cubic, the alloy material has high saturation magnetic induction intensity and low coercive force, so that the Fe-based nano crystal soft magnetic alloy material has the advantages of low cost and good soft-magnetic performance, and has good application prospect.

Owner:LONDERFUL NEW MATERIAL NANTONG

Nanocrystalline magnetic alloy and method of heat-treatment thereof

ActiveUS20160196907A1Growth inhibitionReduce the rate of atomic diffusionInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementNanocrystal

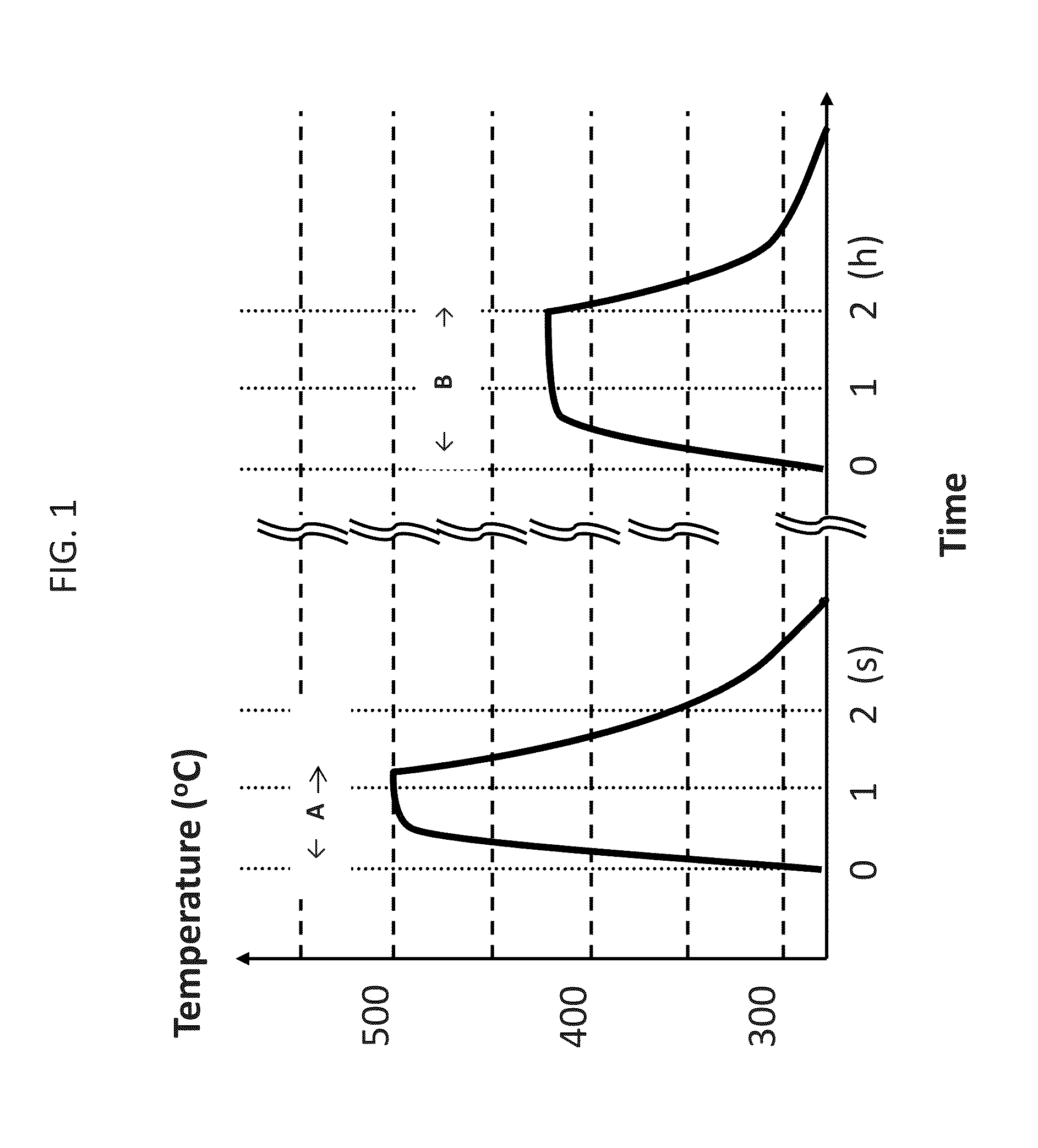

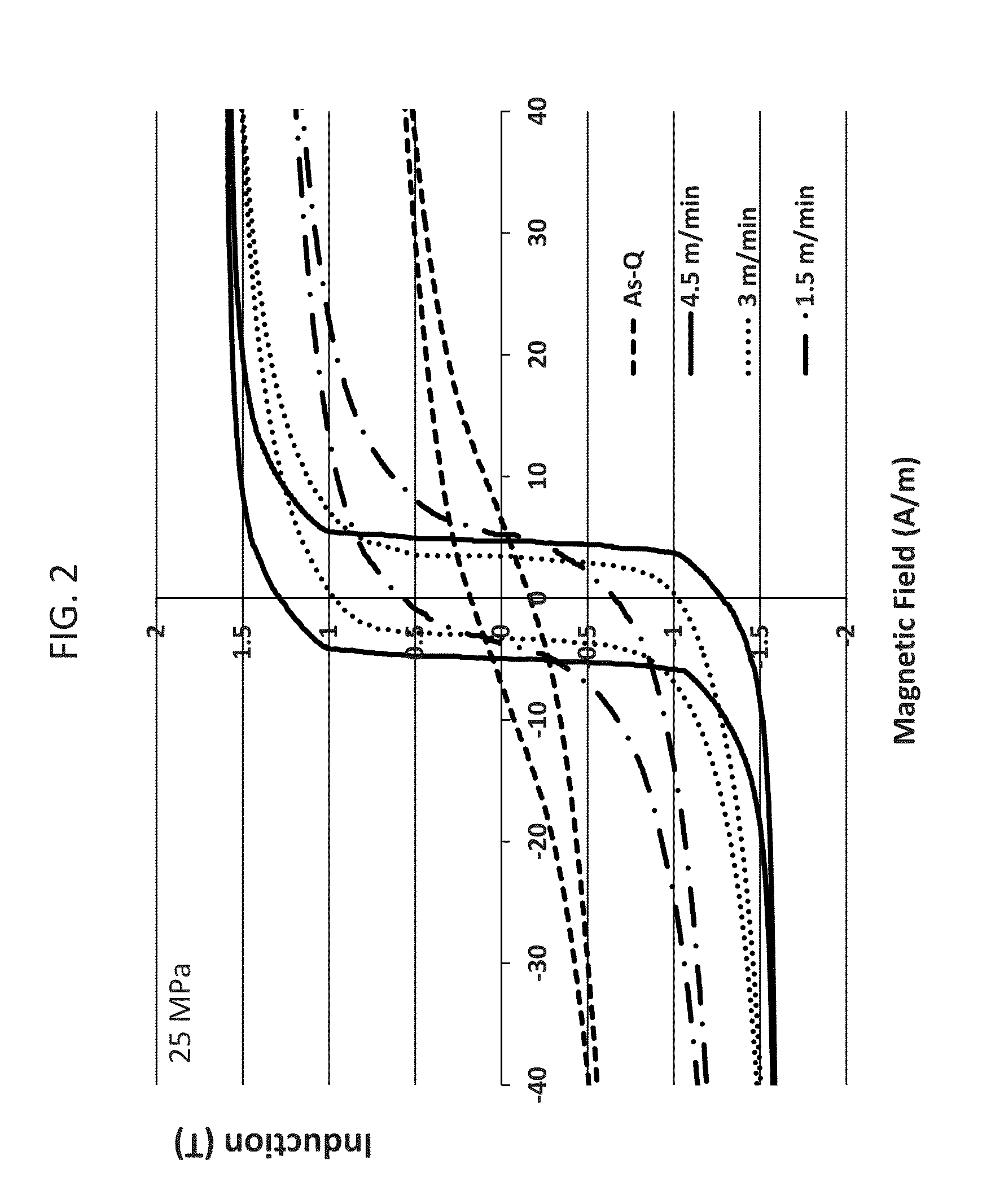

A nanocrystalline alloy ribbon has an alloy composition represented by FeCuxBySizAaXb where 0.6≦x<1.2, 10≦y≦20, 0<z≦10, 10≦(y+z)≦24, 0≦a≦10, 0≦b≦5, with the balance being Fe and incidental impurities, where A is an optional inclusion of at least one element selected from Ni, Mn, Co, V, Cr, Ti, Zr, Nb, Mo, Hf, Ta and W, and X is an optional inclusion of at least one element selected from Re, Y, Zn, As, In, Sn, and rare earth elements, all numbers being in atomic percent. The ribbon has a local structure having nanocrystals with average particle sizes of less than 40 nm dispersed in an amorphous matrix, the nanocrystals occupying more than 30 volume percent of the ribbon and has a radius of ribbon curvature of at least 200 mm.

Owner:METGLAS INC +1

Sulfide and oxy-sulfide glass and glass-ceramic films for batteries incorporating metallic anodes

InactiveUS20190393549A1Good formabilityImprove stabilitySolid electrolytesGlass forming apparatusSolid state electrolyteSulfur

A solid state electrolyte including an oxy-sulfide glass or glass ceramic, solid state electrolyte layer having a thickness in the range of ten micrometers to two hundred micrometers is provide. The composition of the electrolyte layer is the reaction product of a mixture initially including either a glass former including sulfur or a glass co-former including sulfur, and a glass modifier including Li2O or Na2O. The solid-state electrolyte layer is further characterized as having a wholly amorphous microstructure or as having small recrystallized regions separated from each other in an amorphous matrix, the recrystallized regions having a size of up to five micrometers. The solid-state electrolyte layer includes mobile lithium ions or mobile sodium ions associated with sulfur anions chemically anchored in the microstructure.

Owner:GM GLOBAL TECH OPERATIONS LLC

Nitride based semiconductor device using nanorods and process for preparing the same

ActiveUS20090269909A1Inhibit the generation of cracksEasy to implementSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialAmorphous matrix

Owner:SAMSUNG ELECTRONICS CO LTD

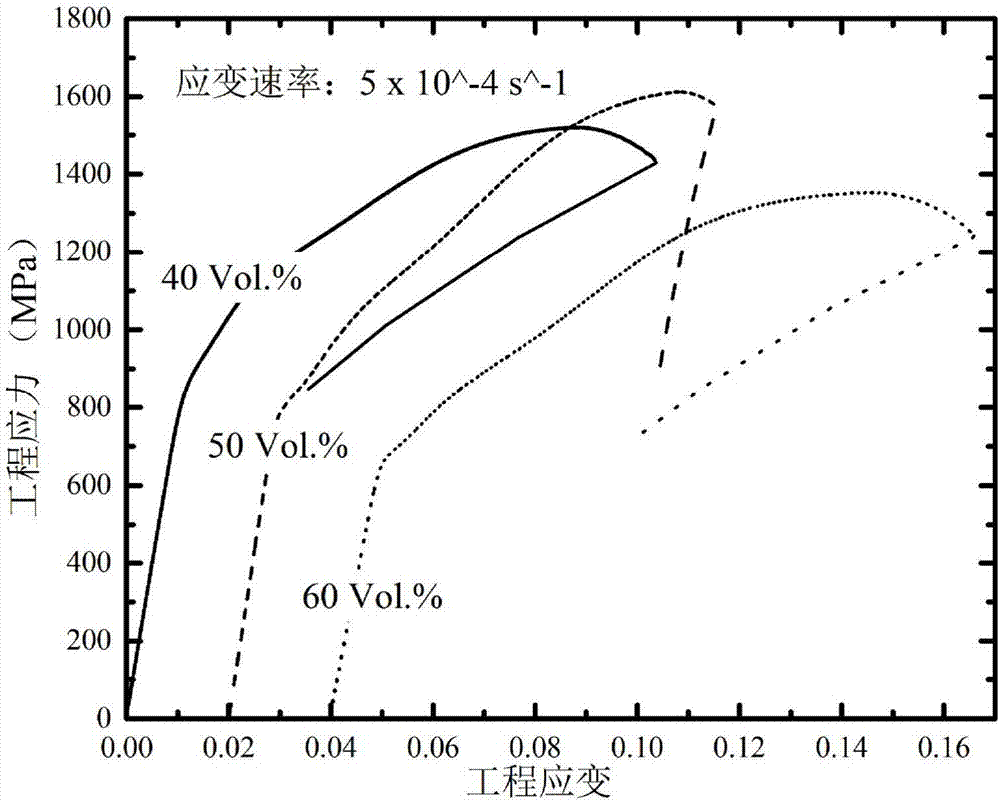

Ti-Zr-Cu-Be four-element amorphous composite with processing hardening capacity and preparation method thereof

ActiveCN107385365ASimple ingredientsImprove the ability to formMartensite transformationChemical composition

The invention discloses a Ti-Zr-Cu-Be four-element amorphous composite with the processing hardening capacity and a preparation method thereof. The composite is a type of amorphous alloy composite containing a dendritic crystal phase, wherein the dendritic crystal phase is prepared from the chemical components of 59-60 parts of Ti, 38-39 parts of Zr and 1-3 parts of Cu, the volume fraction of the dendritic crystal phase is 5-95%, and an amorphous matrix is prepared from the chemical components of 33-34 parts of Ti, 35-36 parts of Zr, 8-9 parts of Cu and 21-24 parts of Be. The dendritic crystal phase has the deformation-induced Martensite phase transformation characteristic, the composite shows excellent comprehensive mechanical properties of high strength, high plasticity, processing hardening and the like under the actions of tension and compression loads, for example, under the tension load, the processing hardening behavior is remarkable, the plastic deformation capacity is 6-15%, and the strength is 1100-1900 MPa. Meanwhile, by means of Martensite phase transformation, the composite has the super-elastic characteristic under the tension load through cyclic loading, for example, elastic deformation can be 2.7-3%. As for the composite, the chemical composition is simple, the chemical components of the second phase are relatively stable, and structural design and controllable preparation of the composite are facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

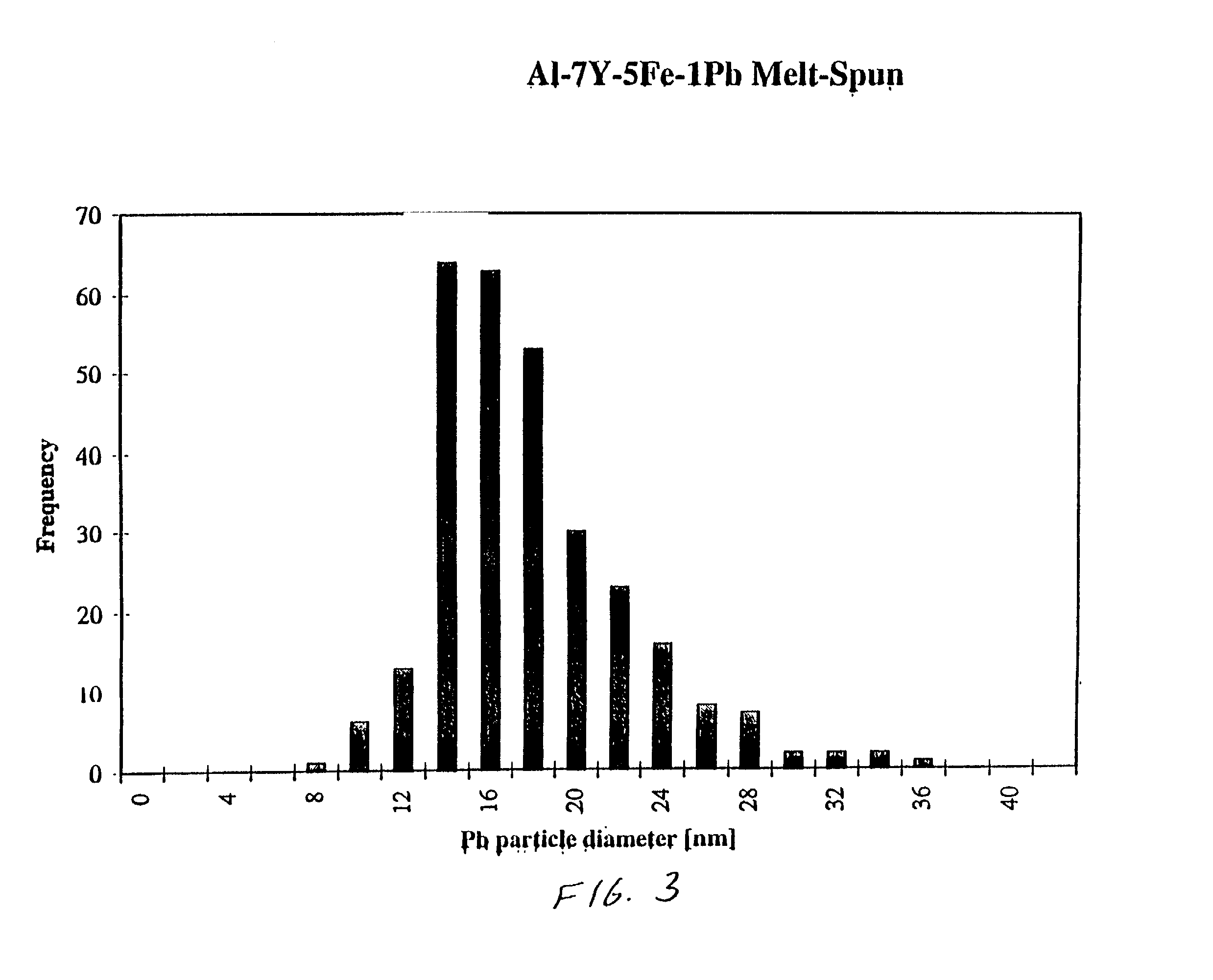

Nanocrystal dispersed amorphous alloys and method of preparation thereof

InactiveUS20010022208A1High strengthImprove magnetic propertiesMagnetic materialsDevitrificationHigh density

Compositions and methods for obtaining nanocrystal dispersed amorphous alloys are described. A composition includes an amorphous matrix forming element (e.g., Al or Fe); at least one transition metal element; and at least one crystallizing agent that is insoluble in the resulting amorphous matrix. During devitrification, the crystallizing agent causes the formation of a high density nanocrystal dispersion. The compositions and methods provide advantages in that materials with superior properties are provided.

Owner:WISCONSIN ALUMNI RES FOUND

Fe-based nanocrystalline soft magnetic alloy and preparation method

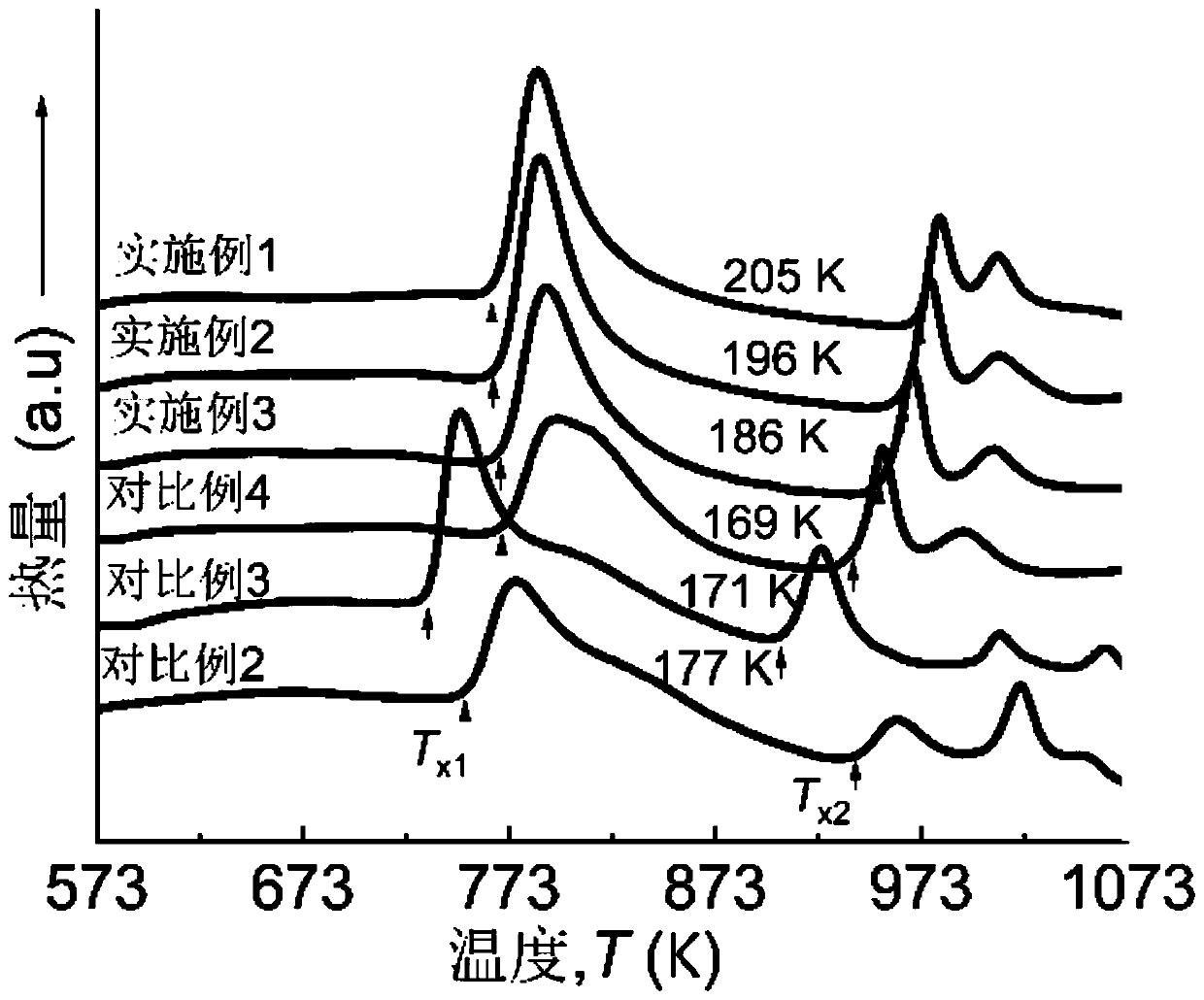

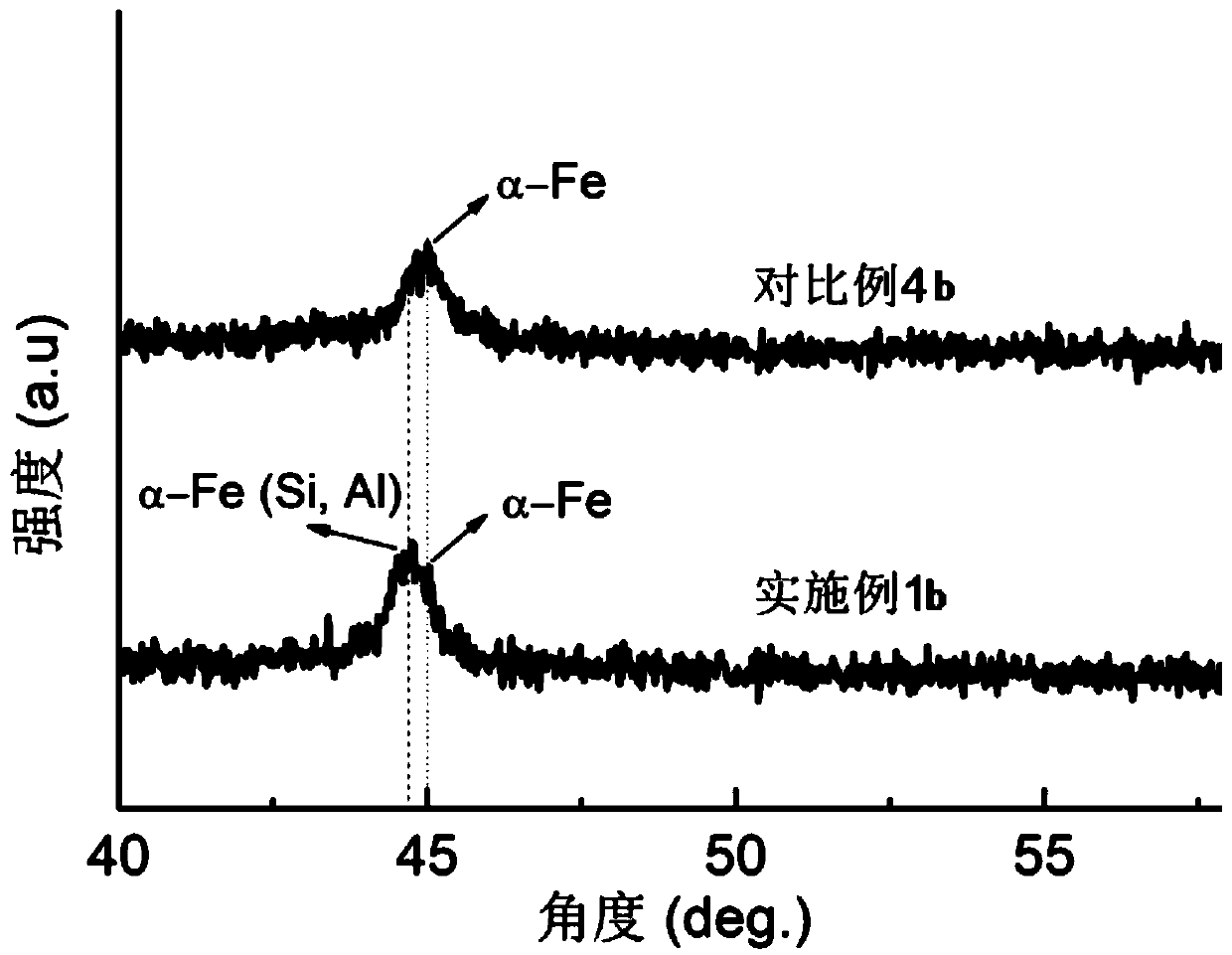

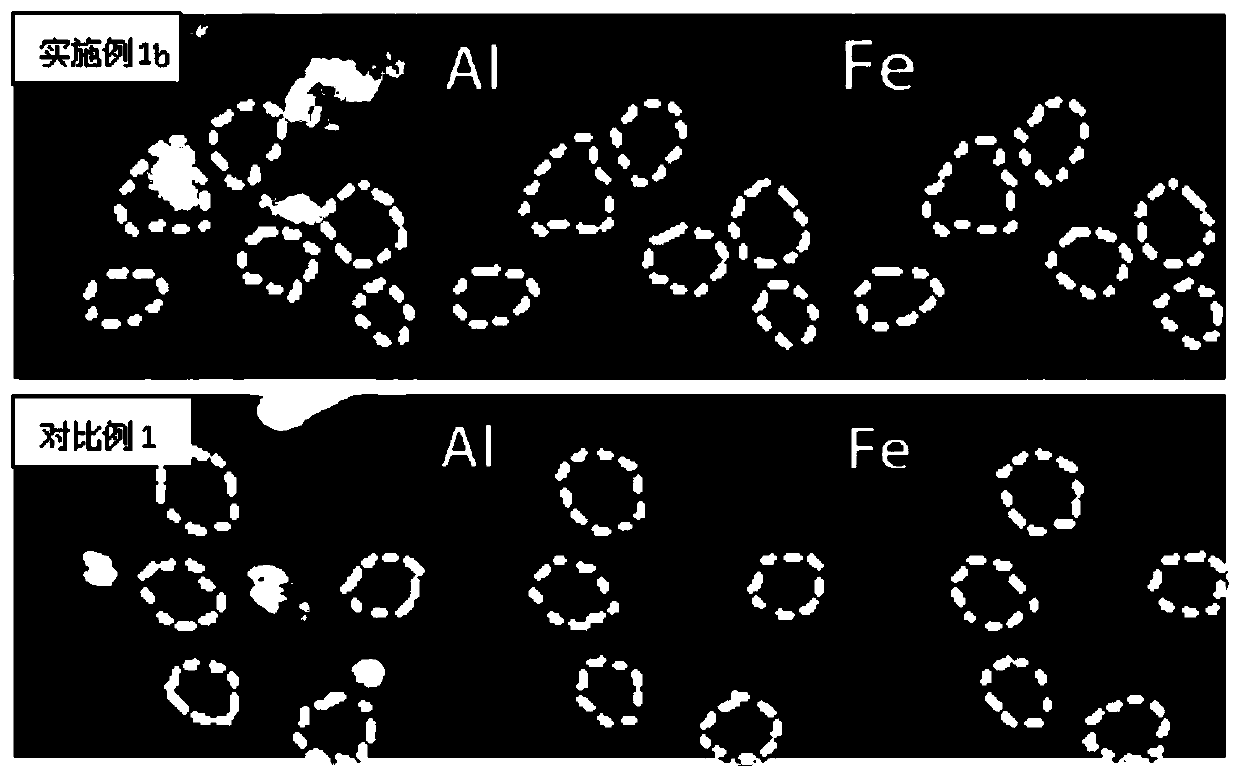

ActiveCN111020410AReduce the content of precious metal elementsImprove thermal stabilityMagnetic materialsAmorphous matrixHeat treated

The invention discloses an Fe-based nanocrystalline soft magnetic alloy. The molecular formula of the alloy is FeaSibBcMdCuePfAlg, M refers to the metallic element Nb, Mo, V, Mn or Cr, a, b, c, d, e,f and g are mole percentage content of corresponding atoms, b is larger than or equal to 6 but smaller than or equal to 15, c is larger than or equal to 5 but smaller than or equal to 12, d is largerthan or equal to 0.5 but smaller than or equal to 3, e is larger than or equal to 0.5 but smaller than or equal to 1.5, f is larger than or equal to 0.5 but smaller than or equal to 3, g is larger than or equal to 0.5 but smaller than or equal to 10, and the balance is Fe and inevitable trace impure elements; the structure of the Fe-based nanocrystalline soft magnetic alloy is the two-phase alloywith the Fe adopting the body-centered cubic structure and Fe(Si, Al) mixed nanocrystalline grains embedded in an amorphous matrix, and the average size ranges from 10 nm to 13 nm. The invention further provides a preparation method of the Fe-based nanocrystalline soft magnetic alloy. The method includes two-step heating and two-step cooling heat treatment. The Fe-based nanocrystalline soft magnetic alloy has the advantages of low cost, excellent soft magnetic property, high corrosion resistance as well as good manufacturability and heat treatment processability, and has the broad applicationprospects in the fields of noise suppression, filtration, wireless charging and the like in complex and harsh environments.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Magneto-elastic amorphous wire material and magnetoelastic displacement transducer

InactiveCN101200792ASimple production processLow costFilament/thread formingMachines/enginesMagneto elasticMeasuring instrument

Magneto-elastic amorphous alloy material and a preparation method thereof are provided. The material is composed of FexReyBz, wherein, Re is one or more than two of La, Sm, Tb, Dy and Y. The preparation method is to mix and melt the FexReyBz into master alloy according to the atom percentage, produce amorphous wires on self-developed wire spraying equipment, strengthen internal stress through drawing the wires and improve the magneto-elastic performance of the wires. The material is provided with the 10<-3> vertical large magnetostrictive coefficient. And through the quenching and rapid setting preparation method, extremely large inner stress gradient from the surface to the core of the wires is made. The material is also provided with large inner stress anisotropy performance, and part of magneto-elastic performance is produced. The surface crystallization layer of the wires, the thickness of which is tens of nanometers to hundreds of nanometers, and amorphous matrixes produce magnetocrystalline anistotropy energies which strengthen the magneto-elastic performance of the wires. The material is provided with the vertical large magnetostrictive coefficient and makes use of a self-developed displacement sensor and a measurement instrument. Compared with the present import super-magnetostrictive displacement sensor, the sensor has the advantages of large investigation depth, high precision and strong vibration resistance capacity.

Owner:北京国浩微磁电子智能传感器技术研究所

Soda-lime-silica glass-ceramic material

InactiveUS20120202676A1High mechanical strengthImprove scratch resistanceMaterial nanotechnologySilica gelAmorphous matrix

The invention relates to a glass-ceramic material having SiO2, Na2O and CaO as main components and comprising crystalline particles of SiO2 dispersed homogeneously in the volume of an amorphous matrix. Such a material has good mechanical strength, in particular good resistance to scratch propagation and allows improved tempering. This material furthermore has a pleasant aesthetic appearance.

Owner:AGC GLASS EUROPE SA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com