Nano-porous copper-loaded shape-controlled copper-based oxide composite as well as preparation method and application thereof

A technology of nanoporous copper and composite materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of complex preparation process and energy waste, and achieve the effects of simplifying the preparation process, avoiding energy waste and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Select alloy composition Ti 50 Cu 45 Zr 5 According to the atomic percentage of each alloy element in the target alloy: Cu is 50at.%, Ti is 45at.%, and Zr is 5at.%. Weigh high-purity copper sheets, titanium rods, and zirconium rods with a mass fraction of 99.99% as the mother Alloy raw materials for standby (8g); put the weighed raw materials into a vacuum melting furnace, and repeatedly smelt them 5 times under the protection atmosphere of high-purity argon (purity is 99.99%) to ensure the uniformity of the master alloy composition, and obtain Ti 50 Cu 45 Zr 5 master alloy ingot.

[0039] Crush the master alloy ingot, take 2~3g and place it in a quartz tube with a hole in the lower end (0.7mm~1mm in diameter), and heat it to a molten state through an induction coil under a high-purity argon protective atmosphere, using a pressure difference (0.02MPa ~0.05MPa) spray-cast the molten alloy onto a high-speed rotating copper roller, and rapidly solidify to obtain an am...

Embodiment 2

[0051] The preparation of the amorphous ribbon is the same as in Example 1, except that the constant voltage parameter is set to 0.6V, and the time is 300 minutes to prepare the nanoporous copper-loaded nanosheet copper oxide composite material. All the other steps are the same as in Example 1.

[0052] The specific capacitance of the supercapacitor electrode sheet prepared in this example is 277.82F / g.

Embodiment 3

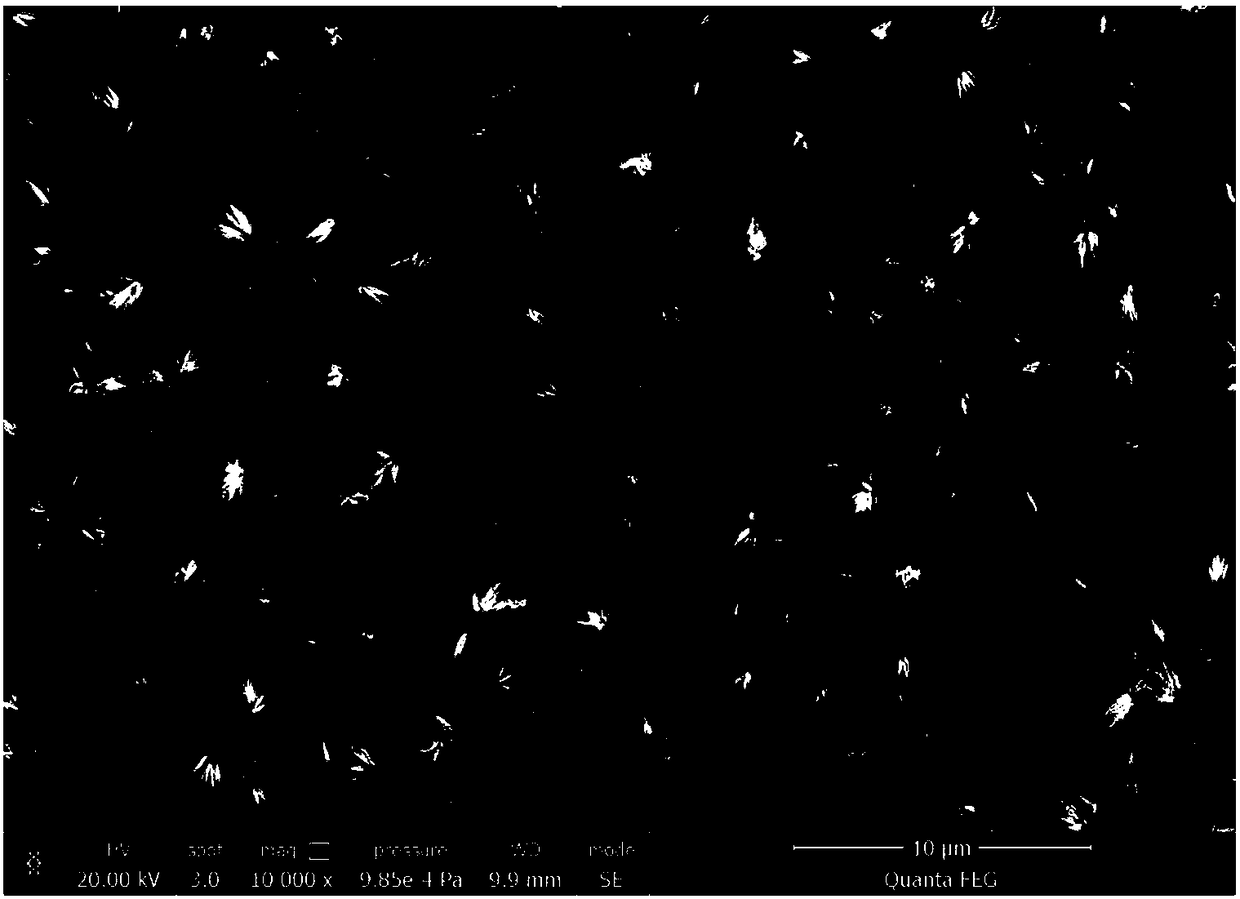

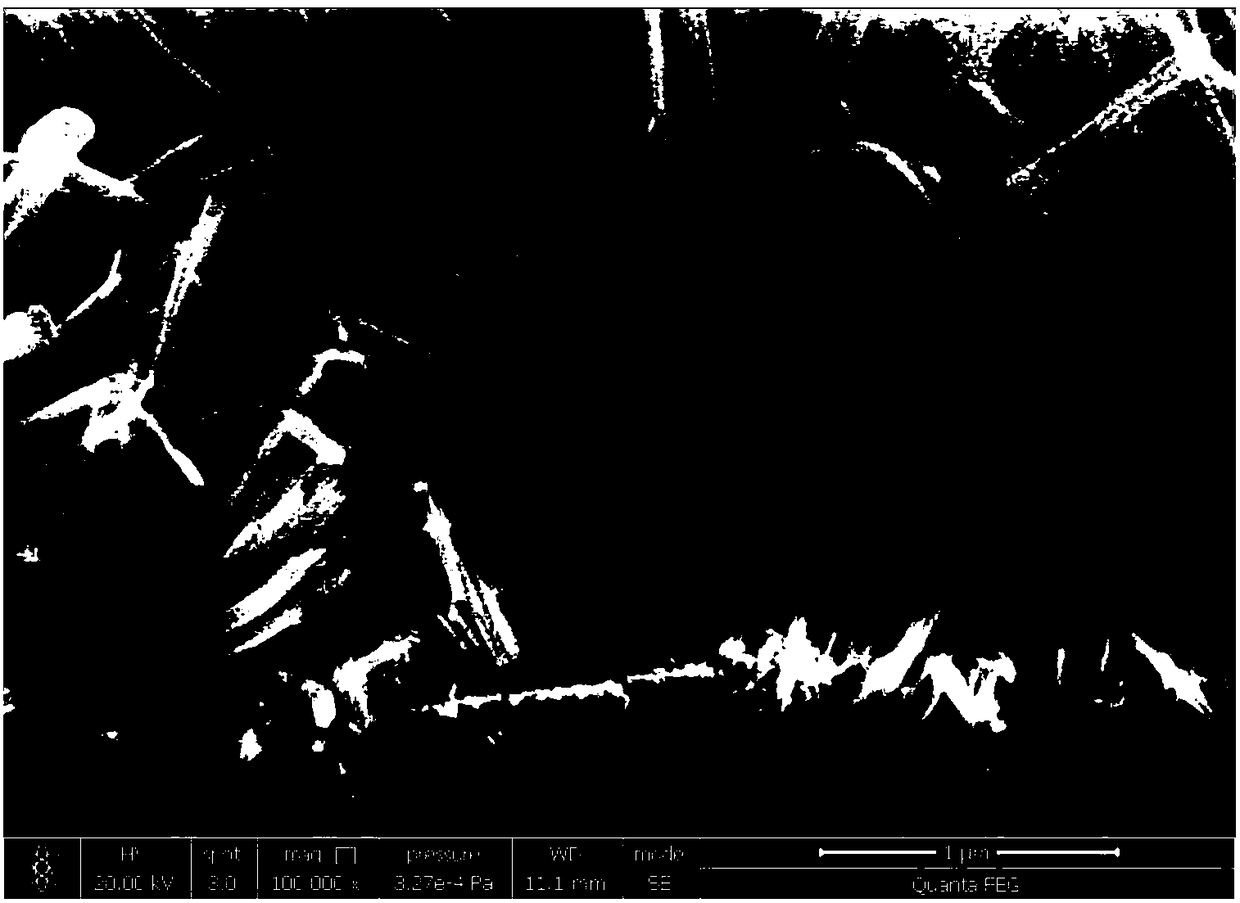

[0054] The preparation of the amorphous strip is the same as in Example 1, the constant voltage parameter is set to 0.3V, and the time is 40 minutes to prepare a nanowire copper oxide composite material (diameter 5-10nm, length 3-7μm) loaded with nanoporous copper and a large aspect ratio. . All the other steps are the same as in Example 1.

[0055] The specific capacitance of the supercapacitor electrode sheet prepared in this example is 622.51 F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com